Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36 results about "Ethyl acetate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ethyl acetate (systematically ethyl ethanoate, commonly abbreviated EtOAc, ETAC or EA) is the organic compound with the formula CH3–COO–CH2–CH3, simplified to C4H8O2. This colorless liquid has a characteristic sweet smell (similar to pear drops) and is used in glues, nail polish removers, decaffeinating tea and coffee. Ethyl acetate is the ester of ethanol and acetic acid; it is manufactured on a large scale for use as a solvent. The combined annual production in 1985 of Japan, North America, and Europe was about 400,000 tonnes. In 2004, an estimated 1.3 million tonnes were produced worldwide.

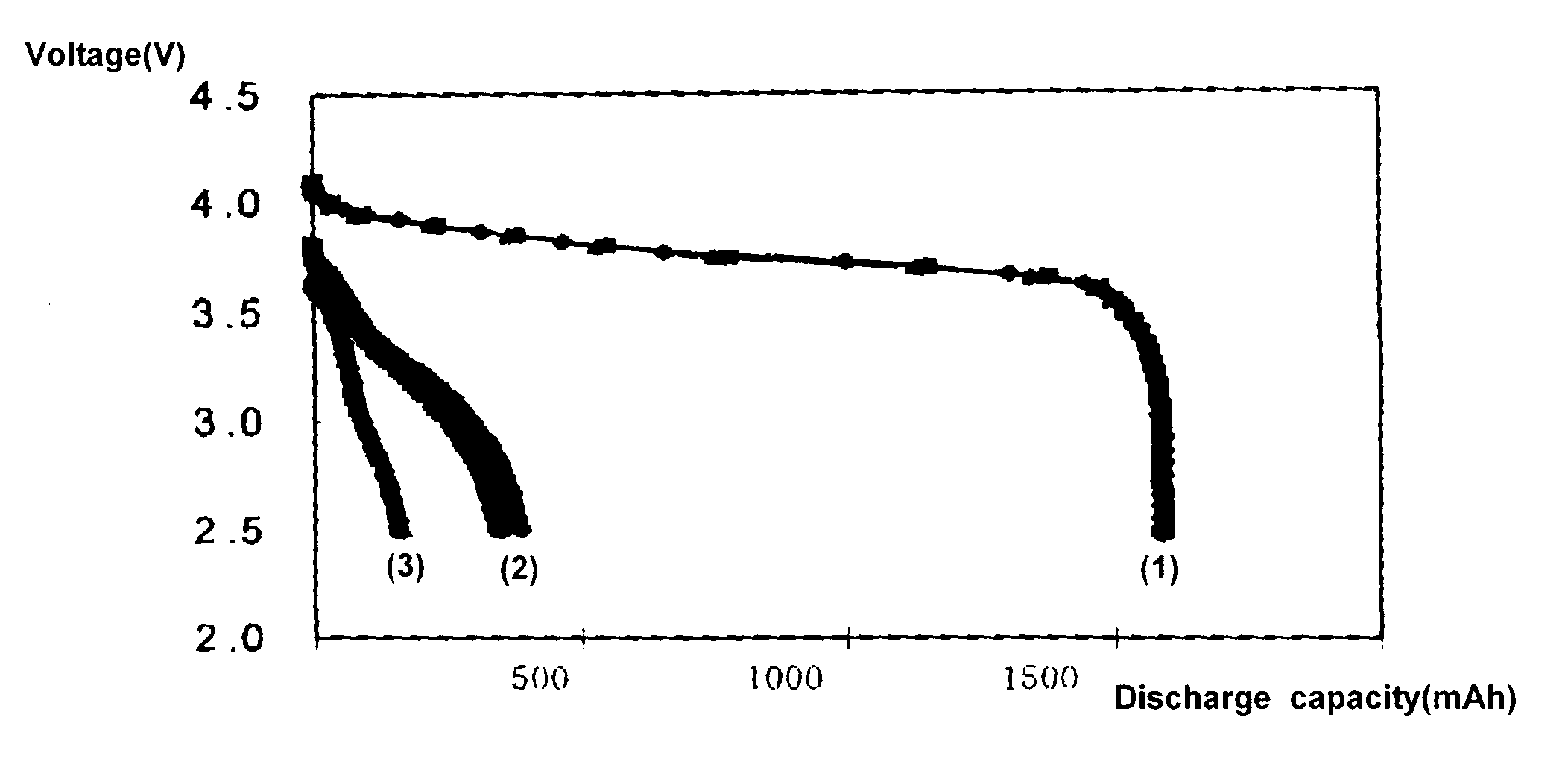

Electrolyte for rechargeable lithium battery and rechargeable lithium battery comprising the same

Owner:SAMSUNG SDI CO LTD

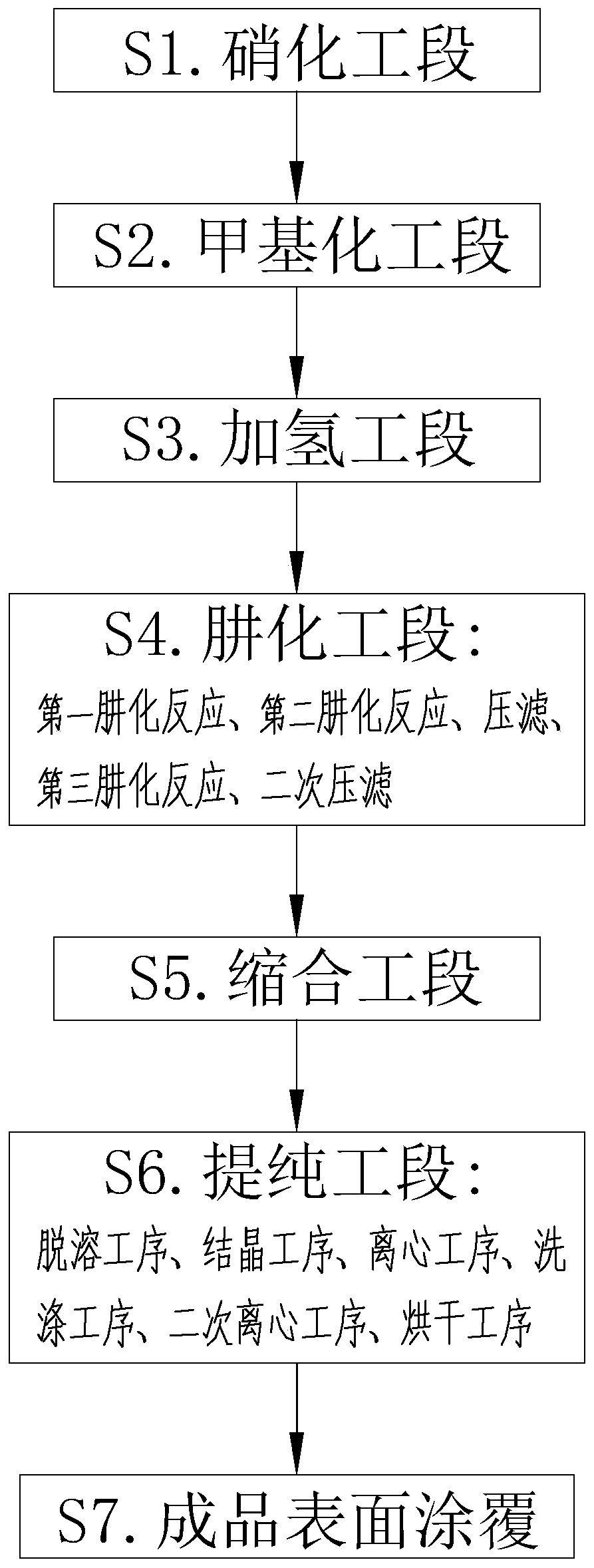

Method for preparing pirfenidone

InactiveCN102558040AReduce energy consumptionSimple and fast operationOrganic chemistryPurification methodsChemical products

The invention discloses a method for preparing pirfenidone, comprising the following steps: subjecting 2-amino-5-methylpyridine which is a starting material to inverse diazotization and hydrolysis, extracting with extraction solvent, and recrystallizing with recrystallization solvent to obtain 2-hydroxy-5-methylpyridine; heating the 2-hydroxy-5-methylpyridine together with iodobenzene in the presence of anhydrous potassium carbonate and active copper to subject the 2-hydroxy-5-methylpyridine and the iodobenzene to nucleophilic substitution reaction to generate a target compound which is the crude pirfenidone; and recrystallizing the crude pirfenidone for one time for purification with recrystallization solvents which are ethyl acetate and anhydrous ethyl alcohol to obtain the pure pirfenidone. Compared with the prior art, the method for preparing the pirfenidone has the characteristics that: the 2-amino-5-methylpyridine which is the starting material is a commercial chemical product, is cheap and is easy to get, the inverse diazotization replaces the conventional diazotization reaction so that the operation is simple, and the purification methods of the 2-hydroxy-5-methylpyridine and the end product which is the pirfenidone are easy to operate and have high yield. The method for producing the pirfenidone consumes less energy, and the production cost is lowered due to the adoption of the method.

Owner:CISEN PHARMA

Lightning protected cable for communication base station

ActiveCN103325489ALower the resistance valueSmall short-term calorific valueCommunication cablesInsulated cablesAluminium hydroxideEngineering

The invention belongs to the technical field of cables and relates to a lightning protected cable for a communication base station. The lightning protected cable for the communication base station comprises a cable core, an inner protecting sleeve, an armor layer, an outer protecting sleeve and a ground layer. The lightning protected cable for the communication base station is characterized in that a first protecting layer is arranged outside the cable core, the inner protecting sleeve is arranged outside the first protecting layer, a second protecting layer is arranged outside the inner protecting sleeve, the ground layer is arranged outside the second protecting layer, the armor layer is arranged outside the ground layer, and the armor layer is coated with the outer protecting sleeve; the armor layer is a single-face film covering steel belt and the face, in contact with the ground layer, of the armor layer is a non-film-covering face; the first protecting layer and the second protecting layer are both mica tapes; the outer protecting sleeve comprises, by weight, the following raw materials of 71 parts of polyethylene, one part of anti-oxygen 1010, 12 parts of aluminum hydroxides, 0.5 part of HK-type antistatic agent, 3 parts of ethyl acetate, 1 part of carbon black, 10 parts of zirconium oxide and 1.5 parts of polyethylene wax. The lightning protected cable for the communication base station has the advantages of being simple in manufacturing, high in production speed, capable of enabling the electrical resisting rate of the ground layer to be low, low in maintaining cost, small in dust adsorption, pressure resistant, and good in flame resistance.

Owner:JIANGSU ZHONGLI GRP CO LTD

Preparation method of corrosion inhibitor of methanol gasoline

ActiveCN103725335AGood compatibilityAdd lessLiquid carbonaceous fuelsFuel additivesActive agentPolyethylene glycol

Owner:南通市通州区五接农业机电管理站有限公司

Method for preparing chloroprene rubber adhesive agent

InactiveCN101781538APromote environmental protectionHigh affinitySolesGraft polymer adhesivesPolymer scienceBenzoyl peroxide

Owner:NANTONG GUANGTAI BIOCHEM PROD

Method for determining methamidophos in rice wine

The invention discloses a method for determining methamidophos in rice wine and particularly discloses a method for detecting the content of methamidophos in rice wine by utilizing gas chromatography and liquid chromatography-tandem mass spectrometry. The method comprises the following steps: (1) extraction and purification: utilizing a solid phase extraction column to extract the methamidophos in the rice wine and using ethyl acetate to elute the methamidophos adsorbed on the solid phase extraction column; (2) preparation of matrix matched standard working solution; (3) qualitative screening and quantification by utilizing gas chromatography; (4) qualitative confirmation of positive samples by using liquid chromatography-tandem mass spectrometry; (5) blank test; and (6) result calculation and representation. The method has the following beneficial effects: the pretreatment operation is simple and practical, and the recovery rate of the methamidophos is high; and by adopting the matrix matched standard working solution, the problem of matrix effect of the methamidophos on the gas chromatograph is solved, and accurate quantification is implemented.

Owner:SHAOXING ENTRY EXIT INSPECTION & QUARANTINE BUREAU OF THE PEOPLES REPUBLIC OF CHINA

Polyvinyl alcohol water-based architectural paint

Owner:苏州市超邦涂料有限公司

Preparation method of silicon dioxide antireflection film

The invention discloses a preparation method of a silicon dioxide antireflection film. The preparation method comprises the following steps of preparing a clear sol by using raw materials like a silicon compound, a solvent, a suppressor, deionized water and acid catalyst under an acidic condition through a sol-gel method; stirring and adding aqueous ammonia and ethyl acetate into the clear sol, and reacting for 0.5-24 hours in a 40-100DEG C constant temperature backflow condition, so as to prepare milky white silicon dioxide sol, wherein the milky white silicon dioxide sol contains 2-10 mass percent of silicon compound, 60-90 mass percent of solvent and 1-40 mass percent of water; and applying the milky white silicon dioxide sol onto a substrate with the surface treated, so as to obtain acoating. The silicon dioxide antireflection coating prepared by the method has higher air porosity and lower refractive index, and has much better antireflection effect while maintaining the frictionresistance. The preparation method is low in production cost, slightly affects surrounding environment, and is suitable for large-scale production and application of industry.

Owner:HUNAN XINGWEI NEW MATERIAL CO LTD

Preparation method for trelagliptin and salt thereof

InactiveCN105985316AReduce generationSimple separation and purification methodOrganic chemistryAcetic acidOrganic solvent

The invention discloses a preparation method for trelagliptin and a salt thereof. The preparation method comprises the following steps: a, subjecting a compound 3, Pd(OAc)2, ligand, K3PO4, 3-tertbutyloxycarbonyl-aminopiperidine, and an organic solvent to a reaction with stirring under the protection of nitrogen so as to obtain a reaction solution; b, carrying out separation and purification so as to obtain a compound 6; c, subjecting the compound 6, ethyl acetate and an ethyl acetate solution of HCl to a reaction with stirring and then carrying out separation and purification so as to obtain a solid; and d, dissolving the solid obtained in the step c in water, adjusting a pH value to 8 to 9 and then carrying out separation and purification so as to obtain a compound 4, i.e., trelagliptin. The preparation method provided by the invention reduces side reactions and production of impurity compounds; the method is simple and convenient in separating and purifying trelagliptin and has the advantages of short production period, high yield, high purity, low cost, etc.; and the yield of trelagliptin in the invention can reach 95% or above, and the preparation method is suitable for industrial production.

Owner:SICHUAN KELUN PHARMA RES INST CO LTD

Traditional Chinese medicine composition and application thereof

Owner:SHANGHAI UNIV OF T C M

Synthetic method for bifenazate

Owner:绍兴上虞新银邦生化有限公司

Alcohol-soluble nitrocotton optically variable ink and preparation process thereof

The invention discloses an alcohol-soluble nitrocotton optically variable ink. The alcohol-soluble nitrocotton optically variable ink is characterized in that: ethanol is adopted as a main solvent, and other components include: 16.0-20.0% of alcohol-soluble nitrocotton, 4.0-8.0% of alcohol-soluble rosin, 0.0-5.0% of acetyl tributyl citrate, 8.5-9.5% of an optically variable pigment, 45.0-62.0% ofethanol, 8.0-12.0% of ethyl acetate, 2.0-5.0% of dipropylene glycol methyl ether, and 0-0.5% of alcohol-soluble color ink. Resin dissolution, optically variable pigment dispersion, color matching andinspection process methods are adopted to prepare the alcohol-soluble optically variable ink, the invention aims to prepare the optically variable ink that can save energy, reduce emission, lower thecost, meets the requirements of the existing market, and at the same time meets the requirements of environmental protection condition for VOC emission indexes, and the alcohol-soluble nitrocotton optically variable ink has higher economic benefits and social benefits.

Owner:JIANGSU TIGER INK CO LTD

Preparation method of cordyceps sinensis mycelium extract

Owner:SUZHOU TIANLING CHINESE TRADITIONAL MEDICINE SLICE

Fuel oil additive mixture

Owner:黄慧娟

Anti-fog UV coating for automobile exterior trim lamp part, preparation method thereof and paint film formed by coating

ActiveCN110616034AImprove the level ofGood lookingPolyurea/polyurethane coatingsButyl acetateAcrylic resin

The invention discloses an anti-fog UV coating for an automobile exterior trim lamp part, a preparation method thereof, and a paint film formed by the anti-fog UV coating. The anti-fog UV coating forthe vehicle lamp comprises the following raw materials in parts by weight: 9-functionality aliphatic polyurethane acrylic resin, 4-functionality aliphatic polyurethane acrylic resin, 6-functionality organic silicon modified polyurethane acrylic resin, 2-functionality aliphatic polyurethane acrylic resin, an ultraviolet initiator 184, an ultraviolet initiator TPO, a flatting agent, an anti-doodlingaid, ethyl acetate and butyl acetate. The anti-fog UV coating provided by the invention can obviously improve the problem of aerial fog residue on a car lamp and improve the self-cleaning property ofthe surface of a paint film, and can completely meet the VW TL221 standard by Volkswagen.

Owner:WUHU CHUNFENG NEW MATERIAL

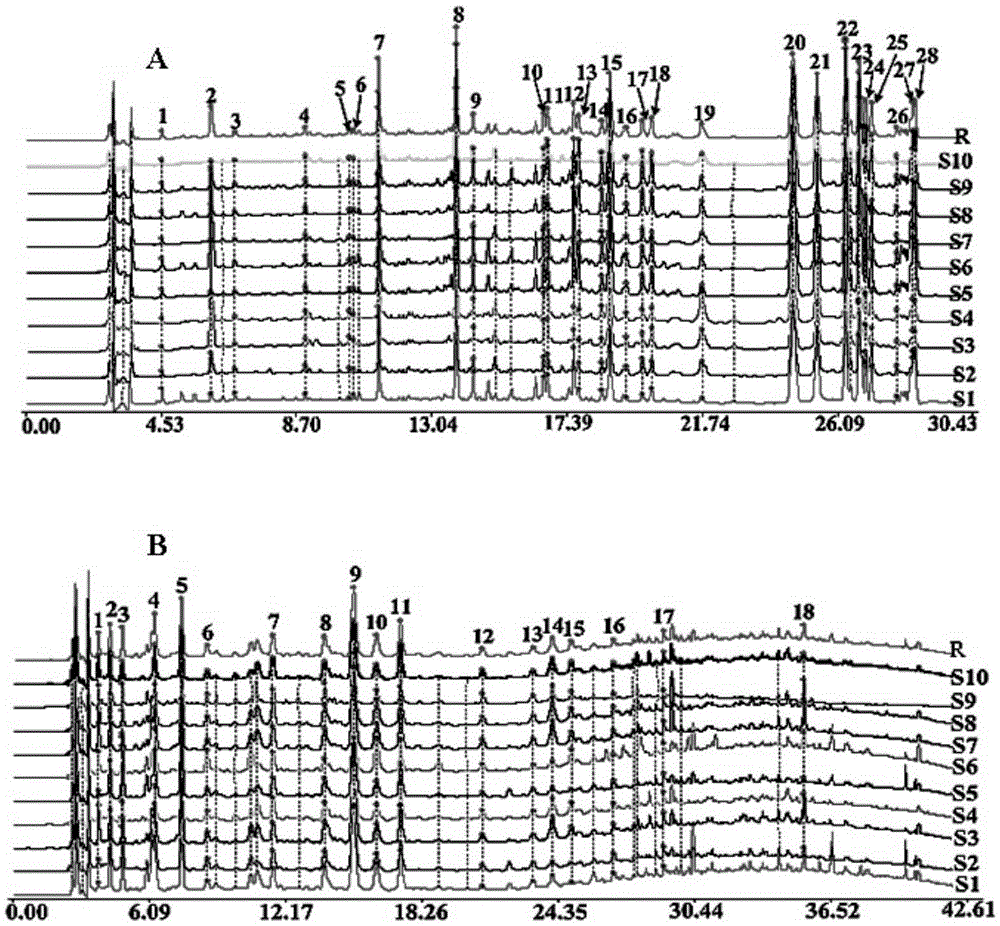

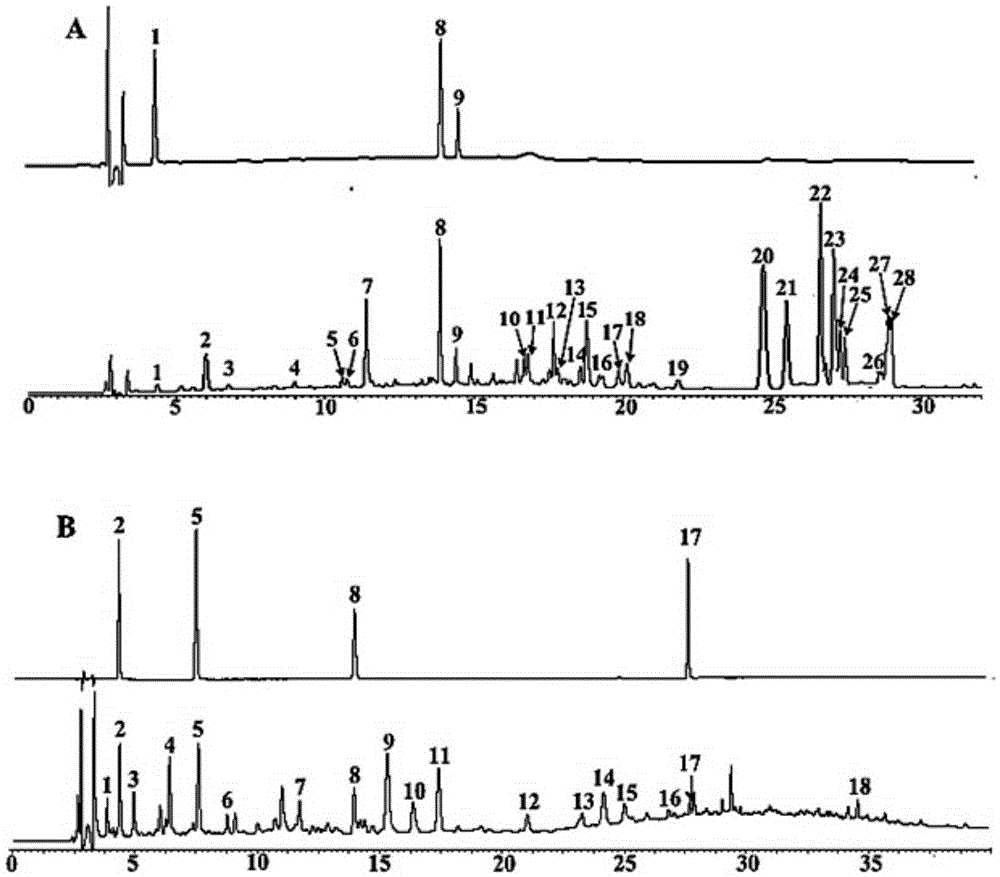

HPLC with evaporative Light-scatter measuring method for huangyangning, cyclovirobuxine D, buxus alkaloid and relative alkaloid content

This invention discloses one high effective liquid phase spectrum evaporation diffusion test method for Huangyangning, ring Huangyangxing D and Huangyangsheng alkaloid and relative contents, which comprises the following steps: its color spectrum is fixed with silicon gel as stuff agent; the flow phase adopts tetrahydrofuran - carbinol - acetonitrile - intense ammonial solution or acetic acid ethyl ester - carbinol - intense ammonial solution; the test device adopts evaporation diffusion light tester.

Owner:杭太俊 +5

Method for obtaining cucurbitacine B

Owner:烟台利天生物科技有限公司

Method of extracting active ingredients of Dendropanax dentiger leaves with ultrasonic waves

ActiveCN104840497AImprove immunitySimple extraction methodImmunological disordersPlant ingredientsSolventBULK ACTIVE INGREDIENT

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

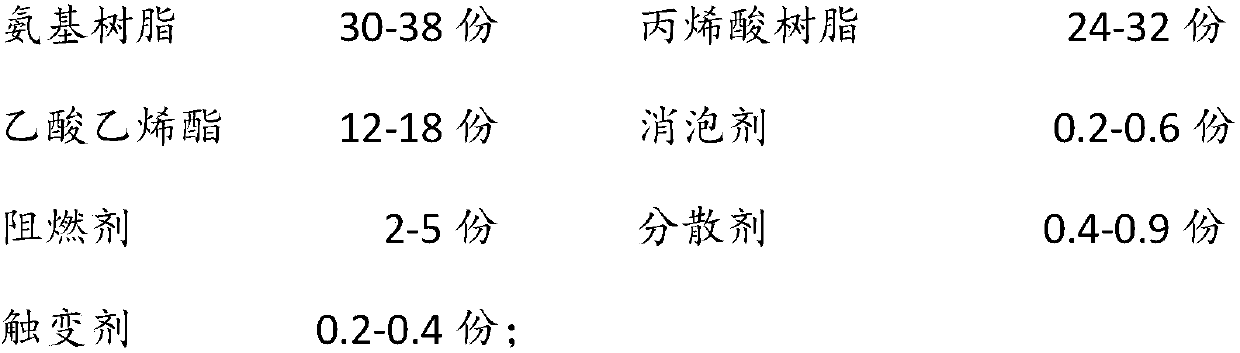

Flame-retardant finish paint for furniture

InactiveCN107629661AImprove flame retardant performanceStrong impact resistanceFireproof paintsPolyurea/polyurethane coatingsAcrylic resinLacquer

Owner:佛山市三水区白坭镇巨财红木厂

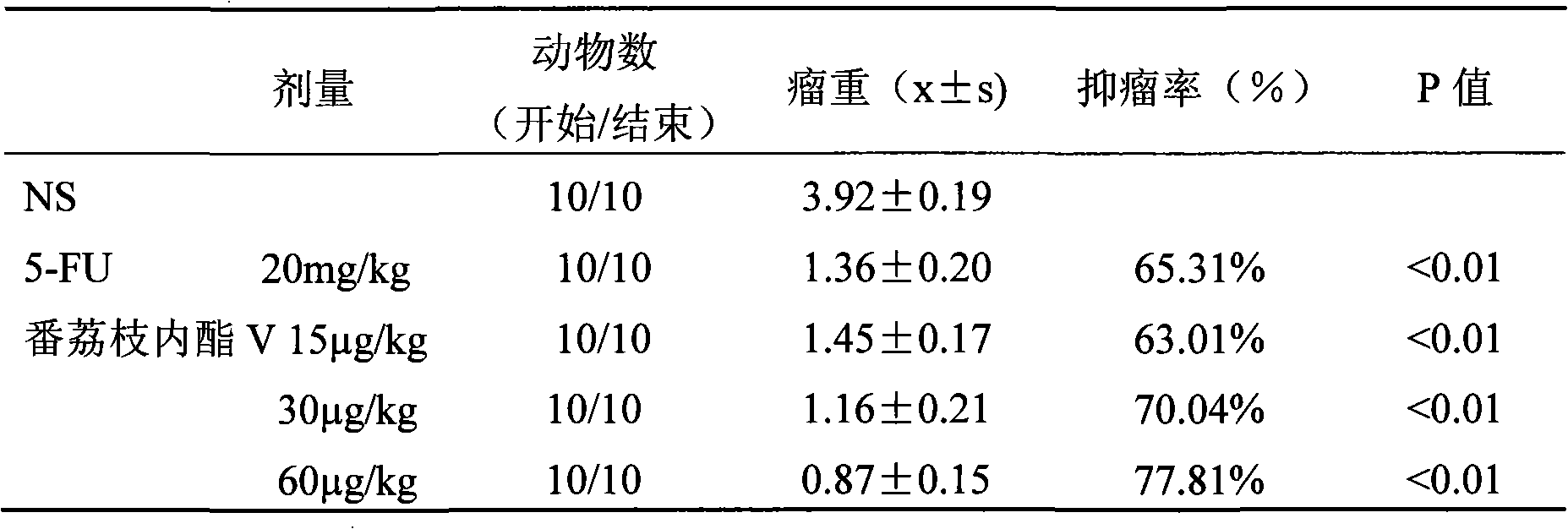

Application of sugar apple lactone compound V in preparing cancer-treating and anti-cancer medicine

InactiveCN101342202AHigh anticancer activityImprove the clinical efficacy of anti-cancerOrganic active ingredientsAntineoplastic agentsCancer cellAnnonaceous Acetogenins

Owner:NANJING UNIVERSITY OF TRADITIONAL CHINESE MEDICINE

Lubricating oil for oil field operation drill pipe

InactiveCN108300549AExtensive sources of raw materialsWide variety of sourcesDrilling compositionLubricant compositionEthyl acetateSodium sulfate

Owner:NANTONG JINNIU MACHINERY MFR

Automobile cushion care agent

InactiveCN106566899AGood weather resistanceImprove softness and elasticityLeather surface finishingLeather impregnationAcetic acidWeather resistance

Owner:SUZHOU WANLONG AUTO PARTS

Method for developing and extracting biological trace evidence

ActiveUS20210080395A1Reduce workloadImprove investigation efficiencyAnalysis using chemical indicatorsMicrobiological testing/measurementAlcoholGlycerol

Owner:SUZHOU XIAOSONG TECH DEV

Wood plant type mildew-proof agent and preparation method

Owner:GUIZHOU JIANTAO WOOD IND TECH CO LTD

Method for extracting vavasu from Ceiba pentandra (L.) Gaertner

Owner:NANJING ZELANG MEDICAL TECH

Preparation method of aryl borate

ActiveCN111875627AReduce pollutionCheap sourceGroup 3/13 element organic compoundsSulfonyl chlorideAlkane

Owner:YANTAI DERUN LIQUID CRYSTAL MATERIALS

Characteristic map detection method of powerful gastrodia elata-eucommia ulmoides capsules

Owner:GUIZHOU MEDICAL UNIV

Special coating for solar cell backboards, and preparation method thereof

InactiveCN107325622AImprove antioxidant capacityImprove uniformityCoatingsPhotovoltaic energy generationCyclohexanoneToluene diisocyanate

The invention discloses a special coating for solar cell backboards, and a preparation method thereof, wherein the coating comprises toluene diisocyanate, ethyl acetate, acetone, bisphenol, dimethylacetamide, trimellitic anhydride, benzotriazole, anhydrous xylene, pyrophosphate, cyclohexanone, an alkoxy fatty acid titanate coupling agent, tetrabutyl titanate, zinc acetate, and ethylene glycol. The preparation method comprises: carrying out mixing heating on toluene diisocyanate, ethyl acetate, acetone, bisphenol, dimethylacetamide, trimellitic anhydride, benzotriazole, anhydrous xylene, cyclohexanone and tetrabutyl titanate to achieve a temperature of 450-550 DEG C to obtain a component A; carrying out mixing heating on pyrophosphate, zinc acetate and ethylene glycol to a temperature of 100-180 DEG C, adding an alkoxy fatty acid titanate coupling agent in a dropwise manner, and stirring to obtain a component B; and uniformly mixing the component A and the component B to obtain the product. According to the present invention, by using the synergetic effect of pyrophosphate and bisphenol, the anti-oxidation performance of the backboard is improved, the yellowing index [delta]b is 1.8-2.1, and the service life of the whole solar cell is prolonged.

Owner:JURONG GCL SYST INTEGRATION TECH CO LTD

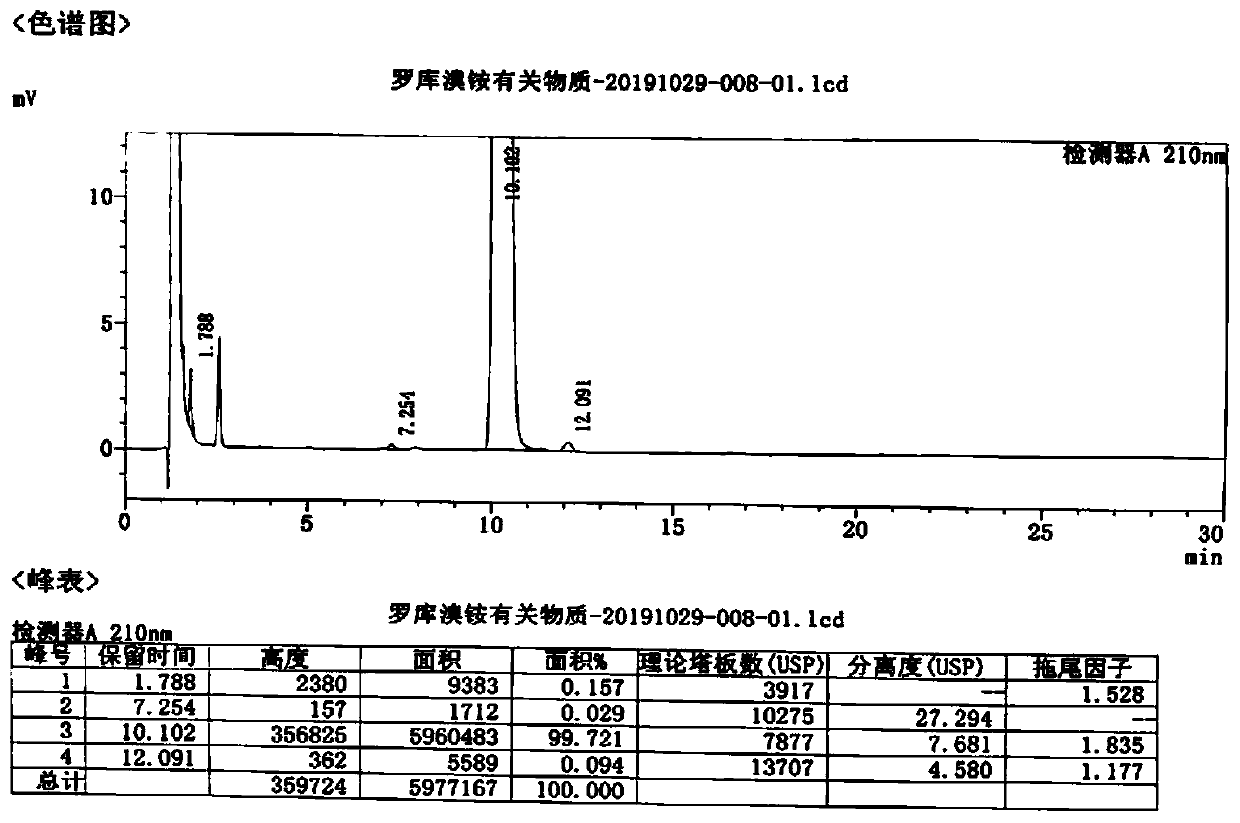

Preparation method of rocuronium bromide

Owner:武汉华龙生物制药有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap