Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

20 results about "Base oil" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Base oils are used to manufacture products including lubricating greases, motor oil and metal processing fluids. Different products require different compositions and properties in the oil. One of the most important factors is the liquid’s viscosity at various temperatures. Whether or not a crude oil is suitable to be made into a base oil is determined by the concentration of base oil molecules as well as how easily these can be extracted.

Asphalt regenerating agent with modification function and preparation method thereof

ActiveCN104788975AIncrease elasticityImprove temperature stabilityBuilding insulationsSocial benefitsEngineering

Owner:WUHAN UNIV OF TECH

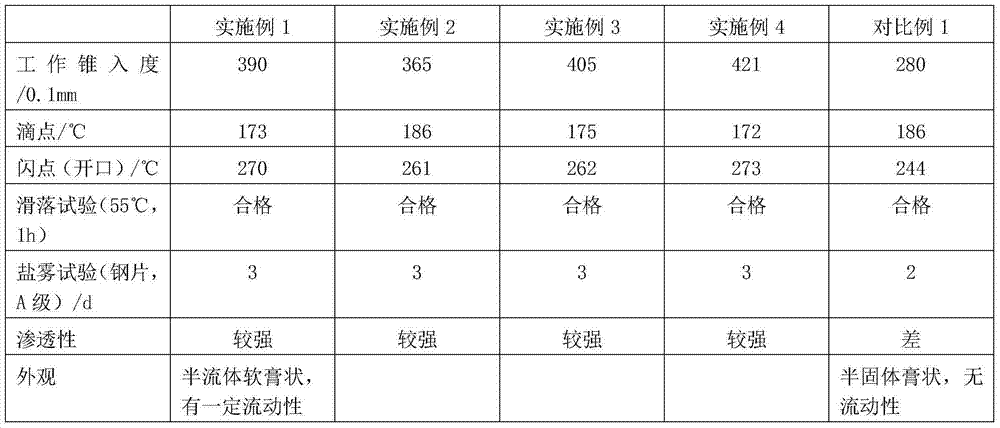

Lubricating grease composition for elevator wire ropes and preparation method thereof

ActiveCN103484218AImprove adhesionImprove permeabilityLubricant compositionMicrocrystalline waxOleic Acid Triglyceride

Owner:WUJIANG JUNDA ELEVATOR PARTS

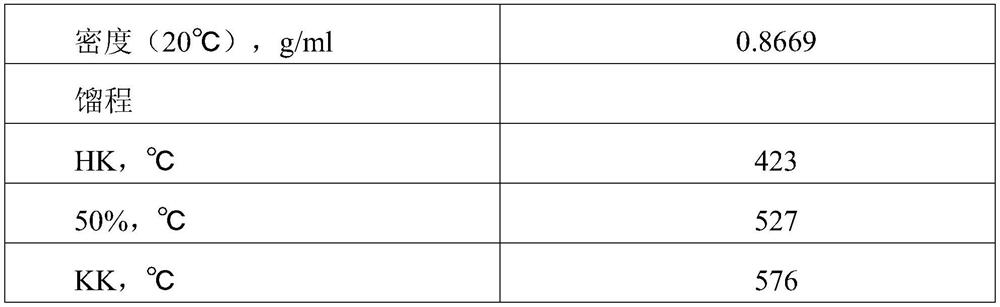

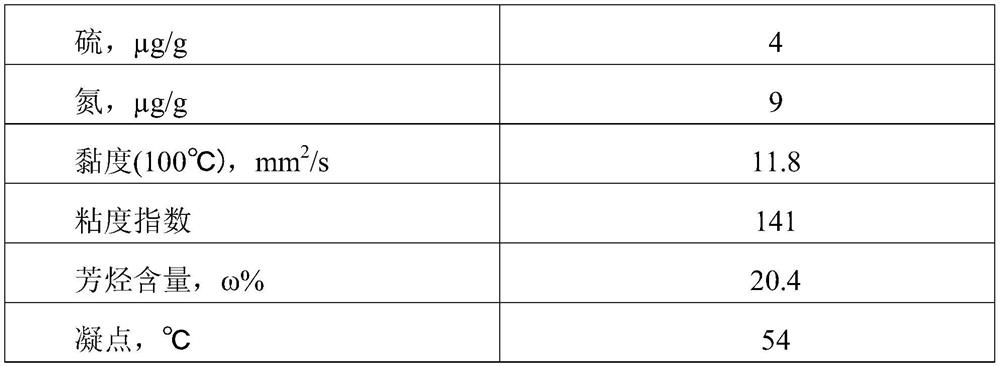

Full oil base drilling fluid with high dynamic shear force ratio

ActiveCN103146365AHigh ratio of dynamic plasticImprove rheologyDrilling compositionBase oilPotentiator

The invention discloses full oil base drilling fluid with high dynamic shear force ratio. The full oil base drilling fluid comprises base oil and other ingredients on the basis of the volume of the base oil: 1.5-2.5% of main emulsifying agent, 0.5-1.0% of auxiliary emulsifying agent, 0.8-1.0% of reverse wetting agent, 0.8-1.0% of shearing potentiator, 0.3-0.5% of thermoplastic flow type regulating agent, 2.0-3.0% of calcium oxide, 1.0-3.0% of organic soil, 1.5-2.0% of fluid loss additive and weighting material, and due to the addition amount of the weighting material, the density of the full oil base drilling fluid is 0.89-2.50g / cm<3>. The addition amount of the organic soil in the full oil base drilling fluid system is reduced by 1.0-3.0% through adding the thermoplastic fluid type regulating agent, the dynamic shear force ratio of the system is obviously improved and can achieve more than 0.45, the rheological property of the system can be improved, the comprehensive properties can be improved, and the production cost can be saved.

Owner:CHINA NAT PETROLEUM CORP +1

Antirust oil and preparation method thereof

InactiveCN107653045AWork fasterImprove rust resistanceLubricant compositionAntioxidantRoom temperature

The invention relates to antirust oil and a preparation method thereof. The antirust oil is prepared from the following components by weight percent: 20 to 35 percent of film forming agent, 5 to 15 percent of antirust agent, 0.1 to 5 percent of co-solvent, 0.1 to 2 percent of antioxidant and 40 to 75 percent of basic oil. The preparation method comprises the following steps: preparing all raw materials according to the components and the weight ratio, adding the basic oil into a reactor, heating and stirring, when the temperature is increased to 90 to 120 DEG C, adding the antirust agent, theco-solvent and the antioxidant, sufficiently stirring, completely dissolving, lowering the temperature in the reactor to 50 to 80 DEG C, then slowly adding the film forming agent and the residual basic oil, sufficiently stirring, completely dissolving, cooling to the room temperature, detecting, discharging the material, thus obtaining the antirust oil. The antirust oil of the invention is high inactually completely drying speed and has good antirust effects for the long-term storage and transportation of various metals such as iron, copper, aluminum, magnesium alloy and the like.

Owner:SHANGHAI YOUDAO NEW ENERGY TECH CO LTD +1

Compound ozone oil and preparation method

InactiveCN106728416AEfficient killingSignificantly sterilizedAntibacterial agentsInorganic active ingredientsTreatment effectCnidium monnieri

Owner:黄庆文 +1

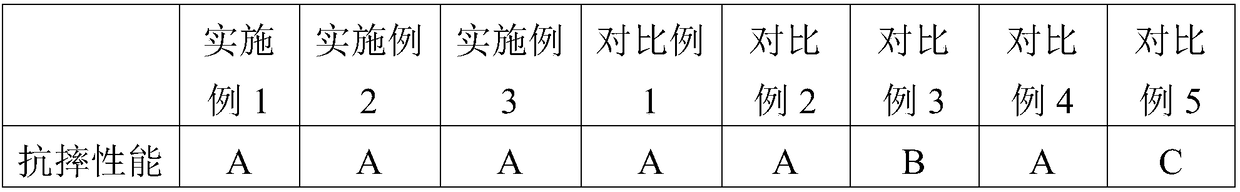

Grease composition

InactiveUS20120098269A1Long life-timeSuppressing bearing wearPump componentsAdditivesBase oilViscosity

Owner:IDEMITSU KOSAN CO LTD

Thermoplastic elastomer composition

Owner:IDEMITSU KOSAN CO LTD

Quick-drying stable antirust oil

Owner:铜陵华兴精细化工有限公司

Silicone grease and preparation method thereof, and ink following agent using silicone grease, and preparation method thereof

Owner:SHANGHAI M&G STATIONERY INC

Palm moxibustion essential oil

InactiveCN107929681AWith expelling wind and dampnessWith relaxing muscles and collateralsHydroxy compound active ingredientsAntipyreticMedicineArtemisia vulgaris

Owner:岳阳市翻天应生物科技有限公司

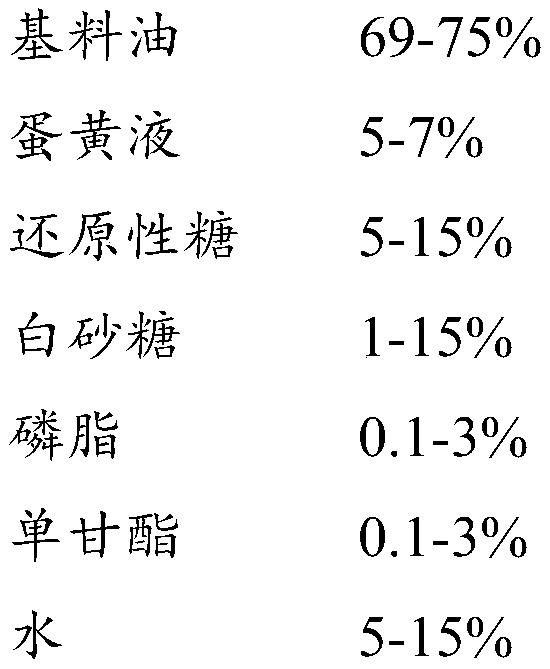

Egg yolk flavor grease composition and preparation method thereof, and food.

PendingCN110200082AGuaranteed tasteGuaranteed flavorEdible oils/fats ingredientsEdible oils/fats production/working-upFlavorYolk

Owner:GUANGZHOU NANQIAO FOOD +2

Optical fiber ribbon coating paste used in band shape optical cable and preparation method thereof

ActiveCN102207595AMoisture-proofImprove waterproof performanceFibre mechanical structuresBand shapeOil separation

Owner:SHANGHAI HONGHUI OPTICS COMM TECH

Cold rolling lubricant for antimony and antimony alloy plate strip

Owner:GUANGXI UNIV

Odor masking tablets

InactiveUS20180015195A1Dissolve fastActive surfaceGaseous substancesWater treatment locationMedicineBase oil

Owner:BRUNETT MICHAEL N

Environment-friendly water-soluble stainless steel wire drawing liquid

InactiveCN112048364AEffective protectionPrevents minor abrasionsLubricant compositionActive agentSS - Stainless steel

Owner:江苏赢新润滑科技有限公司

Catalyst for preparing lubricant base oil and preparation method of carrier of catalyst

PendingCN114471679AHigh catalytic activityHigh viscosity indexMolecular sieve catalystsCatalyst activation/preparationMolecular sievePtru catalyst

Owner:PETROCHINA CO LTD

Long-life wear-resistant gearbox oil and preparation method thereof

ActiveCN107629850AMeet the requirements of lubrication protectionReasonable combinationLubricant compositionDispersitySocial benefits

Owner:广东布雷达科技股份有限公司

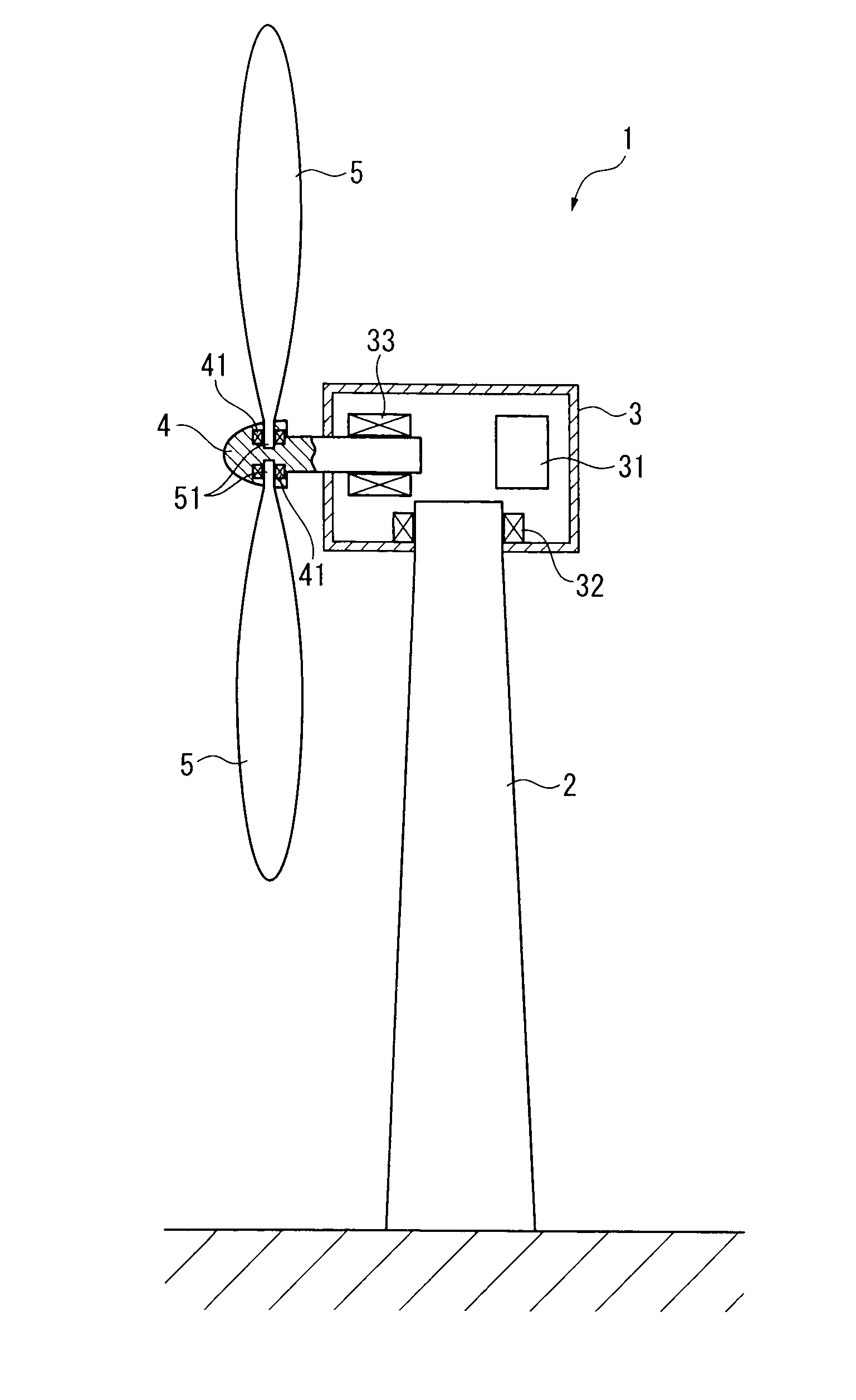

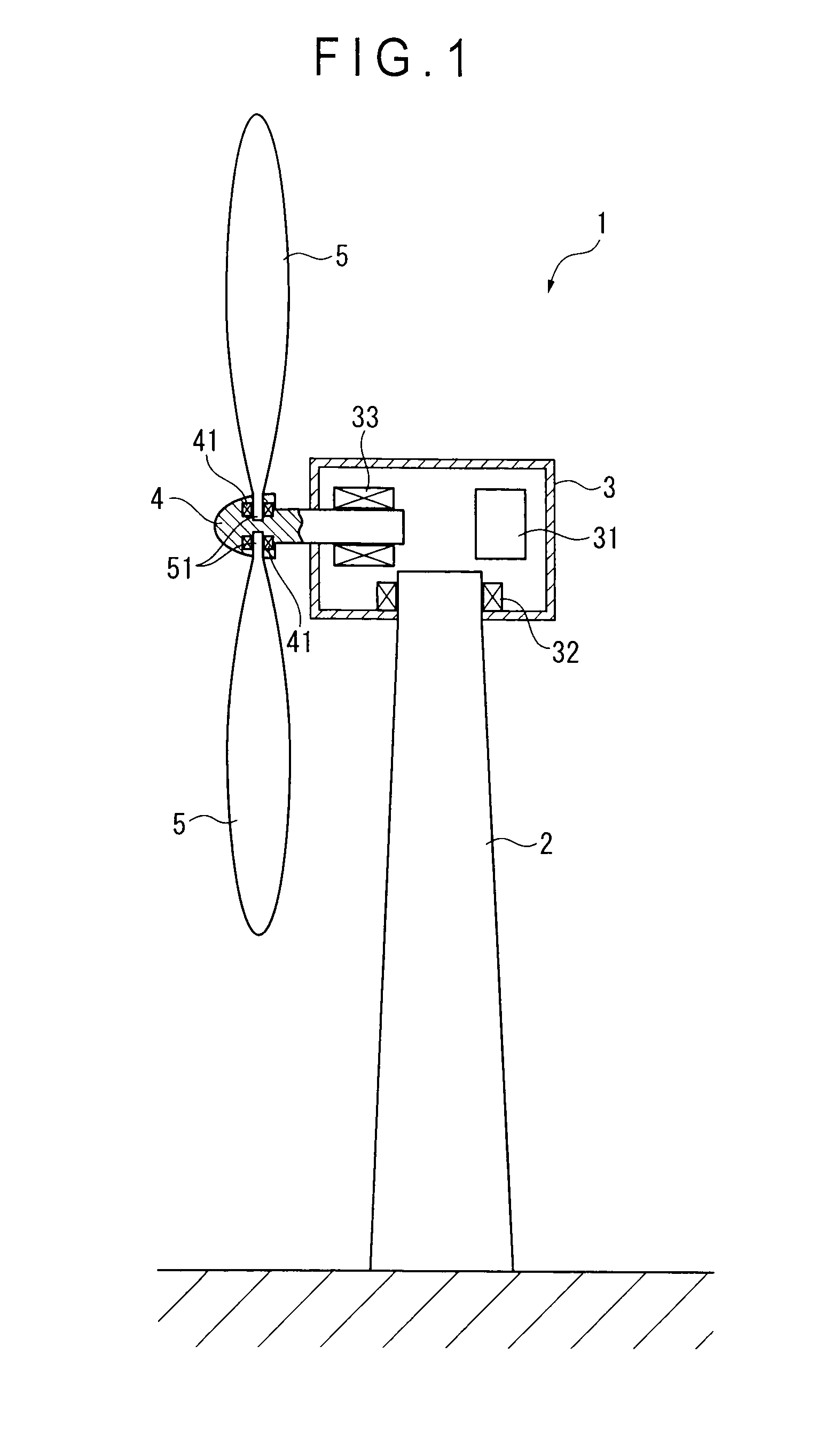

Grease composition for rolling bearing

InactiveUSRE48187E1Excellent acoustic durabilityReduction of bearing torqueBearing componentsThickenersFiberPolymer science

A grease composition for rolling bearing comprising a metal soap-based thickening agent containing a long fiber-like material having a major axis length of at least 3 μm incorporated in a base oil comprising a lubricant having a polar group in its molecular structure and a non-polar lubricant blended in combination.

Owner:NSK LTD +1

Anti-attrition lubricating oil

The invention discloses an anti-attrition lubricating oil. The anti-attrition lubricating oil is composed of base mineral oil, hydrogenated styrene-diene copolymer, polymethylemethaerylate, tea polyphenol, ascorbyl palmitate, mahogany petroleum sulfonate, lauryl alcohol and butyl stearate. Therefore, the anti-attrition lubricating oil can ensure rapid relative sliding between a piston and a cylinder as well as between a main shaft and a bearing bush of an automobile to avoid rapid wearing of parts and to prolong the service life of the parts and further to prolong the service life of the automobile and save maintenance and replacement cost.

Owner:SUZHOU RICHELI NEW MATERIAL CO LTD

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap