Radial heat tube-ordinary heat exchange tube combined type waste heat recovery device for flue tail gases

A technology of waste heat recovery device and radial heat pipe, which is applied in the steam generation method using heat carrier, etc., can solve the problems such as the reduction of heat exchange efficiency, and achieve the effects of improving heat utilization rate, avoiding dew point corrosion, and high heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing.

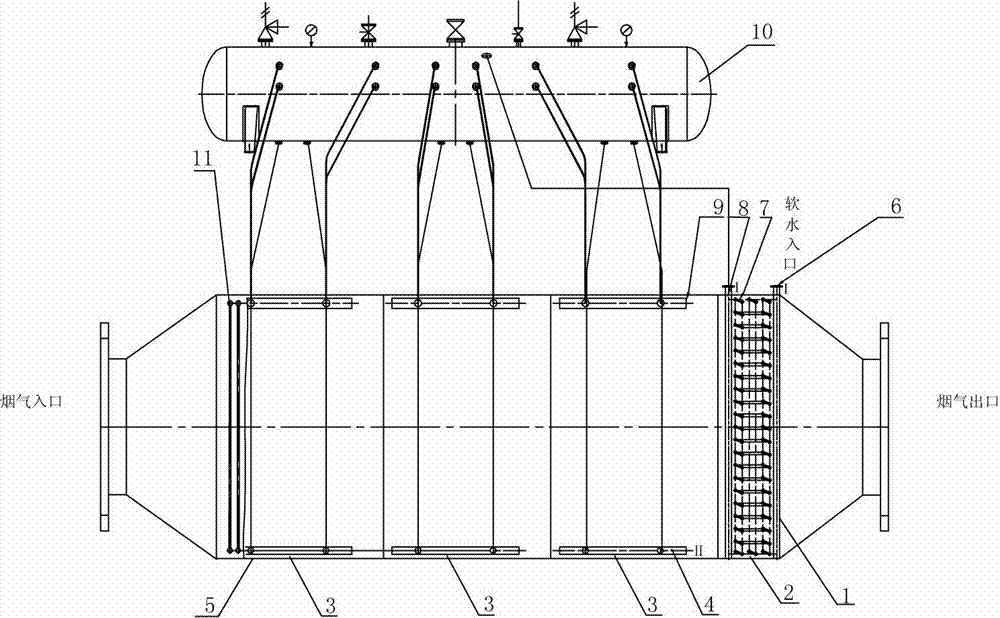

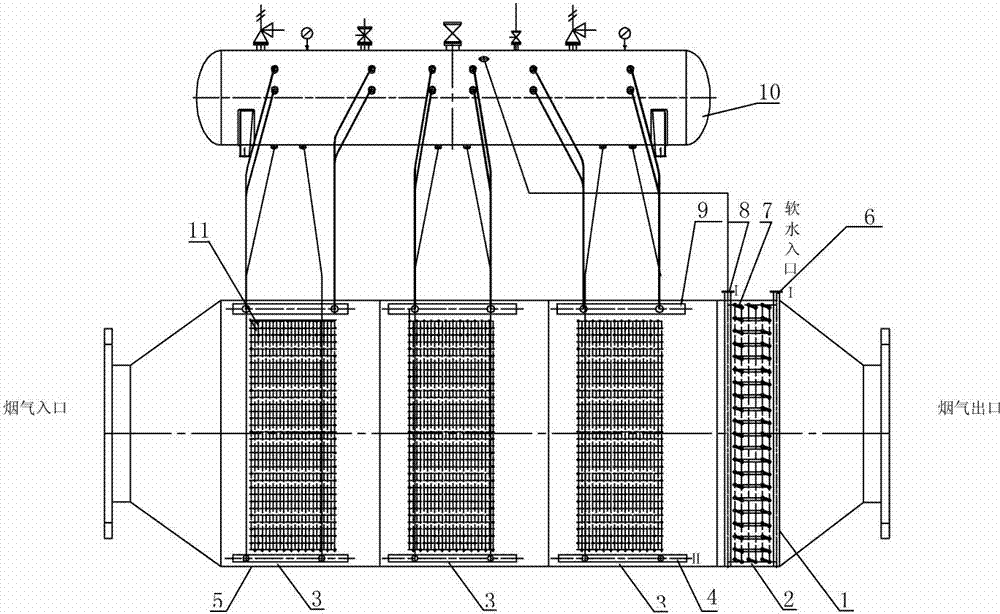

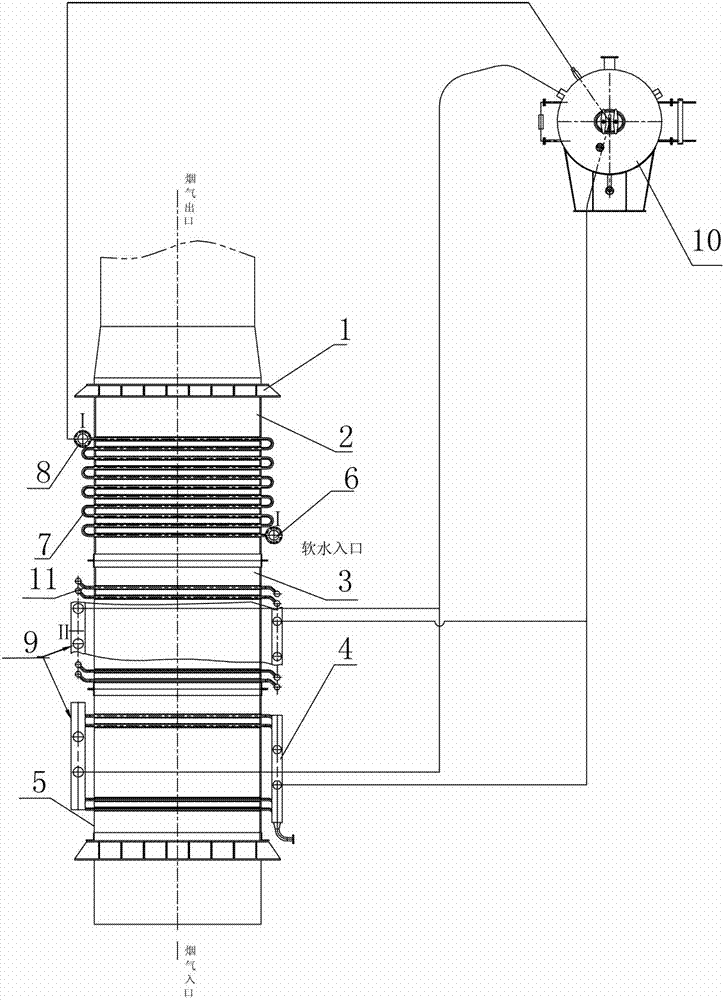

[0030] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, the radial heat pipe-ordinary heat exchange tube combined waste heat recovery device for flue tail gas of the present invention includes a gas box 1 and a heat exchange device arranged in the gas box 1, and is characterized in that:

[0031] The side plate of the gas box 1 is a tube plate 5, and a through hole is opened on the tube plate 5. The two ends of the gas box 1 are respectively a flue gas inlet and a flue gas outlet. The upper part of the casing 1 is provided with a steam-water separator 10,

[0032] The heat exchange device of the present invention is composed of a preheating heat exchange tube group 2 and an evaporation heat exchange tube group 3,

[0033] The preheating heat exchange tube group 2 is composed of a radial heat pipe 7 and an inlet header I6 and an outlet header I8 connected

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap