Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

18 results about "Steam turbine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A steam turbine is a device that extracts thermal energy from pressurized steam and uses it to do mechanical work on a rotating output shaft. Its modern manifestation was invented by Charles Parsons in 1884.

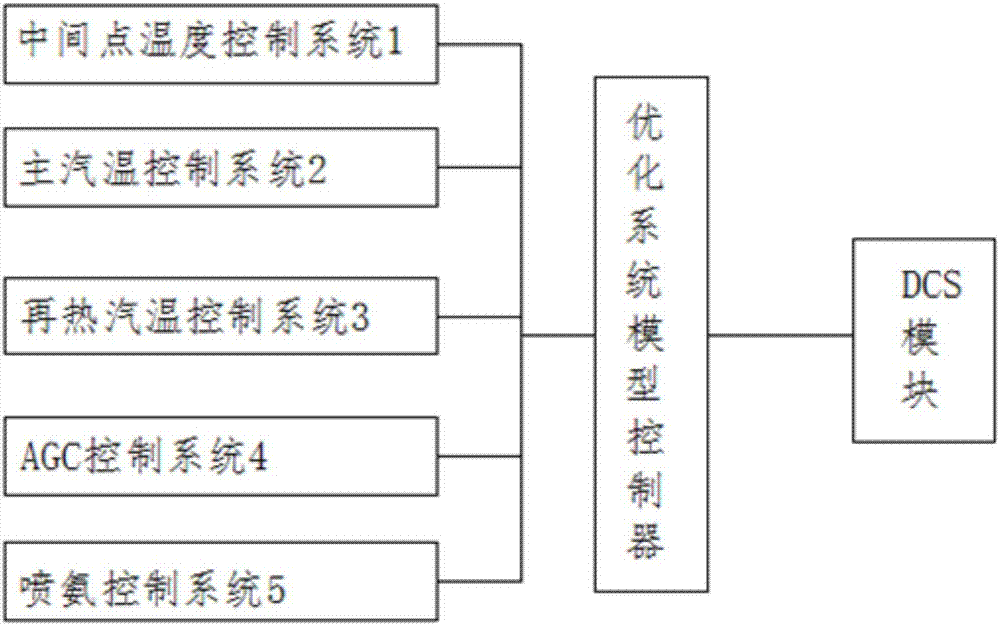

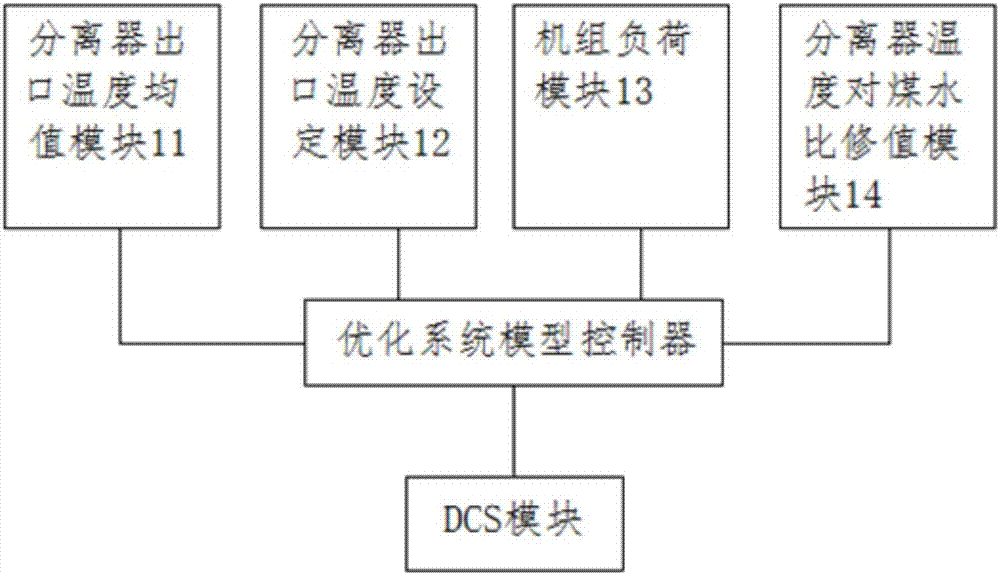

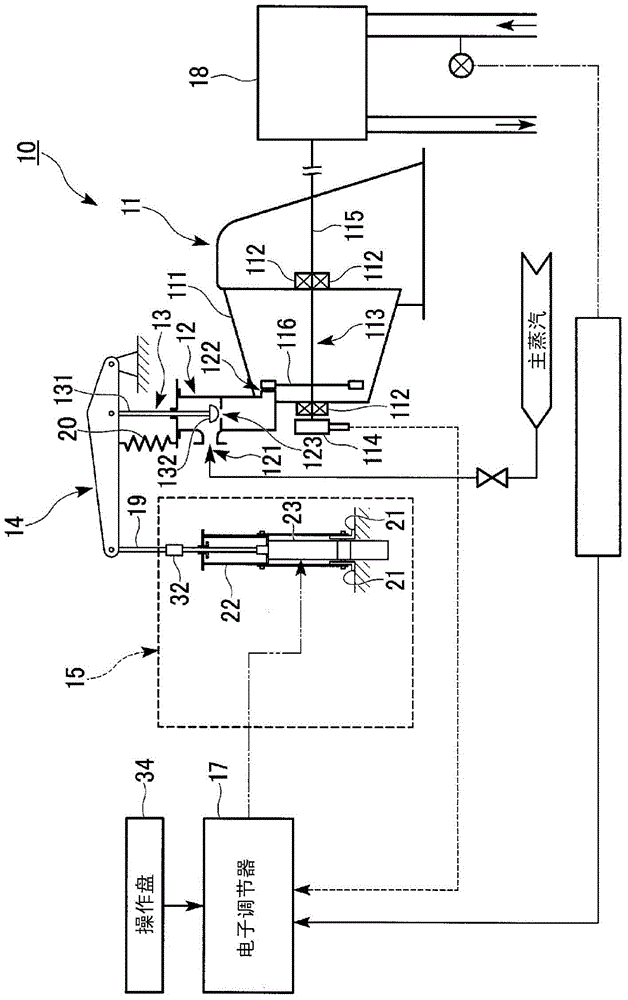

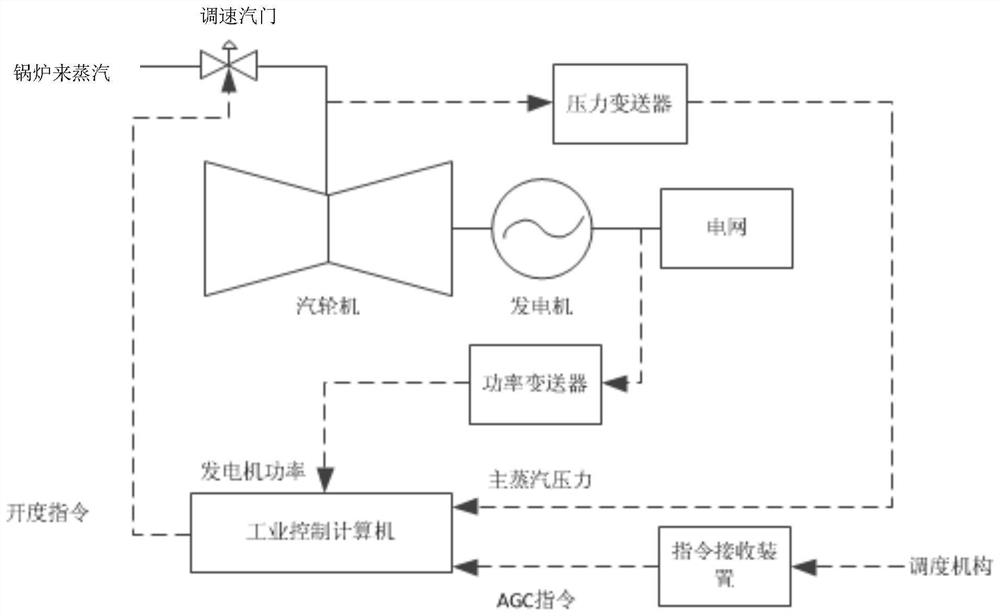

Ultra-supercritical thermal generator set coordinated control system

Owner:JIANGSU DATANG INT LUSIGANG POWER GENERATION

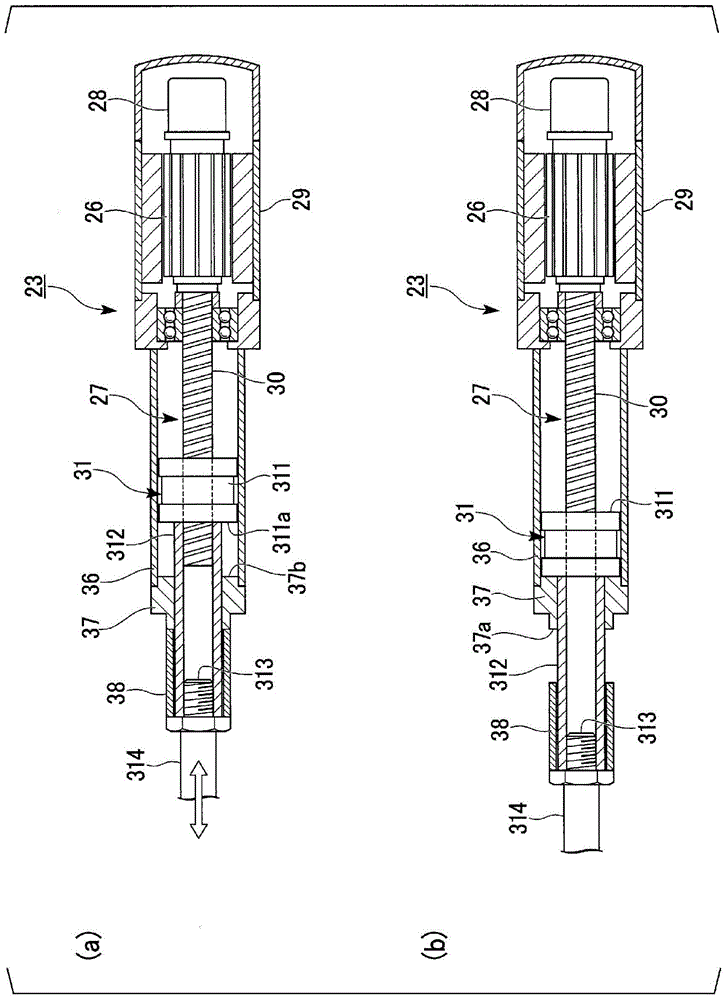

Steam turbine nozzle assembly having flush apertures

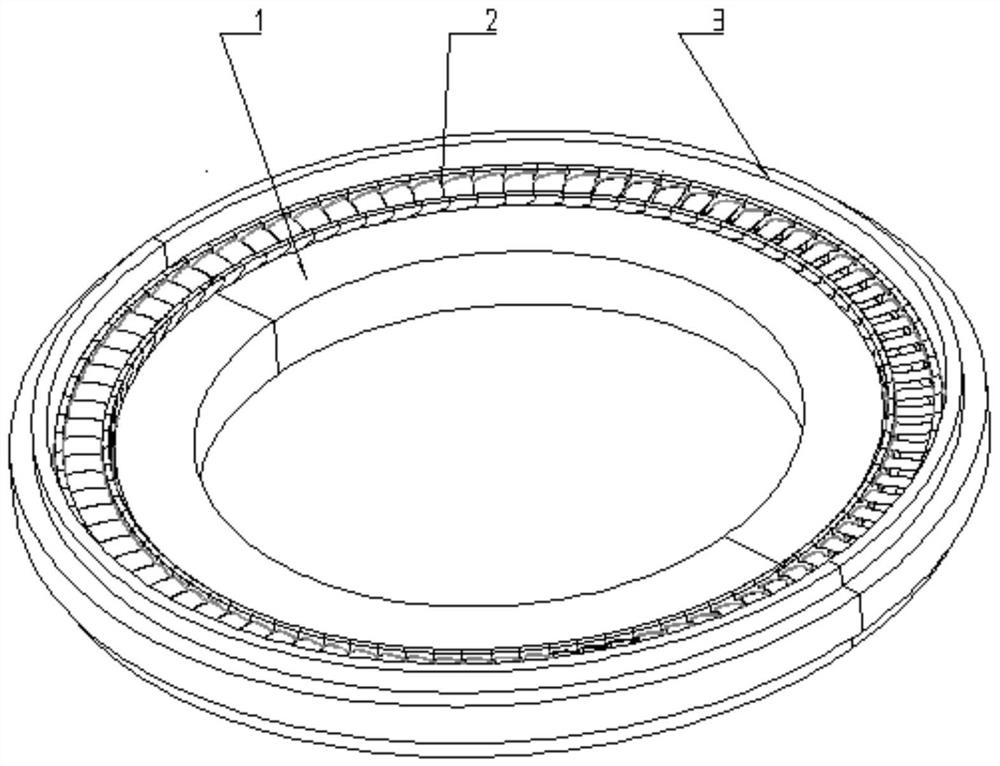

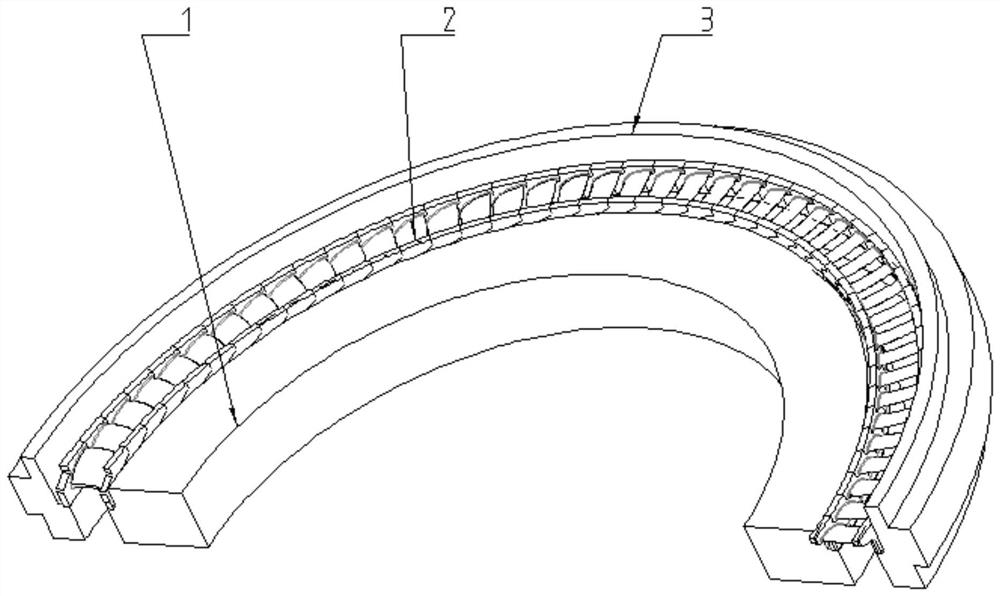

A steam turbine nozzle assembly having a flush aperture is disclosed. In one embodiment, the steam turbine nozzle assembly includes a diaphragm assembly comprising: an inner diaphragm ring segment; an outer diaphragm ring segment; a static nozzle blade positioned between the inner diaphragm ring segment and the outer diaphragm ring segment; and a first cavity between the static nozzle blade and one of the inner diaphragm ring segment or the outer diaphragm ring segment; wherein the one of the inner diaphragm ring segment or the outer diaphragm ring segment includes a first aperture fluidly connected with the first cavity.

Owner:GENERAL ELECTRIC CO

Method and device for improving output of coal mill based on lignite coal pulverizing system

InactiveCN111167566AImprove drying outputReduce power consumptionGrain treatmentsBrown coalCombustion

The invention relates to a method and device for improving the output of a coal mill based on a lignite coal pulverizing system. The device for improving the output of the coal mill based on the pulverizing system comprises that a grinding disc is arranged in the coal mill; nozzles are arranged on the periphery of the grinding disc; a grinding roller is arranged at the upper end of the grinding disc; one end of a high-temperature superheated steam pipeline is connected with a steam turbine, the other end of the high-temperature superheated steam pipeline penetrates through the cylinder wall ofthe coal mill, and then the other end of the high-temperature superheated steam pipeline is introduced into a grinding area of the grinding disc through a grinding roller gap; a valve is arranged onthe high-temperature superheated steam pipeline; and a primary fan conveys hot primary air into the coal mill through a primary air duct. According to the method and the device, raw coal is instantlyheated by using high-temperature superheated steam, and the temperature of the raw coal can be increased by 10-20 DEG C. Under the premise of ensuring the normal air-powder ratio, the outlet temperature can also be ensured, so that the drying output problem of burning lignite is solved. The combustion efficiency of a boiler is improved, meanwhile, the abrasion of related equipment of the pulverizing system and a pulverized coal pipeline is reduced, and the operation safety of the pulverizing system is improved.

Owner:BEIJING LAD ELECTRIC POWER TECH CO LTD

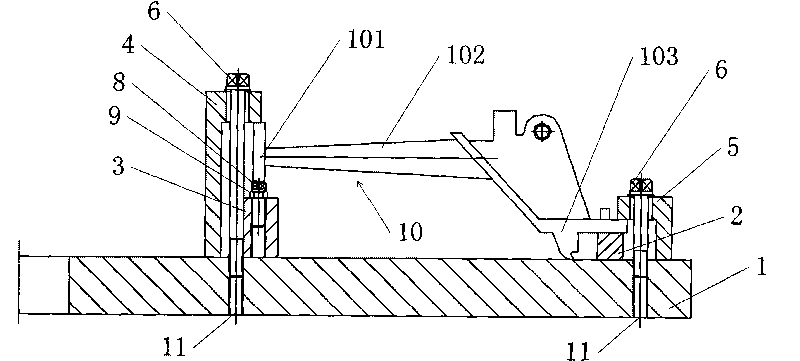

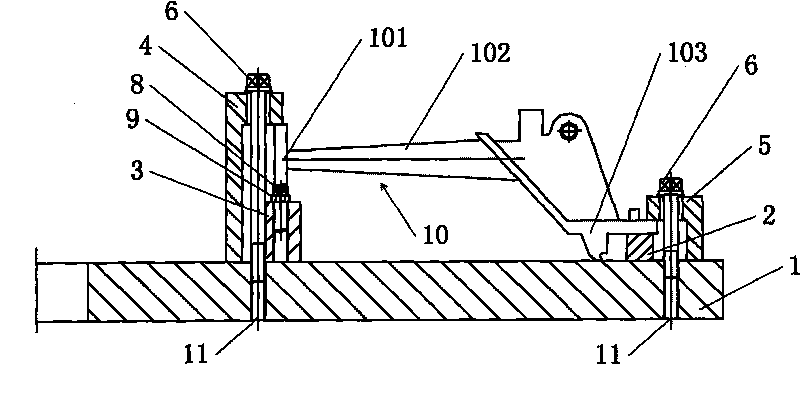

Device for thermal treatment after welding of partition board of steam turbine

ActiveCN101724739ASolve the deformationGuaranteed sizeFurnace typesHeat treatment furnacesEconomic benefitsEngineering

Owner:SHANGHAI ELECTRIC POWER GENERATION EQUIPMENT CO LTD

Online real-time optimization method and device for steam power system

ActiveCN112783115AGuaranteed accuracyImprove enforceabilityTotal factory controlProgramme total factory controlSteady state detectionData set

The invention discloses an online real-time optimization method and device for a steam power system, and solves the defects in the prior art, and the method comprises the following steps: 1, collecting equipment operation data, environment data, price data and test analysis data, storing the data in a real-time database, carrying out the data preprocessing and steady-state detection and obtaining a data set of the steam power system; 2, performing Gaussian transformation on the data set of the steam power system; 3, establishing a steam power system optimization model by taking the lowest operation cost of the steam power system as a target function, and performing optimization solution on the target function within a constraint condition range; and 4, carrying out system steady state judgment, if the system is in a steady state, writing an optimization result in the step 3 into a real-time database, taking the optimization result as deviation compensation of controlled variable set values of the boiler APC and the steam turbine DEH, and adjusting a process state to enable the process state to reach an optimized value.

Owner:ZHEJIANG SUPCON TECH +1

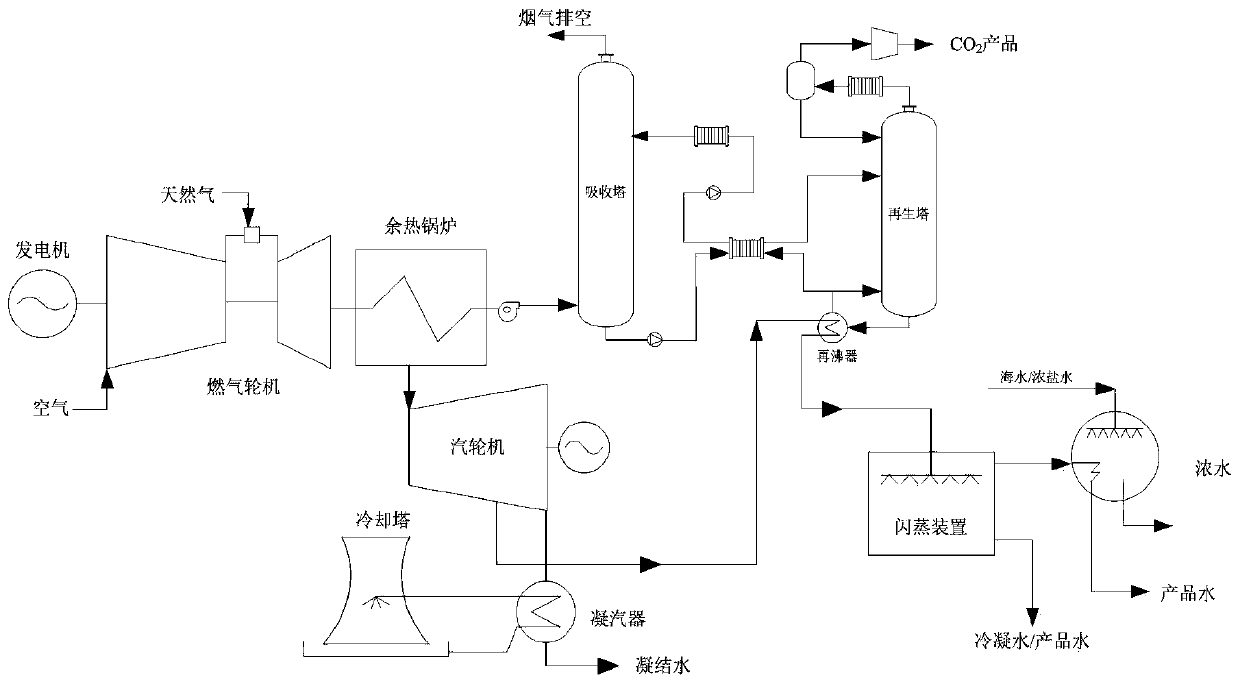

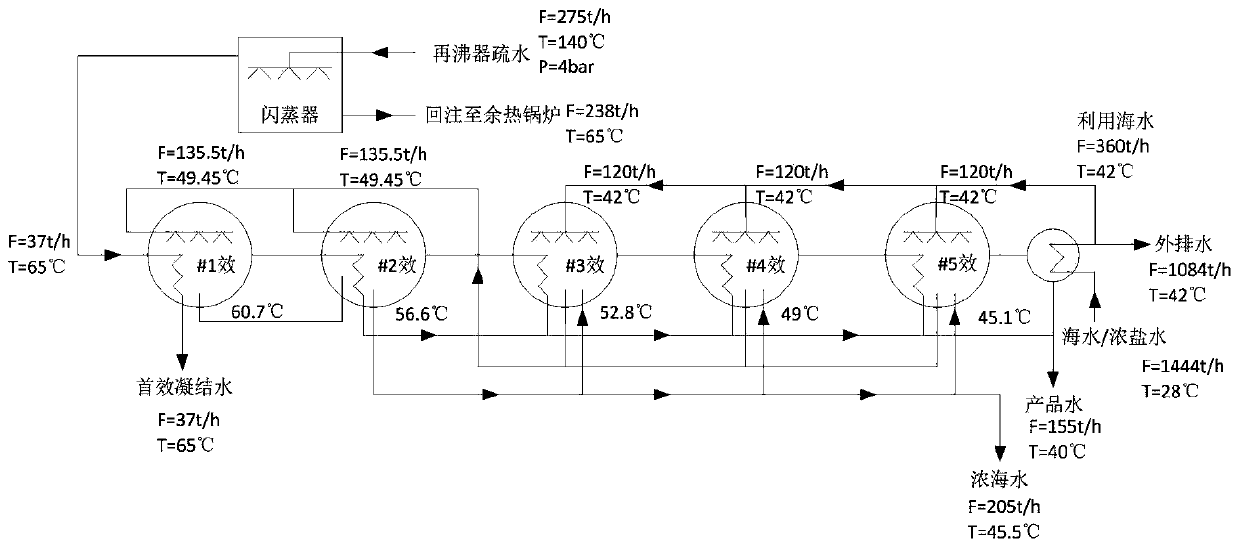

Steam waste heat gradient utilization system for carbon capture absorbent regeneration system

InactiveCN111420516AReduce the temperatureMake full use of waste heatDispersed particle separationSteam useReboilerWater circulation

Owner:北京中冶设备研究设计总院有限公司

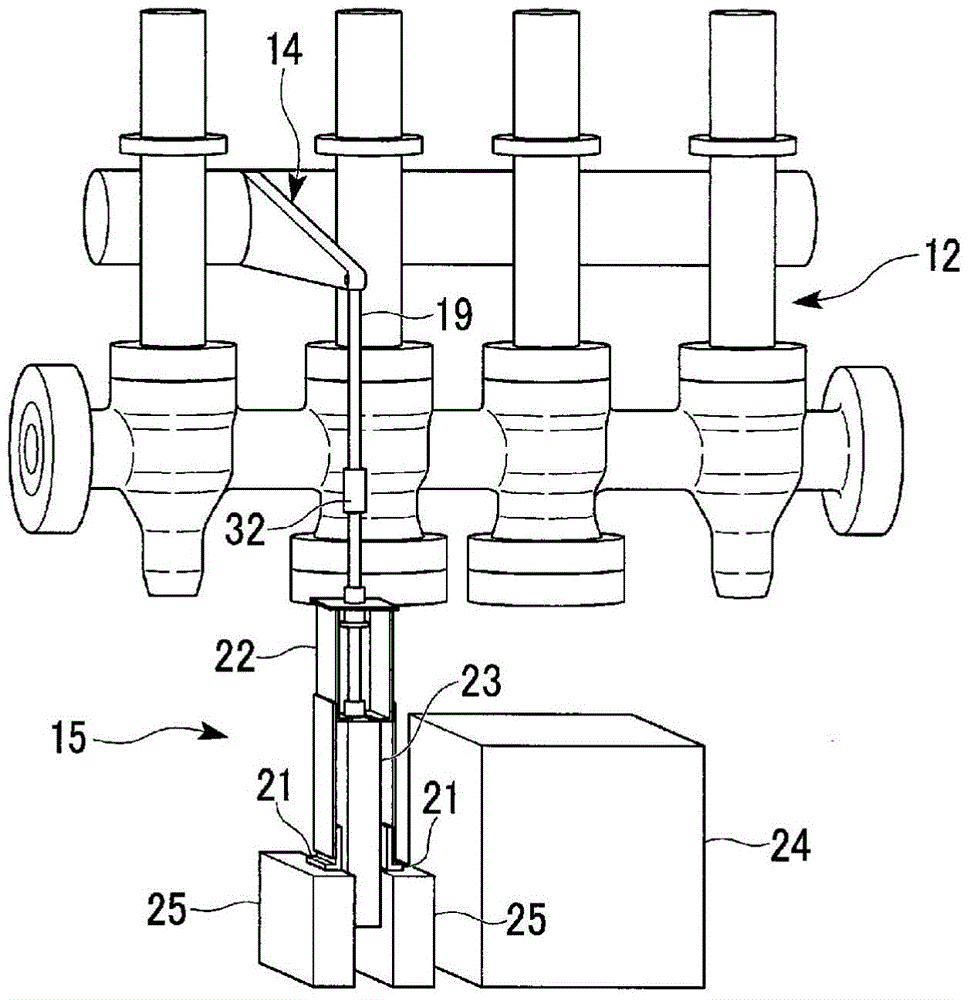

Steam turbine

Owner:MITSUBISHI HEAVY INDUSTIES COMPRESSOR CORP

Hydraulic hybrid turbo transmission

InactiveUS20090313984A1Energy lossLess componentsRotary clutchesFluid gearingsMulti-valveEnergy transfer

Improvements in a transmission is provided for transferring power from a power source to a work unit. The pump transfers energy received from the power source into a fluid or gas. The first turbine is fixed to output shaft, and a plurality of additional turbines are fixed on either one-way overrunning clutches or multi-disc clutches and these clutches are fixed to the output shaft and after each turbine is a multi-valves that discharges the fluid or gas. After all of the multi-stage turbines a first planetary gear set connects the transmission to the vehicle or work unit. The second planetary gear set is located between the last turbine and the first planetary gear set. During braking the planetary gear set reverses turning direction of the turbines and convert the turbines into pumps where they will pump low pressure fluid to a high pressure accumulator.

Owner:MUSTAFA REZ

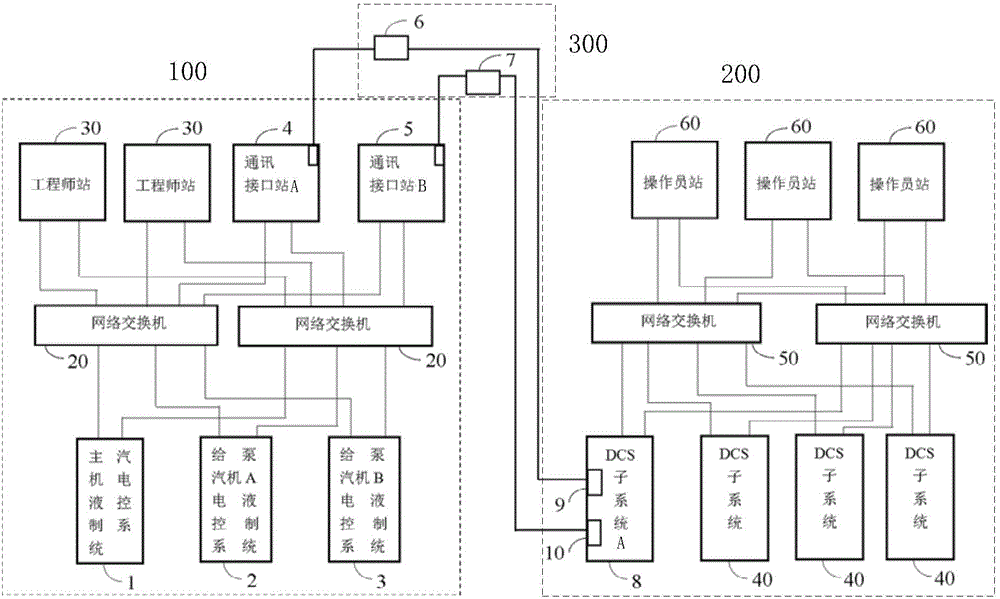

Integrated monitoring system for power station steam turbine electric hydraulic control system based on Modbus protocol

ActiveCN105867316ARealize the monitoring functionRealize the operation functionTotal factory controlProgramme total factory controlAutomatic controlE communication

Owner:BAOSHAN IRON & STEEL CO LTD

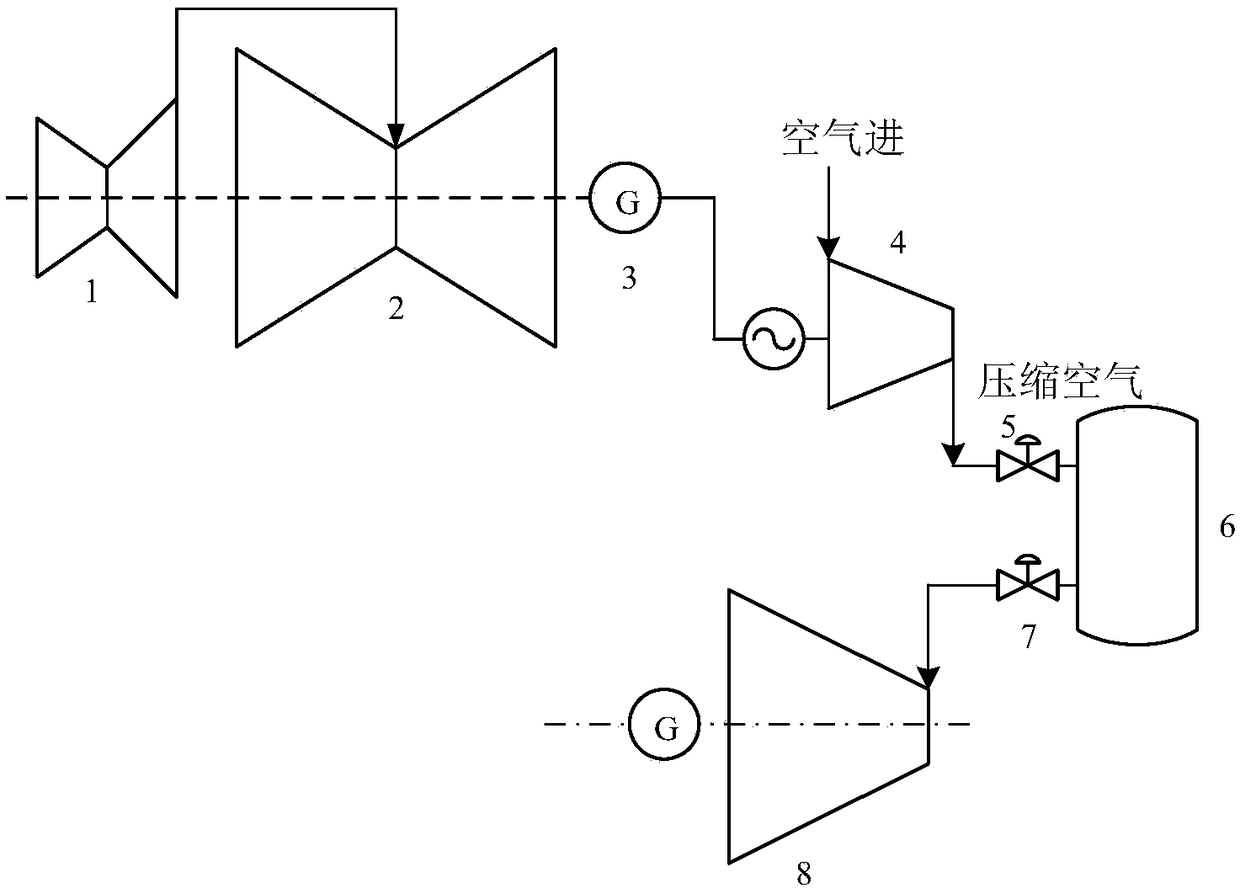

Energy storage peak load regulation system taking air as medium

PendingCN109494772AIncrease profitabilityPromote digestionElectrical storage systemAc network load balancingPeak loadElectric power

Owner:XIAN XIRE ENERGY SAVING TECH

Thermal power generating unit flexible regulation and control system integrated with steam energy accumulator and working method

ActiveCN114837763AIncrease the variable load rateReduce working mediumLiquid degasificationSteam useControl systemDeaerator

The invention discloses a thermal power generating unit flexible regulation and control system integrated with a steam accumulator and a working method. During low-load operation or load reduction of a unit, exhaust steam of a high-pressure cylinder is injected into a medium-pressure steam accumulator for steam storage; exhaust steam of the medium-pressure cylinder is injected into the low-pressure steam accumulator for steam storage, working media of the medium-pressure cylinder and the low-pressure cylinder are reduced by storing the steam, and low-load operation or rapid load reduction of the unit is achieved. When the load of the unit is increased, steam in the medium-pressure steam accumulator is released to serve as heating steam of the high-pressure heater and the deaerator; and steam in the low-pressure steam accumulator is released to serve as heating steam of the first low-pressure heater and the second low-pressure heater, so that steam extraction of the steam turbine is reduced, and rapid load rising of the unit is achieved. By storing and releasing steam of the medium-pressure steam accumulator and the low-pressure steam accumulator, the variable load rate of the unit is increased, the operation range of the coal-fired power generation unit can be widened, ultra-low load operation is achieved, and the power generation efficiency of the coal-fired power generation unit during rapid variable load operation is improved.

Owner:HUANENG POWER INT INC +2

Joint calculation method for strength of transverse stationary blade and cylinder body of steam turbine based on finite elements

The invention discloses a joint calculation method for strength of a transverse stationary blade and a cylinder body of a steam turbine based on finite elements, and belongs to the field of steam turbine design. The invention aims to solve the safety problem caused by the fact that only steam stress is considered and thermal deformation and thermal stress of a cylinder caused by temperature are not considered in the existing design. The method comprises the following steps: a calculation method can accurately solve an equivalent stress of a transverse stationary blade under the influence of a thermal deformation of a cylinder, and a basis is provided for the design of the transverse stationary blade of a steam turbine; finite element solution is conducted on the coupling of the transverse stationary blade with a cylinder body structure, temperature-stress-strain distribution of all nodes is obtained, and a CEEQ criterion is used to check whether the structure is invalid or not; the stress-strain value obtained through the calculation method can be used for evaluating the safety of the turbine transverse stationary blade during a steady-state operation, and a reliable calculation method is provided for calculation of the stress-strain field of the transverse stationary blade of the steam turbine under the thermosetting coupling condition. The method is mainly used for calculating the equivalent stress, a maximum stress and an equivalent creep strain of the transverse stationary blade and the cylinder.

Owner:HARBIN TURBINE +1

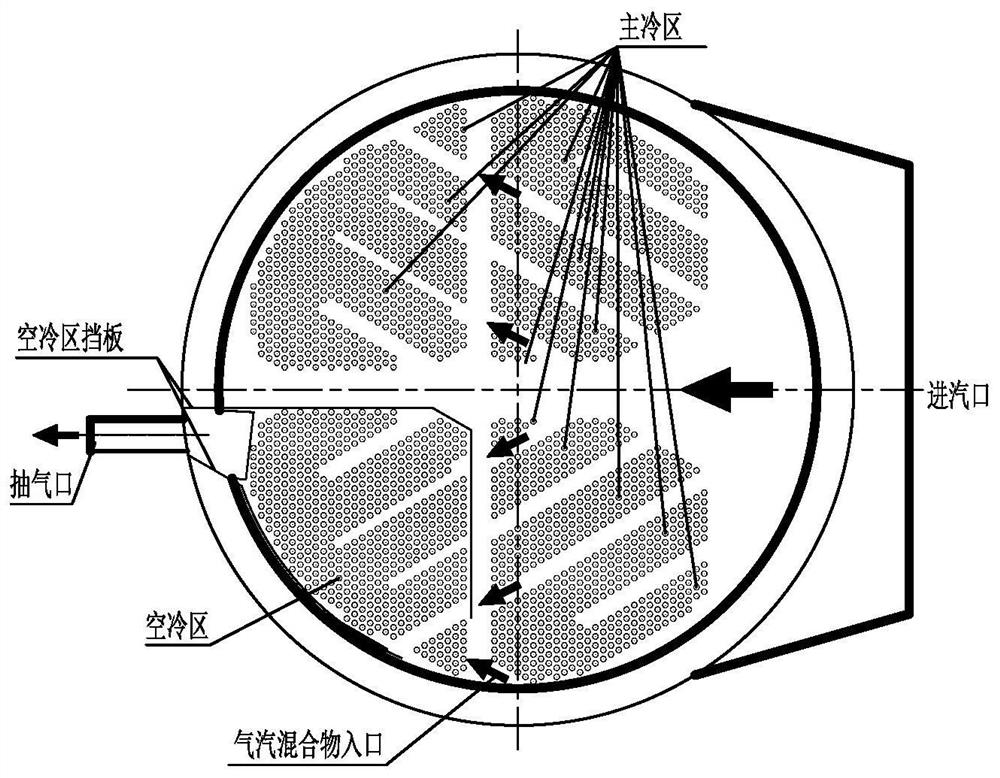

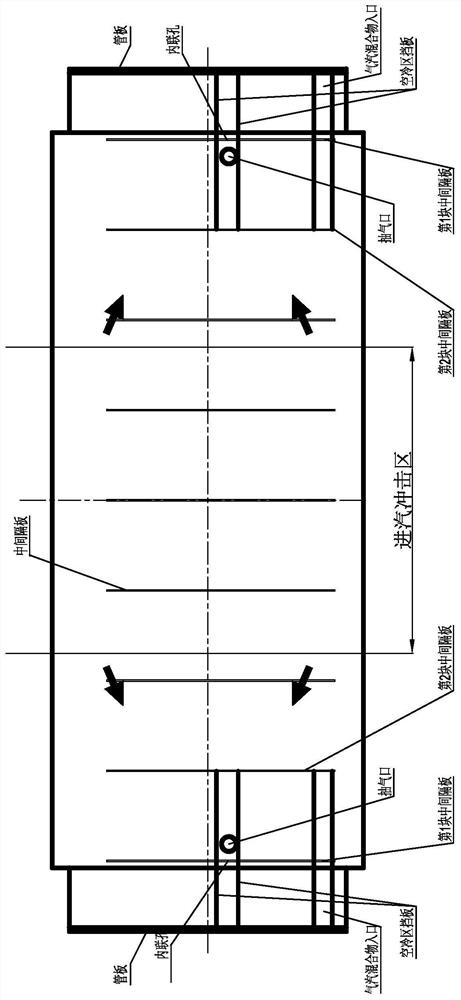

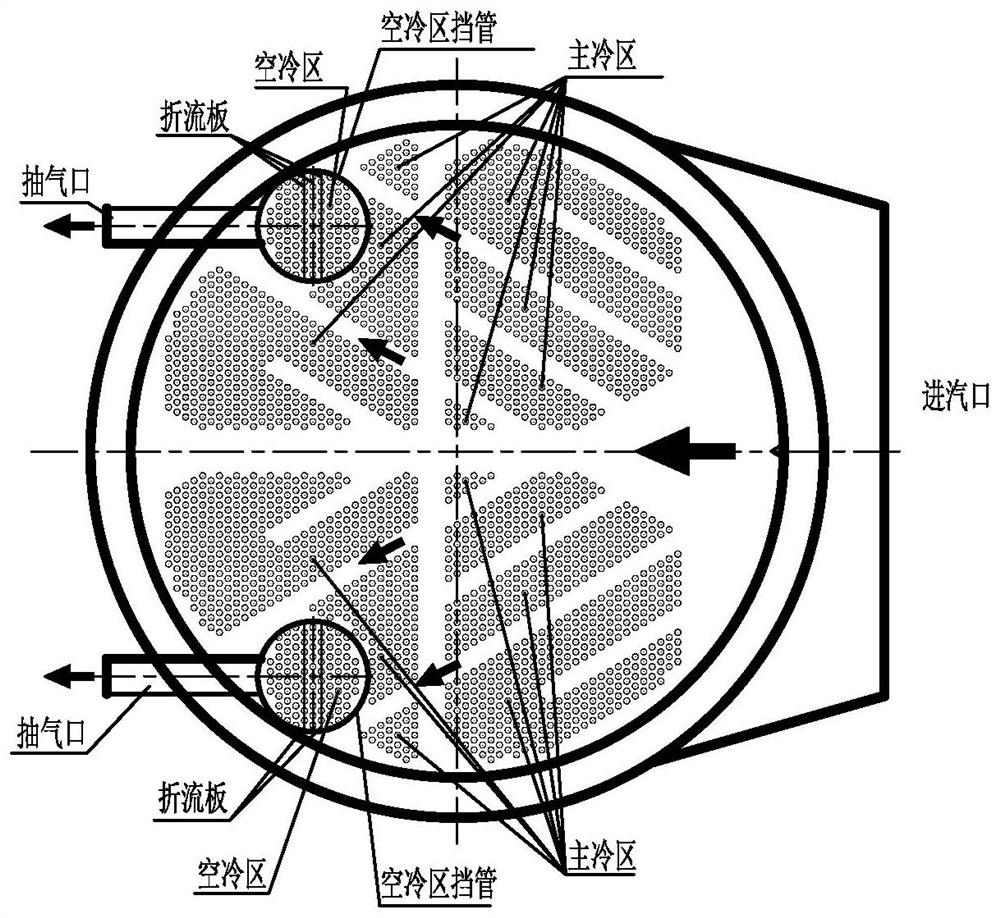

Air cooling area arrangement method of large-length-diameter-ratio lateral steam admission condenser

ActiveCN113686166AImprove heat transfer efficiencyReduce trafficSteam/vapor condensersMechanicsThermal efficiency

Owner:HANGZHOU GUONENG STEAM TURBINE ENGINEER

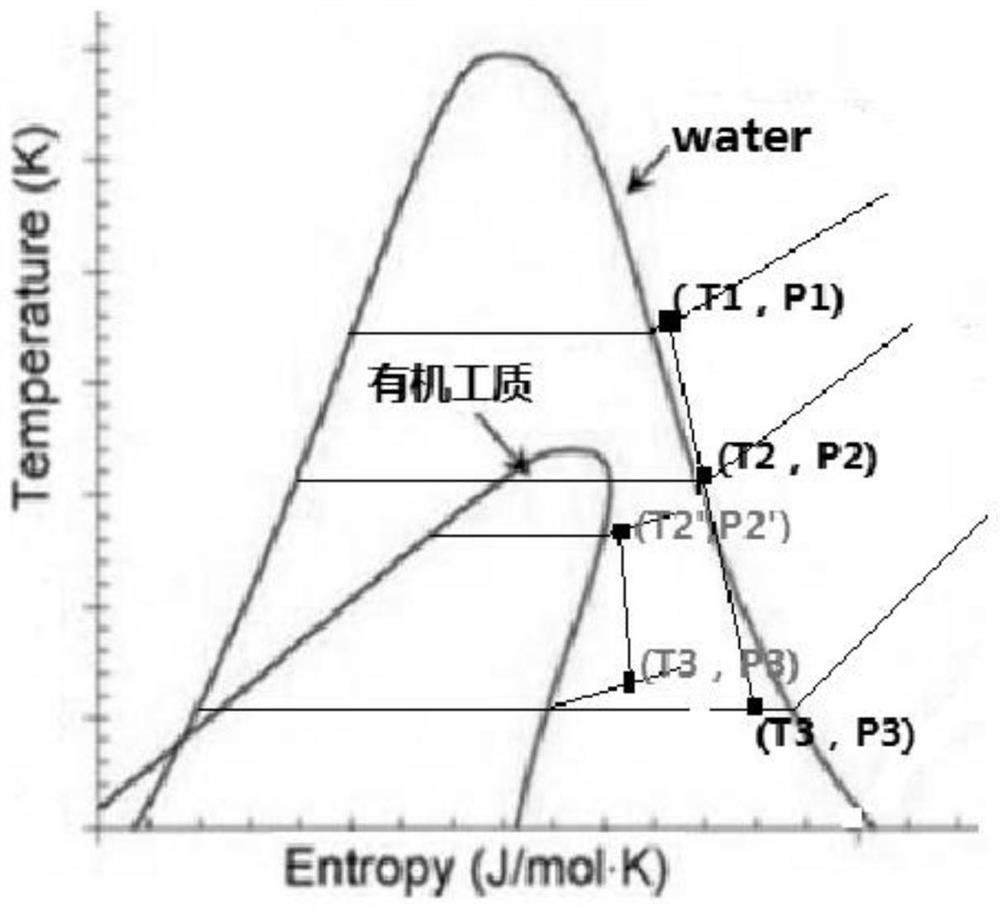

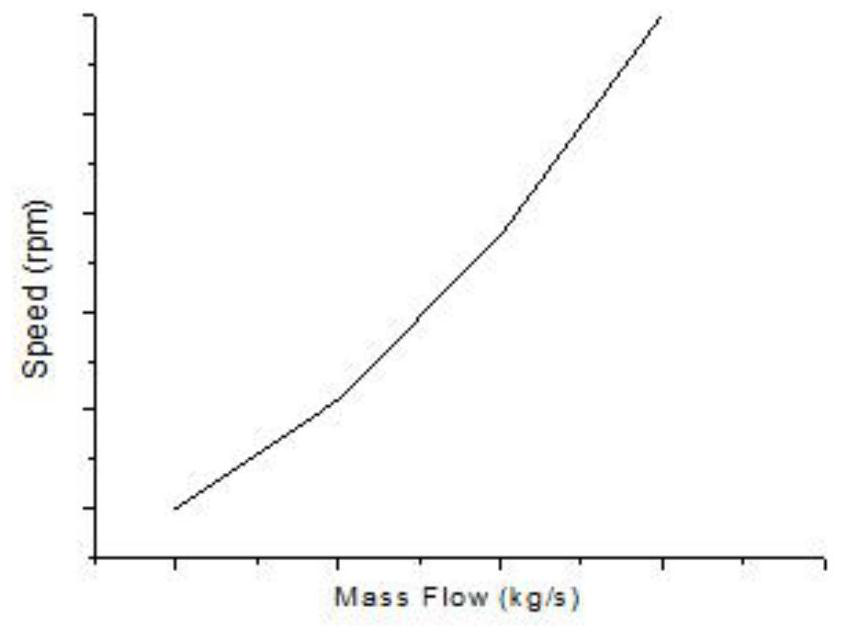

Combined power generation system for high-efficiency low-temperature and low-pressure steam waste heat utilization and control method thereof

PendingCN113738468ARealize cascade utilizationIncrease profitSteam useProcess engineeringElectric generator

Owner:CHONGQING JIANGJIN SHIPBUILDING IND

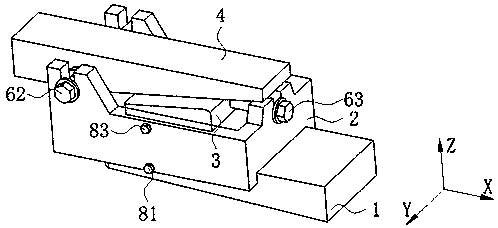

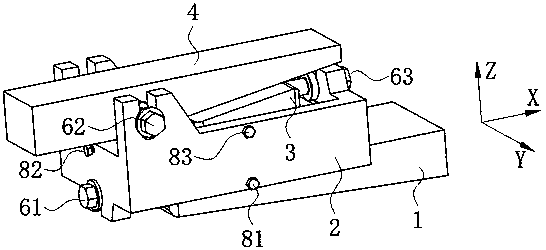

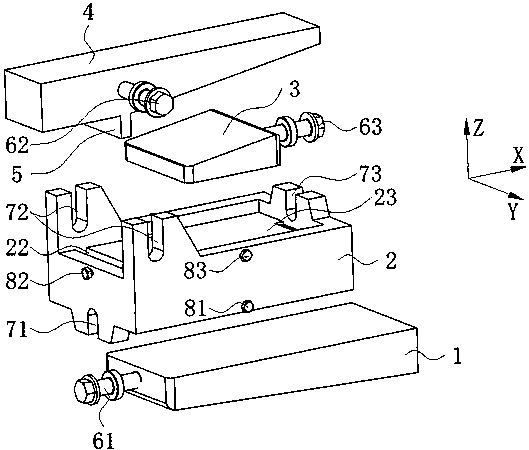

Six-direction adjusting supporting device used for assembling steam turbine stator part

ActiveCN109372599ASimple structureEasy to manufactureMachines/enginesEngine componentsEngineeringWedge shape

Owner:DONGFANG TURBINE CO LTD

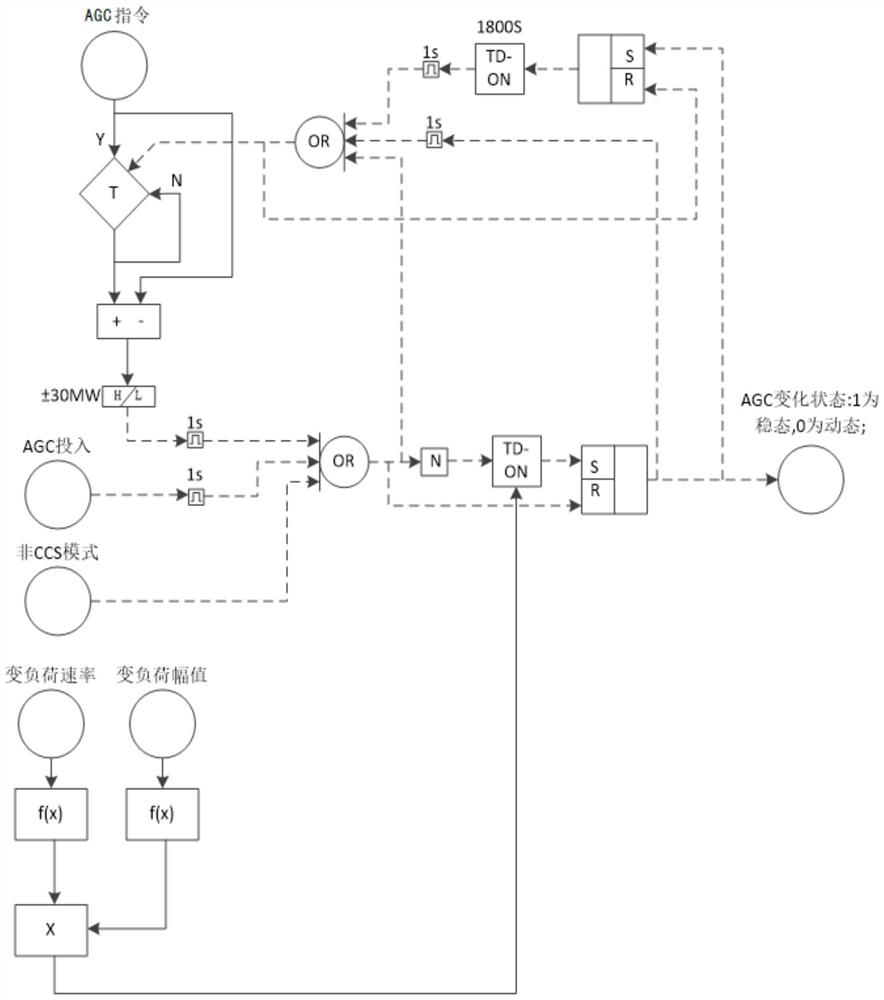

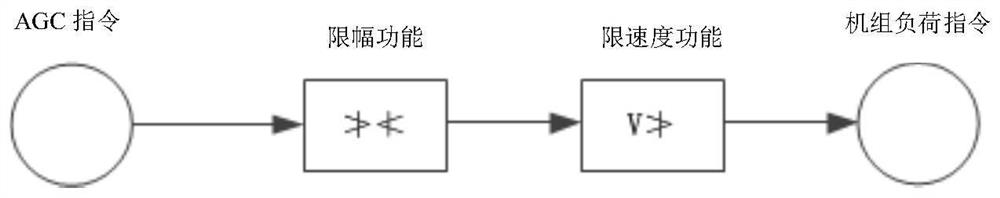

Coal-fired unit variable-rate load control method and device based on AGC instruction state change judgment

PendingCN114609902AImprove responsivenessImprove load regulation performance indicatorsSingle network parallel feeding arrangementsMachines/enginesSteam pressureLoad instruction

Owner:浙江浙能温州发电有限公司

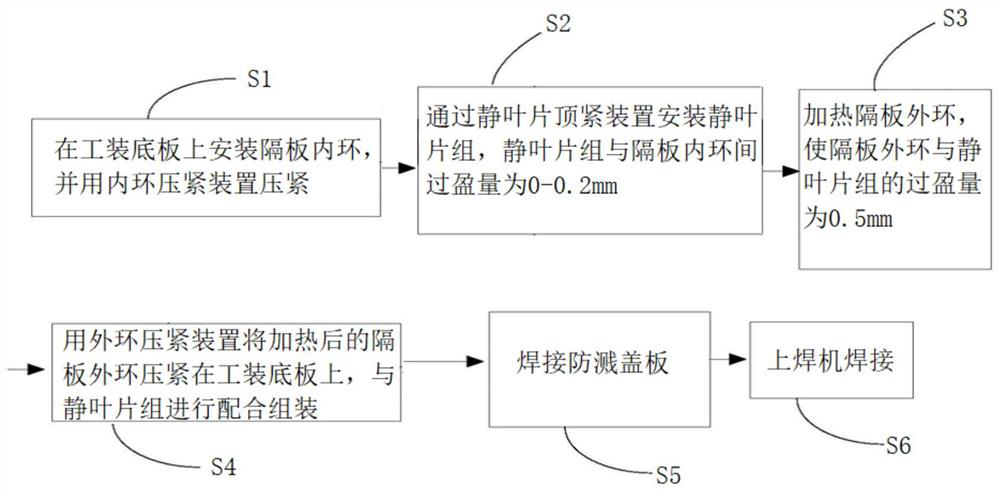

Full-circle assembling method for crown type grinding-fitting type partition plate of steam turbine

ActiveCN112377278AFacilitate the realization of full circle welding processEliminate gapsAssembly machinesMachines/enginesEngineeringSpot welding

Owner:北京国能龙威发电技术有限公司

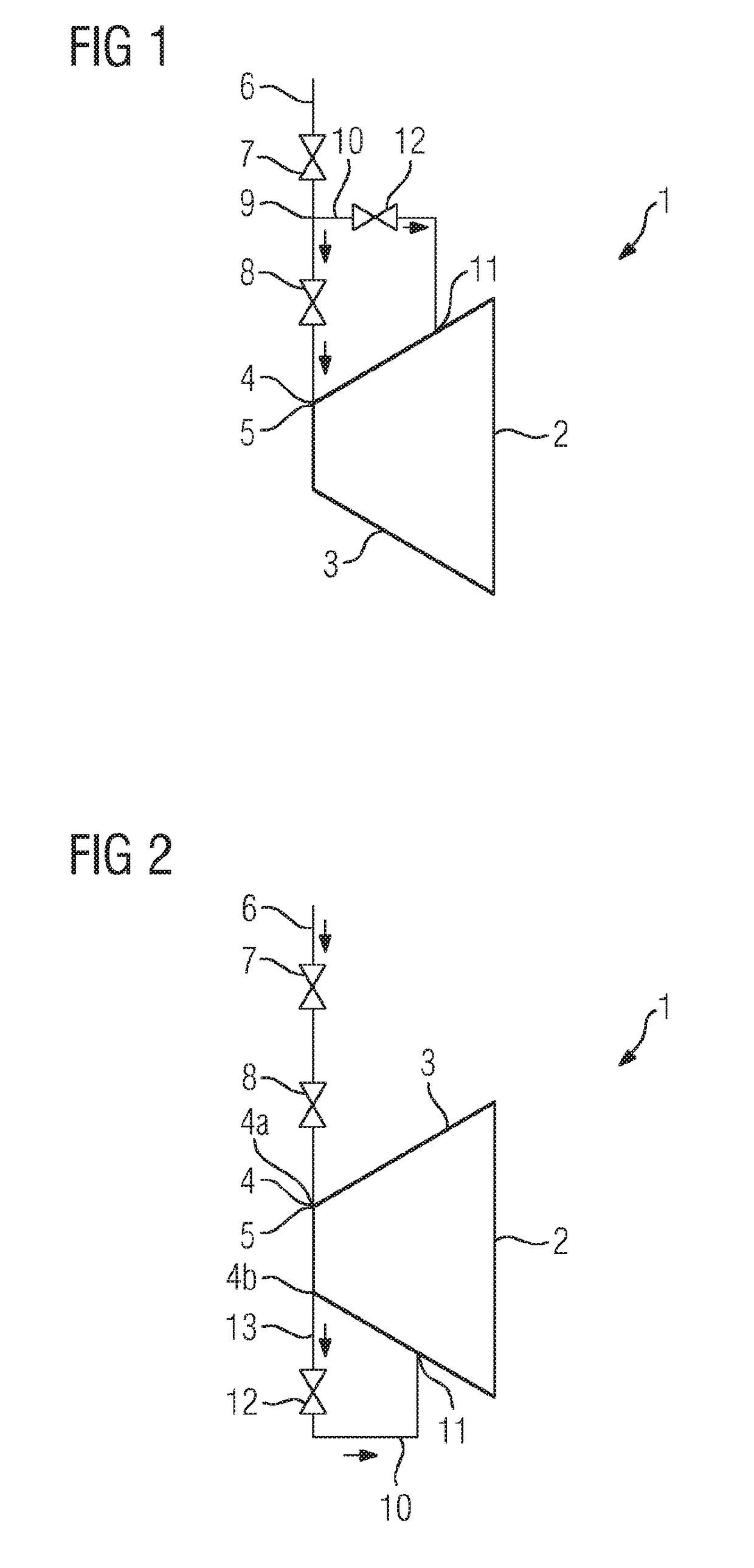

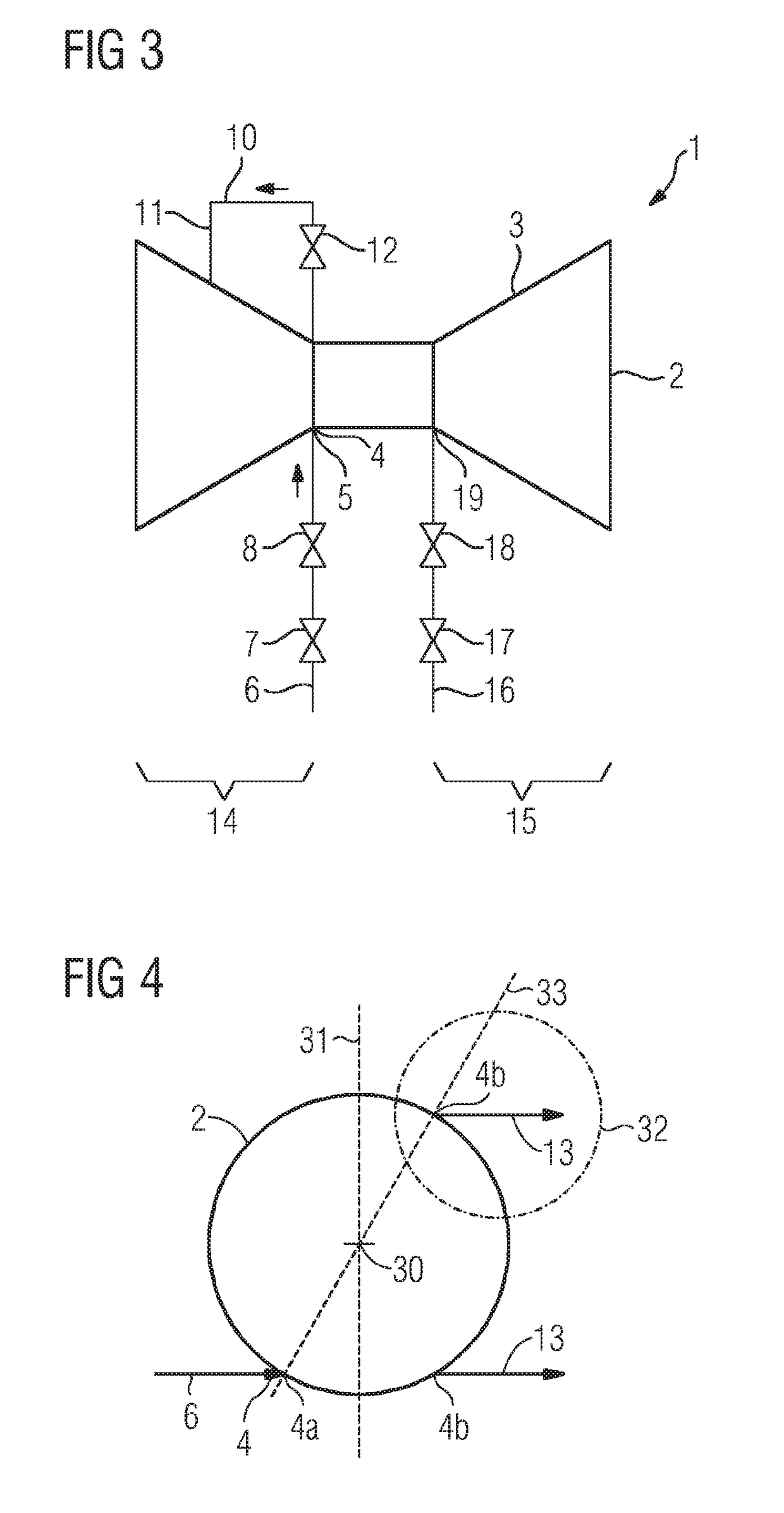

Overload introduction into a steam turbine

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap