Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

62 results about "Liquid phase" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Liquid phase (plural liquid phases) (physics) One of the three fundamental structural phases of matter in which the thermal mobility of molecules or atoms is comparable with the cohesiveness, having them connected but fluid in a mass.

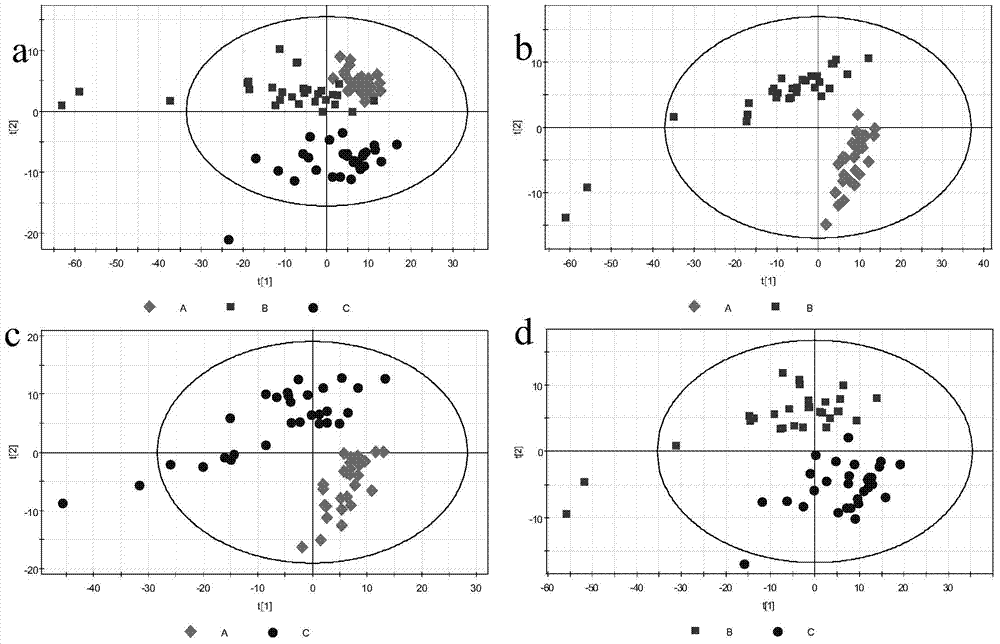

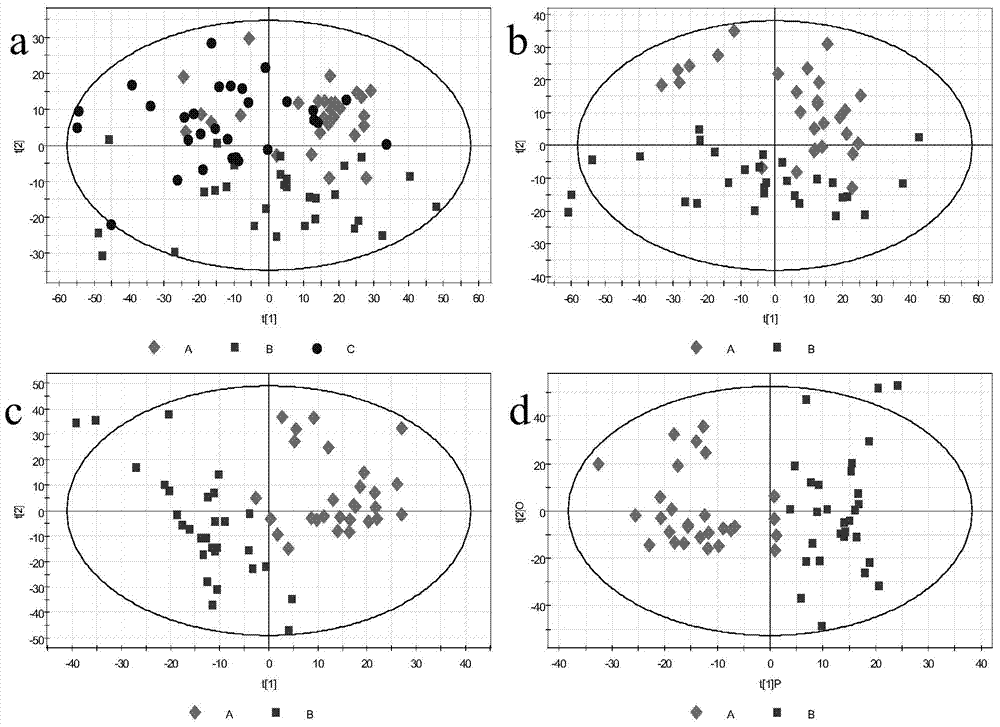

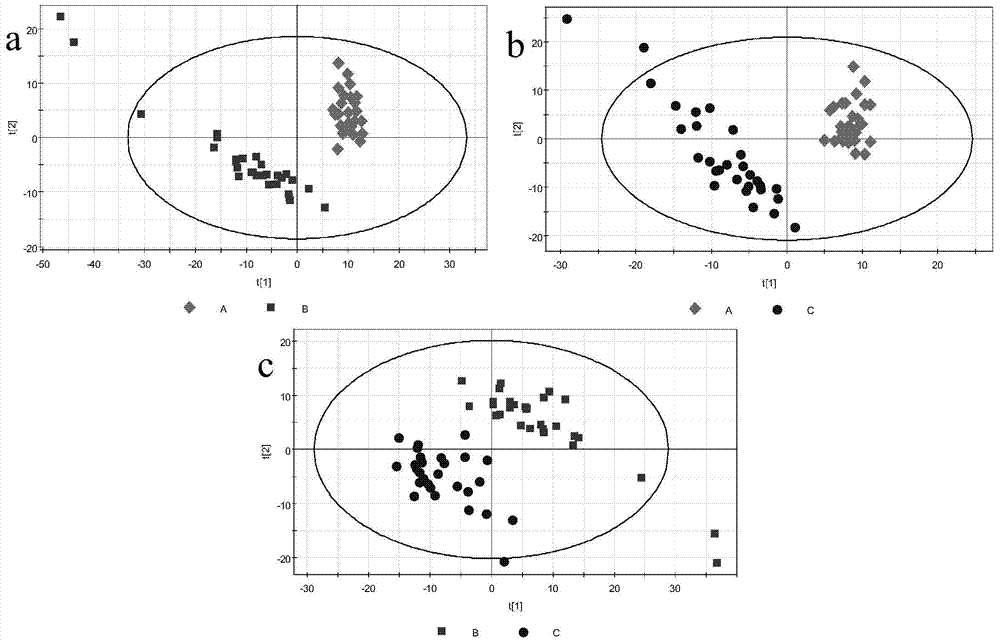

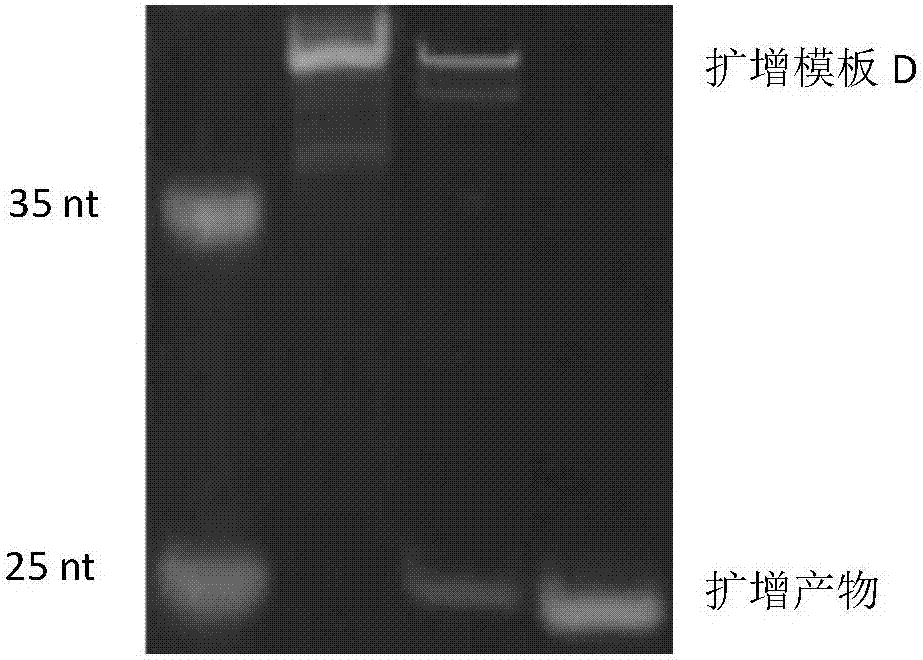

Serum specificity metabolite spectrum for patient with lung cancer, and building method thereof

ActiveCN103616450AEasy to handleStrong qualitative analysis abilityComponent separationGas phaseOriginal data

Owner:HUZHOU CENT HOSPITAL

Method for producing ethanol from crop straw

ActiveCN101186943AEasy to separateTake advantage ofBiofuelsMicroorganism based processesSolid componentFiltration

The invention provides a process for producing ethanol with raw materials of straws. The process comprises preliminary treatment to crops straws, solid-liquid separation, hydrolyzed solid components and fermentation with yeasts after hyperfiltration and filtration enrichment by RO combination. The invention can simultaneously conduct evaporating concentration to liquid components, and produce corresponding by-product of lignosulfonate by adding sulfonating agent. The ethanol producing process of the invention greatly decreases the cost of industrial production which ferments straws to produce ethanol, and efficiently utilizes all the ingredients of crops straws.

Owner:ANHUI BBCA FERMENTATION TECH ENG RES

Dephosphorizing agent and application thereof

The invention relates to a dephosphorizing agent and application thereof, belonging to the technical field of ferrous metallurgy. The dephosphorizing agent solves the problems of low dephosphorizing efficiency, high residue consumption, environment pollution and difficulty in resource comprehensive utilization in the existing calcium-oxide-based molten iron pretreatment dephosphorizing agent. The dephosphorizing agent comprises the following components in percentage by mass: 25-50% of FeOt, 20-45% of CaO, 15-30% of SiO2, 2-10% of Na2O and 3-12% of Al2O3. After being molten, the molten iron dephosphorizing can form a solid-phase / liquid-phase coexistent multiphase residue system at 1300-1400 DEG C, wherein the solid phase is a 2CaO.SiO2 phase capable of providing a place for enriching oxidized phosphorus in molten iron, so that the dephosphorizing agent has the characteristics of favorable dephosphorizing effect, low slag consumption, no fluorine and small environmental pollution and is beneficial to comprehensive utilization of dephosphorizing slag.

Owner:CENT SOUTH UNIV

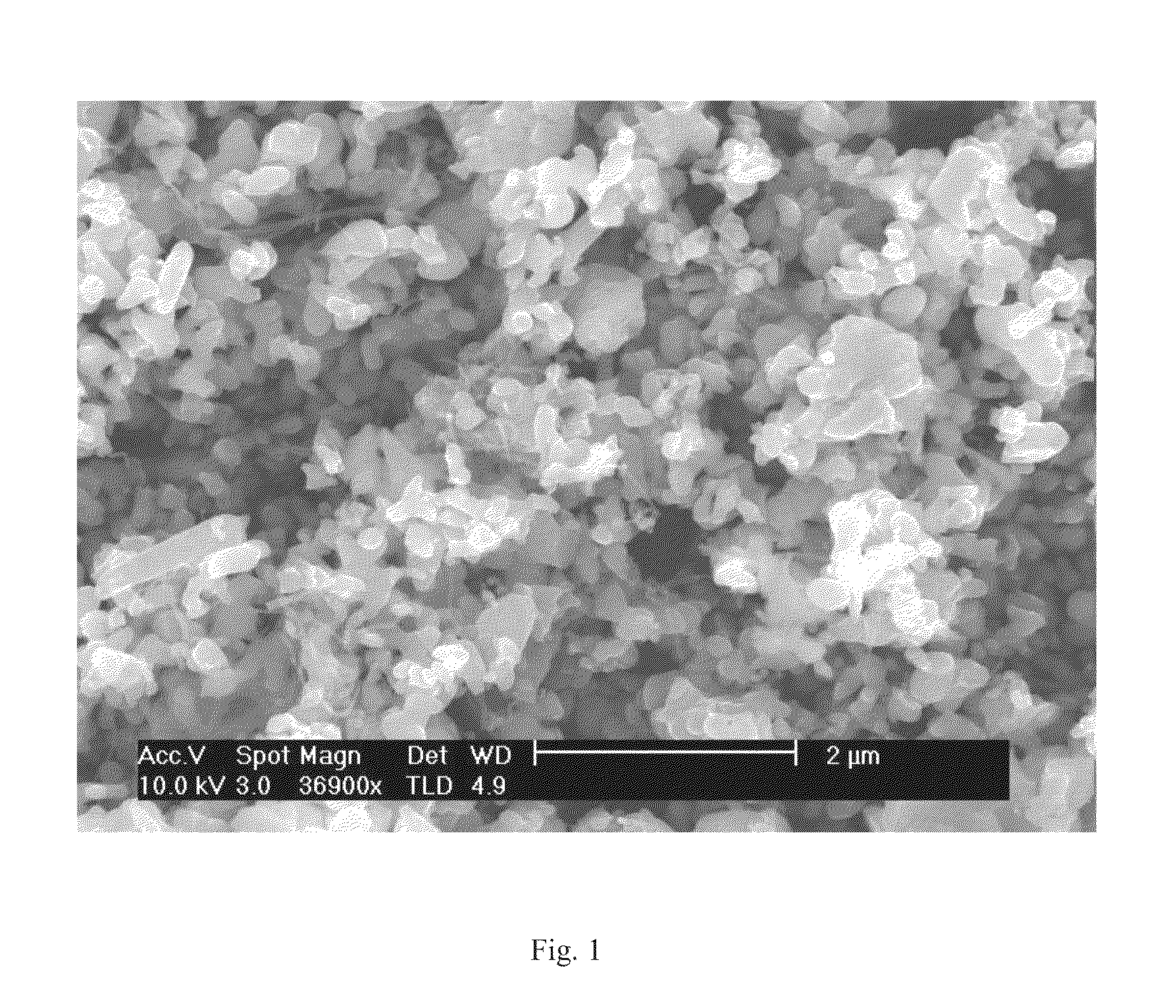

Auto-thermal evaporative liquid-phase synthesis method for cathode material for battery

InactiveUS20140239235A1Simple processReduce energy consumptionNon-metal conductorsPhosphatesInternal resistanceSynthesis methods

Owner:SHENZHEN DYNANONIC

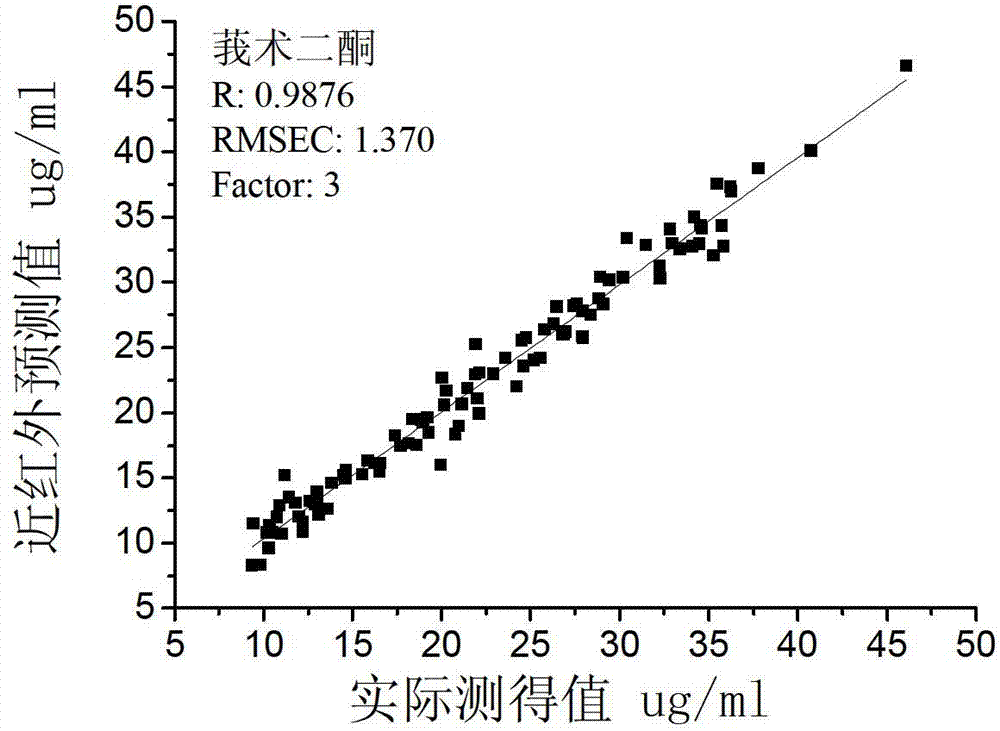

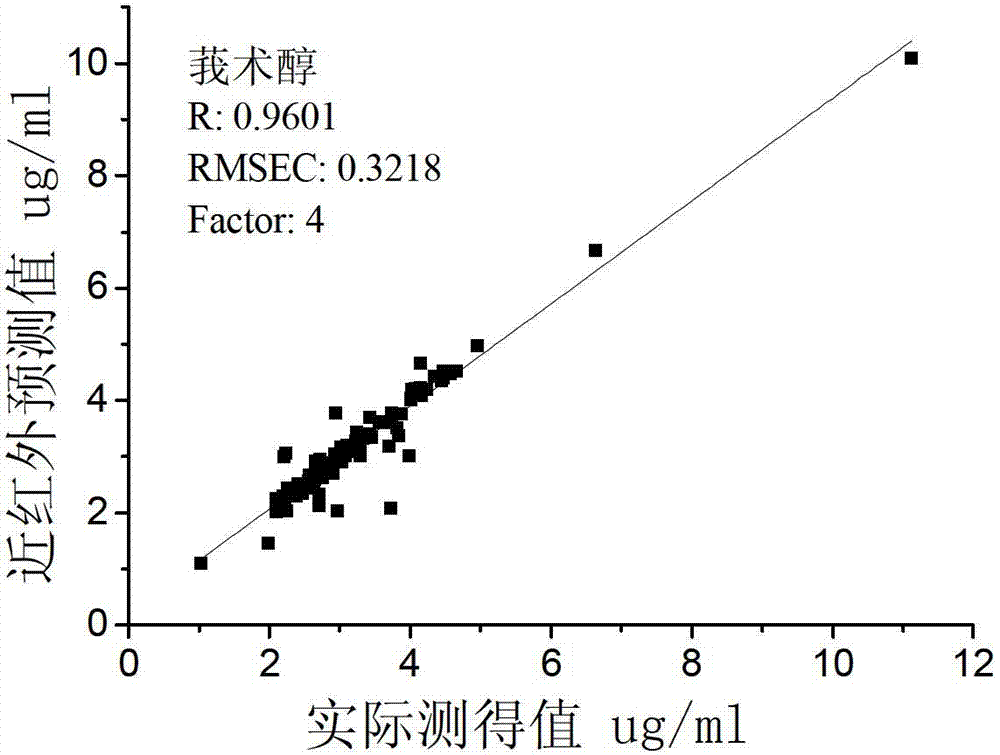

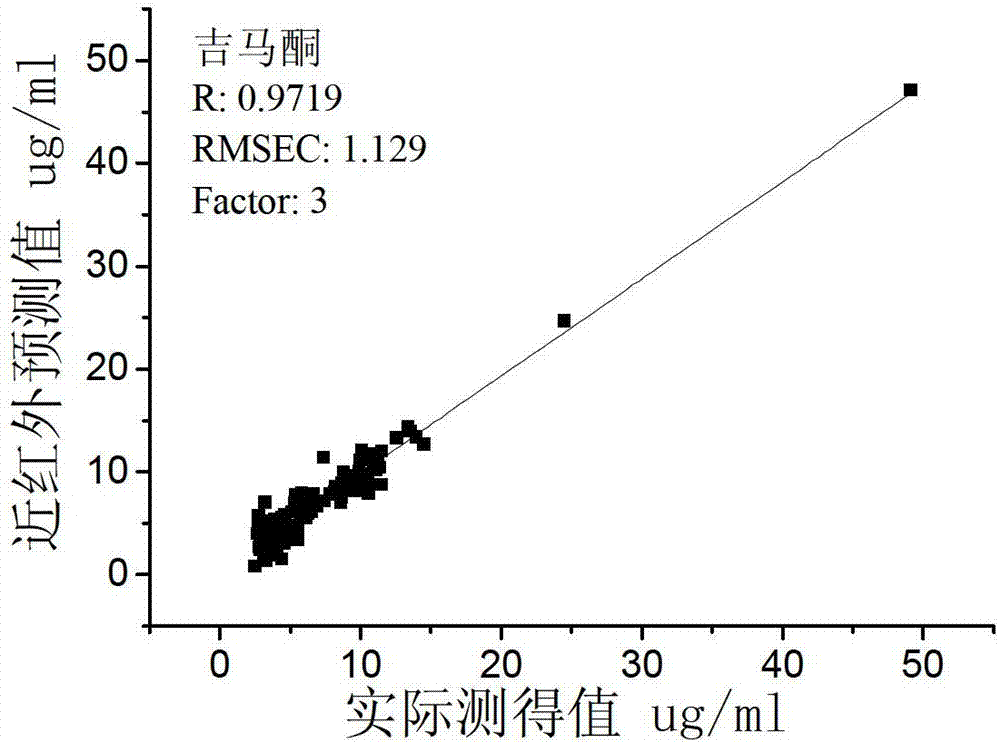

Rapid center control testing method of Xingnaojing injection

ActiveCN102928352AImprove quality controlRapid determinationColor/spectral properties measurementsInfraredDiketone

Owner:WUXI JIMIN KEXIN SHANHE PHARMA +1

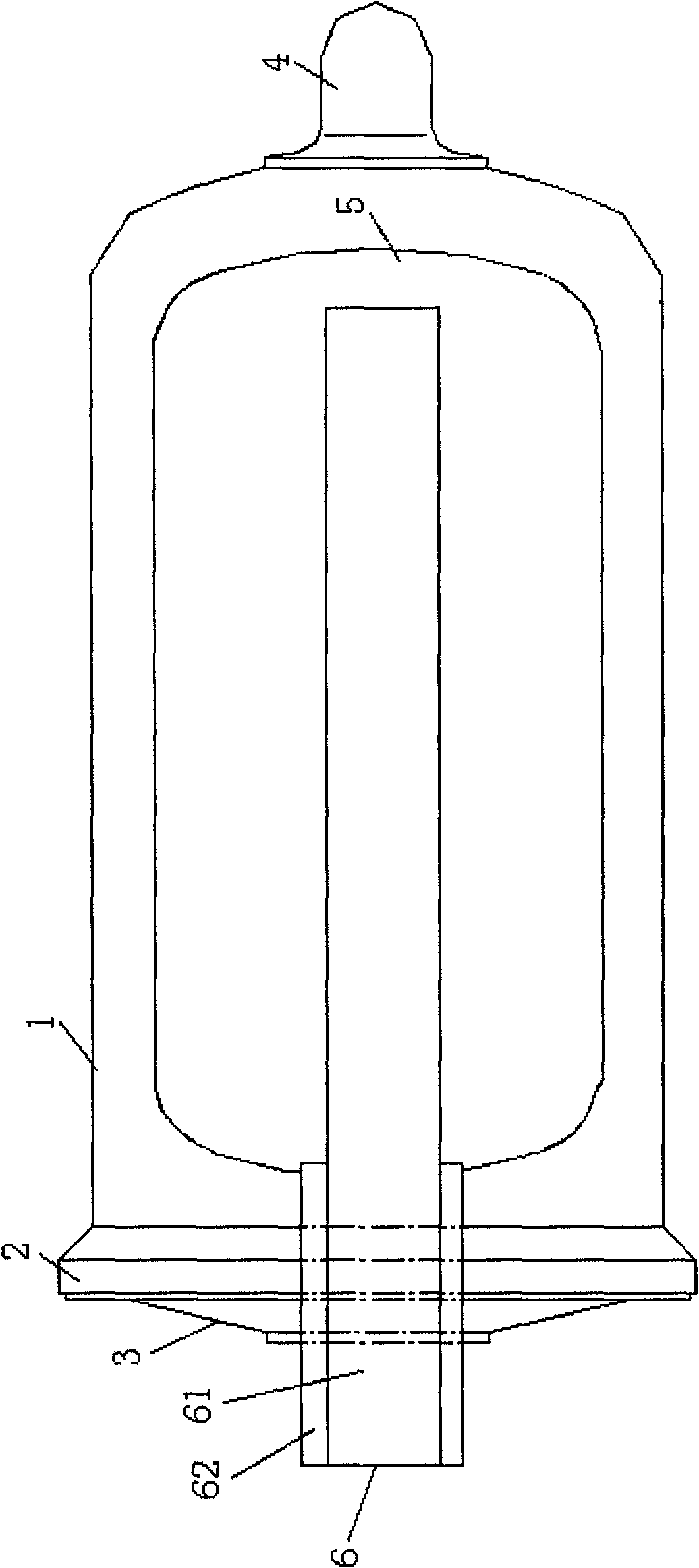

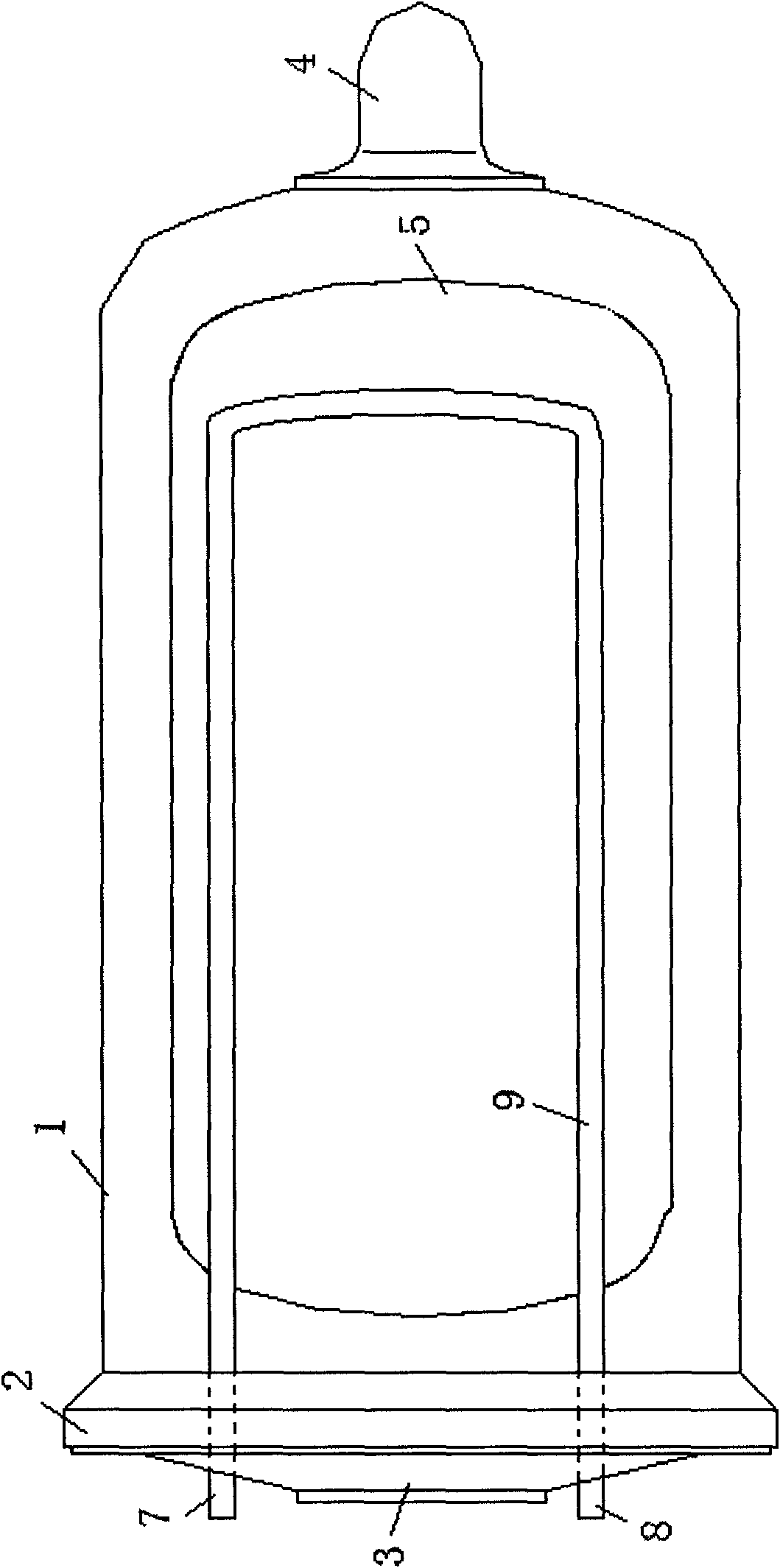

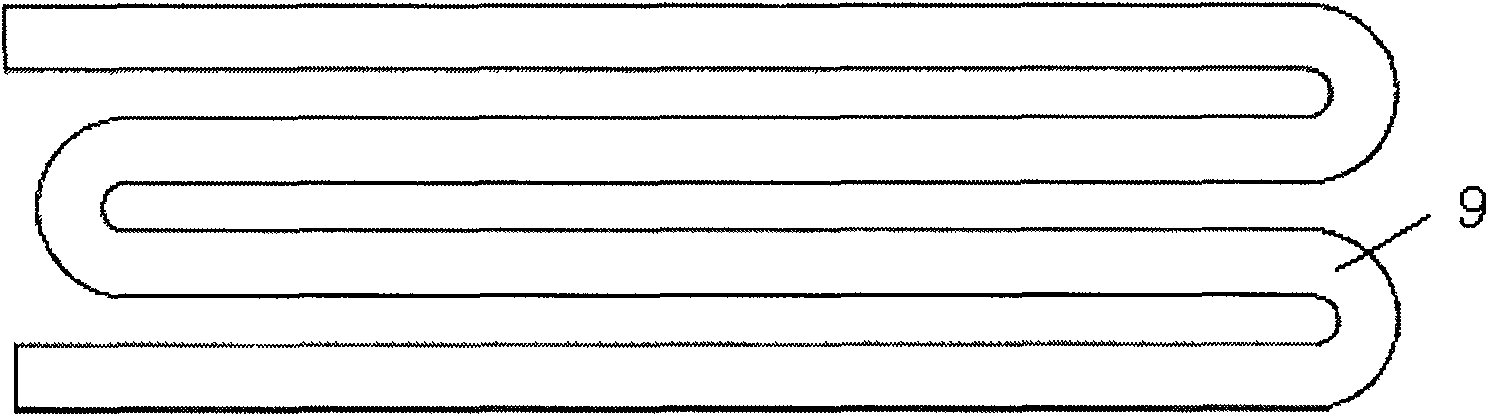

Thermal storage type vacuum tube

InactiveCN101639296AExtended service lifeIncrease the heat exchange areaHeat storage plantsSolar heat devicesSolar waterMetallic materials

Owner:北京桑达太阳能技术有限公司

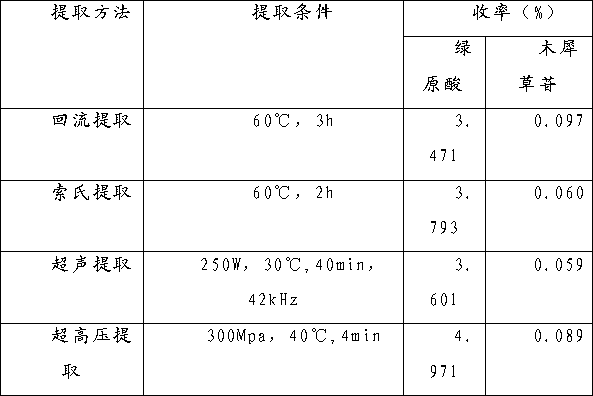

Chlorogenic acid and galuteolin in honeysuckle flower superhigh pressure extraction method and HPLC quantitative analysis method

Owner:SUZHOU UNIV

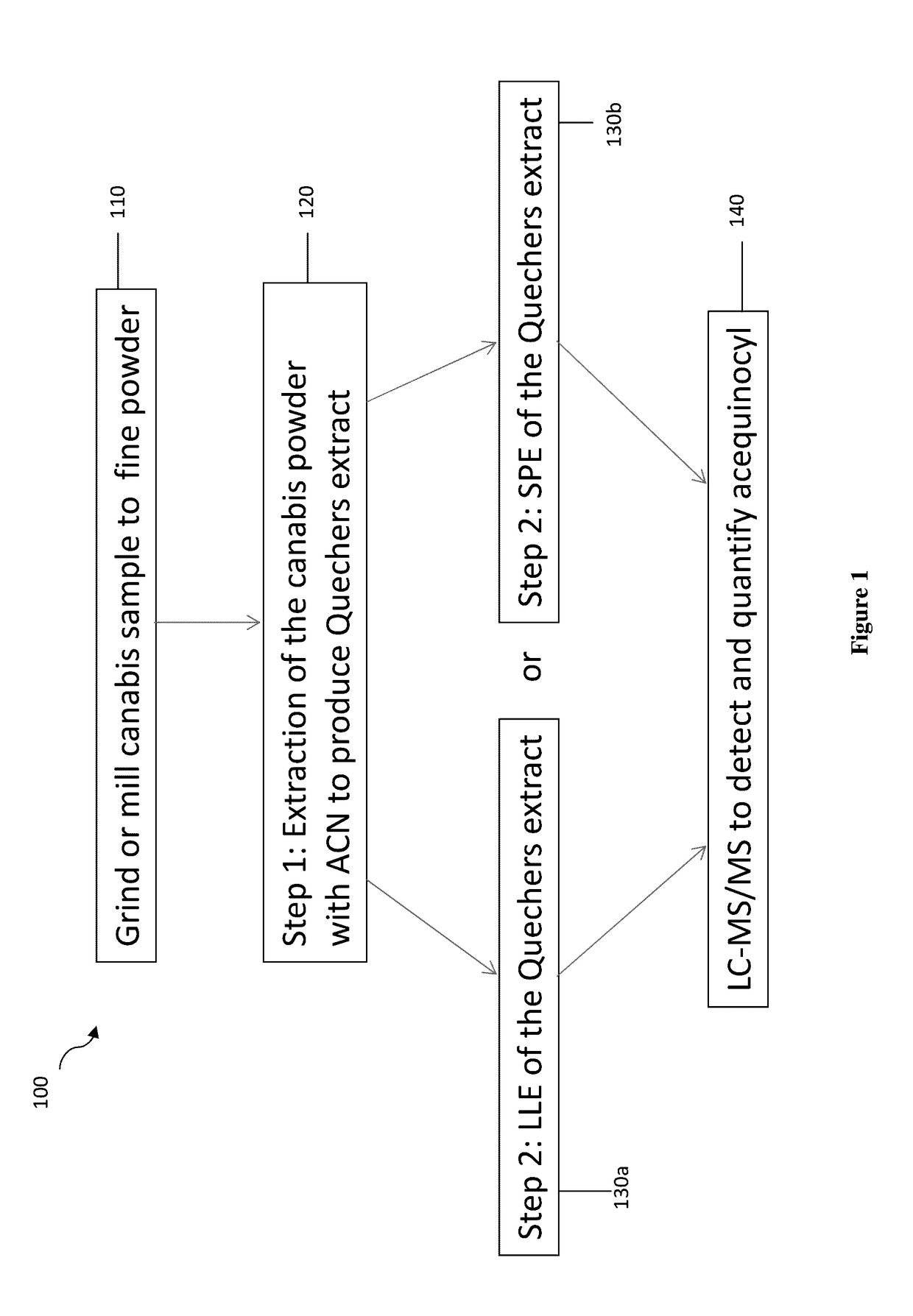

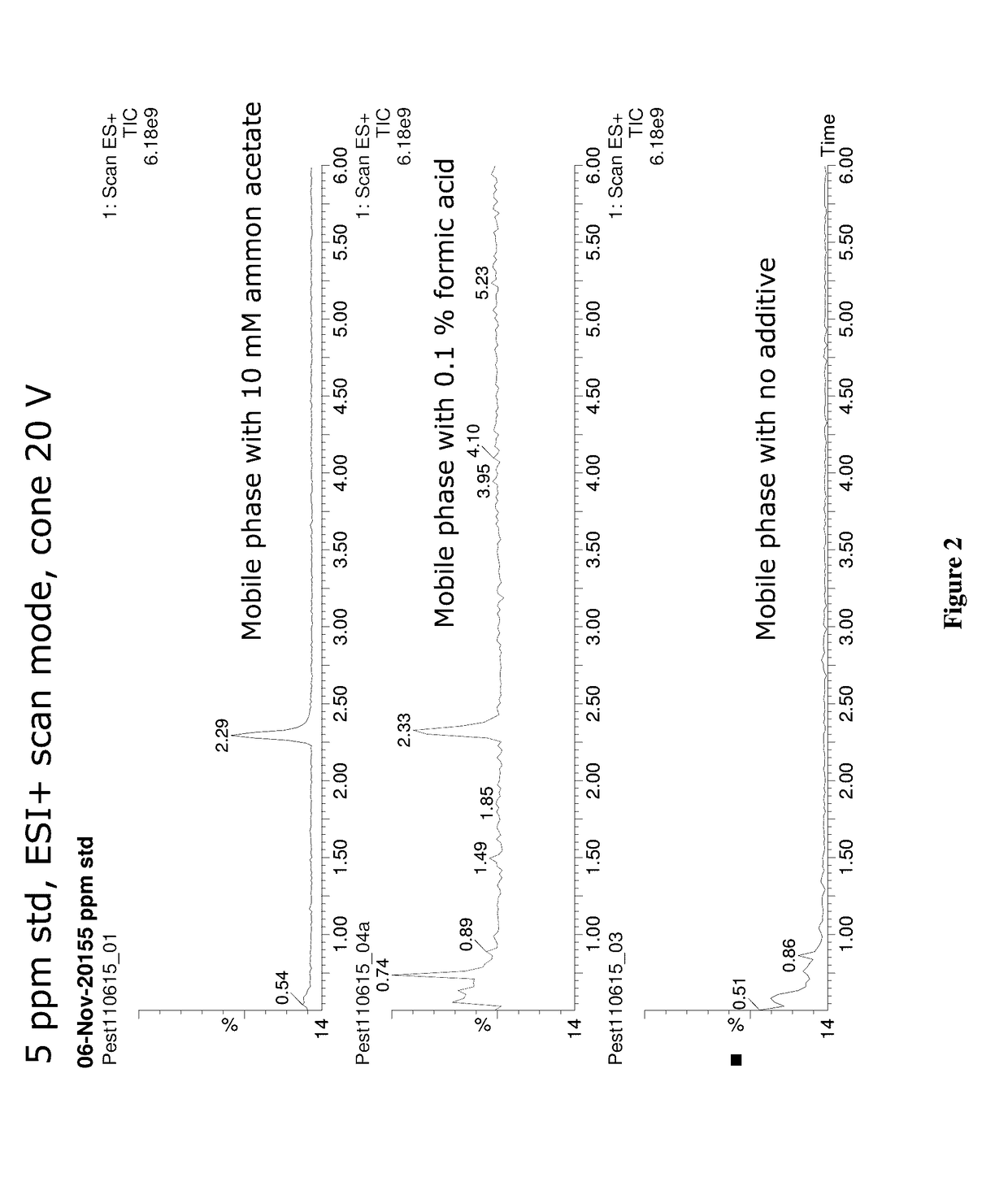

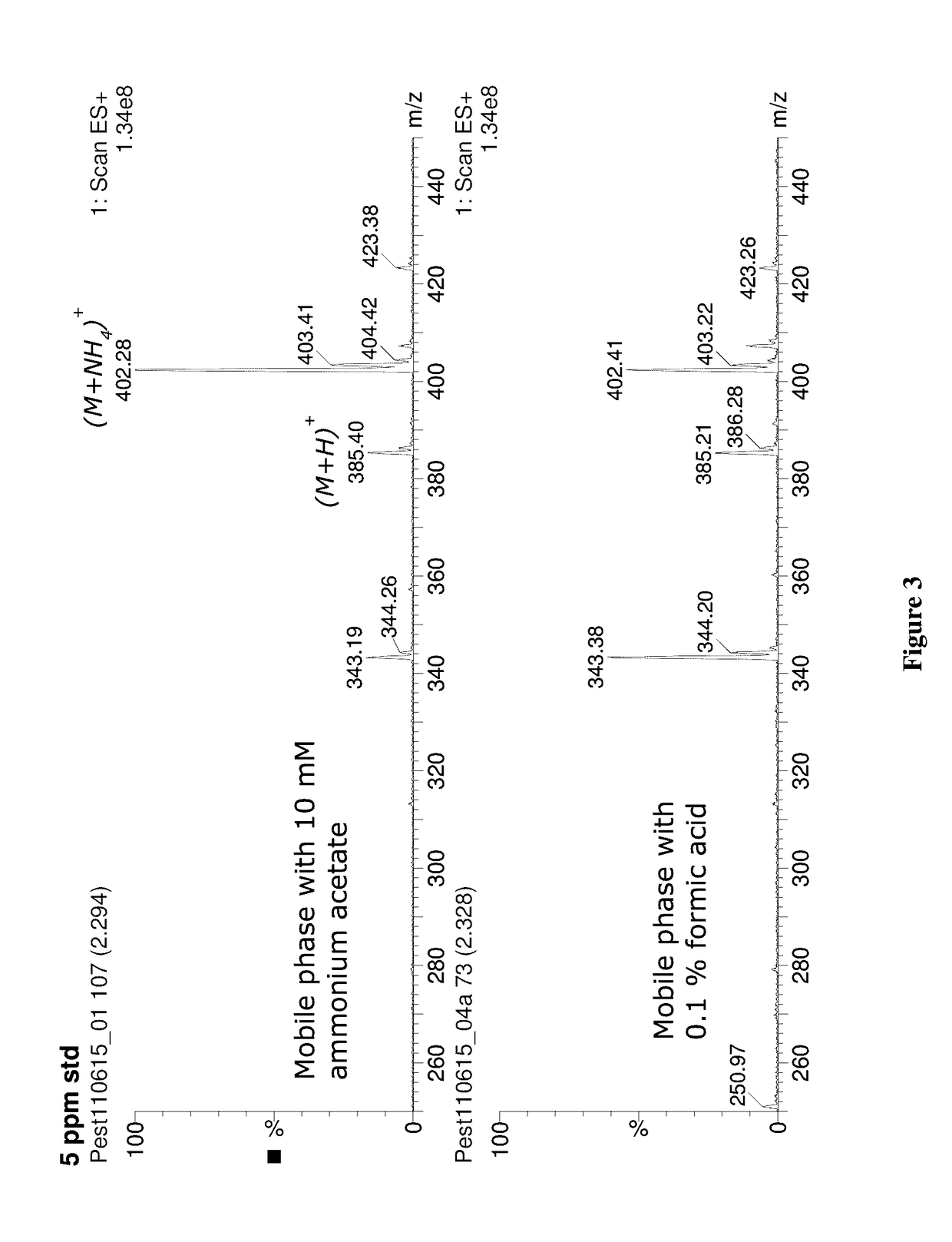

Methods for detecting and quantifying non-polar analytes with high sensitivity

Owner:WATERS TECH CORP

Metal glass micron foil and preparation method thereof

InactiveCN108339853AThickness is easy to controlPrecise thickness controlRoll mill control devicesMetal rolling arrangementsMicron scaleElectromagnetic shielding

Owner:SHANGHAI JIAO TONG UNIV

Method and equipment thereof for synthesizing methyl isobuthl ketone with acetone two-step method

ActiveCN108002995AReduce the problem of high DAA contentReduce generationOrganic compound preparationEnergy inputHydrogenMethyl isobutyl ketone

The invention discloses a method and equipment thereof for synthesizing methyl isobuthl ketone with an acetone two-step method. The method includes the steps that a, DAA and MSO are generated by condensation and dehydration of the raw material of acetone in a catalytic distillation column, products rich in MSO and water are side taken off from the catalytic distillation column; b, a material containing DAA is side taken off from the catalytic distillation column, and put into a DAA decomposition reactor, DAA in the material is transformed into acetone and MSO, the products are separated by flash evaporation to obtain a gas phase rich in acetone and a liquid phase rich in MSO and water, the gas phase and the liquid phase are respectively circulated back to the column; c, the liquid phase products in the step a are cooled and divided into phases, an organic phase rich in MSO and a water phase containing small amounts of organic matter are obtained, the water phase enters into a recoverytower to recycle organic matter; d, MIBK is generated by the hydrogenation of the organic phase in the step c, after hydrogen gas is recycled by flash evaporation, then enters into an MIBK refining tower, and a MIBK product is side taken off. The total conversion rate of acetone is 99.0%, and the product MIBK purify is up to 99.5%.

Owner:CHANGCHENG NEW ENERGY CO LTD +1

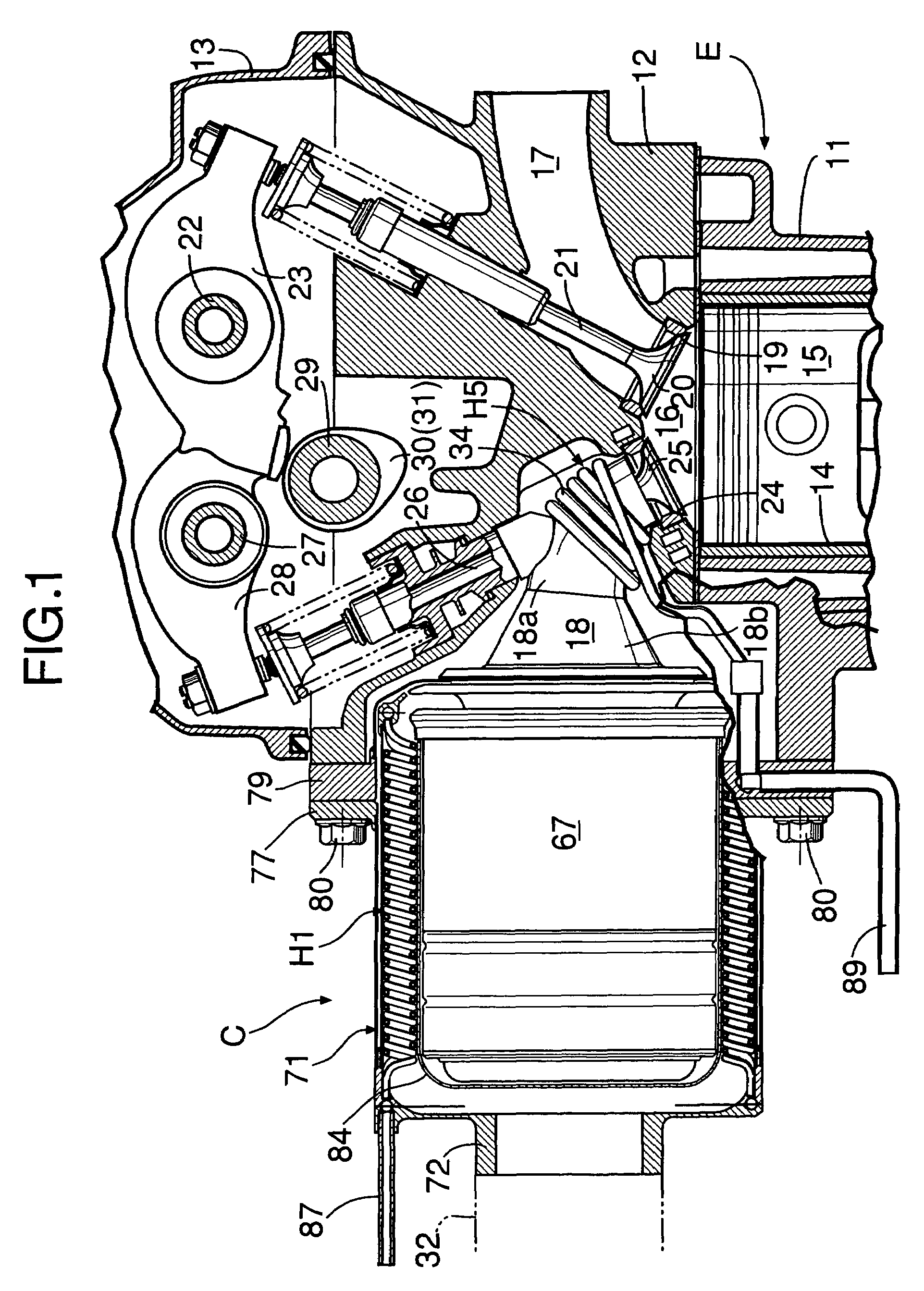

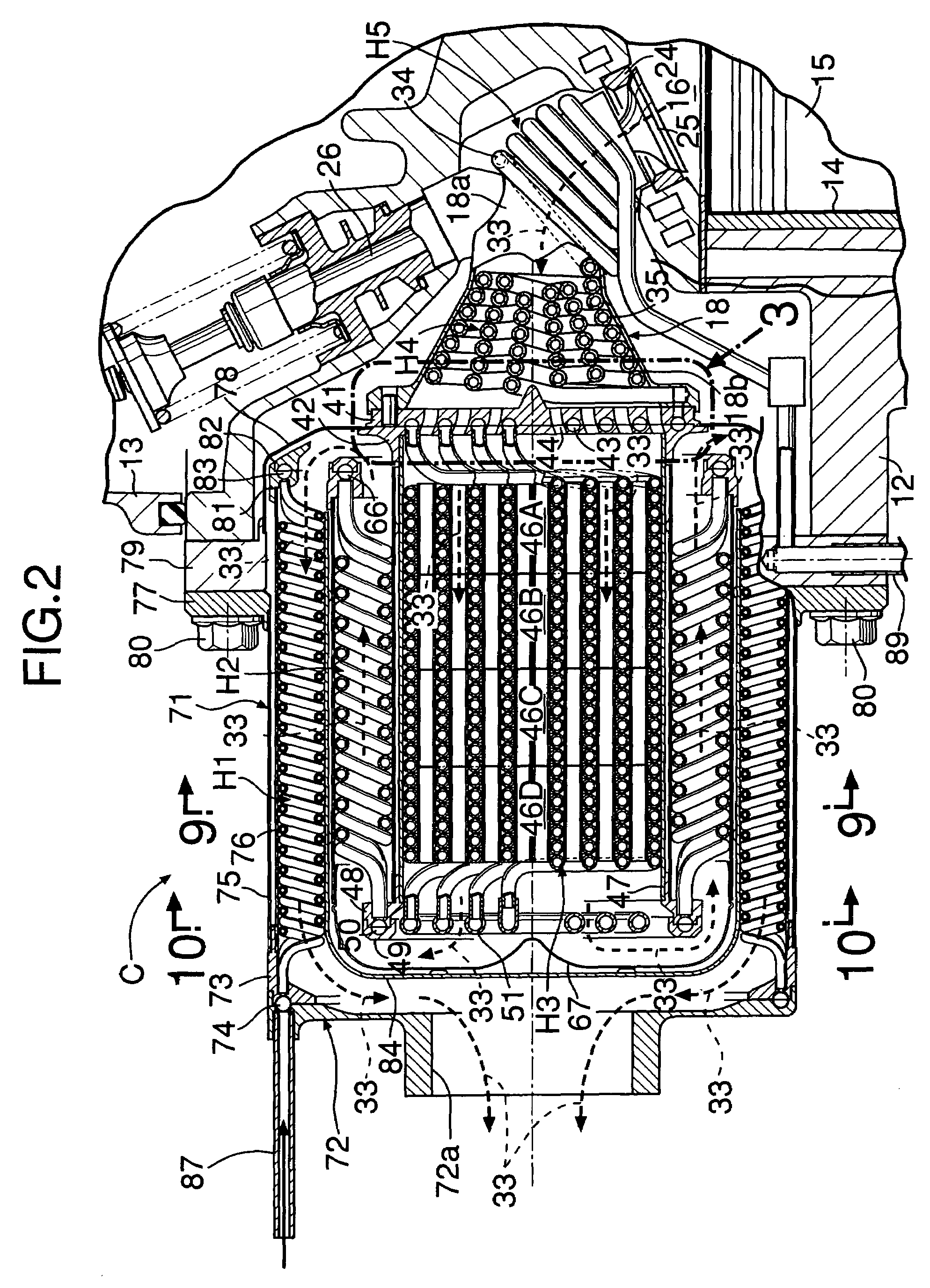

Internal combustion engine

InactiveUS7096664B2Improve exhaust gas purification performanceEfficient use ofInternal combustion piston enginesExhaust apparatusEngineeringTemperature difference

Owner:HONDA MOTOR CO LTD

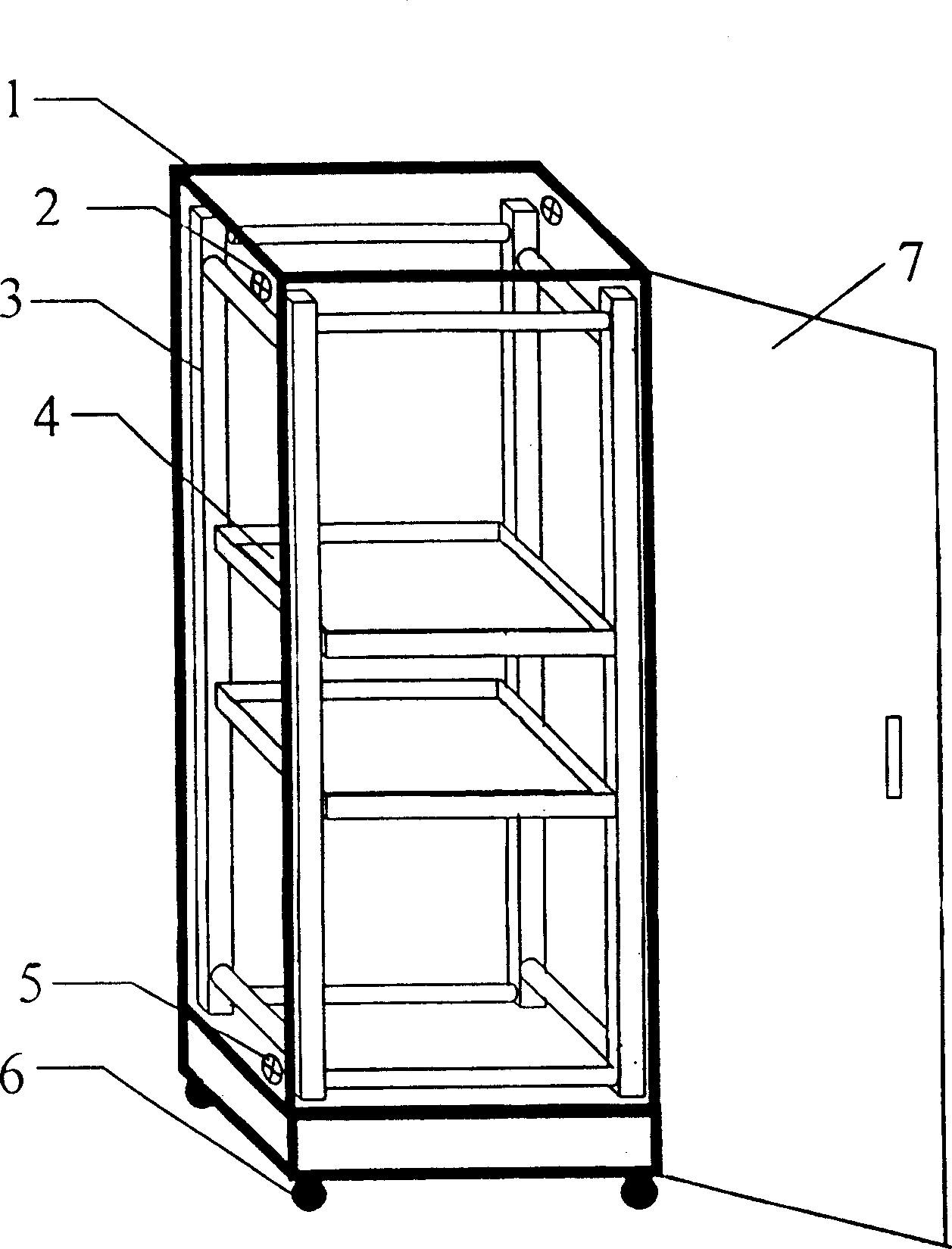

High-purity spore powder production process and verticle multi-layer spore-generating box thereof

InactiveCN1710059AUniform humidityIncrease production capacityTissue/virus culture apparatusSporeEngineering

Owner:ZHEJIANG UNIV

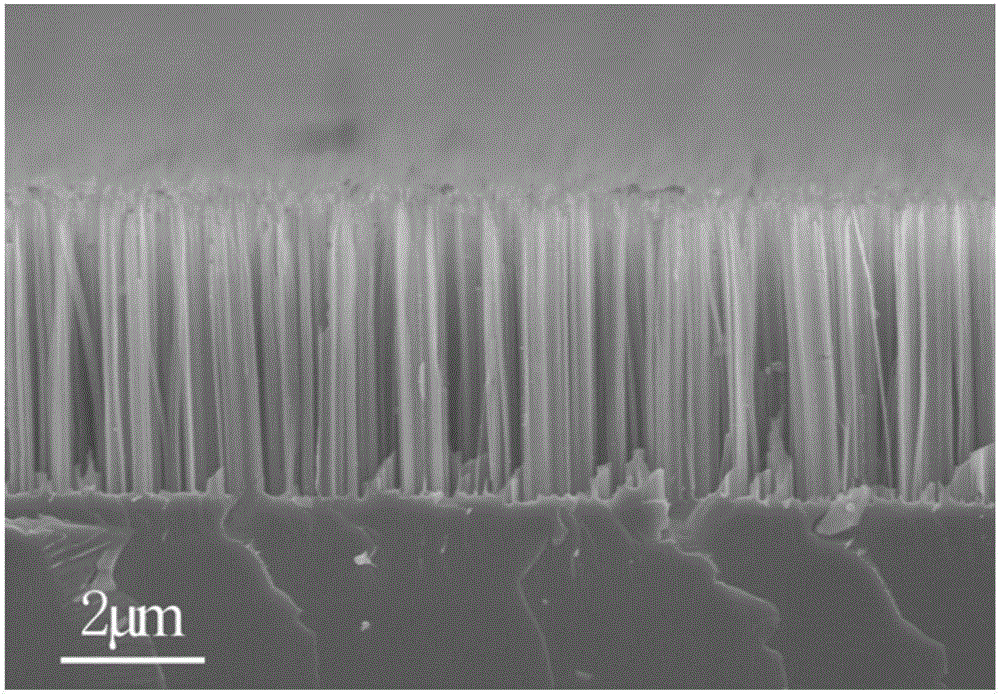

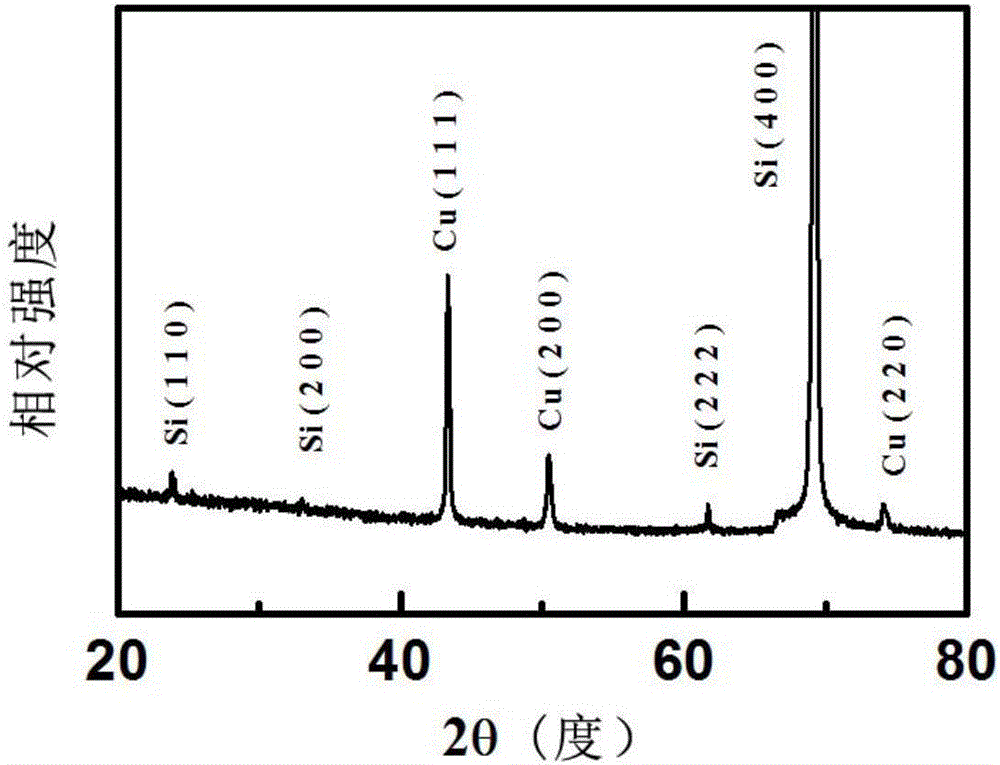

Self-driven Schottky junction near-infrared photoelectric detector based on silicone nanowire array and preparation method of photoelectric detector

InactiveCN105702774AGood process compatibilityRealize industrial productionFinal product manufactureSemiconductor devicesEtchingOhmic contact

Owner:HEFEI UNIV OF TECH

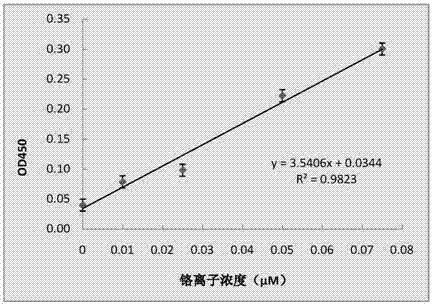

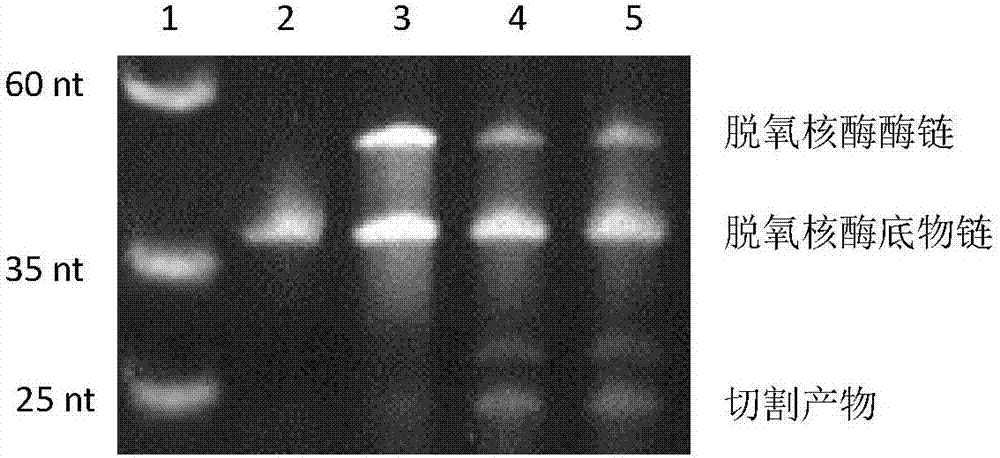

Chromium-based functional nucleic acid sensor and application thereof

ActiveCN107988323AHigh sensitivityStrong specificityMaterial analysis by observing effect on chemical indicatorMicrobiological testing/measurementHeminBiology

Owner:CHINA AGRI UNIV

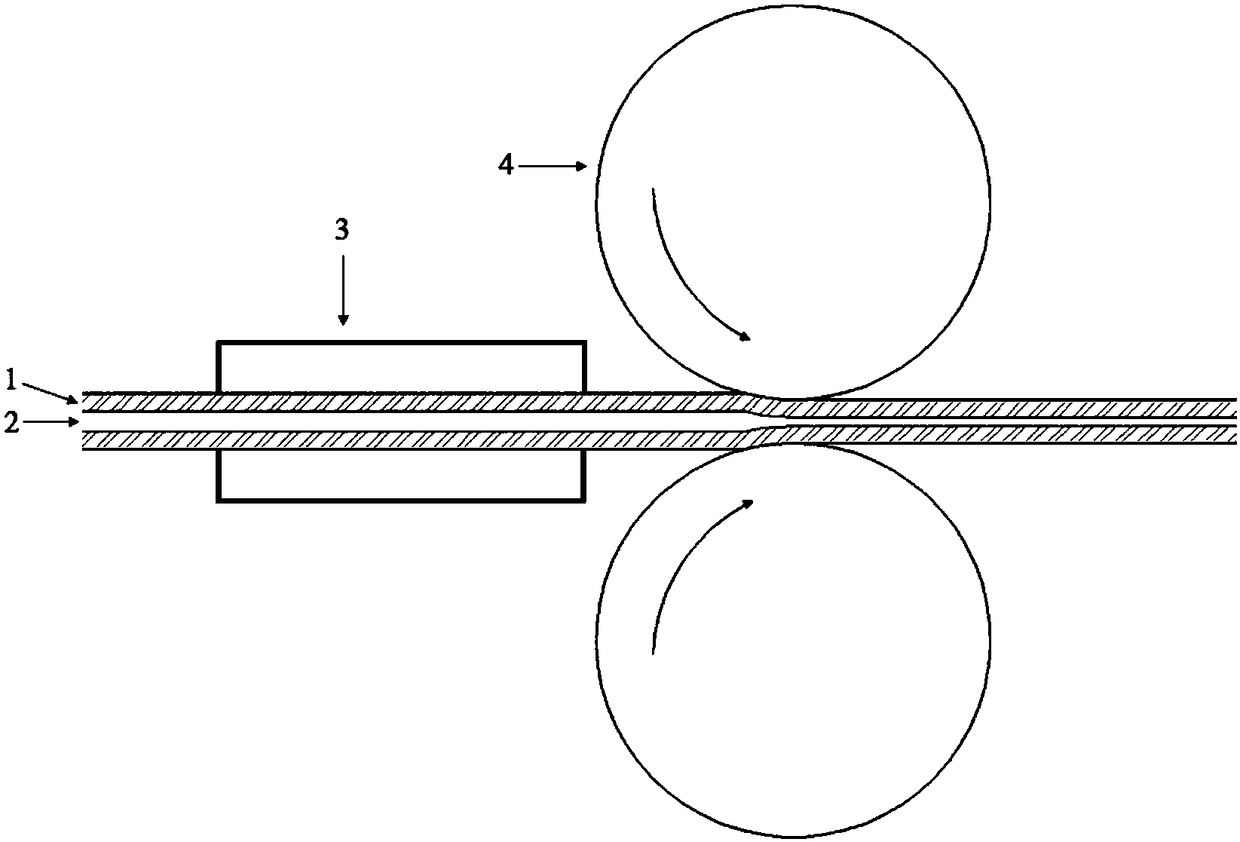

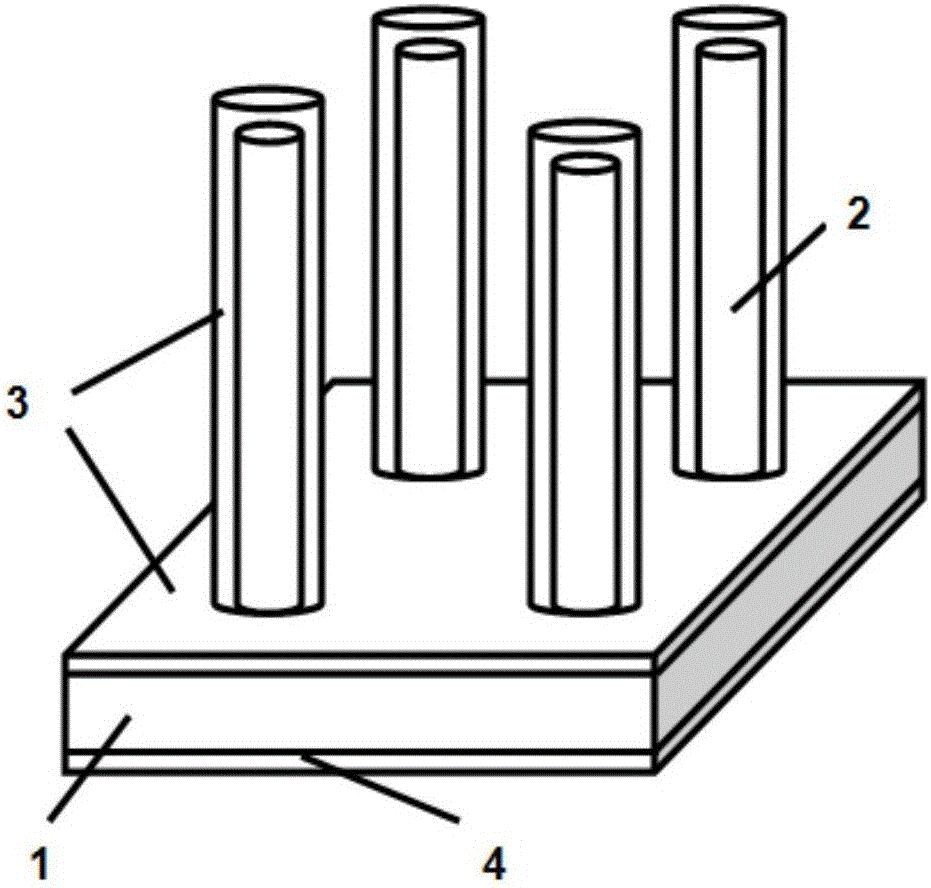

Preparation method of TiC ceramic coating

InactiveCN1807700AImprove bindingGuaranteed bondingElectrolytic inorganic material coatingElectrochemical responseCeramic coating

The invention discloses a TiC ceramic coating preparing method, which comprises the following steps: 1) placing block metal Ti electrode(1) and working electrode(4) in coal oil(2); 2) connecting anode of impulsing power source(3) to block metal Ti electrode(1); linking up with cathode of impulsing power source(3) and work electrode(4); 3) making connection with impulsing power source(3); carrying on electrochemical reaction with Ti metallic ion released form metal and C ion ionized from coal oil(2); compounding ceramic coating(5) of ceramic film TiC and depositing on the surface of work electrode. The invention improves the stability of craft and cementing property of basilemma.

Owner:GUANGDONG UNIV OF TECH

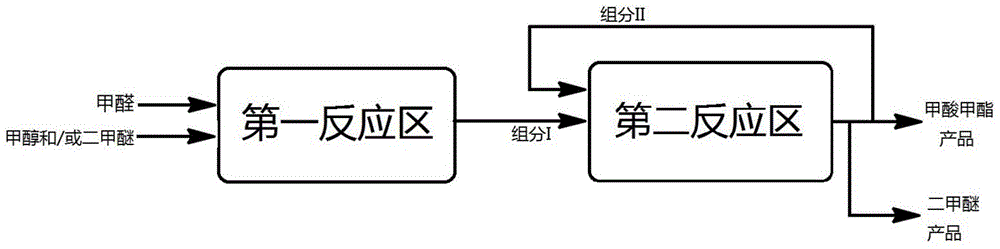

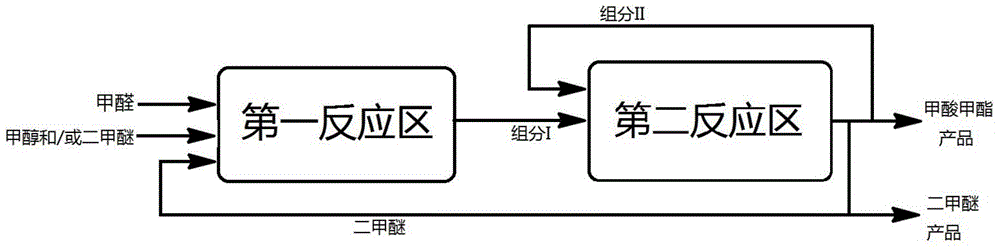

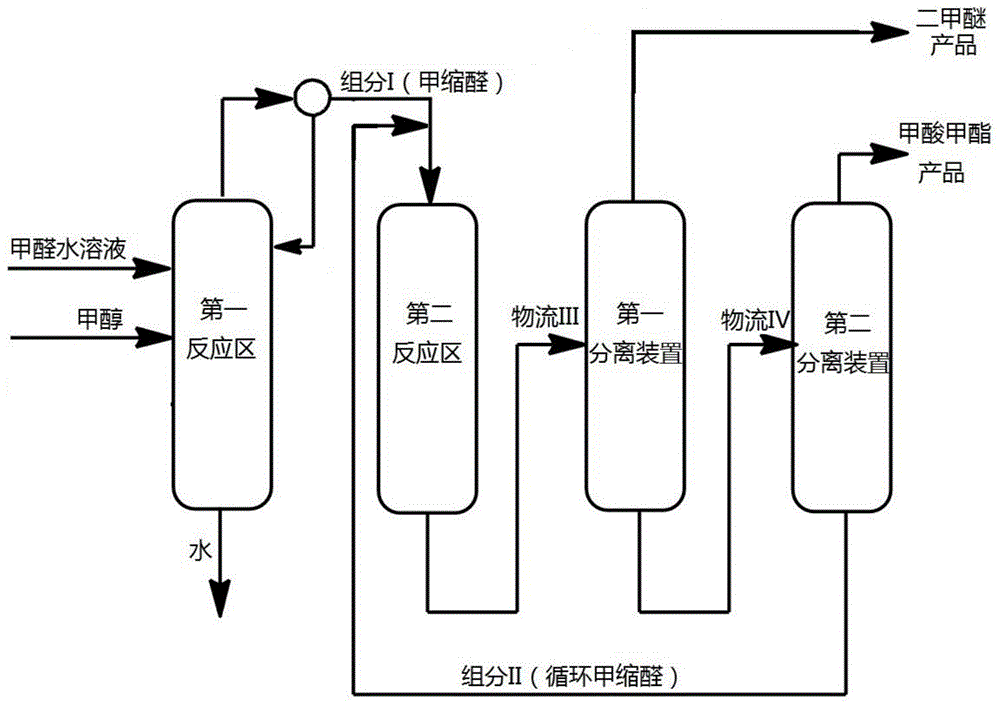

Method for preparing methyl formate and coproducing dimethyl ether

ActiveCN105669452AEasy to separateReduce energy consumptionOrganic compound preparationCarboxylic acid esters preparationGas phaseReaction zone

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

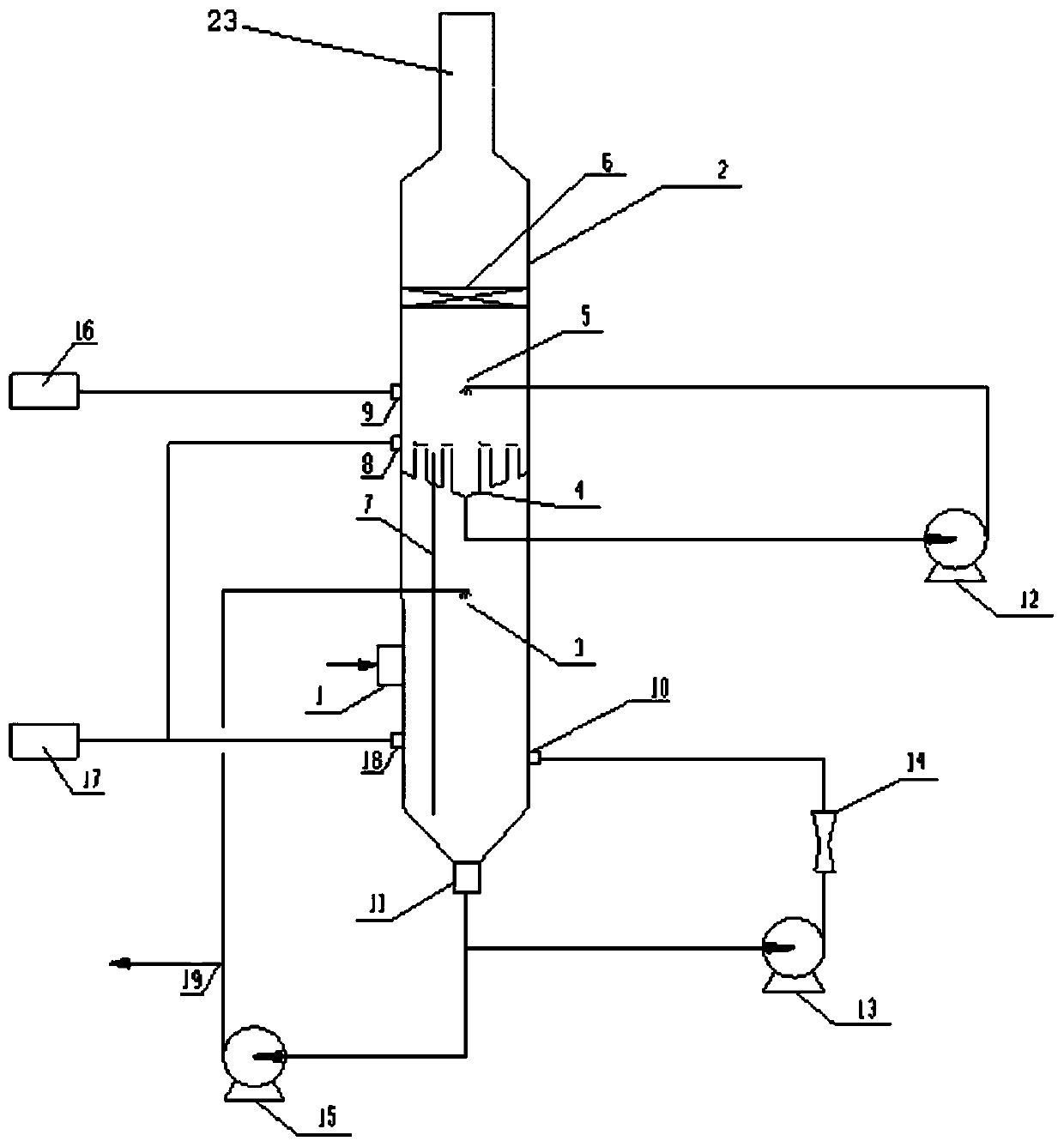

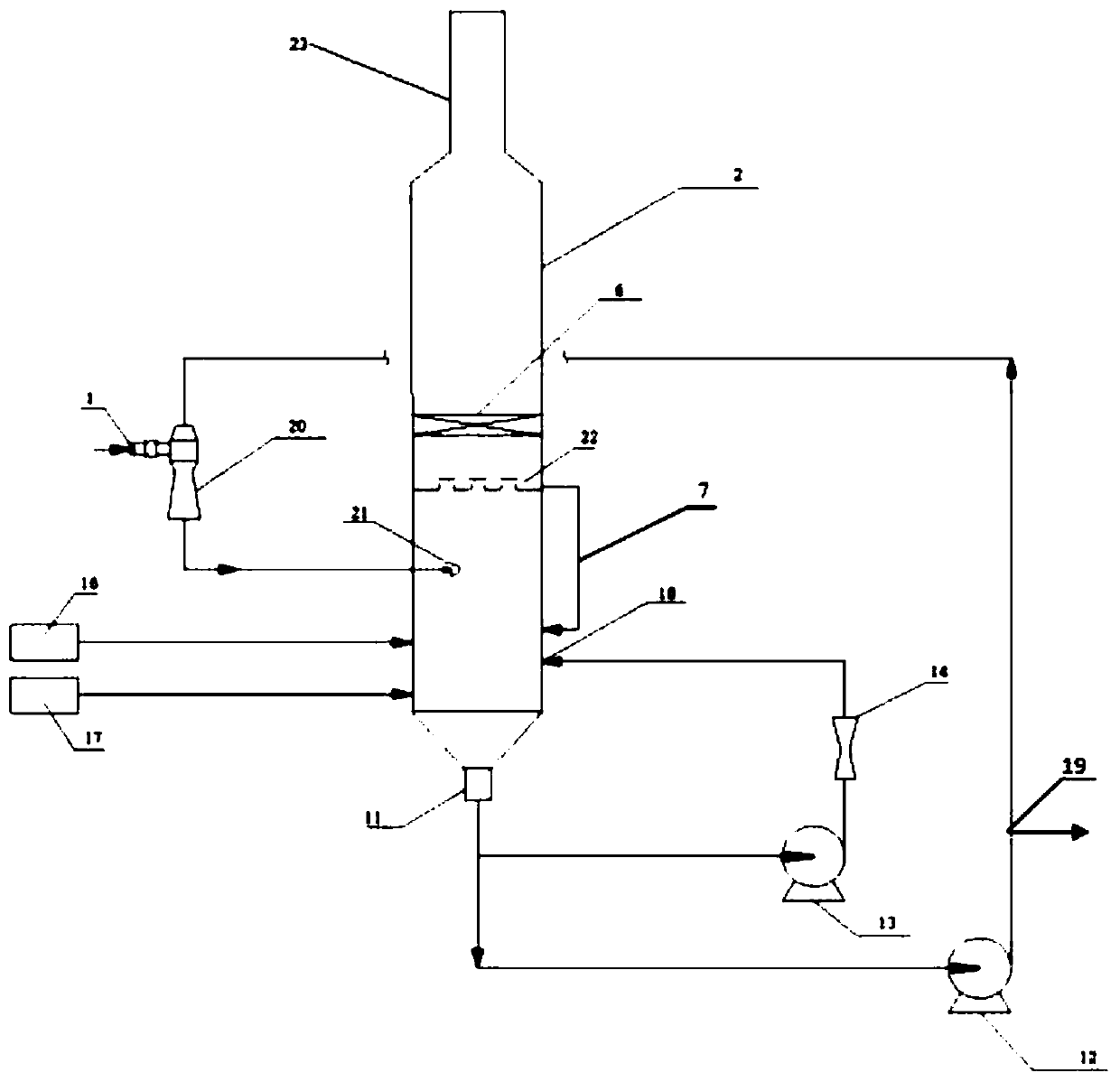

Device and technology for flue gas desulfurization through soda ash method

PendingCN110433637ANo noiseAchieve securityCombination devicesGas treatmentSulfite saltSodium sulfite

Owner:大连汉诺工程技术有限公司

Method for determining methamidophos in rice wine

The invention discloses a method for determining methamidophos in rice wine and particularly discloses a method for detecting the content of methamidophos in rice wine by utilizing gas chromatography and liquid chromatography-tandem mass spectrometry. The method comprises the following steps: (1) extraction and purification: utilizing a solid phase extraction column to extract the methamidophos in the rice wine and using ethyl acetate to elute the methamidophos adsorbed on the solid phase extraction column; (2) preparation of matrix matched standard working solution; (3) qualitative screening and quantification by utilizing gas chromatography; (4) qualitative confirmation of positive samples by using liquid chromatography-tandem mass spectrometry; (5) blank test; and (6) result calculation and representation. The method has the following beneficial effects: the pretreatment operation is simple and practical, and the recovery rate of the methamidophos is high; and by adopting the matrix matched standard working solution, the problem of matrix effect of the methamidophos on the gas chromatograph is solved, and accurate quantification is implemented.

Owner:SHAOXING ENTRY EXIT INSPECTION & QUARANTINE BUREAU OF THE PEOPLES REPUBLIC OF CHINA

Nematic liquid crystal composition, and liquid crystal display element using same

ActiveCN108779395AWith burn-inImprove display qualityLiquid crystal compositionsNon-linear opticsCrystallographyDielectric anisotropy

The present invention addresses the problem that a negative [delta][epsilon] value having a large absolute value, a small rotational viscosity ([gamma]1), a large elastic modulus (K33), a low (solid phase)-(nematic phase) transition temperature (Tcn), a high (nematic phase)-(isotropic liquid phase) transition temperature (Tni) and a large voltage holding ratio (VHR) are demanded. The present invention also addresses the problem of providing a rapid-response liquid crystal display element of a VA type, a PSVA type, a PSA type, a FFS type or the like, which is produced using the same, rarely undergoes or never undergoes display failures such as burning-in and display unevenness and has excellent display quality. Provided are: a liquid crystal composition which contains a compound representedby formula (I-1) as a first component and a compound represented by formula (I-2) as a second component and has a negative dielectric anisotropy ([delta][epsilon]) value; and a liquid crystal displayelement produced using the liquid crystal composition.

Owner:DIC CORP

Method for estimating in-vitro detoxification effect of mycotoxin detoxification agent by using liquid chromatography

InactiveCN105301134AApplicable adsorption rate evaluationThe evaluation results are close toComponent separationMycotoxinSorbent

Owner:江苏奥迈生物科技有限公司

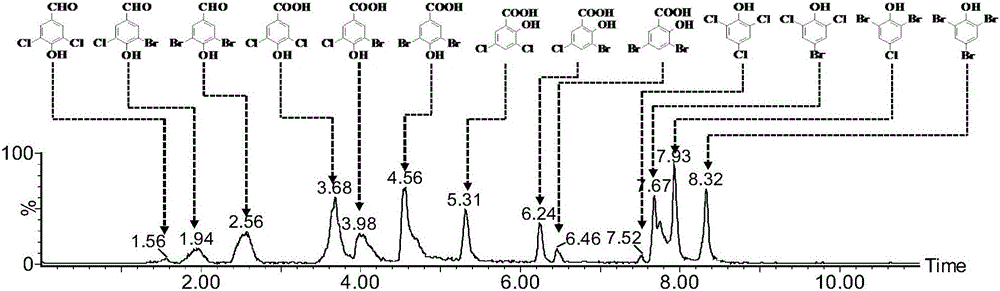

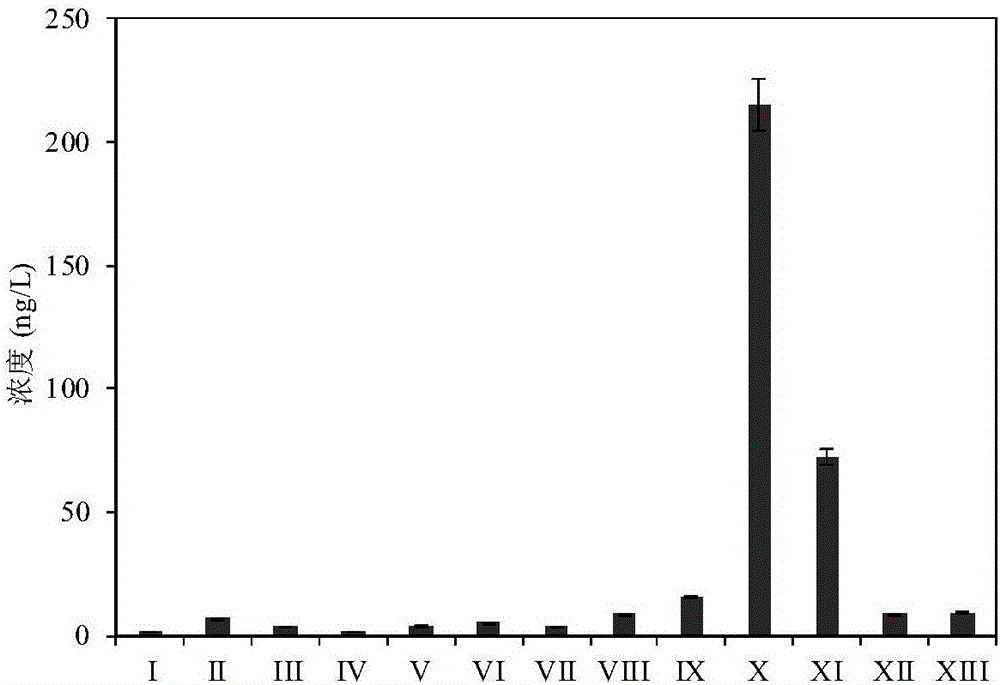

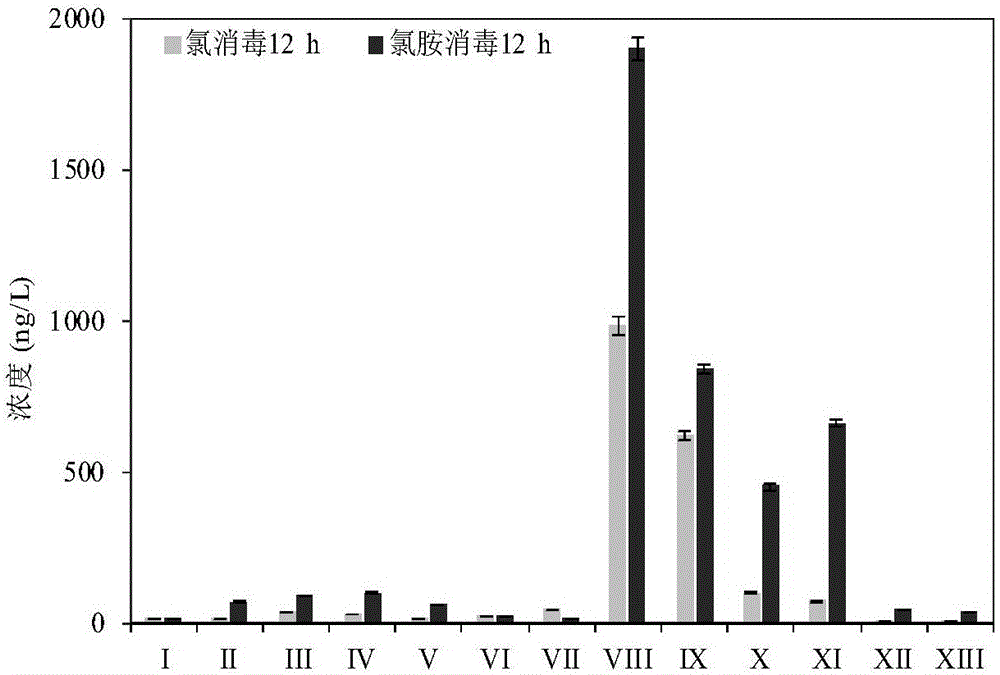

Method for detecting polar phenol type chlorinated/brominated disinfection by-products in water

Owner:NANJING UNIV

Method for separating and purifying crude lanosterol product

InactiveCN101691391AMake up for the disadvantage of low solubilityIncrease productionSteroidsSolubilityLanosterol

The invention discloses a method for separating and purifying a crude lanosterol product in the technical field of the purification of organic substances, which comprises the steps of: dissolving the crude lanosterol product into an organic solvent at a temperature of between 25 and 40 DEG C through ultrasonic treatment to obtain a lanosterol solution; and filtering the lanosterol solution by a filter membrane, then using preparative high performance liquid chromatography to adopt overlapping injection for separation and purification treatment to obtain purified lanosterol. The method adopts reversed-phase high performance liquid chromatography, can ensure the characteristics of good resolution, high yield, high recovery rate, good purity and the like, can directly separate to obtain the lanosterol with the purity over 97 percent, and can be used for various sterol-related diseases and the research and development of biosynthetic pathways of various natural products. The method applies technology such as overlapping injection and linear amplification to overcome the disadvantage of low solubility caused by using reversed-phase chromatography to separate the lanosterol, uses a preparation column with the inner diameter of 20mm and the column length of 250mm, ensures that the daily preparation amount can reach near 250mg, and can meet various scientific and research requirements.

Owner:SHANGHAI JIAOTONG UNIV

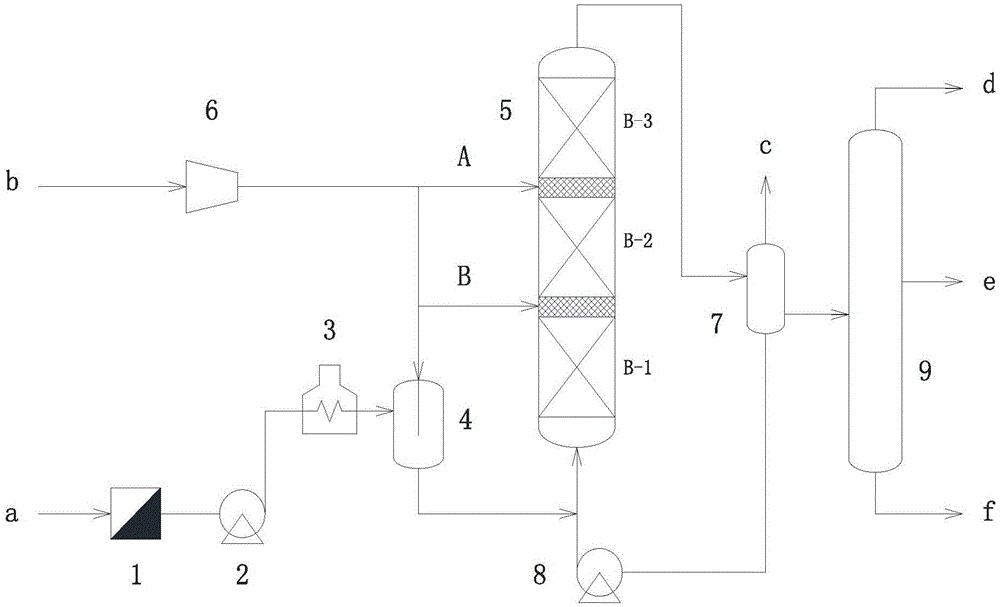

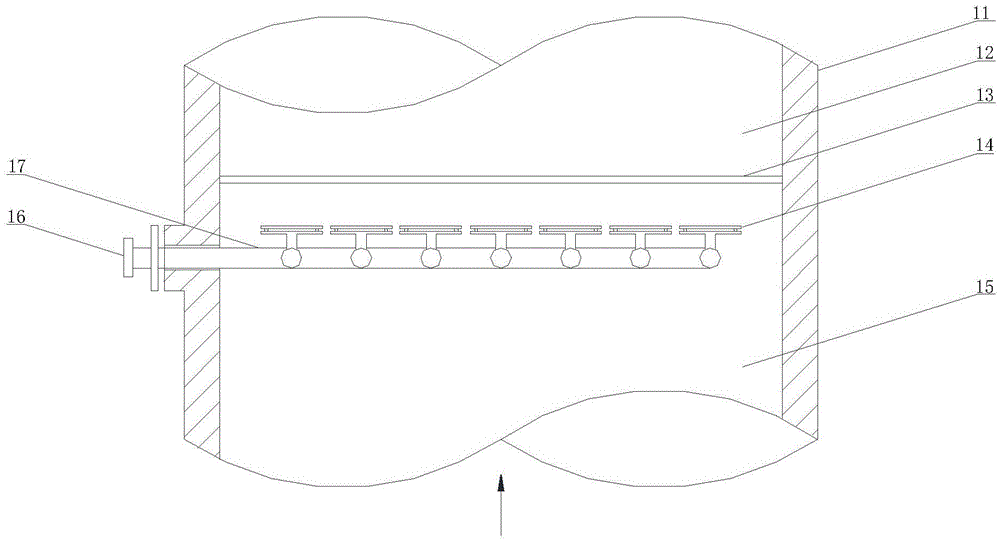

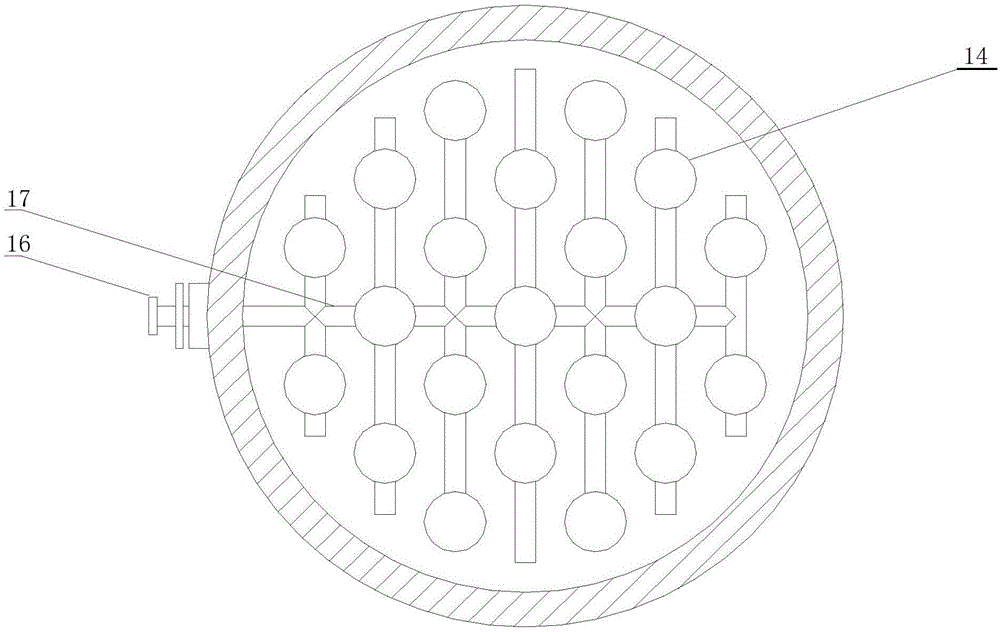

Coal tar all-fraction liquid-phase hydrogenation system and method

InactiveCN105087066AImprove internal space utilizationLess investmentTreatment with hydrotreatment processesHydrogenPre treatment

Owner:SHAANXI MEISILIN ENERGY SCI & TECH RES INST

Tylonolide content detection method

The invention provides a Tylonolide content detection method. Analysis is performed with an Agilent-1260 high performance liquid chromatograph, a DAD (diode array detector) is used, the detection wavelength is 216 nm, the sample size is 20 mu l, and the chromatographic condition is as follows: a chromatographic column takes octadecylsilane chemically bonded silica as filler, and an Agilent-1260 high performance liquid chromatography Wondasil C18 column is used for determination; the mobile phase is acetonitrile-0.5% formic acid, and the volume fraction of acetonitrile is in a range of 65%-80%; the flow velocity is in a range of 0.6-1.5 ml / min; the column temperature is in a range of 20-40 DEG C, automatic sample injection is performed on a standard substance and a to-be-tested substance respectively, and the Tylonolide content is calculated by the aid of the peak area with an external standard method; the Tylonolide content detection method is simple, convenient, good in separation effect and high in precision and accuracy.

Owner:TIANJIN ZHONGSHENG TIAOZHAN BIOTECH

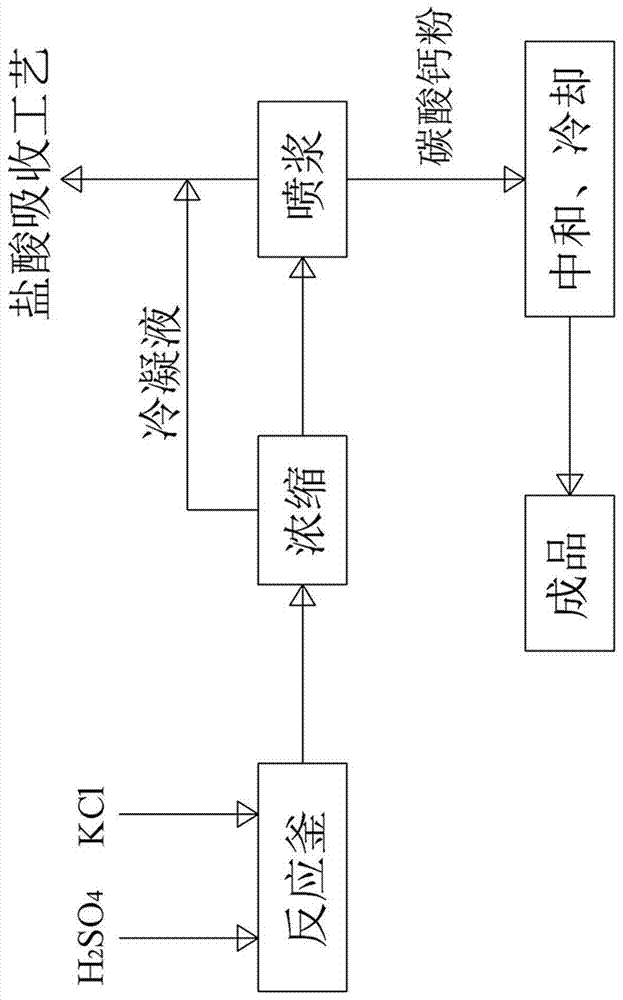

Technology for producing potassium sulphate by liquid-phase grouting method

InactiveCN107032834AImprove product qualitySolve complexityCalcareous fertilisersSulfate/bisulfate preparationHigh energyDecomposition

Owner:KAIFENG UNIV

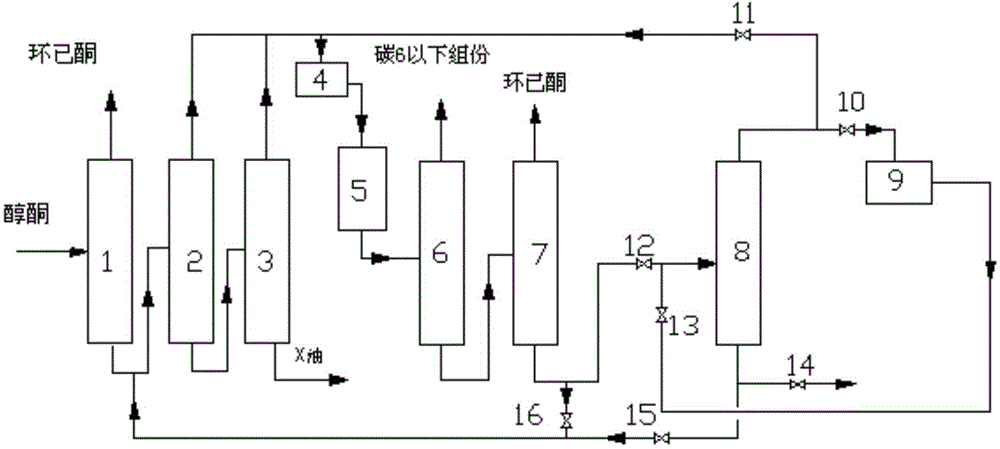

Method for preparing cyclohexanone through cyclohexane liquid-phase oxidation method

ActiveCN104402694AImprove product qualityLower light component contentOrganic compound preparationHydroxy compound preparationCyclohexanoneCarbon number

Owner:QUZHOU JUHUA POLYAMIDE FIBER

New method for extracting plant essential oil by aqueous enzymatic method

Owner:TIANJIN NAER BIOTECH

Pouring method of aluminum alloy thin-walled workpiece

ActiveCN107297483AReduce roughnessImprove quality and efficiencyFoundry mouldsCoatingsSiliconMaterials science

Owner:安徽昕悦铸造科技有限公司

Method for preparing 4-amino-2,6-dihydroxypyrimidine by virtue of dry frying process

InactiveCN107721938AReduce manufacturing costReduce preparation energy consumptionOrganic chemistrySodium methoxideChemical synthesis

Owner:王微

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap