Preparation method of rocuronium bromide

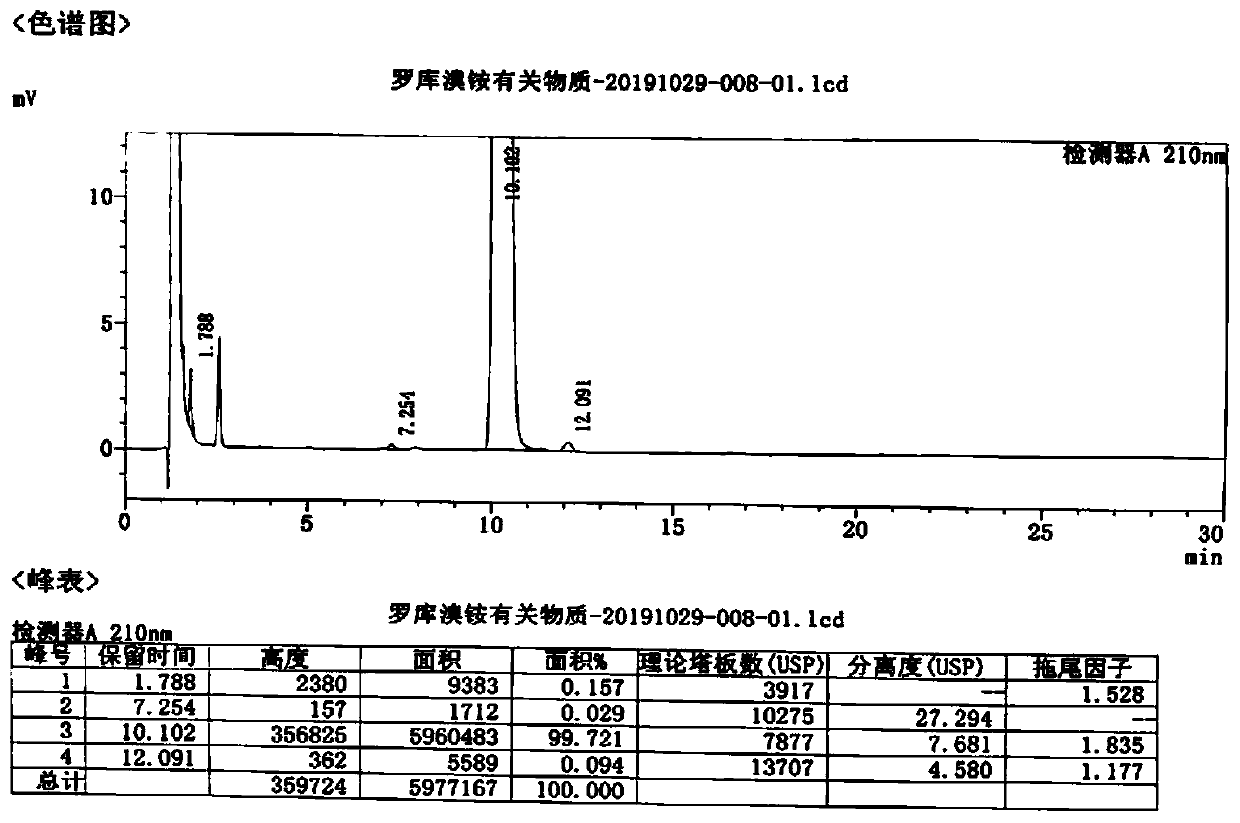

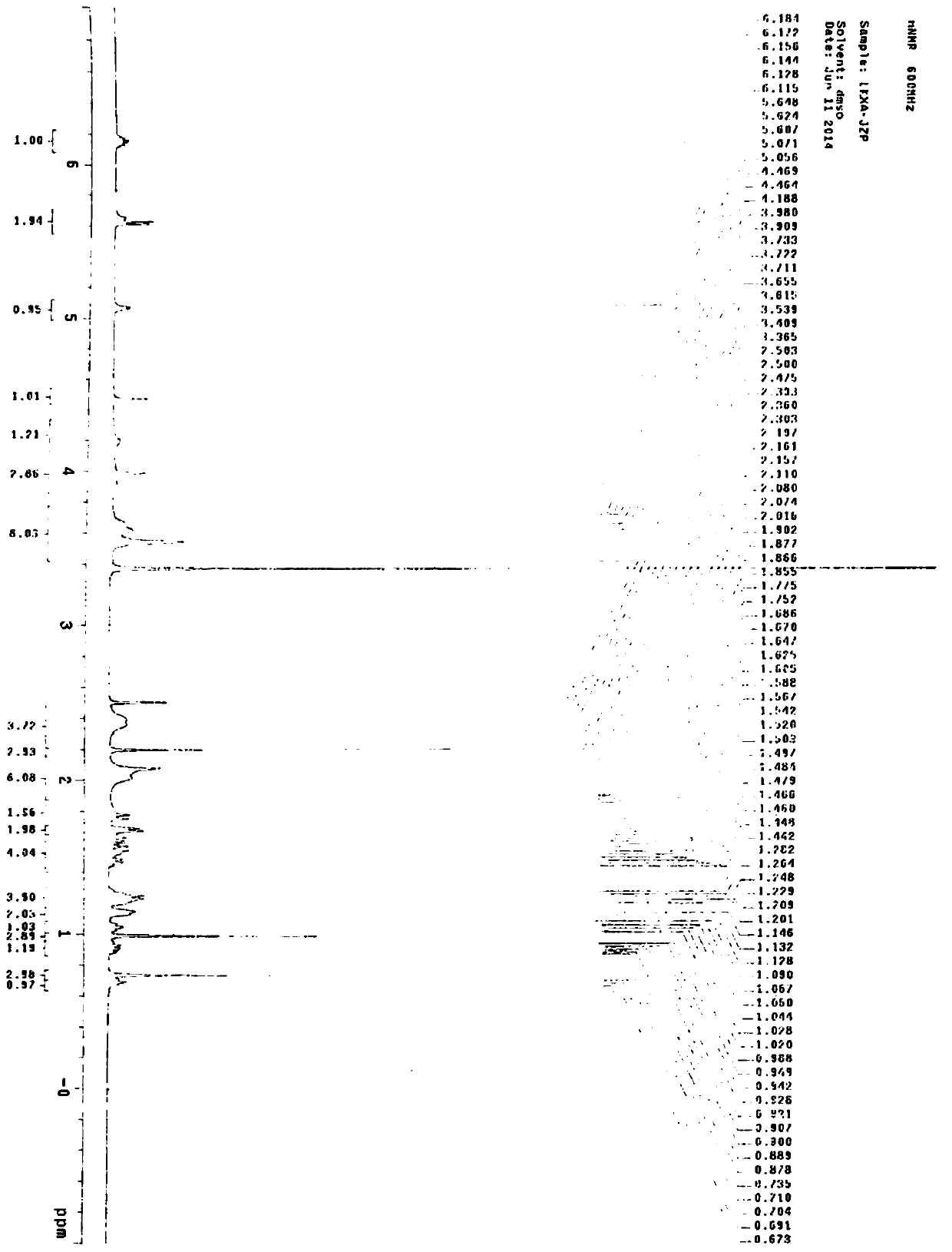

A technology of rocuronium bromide and allyl bromide, applied in the direction of steroids, organic chemistry, etc., can solve the problems of easily exceeding the standard of hydrolyzed impurities, low yield, excessive impurities and solvent residues, etc., to achieve simple operation, reduce The amount of solvent used, the effect of avoiding a large amount of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1 of the present invention provides a kind of preparation method of rocuronium bromide, comprises the steps:

[0038](1) Preparation of Compound III

[0039] Pump 72kg of dichloromethane into the reaction kettle at 25°C-30°C, start stirring, add 1.6kg of starting materials, stir and disperse; add 0.63kg of acetyl chloride dropwise, after dropping, keep the temperature of the material liquid at 25°C-30°C and stir React for 5 to 8 hours, the reaction solution is not processed, directly dropwise add 4.1kg of 10% hydrochloric acid solution to the reaction solution, after the drop is complete, keep the reaction at 25°C to 30°C for 20 hours, let stand and separate, remove 46.7kg of the organic layer, Add about 20.6 kg of 10% sodium carbonate aqueous solution to the remaining reaction solution to adjust pH=7 to 9, separate the organic phase, add 3.8 kg of silica gel to the organic phase, stir and absorb for 10 min, filter under reduced pressure, and then use 32.3 kg of

Embodiment 2

[0044] In this embodiment, except step 3 is changed to "the mass ratio of dichloromethane to methyl tert-butyl ether-ethyl acetate in the dichloromethane-methyl tert-butyl ether-ethyl acetate system is 8:20:20" , all the other are with embodiment 1.

Embodiment 3

[0046] In this embodiment, except that step 3 is changed to "the mass ratio of dichloromethane to methyl tert-butyl ether-ethyl acetate in the dichloromethane-methyl tert-butyl ether-ethyl acetate system is 3:25:25" , all the other are with embodiment 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap