Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

12 results about "Chemical resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The chemical resistance of a material or surface can be determined in compliance with ISO 2812 Paints and varnishes – Determination of resistance to liquids – Part 1: Immersion in liquids other than water (ISO 2812-1:2007); German Version EN ISO 2812-1:2007 or Part 4: Spotting methods (ISO 2812-4:2007); German Version EN ISO 2812-4:2007. With these methods, a material or surface is exposed to the relevant chemical for a longer, defined period of time and the relevant area then inspected microscopically. Possible changes which could occur include...

Molded Article for Clean Room and Method for Producing Same

Owner:FUJI BAKELITE +2

Fluorine-containing aqueous coating composition

InactiveCN1738878AGood chemical resistanceImprove water resistancePolyurea/polyurethane coatingsWater dispersibleSolvent

A fluorine-containing aqueous coating composition composed of (A) an aqueous emulsion of a functional group-containing fluororesin obtained by dispersing, in water, a fluoroolefin copolymer having a functional group that is obtained through solution polymerization and (B) a water-dispersible unblocked isocyanate compound is disclosed. The fluororesin aqueous coating composition can be cured at ordinary temperature, and a coating formed therefrom is excellent in chemical resistance, water resistance, solvent resistance, contamination resistance, hardness, weathering resistance and durability.

Owner:DAIKIN IND LTD

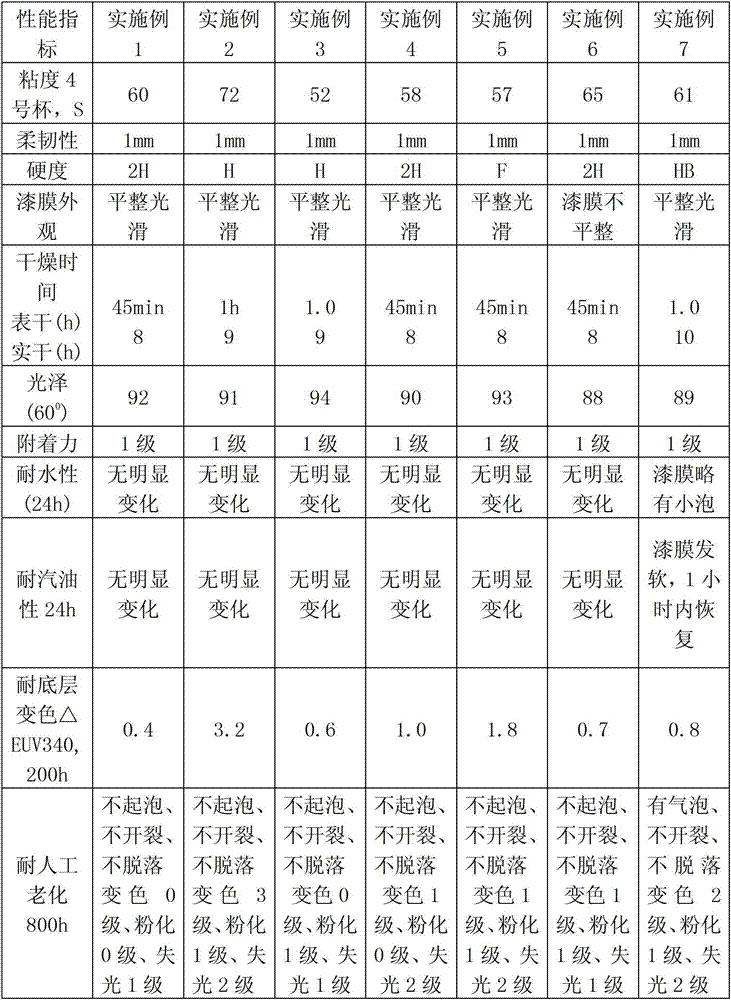

Varnish resisting ultraviolet and preventing bottom-layer discoloration, and preparation method thereof

ActiveCN102850880ALong-term effective absorptionPrevent discolorationCoatingsAcrylic resinDual effect

Owner:ZHEJIANG TIANNU GROUP PAINT MFG

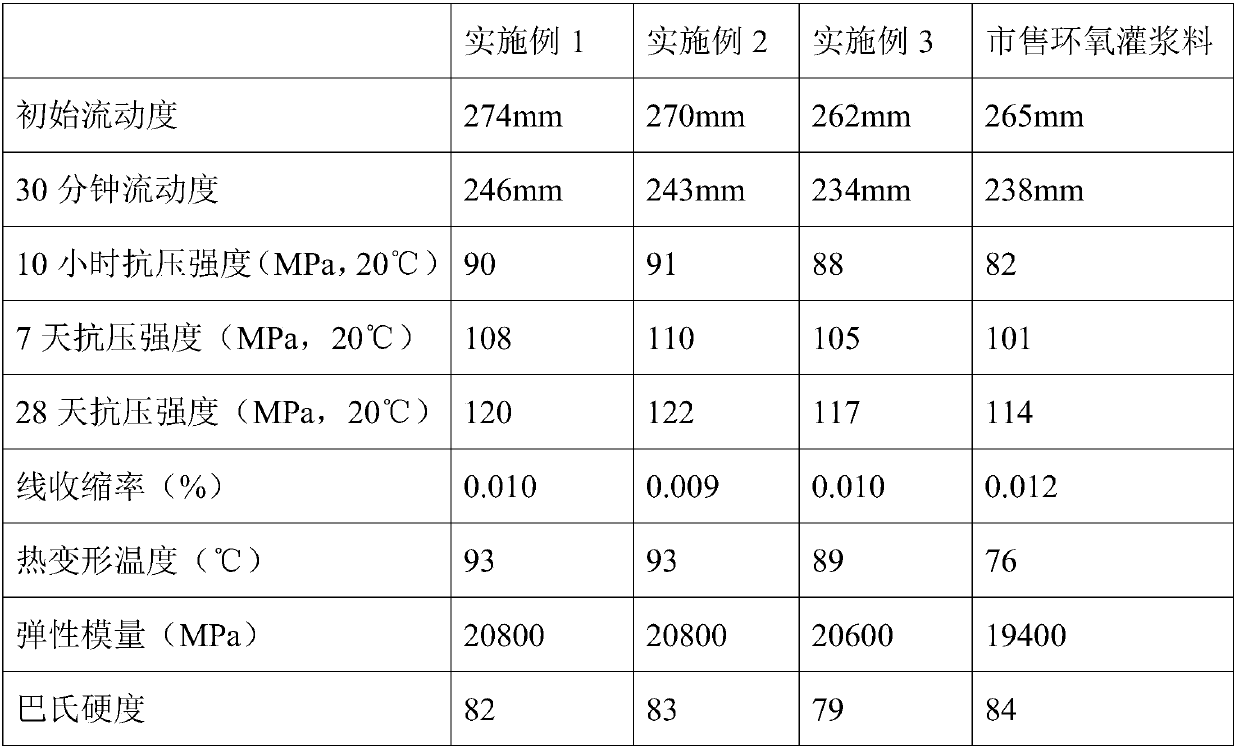

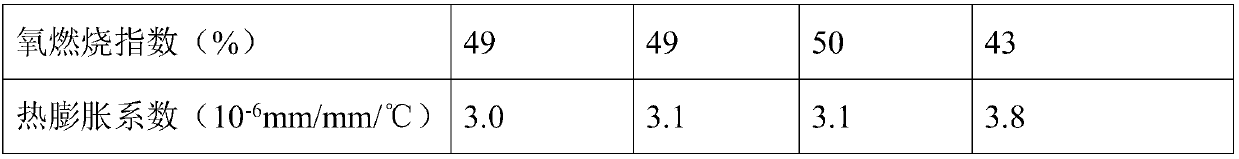

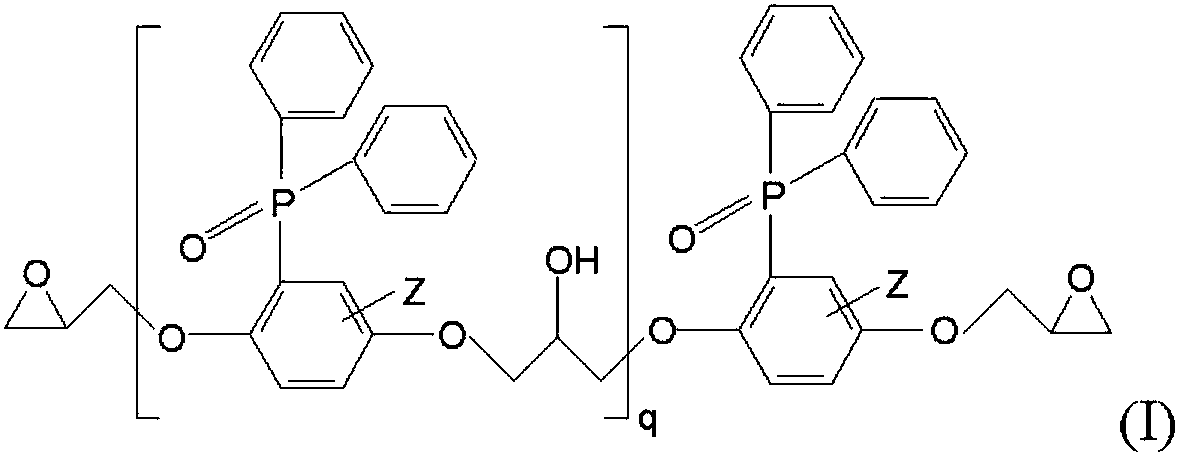

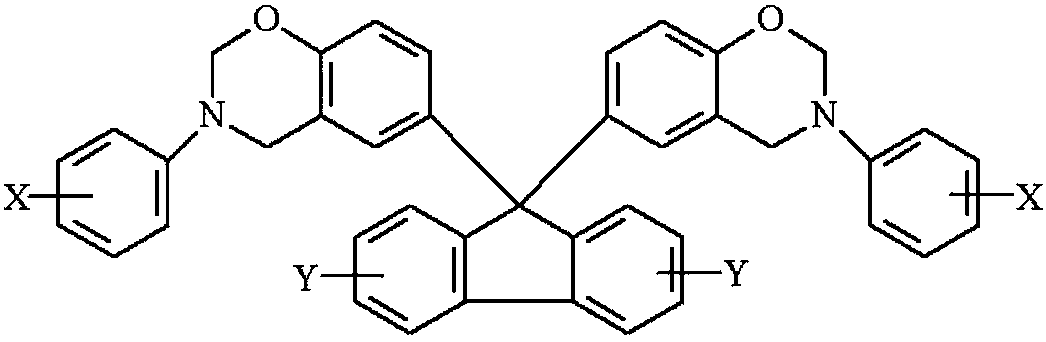

Polyaryletherketone modified high-temperature-resistant epoxy grouting material and preparation method thereof

InactiveCN107903585AHigh temperature and high humidity resistanceChemically resistantEpoxyHigh humidity

Owner:HUNAN CHENLI NEW MATERIAL CO LTD

Chemical sensors for detecting hydrogen and methods of use

InactiveUS20100224507A1Weather/light/corrosion resistanceVolume/mass flow measurementChemical physicsNanoparticle

The presently-disclosed subject matter provides sensors and methods for detecting hydrogen by determining the conductivity of a chemiresistant film upon exposure to hydrogen, including for example chemiresistant films comprised of alkylamine-, alkylthiolate-, and / or surfactant-coated metal alloy nanoparticles.

Owner:UNIV OF LOUISVILLE RES FOUND INC

Halogen free thermosetting resin composition, and prepreg, laminated board, metal foil layer-coated laminated board and printed circuit board using halogen free thermosetting resin composition

ActiveCN108192281ALow water absorptionImprove heat resistanceLaminationLamination apparatusEpoxyMetal foil

Owner:江西生益科技有限公司

Coating process of outer surface of sculpture

InactiveCN105921387APrevent metal oxidationSufficient adhesionPretreated surfacesSpecial surfacesWeather resistanceSurface roughness

Owner:NANJING CHENGUANG ART ENG CO LTD

Novel moisture-curing flame-retardant polyurethane hot melt adhesive and preparation method thereof

InactiveCN109679562AImprove performanceImprove flame retardant performanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterMethacrylate

Owner:SHUNDE POLYTECHNIC

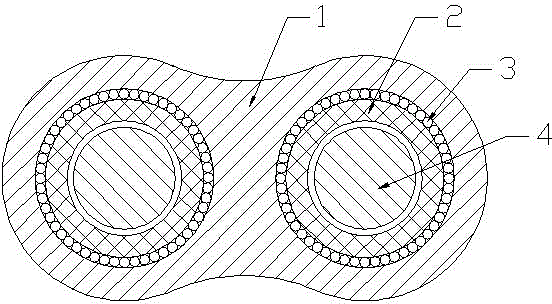

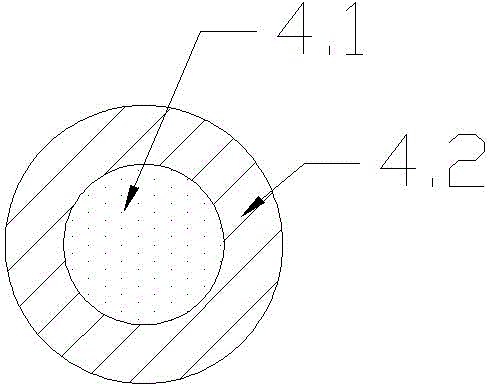

High strength anti-aging braking cable

InactiveCN105697523AEasy to shapeLight in massBrake actuating mechanismsCoatingsFiberWeather resistance

Owner:李士清

Flubendiamide and natural pyrethrins compounded suspending agent and preparation method thereof

InactiveCN102524313ABroad spectrum of prevention and treatmentDrug resistanceBiocideAnimal repellantsOrganic solventFlubendiamide

Owner:SOUTH CHINA UNIV OF TECH

Tear-resistant blown film and preparation process thereof

PendingCN114851665AImprove tear resistanceImprove puncture abilityWrappersFlexible coversBlow moldingPolymer science

Owner:绍兴新航塑料制品有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap