Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46results about "Liquid carbonaceous fuels" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lubricant containing molybdenum compound and secondary diarylamine

InactiveUSRE38929E1Low treat levelLow costLiquid carbonaceous fuelsAdditivesSulfurMolybdenum compounds

Owner:AFTON CHEM INTANGIBLES

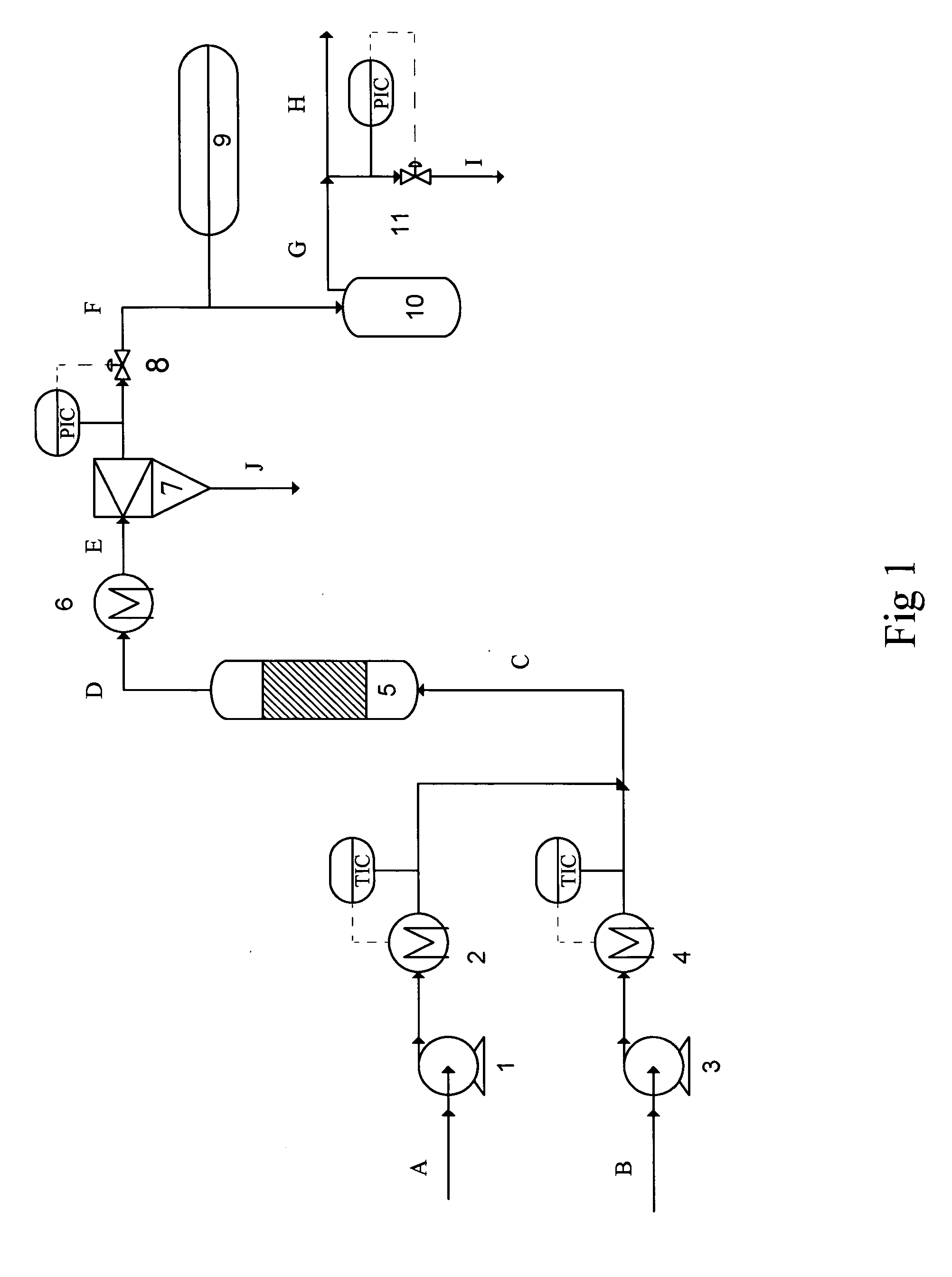

Method and apparatus for converting organic material

ActiveUS20060260186A1Apparatus is enlargedCatalytic crackingByproduct vaporizationHomogeneous catalysisHydrocarbon

Owner:SCF TECH AS

Methanol gasoline and its preparation method

InactiveCN102260548AEasy to prepareImprove performanceLiquid carbonaceous fuelsFuel additivesNew energyOil additive

The invention discloses a methanol gasoline and a preparation method thereof, relating to the field of new energy. The methanol gasoline comprises 15-30wt% of methanol, 67-83wt% of gasoline and 2-3wt% of additive. The preparation method comprises the following steps: pouring solubilizer, energy increasing and consumption reducing agent, anti-oxidant, metal corrosion inhibitor, rubber swelling inhibitor into a reaction vessel according to a required proportion with stirring, mixing uniformly to obtain an additive; mixing the additive with methanol according to a required proportion to obtain modified methanol; and mixing the modified methanol with gasoline according to a required proportion to obtain the methanol gasoline. The methanol gasoline disclosed in the invention has the advantagesof simple preparation and good performance, can be used mixed with a national standard gasoline in any proportion with similar energy consumption with the national standard gasoline and emission indexes that conforms to requirements of environmental protection, and can be widely used for various petrol-engined motor vehicles, such as car, carriage, fork truck, power-assisted vehicle, farm vehicle, motorcycle, load wagon and forklift.

Owner:YONGZHOU JINZHEN NEW ENERGY DEV CO LTD

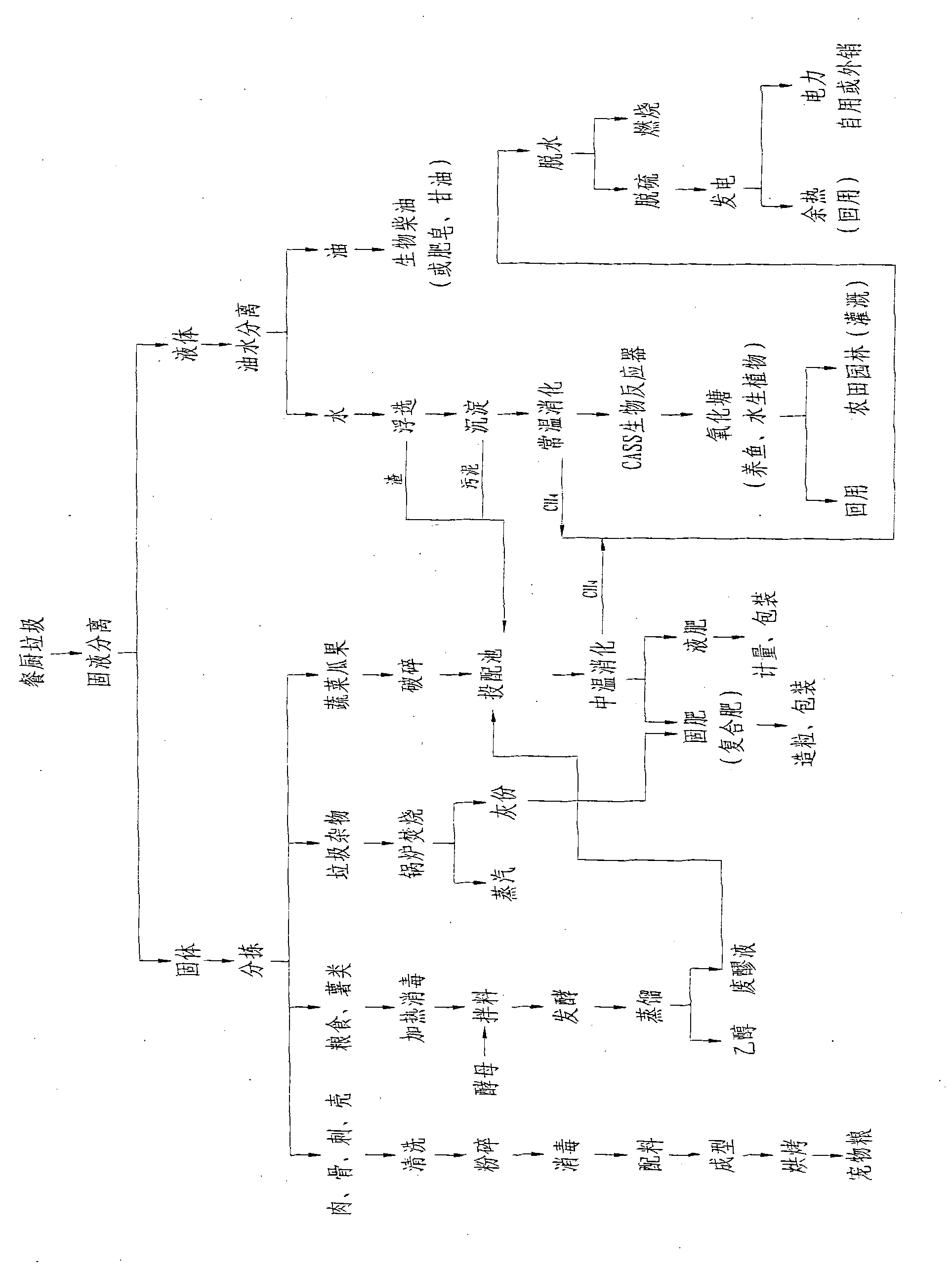

Processing method of changing food waste into resources

InactiveCN101850349AIncrease valueEmission reductionFatty oils/acids recovery from wasteBio-organic fraction processingWater useBiodiesel

Owner:云南天兰环保科技开发有限公司 +1

Method and composition for improving fuel combustion

InactiveUS20050081430A1Promote combustionLighting and heating apparatusGaseous fuelsCombustionMethyl isobutyl ketone

Owner:CARROLL & ASSOC LLC

Preparation method of corrosion inhibitor of methanol gasoline

ActiveCN103725335AGood compatibilityAdd lessLiquid carbonaceous fuelsFuel additivesActive agentPolyethylene glycol

Owner:南通市通州区五接农业机电管理站有限公司

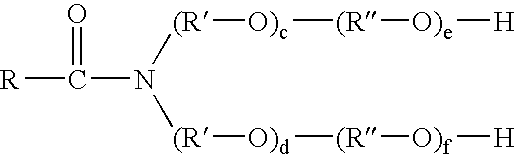

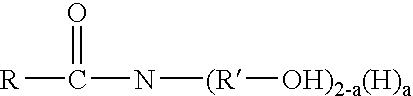

Fuel additive composition and fuel composition containing the same

ActiveUS20040154217A1Enhance acceleration response and driving performanceImprove acceleration performanceNon-fuel substance addition to fuelLiquid carbonaceous fuelsOxideInternal combustion engine

A fuel additive composition containing an alkylene-oxide-adducted hydrocarbyl amide and a friction modifier is disclosed. The alkylene-oxide-adducted hydrocarbyl amide and friction modifier are surprisingly useful for improving the acceleration response and the driving performance of vehicles having internal combustion engines when used as fuel additives in hydrocarbon-based fuels, such as gasoline fuel or diesel fuel.

Owner:CHEVRONTEXACO JAPAN

Grease composition

InactiveUS20120098269A1Long life-timeSuppressing bearing wearPump componentsAdditivesBase oilViscosity

Owner:IDEMITSU KOSAN CO LTD

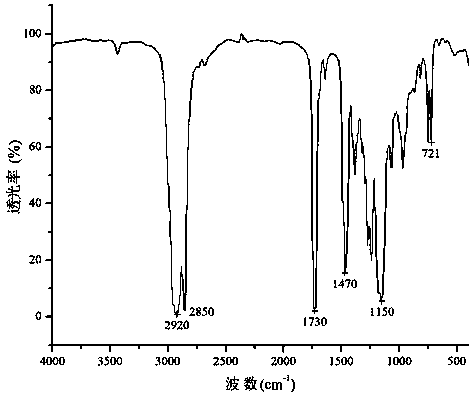

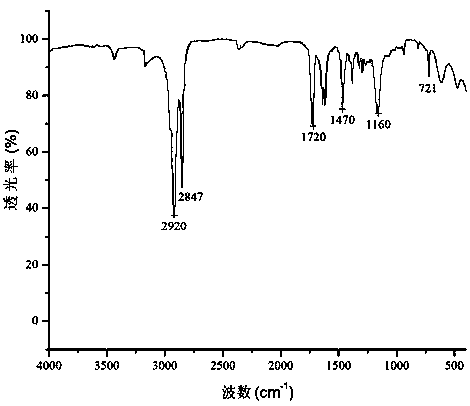

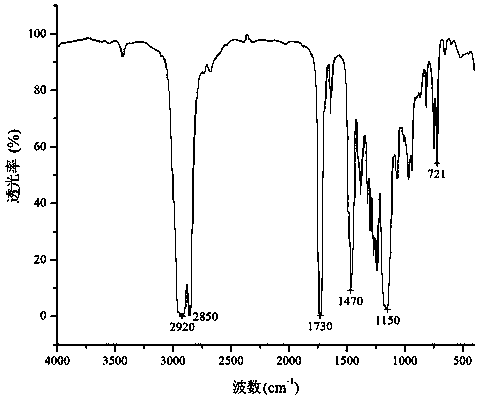

Polymethylacrylic acid higher ester pour point depressant, and preparation method and application thereof

Owner:XI'AN PETROLEUM UNIVERSITY

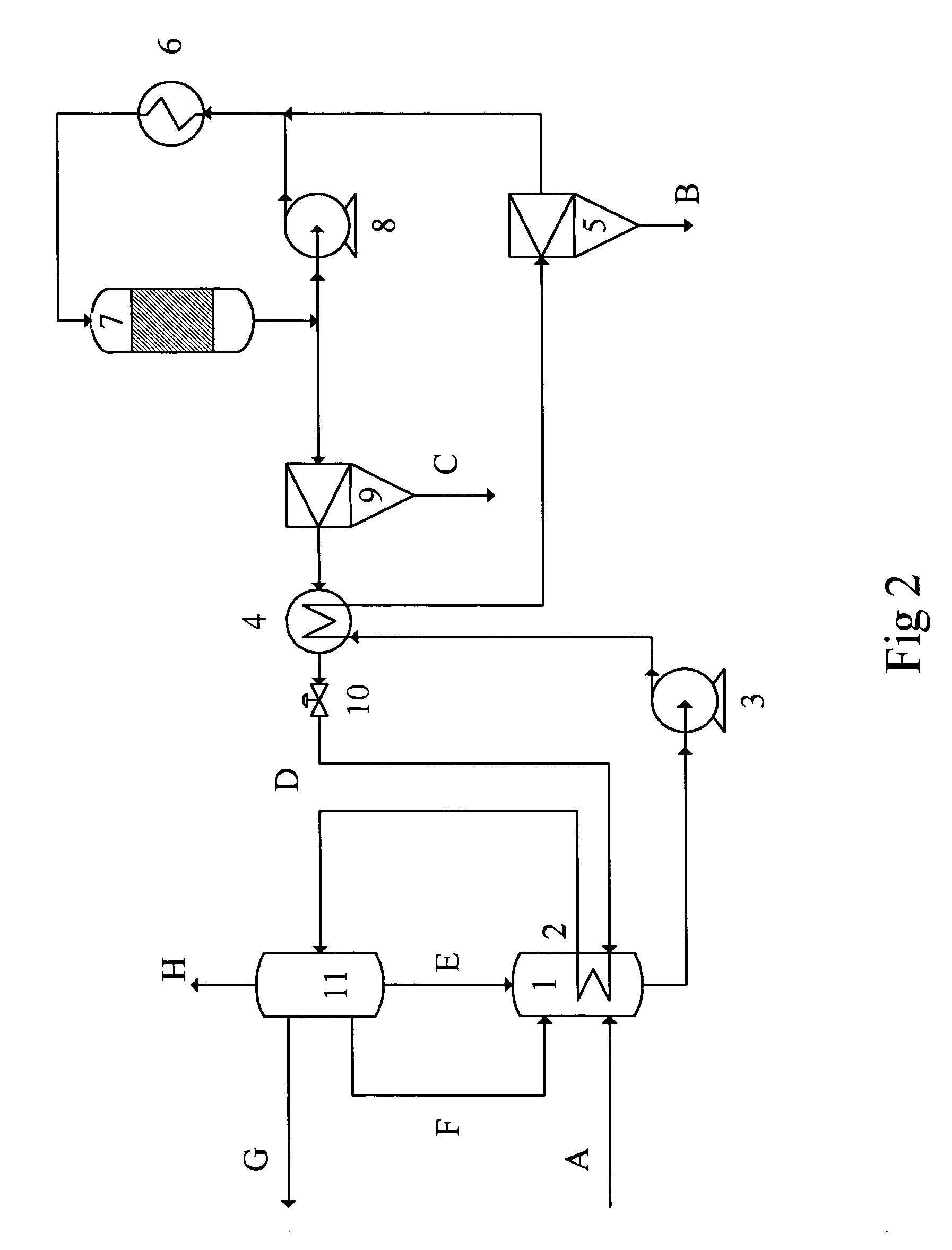

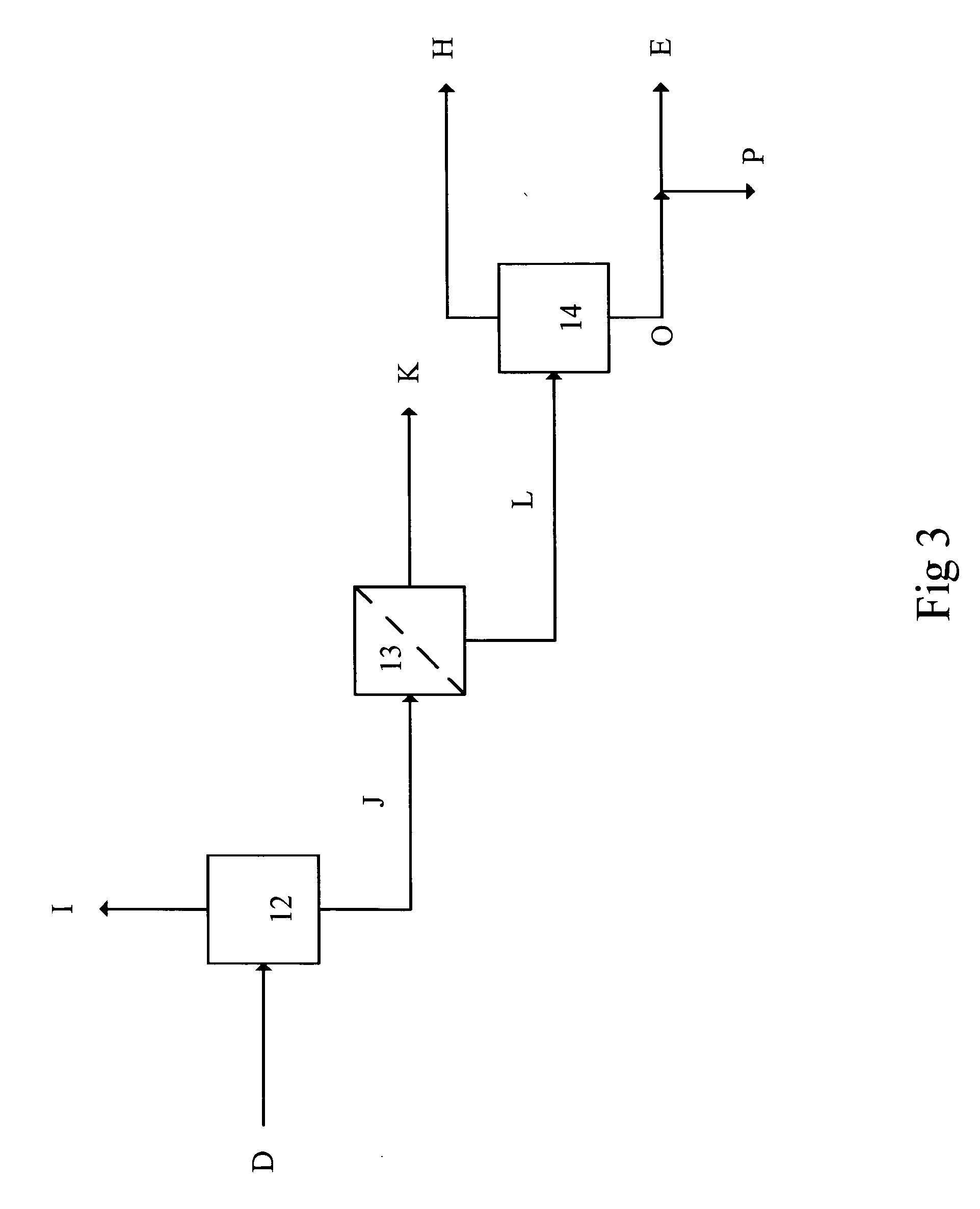

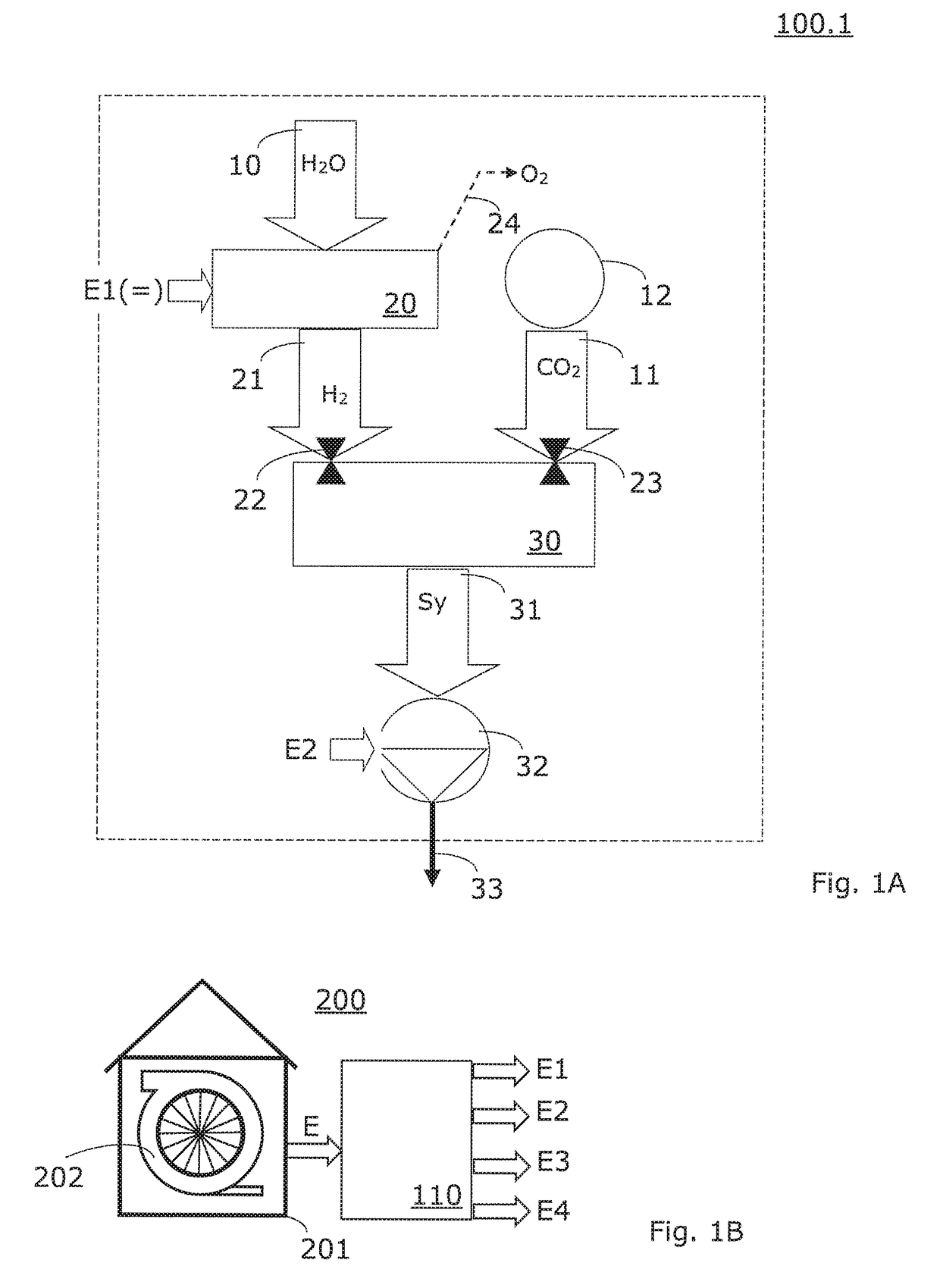

Ecological and economic method and apparatus for providing hydrogen-based methanol

InactiveUS20170166503A1Provide electric output powerNon-fuel substance addition to fuelOrganic compound preparationHydrogenMethanol

Owner:SWISS LIQUID FUTURE AG

Vanadium inhibitor, preparing method of vanadium inhibitor, vanadium inhibition composition, application of vanadium inhibition composition and preparing method of vanadium inhibition composition

The invention relates to a vanadium inhibitor, a preparing method of the vanadium inhibitor, a vanadium inhibition composition, application of the vanadium inhibition composition and a preparing method of the vanadium inhibition composition. The vanadium inhibitor comprises an active center and a wrapping layer. The active center comprises nanometer magnesium oxide. The wrapping layer comprises maleic anhydride grafted alpha-olefin, and the wrapping layer is connected with the active center through an ester bond. The vanadium inhibitor is good in oil dissolubility and strong in hydrolysis resistance.

Owner:SHENZHEN GCD PETROLEUM ADDITIVE CO

Methanol gasoline

InactiveCN106957697ALow costImprove performanceLiquid carbonaceous fuelsFuel additivesGasoline fuelAntioxidant

Owner:泸州清大能源股份有限公司

Viscosity Modifiers Comprising Blends of Ethylene-Based Copolymers

The present invention is directed to polymer blend compositions for use as viscosity modifiers comprising at least two ethylene-based copolymer components. The viscosity modifiers described herein comprise a first ethylene-based copolymer having an ethylene content of from about 44 to about 52 wt % and / or a heat of fusion of from about 0 to about 15 J / g and a second ethylene-based copolymer having an ethylene content of from about 68 to about 75 wt % and / or a heat of fusion of from about 40 to about 65 J / g. The invention is also directed to lubricant compositions comprising a lubricating basestock and a polymer blend of the invention.

Owner:EXXONMOBIL CHEM PAT INC

Gas furnace controller

A gas furnace controller for disrupting the flow of gas to a gas furnace upon detection of excessive levels of carbon monoxide comprises an air sample collector in fluid communication with a carbon monoxide detector, a gas supply shutoff circuit for controlling a valve in a gas supply line to the gas furnace; and a controller in electrical communication with the carbon monoxide detector and the gas supply shutoff circuit. The controller is adapted to actuate the gas supply shutoff circuit and sound an audible alarm in response to detection by the carbon monoxide detector of a predetermined level of carbon monoxide.

Owner:BROWN DELTON R

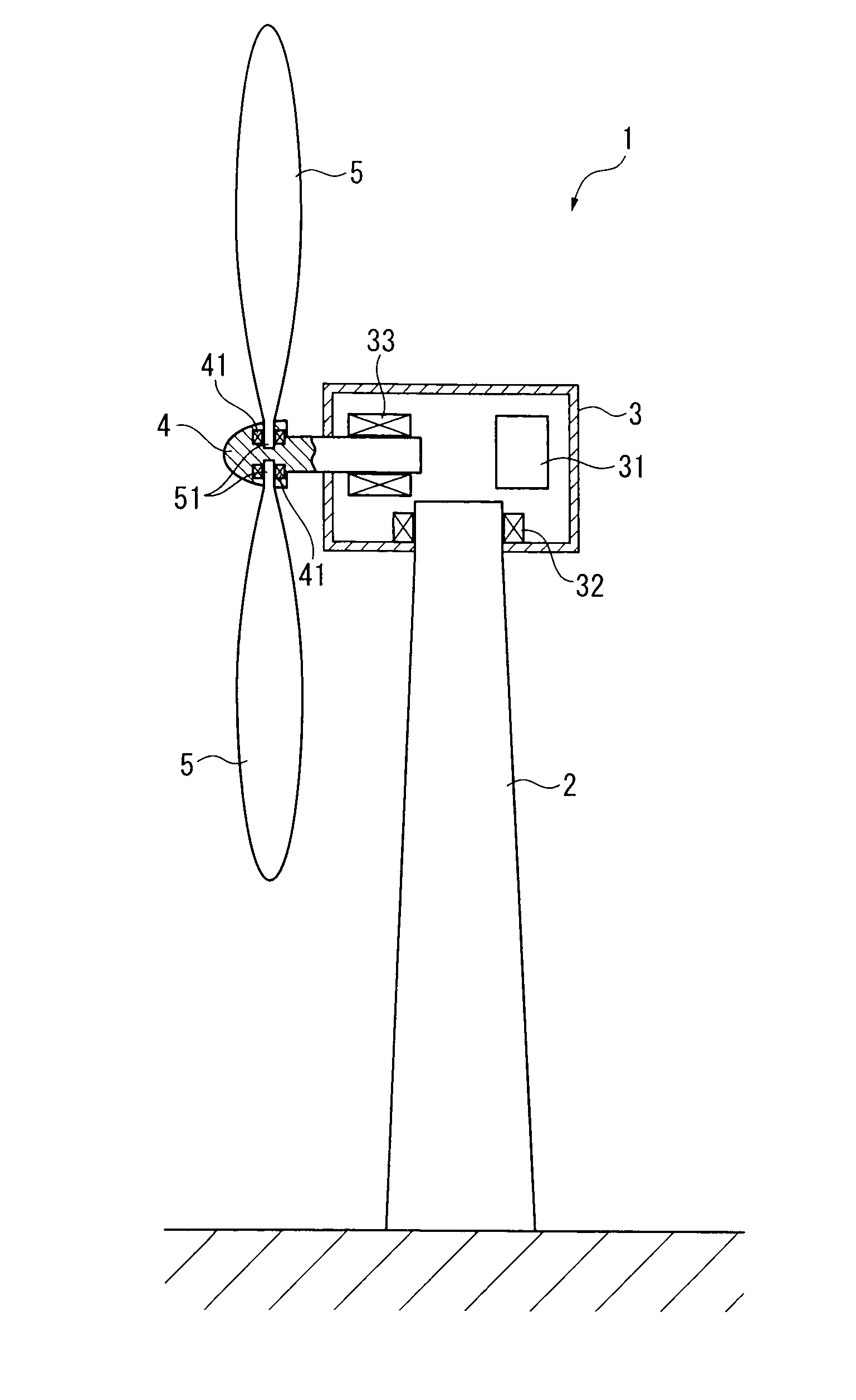

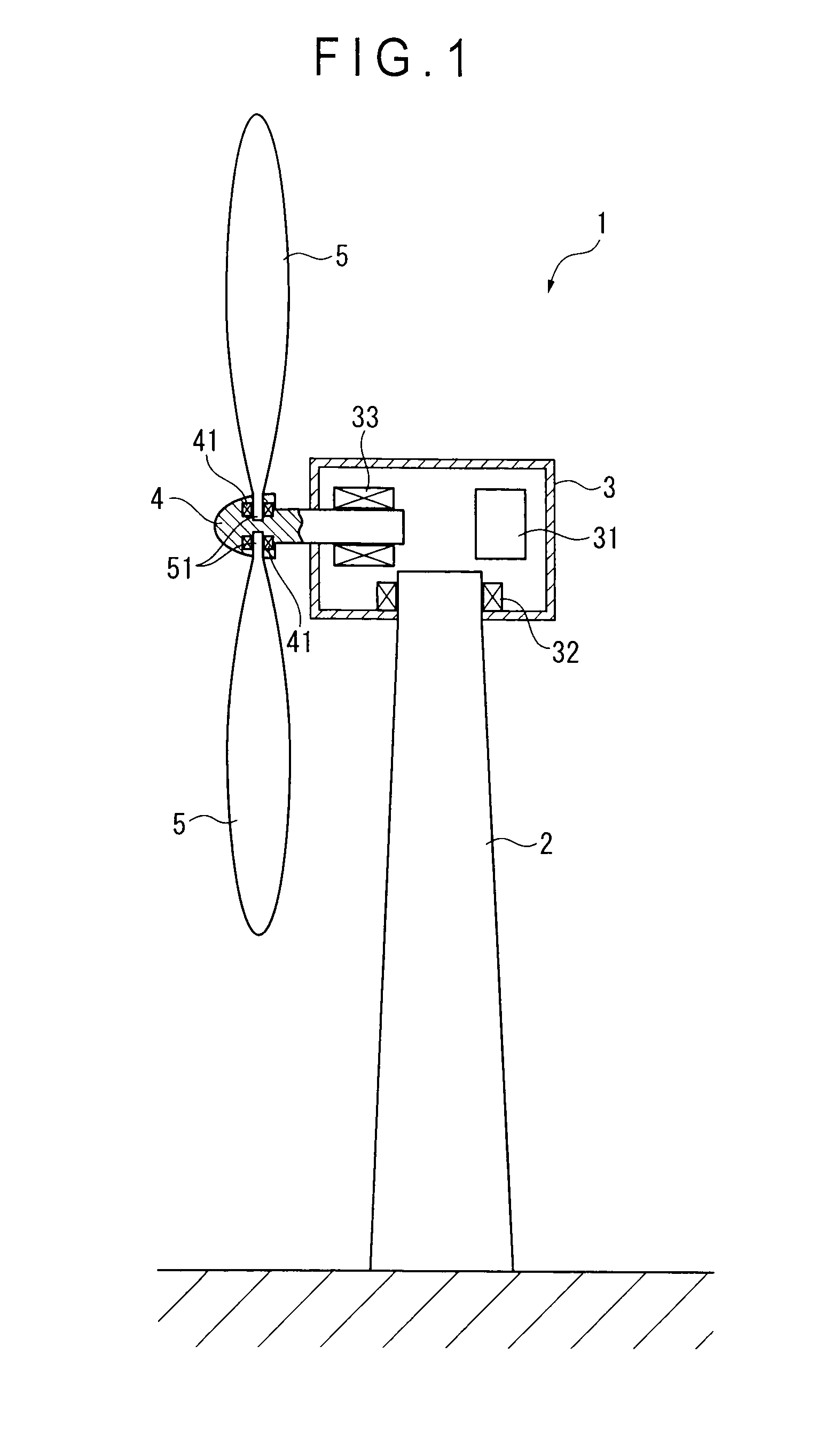

Viscosity index improver, method for producing same, and oil composition

Owner:KURARAY CO LTD +1

Emulsion Composition

Owner:THE LUBRIZOL CORP

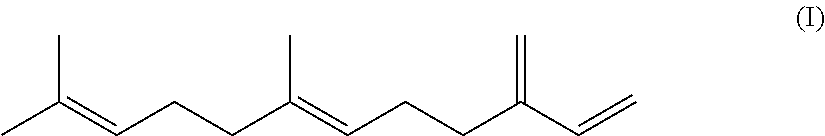

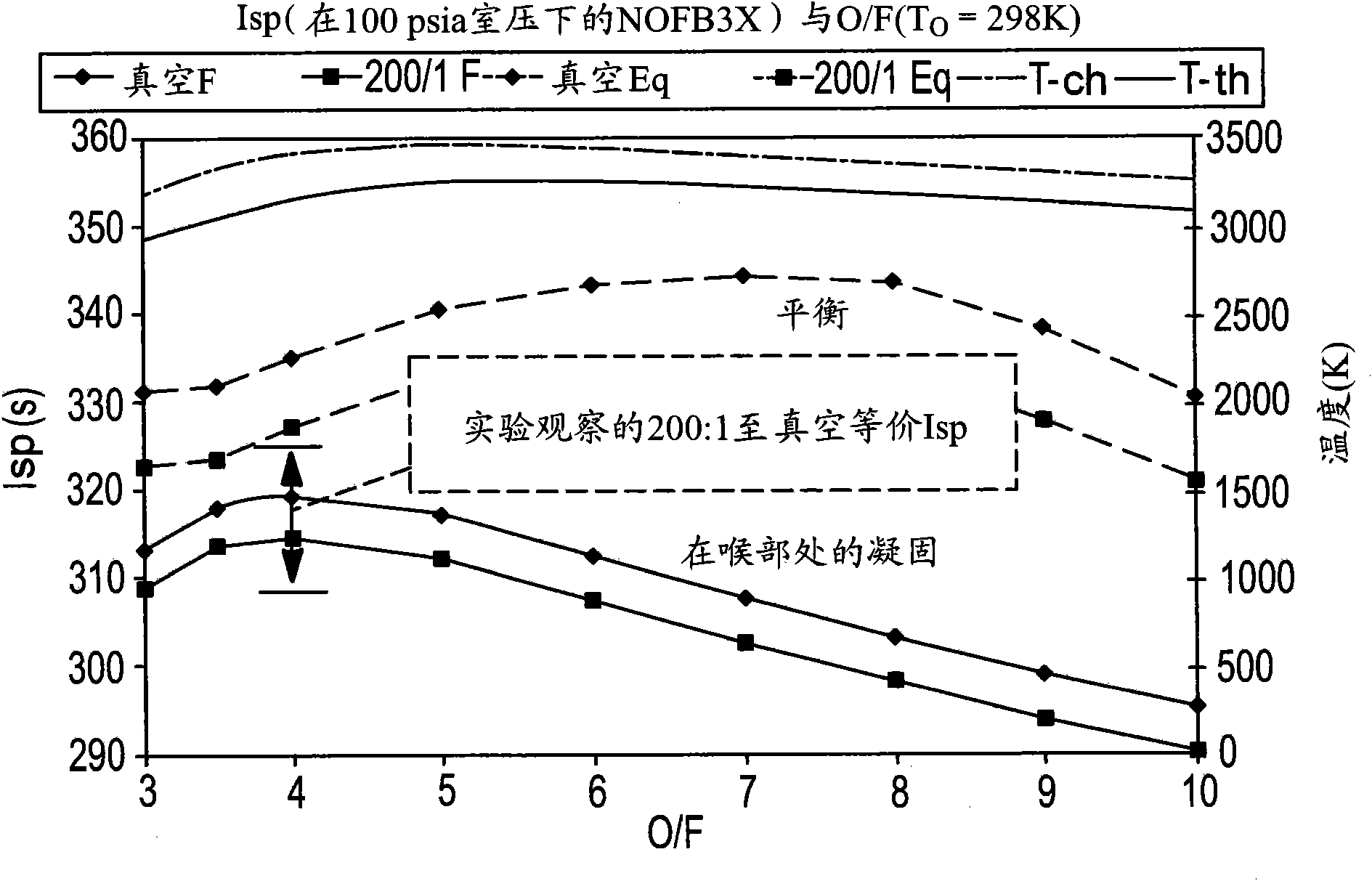

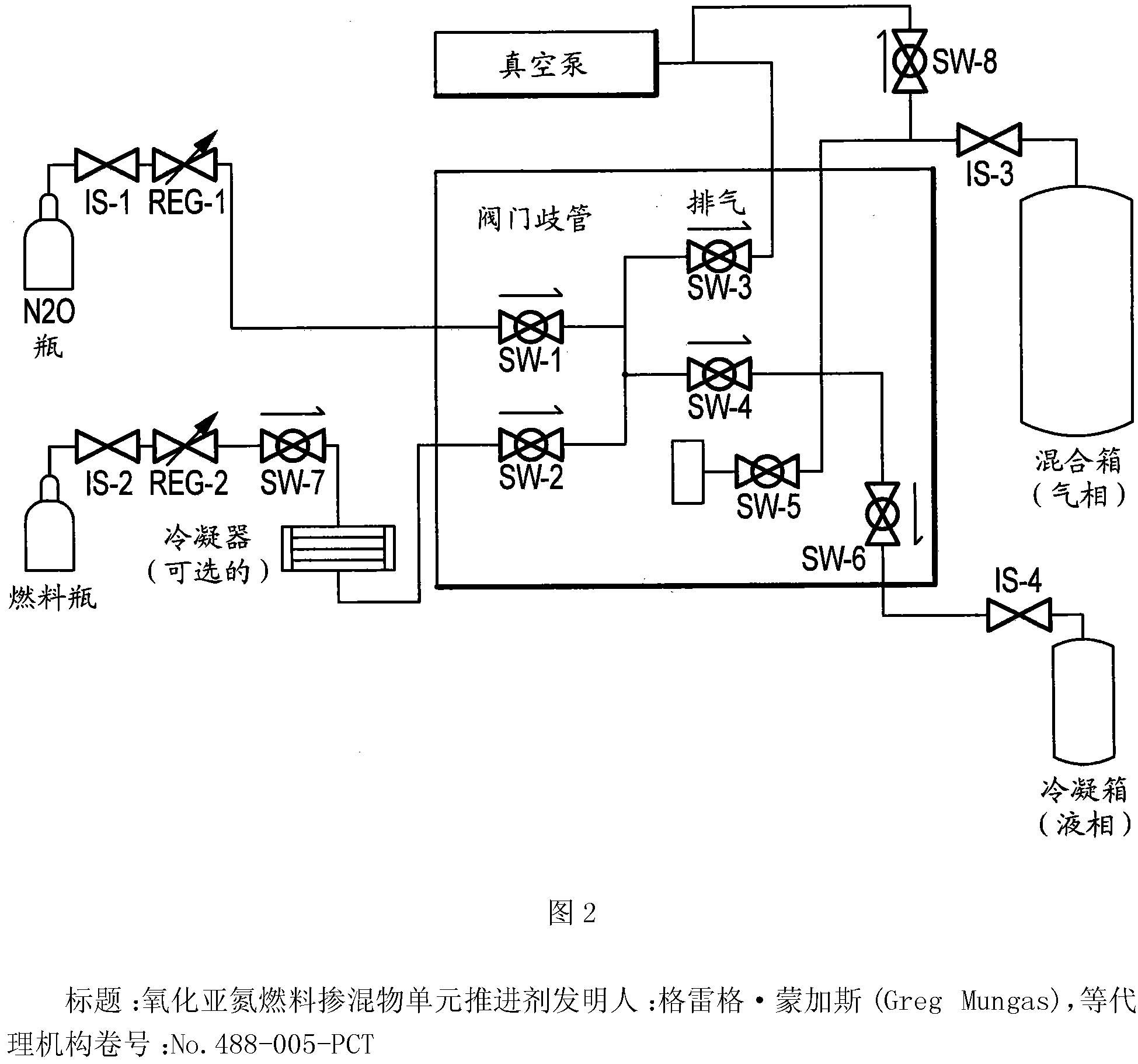

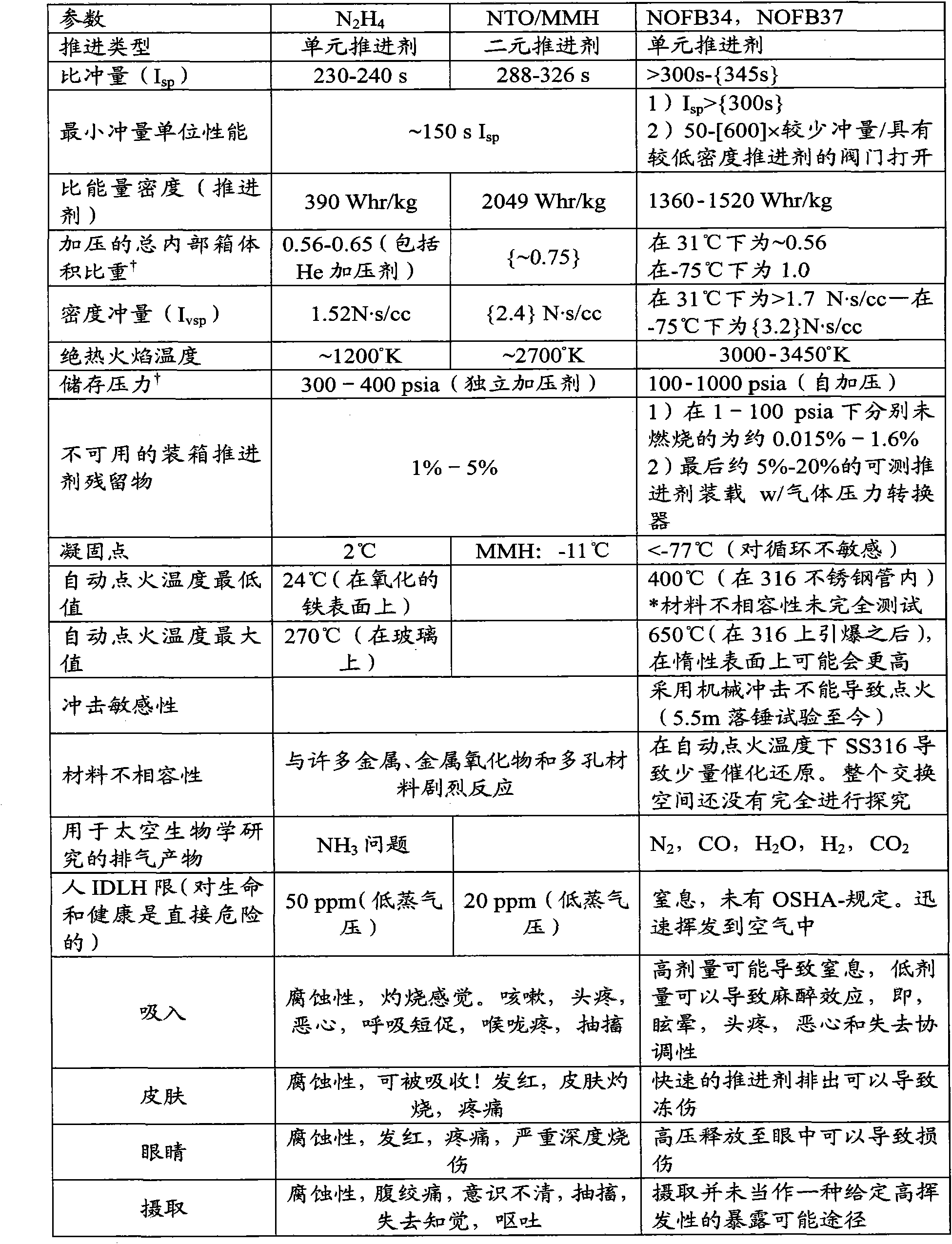

Nitrous oxide fuel blend monopropellants

Owner:FIRESTAR ENG

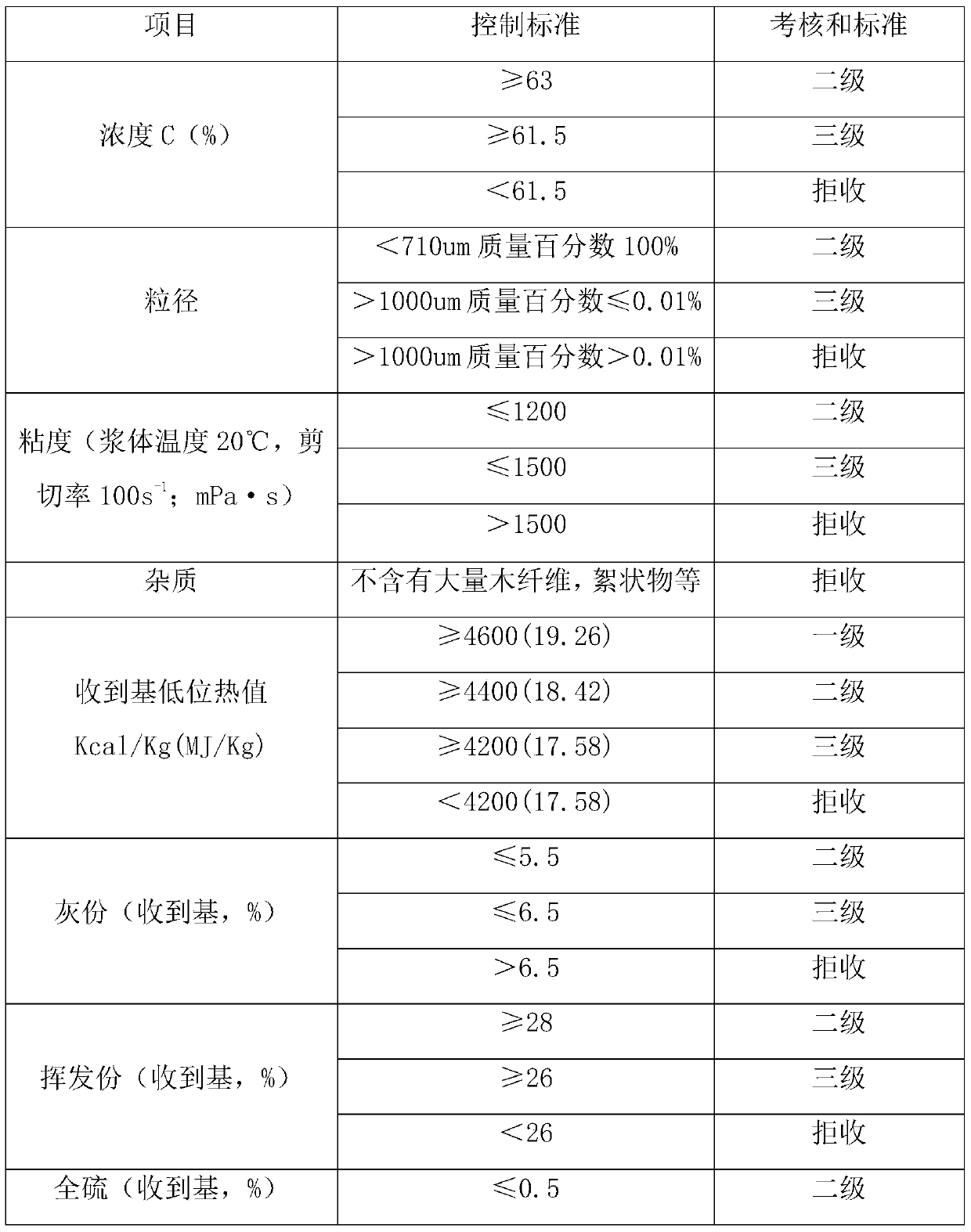

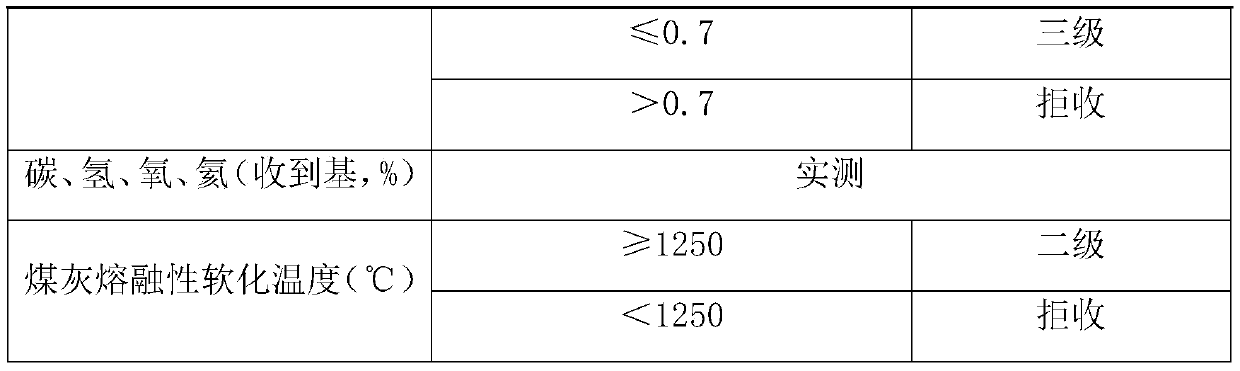

Method for preparing sodium polystyrenesulfonate by sulfonating waste polystyrene and application of sodium polystyrenesulfonate in coal water slurry

InactiveCN113430022AReduce manufacturing costIncrease concentrationLiquid carbonaceous fuelsCoal waterRotary evaporator

The invention discloses a method for preparing sodium polystyrenesulfonate by sulfonating waste polystyreneand application of the sodium polystyrenesulfonate in coal water slurry. The preparation method comprises the following steps: step 1, cleaning and drying waste polystyrene foam; step 2, adding the waste polystyrene foam dried in the step 1 and an organic solvent into a container, and performing mechanical stirring to completely dissolve the waste polystyrene foam and the organic solvent; step 3, adding a sulfonating agent into the solution obtained in the step 2, and after the sulfonating agent is degraded, performing heating, and performing sulfonation reaction; and step 4, after the sulfonation reaction is finished, recovering the organic solvent by using a rotary evaporator, and adding a sodium hydroxide aqueous solution into a reaction product to obtain a sodium polystyrene sulfonate solution. The sodium polystyrenesulfonate prepared from the waste polystyrene can be used as a coal water slurry additive to realize clean utilization of coal resources, waste is turned into wealth, and social benefits and ecological benefits are remarkable. The preparation method has the advantages of simplicity in operation, short flow, high industrial application value and the like.

Owner:NANJING UNIV

Alcohol-ether-ester methanol fuel

Owner:东奇能源技术有限公司

Fuel oil additive mixture

Owner:黄慧娟

Micro-emulsified methanol diesel dispersing agent and application thereof

The invention provides a micro-emulsified methanol diesel dispersing agent which mainly comprises an emulsifier, a solubilizer and a stabilizer. The emulsifier is one or a compound of Span80 and Tween 80, the solubilizer is one or a compound of two of C10-C20 long-chain fatty acids and C6-C14 fatty alcohol, and the stabilizer is one of C8-C9 dicarboxylic acid monoester, glycol ether and propylene glycol ether. When the content of the emulsifier is 0.05-1 w%, the content of the solubilizer is 4-25 w%, and the content of the stabilizer is 0.05-1 w%, the micro-emulsified methanol and diesel mixed fuel with the methanol content of 5-50 w% can be prepared. The micro-emulsified methanol diesel dispersing agent is simple and convenient in dispersing process and easy to operate, has the characteristics of wide additive source, relatively low price and simple preparation process, and is beneficial to popularization and application. And compared with the traditional dispersant, the dispersing agent has a good micro-emulsification effect, is environment-friendly and belongs to an environment-friendly methanol diesel dispersant.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Gasoline environmental-protection and energy-saving additive and environmental-protection and energy-saving gasoline

InactiveCN106590775AReduce consumptionImprove synchronous combustionLiquid carbonaceous fuelsEngineeringPetroleum

Owner:国科蓝天清洁能源技术有限公司

Efficient engine-cleaning and power-increasing liquid as well as preparation method and application thereof

InactiveCN108300527ANo pollution in the processImprove the stability of useLiquid carbonaceous fuelsFuel additivesEthyleneglycol monobutyl etherMethyl carbonate

The invention provides efficient engine-cleaning and power-increasing liquid as well as a preparation method and application thereof. The efficient engine-cleaning and power-increasing liquid is prepared from the following components in percentage by volume: 5 percent to 10 percent of methyl tert-butyl ether, 10 percent to 20 percent of dimethyl carbonate, 5 percent to 10 percent of ethylene glycol monobutyl ether, 5 percent to 10 percent of xylol, 10 percent to 20 percent of tert-butyl alcohol, 5 percent to 10 percent of isopropyl acetate, 5 percent to 10 percent of dilinoleic acid, 10 percent to 20 percent of polymethoxydimethyl ether, 1 percent to 5 percent of ethanolamine and 1 percent to 5 percent of ester amide quaternary ammonium salt. By adopting the efficient engine-cleaning and power-increasing liquid provided by the invention, the utilization stability of ethanol gasoline can be improved, deposited carbon is reduced, an engine is cleaned and tail gas emission is reduced. Theefficient engine-cleaning and power-increasing liquid is also applicable to gasoline for vehicles; the efficient engine-cleaning and power-increasing liquid is added according to the ratio on the basis of adding national standard gasoline; meanwhile, the efficient engine-cleaning and power-increasing liquid has functions of enhancing vehicle power, improving the utilization stability of fuel, cleaning the engine and reducing the tail gas emission.

Owner:SHAANXI YANENG QIANGLI CLEAN ENERGY CO LTD

Esterification reaction tower for producing biodiesel

InactiveCN103224838ABlocking dischargeExtended reaction timeFatty acid esterificationBiofuelsBiodieselHeat conducting

The invention discloses an esterification reaction tower for producing biodiesel. The invention is characterized by mainly comprising a tower body, a redistributor, deflector plates, an access hole, a distributor, a gas-phase methanol inlet, a discharge port, a water outlet, a heat-conducting oil inlet, a heat-conducting oil outlet, a heat-conducting oil jacket, a feed port, a water inlet, a safety valve, a thermometer, a pressure meter and a gas-phase methanol outlet, wherein the outer bottom of the tower body is respectively provided with the gas-phase methanol inlet and water outlet; the distributor on the inner bottom is communicated with a pipeline of the gas-phase methanol inlet; the lower part is provided with the heat-conducting oil jacket, heat-conducting oil inlet, heat-conducting oil outlet and access hole; the inner top is provided with the redistributor; the inner cylindrical wall is uniformly distributed with the plurality of deflector plates; and the outer top is provided with the feed port, water inlet and gas-phase methanol outlet. The invention has the characteristics of no need of catalyst, no environmental pollution, low reaction pressure, low reaction temperature, low energy consumption, low investment and operating cost, wide application range of raw materials, high yield and the like.

Owner:YANGGU KAIGE NEW ENERGY BIOTECHNOLOGY CO LTD

Novel modified fuel methanol

Owner:长沙誉洲新能源科技有限公司

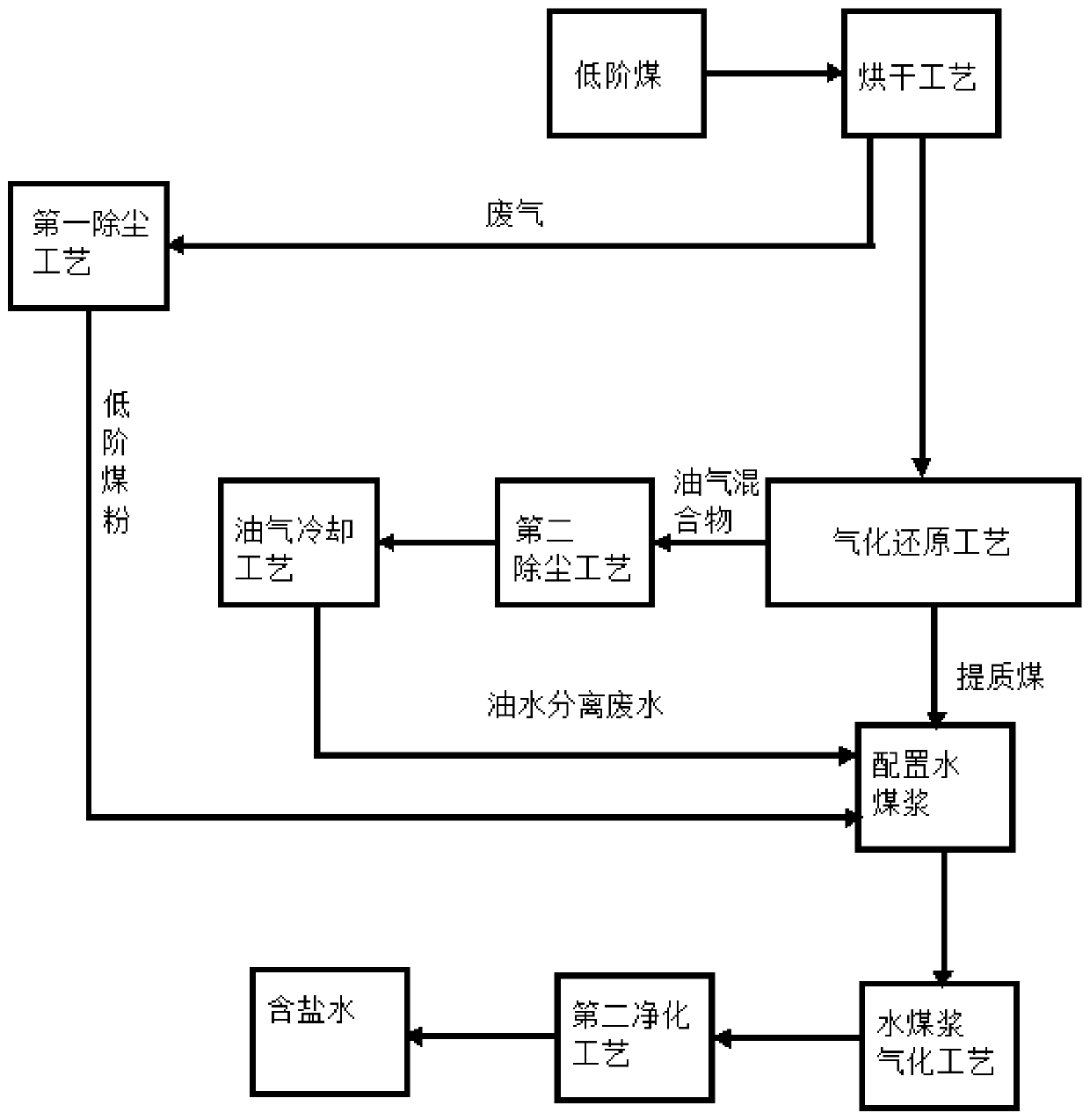

Method for harmlessly treating organic wastewater of quality-based utilization of low-rank coal

PendingCN110055105AReduce moisture contentHigh COD valueGasification processes detailsLiquid carbonaceous fuelsSyngasCoal water

Owner:浙江天禄环境科技有限公司

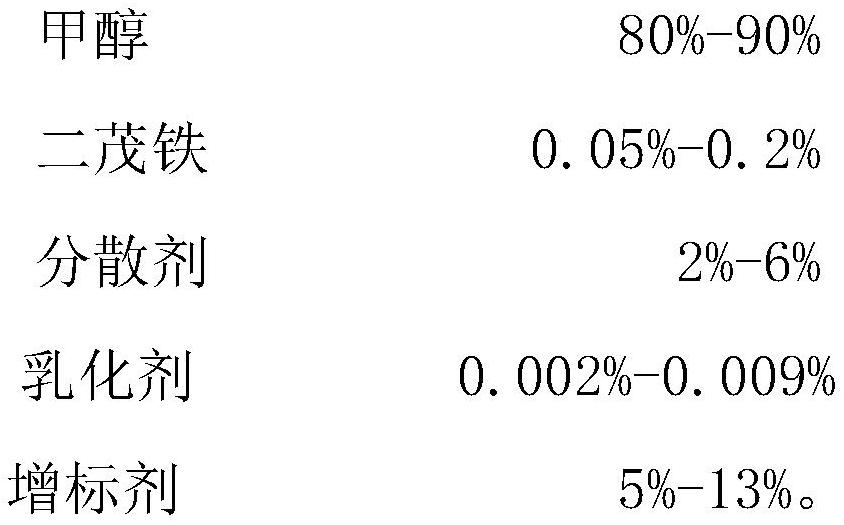

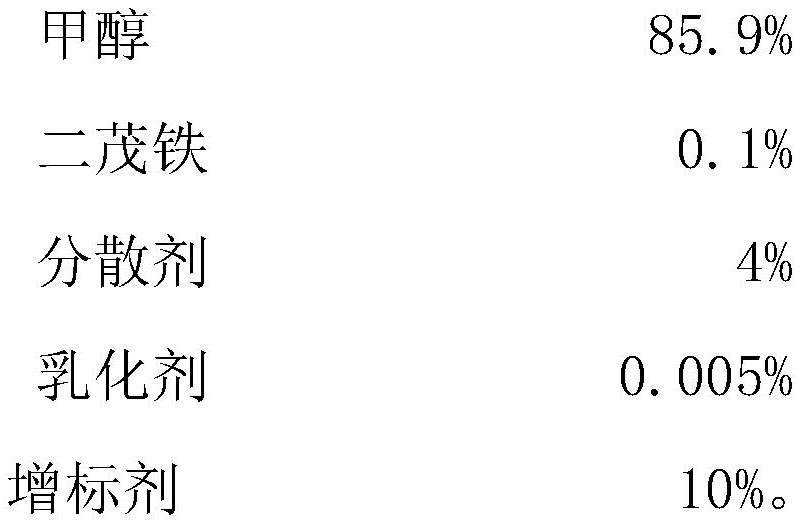

High-cleanliness gasoline additive and preparation method thereof

PendingCN114525158AInternal combustion piston enginesLiquid carbonaceous fuelsChemistryCombustion chamber

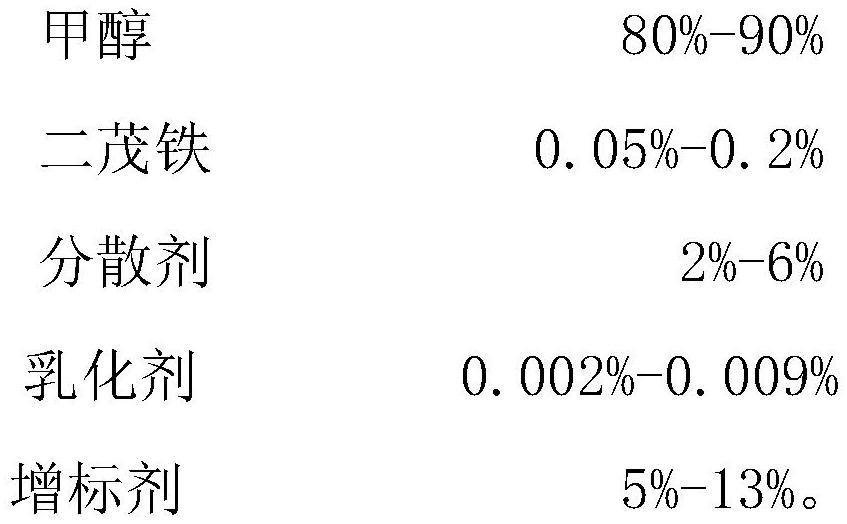

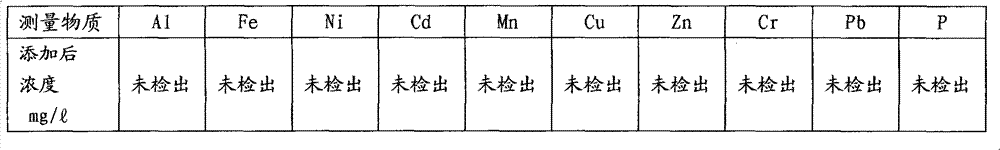

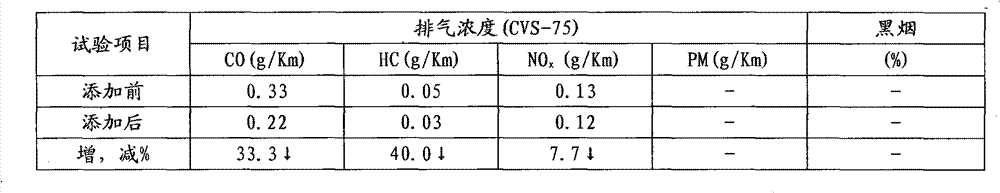

The invention discloses a high-cleanliness gasoline additive and a preparation method thereof, and the additive is prepared from the following raw materials by mass: 80%-90% of methanol; 0.05% to 0.2% of ferrocene; 2%-6% of a dispersant; 0.002% to 0.009% of an emulsifier; and 5%-13% of a standard increasing agent. The raw materials are mixed and stirred. The lubricating oil has the effects of improving power, promoting combustion acting, resisting oxidation and wear, cleaning, dispersing, demulsifying, preventing corrosion, lubricating and the like, and can improve heat efficiency, reduce oil consumption and reduce emission. The engine body abrasion of a combustion system is reduced, an oil way is smooth, the service life of the engine body is prolonged, the maintenance frequency is reduced, the tail gas of an engine is obviously purified, hydrocarbon and carbon monoxide in the tail gas of a gasoline engine are reduced, meanwhile, emission of NOx and solid particles can be reduced, fuel oil in a combustion chamber of the engine is combusted more sufficiently, and the oil-saving effect is achieved; and the oil-saving effect of gasoline with low grade is more obvious.

Owner:上海援鸣新能源科技集团有限公司

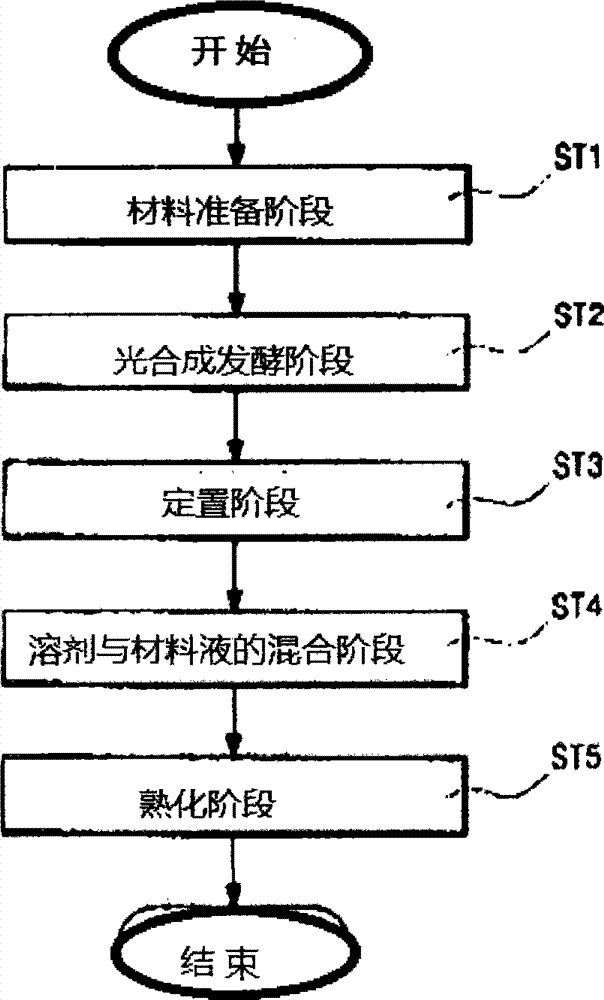

Fuel additive for promoting combustion of liquid fuels and manufacturing method thereof

InactiveCN102952591ASave fuelLower discharge temperatureLiquid carbonaceous fuelsFermentationIodineAtmospheric temperature

Owner:程刚

Methanol fuel safety additive an dits adding method

Owner:山西佳新能源化工实业有限公司

Biodiesel refining method

InactiveCN106433947AImprove harvesting efficiencyEliminates the drying stepFatty acid esterificationBiofuelsBiodieselEngineering

Owner:QINGDAO WINCHANCE TECH

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap