Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48 results about "Weather resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

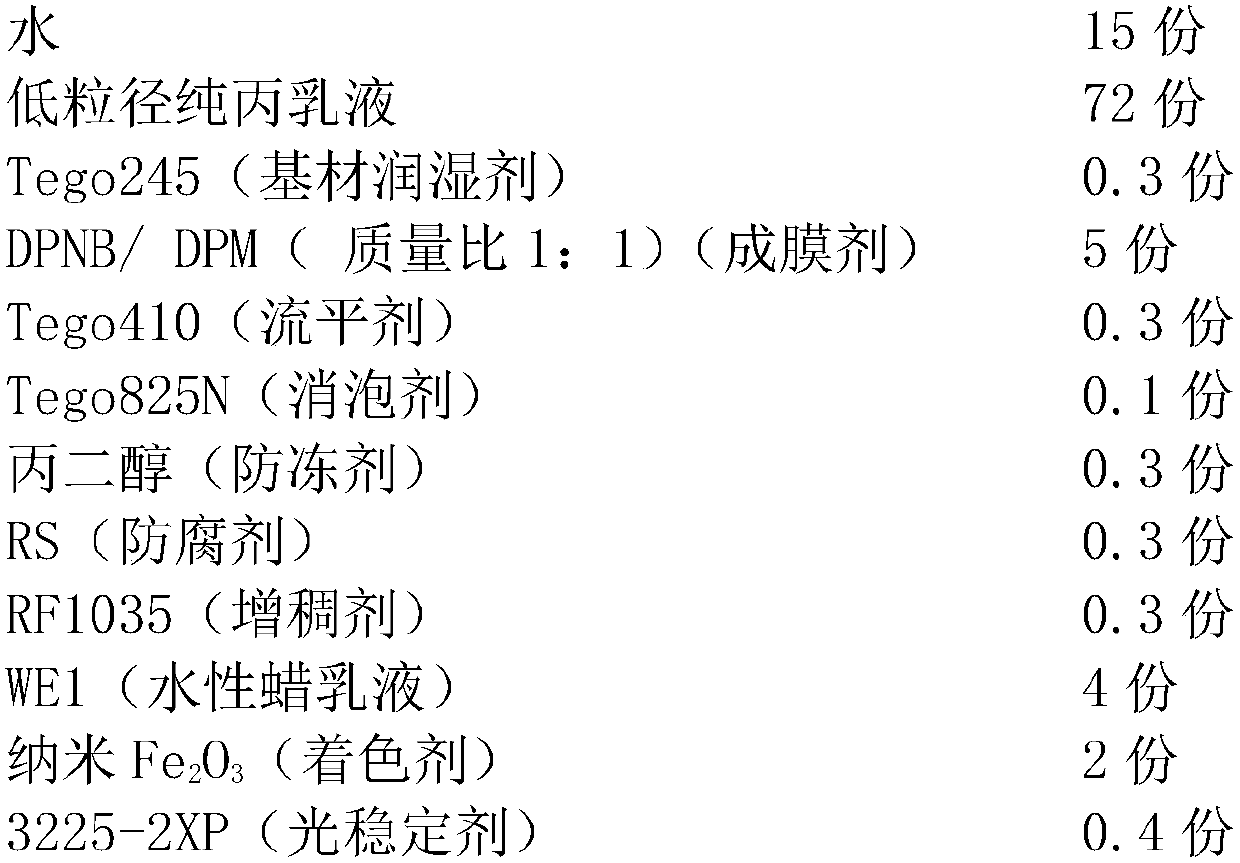

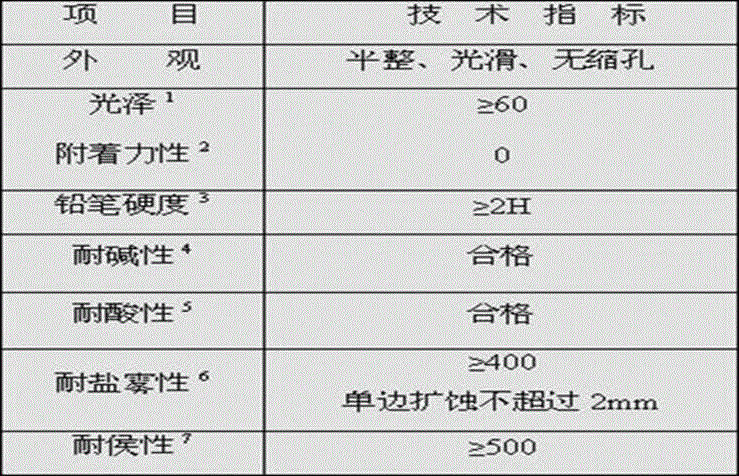

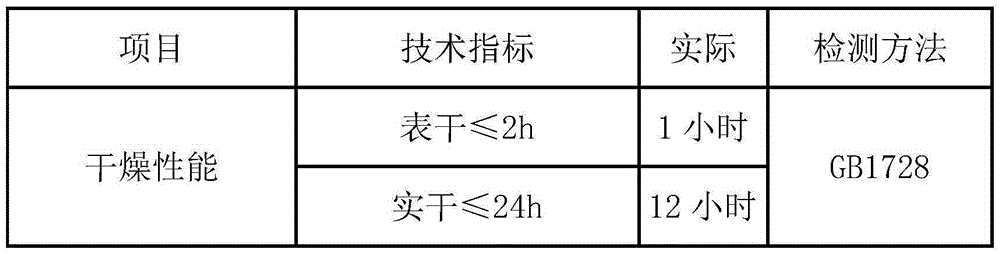

Outdoor waterborne woodenware penetration paint and preparation method thereof

InactiveCN107936742AReduced shear damageResist moisture intrusionPolyurea/polyurethane coatingsEmulsionLacquer

The invention belongs to the field of coatings for architectural ornament, and particularly relates to an outdoor waterborne woodenware penetration paint and a preparation method thereof. The penetration paint is prepared from the following components by weight: 10 to 15 parts of water, 65 to 80 parts of waterborne emulsion, 2 to 5 parts of coalescing agent, 2 to 25 parts of coloring agent and 4.5to 9 parts of other aids. The outdoor waterborne woodenware penetration paint prepared by the method has good base material closing property, excellent weather fastness and water resistance on the basis of a traditional woodenware paint; in addition, the cracking of a substrate can be reduced and the substrate can be protected from being corroded to a certain extent.

Owner:SHENYANG RES INST OF CHEM IND

Cathode electrophoresis paint with combined bottom surfaces and preparation method and application method thereof

ActiveCN103333595APolyurea/polyurethane coatingsPaints for electrolytic applicationsWeather resistanceFirming agent

Owner:GUANGDONG KODEST EP SC CO LTD

Good-weather and water resistance water-based alkyd resin

Owner:深圳海德新材料科技有限公司

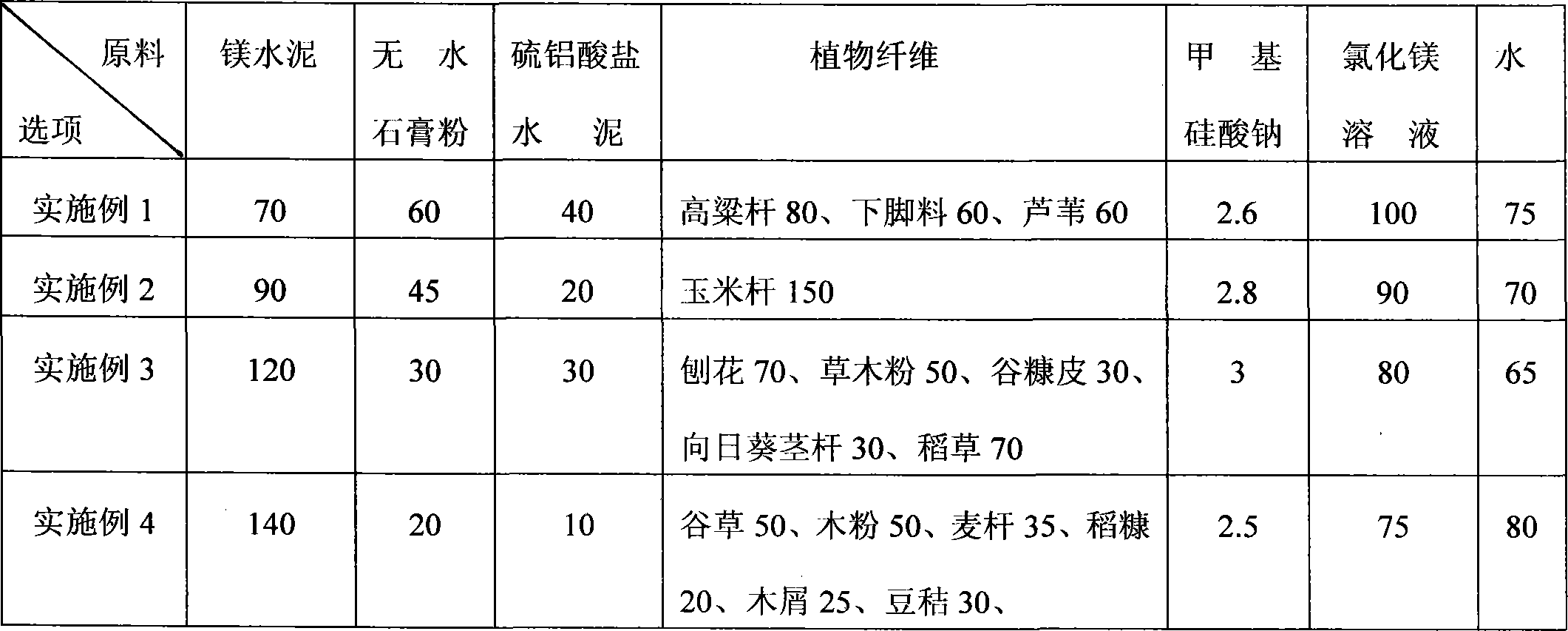

Magnesium-calcium pyrophyte pressed-fibre board and method of manufacturing the same

InactiveCN101172825AObvious beneficial effectGood effectSolid waste managementWeather resistancePlant fibre

Owner:谢涛

Fluorine-containing aqueous coating composition

InactiveCN1738878AGood chemical resistanceImprove water resistancePolyurea/polyurethane coatingsWater dispersibleSolvent

A fluorine-containing aqueous coating composition composed of (A) an aqueous emulsion of a functional group-containing fluororesin obtained by dispersing, in water, a fluoroolefin copolymer having a functional group that is obtained through solution polymerization and (B) a water-dispersible unblocked isocyanate compound is disclosed. The fluororesin aqueous coating composition can be cured at ordinary temperature, and a coating formed therefrom is excellent in chemical resistance, water resistance, solvent resistance, contamination resistance, hardness, weathering resistance and durability.

Owner:DAIKIN IND LTD

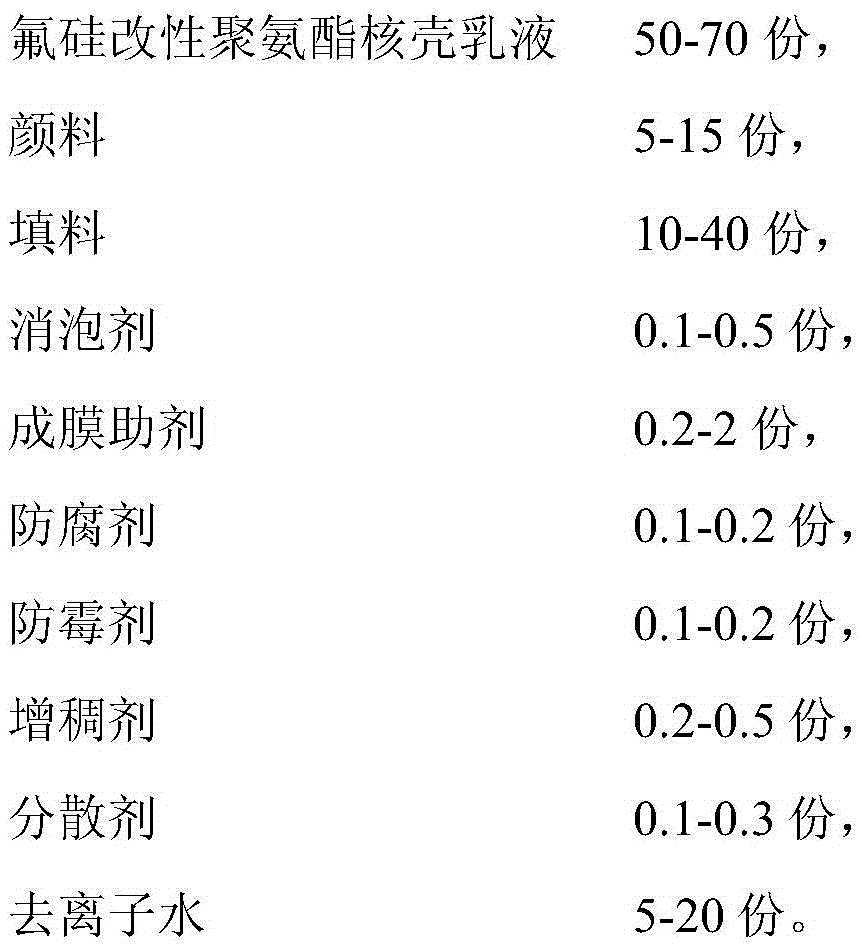

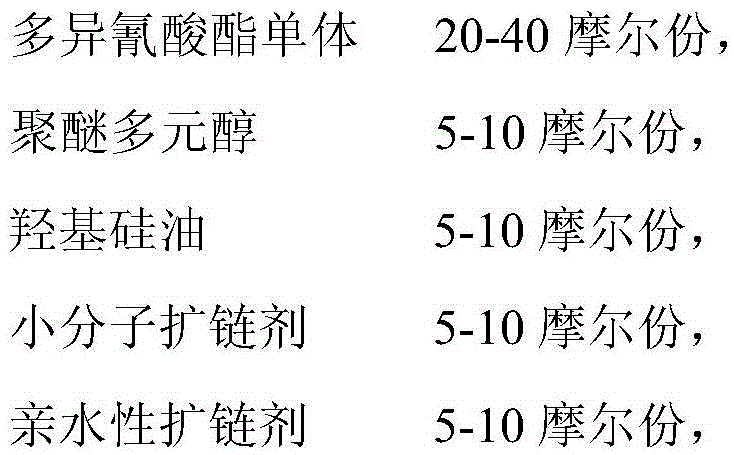

Water-based anti-doodling paint and preparation method thereof

ActiveCN105482604ALow VOC emissionsLow weather resistanceAntifouling/underwater paintsPaints with biocidesWater basedDefoaming Agents

Owner:HANGZHOU JIHUA POLYMER MATERIAL CO LTD

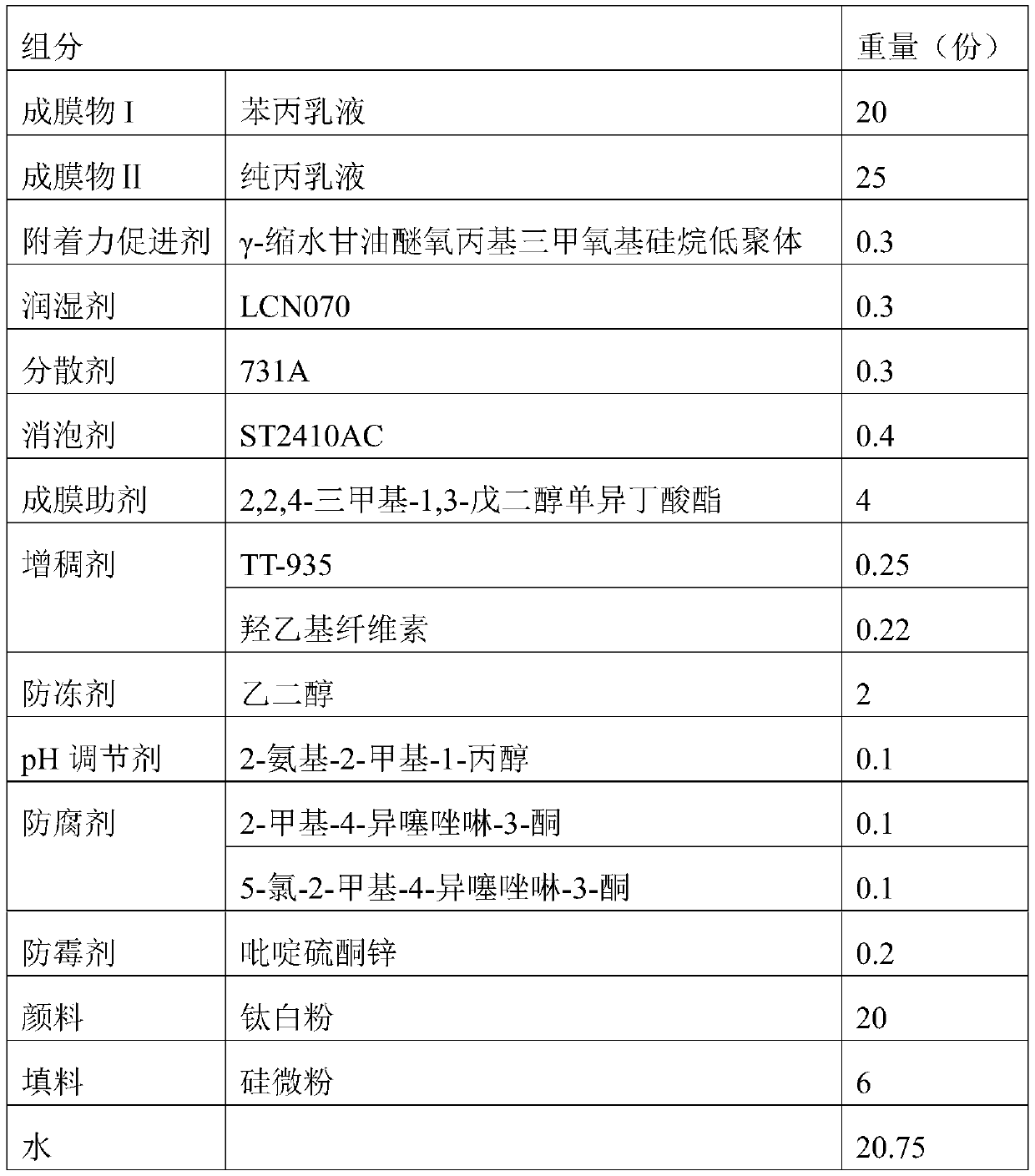

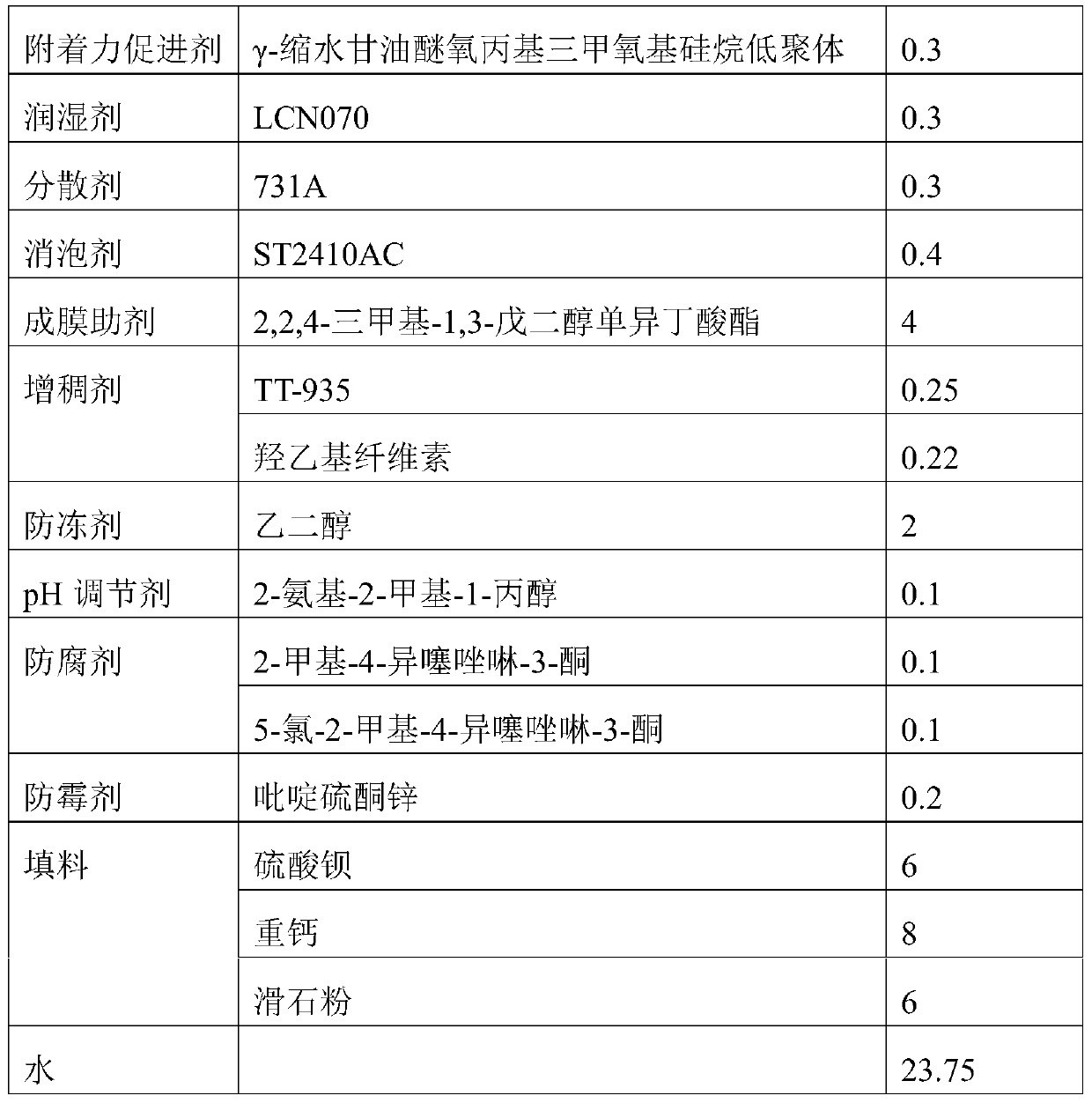

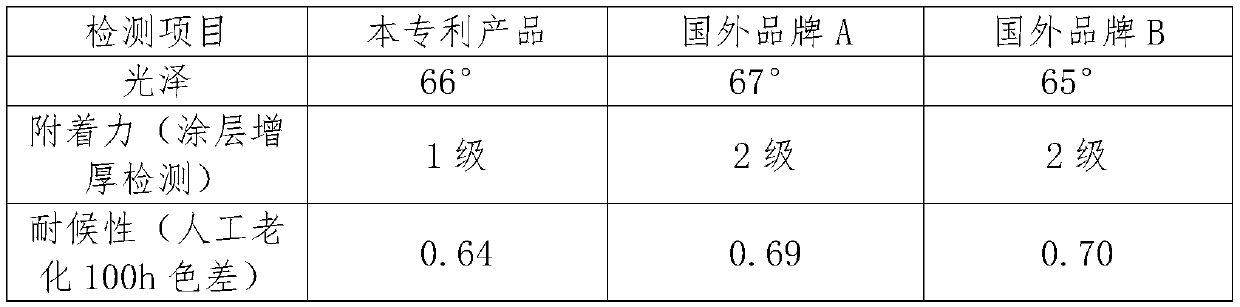

Direct-coating water-based single-component ceramic tile renovating coating and preparation method thereof

InactiveCN110317505AAntifouling/underwater paintsPaints with biocidesWeather resistanceDefoaming Agents

Owner:CARPOLY CHEM GRP

Elastic thermal insulating coating

InactiveCN103342936ABroad market spaceImprove environmental friendlinessReflecting/signal paintsWeather resistanceTitanium dioxide

The invention belongs to the technical field of architectural coating and particularly relates to an elastic thermal insulating coating. The elastic thermal insulating coating comprises the following components by weight percent: 40-50% of film forming agent, 10-20% of titanium dioxide, 4-10% of hollow glass bead, 5-7.5% of filler, 3-6% of dispersing agent, 1-3% of wetting agent, 1.6-4.0% of coalescing agent, 0.1-0.2% of cellulose, 0.1-0.5% of thickening agent, 0.2-0.5% of antifoaming agent and the balance of water. According to the technical scheme, all the materials are environment-friendly, and excellent thermal insulating effect and weather resistance are achieved due to the adoption of the hollow glass bead and rutile-type nanometer titanium dioxide. The hollow glass bead coating has a broad market space.

Owner:KUNSHAN DACHUAN COLORANT MATERIAL

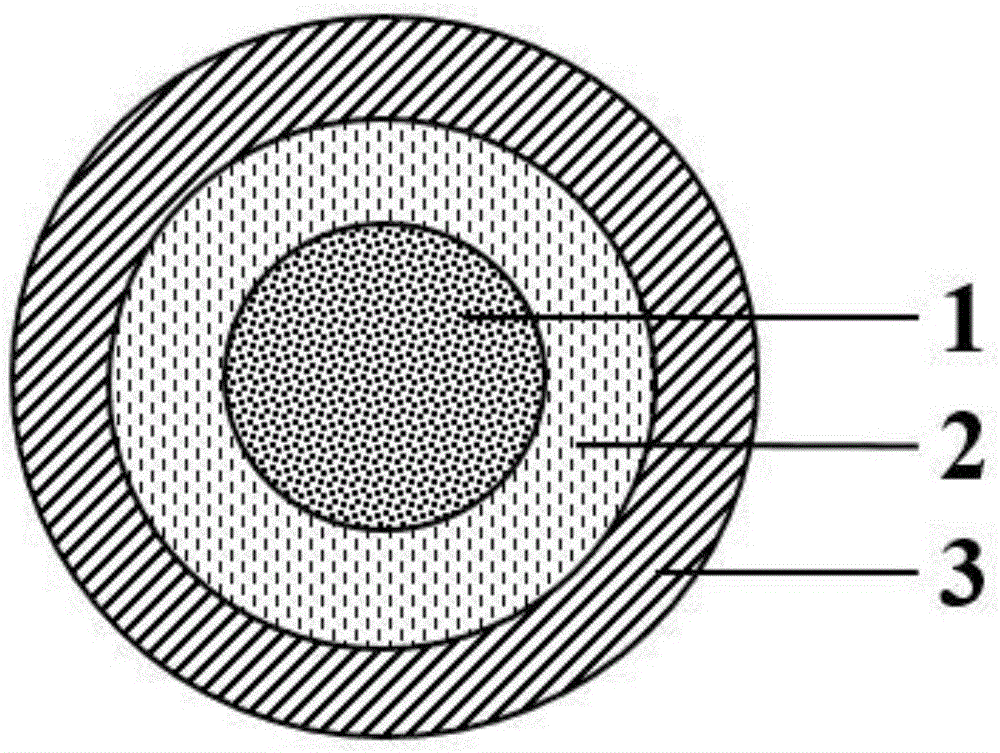

Irradiation-crosslinked halogen-free flame-retardant photovoltaic cable, and preparation method and application thereof

InactiveCN106432895AImprove flame retardant performanceImproved color stabilityPlastic/resin/waxes insulatorsInsulated cablesChemistryWeather resistance

The invention discloses an irradiation-crosslinked halogen-free flame-retardant photovoltaic cable, and a preparation method and application thereof. The photovoltaic cable comprises a conductive core wire, an insulation layer and a sheath layer. The insulation layer and sheath layer are respectively prepared from the following raw materials: 100 parts of polyolefin resin, 5-15 parts of compatilizer, 40-100 parts of compound flame retardant, 1-3 parts of lubricant, 0.5-2.5 parts of antioxidant, 1-2.5 parts of sensitizer, 0.5-2 parts of modified silicone and 3-5 parts of titanium white. The preparation method comprises the following steps: 1) preparing the insulation layer cable material; 2) preparing the sheath layer cable material; and 3) carrying out coextrusion on the conductive core wire, insulation layer cable material and sheath layer cable material, and carrying out irradiation crosslinking. The photovoltaic cable product has the advantages of excellent flame retardancy, no halogen, environment friendliness, high / low temperature resistance, ultraviolet resistance, mold resistance, damp heat resistance, salt spray resistance, high color stability, excellent mechanical properties, excellent weather resistance, long service life, simple production technique and low production cost, and can be widely used for photovoltaic industry.

Owner:GUANGZHOU KAIHENG SPECIAL WIRE & CABLE

High-performance bridge steel with yield strength not smaller than 500 MPa and preparation method and application of high-performance bridge steel

The invention belongs to the technical field of metallurgy, and particularly relates to high-performance bridge steel with the yield strength not smaller than 500 MPa and a preparation method and application of the high-performance bridge steel. The bridge steel is prepared from the following components: 0.03% to 0.06% of C, 0.10% to 0.25% of Si, 1.30% to 1.50% of Mn, less than or equal to 0.015% of P, less than or equal to 0.003% of S, 0.010% to 0.040% of Als, 0.25% to 0.45% of Cr, 0.05% to 0.20% of Mo, 0.20% to 0.30% of Cu, 0.25% to 0.40% of Ni, 0.030% to 0.040% of Nb, 0.010% to 0.040% of Ti and the balance Fe and impurities. According to the high-performance bridge steel with the yield strength not smaller than 500 MPa and the preparation method and application of the high-performance bridge steel, microalloying design is adopted, a TMCP technology is matched, precious elements are reduced, the structure is fine and uniform, and a prepared steel plate has high toughness, a low yield ratio, weather resistance, weldability and the anti-fatigue performance.

Owner:SD STEEL RIZHAO CO LTD

Solar energy electrical conduction slurry and preparation method thereof

InactiveCN102938260ANon-conductive material with dispersed conductive materialCable/conductor manufactureWeather resistanceSilane coupling

Owner:DONGFANG ELECTRIC YIXING MAGI SOLAR POWER TECH

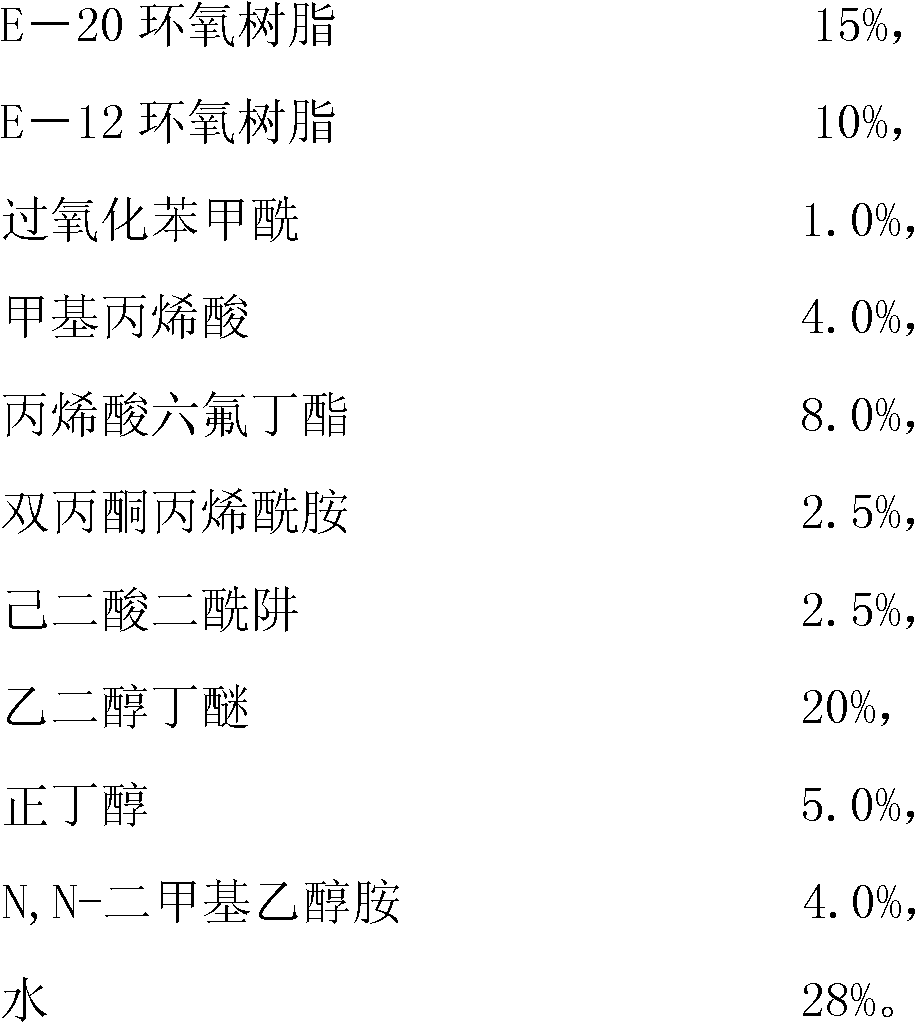

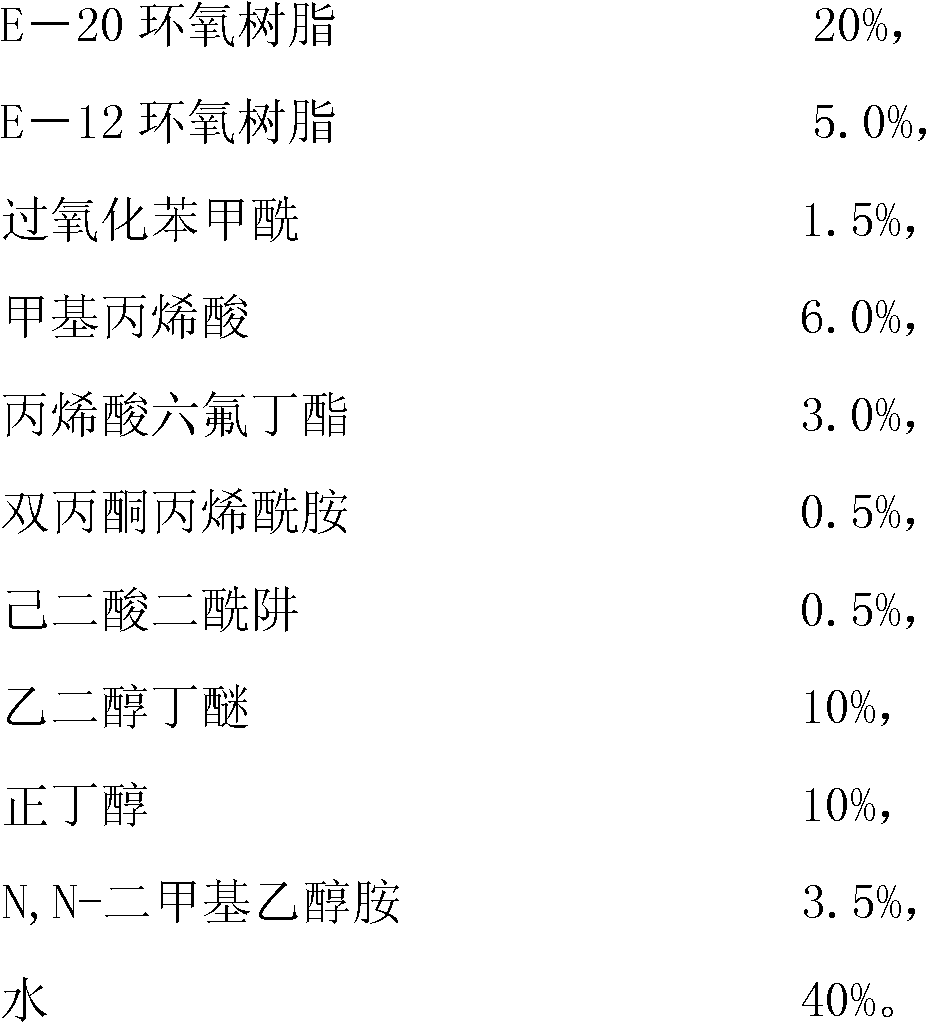

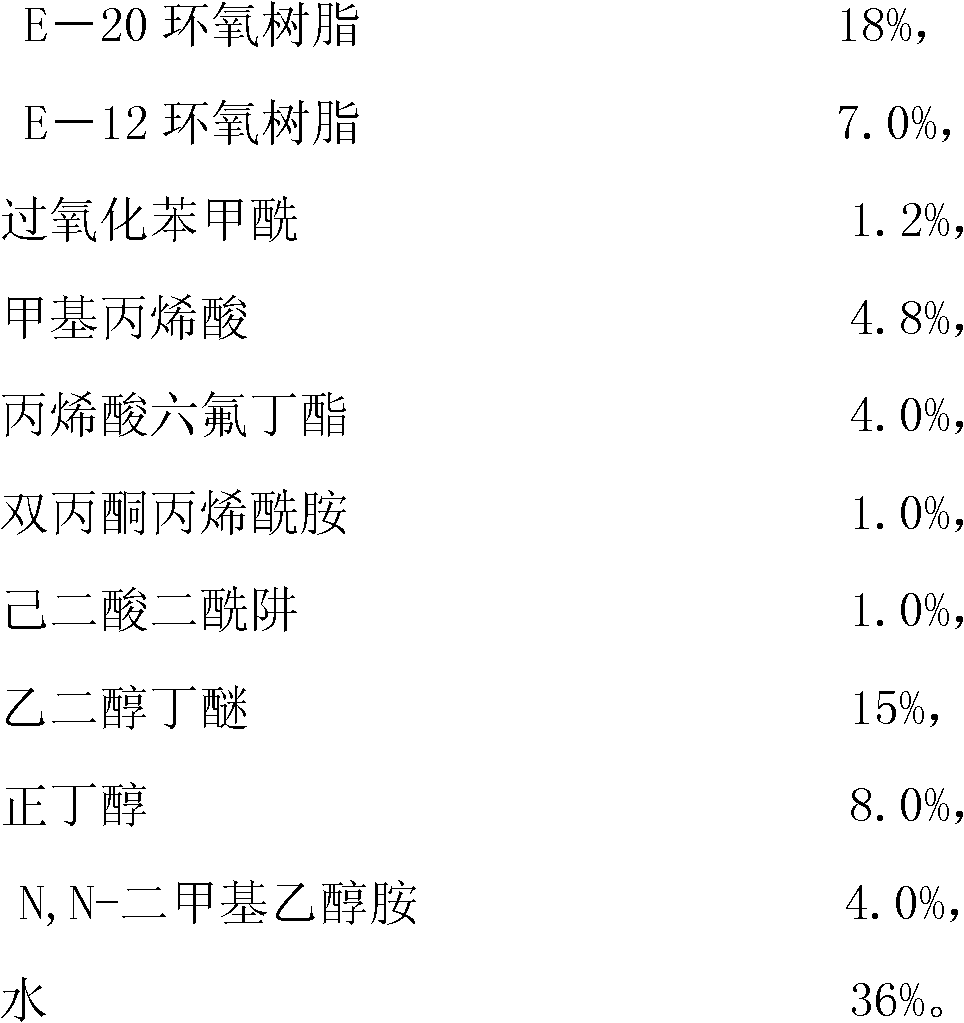

Epoxy emulsion cured at room temperature with high aquosity and weather resistance as well as preparation method of epoxy emulsion

InactiveCN102604047AGood film formingGood physical and mechanical propertiesCoatingsEpoxyBenzoyl peroxide

Owner:JIANGSU UNIV OF SCI & TECH

Preparation method of water-soluble acrylic acid solid resin

Owner:安徽红太阳新材料有限公司

Preparation method of high-activity waterproof soap-free emulsion polymer

InactiveCN110669169AHigh activityEntanglement effect is significantCoatingsHydrophilic monomerPolymer science

Owner:HUBEI UNIV OF TECH

Photocurable fluorinated copolymer composition

InactiveUS20140212673A1High transparencyExcellent abrasion resistanceSynthetic resin layered productsPolyurea/polyurethane coatingsSilane compoundsEpoxy

Owner:ASAHI GLASS CO LTD

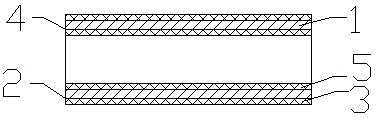

Plastic-coated composite steel tube

Owner:丁春英

Coating process of outer surface of sculpture

InactiveCN105921387APrevent metal oxidationSufficient adhesionPretreated surfacesSpecial surfacesWeather resistanceSurface roughness

Owner:NANJING CHENGUANG ART ENG CO LTD

Low-temperature curing touch screen conductive silver paste suitable for laser etching processing

InactiveCN106898411AApparatus for manufacturing conducting/semi-conducting layersNon-conductive material with dispersed conductive materialSolventWeather resistance

Owner:北京市合众创能光电技术有限公司

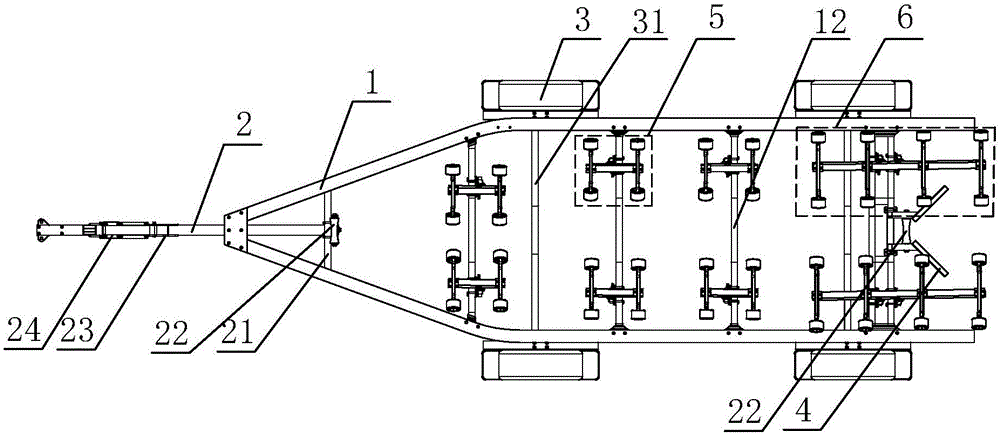

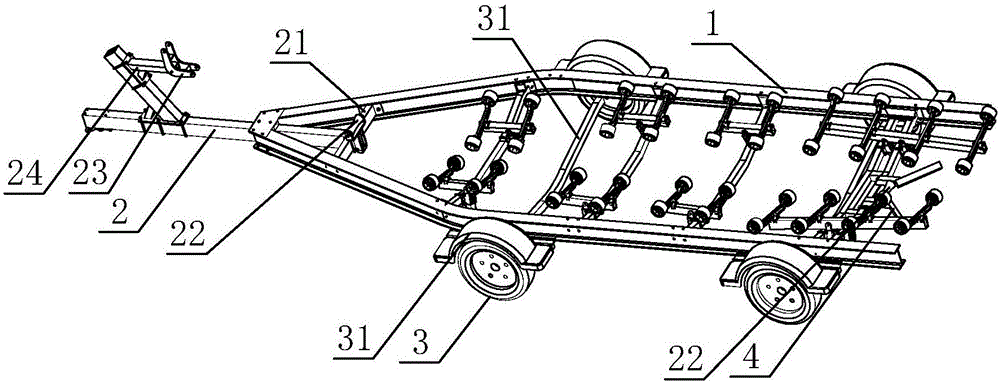

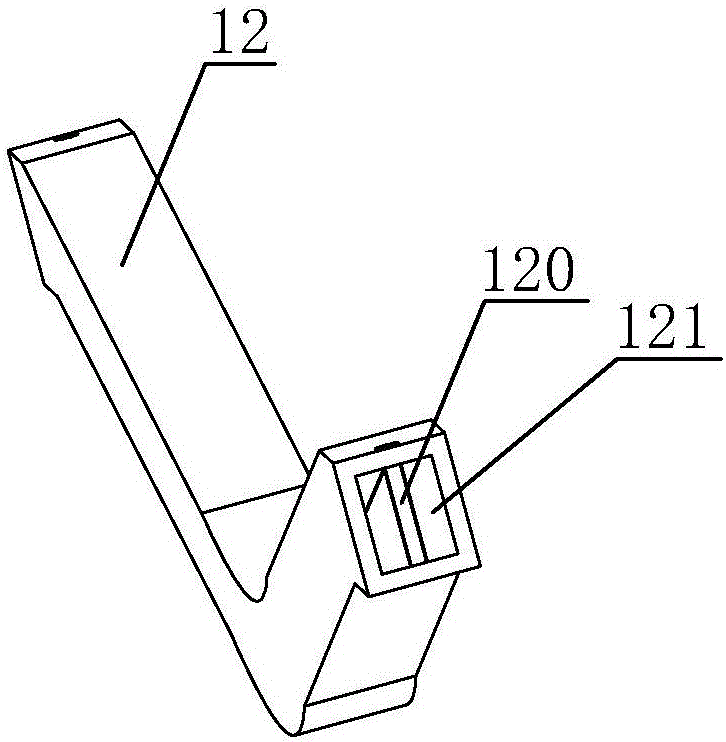

Boat trailer with high weather resistance

ActiveCN106740395AAvoid pollutionReduce pollutionItem transportation vehiclesVehicle carriersWeather resistanceAluminum can

Owner:山东双一游艇有限公司

Antibacterial and anti-static paint and preparation method thereof

InactiveCN106519927AGood dispersionImprove adhesionFireproof paintsAntifouling/underwater paintsEpoxyAntistatic agent

Owner:WUXI BENNIU BIOTECH CO LTD

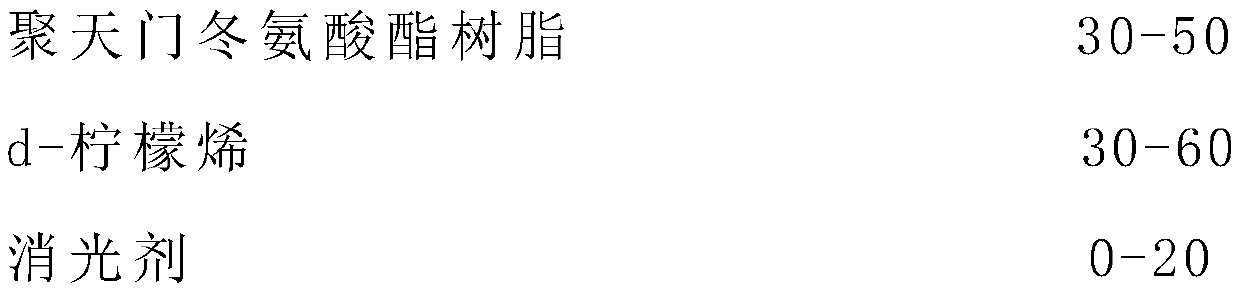

Two-component environment-friendly coating rich in d-limonene, and preparation method thereof

PendingCN111117462AImprove waterproof performanceEfficient sterilizationAntifouling/underwater paintsPaints with biocidesPolyaspartic acidOrganic solvent

Owner:广东立盈新材料有限公司

Liquid gas silicon dioxide amine electrolyte for storage battery

InactiveCN102891338AImprove discharge performanceHigh energy ratioLead-acid accumulatorsGas phaseSilicic acid

Owner:YANCHENG XINYUE ENERGY

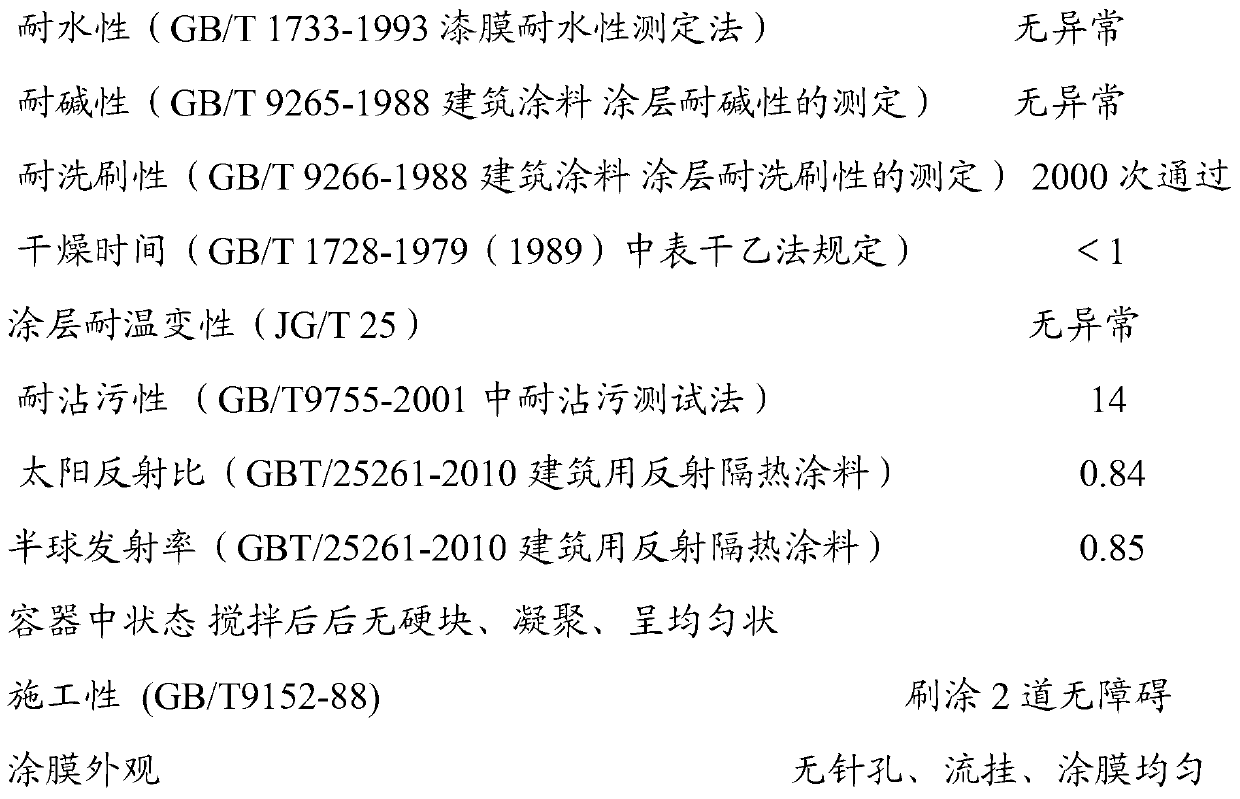

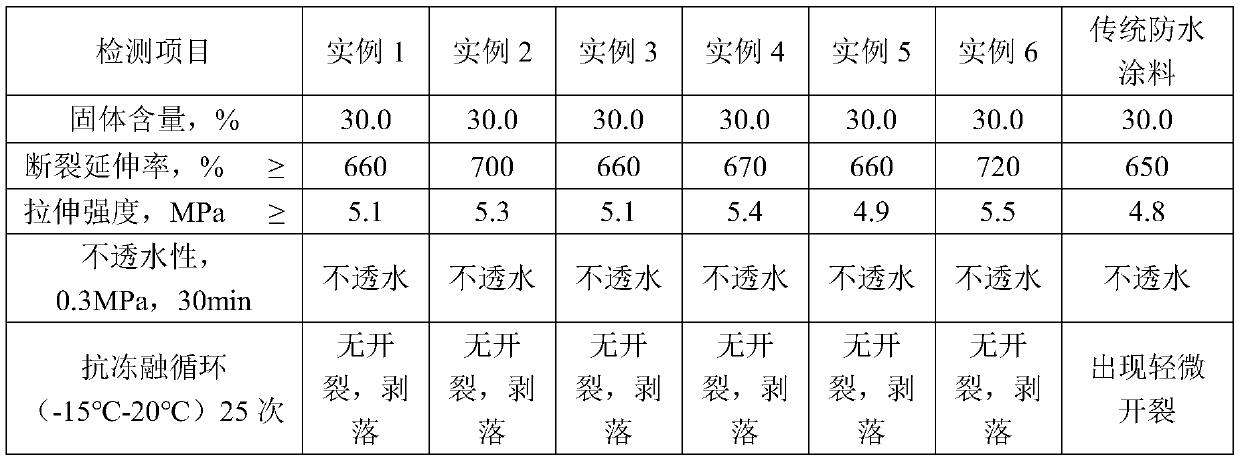

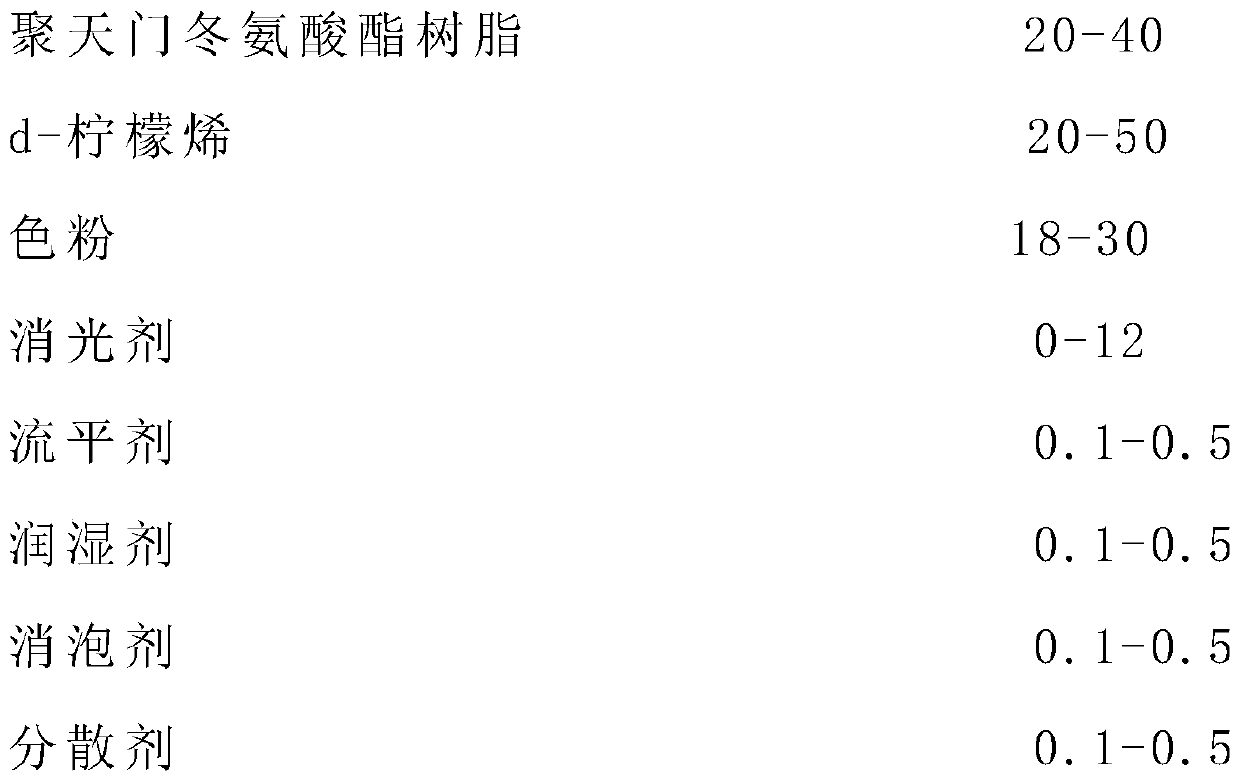

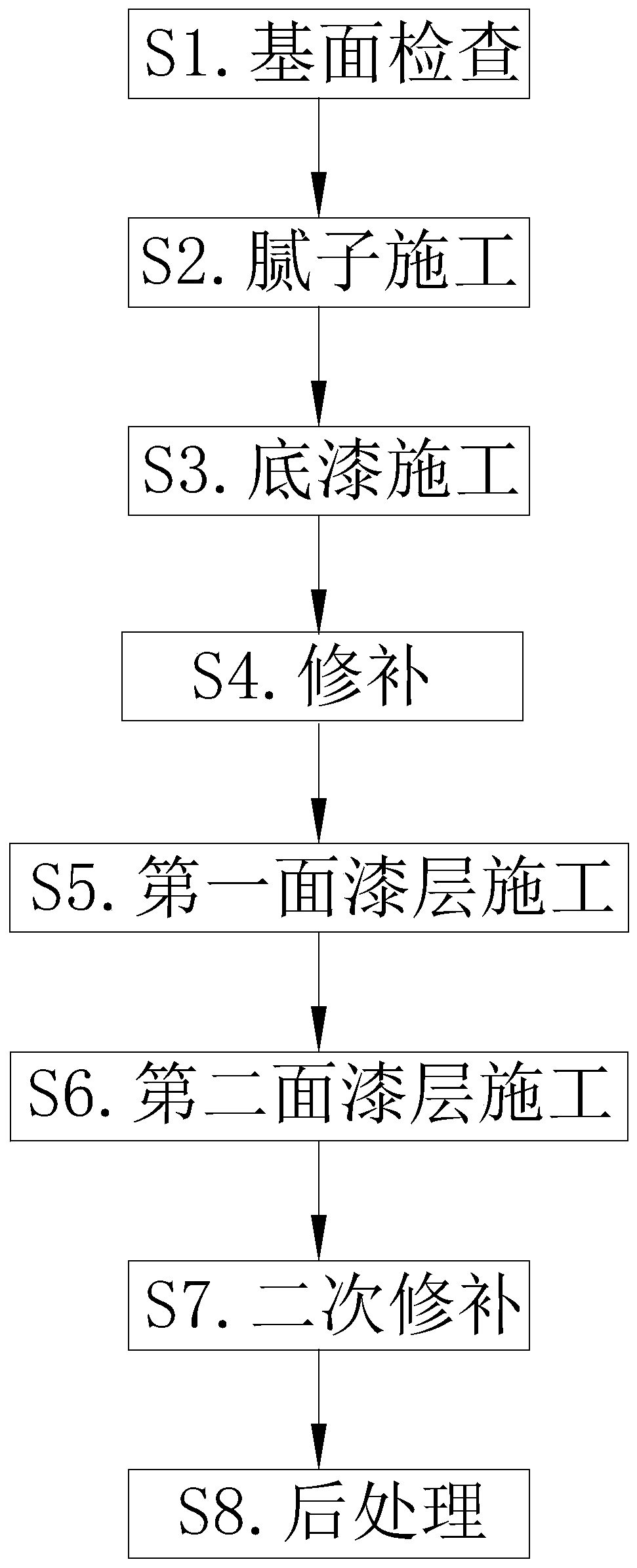

Building exterior wall coating with good weather resistance and exterior wall coating construction process

Owner:深圳陆城装饰设计工程有限公司

Mildew-proofing and antibacterial PVC modified material used for placemats and preparation method of same

InactiveCN107286517AImprove anti-mold and anti-bacterial propertiesImprove anti-static effectWeather resistanceAntistatic agent

Owner:广东祺龙科技有限公司

Fireproof coating used for steel structure buildings, preparation method thereof and coating process

Owner:LIYANG TECH DEV CENT

Automobile cushion care agent

InactiveCN106566899AGood weather resistanceImprove softness and elasticityLeather surface finishingLeather impregnationAcetic acidWeather resistance

Owner:SUZHOU WANLONG AUTO PARTS

Vinyl phosphate flame retardant and preparation method thereof

InactiveCN111363397AGood for the environmentGood application prospectFireproof paintsGroup 5/15 element organic compoundsDichloromethaneWeather resistance

The invention discloses a vinyl phosphate flame retardant, wherein phenylphosphonic dichloride and alkyl acrylate are subjected to a reaction in one of dichloromethane, diethyl ether or tetrahydrofuran serving as a solvent under the action of a catalyst triethylamine or pyridine to generate a final target product, wherein the two chlorides of phenylphosphonic dichloride are disubstituted by alkylacrylate to obtain the product phenylphosphane alkene ester. According to the invention, the vinyl phosphate flame retardant does not contain halogen, is non-toxic, is beneficial to environmental protection, has high thermal stability and high charring property, is a reactive organophosphorus flame retardant, can be widely applied to preparation of various acrylic acid and acrylate flame-retardantcoating material emulsions, does not affect the adhesion, weather resistance and other properties of coating materials after being added into the coating materials, and can achieve high flame-retardant effect under the condition that the addition amount of the flame-retardant agent in the coating material is small.

Owner:KUNMING UNIV OF SCI & TECH

10PB 6.5/8 pigment composition and technical method for preparing color characterization substances by using same

InactiveCN101684282AGood weather resistanceImprove stabilityCoatings with pigmentsColor measuring devicesPolymer scienceColored white

The invention discloses a 10PB 6.5 / 8 pigment composition, which comprises the following components in part by weight: 995 to 1,005 parts of CSC-B base material, 5.23 to 5.36 parts of PV23 containing 30 percent of pigment, 0.46 to 0.52 part of PB15:3 containing 27 percent of pigment and 0.11 part of PBK7 containing 9 percent of pigment. The main component of the CSC-B base material is ethylene methacrylic acid (EMAA) copolymer of which the content is 30 to 40 percent and the average molecular weight range is between 150,000 and 200,000. TiO2 is used as a main white pigment with the content between 8 and 12 percent. The base material has the contrast ratio of between 0.78 and 0.82, the stormer viscosity of between 90 and 100 KU and the glossiness of between 5 and 10 degrees when the incidentangle is 85 degrees. The composition has high weather resistance and stability and good proportioning repeatability, and raw materials and processes used meet the environmental requirements and standards of low VOC and zero VOC; and the physical color block has small color difference with a standard value in a theoretical model of 'Chinese color system', high accuracy of color realization, fine process and high practical value.

Owner:SHENZHEN OCEAN POWER INDUSTRIAL CO LTD +1

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap