Device and technology for flue gas desulfurization through soda ash method

A desulfurization device and flue gas technology, which is applied in the field of soda ash flue gas desulfurization, can solve the problems of high energy consumption of circulating pumps, complex devices, and high content of flue gas particles, and achieve the goal of reducing the cost of alkali, reducing the cost of desulfurization, and high emission concentration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

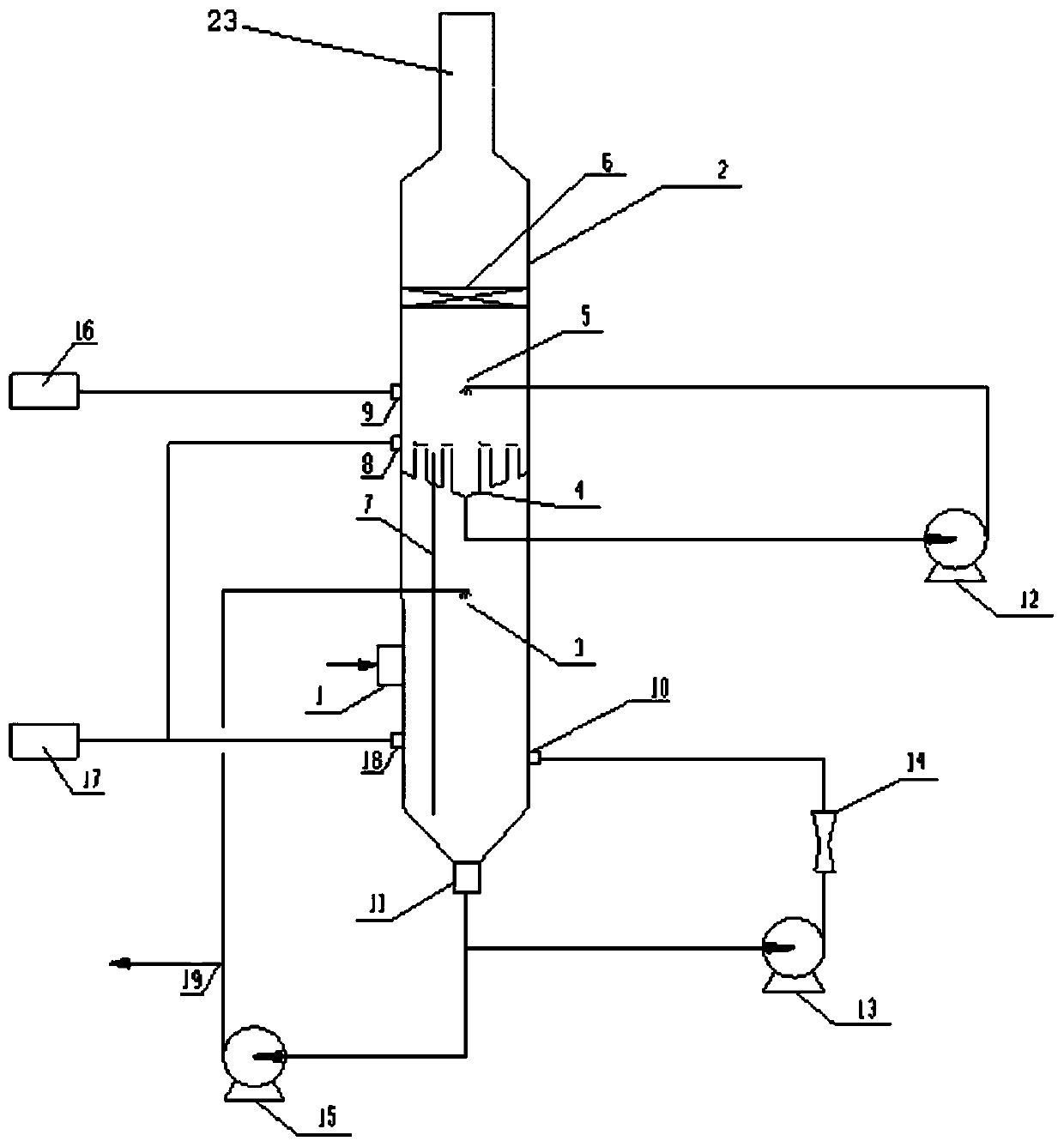

[0028] Such as figure 1 As shown, it is a structural schematic diagram of the technical solution of the empty tower spray pretreatment system. The specific implementation method adopts the following technical solution: including flue gas inlet 1, desulfurization tower 2, quenching nozzle 3, liquid collection tank 4, spray nozzle 5, desulfurization Mister 6, liquid level connecting pipe 7, second lye inlet 8, fresh water inlet 9, tower kettle side wall gas-liquid inlet 10, washing liquid outlet 11, washing circulation pump 12, oxidation circulation pump 13, oxidation jet nozzle 14 , quenching circulation pump 15, process water conveying system 16, sodium carbonate preparation system 17, first lye inlet 18, drain outlet 19, chimney 23; chimney 23 is arranged at the top of desulfurization tower 2, and washing liquid outlet 11 is arranged at the bottom of desulfurization tower , the mist eliminator 6 is located inside the desulfurization tower 2 and is located below the chimney 23;

Embodiment 2

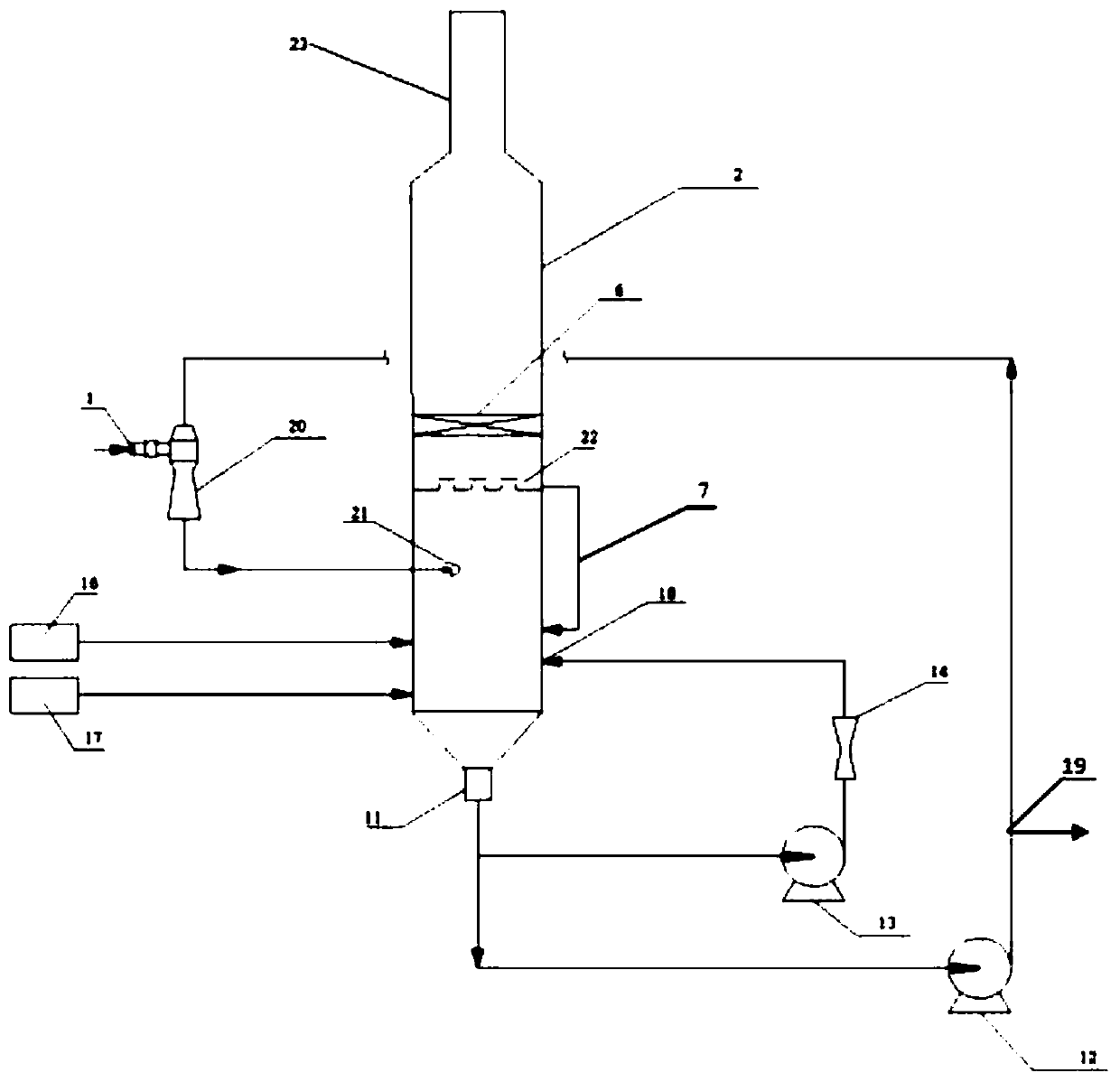

[0038] Such as figure 2 As shown, it is a structural schematic diagram of the technical solution of the spraying Venturi pretreatment system. This specific embodiment adopts the following technical solution: including flue gas inlet 1, desulfurization tower 2, demister 6, tower kettle side wall gas-liquid inlet 10, washing Liquid outlet 11, washing circulation pump 12, oxidation circulation pump 13, oxidation jet nozzle 14, process water delivery system 16, sodium carbonate preparation system 17, water outlet 19, high-energy Venturi injector 20, gas-liquid inlet 21, gas distribution plate 22; The top of the desulfurization tower 2 is provided with a chimney 23, the bottom of the desulfurization tower is provided with a washing liquid outlet 11, and the demister 6 is located inside the desulfurization tower 2, located below the chimney 23;

[0039] The flue gas inlet 1 is the gas phase inlet of the high-energy Venturi injector 20; the gas-liquid inlet 21 is located inside the des

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap