Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

113 results about "Magnesium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

This medication is a mineral supplement used to prevent and treat low amounts of magnesium in the blood. Some brands are also used to treat symptoms of too much stomach acid such as stomach upset, heartburn, and acid indigestion.

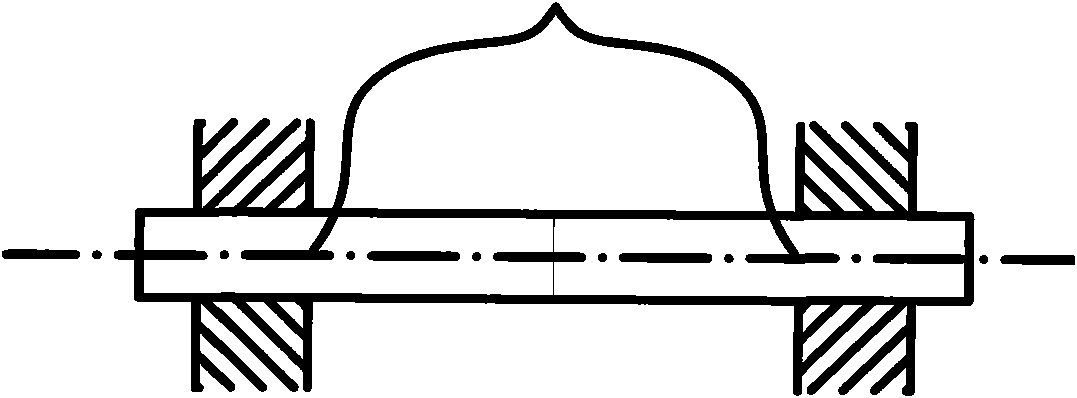

Method for enhancing surface of magnesium aluminium alloy by laser remelting

InactiveCN101532134AHigh strengthImprove corrosion resistanceMolten spray coatingSuperimposed coating processOxygenLaser beams

The invention relates to a method for enhancing the surface of magnesium aluminium alloy by laser remelting, aiming at enhancement processing of the surfaces of magnesium aluminium alloy plates and magnesium aluminium alloy rods by the methods of flame spraying of alloyed powder and laser remelting. The method is characterized by cleansing the surface of the magnesium aluminium alloy, carrying out oxy-acetylene flame spraying on the alloyed powder, namely aluminium nickel alloy powder, nickel-chromium-boron-silicon-iron master alloy powder and neodymium powder, carrying out remelting and curing on the surface of the magnesium aluminium alloy on a laser processor, carrying out omnibearing radiation by laser beams according to trace curves set by computer programs so that a nickel base alloy layer is melted and cured on the surface of the magnesium aluminium alloy to form the alloy layer, therefore, the hardness of the surface of magnesium aluminium alloy is greatly improved by 8-10 times as high as that before processing, the wearing resistance and corrosion resistance of the surface of magnesium aluminium alloy are greatly improved respectively by 56% and 56.4%. The method has short process flow, easy realization, safety, stability and reliability and firm solid melting layer, is not easy to fall off and can enhance the surfaces of the magnesium aluminium alloys with various profiles.

Owner:TAIYUAN UNIV OF TECH

Cement composition

InactiveUS20050016421A1High strengthImprove abilitiesOrganic fertilisersSoil conditioning compositionsPhosphateSilicic acid

To provide a novel cement which is alkalescent, capable of solidifying a wide range of soil and applicable to biological environment. That is, a cement composition comprising 100 parts by weight of magnesium oxide comprising 5 to 25% by weight of at least any one of silicic acid, alumina and iron oxide, 3 to 35 parts by weight of a phosphate, 2 to 30 parts by weight of gypsum and 0.005 to 7 parts by weight of an oxycarboxylic acid or a ketocarboxylic acid.

Owner:NAT AGRI & FOOD RES ORG +1

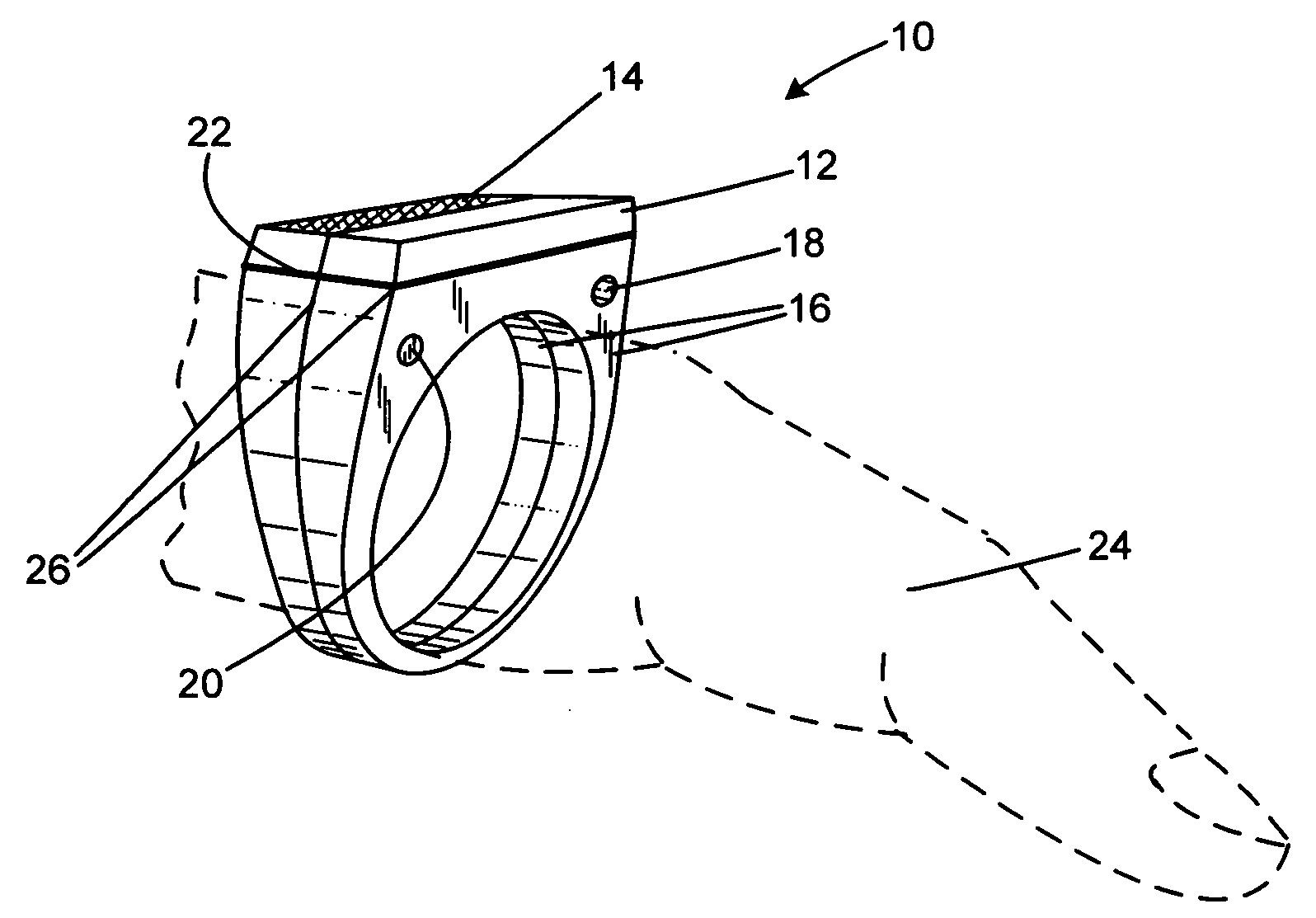

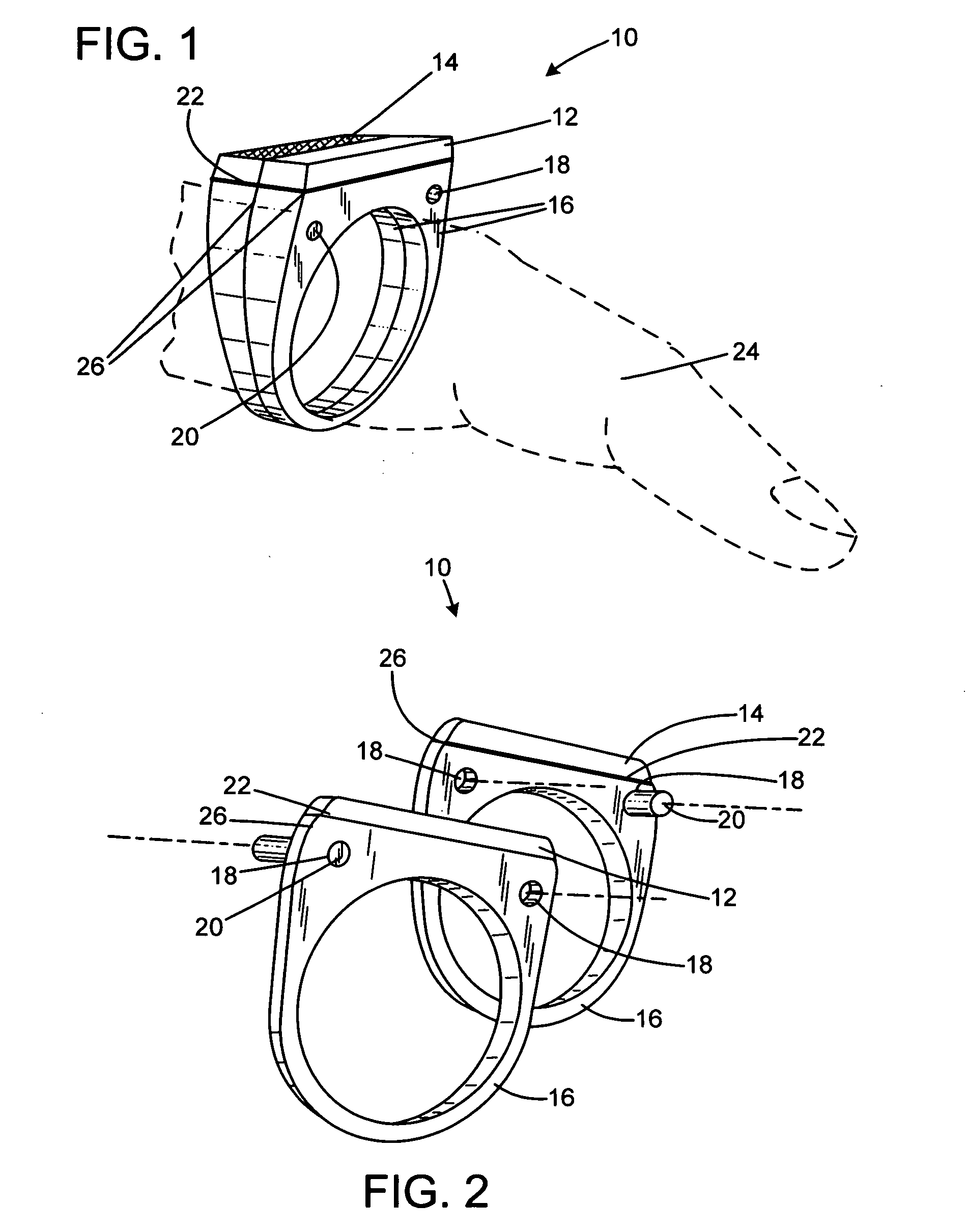

Wearable firestarter

Owner:WOODWARD JOEL

Rare earth aluminum alloy wire for thermal spraying

Owner:JIANGSU CUMT DAZHENG SURFACE ENG TECH

Method for desulphurizing, denitrating and decoking fire coal

The invention discloses a method for desulphurizing, denitrating and decoking fire coal. In the method, in a raw coal burning stage, a synergist is added in an amount of 0.2 to 0.3 weight percent based on the total weight of the raw coal into the fire coal, and a catalytic active agent is added in an amount of 0.002 to 0.008 weight percent based on the total weight of the raw coal into a slurry boax in a desulphurizing system at the same time. The synergist comprises 8 to 25 mass percent of calcium carbona, 5 to 15 mass percent of magnesium oxide, 5 to 10 mass percent of silicon dioxide, 5 to10 mass percent of zinc oxide, 8 to 10 mass percent of manganese dioxide, 15 to 40 mass percent of calcium oxide, 5 to 10 mass percent of barium hydroxide, 3 to 8 mass percent of aluminum oxide and 8to 15 mass percent of potassium permanganate; and the catalytic active agent comprises 0 to 40 mass percent of active calcium oxide, 20 to 30 mass percent of active carbon, 10 to 15 mass percent of calcium ammonium nitrate, 5 to 20 mass percent of ferric oxide and 2 to 10 percent of zinc oxide. Under the condition of not changing the conventional boiler equipment and process, the method can realize fire coal combustion-supporting and coal-saving functions at one time so as to perform desulphurization, denitration and decoking.

Owner:GUANGZHOU ZHONGKE GAOCHENG ENVIRONMENTAL PROTECTION TECH CO LTD

Acetylacetone based composite heat stabilizer

InactiveCN101508636AImprove thermal stabilityPreparation of aldehyde/ketone chelatesAcetylacetoneMagnesium

The invention provides an acetylacetone-based composite thermal stabilizer which is a mixture obtained by mixing zinc acetylacetonate, calcium acetylacetonate or magnesium acetylacetonate and hydrotalcite pro rata. The composite thermal stabilizer is suitable for chloride-containing high polymer, such as polyvinyl chloride, chlorinated polyethylene, chlorinated polyvinyl chloride, copolymer of vinyl chloride-ethylene or copolymer of vinyl chloride-vinyl acetate, has better thermal stability, prolongs the thermal aging time of the chloride-containing high polymer, and overcomes the shortcomings of poor long-term performance of single stabilizer of zinc acetylacetonate, poor transparency of stabilizer of calcium acetylacetonate, and poor initial colorability of stabilizer of hydrotalcite. The composite thermal stabilizer has low cost, good initial colorability, excellent long-term performance and good transparency, and is an efficient composite thermal stabilizer.

Owner:BEIJING UNIV OF CHEM TECH

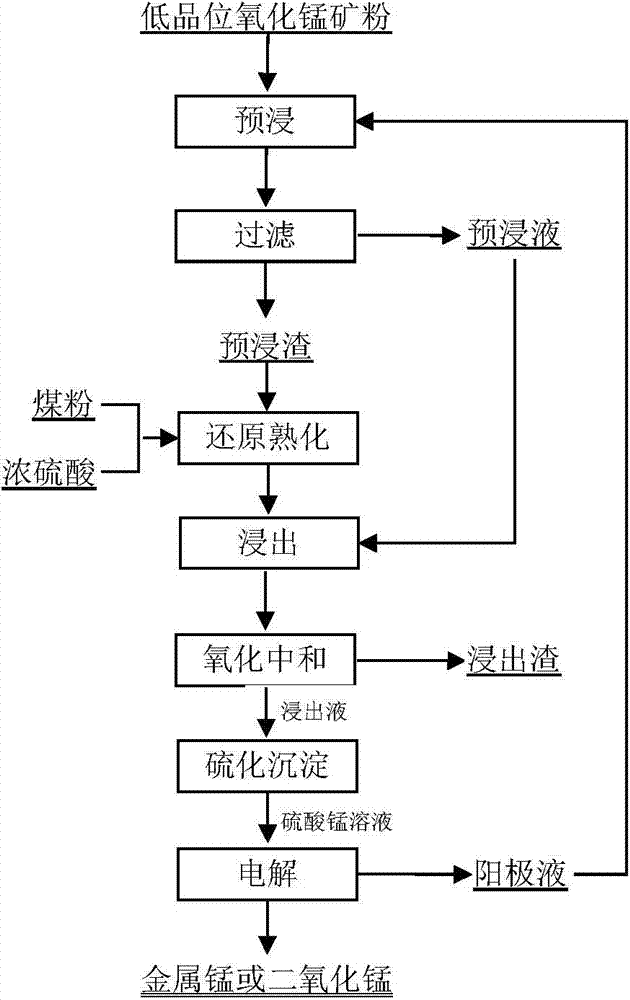

Solution preparation method for producing electrolytic manganese or manganese dioxide from low-grade manganese oxide ores

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

Lubricating oil special for motorcycle engine and preparing method thereof

ActiveCN104031729AExtended service lifeThe steps are simple and environmentally friendlyLubricant compositionAntioxidantViscosity index

The invention discloses a lubricating oil special for a motorcycle engine, and belongs to the technical field of lubricating oil. The lubricating oil is obtained through a reaction carried out on 80 parts to 90 parts of base oil, 2 parts to 5 parts of abrasion resistance agents, 5 parts to 10 parts of corrosion resistance agents, 2 parts to 5 parts of cleaning factors, 5 parts to 15 parts of antioxidant, 1 part to 3 parts of metal deactivator and 8 parts to 12 parts of viscosity modifier. The base oil is composed of 30 parts to 40 parts of PAO and 40 parts to 50 parts of naphthenic base oil. The cleaning factors are any one of metal-based sodium or metal-based calcium or metal-based magnesium. The invention further discloses a preparing method of the lubricating oil. According to the lubricating oil special for the motorcycle engine, the cost of the base oil is controlled, and the better viscosity index and the high abrasion resistance performance can be ensured at the same time; viscous black carbon mud particles wrapped on engine parts can be effectively removed through matched addition of auxiliaries, the service life of the engine is prolonged, the equipment maintenance cost is reduced, and the clean abrasion protection mode is provided for the motorcycle engine. The preparing method of the lubricating oil is simple in steps, environmentally friendly, and easy to implement.

Owner:BAOJIE LUBRICATING OIL ZHENJIANG CO LTD

Cast aluminum alloy high in thermal conductivity

Owner:天津凯鑫程铝业股份有限公司

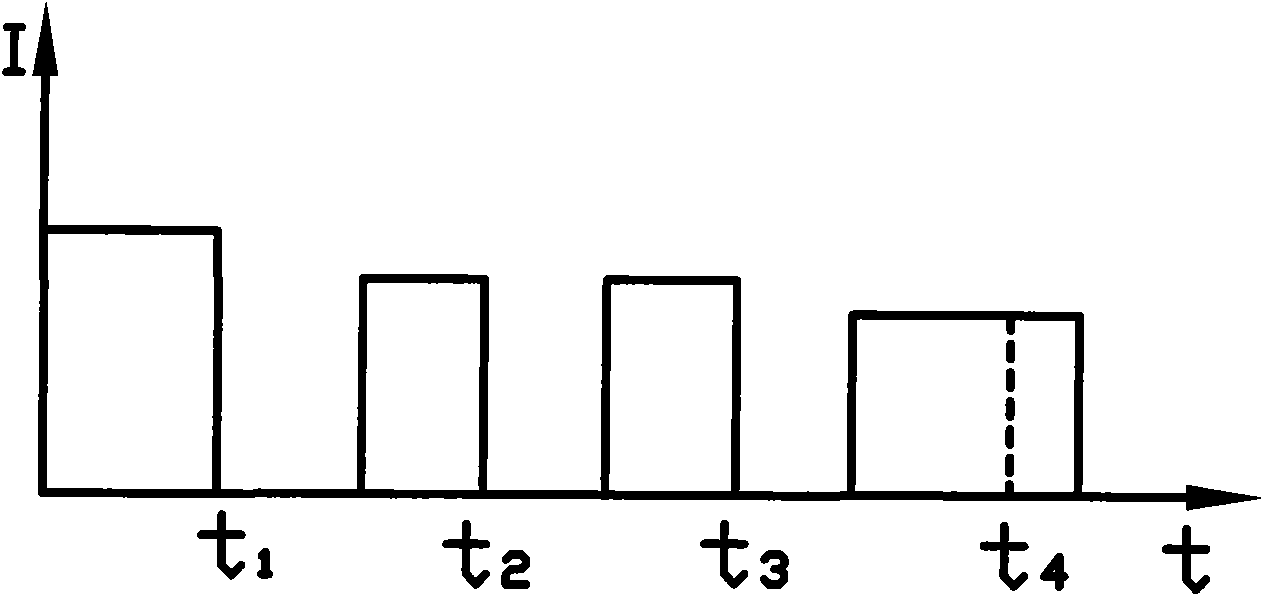

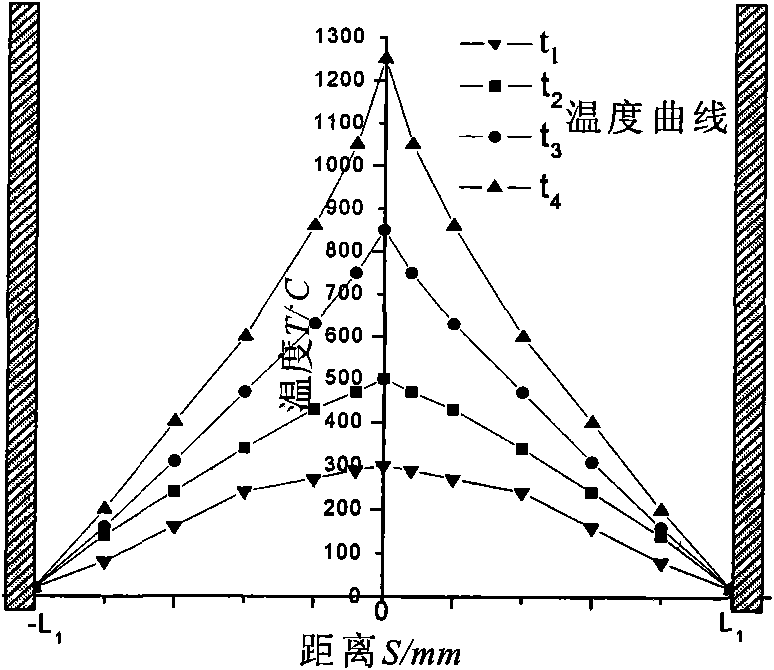

Butt welding method of small caliber metallic resistances

ActiveCN101596643ALess heat productionReduce the impactResistance welding apparatusButt weldingEngineering

Owner:BEIJING UNIV OF TECH

Method for extracting lithium from brine to prepare battery-grade lithium carbonate by ion exchange method

ActiveCN106629789AHigh recovery rateLarge particle sizeHydrotalciteLithium carbonates/bicarbonatesDesorptionManganese

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

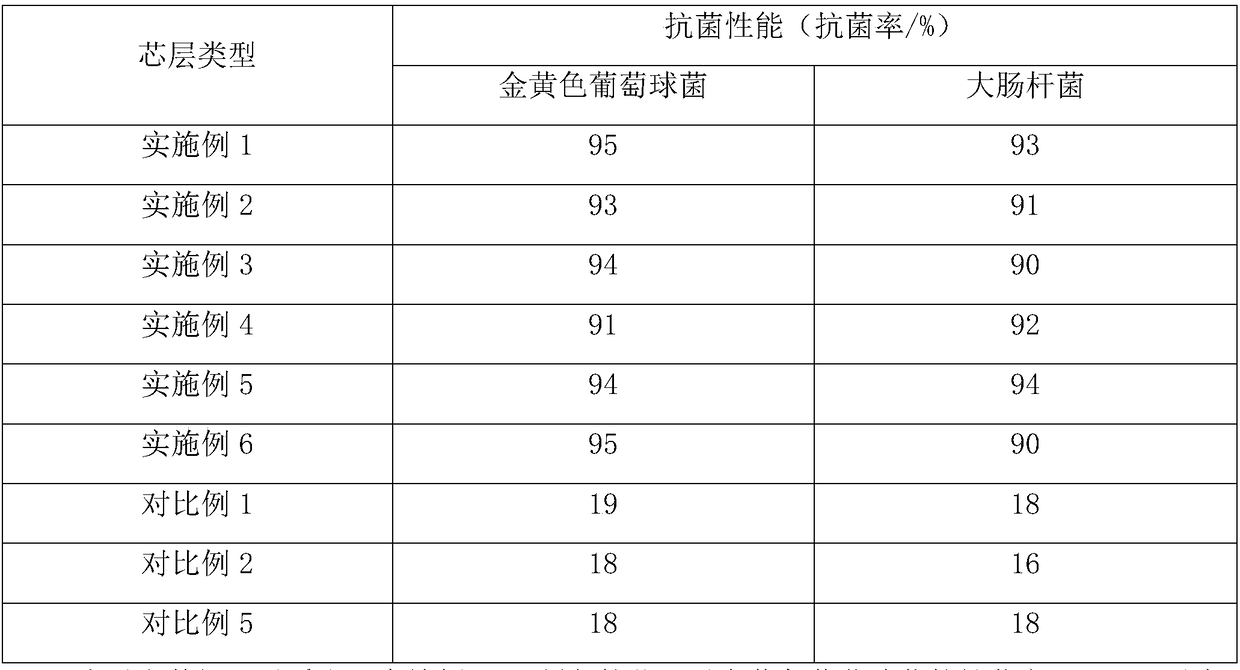

Aluminum plastic plate flame-retardant core layer and aluminum-plastic plate

ActiveCN109111617AReduce corrosionExtended service lifeSynthetic resin layered productsMetal layered productsLow-density polyethyleneAntioxidant

Owner:台州市佳信新材料科技有限公司

Oil resistant rubber

The invention discloses an oil resistant rubber, which is composed of the following components by weight: 40-60 parts of fluorine rubber, 20-30 parts of natural rubber, 10-15 parts of nitrile rubber, 20-40 parts of carbon black, 15-30 parts of white carbon black, 0.5-2 parts of antioxidant RD, 1-2 parts of antioxidant 4010 Na, 2-4 parts of paraffin, 25-35 parts of light calcium carbonate, 2-3 parts of eleaostearic acid, 3-5 parts of zinc oxide, 5-10 parts of magnesium oxide, 1-2 parts of 2, 2'-dibenzothiazyl disulfide, 3-4 parts of coumarone and 0.2-0.8 parts of vulcanizing agents. The oil resistant rubber provided by the invention has the advantages of oil resistance, airtight and good high temperature resistance.

Owner:GUANGZHOU CHONGQI IND CO LTD

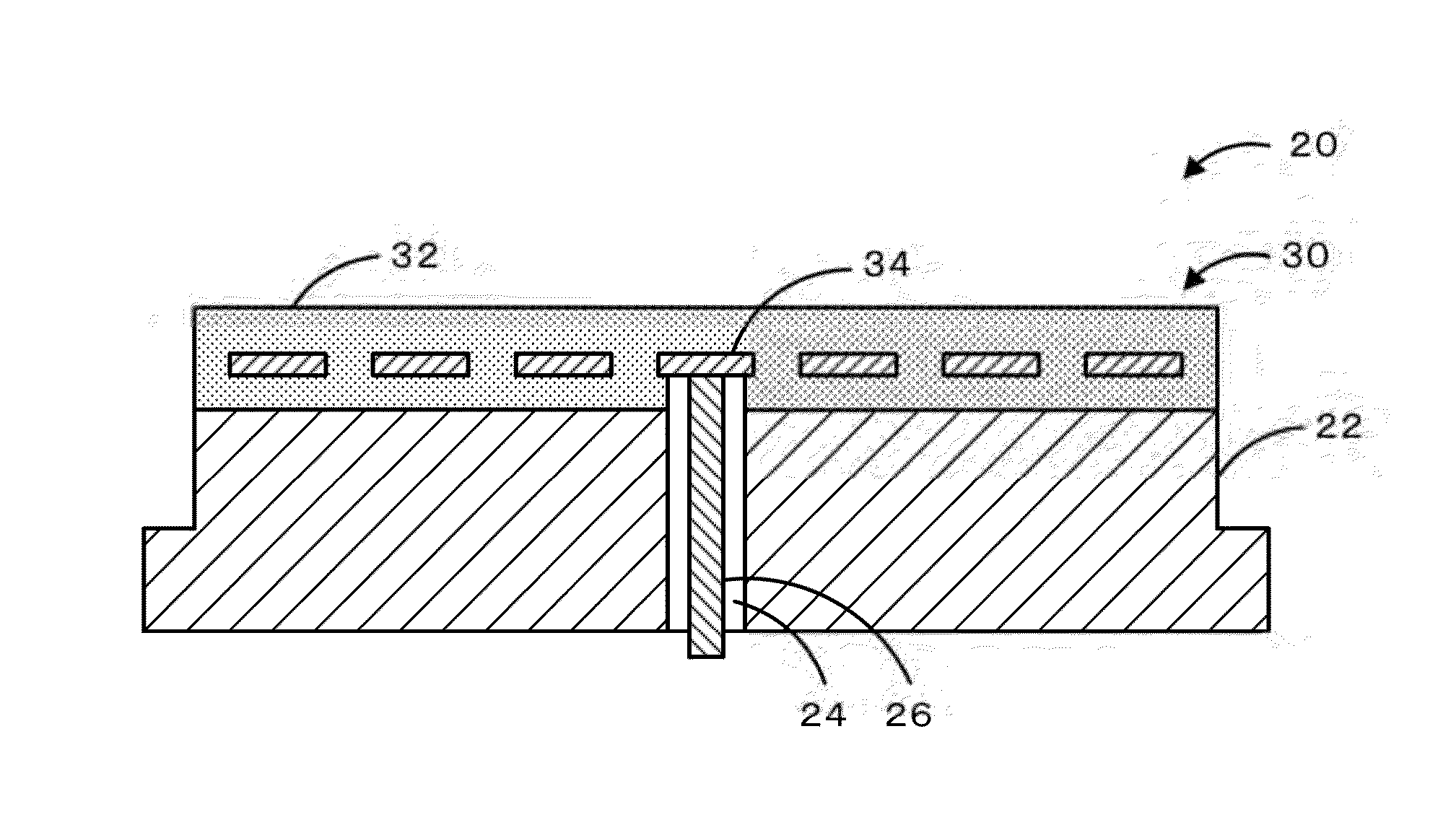

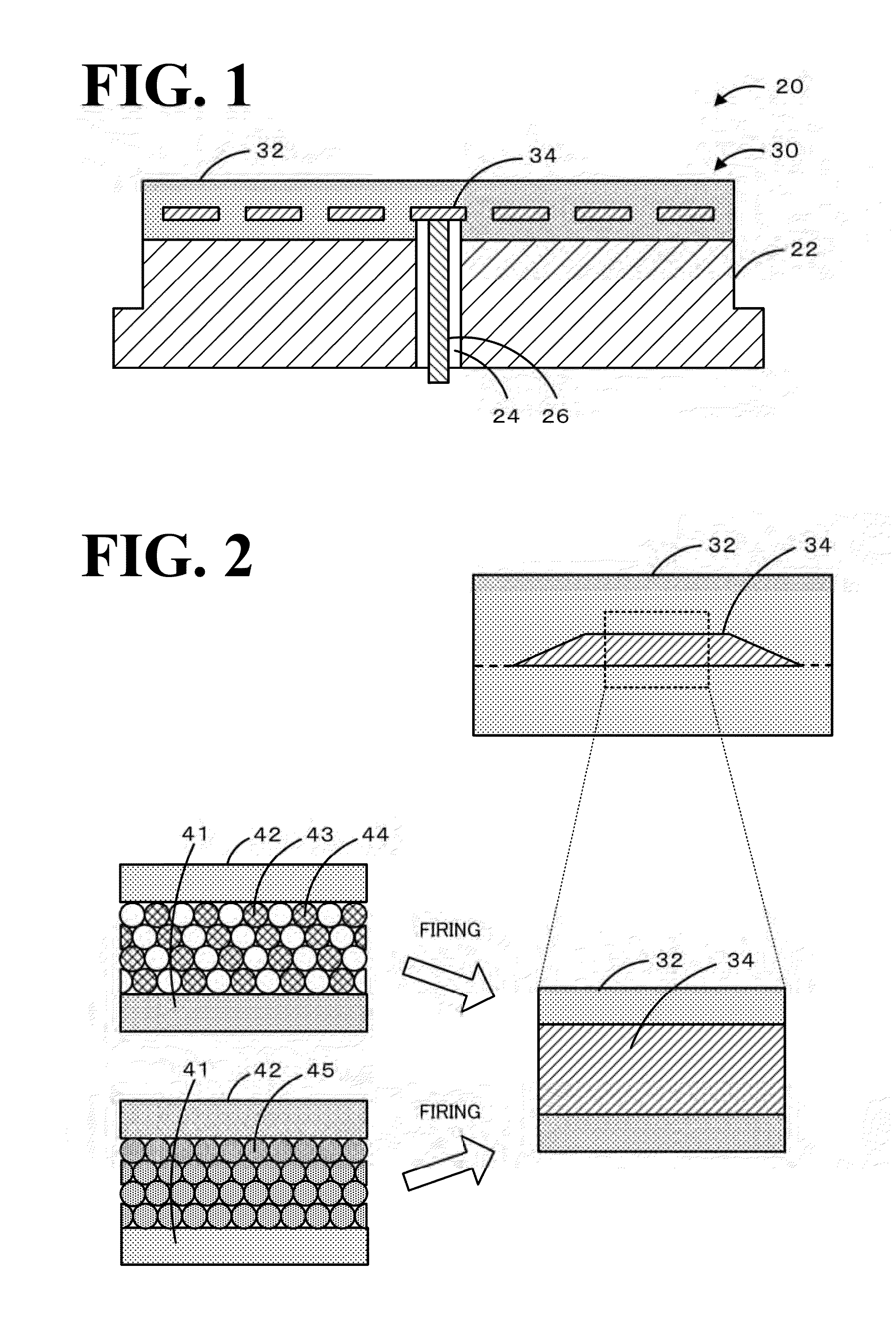

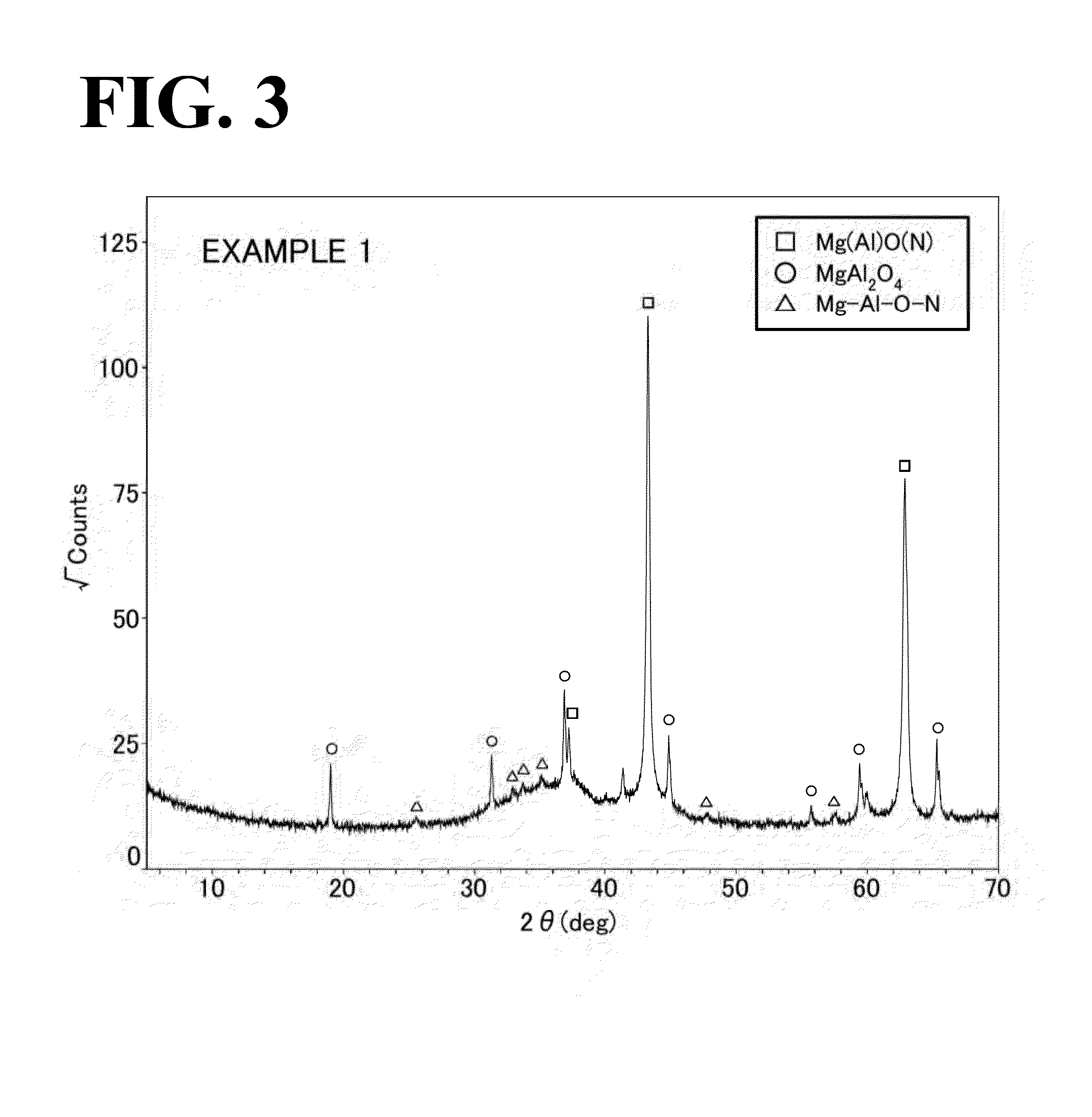

Ceramic member and member for semiconductor manufacturing equipment

ActiveUS20140285943A1Avoid crackingLow resistivitySemiconductor/solid-state device manufacturingPositioning apparatusRutheniumAlloy

Owner:NGK INSULATORS LTD

Integrated thermal door component for head mounted display

InactiveUS20190104650A1Near-field for read/write/interrrogation/identification systemsDetails for portable computersDisplay deviceConductive materials

A head mounted display (HMD) device for supporting virtual reality and augmented reality includes a frame and a thermal door component between which a mobile device may be sandwiched. The thermal door component includes a first portion that is substantially planar for reversibly coupling with a portion of a back surface of the mobile device and a heat sink. The heat sink includes a substantially planar portion coupled to a surface of the first portion of the thermal door component. The heat sink may be made of magnesium or other thermally conductive material. A second portion is coupled to the back of the first portion. An opening, channel, or recess that allows access to the interior of the thermal door component by ambient air to allow the thermal door component to draw heat away from the mobile device and the HMD device.

Owner:GOOGLE LLC

Alloy of high temperature resisting aluminum alloy furnace end and manufacturing method thereof

Owner:浙江艾默樱零部件有限公司

Glass ceramics prepared from tailings obtained by nickel-molybdenum ore dressing and smelting and preparation method thereof

The invention provides glass ceramics prepared from tailings obtained by nickel-molybdenum ore dressing and smelting and a preparation method thereof. The glass ceramics use the tailings obtained by nickel-molybdenum ore dressing and smelting as main raw materials and silica or quartz sand (SiO2), limestone or calcite (CaCO3), sodium carbonate (Na2CO3), alumina (Al2O3), potassium carbonate (K2CO3), magnesium oxide (MgO) and calcium fluoride (CaF2) as auxiliary raw materials. The preparation method comprises the steps of grinding the tailings obtained by nickel-molybdenum ore dressing and smelting and the auxiliary raw materials, sieving the powder with a 20-mesh sieve, and mixing the powder uniformly in a mixer to obtain a base batch; melting the base batch at the temperature of 1450-1550 DEG C, homogenizing and clarifying the melt to obtain qualified molten glass, and then forming a base glass plate or granules through moulding by casting or water quenching of the molten glass; finally filling the base glass plate or the granules into a mould, and then carrying out crystallization thermal treatment, thus obtaining the glass ceramics prepared from the tailings obtained by nickel-molybdenum ore dressing and smelting. The preparation process is simple in operation course and has the effects of not only expanding the way of resource comprehensive utilization of the tailings obtained by nickel-molybdenum ore dressing and smelting but also reducing the environmental pollution of the tailings.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Silicon-calcium-barium-magnesium desoxidant for steelmaking and/or electroslag

The invention relates to a silicon-calcium-barium-magnesium desoxidant for steelmaking and / or electroslag. The desoxidant is composed of the following chemical components in mass percent: 20-50% of Si, 10-40% of Ca, 5-20% of Ba, 2-10% of Mg, 0-10% of RE, not larger than 0.030% of P, not larger than 0.040% of S, 0-2% of C and the balance of Fe. The preparation method comprises the following steps: firstly smelting iron and silicon in a melting furnace to an intermediate alloy, adding barium, calcium, magnesium and / or rare earth, melting and casting to an alloy block, and controlling the specific gravity of the silicon-calcium-barium-magnesium desoxidant to 3-5 g / cm<3>. When in use, the silicon-calcium-barium-magnesium desoxidant is directly thrown into a steel furnace and / or an electroslag remelting crystallizer slag bath, the specific gravity of the desoxidant is increased, the vapor pressure is reduced, the desoxidant is deposited at a slag-steel interface to generate a CaO-BaO-SiO2 type impurity, and the CaO-BaO-SiO2 type impurity is larger in granule, lower in melting point, easy to be captured by the slag and easy to float to be removed, so that the cleanness of molten steel is improved.

Owner:ZHONGYUAN SPECIAL STEEL

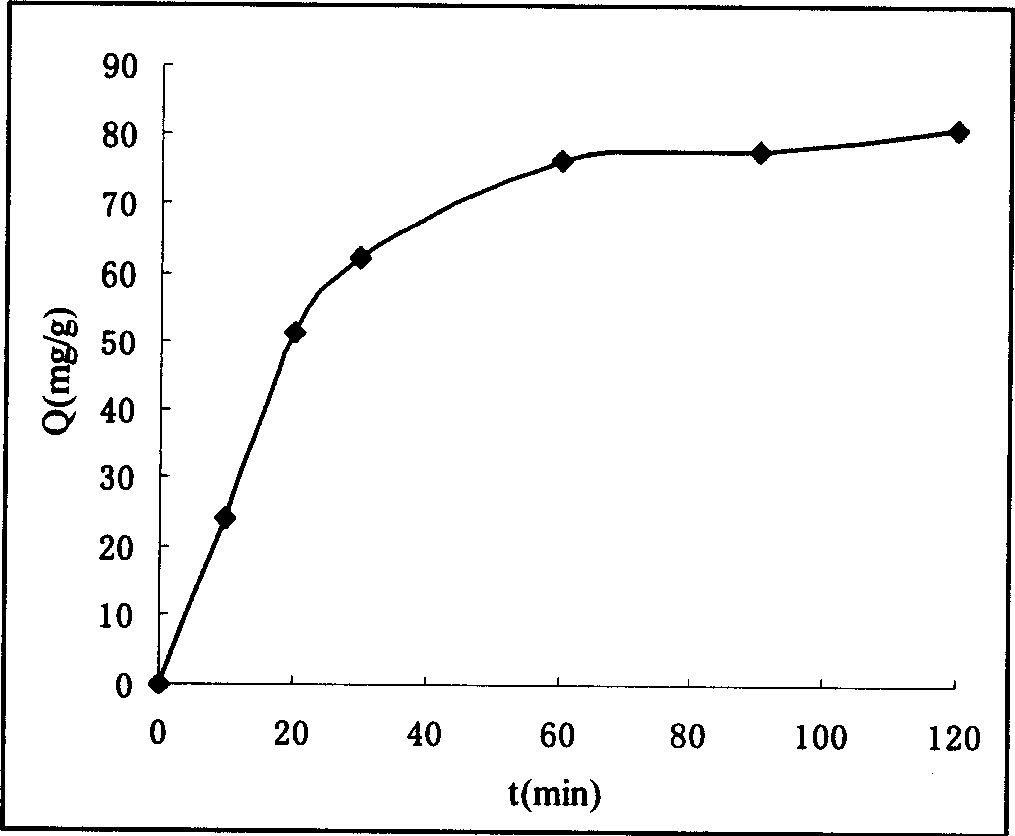

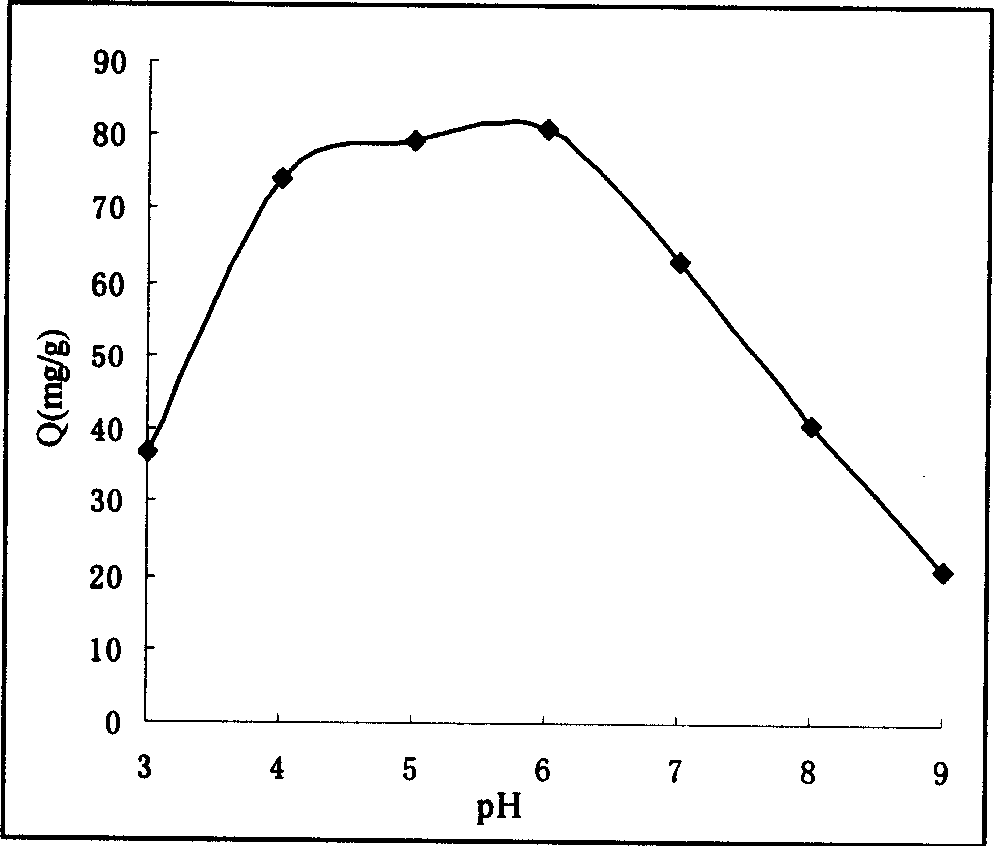

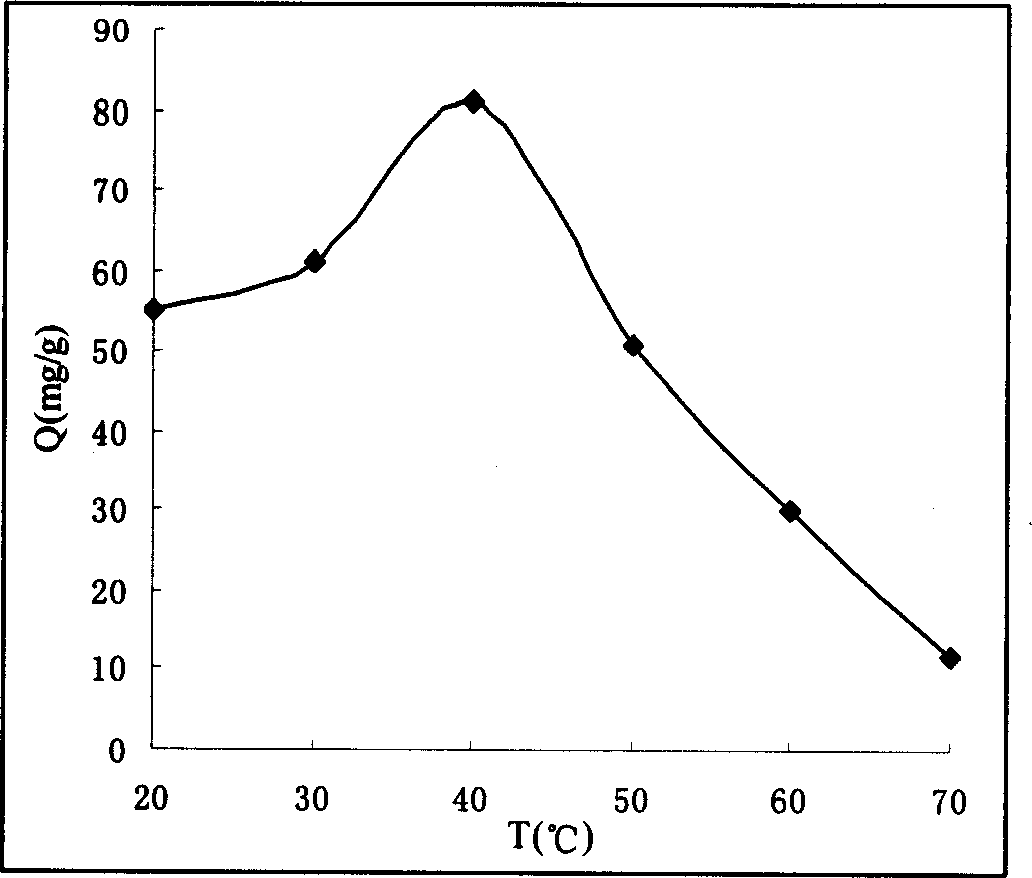

Use of zinc magnesium aluminium ternary hydrotalcite calcining matter in hexavalent chromium of adsorbed water

InactiveCN1736942AEasy to recycleImprove adsorption capacityWater/sewage treatment by sorptionHydrotalciteZinc

Owner:ZHEJIANG UNIV OF TECH

Sodium bentonite processing agent for blue-green algae and preparation method thereof

InactiveCN104495960AFast gatheringQuick gather salvageBiocideDisinfectantsSodium BentoniteEutrophication

A sodium bentonite processing agent for blue-green algae is prepared from the following raw materials in parts by weight: 10-20 parts of serpentine, 40-45 parts of sodium-base bentonite, 2-3 parts of magnesium chloride, 8-13 parts of calcium chloride, 15-20 parts of potassium ferrate(VI), 12-16 parts of equisetum hyemale, 13-16 parts of pericarpium granati, 3-5 parts of polymaleic acid, 3-4 parts of sodium pyrophosphate, 2-3 parts of urea, 3-5 parts of anhydrous sodium sulfate, 3-5 parts of boric acid, 4-6 parts of polyvinyl alcohol, proper amount of water, and 3-4 parts of an adsorption auxiliary agent. By adding potassium ferrate(VI), the processing agent for blue-green algae has synergic effects of oxidation, adsorption, flocculating, precipitation, sterilization, disinfection, decoloring and deodoring, also does not generate any toxic and harmful substances, is capable of increasing water dissolved-oxygen content, has good removal effects on ammonia nitrogen, nitrites and algae in water, and is used to remove fulvic acid and suspensions in water and eutrophication phenomenon in fresh water. The processing agent for blue-green algae is good in dispersing suspending property and good in adsorption property, and can help to rapidly aggregate and salvage blue-green algae.

Owner:WUHU XIANGRONG FOOD

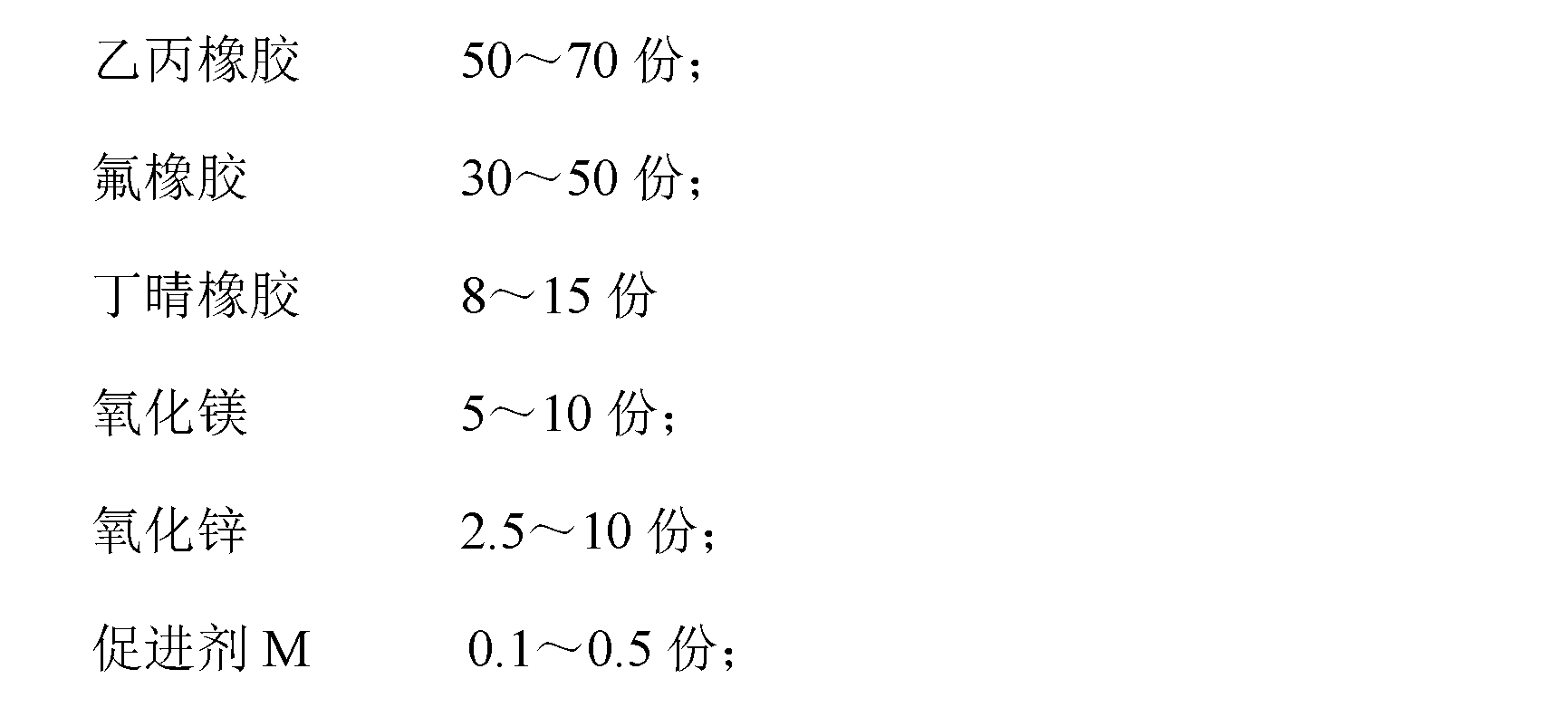

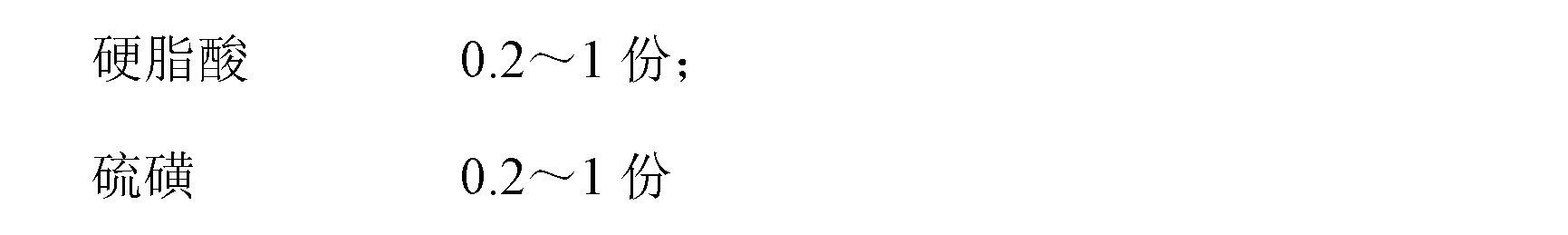

Formula of fluororubber-ethylene propylene rubber mixing rubber compound

ActiveCN103232643AImprove media resistanceImprove low temperature resistancePolymer scienceStearic acid

Owner:扬中市橡胶塑料厂有限公司

Air-added brick and preparation method thereof

Owner:明光市凯旋新型建材厂

Flame-retardant polyethylene insulated cable material

InactiveCN104861271ANot easy to smoke and dustNot easy to producePlastic/resin/waxes insulatorsHalogenMagnesium

The invention discloses a flame-retardant polyethylene insulated cable material, and relates to the technical field of cables. The flame-retardant polyethylene insulated cable material is prepared from the following raw materials in parts by weight: 80 parts of polyethylene, 5 parts of aluminum oxide, 20-35 parts of magnesium hydroxide and 1-5 parts of an anti-aging agent. According to the invention, the flame-retardant polyethylene insulated cable material is unlikely to combust and can prevent combustion, has a flame retardant rating of V-0, is not liable to produce halogen-containing toxic substances or smoke dust when the cable material is combusted, and is applicable to high and low voltage power cables.

Owner:ANHUI MEITENG SPECIAL ELECTRIC CABLE MATERIALS

Modified graphene reinforced magnesium matrix metal material and preparation method thereof

The invention discloses a modified graphene reinforced magnesium matrix metal material and a preparation method thereof. The modified graphene reinforced magnesium matrix metal material comprises the following components in percentages by mass: 0.02-0.5wt% of modified graphene, 5.9-11.2wt% of copper, 1.2-4.6wt% of silicon dioxide, 1.4-5.6wt% of aluminum oxide, 1.3-7.8wt% of carbon nanotubes, 4.5-7.9wt% of nickel, 1.3-3.8wt% of titanium dioxide, 1.3-4.6wt% of lanthanum oxide and the balance of magnesium. The mechanical property of the modified graphene reinforced magnesium matrix metal material can still be good at the temperature of minus 20 DEG C; and the performance parameters such as the tensile strength and the elongation of the magnesium matrix metal material are increased, and are higher than the performance parameters of commercial alloy by 7-11%.

Owner:SUZHOU NETABHAPE COMPOSITE MATERIALS

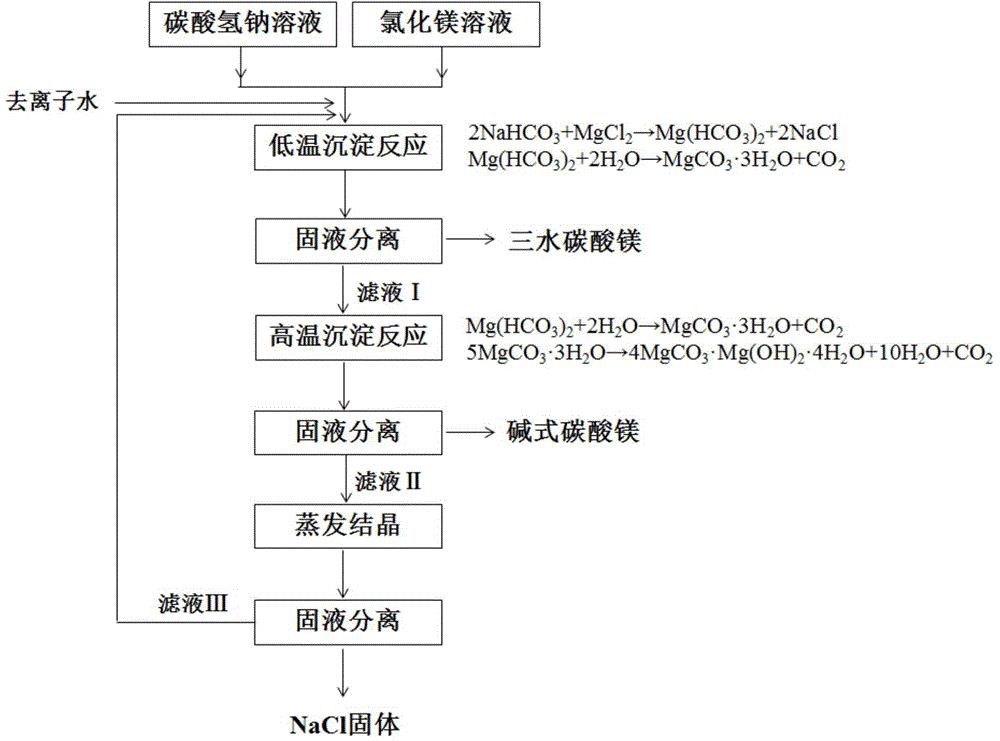

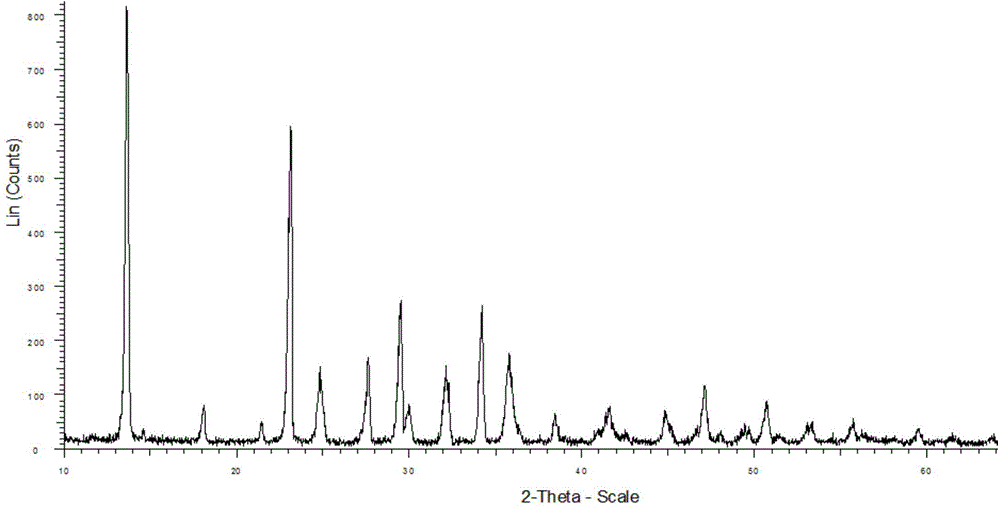

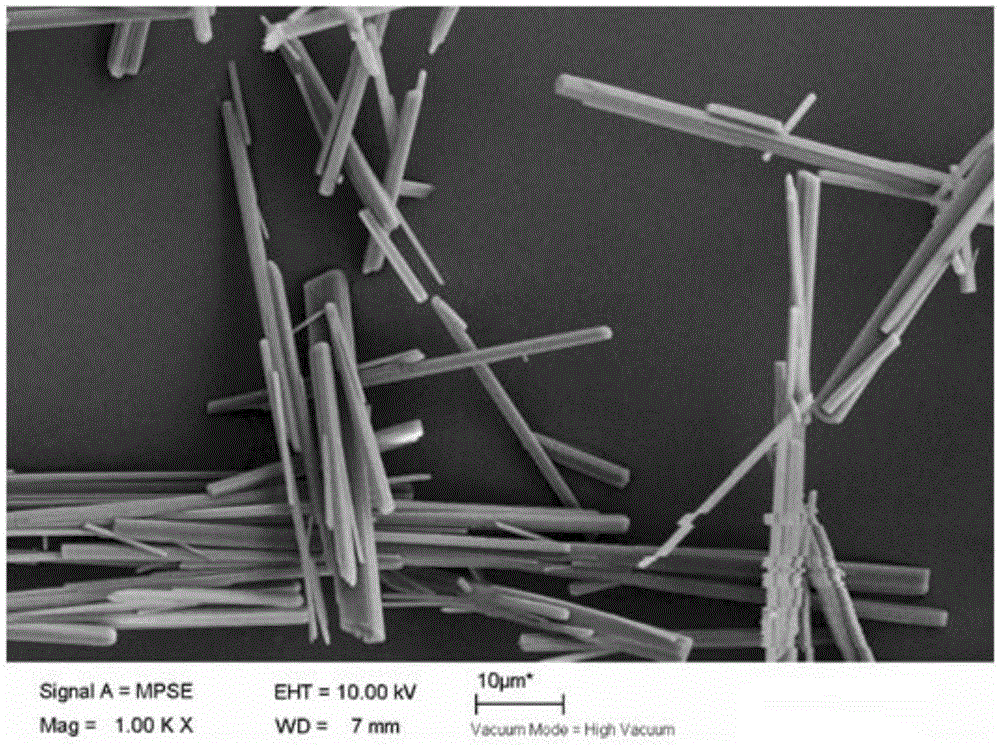

Method for preparing nesquehonite whiskers and nano flaky basic magnesium carbonate

InactiveCN104828847AGood dispersionHigh purityMagnesium carbonatesNanotechnologyDispersitySodium bicarbonate

Owner:COSL CHEM TIANJIN

Weather-resistant impact-resistant waterproof plugging material with stable quality and its preparation method

Owner:HEFEI OUSHIJIA ELECTRICAL & MECHANICAL EQUIP CO LTD

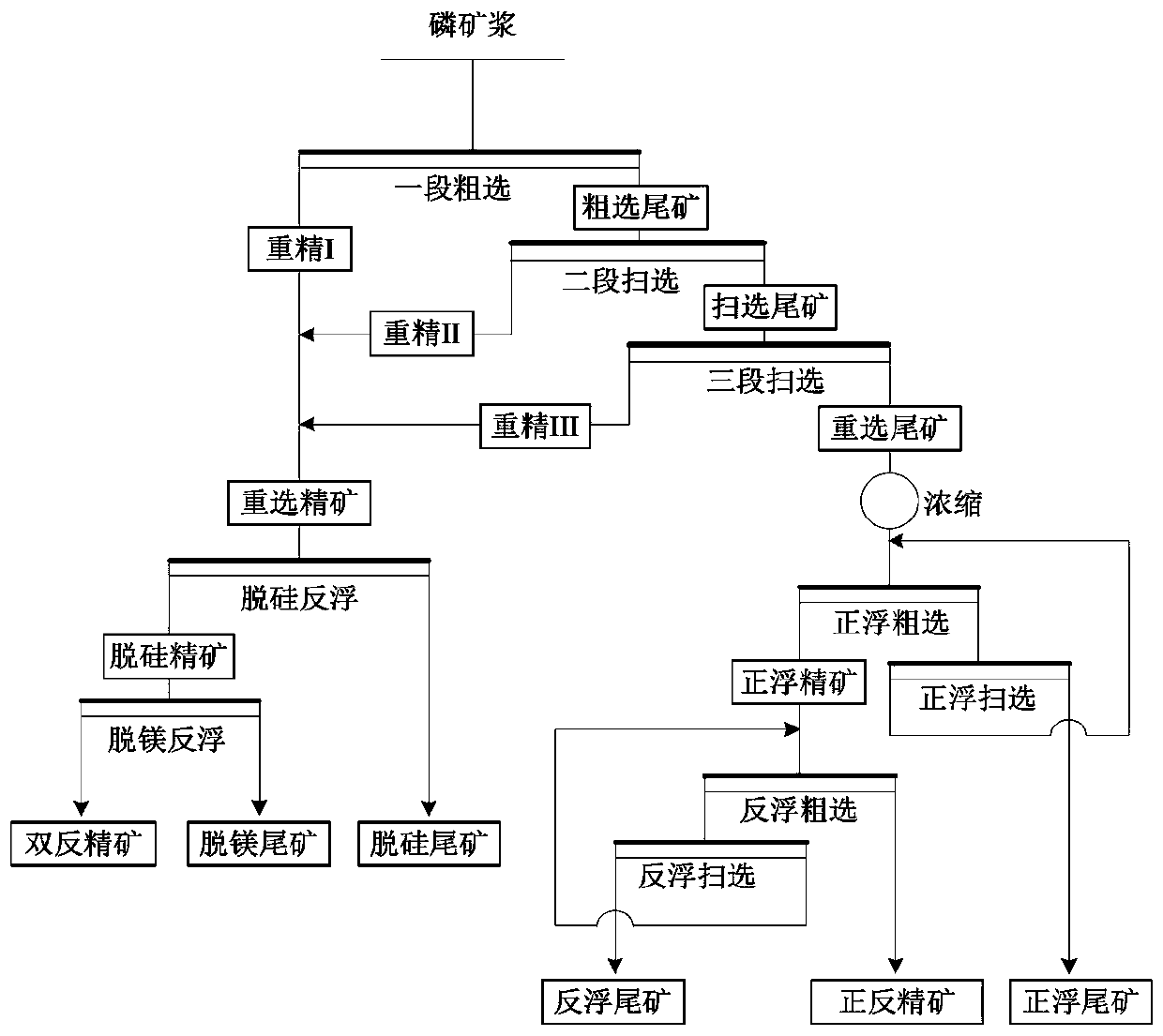

Gravity separation-flotation combined beneficiation process for phosphate ores

PendingCN110369120AReduce grinding costsReduce adverse effectsFlotationWet separationPhosphoriteReverse flotation

Owner:HUBEI XINGFA CHEM GRP CO LTD

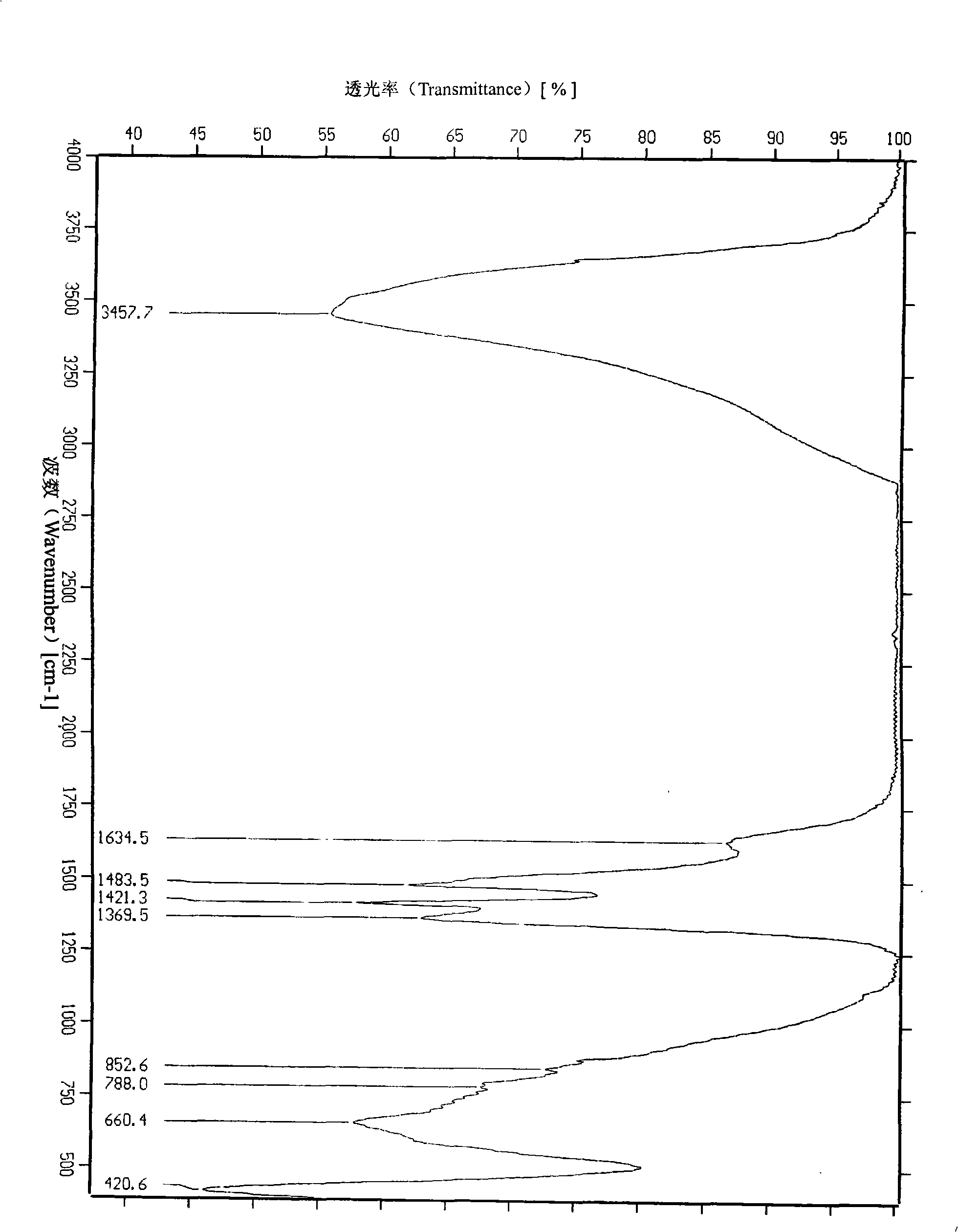

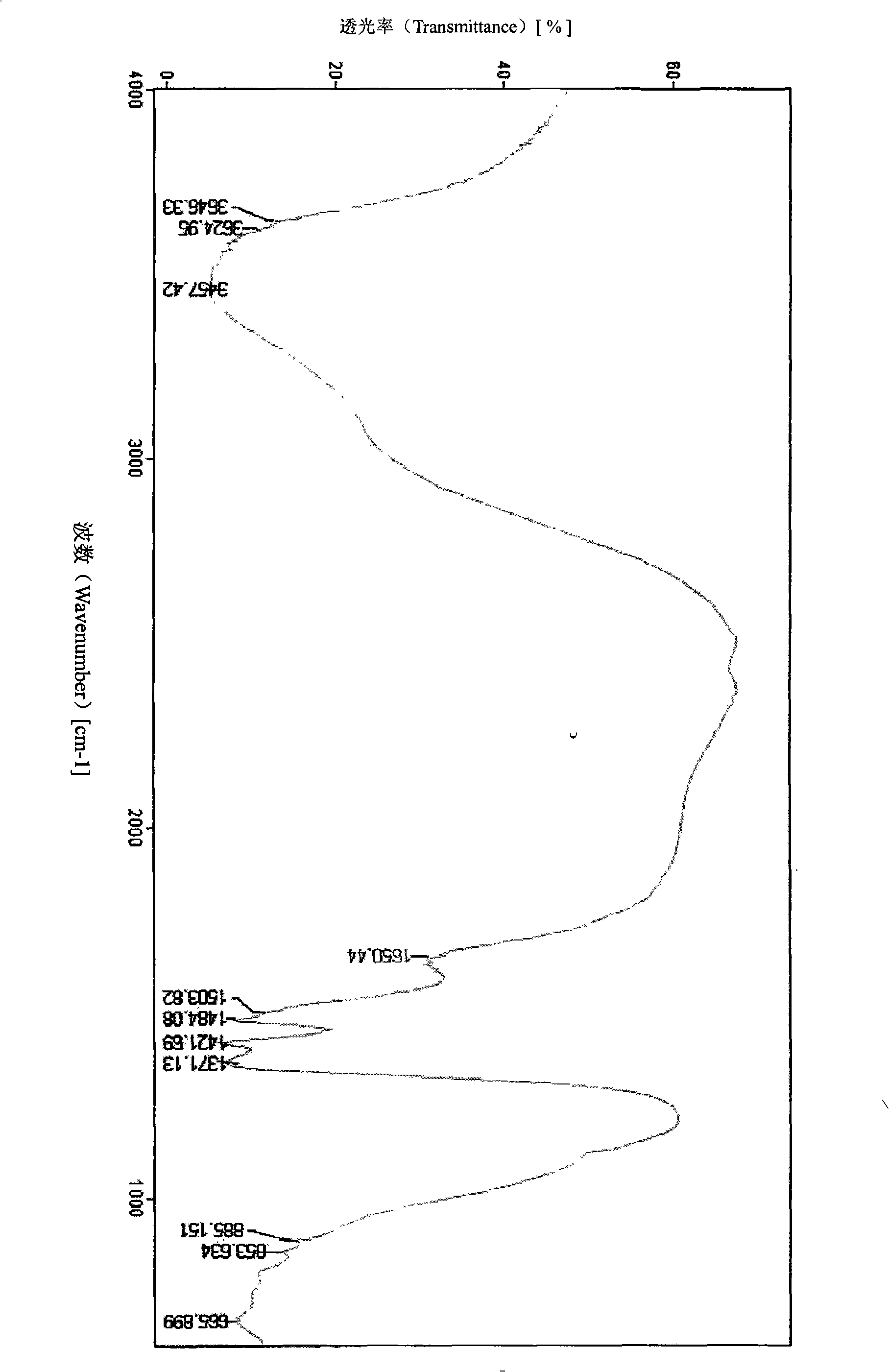

Method of preparing aluminum magnesium carbonate

InactiveCN101343078AHigh purityHigh yieldAluminium compoundsMagnesium carbonatesMedicinal chemistryCarbonate

Owner:IL YANG PHARMA CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap