Combined power generation system for high-efficiency low-temperature and low-pressure steam waste heat utilization and control method thereof

A low-temperature, low-pressure, steam waste heat technology, applied in steam applications, steam engine devices, machines/engines, etc., can solve the problems that low-temperature waste heat steam energy cannot be fully recovered and utilized, and steam turbines cannot achieve high-efficiency operation, so as to reduce design difficulty and ensure The effect of improving service life and utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

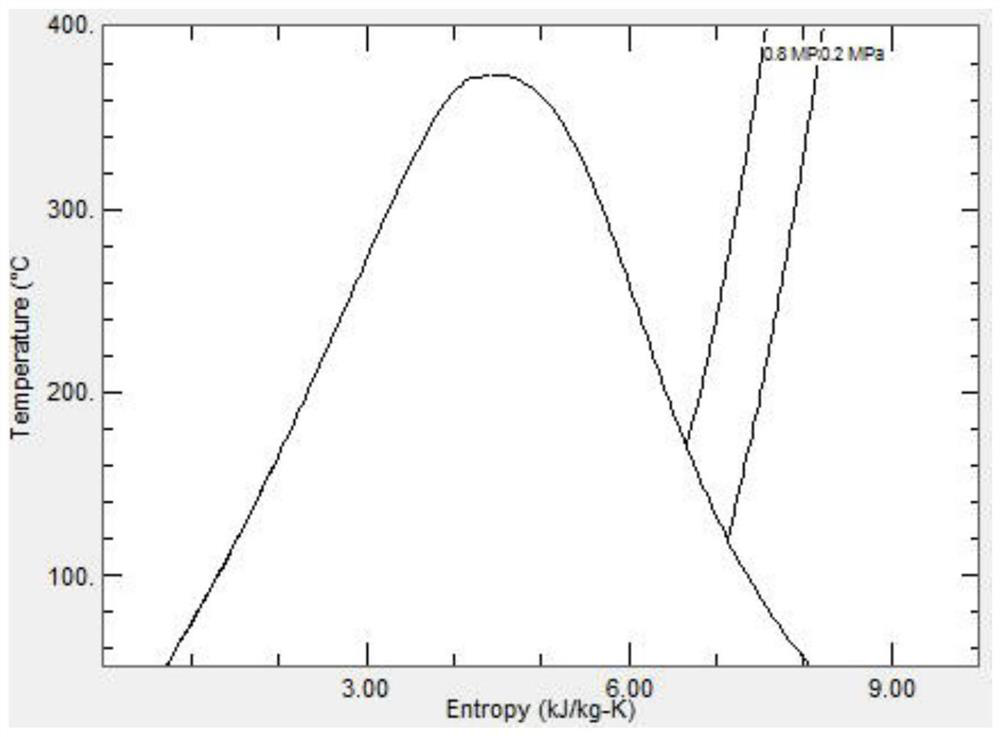

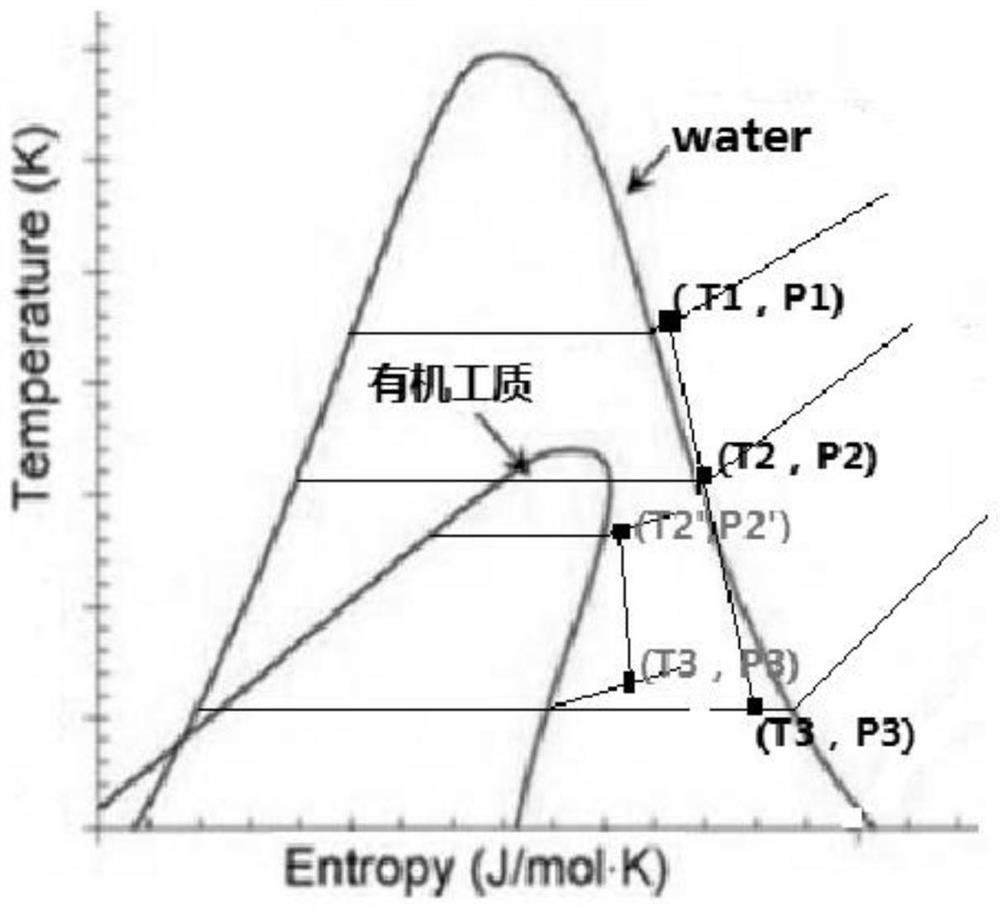

[0025] see Figure 5 , the present invention provides a high-efficiency low-temperature and low-pressure steam waste heat utilization combined power generation system, including:

[0026] Steam turbine 1, evaporator 2, organic working medium turbine 3, double extension shaft generator 4 and working medium circulation mechanism 5, the evaporator 2 is connected to the steam turbine 1, the organic working medium turbine 3 is connected to the The evaporator 2 is connected, the two ends of the double extension shaft generator 4 are respectively connected with the steam turbine 1 and the organic working medium turbine 3, and the working medium circulation mechanism 5 is arranged on the organic working medium turbine 3 and between the evaporator 2.

[0027] In this embodiment, the waste heat steam drives the steam turbine 1 to rotate; by using the waste heat steam from the tail of the steam turbine 1 to exchange heat with the liquid organic working medium, the working medium becomes a

Embodiment 2

[0031] see Figure 6 , the present invention provides a high-efficiency low-temperature and low-pressure steam waste heat utilization combined power generation system, including:

[0032] Steam turbine 1, evaporator 2, organic working medium turbine 3, double extension shaft generator 4 and working medium circulation mechanism 5, the evaporator 2 is connected to the steam turbine 1, the organic working medium turbine 3 is connected to the The evaporator 2 is connected, the two ends of the double extension shaft generator 4 are respectively connected with the steam turbine 1 and the organic working medium turbine 3, and the working medium circulation mechanism 5 is arranged on the organic working medium turbine 3 and between the evaporator 2.

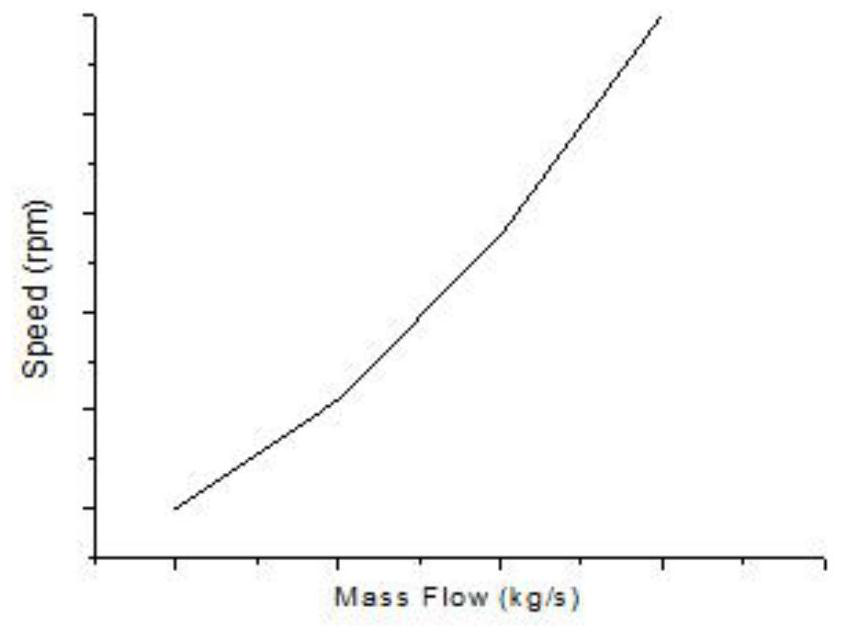

[0033] The double extension shaft generator 4 includes a motor body 41, a steam reducer 42 and a working medium reducer 43, and the two ends of the motor body 41 are respectively connected with the steam reducer and the working medium redu

Embodiment 3

[0047] see Figure 7 , the present invention provides a high-efficiency low-temperature and low-pressure steam waste heat utilization combined power generation system, including:

[0048] Steam turbine 1, evaporator 2, organic working medium turbine 3, double extension shaft generator 4 and working medium circulation mechanism 5, the evaporator 2 is connected to the steam turbine 1, the organic working medium turbine 3 is connected to the The evaporator 2 is connected, the two ends of the double extension shaft generator 4 are respectively connected with the steam turbine 1 and the organic working medium turbine 3, and the working medium circulation mechanism 5 is arranged on the organic working medium turbine 3 and between the evaporator 2.

[0049] The double extension shaft generator 4 includes a motor body 41, a steam reducer 42, a working medium reducer 43 and an overrunning clutch 44, and the two ends of the motor body 41 are connected to the steam reducer and the working

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap