Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Improve water resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water-based ink for ink-jet recording

InactiveUS6758559B1Improve light resistanceImprove water resistanceMeasurement apparatus componentsDuplicating/marking methodsCarbon blackInkjet printing

Owner:KAO CORP

AKD emulsion and preparation method thereof

ActiveCN104499363AThe emulsification process is streamlinedLow impurity contentWater-repelling agents additionWaxStarch gelatinization

The invention discloses an AKD emulsion and a preparation method thereof. According to the preparation method of the AKD emulsion, as the process of starch gelatinization is saved, and AKD waxes and other raw materials are simultaneously added in the emulsification process, the operation is simple, and the consumed time is obviously shortened. According to the preparation method, equipment and manpower inputs are reduced, and the inventory of the raw materials are also reduced; in addition, as the prepared emulsified product can be used while being produced, the aging rate of paper leaving the machine is high, the hydrolysis degree of the AKD is greatly lowered, the sizing effect is ensured, and the economical benefit is obvious.

Owner:GUANGZHOU TINCI MATERIALS TECH +1

Vinyl acetate-ethylene copolymer emulsion as electrostatic spinning adhesive and synthesis method thereof

ActiveCN102030857AGood adhesionImprove water resistanceMonocarboxylic acid ester polymer adhesivesLiquid surface applicatorsCross-linkPolymer science

The invention relates to a vinyl acetate-ethylene copolymer emulsion as an electrostatic spinning adhesive and a synthesis method thereof. Organic peroxides and zinc formaldehyde sulfate are taken as an initiator; vinyl acetate, ethylene, acrylic ester monomers and cross-linking monomer N-hydroxymethyl acrylamide are taken as comonomers; a nonionic emulsifier, and the synthetic emulsion and the protective colloid of an amphoteric emulsifier are matched to be taken as an emulsification system; and the copolymer emulsion is prepared through emulsion polymerization. Compared with the VAE (vinyl acetate-ethylene) emulsion prepared by the conventional preparation method, the product in the invention has the advantages of good water resistance, strong adhesion on low-surface-energy materials (polyethylene, polypropylene and the like), fine grain and the like. The vinyl acetate-ethylene copolymer emulsion is suitable for being as the adhesive to be applied to the field of the electrostatic spinning in textile industry and the fields of waterproofing and packaging.

Owner:CHINA PETROCHEMICAL CORP +1

Transparent thermal insulation coating material system for glass substrate

InactiveCN102942841AInstant cureReduce energy consumptionPolyurea/polyurethane coatingsEpoxy resin coatingsThermal insulationUltraviolet lights

The present invention discloses a transparent thermal insulation coating material system for a glass substrate. The coating material system is a double layer coating material system formed by a separately-prepared primary coating and a separately-prepared surface coating, wherein the surface coating is coated on the primary coating, the primary coating comprises the following components, by mass, 0.05-3 parts of a silicane coupling agent or a titanate coupling agent, 0.2-5 parts of a hydrolysis catalyst, and 95-99 parts of a solvent, and the surface coating comprises the following components, by mass, 50-80 parts of a light curable resin, 5-35 parts of an active diluent, 1-8 parts of a photoinitiator, 5-35 parts of an antimony tin oxide nanometer thermal insulation powder slurry or an indium tin oxide nanometer thermal insulation powder slurry, 100-140 parts of an inert diluent, and 0.01-0.15 part of a leveling agent. With the coating material system, a film can be formed through a conventional film forming method, and the film layer can be cured within a few seconds after ultraviolet light irradiation. In addition, the coating material system has characteristics of high hardness, excellent adhesion and excellent water resistance.

Owner:刘志钊 +1

Propping agent for resin coating film and preparation method thereof

InactiveCN102899019AImprove water resistanceImproves breakage resistanceFluid removalBreakage rateResin coating

The invention discloses a propping agent for a resin coating film and a preparation method thereof. The propping agent comprises an aggregate, a resin, a curing agent and a dispersing agent, wherein the dosage of the resin is 1%-10% of the weight of the aggregate; the dosage of the curing agent is 0.5%-5% of the weight of the aggregate; and the dosage of the dispersing agent is 0.2%-2% of the weight of the aggregate. The propping agent for the resin coating film provided by the invention has the functions of allowing oil gas to smoothly penetrate and preventing water from penetrating through the propping agent, so that the separating effect of oil gas and water is enhanced by the functions and the oil extraction cost is lowered; due to the excellent hydrophobic property of the resin film, the propping agent has excellent water resistance, the anti-breaking capability of the propping agent is increased and the long-term flow-guiding effect is good; a triple film coating technology is adopted by the invention and the calcium stearate is taken as a dispersing agent, so that the quality is greatly increased, the yield is increased to above 80%, the cost is greatly lowered and the production efficiency is increased; and the preparation method provided by the invention is simple, the product yield is high and the breakage rate of the product is obviously reduced.

Owner:YIXING TENGFEI OIL FRACTARING PROPPANT

Paper making method with pulp and product of high-surface-intensity offset printing paper

ActiveCN103526630AImprove retentionHigh strengthWater-repelling agents additionInorganic compound additionCalcium silicateFiber

The invention discloses a paper making method with pulp and a product of high-surface-intensity offset printing paper. The paper making method with the pulp comprises the steps that (1) multi-hole calcium silicate and mixed wood pulp fibers are subjected to mixing pulping, mixed pulp is obtained; (2) retention and drainage agents A, sizing agents and retention and drainage agents B are added into the mixed pulp in sequence, even stirring is carried out, papermaking pulp is obtained; (3) the papermaking pulp is subjected to papermaking, squeezing and drying, body paper is obtained; (4) surface sizing agents are used for carrying out surface sizing on the body paper, and the offset printing paper is obtained. The multi-hole calcium silicate is used as the papermaking padding, during a papermaking process, paper pulp / padding medium-high-concentration mixing pulping, CS / CPAM double-element retention and surface sizing agent formula improving and other measures are used, the padding retention rate is improved, paper intensity is effectively improved, and the waterproof performance, the oil resistance, the paper surface intensity, the tensile strength and other performance indexes of paper are obviously improved.

Owner:DATANG INT HIGH ALUMINA COAL R & D CENT

Fluorine-containing aqueous coating composition

InactiveCN1738878AGood chemical resistanceImprove water resistancePolyurea/polyurethane coatingsWater dispersibleSolvent

A fluorine-containing aqueous coating composition composed of (A) an aqueous emulsion of a functional group-containing fluororesin obtained by dispersing, in water, a fluoroolefin copolymer having a functional group that is obtained through solution polymerization and (B) a water-dispersible unblocked isocyanate compound is disclosed. The fluororesin aqueous coating composition can be cured at ordinary temperature, and a coating formed therefrom is excellent in chemical resistance, water resistance, solvent resistance, contamination resistance, hardness, weathering resistance and durability.

Owner:DAIKIN IND LTD

Modified polyurethane acrylic resin and preparation method thereof

InactiveCN107353865ANot yellowingGood weather resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterAdhesive

The invention discloses a modified polyurethane acrylic resin, which is prepared by polymerization among hydroxyl acrylate, diisocyanate, alkylated 4,4'-dicyclohexanol, and polyester / polyether glycol. The invention provides a method of preparing the modified polyurethane acrylic resin at the same time. The provided modified polyurethane acrylic resin does not contain active functional group such as phenyl ring, amino group, or the like, so the modified polyurethane acrylic resin will not become yellow even if the modified polyurethane acrylic resin is irradiated by light, and the weatherability is good. The resin can be applied to an adhesive, and has a good waterproof performance, good anti-falling performance, good drug resistant property, and excellent thermal stability.

Owner:SHENZHEN BAILICHU GLUE IND CO LTD

Infrared transmission film, optical film, antireflection film, optical component, optical system and image pickup device

ActiveCN107102383AEasy to make filmImprove water resistanceCoatingsOptical elementsAttenuation coefficientFar infrared

Owner:TAMRON

Environment-friendly modified isocyanate resin aqueous emulsion and manufacturing method thereof

The invention discloses an environment-friendly modified isocyanate resin aqueous emulsion and a manufacturing method thereof. According to the method, isocyanate resin, polyamide polyepoxy active molecular compounds, amino nitrile molecular compounds and ammonium chloride are adopted for a chemical reaction according to a certain ratio, the modified isocyanate resin aqueous emulsion is prepared through emulsification, and glue is applied to fibers in the dynamic stirring process by conducting double-channel spray gluing and mixing the modified isocyanate resin aqueous emulsion with wood fibers. The glued fibers need to be dried by hot air in the stirring process, and after glued fiber plate blanks are pressed under high-temperature and high-pressure conditions, formaldehyde-free plates with the thickness of 5-200 mm and the density of 0.1-1.2 g / cm<3> can be obtained. According to the technology, the isocyanate resin aqueous emulsion can form a twined and cross-linked bionic structuresystem in a series of functional modification processes and has the advantages of being excellent in performance, environmentally friendly, low in cost and the like.

Owner:广东木森态新材料科技有限公司

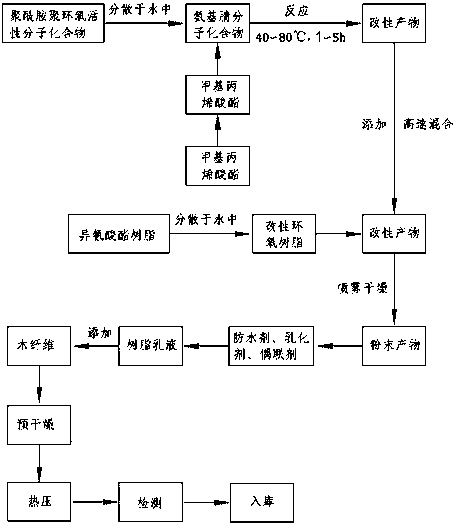

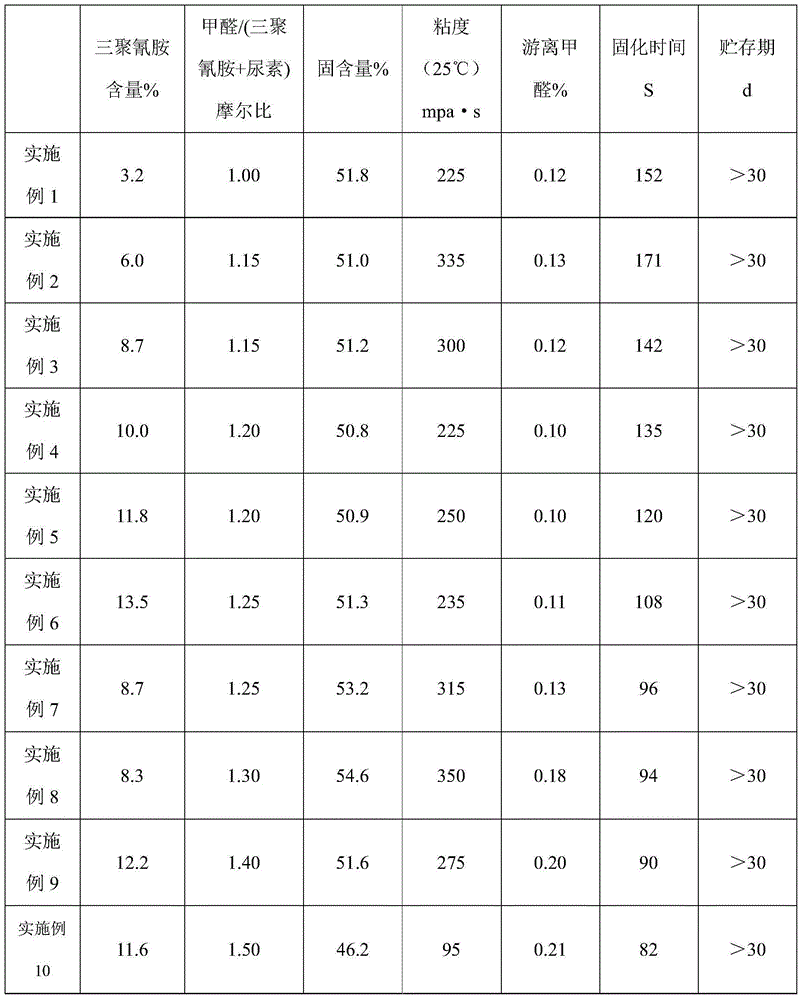

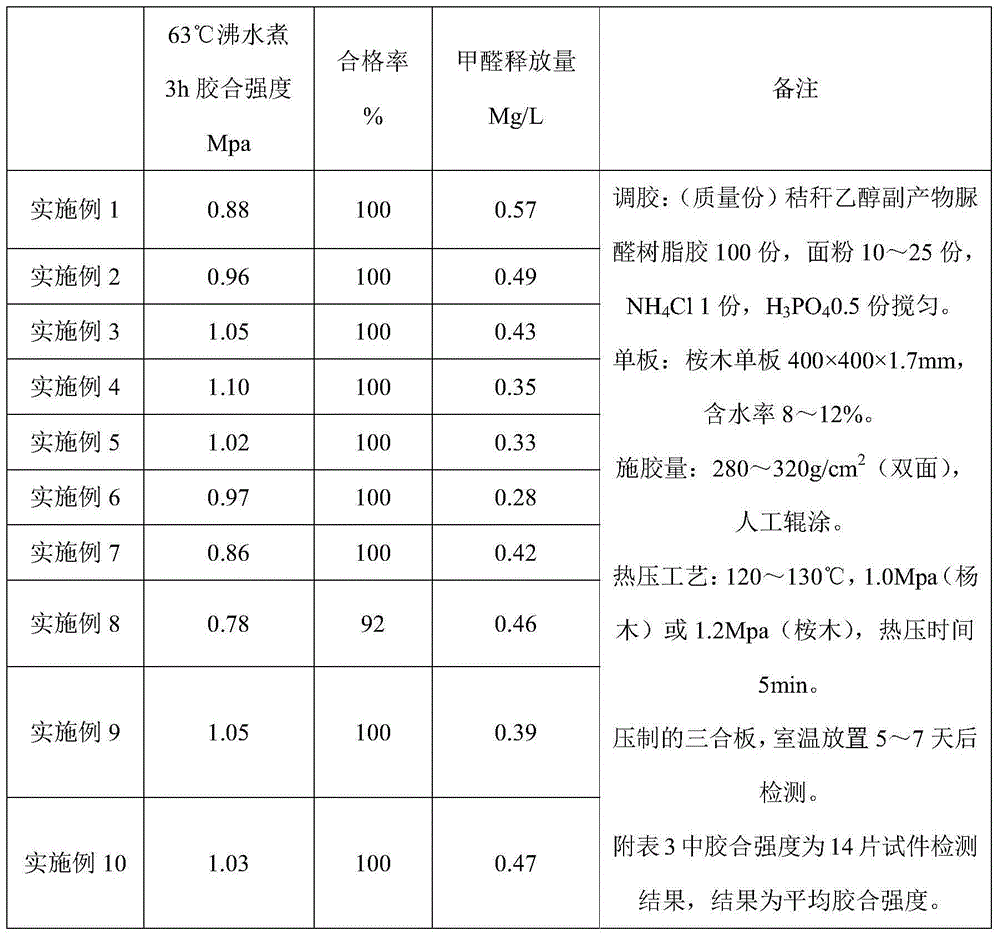

Preparation method of urea-formaldehyde resin from straw ethanol byproduct

ActiveCN104086731AImprove water resistanceLow sugarAldehyde/ketone condensation polymer adhesivesMacromolecular adhesive additivesChemistryCloud point

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Hexahydroxy copolymer water-based pressure-sensitive adhesive without adhesive residue and preparation method of hexahydroxy copolymer water-based pressure-sensitive adhesive

The invention relates to a hexahydroxy copolymer water-based pressure-sensitive adhesive without adhesive residue and a preparation method of the hexahydroxy copolymer water-based pressure-sensitive adhesive. The preparation method of the hexahydroxy copolymer water-based pressure-sensitive adhesive comprises the following steps: (1) taking water as solvent, uniformly mixing polyvinyl alcohol, anionic surfactant, emulsifier and pH regulator, increasing temperature to 50 DEG C, and adding acrylic monomer, cross-linking monomer and polymerization degree regulator to react for 1h at the temperature of 60-65 DEG C, thus obtaining a pre-emulsified solution; (2) uniformly mixing 25% of pre-emulsified solution with 40% of initiator, increasing the temperature to 80-85 DEG C, adding the rest of pre-emulsified solution when the liquid turns blue, adding 20% of initiator every 1h so as to drip off all the initiator within 3h, at last replenishing surplus initiator, and keeping temperature for reflux for 1-1.5h at the temperature of 90 DEG C; and (3) lowering the temperature of the reaction liquid to 40 DEG C, adding a bridging agent, and after uniformly mixing the mixture, cooling the mixture to room temperature. The hexahydroxy copolymer water-based pressure-sensitive adhesive has the advantages of low price, high production rate, strippability and the like and can avoid the pollution of solvent type pressure-sensitive adhesive to environment, thus being an environment-friendly water-based strippable pressure-sensitive adhesive.

Owner:SHANGHAI ZHONGXIN YUXIANG CHEM

Digital paint

InactiveCN104514179AHigh glossGood ink fixing performanceCoatings with pigmentsDefoamers additionIr reflectionUv absorbance

Disclosed is digital paint, which is characterized by comprising specific components of 8-10 parts by weight of a high water-retention resin of polyvinyl alcohol, 2-3 parts by weight of polyvinyl acetate latex, 1-2 parts by weight of titanium dioxide, 10-13 parts by weight of nano-silica, 2-5 parts by weight of a master batch, 15-30 parts by weight of light calcium carbonate, 0.1-0.3 part by weight of a dispersant, 0.05-0.1 part by weight of an antifoaming agent, 1-3 parts by weight of a cationic fixing agent, and 30-50 parts by weight of deionized water. The completely hydrolyzed polyvinyl alcohol has a mediate or low molecular, the efficacy of ink absorption and fast drying, and characteristics of appropriate viscosity and the like. The nano-silica has an extremely great ultraviolet absorption function and an infrared reflection property, and has perfect ink fixing performance. The master batch is a thermoplastic hollow sphere-shaped aqueous dispersion and has functions of enhanced hiding power and improved fullness and lustrousness of paint. The cationic fixing agent is ammonium salt-containing polyacrylic acid, which can improve print effect.

Owner:QINGDAO XINGGUO PAINT CHEM

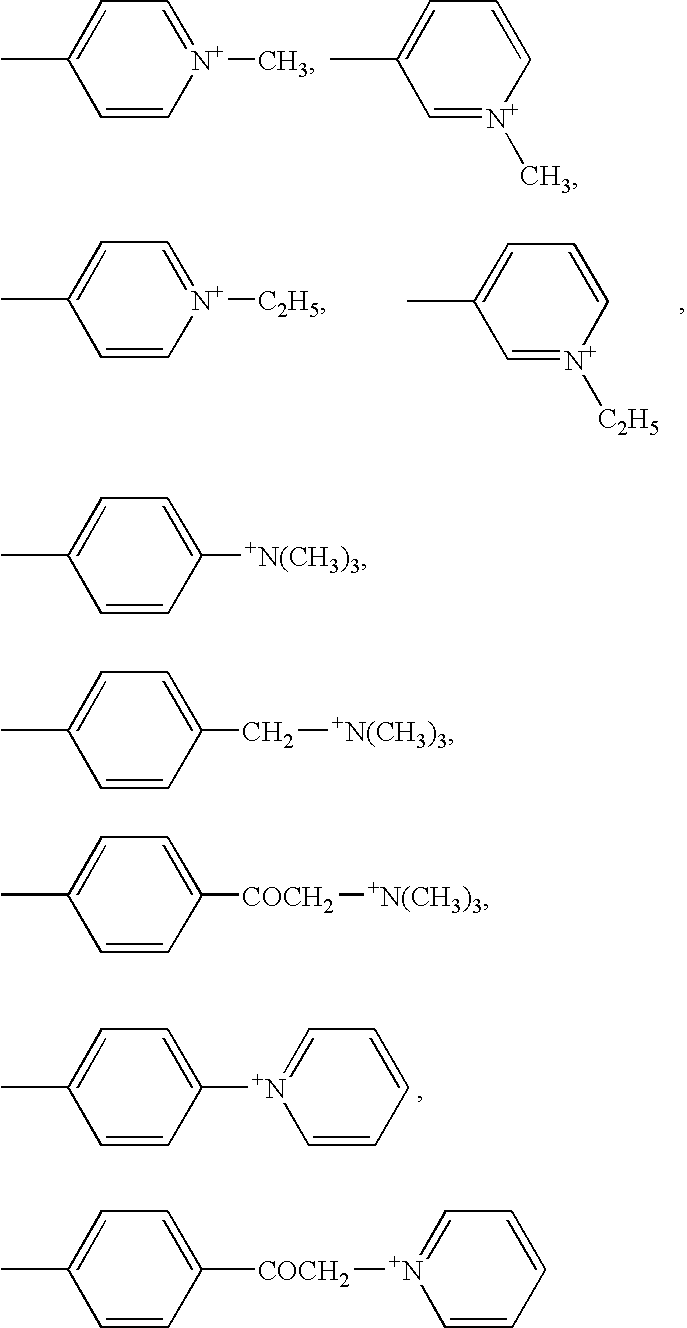

Ink set for inkjet recording, recording method, and colored material produced using the ink set

InactiveUS20130328979A1Convenient lightingIncrease resistanceMeasurement apparatus componentsDuplicating/marking methodsOrganic solventWater soluble

An ink set for inkjet recording, which has excellent water resistance and light resistance in the hue range of yellow-orange-magenta. The ink set includes two-color ink compositions, i.e., a) a magenta ink composition and b) an yellow ink composition, each of which includes a dye, water and a water-soluble organic solvent, wherein the magenta ink composition a) contains a compound produced by sulfonating a compound represented by the formula (1), a salt of the compound, or a mixture thereof as a coloring agent.

Owner:NIPPON KAYAKU CO LTD

Complex fertilizer for increasing oil tea yield

InactiveCN107840751AGood sustained release effectImprove fertilizer efficiencyCalcareous fertilisersMagnesium fertilisersAmmonium hydroxideNitrogen fertilizer

The invention discloses a complex fertilizer for increasing oil tea yield. The complex fertilizer comprises the following raw materials in parts by weight: 70-80 parts of a main material, 30-50 partsof fermented castor seed oil, 10-20 parts of soybean meal, 4-12 parts of diatomite, 4-10 parts of radish sprout, 6-12 parts of coconut shell flour, 4-12 parts of oat bran, 1-2 parts of trace element,2-4 parts of pectin, 2-8 parts of vermiculite powder, 1-8 parts of coal slag, and 1-3 parts of perlite; and the main material comprises the following components in parts by weight: 50-65 parts of a composite nitrogenous fertilizer, 4-18 parts of a calcium magnesium phosphate fertilizer, and 2-8 parts of potassium nitrate. A method for preparing the composite nitrogenous fertilizer comprises the following steps: calcining Chinese medical stone powder, under a stirring state, adding ammonium hydroxide, then placing the materials in a polyvinyl alcohol aqueous solution, uniformly stirring the materials, then adding urea and carboxymethylcellulose sodium, heating the materials and stirring the materials, and performing spray drying to obtain the composite nitrogenous fertilizer.

Owner:安庆市望马楼生态农业发展有限公司

Night vision compatible film and preparation method and application thereof

ActiveCN112409619AHigh light transmittanceImproves UV protectionAnti-corrosive paintsRadiation-absorbing paintsUv absorbanceAcrylic resin

The invention belongs to the field of materials, and discloses a night vision compatible film and a preparation method and application thereof. The night vision compatible film comprises a layer of transparent base material and a coating applied to the transparent base material. The coating is mainly prepared from acrylic resin, amino resin, nano TiO2 sol, graphene oxide, an ultraviolet absorbent,filler, a resin curing agent and a solvent. The night vision compatible film is high in light transmittance within the range of 400nm to 630nm and high in ultraviolet-proof capacity. The light transmittance within the range of 400nm to 630nm is 55% or above; the light transmittance within the range of 660nm to 930nm is 1.0% or less; and the light transmittance at 320-400nm is 1.2% or less. The night vision compatible film has good water mist resistance and salt mist resistance, can adapt to severe environments and is wide in application scene. The night vision compatible film can be applied to a night vision device.

Owner:BEIJING FALCON TECH CO LTD

Polymer bonding mortar and preparation method thereof

The invention discloses a polymer bonding mortar and a preparation method of the polymer bonding mortar. The bonding mortar uses a modified redispersible powder to replace the traditional sizing material, the redispersible powder modified by paraffin and micron sized silica aerogel is better in water resistance and dispersibility, the bonding strength between the redispersible powder and an aggregate is stronger, in addition, a certain amount of aramid pulp and activated carbon powder are added as the aggregate, the degree of compacting of the mortar and the internal permeability of the mortar are improved, the bonding speed of the mortar is accelerated, the uneven hydration is avoided, the solidified mortar is excellent in anti-permeability, an introduced water retention particle is a long-acting reversible product, the water retaining property of the mortar is effectively improved, and the comprehensive performance of the mortar are further improved. The prepared bonding mortar is green and environmentally friendly, is economical and efficient, and has a prominent application advantage in an external wall insulation system.

Owner:HEFEI SHENZHOU CONSTR GRP CO LTD

Energy-saving phase-transformation anti-cracking polymer special mortar and preparation method thereof

Owner:绍兴职业技术学院

Shoe cellulose powder modified polyurethane adhesive and preparation method thereof

InactiveCN105925229AImprove fastness and hydrolysis resistanceImprove rigidityPolyureas/polyurethane adhesivesSolventIsocyanate compound

The invention discloses a shoe cellulose powder modified polyurethane adhesive and a preparation method thereof. The shoe cellulose powder modified polyurethane adhesive is prepared from the following components in parts by mass: 150 to 200 parts of diphenylmethane diisocyanate, 20 to 50 parts of isophorone diisocyanate, 200 to 400 parts of polyester glycol, 30 to 60 parts of chain extender, 1 to 10 parts of cellulose powder, and 2000 to 4000 parts of solvent. The preparation method has the advantages that under the synergistic action of two types of active isocyanate, by adopting different types of hydroxyl raw materials, the initial viscosity, hydrolysis resistance, wet and heat aging resistance and the like of products are improved; the technology implementing is good, and the environment-friendly and non-pollution effects are realized.

Owner:LI NING CHINA SPORTS GOODS +2

Emulsifying method of polyurethane micro-powder, polyurethane micro-powder emulsion, leather mending agent and application thereof

InactiveCN111072996AHigh strengthIncrease coagulation resistanceLeather surface finishingPolymer scienceEmulsion

The invention discloses an emulsifying method of polyurethane micro-powder, a polyurethane micro-powder emulsion, a leather mending agent and application of the leather mending agent, and the emulsifying method comprises the following steps: mixing nonionic surfactants with different HLB values to obtain a compound emulsifier; adding the polyurethane micro-powder into the composite emulsifier to obtain a polyurethane micro-powder suspension; dropwise adding deionized water into the polyurethane micro-powder suspension; dropwise adding a curing agent into the polyurethane micro-powder suspension, adjusting the pH value of the system to 7.5-9, and stirring to obtain the polyurethane micro-powder emulsion; according to the invention, the problem that in the prior art, polyurethane micro-powder is difficult to form a stable body in a water phase or a solvent phase is solved; the technical problem that the application of the polyurethane micro-powder emulsion in leather finishing is limitedin the prior art is solved, the polyurethane micro-powder emulsion is formed and applied to the leather mending agent, the performance of the leather mending agent is improved, and meanwhile, if theleather mending agent containing the polyurethane micro-powder is applied to the grain surface of crust leather, the mending effect can be remarkably improved.

Owner:XINGYE LEATHER TECH CO LTD

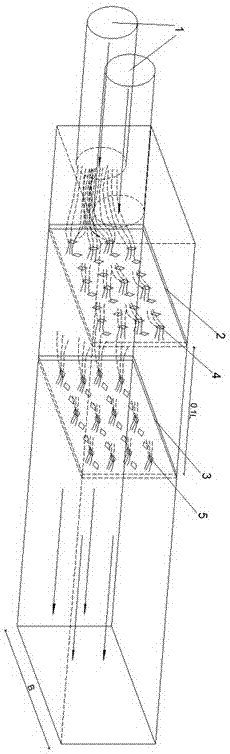

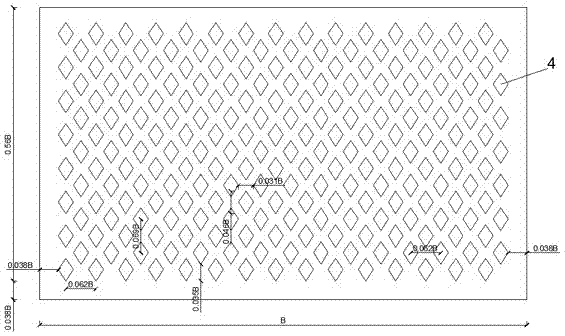

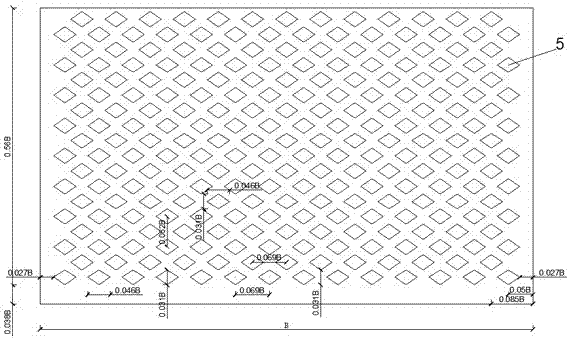

Rhombus perforated water-distributing lattice wall for pre-sinking aeration tank of water intake pumping station and rectifying method thereof

ActiveCN106975252ASlow down the longitudinal velocity differenceReduce buried depthSettling tanks feed/dischargeEngineeringStructural engineering

The invention relates to a rhombus perforated water-distributing lattice wall for a pre-sinking aeration tank of a water intake pumping station and a rectifying method thereof. The rhombus perforated water-distributing lattice wall comprises an incoming flow water pipeline and a pre-sinking tank; the incoming flow water pipeline is communicated with an inlet of the pre-sinking tank; a first rhombus perforated water-distributing lattice wall is arranged at the inlet of the pre-sinking tank; a second rhombus perforated water-distributing lattice wall is arranged in the pre-sinking tank; a distance between the second rhombus perforated water-distributing lattice wall and the first rhombus perforated water-distributing lattice wall is 0.1 times of the length of the pre-sinking tank; the height of the first rhombus perforated water-distributing lattice wall and the height of the second rhombus perforated water-distributing lattice wall are both 0.56 times of the width of the pre-sinking tank; a plurality of vertical rhombus holes are formed in the first rhombus perforated water-distributing lattice wall; horizontal rhombus holes are formed in the second rhombus perforated water-distributing lattice wall; the vertical rhombus holes are distributed in the first rhombus perforated water-distributing lattice wall in a staggered form. According to the invention, the velocity distribution of water flow in the pre-sinking tank is more uniform and smooth and the settling effect of solid particle suspensions, such as silt, is promoted.

Owner:YANGZHOU UNIV

Aerogel modified magnesium oxysulfate fireproof insulation board and preparation method thereof

The invention provides an aerogel modified magnesium oxysulfate fireproof insulation board and a preparation method thereof. The insulation board is composed of fiber-containing aerogel powder composite powder, magnesium sulfate heptahydrate, light calcined magnesia powder and an additive. The preparation method mainly comprises the following steps: S1, preparing a magnesium sulfate aqueous solution; s2, dispersing the magnesium sulfate solution, the aerogel composite powder, an additive and the like into slurry fluid through a high-speed dispersion machine; s3, doping light calcined magnesia powder and stirring evenly to form slurry, then pouring in a board making machine mold, and obtaining the magnesium oxysulfate fireproof insulation board through curing forming, cutting and curing. Compared with a traditional magnesium oxysulfate board, the fireproof insulation board has the advantages that the strength of the board is guaranteed, the density is lower, the heat insulation performance is better, the water resistance is obviously improved, and the comprehensive performance is obviously improved.

Owner:XIANGSHUI HUAXIA SPECIAL MATERIALS TECH DEV CO LTD

Strong adhesive tape

InactiveCN104710944AIncrease surface tensionImprove water resistanceFilm/foil adhesivesChemistryPolyester

The present invention discloses a strong adhesive tape, which comprises a polyester film layer and a chemical coating layer, wherein the chemical coating layer is a poly ammonia resin layer. According to the present invention, a layer of a chemical coating liquid is coated on the surface of the polyester film, such that the polyester film coating layer has high surface tension and water resistance, therefore, the strong adhesive tape has characteristics of good bonding property and strong adhesion under high temperature and high humidity conditions.

Owner:北海明世科技开发有限公司

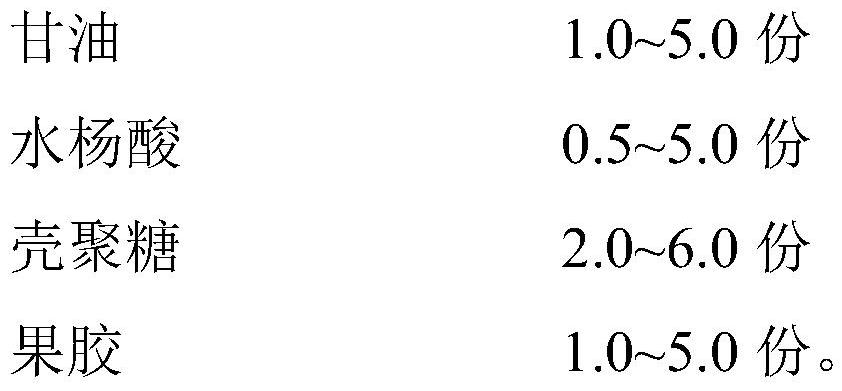

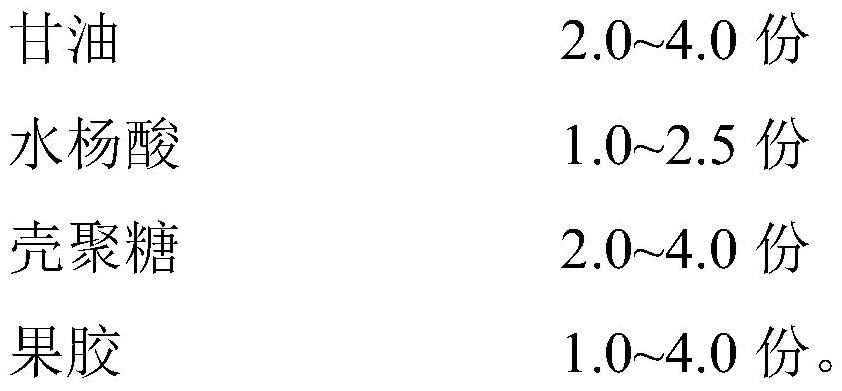

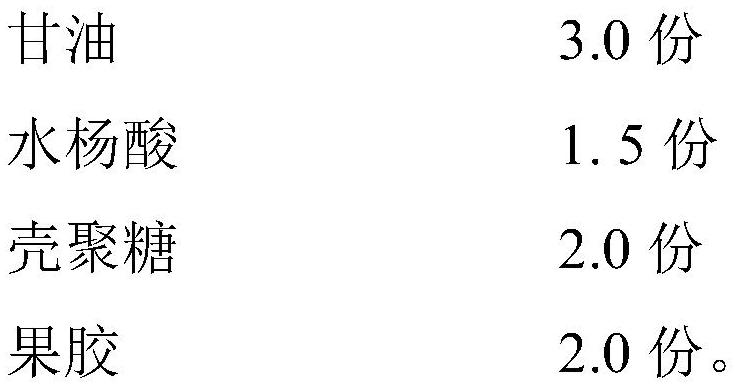

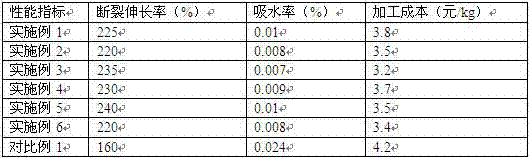

Chitosan-pectin-salicylic acid composite film for preventing and treating Psidium guajava Linn. cold damage, and preparation method of chitosan-pectin-salicylic acid composite film

PendingCN113812459AFruits/vegetable preservation by coatingFood ingredient as coating agentSalicylic acidGuava extract

Owner:GUANGZHOU UNIVERSITY

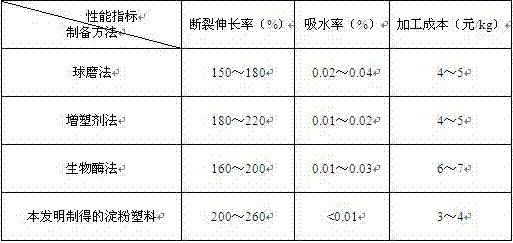

Low-cost method for preparing starch bioplastic

The invention belongs to the technical field of plastic preparation and provides a low-cost method for preparing starch bioplastic. The method comprises the following steps: preparing a precursor solution from butyl acrylate, methyl methacrylate, acrylic acid, an emulsifier and deionized water; adding starch superfine particles and performing ultrasonic dispersion; further adding an initiator to initiate a polymerization reaction to generate a hyperbranched polymer, and coating the starch superfine particles in a cavity; performing extrusion granulation with matrix resin and processing auxiliaries to obtain the starch bioplastic. Compared with traditional methods, the method provided by the invention has the advantages of simple preparation process, easily available raw materials, low energy consumption, low processing difficulty, relatively low cost and high environmental friendliness; moreover, the prepared starch bioplastic has relatively good water resistance, physical and mechanical properties and the like and can be applied to large-scale popularization and production.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Water-resistant building material paint

InactiveCN107163765AImprove corrosion resistanceImprove water resistanceAnti-corrosive paintsPolyester coatingsAcrylonitrileAntioxidant

Owner:钱小平

Method for producing transition-metal-containing zeolite, transition metal zeolite produced by the method, and exhaust gas purification catalyst including the zeolite

InactiveUS20180178205A1Increased durabilityImprove waterproof performanceGas treatmentMolecular sieve catalystsWater vaporSorbent

Provided is a method for producing a transition-metal-containing silicoaluminophosphate that is highly suitable as a catalyst or an adsorbent and has excellent high-temperature hydrothermal durability and excellent water resistance, that is, excellent durability against water submersion (water-submersion durability), in a simple and efficient manner. A method for producing a transition-metal-containing zeolite, the method comprising a steam treatment step in which a transition-metal-containing zeolite is stirred at 710° C. or more and 890° C. or less in the presence of water vapor, the transition-metal-containing zeolite containing a transition metal in a zeolite having a framework structure including silicon atoms, phosphorus atoms, and aluminium atoms.

Owner:MITSUBISHI CHEM CORP

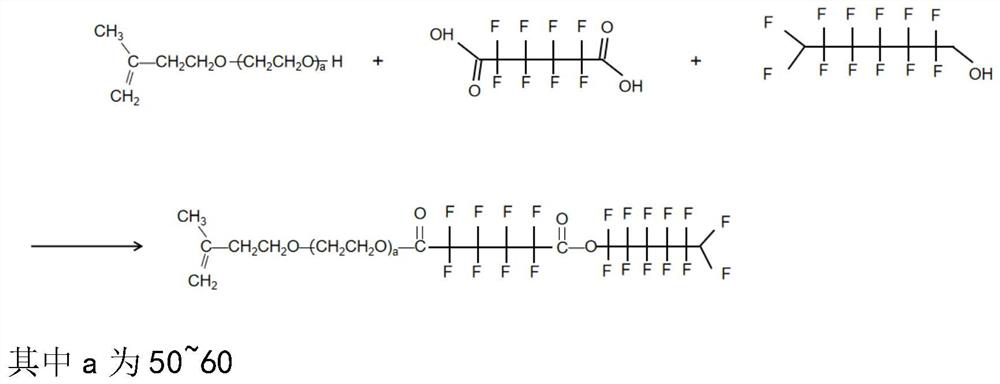

Preparation method of soap-free emulsion for concrete protective coating and equipment

PendingCN113912787AProcess control/regulationHeating or cooling apparatusButyl methacrylateFluorocarbon Emulsions

Owner:NAT ENG LAB FOR HIGH SPEED RAILWAY CONSTR +2

Inner liner rubber for tubeless tire

The invention discloses inner liner rubber for a tubeless tire. Butadiene styrene rubber is added, has a good anti-ageing property and heat resistance and has more uniform texture than natural rubber; additionally, chloroprene rubber is added, rubber molecules contain chlorine atoms, and the chloroprene rubber has good anti-oxidant and ozone-resistant properties, is nonflammable, can be self-extinguished after being ignited and has good oil resistance, solvent resistance, acid-base resistance, ageing resistance and air tightness; acrylonitrile-butadiene rubber has great gasoline and aliphatic hydrocarbon oil resistance, good heat resistance, relatively good air tightness, wear resistance, water resistance and the like and high bonding force. Besides, other auxiliary ingredients are added, the prepared inner liner rubber for the tubeless tire is low in air transmittance, the tire has good air tightness, good oil resistance and heat resistance, and requirements of the inner liner rubber for the tubeless tire can be fully met.

Owner:SHANDONG YONGTAI CHEM GROUP

PVA film for demolding and preparation method thereof

Owner:广东博维新材料有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap