High-purity spore powder production process and verticle multi-layer spore-generating box thereof

A production process and multi-layer production technology, applied in biochemical instruments, biochemical equipment and methods, tissue cell/virus culture devices, etc., can solve the problems of difficult humidity control, difficult to control, opacity, etc., and achieve convenient production The effect of inspection and monitoring, controllable elimination of production cycle, and simplified process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

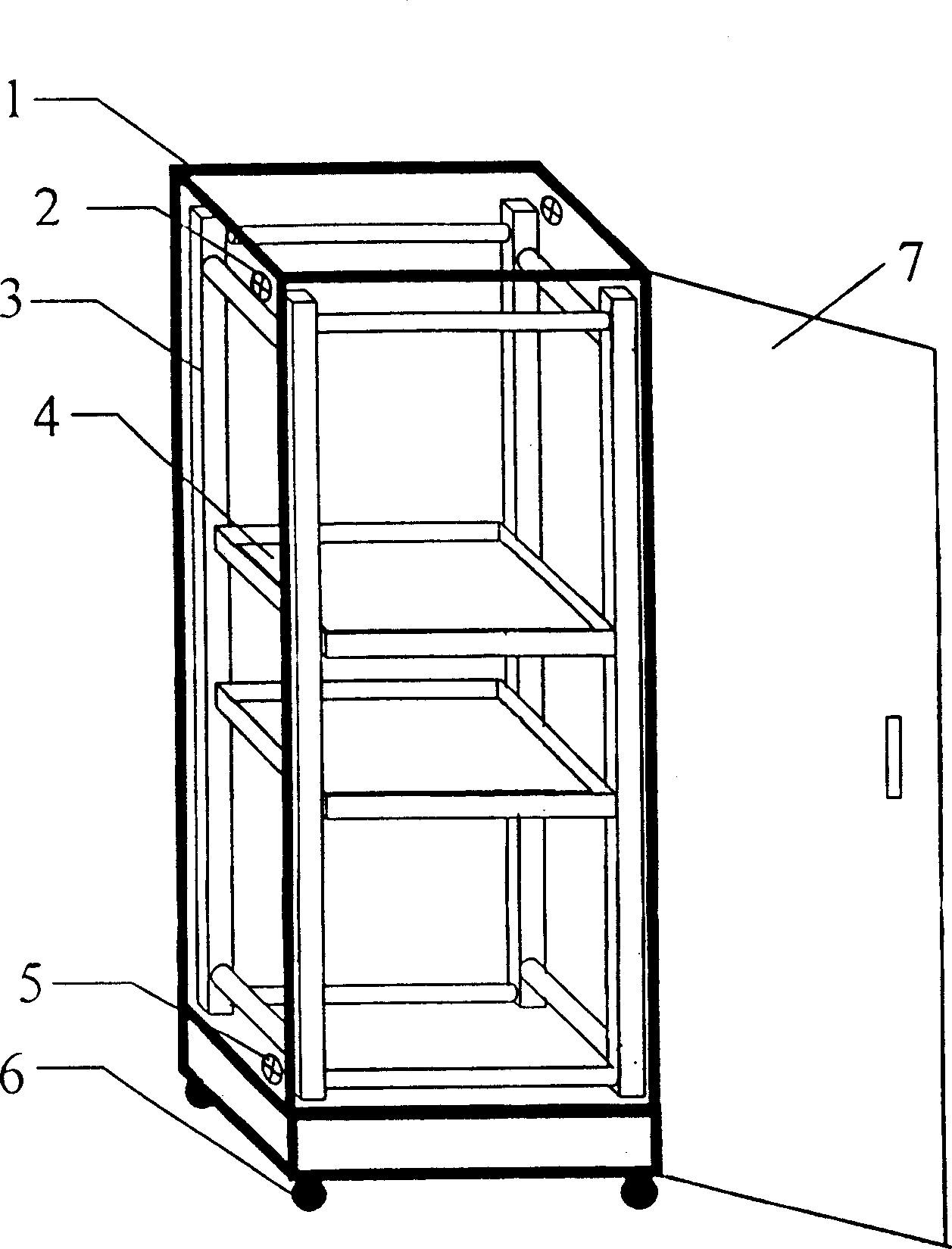

[0026] Specific embodiments of the present invention will be described in detail with reference to the above-mentioned drawings. figure 1 A vertical multi-layer sporulation box is given, which is a cuboid outer wall bracket built by antirust metal pipes, tempered glass panels are arranged on the top and four walls of the outer wall bracket, and ordinary metal plates are arranged on the bottom of the outer wall bracket , thereby forming a sealed transparent box 1 . An openable box door 7 is provided on the side surface directly in front of the box body 1 . A moisture inlet hole 2 is dug through the casing 1 at the upper end of the left and right sides of the casing 1, that is, one end of the moisture inlet hole 2 communicates with the inner cavity of the casing 1, and the other end communicates with the external environment. At the lower end of the left and right sides of the box body 1, two moisture-dissipating holes 5 are dug through the box body 1, that is, one end of the mois

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap