Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

134 results about "Zinc" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Zinc is a chemical element with the symbol Zn and atomic number 30. Zinc is a slightly brittle metal at room temperature and has a blue-silvery appearance when oxidation is removed. It is the first element in group 12 of the periodic table. In some respects zinc is chemically similar to magnesium: both elements exhibit only one normal oxidation state (+2), and the Zn²⁺ and Mg²⁺ ions are of similar size. Zinc is the 24th most abundant element in Earth's crust and has five stable isotopes. The most common zinc ore is sphalerite (zinc blende), a zinc sulfide mineral. The largest workable lodes are in Australia, Asia, and the United States. Zinc is refined by froth flotation of the ore, roasting, and final extraction using electricity (electrowinning).

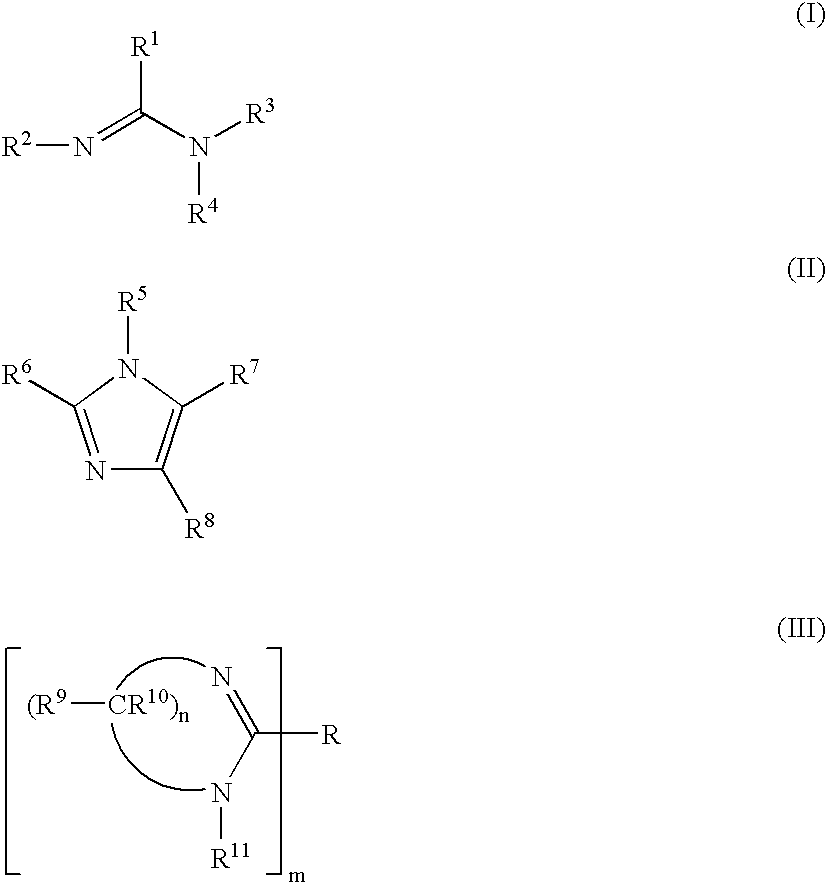

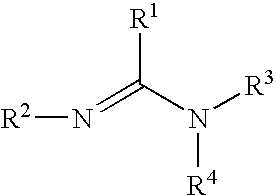

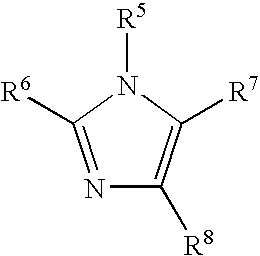

Organometallic compositions and coating compositions

InactiveUS20060036007A1Reduce yellowingImprove moisture resistanceOrganic-compounds/hydrides/coordination-complexes catalystsPolyurea/polyurethane coatingsCarbamateZinc

Owner:KING INDUSTRIES INC

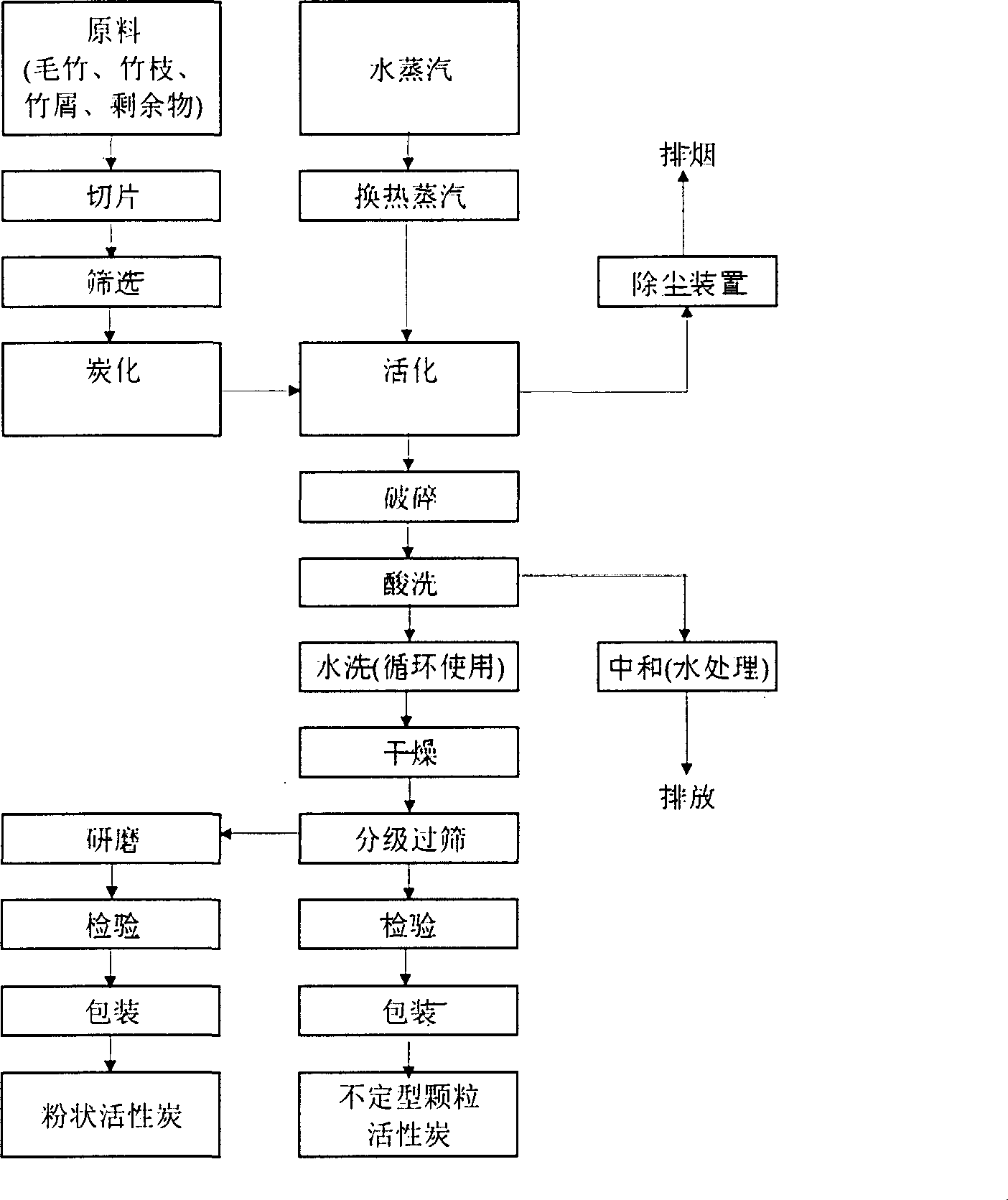

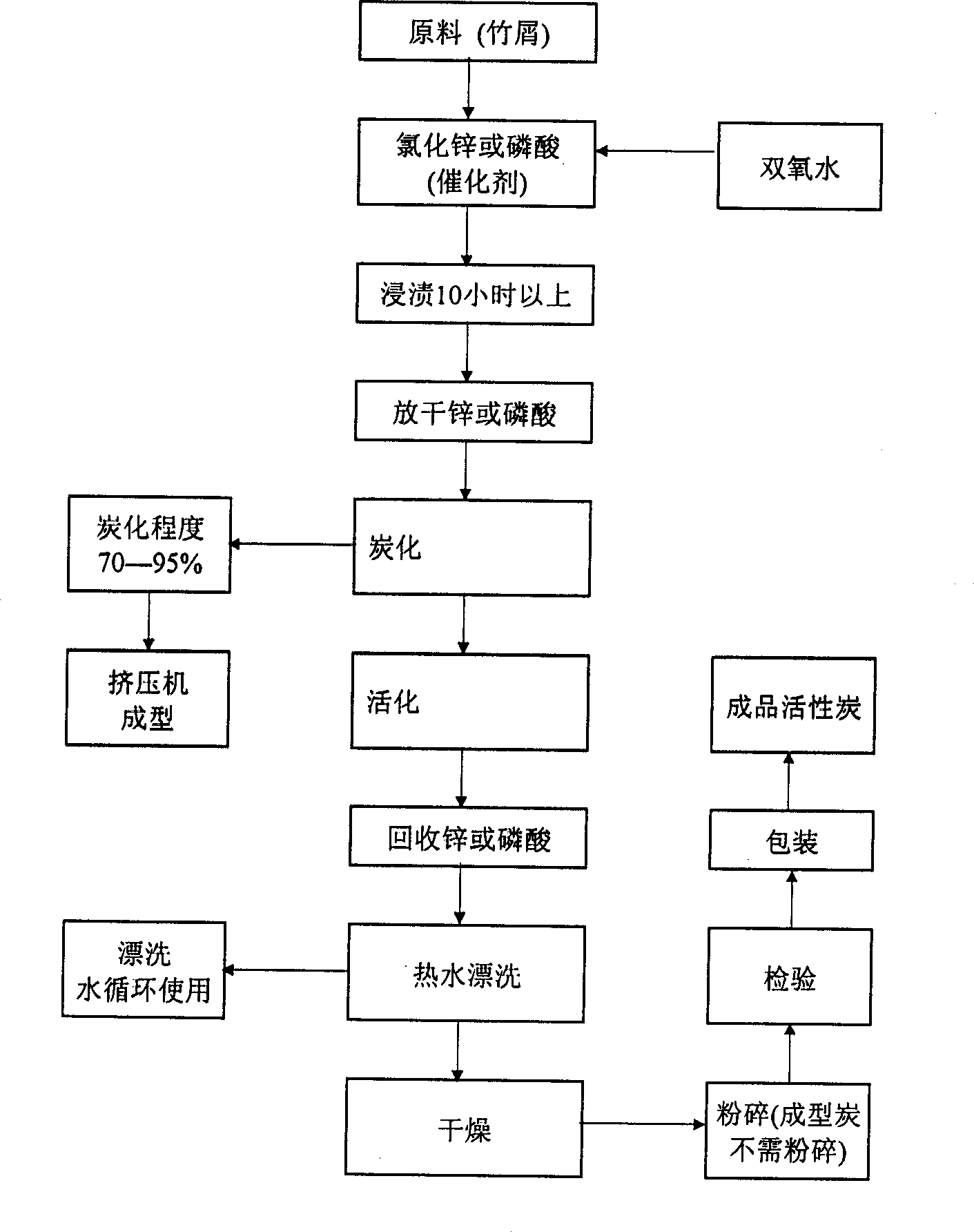

Method for preparing activated char from bamboo material

InactiveCN1333180AImproved decolorizationMesopore developedCarbon compoundsDistillationPhosphoric acid

Owner:尤匡银

Insulation rubber for longitudinal water-tight demagnetization cable used for ship, and manufacture method for insulation rubber

InactiveCN102746587AImprove insulation performanceImprove mechanical propertiesPlastic/resin/waxes insulatorsGas phaseAging resistance

The invention discloses an insulation rubber for longitudinal water-tight demagnetization cables used for ships and a manufacture method for the insulation rubber, belonging to the field of cables. The raw materials of the rubber are 15 parts of terpolymer EP rubber K21, 5 parts of terpolymer EP rubber 4045M; 0.5-0.6 parts of a vulcanizing agent DCP, 0.2-0.3 parts of a vulcanizing agent TAIC, 0.7-0.9 parts of an antioxidant MB, 0.2-0.3 parts of an antioxidant RD, 1.0-2.0 parts of paraffin oil, 1-2 parts of chlorinated paraffin-52, 0.5-1.0 parts of microcrystalline paraffin, 1.0-2.0 parts of zinc oxide, 0.3-0.5 parts of eleaostearic acid, 8-11 parts of powdered talcum, 1.0-1.5 parts of gas phase method silica, and 7-9 parts?of calcined pottery clay. First, mixing the raw rubbers of the terpolymer EP rubbers K21 and 4045 in an internal mixer; then adding the rest of the raw materials except the vulcanizing agents in sequence and mixing for 14-16 minutes, and after the obtained mixture being mixed uniformly, loading the obtained product on an open mill to make triangular bags eight times, followed by rubber sieving and sheets making. The insulation rubber has the advantages of good insulative and mechanical properties, aging resistance and oil resistance, which can satisfy the usage requirements of the longitudinal water-tight demagnetization cables used for ships.

Owner:JIAXING JUNHONG OPTICAL CO LTD

Method for desulphurizing, denitrating and decoking fire coal

The invention discloses a method for desulphurizing, denitrating and decoking fire coal. In the method, in a raw coal burning stage, a synergist is added in an amount of 0.2 to 0.3 weight percent based on the total weight of the raw coal into the fire coal, and a catalytic active agent is added in an amount of 0.002 to 0.008 weight percent based on the total weight of the raw coal into a slurry boax in a desulphurizing system at the same time. The synergist comprises 8 to 25 mass percent of calcium carbona, 5 to 15 mass percent of magnesium oxide, 5 to 10 mass percent of silicon dioxide, 5 to10 mass percent of zinc oxide, 8 to 10 mass percent of manganese dioxide, 15 to 40 mass percent of calcium oxide, 5 to 10 mass percent of barium hydroxide, 3 to 8 mass percent of aluminum oxide and 8to 15 mass percent of potassium permanganate; and the catalytic active agent comprises 0 to 40 mass percent of active calcium oxide, 20 to 30 mass percent of active carbon, 10 to 15 mass percent of calcium ammonium nitrate, 5 to 20 mass percent of ferric oxide and 2 to 10 percent of zinc oxide. Under the condition of not changing the conventional boiler equipment and process, the method can realize fire coal combustion-supporting and coal-saving functions at one time so as to perform desulphurization, denitration and decoking.

Owner:GUANGZHOU ZHONGKE GAOCHENG ENVIRONMENTAL PROTECTION TECH CO LTD

Vinyl acetate-ethylene copolymer emulsion as electrostatic spinning adhesive and synthesis method thereof

ActiveCN102030857AGood adhesionImprove water resistanceMonocarboxylic acid ester polymer adhesivesLiquid surface applicatorsCross-linkPolymer science

The invention relates to a vinyl acetate-ethylene copolymer emulsion as an electrostatic spinning adhesive and a synthesis method thereof. Organic peroxides and zinc formaldehyde sulfate are taken as an initiator; vinyl acetate, ethylene, acrylic ester monomers and cross-linking monomer N-hydroxymethyl acrylamide are taken as comonomers; a nonionic emulsifier, and the synthetic emulsion and the protective colloid of an amphoteric emulsifier are matched to be taken as an emulsification system; and the copolymer emulsion is prepared through emulsion polymerization. Compared with the VAE (vinyl acetate-ethylene) emulsion prepared by the conventional preparation method, the product in the invention has the advantages of good water resistance, strong adhesion on low-surface-energy materials (polyethylene, polypropylene and the like), fine grain and the like. The vinyl acetate-ethylene copolymer emulsion is suitable for being as the adhesive to be applied to the field of the electrostatic spinning in textile industry and the fields of waterproofing and packaging.

Owner:CHINA PETROCHEMICAL CORP +1

Transparent anti-static polyvinylidene fluoride piezoelectric material and preparation method thereof

InactiveCN103102623AImprove antistatic performanceExcellent piezoelectric propertiesCarbon nanotubePolyvinylidene difluoride

The invention relates to a transparent anti-static polyvinylidene fluoride piezoelectric material and a preparation method thereof. The filler is very difficult to uniformly disperse by adding carbon nano-tubes, graphene or zinc oxide to PVDF (Polyvinylidene Fluoride) material in the prior art; and the material is directly transmitted to be conductive from insulating, and is not attractive. The polyvinylidene fluoride piezoelectric material is a mixture of polyvinylidene fluoride and ionic liquid. The preparation method of the transparent anti-static polyvinylidene fluoride piezoelectric material comprises the following steps of: drying the polyvinylidene fluoride and the ionic liquid for 24 hours to 48 hours at 80 DEG C to 110 DEG C in a vacuum environment; adding the dried polyvinylidene fluoride and ionic liquid in a mass ratio of 100:(0.5-40) to a fusion smelting device for melting-blending at 180 DEG C to 200 DEG C to obtain a mixture; and discharging the mixture from the melting-blending device, cooling the mixture to normal temperature and crystallizing the cooled mixture to obtain the polyvinylidene fluoride piezoelectric material. The polyvinylidene fluoride piezoelectric material disclosed by the invention has good antistatic property, good piezoelectricity and excellent transparency. According to the preparation method of the polyvinylidene fluoride piezoelectric material disclosed by the invention, the normal melting-blending device is only needed to be used, and the industrial preparation is simple.

Owner:HANGZHOU NORMAL UNIVERSITY

Method for preparing ZnWO4 nanorod photocatalysis material

InactiveCN102935360APhotocatalyticWith photocatalytic effectMetal/metal-oxides/metal-hydroxide catalystsTungsten compoundsHeat treatedNanorod

Owner:SHAANXI UNIV OF SCI & TECH

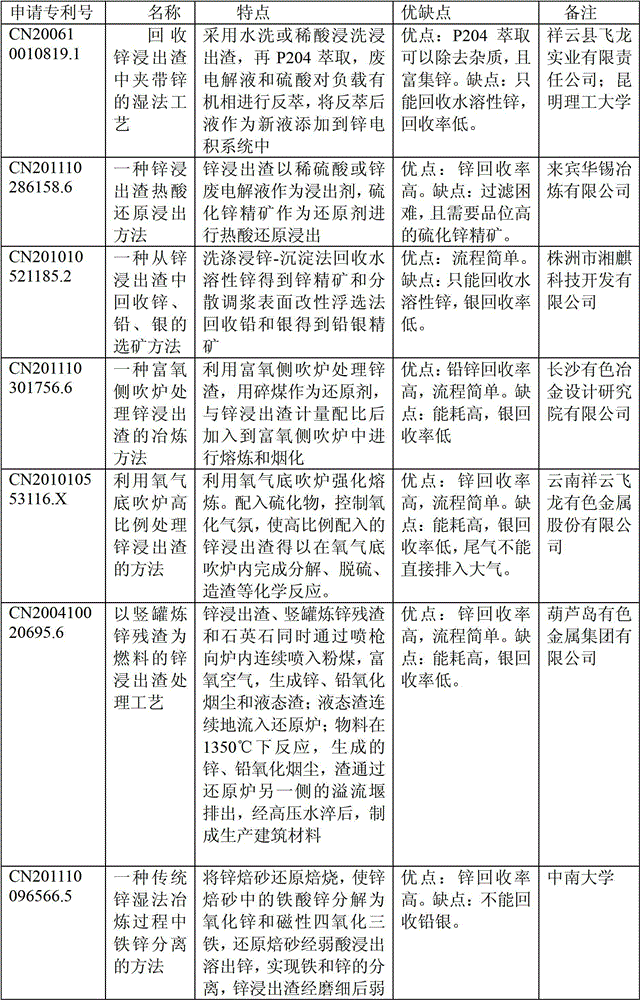

Technology for extracting zinc, lead and silver step by step by processing zinc-leached residues by full wet process

ActiveCN102719668AHigh extraction rateAchieve recyclingProcess efficiency improvementHigh concentrationSlurry

Owner:JIANGXI LONGTIANYONG NONFERROUS METAL CO LTD

High-strength corrosion-resistant micro-alloying copper pipe and manufacturing method thereof

The invention discloses a high-strength corrosion-resistant micro-alloying copper pipe material which consists of the following components in percentage by weight: 0.005-0.04% of phosphorus, 0.2-1.0% of tin, 0-0.04% of lanthanum, 0-0.04% of cerium, 0-0.1% of nickel, 0-0.1% of zinc, 0-0.05% of cobalt, 0-0.1% of manganese, 0-0.05% of zirconium and the balance of copper. By combining phosphorus with rare earth lanthanum and / or cerium to obtain a deoxidizer of molten copper, the content of oxygen in melt is further reduced, the grain structure is refined, the recrystallization temperature is increased to prevent abnormal growth of the weld structure grain, and the ductility and thermal conductivity of copper are further improved. Through solid solution strengthening of tin and improvement of an oxide film on a surface layer, the strength and corrosion resistance of a matrix are improved. By adding trace amount of zinc, nickel and manganese subjected to solid solution into the copper matrix, the strength of the copper matrix is improved; by adding cobalt or zirconium and dispersing into the copper matrix, the strength and heat resistance of the copper matrix are improved; the combination effect is better than the performance and using effect of the existing oxygen-free copper pipe or single phosphorus deoxidization copper pipe.

Owner:NINGBO JINTIAN COPPER TUBE +1

Formula of highly anti-fatigue automobile brake chamber rubber diaphragm material

ActiveCN101302311ASolve the blending problemImprove thermal stabilityPolytetramethylene terephthalateRubber material

The invention provides a rubber material formulation for a high fatigue resistant rubber diaphragm of an automobile brake chamber, which is mainly prepared by natural rubber (NR), styrene butadiene rubber (SBR), polybutylene terephthalate (PBT), vulcanizing agent, zinc oxides, stearic acid, anti-aging agent, dispersant, accelerant, carbon black, aromatic oil and white carbon black. The physical mechanical properties of the rubber diaphragm of the automobile brake chamber prepared by the rubber formulation all reach the novel standard drafted by the Society of Automotive Engineering (SAE) of America; the service life of a platform of the rubber diaphragm reaches over 2 million times; the platform has the advantages of high stress at definite elongation, strength and elongation property, compression fatigue resistivity, flexural deformation resistance and attrition resistance, and maintenance of small variation of the material characteristics within the wide use temperature between 55 and 100 DEG C when the material is used; and the service life of the platform is basically the same as that of an air brake assembly, and resource conservation is greatly promoted simultaneously, thereby realizing conversion of the platform from 'a wearing part' to 'a permanent part'.

Owner:GUIZHOU JINGZHONG RUBBER & PLASTIC IND CO LTD

Composite reinforced multinutrition rice and process thereof

ActiveCN102067969AMeeting nutritional needsShorten soakFood preparationCALCIUM LACTOBIONATEGluconates

Owner:天津知味米有限公司

Process for recovering valuable metal from residues containing zinc

ActiveCN101845551AReduce contentRealize continuous operationProcess efficiency improvementHearthOxygen

Owner:CHINA ENFI ENGINEERING CORPORATION +1

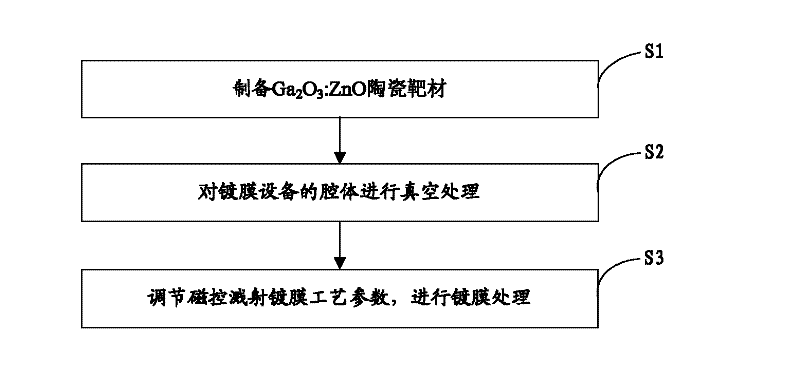

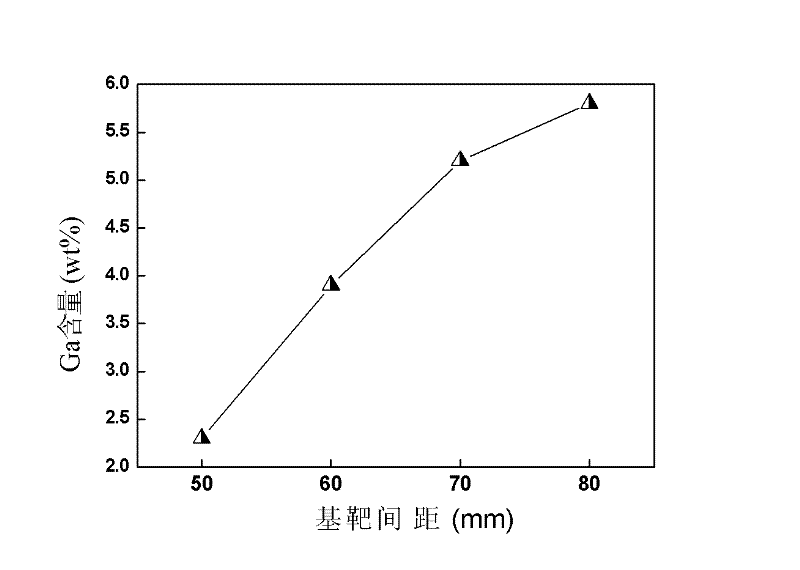

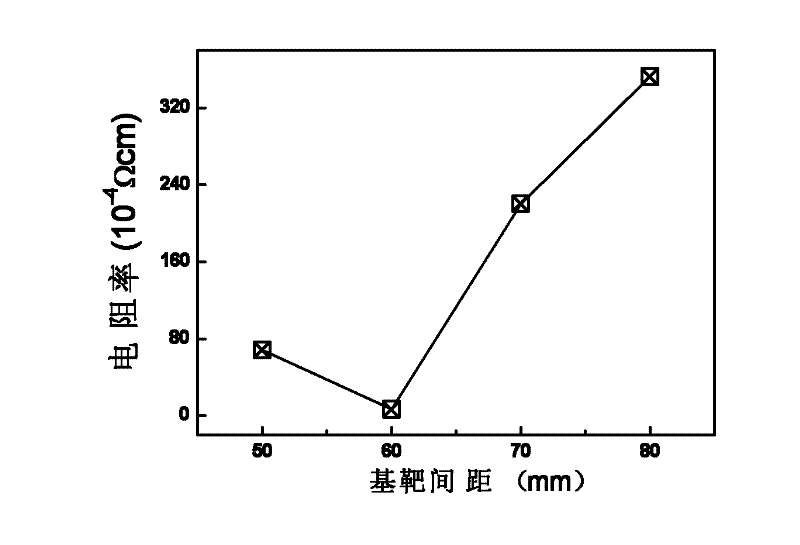

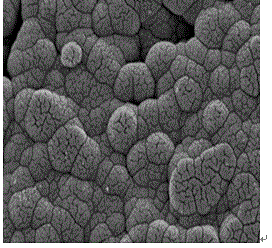

Gallium-doped zinc oxide transparent conducting film, and preparation method and application thereof

InactiveCN102534498AHigh resistivityVacuum evaporation coatingSputtering coatingTransparent conducting filmOmega

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

Oil resistant rubber

The invention discloses an oil resistant rubber, which is composed of the following components by weight: 40-60 parts of fluorine rubber, 20-30 parts of natural rubber, 10-15 parts of nitrile rubber, 20-40 parts of carbon black, 15-30 parts of white carbon black, 0.5-2 parts of antioxidant RD, 1-2 parts of antioxidant 4010 Na, 2-4 parts of paraffin, 25-35 parts of light calcium carbonate, 2-3 parts of eleaostearic acid, 3-5 parts of zinc oxide, 5-10 parts of magnesium oxide, 1-2 parts of 2, 2'-dibenzothiazyl disulfide, 3-4 parts of coumarone and 0.2-0.8 parts of vulcanizing agents. The oil resistant rubber provided by the invention has the advantages of oil resistance, airtight and good high temperature resistance.

Owner:GUANGZHOU CHONGQI IND CO LTD

Acidic electroplating zinc-nickel alloy electrolyte, preparation method and electroplating method

Owner:南通创源电化学科技有限公司

High-performance water-based bicomponent epoxy zinc rich primer and preparation method thereof

ActiveCN107573816AReduce usageImprove protectionAnti-corrosive paintsEpoxy resin coatingsEpoxyCollocation

The invention relates to a high-performance water-based bicomponent epoxy zinc rich primer and a preparation method thereof. A water-based bicomponent epoxy zinc rich coating A in the high-performancewater-based bicomponent epoxy zinc rich primer comprises a water-based epoxy curing agent, an additive A, a complex solubilizer, zinc powder, zinc and an anti-settling agent; a water-based bicomponent epoxy zinc rich coating B comprises a water-based epoxy emulsion and an additive B; the weight ratio of the coating A to the coating B is at 100 to (10-30). The preparation method comprises the following steps: (1) uniformly mixing the components in the coating A at ratio and using a 100-mesh screen for filtering; (2) uniformly mixing the components in the coating B at ratio; and uniformly mixing the coating A with the coating B at the weight ratio in a use process and regulating the construction viscosity. When the high-performance water-based bicomponent epoxy zinc rich primer is used, water is taken as a solvent, so that the use of the organic solvent is greatly reduced and the environmental protection is benefited. The collocation of the anti-settling agent is utilized to solve the problems of storage and construction.

Owner:SHANDONG QIWEI NEW MATERIALS CO LTD

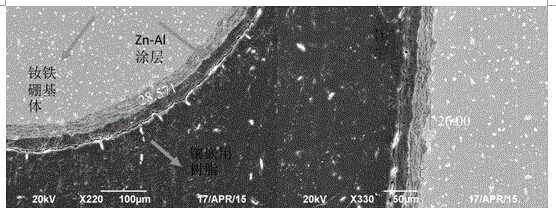

Zinc-aluminum coating enhanced with particles in micro-nano sizes and production method of zinc-aluminum coating

InactiveCN104984889AImprove mechanical propertiesImprove scratch resistancePretreated surfacesSpecial surfacesMicro nanoSilicon oxide

Owner:EARTH PANDA ADVANCE MAGNETIC MATERIAL

Factory formula for aging-resistant rubber strip

Owner:JIANGSU DAHAI PLASTIC

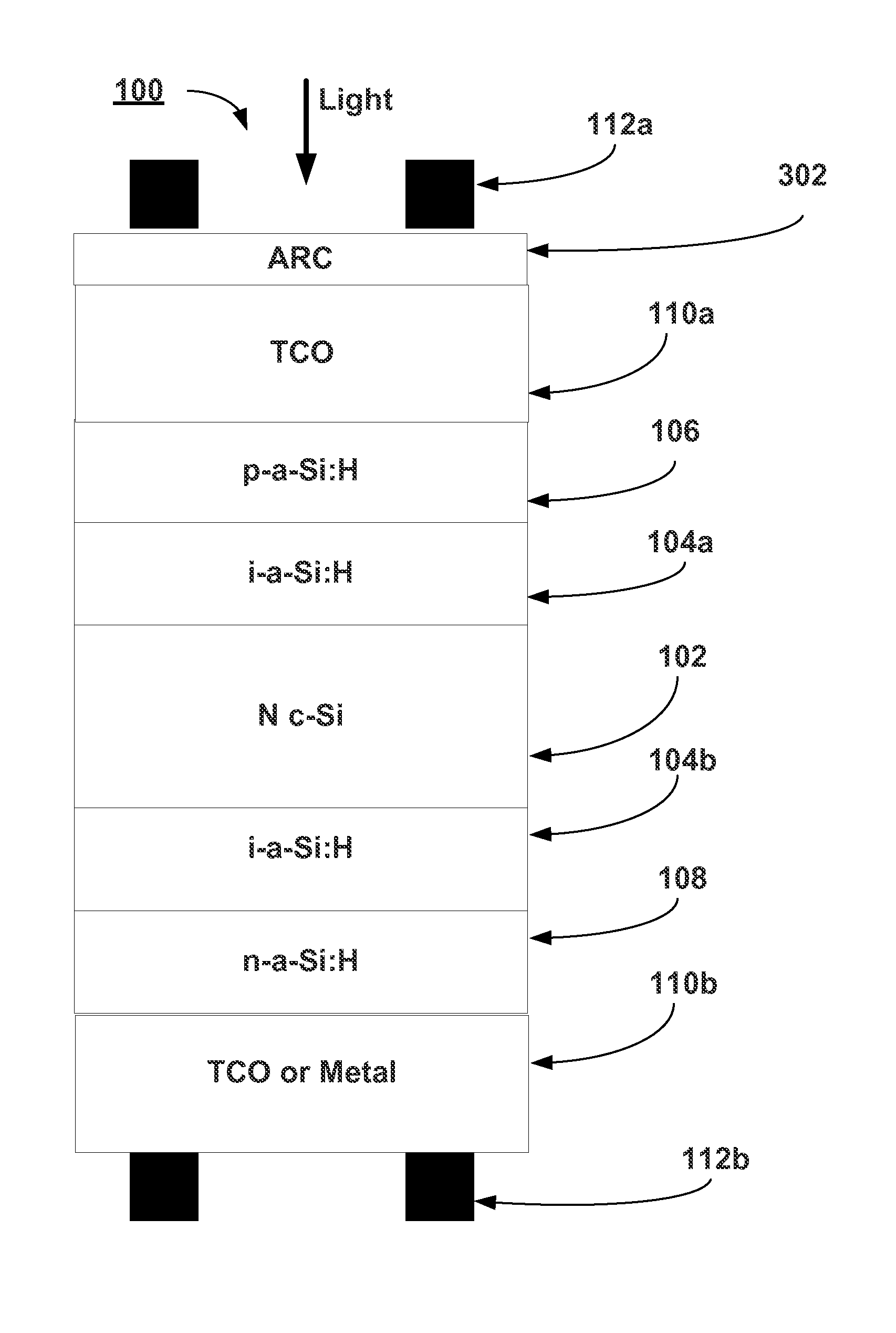

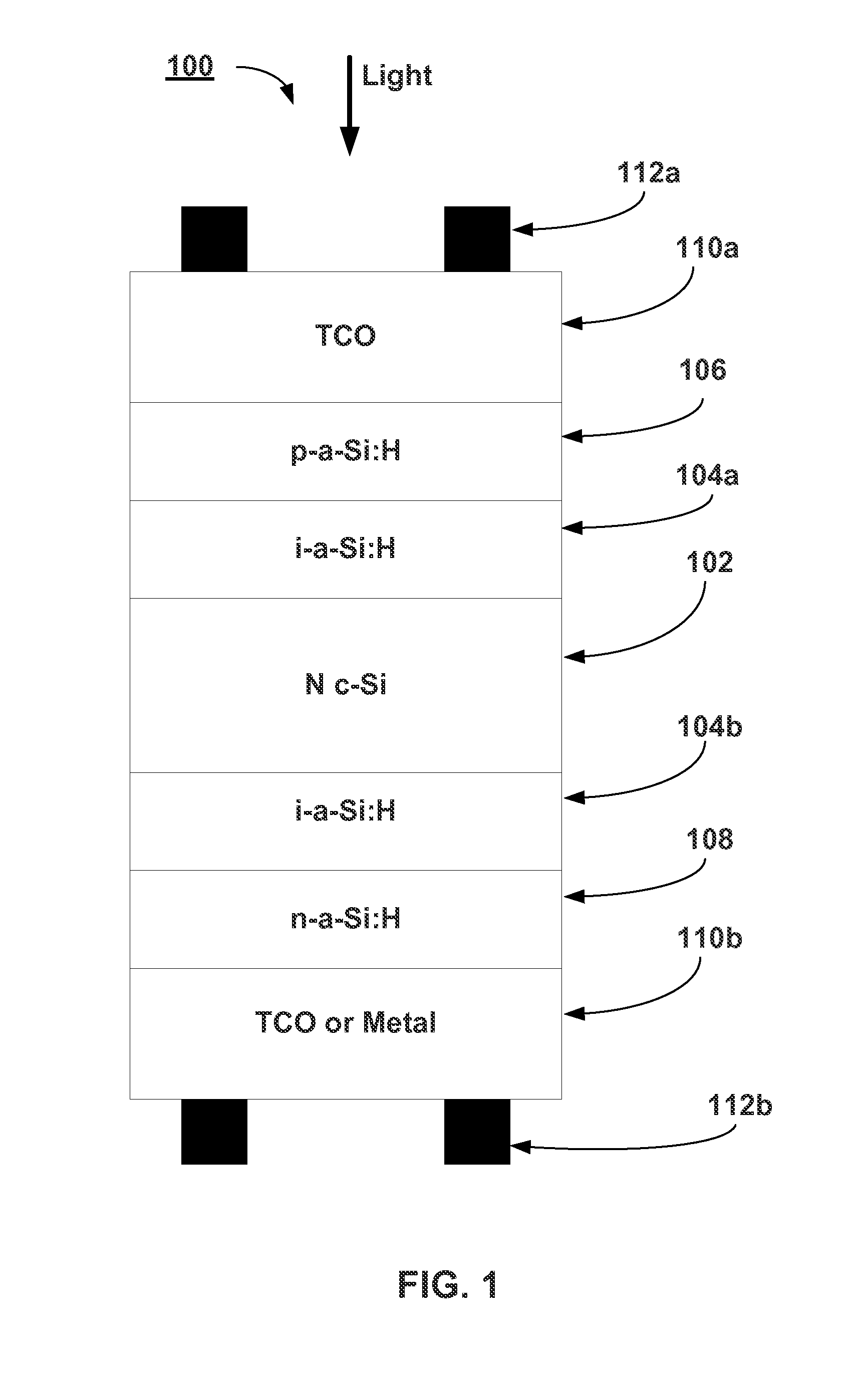

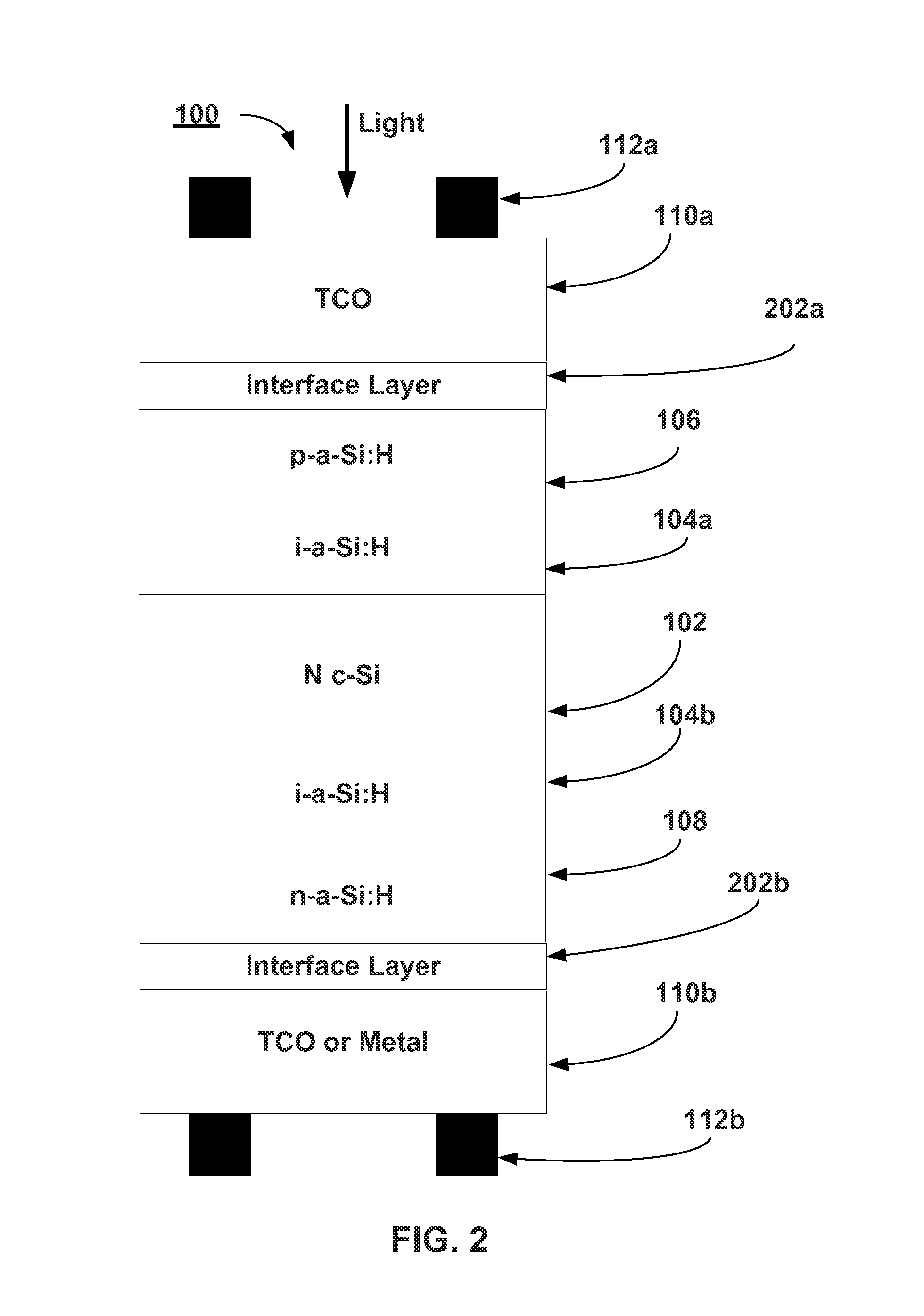

TCOs for Heterojunction Solar Cells

InactiveUS20140261660A1Easy to controlReduce sensitivitySemiconductor/solid-state device manufacturingPhotovoltaic energy generationHeterojunctionIndium

Owner:INTERMOLECULAR

Bicomponent epoxy zinc enriched base paint and its manufacturing method

ActiveCN1912032ALong application periodStrong adhesionAnti-corrosive paintsEpoxy resin coatingsEpoxySilanes

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

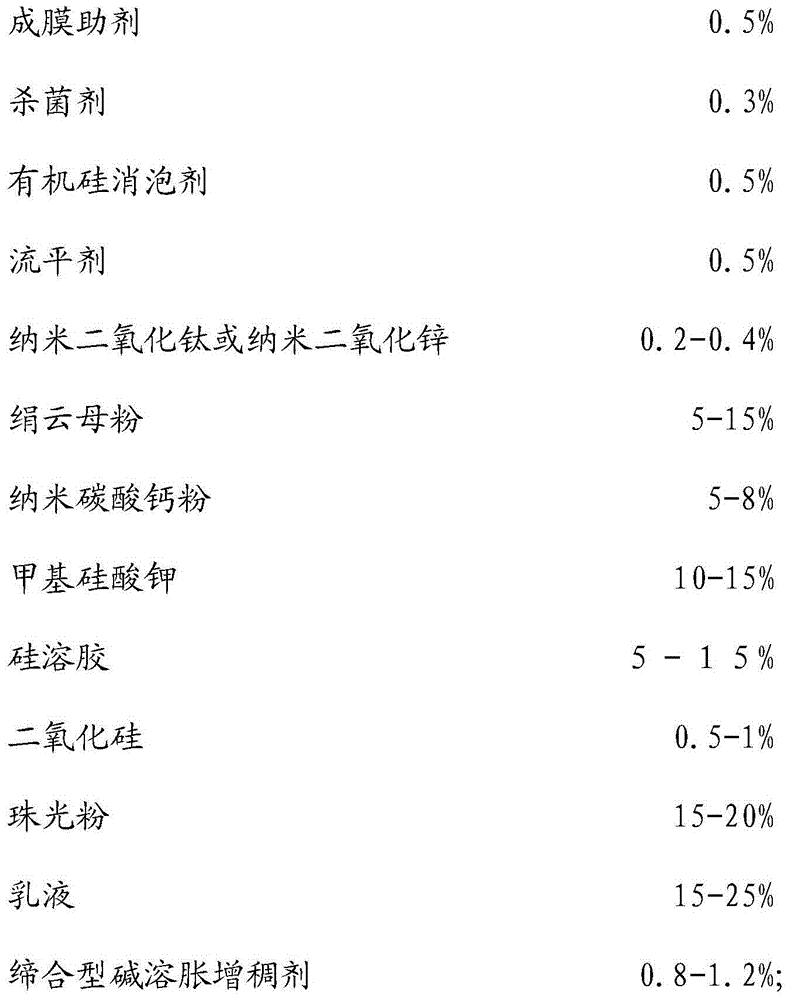

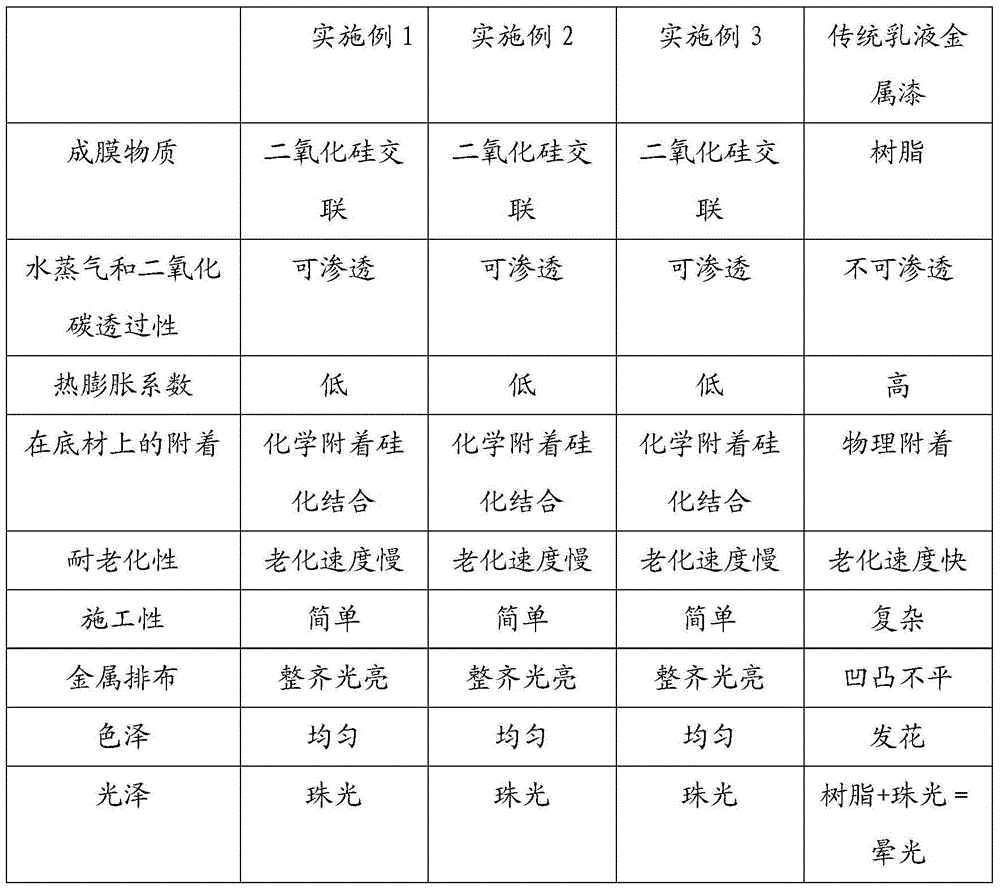

Inorganic water-based metallic paint and preparation method thereof

Owner:佛山市南海万磊建筑涂料有限公司

Soil ecological system restoring organic fertilizer

InactiveCN105565959AHigh substance contentReduce in quantityFertilizer mixturesMicrobial agentPhosphate

Owner:广西天利丰农林科技有限公司

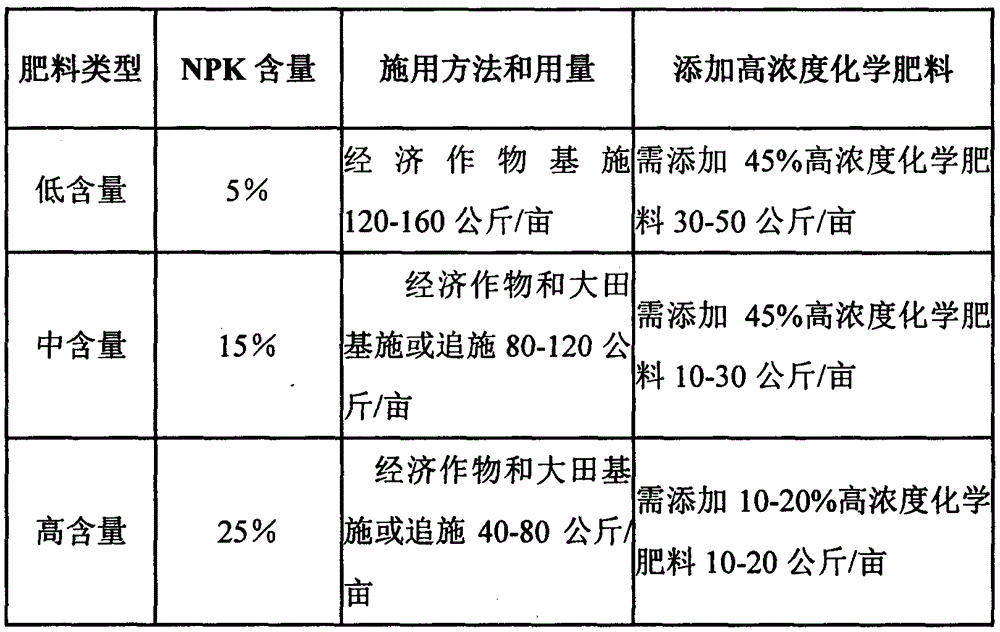

Multifunctional organic/inorganic compound fertilizer and preparation method thereof

Owner:山东华粮生物工程集团股份有限公司

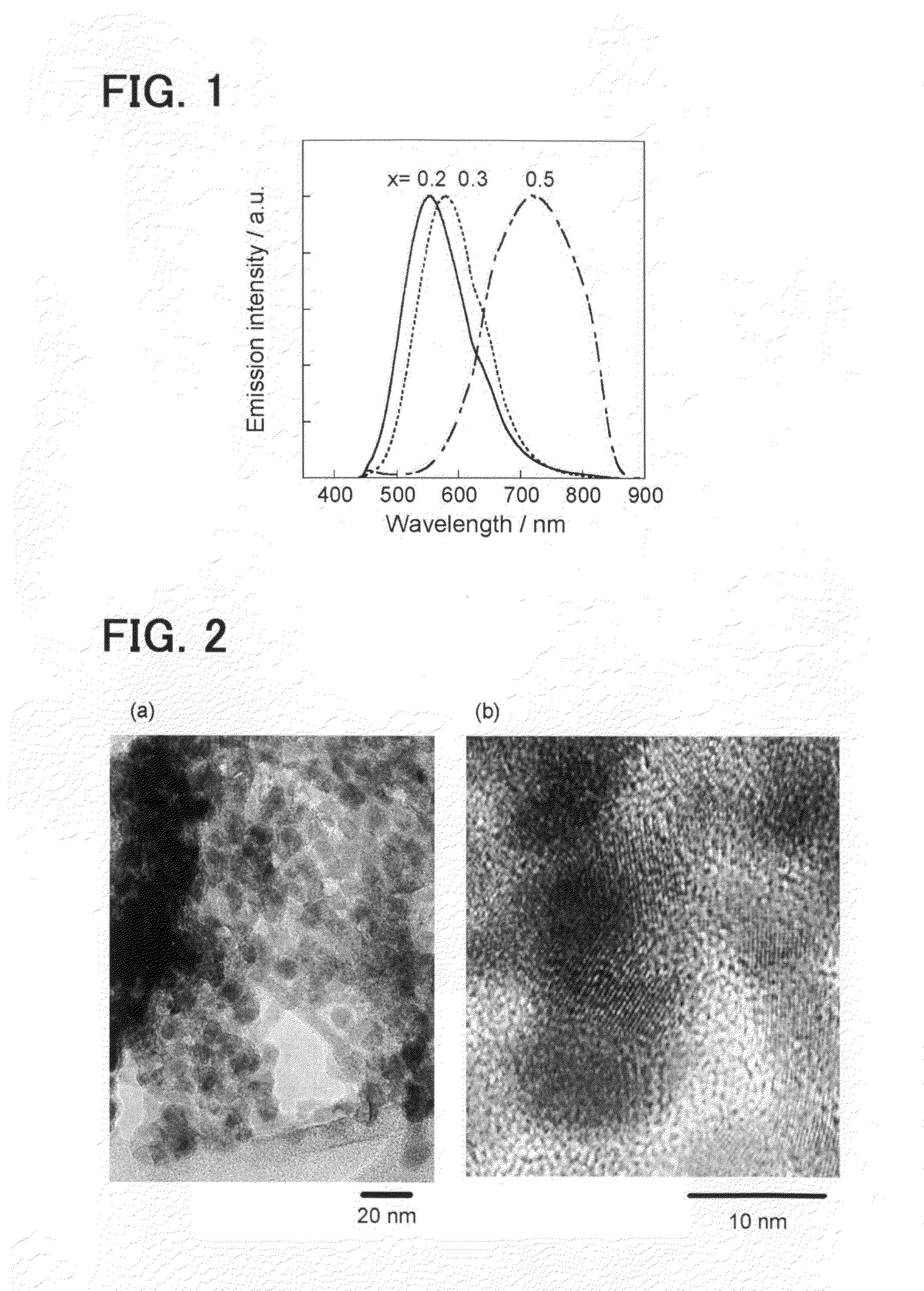

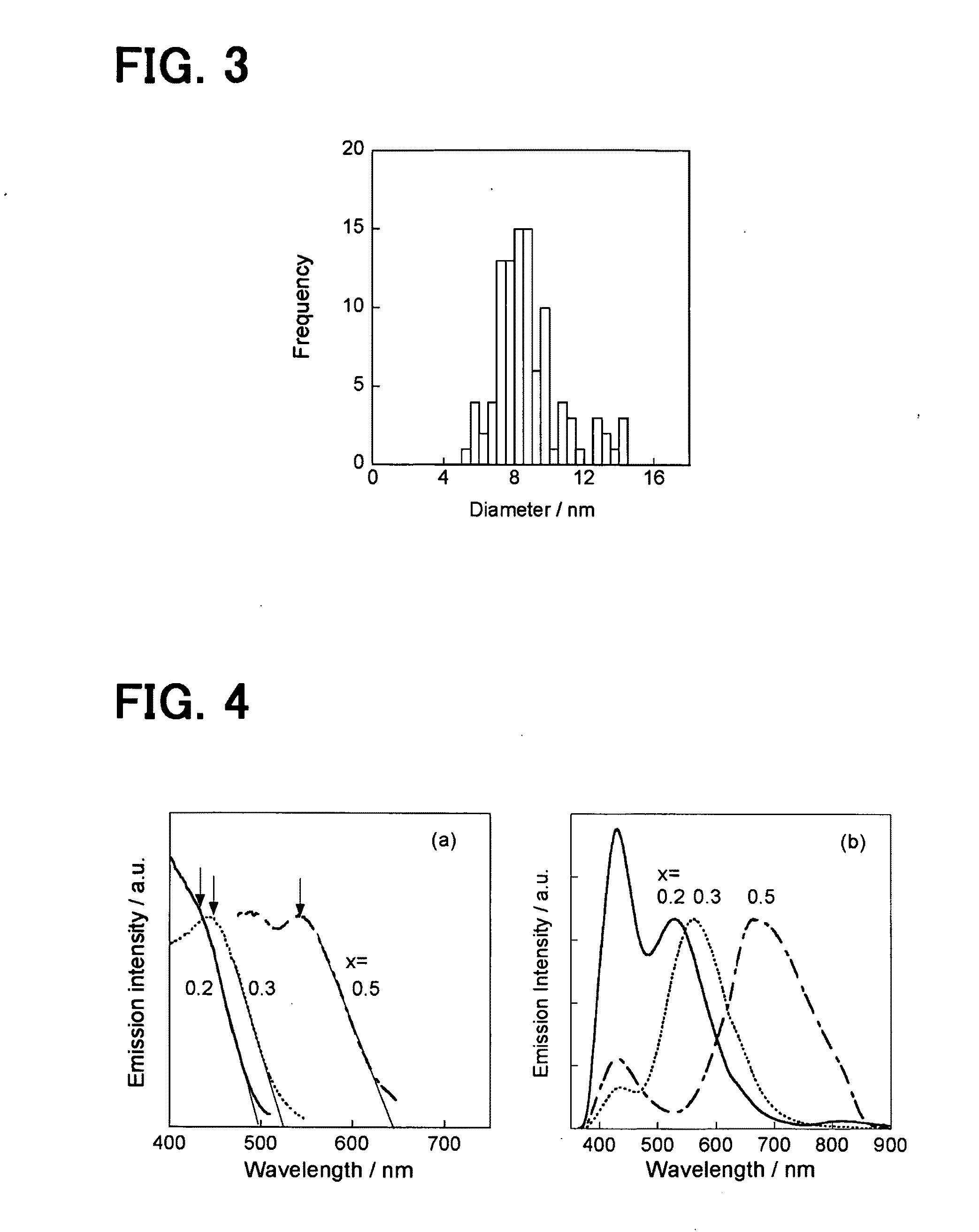

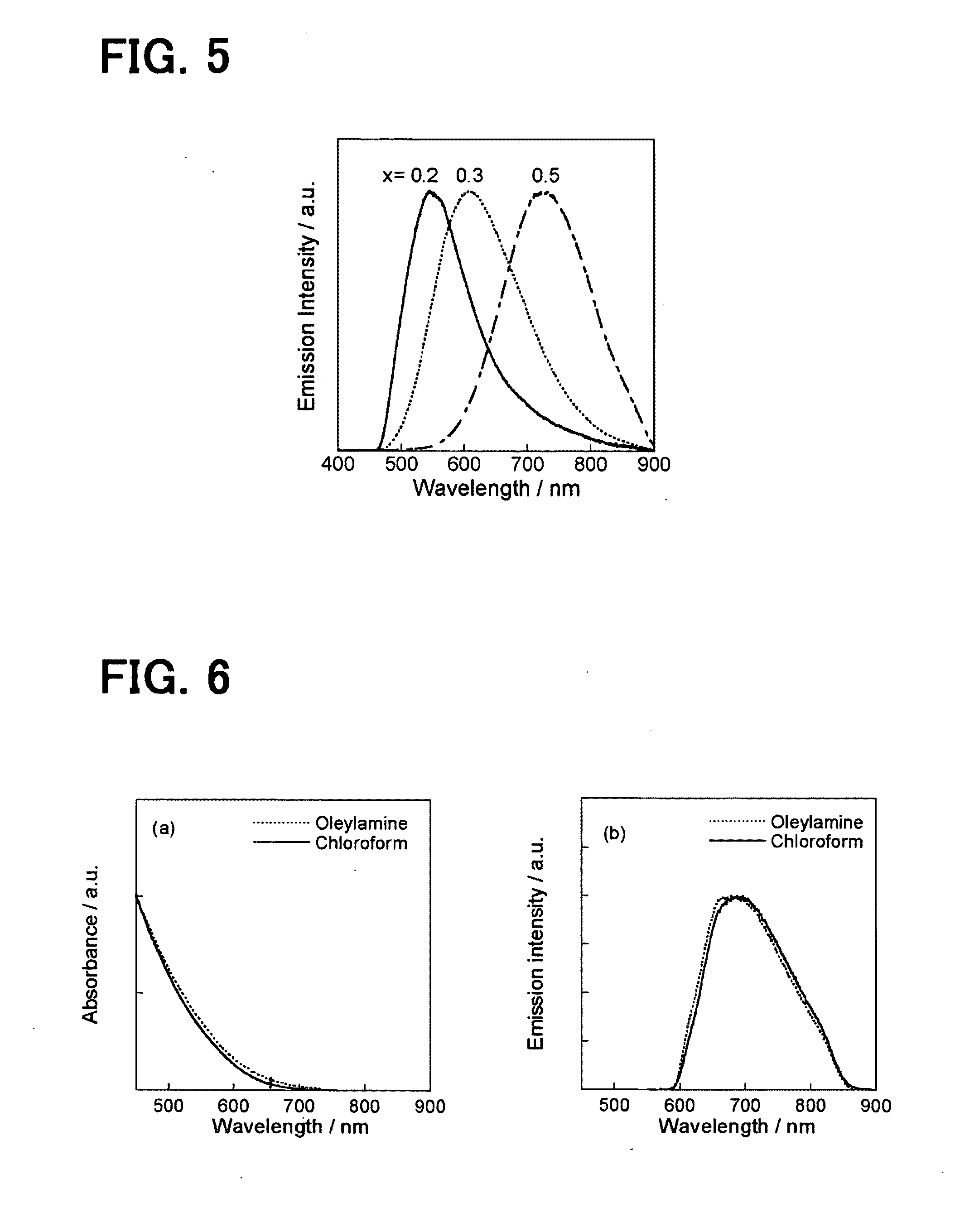

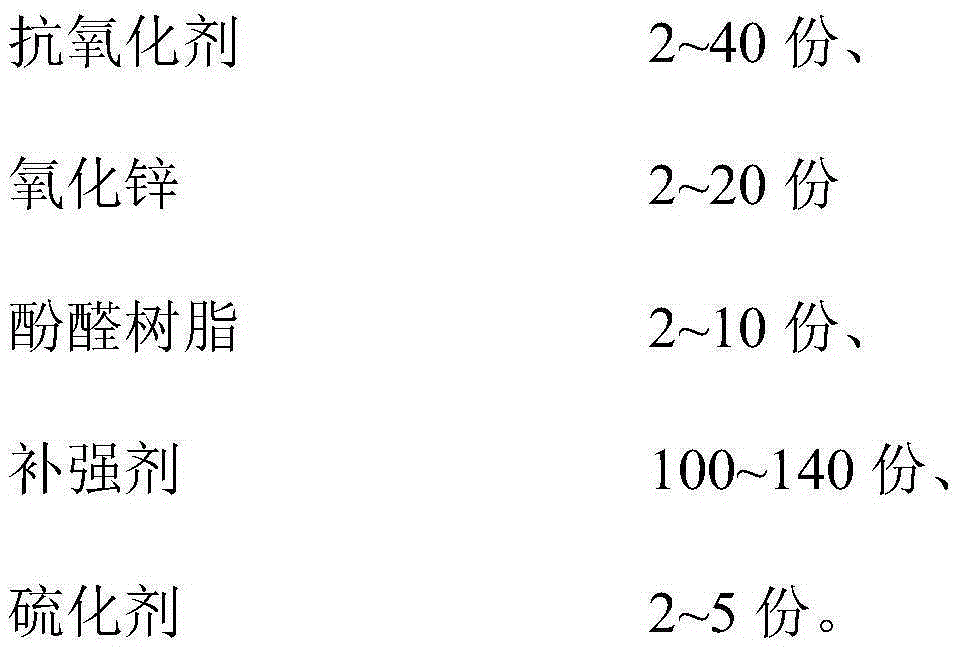

Semiconductor nanoparticle and method of producing the same

Owner:NAGOYA UNIVERSITY +3

High-damping rubber composition and preparation method therefor

InactiveCN105295211AGood vibration dampingGood comprehensive mechanical damping performancePolymer scienceAntioxidant

Owner:ZHEJIANG SHITAI IND CO LTD

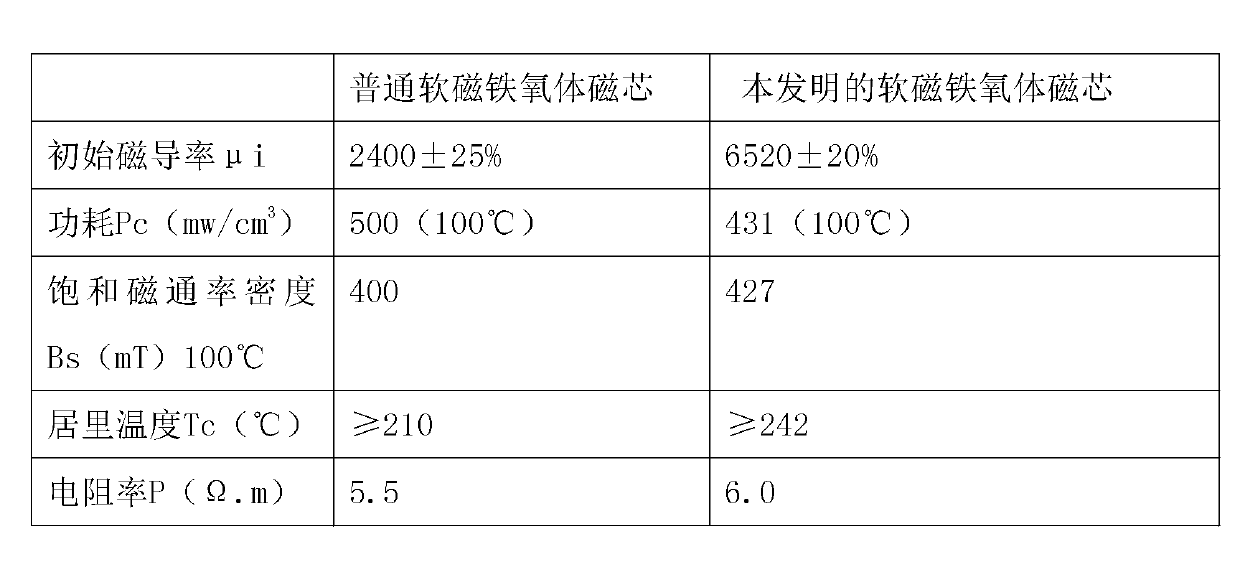

Preparation method of MnZn (Manganese-Zinc) soft magnetic ferrite material containing modified nanoscale titanium dioxide

Owner:浙江大通磁业科技有限公司

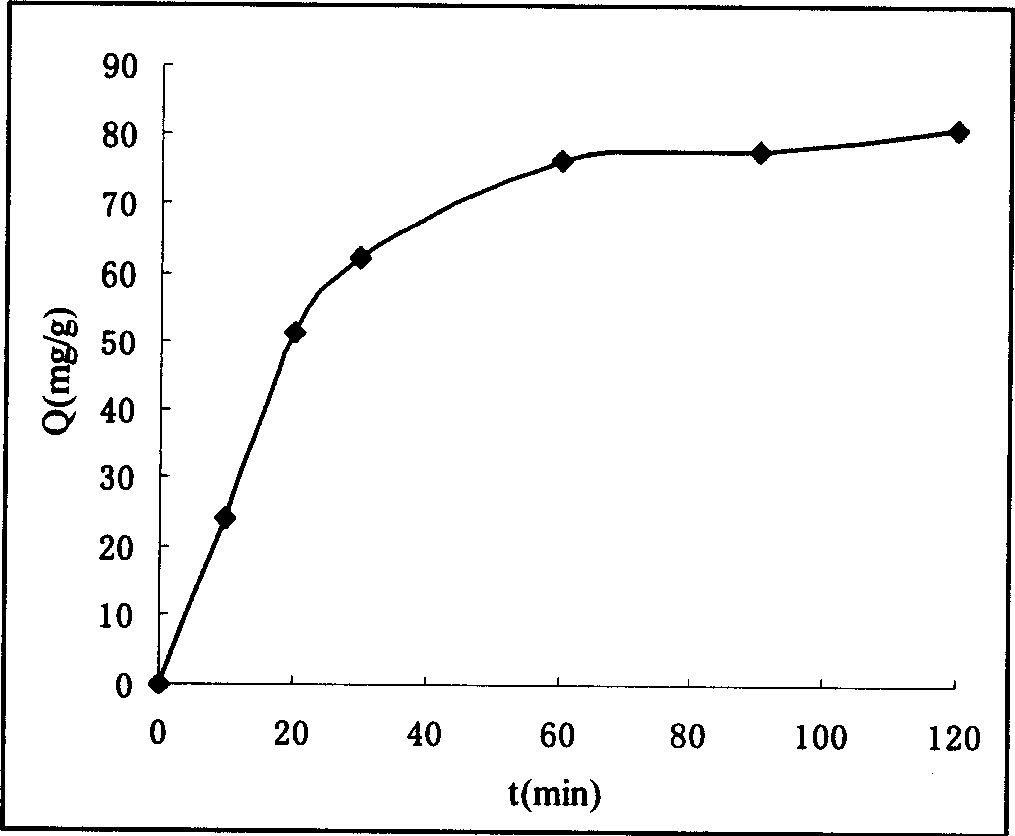

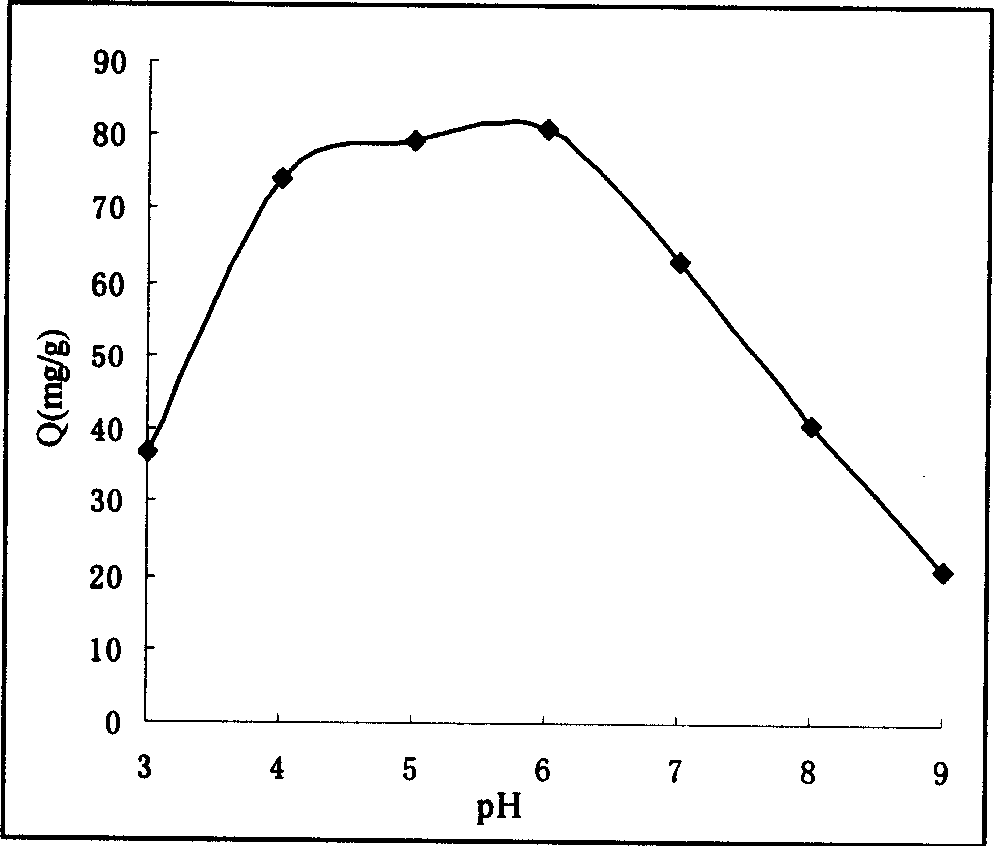

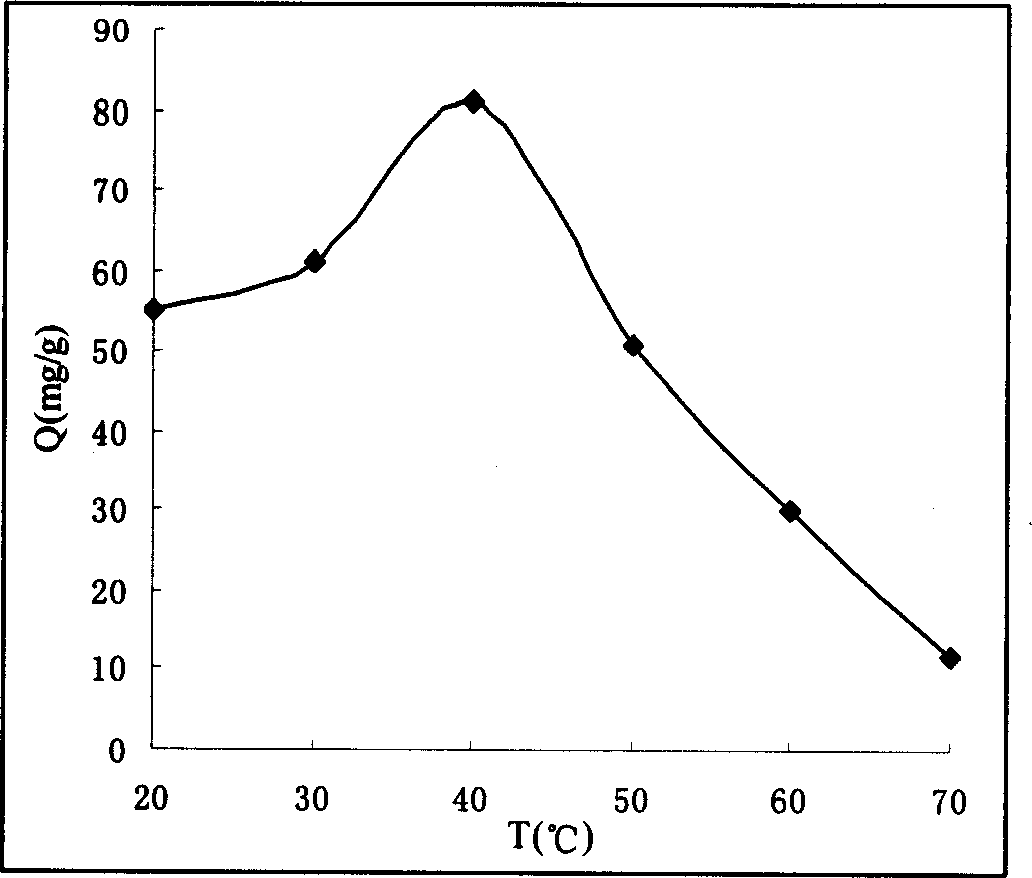

Use of zinc magnesium aluminium ternary hydrotalcite calcining matter in hexavalent chromium of adsorbed water

InactiveCN1736942AEasy to recycleImprove adsorption capacityWater/sewage treatment by sorptionHydrotalciteZinc

Owner:ZHEJIANG UNIV OF TECH

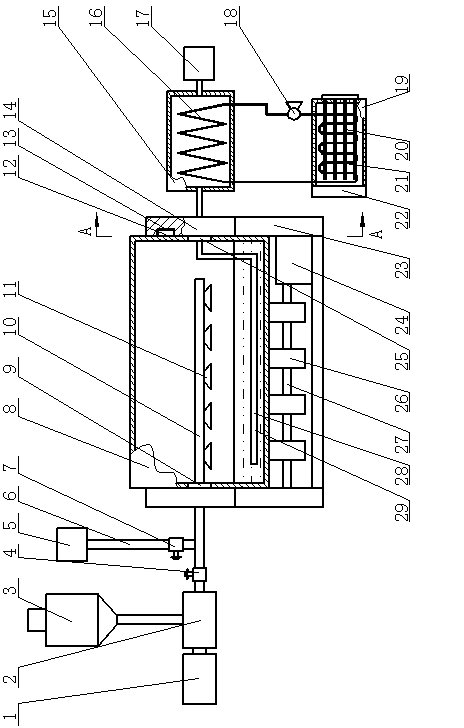

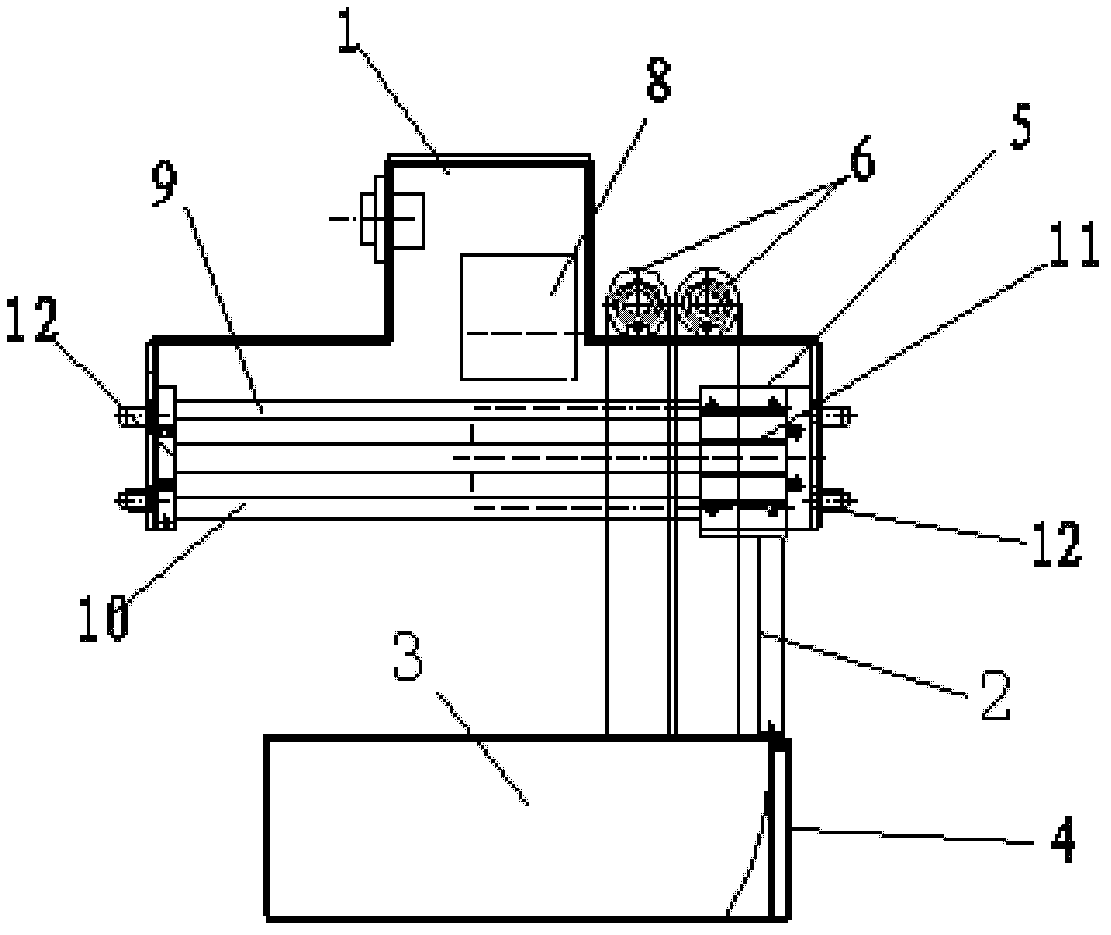

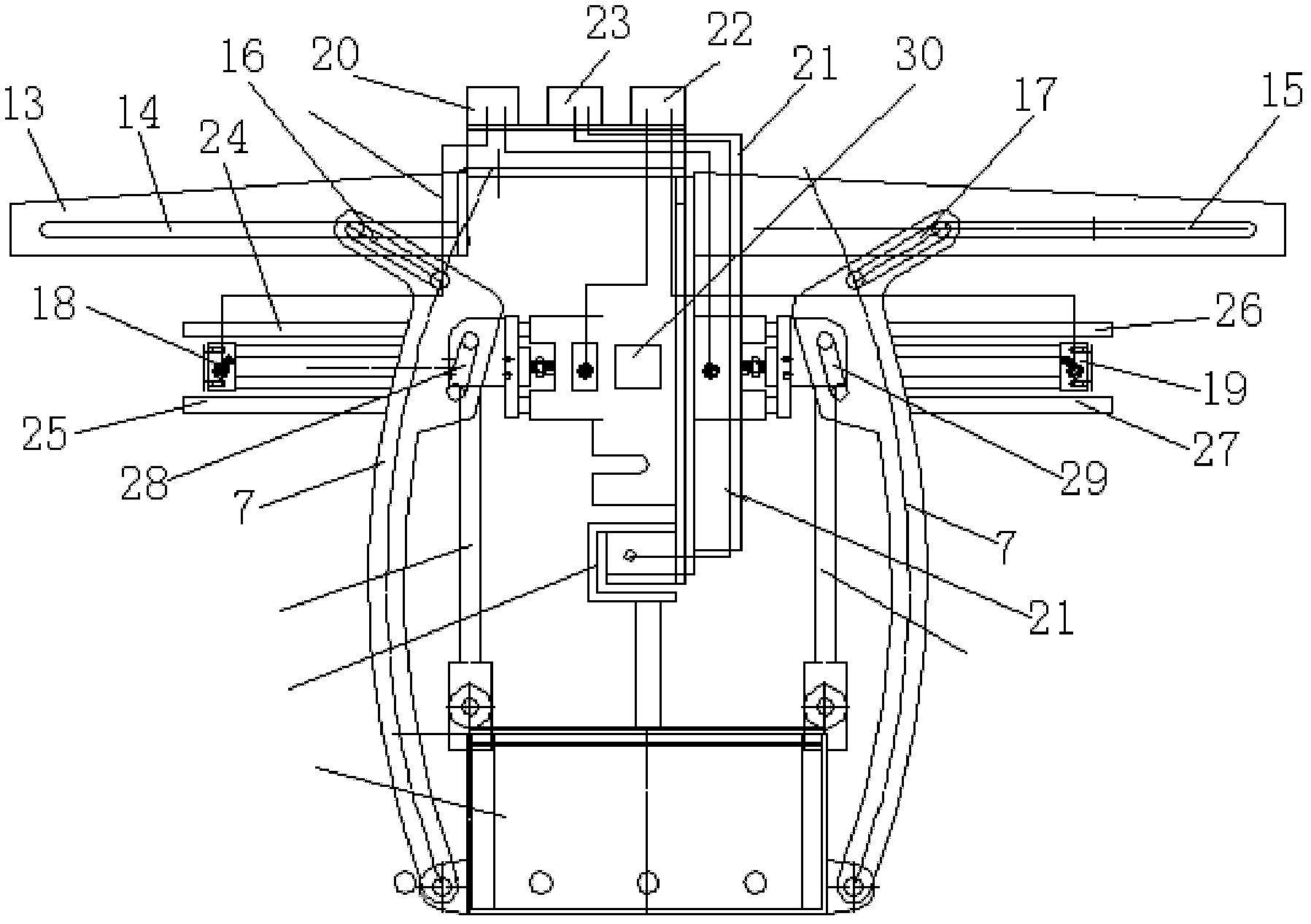

Transmission of manipulator for dredging slag from liquid zinc of zinc pot

InactiveCN102528012AExpand the scope of slag removalContinuous slag unloadingHot-dipping/immersion processesCharge manipulationSlagEngineering

Owner:WUHAN IRON & STEEL (GROUP) CORP

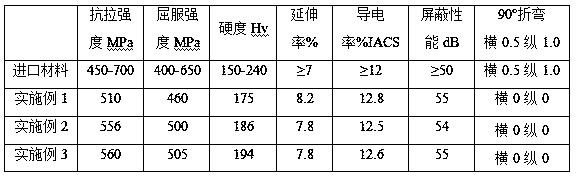

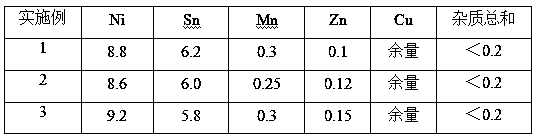

Cu-Ni-Sn alloy belt foil for 5G communication and preparation method thereof

Owner:CNMC ALBETTER ALBRONZE

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap