High-damping rubber composition and preparation method therefor

A rubber composition and high-damping technology, which is applied in the field of high-damping rubber composition and its preparation, can solve problems such as the influence of operating temperature, vibration frequency, and small glass transition temperature range, and achieve good comprehensive mechanical damping performance and vibration reduction good performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

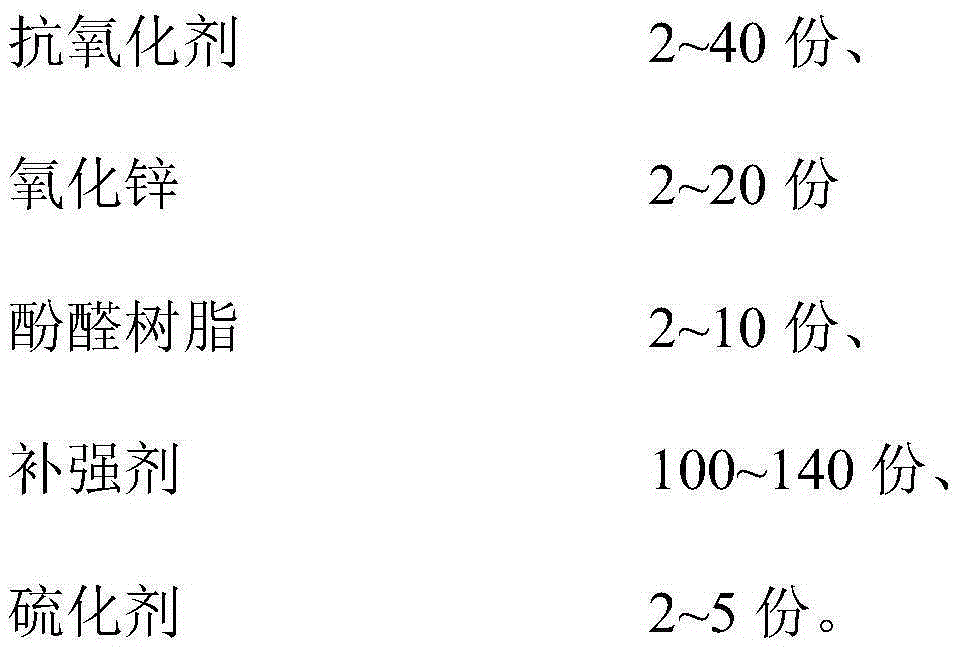

[0025] A high damping rubber composition, comprising the following components in parts by mass:

[0026]

[0027] Wherein, the diene rubber is chlorobutyl rubber, the antioxidant is hindered phenol antioxidant AO-60, the reinforcing agent is mica treated with silane coupling agent, and the vulcanizing agent is sulfur.

Embodiment 2

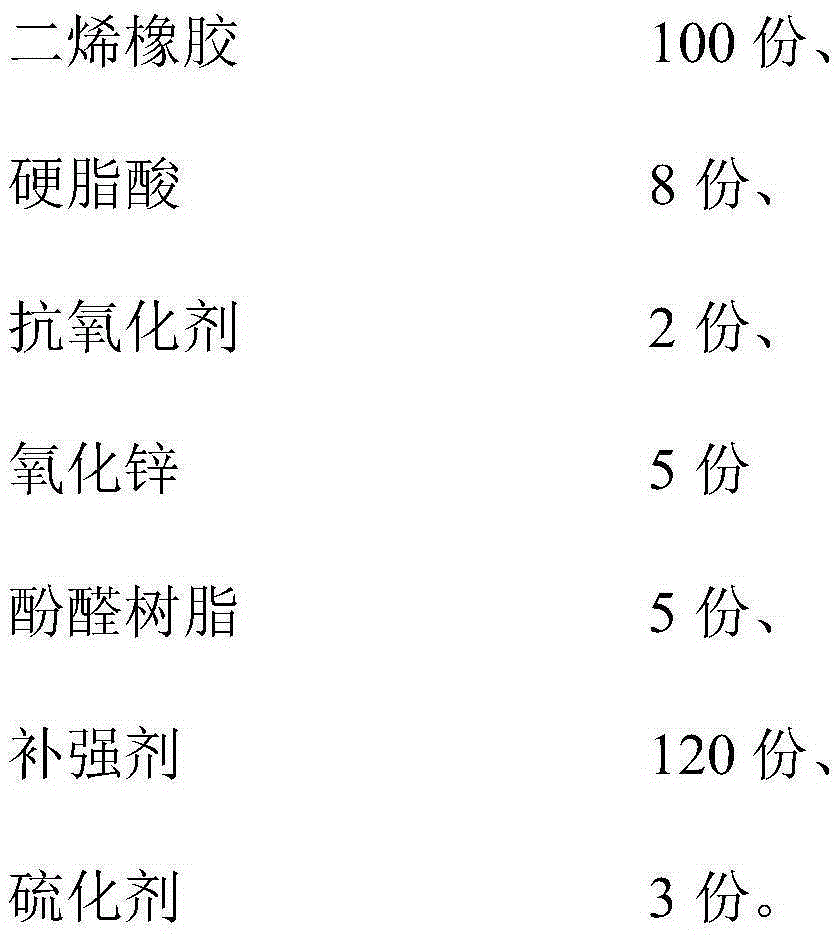

[0029] A high damping rubber composition, comprising the following components in parts by mass:

[0030]

[0031]

[0032] Among them, the diene rubber is chlorobutyl rubber, the antioxidant is hindered phenol antioxidant AO-80, the reinforcing agent is white carbon black, talc and mica treated with silane coupling agent, and the vulcanizing agent is sulfur.

Embodiment 3

[0034] A high damping rubber composition, comprising the following components in parts by mass:

[0035]

[0036] Wherein, the diene rubber is chlorobutyl rubber, the antioxidant is hindered phenol antioxidant AO-60, the reinforcing agent is carbon black and kaolin treated with silane coupling agent, and the vulcanizing agent is sulfur.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap