Fuel additive for promoting combustion of liquid fuels and manufacturing method thereof

A fuel additive, liquid fuel technology, applied in the liquid carbon-containing fuel, fuel, petroleum industry and other directions, can solve the problems of low metal content, rising exhaust temperature, lowering exhaust temperature, etc., and achieve the amount of air pollutants. The effect of reducing, improving combustion efficiency, and reducing exhaust gas temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

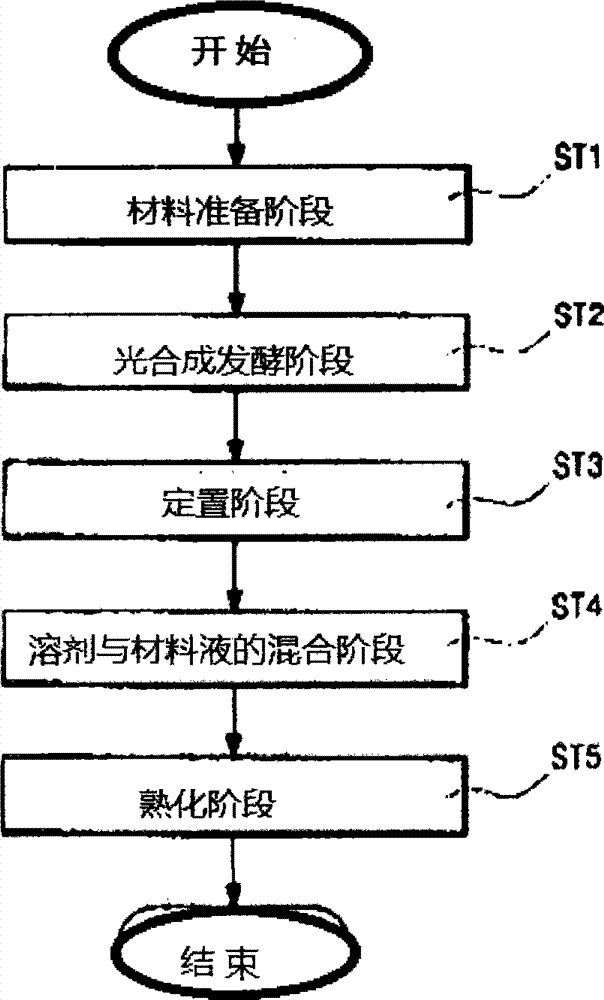

Method used

Image

Examples

example 2

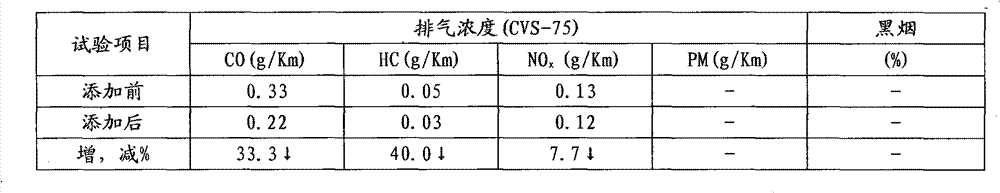

[0056] After adding the fuel additive according to the present invention to bunker oil-C for use, compare and measure its ignition point, residual carbon element, ash content, sulfur content and calorific value before and after use. The results are shown in Table 3.

[0057]

[0058] Table 3 adds the test result of fuel additive of the present invention to marine fuel oil (bunker oil-C)

[0059] It can be seen from the above table 3 that when the fuel additive according to the present invention is added to bunker oil-C, the ignition point is lower than before the addition, and the amount of residual carbon, ash and sulfur decreases.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap