Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

24 results about "Alkene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In organic chemistry, an alkene is an unsaturated hydrocarbon that contains at least one carbon–carbon double bond. The words alkene and olefin are often used interchangeably (see nomenclature section below). Acyclic alkenes, with only one double bond and no other functional groups, known as mono-enes, form a homologous series of hydrocarbons with the general formula CₙH₂ₙ. Alkenes have two hydrogen atoms fewer than the corresponding alkane (with the same number of carbon atoms). The simplest alkene, ethylene (C₂H₄), with the International Union of Pure and Applied Chemistry (IUPAC) name ethene, is the organic compound produced on the largest scale industrially. Aromatic compounds are often drawn as cyclic alkenes, but their structure and properties are different and they are not considered to be alkenes.

AEI-type zeolite, its synthesis and its use in the conversion of oxygenates to olefins

ActiveUS20050197519A1Aluminium compoundsSilicaCrystalline materialsOxygen compound

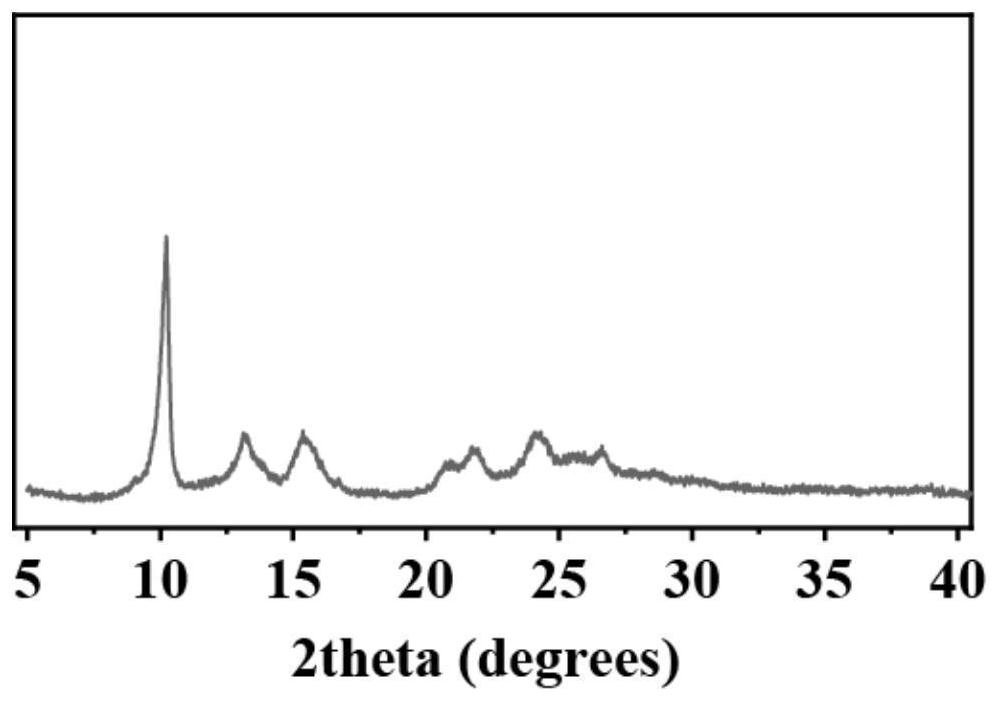

A crystalline material is described that has an AEI framework type, wherein the material, in its calcined, anhydrous form, has a composition involving the molar relationship: (n)X2O3:YO2, wherein X is a trivalent element, Y is a tetravalent element n is from 0 to less than 0.01. The material is normally synthesized in a halide, typically a fluoride, medium and exhibits activity and selectivity in the conversion of methanol to lower olefins, especially ethylene and propylene.

Owner:EXXONMOBIL CHEM PAT INC +1

Molded Article for Clean Room and Method for Producing Same

Owner:FUJI BAKELITE +2

Olefin oligomerization catalyst and preparation method and application thereof

ActiveCN101745422AHigh catalytic activityHigh yieldOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbonsAlcoholOligomer

The invention relates to an olefin oligomerization catalyst, which comprises an ethylchloride zirconyl alcohol adduct with the general formula of Zr (OR) mCl4-m . nROH, wherein m is an integer from 1 to 3, n is 2 to 8, and R is C3 to C8 chain alkyl. The preparation method of the catalyst is simple, the catalyst has higher oligomerization activity when being matched with an organic aluminum catalyst, the content of oligomer in the oligomerization product is low, the content of C12 to C20 olefin is higher, and the yield of alpha-olefin is high.

Owner:CHINA PETROLEUM & CHEM CORP +1

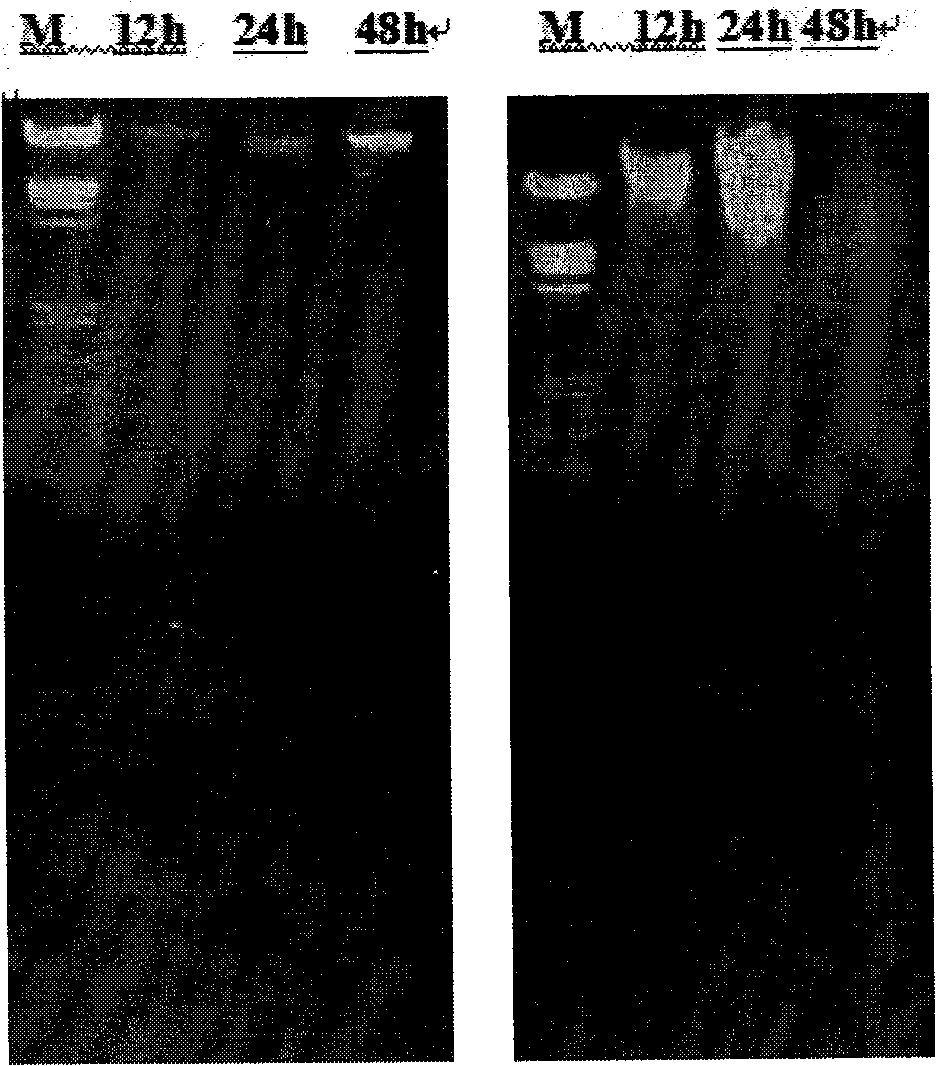

Recomposed escherichia coli base cell for efficient synthesis of terpene chemical compounds as well as preparation method and application thereof

ActiveCN103773729AAbundant resourcesGood synthesis effectBacteriaMicroorganism based processesEscherichia coliLycopene

The invention relates to a recomposed escherichia coli base cell for efficient synthesis of terpene chemical compounds as well as a preparation method and application thereof. Particularly, an escherichia coli endogenous 2-C-methyl-D-erythritol-4-phosphoric acid (MEP) precursor pathway is reconstructed; the reconstructed escherichia coli base cell is utilized to perform the efficient biological synthesis of the terpene chemical compounds; the reconstruction of the precursor pathway mainly comprises the steps of fully digging the MEP precursor pathway gene modules of the sources of other natural microorganisms, screening gene modules with excellent characteristics to be expressed in the escherichia coli, and at the same time, performing the downstream synthesis pathway for integrally assembling the colibacillus chemical compounds in the reconstructed base cell, wherein the colibacillus chemical compounds include sesquiterpene chemical compounds such as amorphadiene, diterpene chemical compounds such as shell alkene, tetraterpenes chemical compounds such as lycopene, polyterpene chemical compounds, other terpene alkaloid chemical compounds and the like. The escherichia coli base cell can remarkably facilitate the synthesis of the terpene chemical compounds.

Owner:CAS CENT FOR EXCELLENCE IN MOLECULAR PLANT SCI

Process for modifying FCC gasoline distillation and co-producing low-carbon olefine and catalyst thereof

InactiveCN1844323AGood transitivityGood reaction selectivityOrganic chemistryNaphtha reformingLiquid productMolecular sieve

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Lower olefins producing catalyst and method for producing lower olefins using same

ActiveUS20120116143A1Improve efficiencyHigh catalytic activityMolecular sieve catalystsMolecular sieve catalystPtru catalystOxygen compound

A lower olefin producing catalyst which has high olefin production efficiency and maintains its activity for a long period of time when lower olefins are produced from an oxygen-containing compound, which is a solid catalyst used in producing lower olefins from an oxygen-containing compound, includes a solid-state catalyst component containing an MFI-type zeolite, in which, at a position where the shortest distance to the outer surface is maximum among all positions inside a structure of the solid catalyst, the thickness defined as a distance twice the shortest distance from the point to the outer surface is in a range of from 0.1 to 2.0 mm, and a method for producing lower olefins.

Owner:MITSUBISHI CHEM CORP +1

Method for preparing gasoline rich in isoparaffin from methanol and/or dimethyl ether

InactiveCN106867564AImprove qualityBroaden the application marketMolecular sieve catalystsLiquid hydrocarbon mixture productionAlkaneMolecular sieve

The invention relates to a method for preparing gasoline rich in isoparaffin from methanol and / or dimethyl ether. A catalyst used in the method is prepared from a molecular sieve-loaded active metal component. Since the catalyst used in the method has excellent selectivity on isoparaffin in a gasoline fraction (hydrocarbons with a carbon atom number of 5 to 11; and low selectivity on olefins and aromatic hydrocarbons, the composition of the gasoline produced by using the method can meet the national gasoline standard VI in China, or even meet requirements on the contents of aromatic hydrocarbons and olefins in world advanced standards for clean fuels (such as the European standard V and standards for motor gasoline in California of the US). The method provides a feasible technical route for direct acquisition of non-petroleum resources and has good market prospects.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

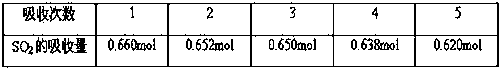

Absorber preparation method

Owner:KUNMING UNIV OF SCI & TECH

N-alkene isomerization catalyst and preparation method and application thereof

ActiveCN106076408AReduce in quantityReduce cokingHydrocarbon by isomerisationMolecular sieve catalystsButeneIsomerization

Owner:山东迅达化工集团有限公司

Preparation method for 22E-alkene-3a,5-ring-5a-cholest-6-ketone

ActiveCN107474096AReduce manufacturing costWide variety of sourcesSteroidsOrganic synthesisFiltration

The invention belongs to the technical field of organic synthesis and relates to a preparation method for 22E-alkene-3a,5-ring-5a-cholest-6-ketone. The method comprises the following steps: placing 22E-alkene-3a,5-ring-5a-cholest-6-alcohol into an organic solvent, adding a catalyst under a certain temperature, performing oxidizing reaction under air or oxygen atmosphere and performing crystal suction filtration on the crude product, thereby obtaining an end product. According to the invention, any one of free radical catalyst, metal salt or free radical catalyst and metal salt is selected as the catalyst system of reaction; the 22E-alkene-3a,5-ring-5a-cholest-6-alcohol is directly oxidized into the 22E-alkene-3a,5-ring-5a-cholest-6-ketone under air or oxygen atmosphere; the yield thereof is above 90% and the content is above 98%; the raw materials are nontoxic or low-toxicity; the catalyst used in the reaction is low-cost and extensively sourced; the operation is safe, simple and convenient, the reaction condition is mild and the three wastes generated in the whole process are far less than those generated in the prior art; the production cost is low; no toxic three-waste emission exists; the total yield is high; the method is beneficial to industrialization.

Owner:JIANGSU QIANYUAN BIOTECHNOLOGY CO LTD

Dialkene-containing gasoline fraction hydrotreating method

InactiveCN102559261AEasy to removeSolve cokingTreatment with hydrotreatment processesFluid phaseReaction temperature

The invention provides a dialkene-containing gasoline fraction hydrotreating method. The method comprises the following steps: (1) directly mixing a dialkene-containing gasoline fraction raw material with a hot hydrogen-donor solvent, and feeding the mixture into a hydropretreating reactor for dialkene-removing reaction when the temperature of the mixture reaches the dialkene-removing reaction temperature; (2) mixing reaction effluent of the hydropretreating reactor with hydrogen gas, feeding the mixture into a heating furnace, heating the mixed material until the temperature of the mixed material reaches the temperature required by the inlet of the hydrotreating reactor, feeding the mixed material into a separator, separating the mixed material into a gas phase and a liquid phase, wherein the liquid phase is mainly the hydrogen-donor solvent and is circulated to the step (1) for use, and the separated gas phase is fed into the hydrotreating reactor so as to be subjected to hydrogenation impurity-removal reaction; and (3) feeding the reaction effluent of the hydrotreating reactor into a separation system, separating out the hydrotreated gasoline fraction and a gas phase, wherein the gas phase is mainly the hydrogen gas and is recycled. Compared with the prior art, the method provided by the invention can be used for effectively solving the coking problem of a dialkene-containing gasoline fraction hydrotreater.

Owner:何裕松

Catalysts containing at least one heterocyclic ligand for improving the catalysts' performance of olefin polymerization

InactiveUS7094723B2Easy to optimizeOrganic-compounds/hydrides/coordination-complexes catalystsNickel organic compoundsSulfurLanthanide

Owner:EQUSR CHEM LP

Electrical devices from polymer resins prepared with ionic catalysts

InactiveUS20020004567A1ClosuresClosure using stoppersCoordination complexAlkene

Owner:EXXONMOBIL CHEM PAT INC

Golf ball

Owner:BRIDGESTONE SPORTS

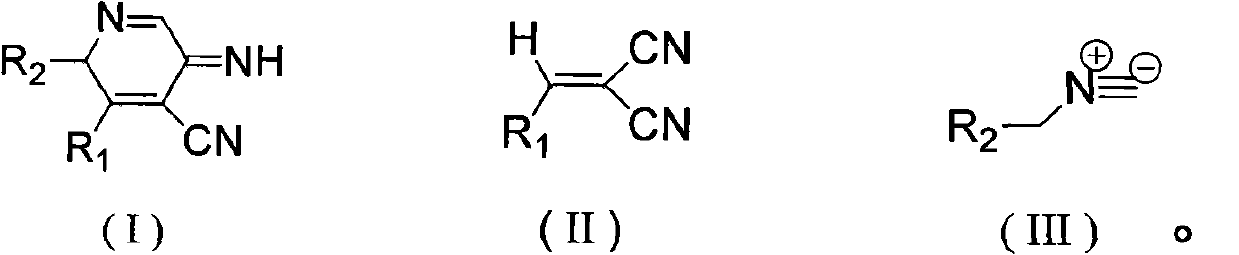

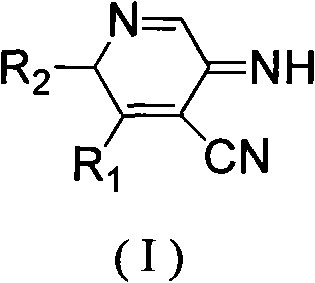

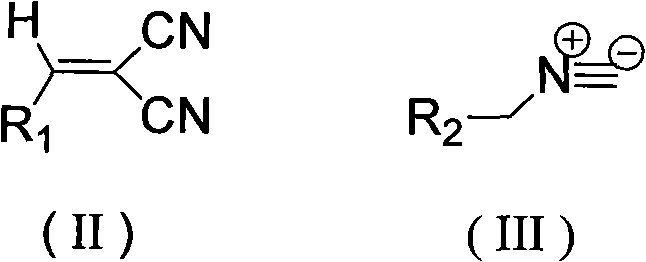

Simple and direct method for synthesizing pyridine monoamine and its derivatives

InactiveCN102351789AEasy to operateMild reaction conditionsOrganic chemistryOrganic solventStructural formula

Owner:TAIZHOU UNIV

Graphene/fluorine-silicon self-crosslinking resin composite heavy-duty anti-corrosion finish paint and preparation method thereof

PendingCN110642970AAvoid the disadvantages of easy reunionEvenly dispersedAnti-corrosive paintsEthyleneglycol monobutyl etherIn situ polymerization

The invention relates to graphene / fluorine-silicon self-crosslinking resin composite heavy-duty anti-corrosion finish paint and preparation thereof. The finish paint is prepared from the following rawmaterials in parts by weight through in-situ polymerization: 30 to 40 parts of hydroxyethyl allyl ether, 50 to 60 parts of vinyl acetate, 25 to 35 parts of undecylenic acid, 10 to 20 parts of ethylene glycol monobutyl ether, 8 to 10 parts of vinyl siloxane, 50 to 60 parts of chlorotrifluoroethylene CTFE, 4 to 20 parts of graphene oxide, 125 to 150 parts of a solvent and 5 to 6 parts of an initiator. A graphene fluorine-silicon self-crosslinking resin composite is prepared by performing in-situ polymerization on a part of free double bonds of graphene oxide and an olefin monomer, namely, dispersing graphene in a polymer monomer for monomer-monomer polymerization and monomer-graphene-monomer polymerization. The preparation process is simple; the graphene oxide is uniformly dispersed in theresin and is firmly combined with the resin; and the defect that the graphene is easy to agglomerate is avoided. After the finish paint is cured, interface strength is improved, so the corrosion resistance of the graphene paint is improved.

Owner:CP NANOMATERIALS RES CENT (DALIAN) CO LTD

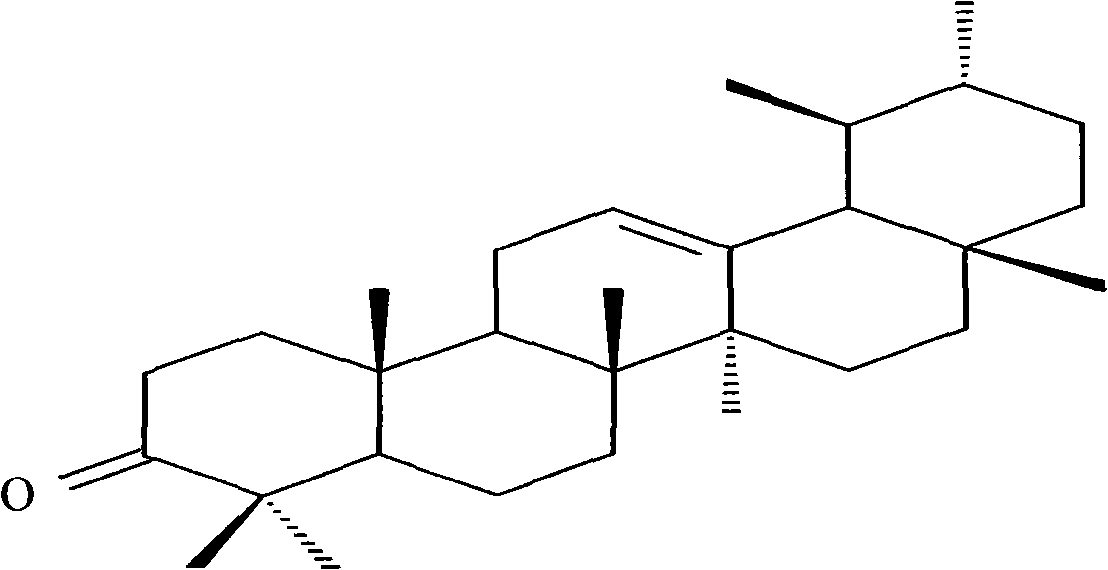

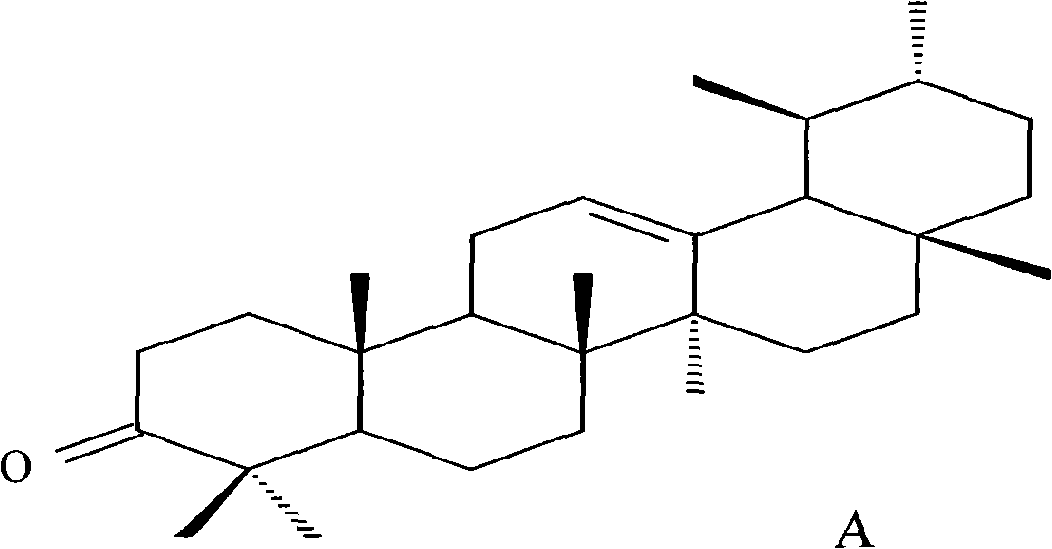

Antitumor usage of 3-carbonyl-12-alkene-ursane compound

InactiveCN101574352AGrowth inhibitionApoptotic effect is obviousOrganic active ingredientsDigestive systemApoptosisWilms' tumor

Owner:FUJIAN AGRI & FORESTRY UNIV

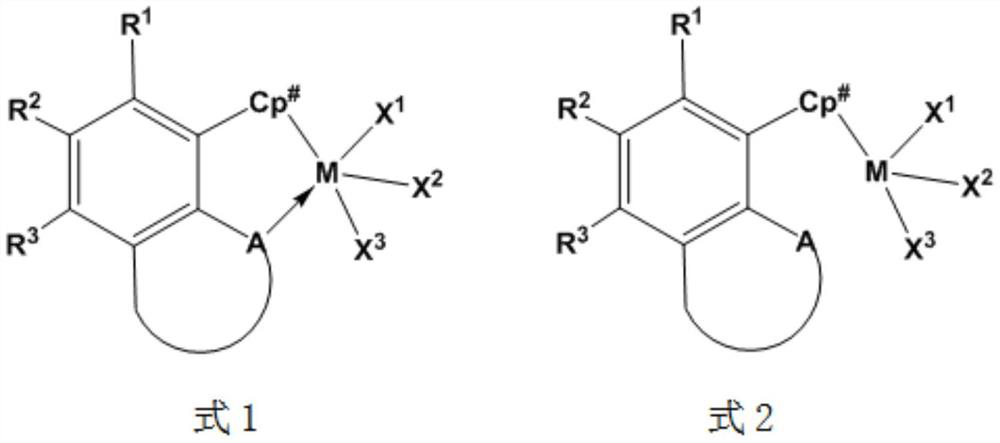

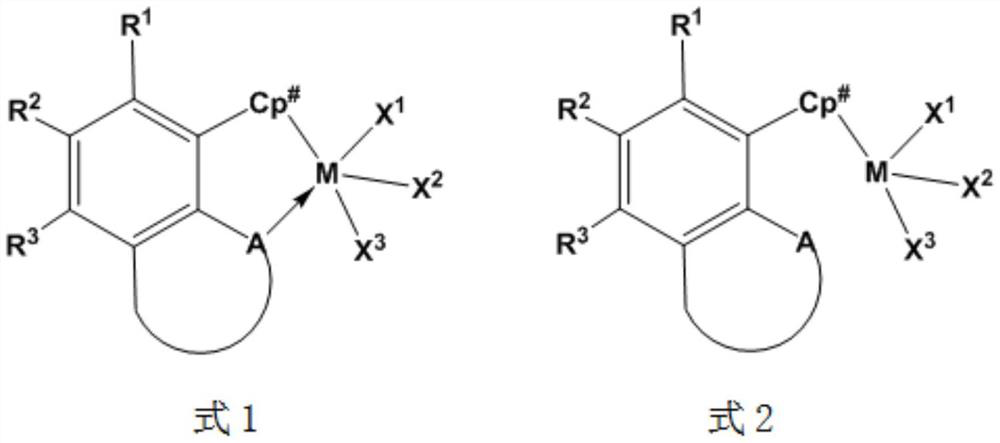

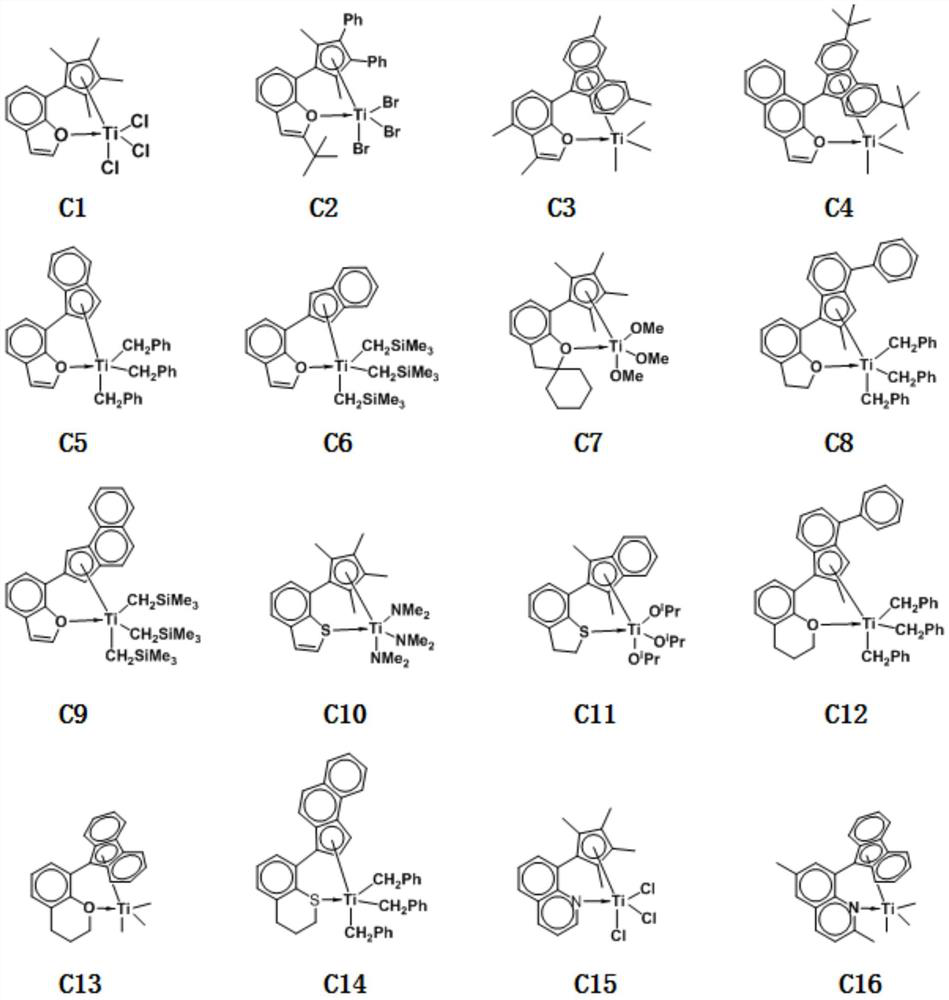

Application of mono-cyclopentadienyl fourth subgroup metal complex containing neutral coordination side group

ActiveCN111729688AStable structureImprove stabilityOrganic-compounds/hydrides/coordination-complexes catalystsTransportation and packagingCarbon numberPolymer science

Owner:JILIN UNIV

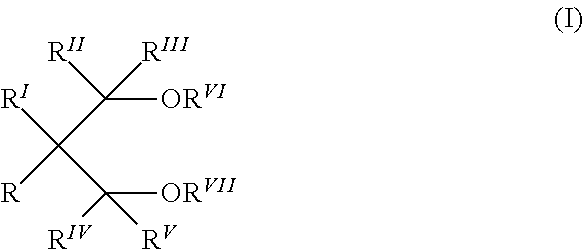

Catalyst components for the polymerization of olefins

InactiveUS20180230247A1PorosityElectron donor

Owner:BASSELL POLIOLEFINE ITAL SRL

Cationic polymerization of olefins using green acids

ActiveUS20190330395A1Organic sulfonic acidIndium

Owner:LEWIS STEWART P

Non-polar olefin block copolymer with adjustable crystal block content and preparation method thereof

Owner:DALIAN UNIV OF TECH

Method for synthesizing naphthopyran-2-ketone compound

ActiveCN111205261AReduce dosageSimple and mild reaction conditionsOrganic chemistryMeth-Ptru catalyst

Owner:HARBIN INSTITUTE OF TECHNOLOGY SHENZHEN (INSTITUTE OF SCIENCE AND TECHNOLOGY INNOVATION HARBIN INSTITUTE OF TECHNOLOGY SHENZHEN)

A method of recovering olefins in a solution polymerisation process

Owner:BOREALIS AG

Process for the preparation of an olefinic product from an oxygenate

InactiveUS20150353441A1Equipment foulingHydrocarbon purification/separationHydrocarbon from oxygen organic compoundsOxygenateAlkene

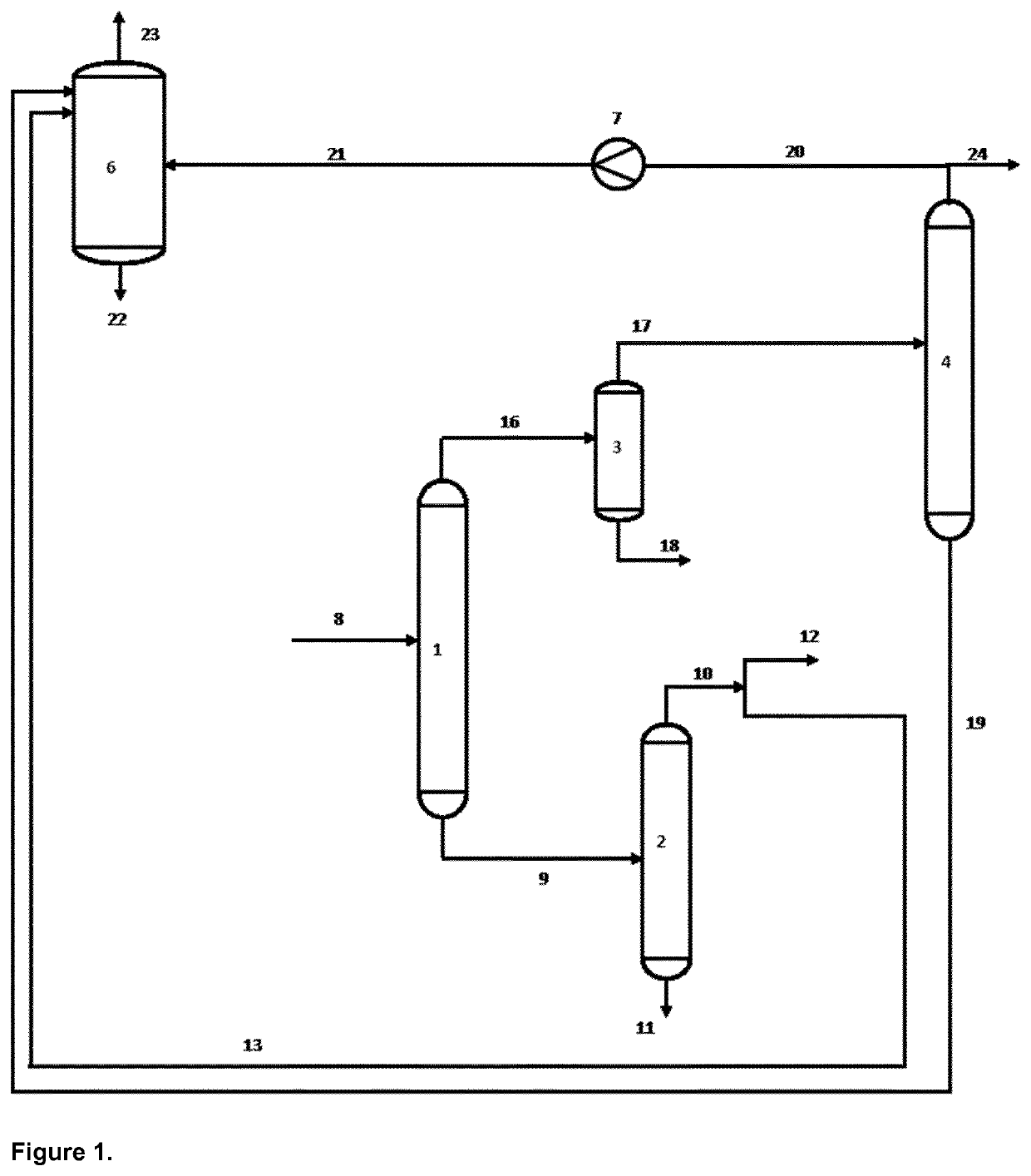

The invention relates to a process for the preparation of an olefinic product comprising ethylene and / or propylene from an oxygenate comprising: a) an oxygenate conversion step wherein a gaseous effluent comprising olefins is obtained; b) separation of water from the effluent; c) compression of the effluent; d) acid gas removal from the effluent wherein the water-depleted compressed gaseous effluent is treated with a caustic solution in a caustic tower and a non-aqueous liquid stream comprising one or more aromatic C7+ hydrocarbons is added to the caustic solution to control the formation of red oil; and e) separating the olefinic product from the gaseous effluent treated in step d).

Owner:SHELL OIL CO

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap