Catalyst for preparing lubricant base oil and preparation method of carrier of catalyst

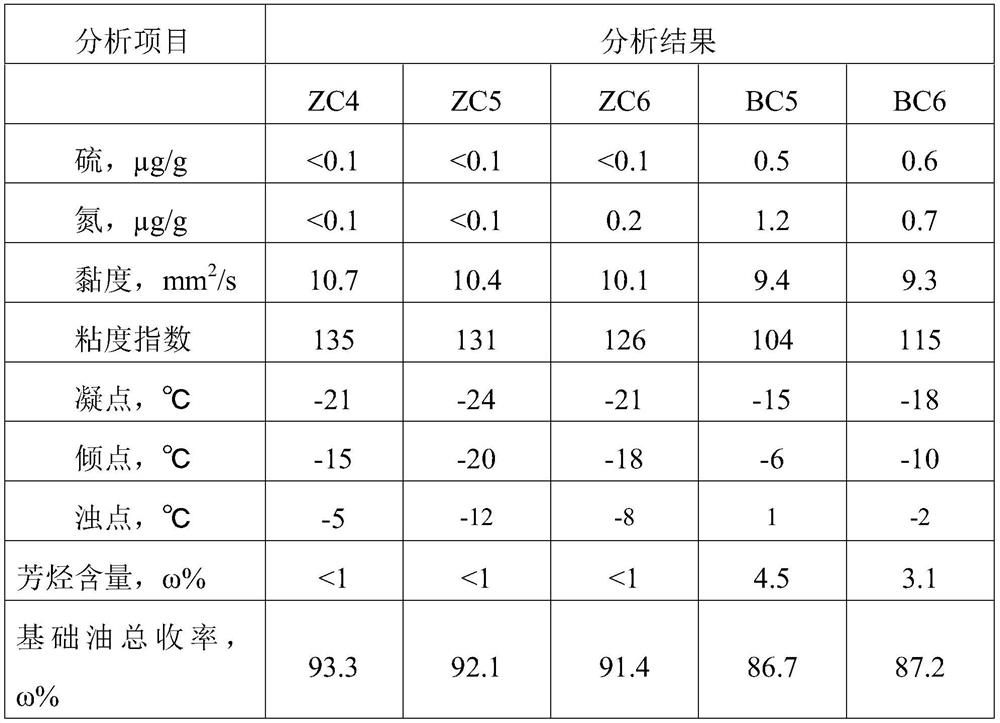

A lubricating oil base oil and catalyst carrier technology, which is applied in the direction of catalyst activation/preparation, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problem of large loss of base oil viscosity index and inability to effectively solve the problem of low-temperature fluidity and cloud point performance of base oil and other problems, to achieve the effect of high viscosity index, low pour point and high total yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The preparation method of the catalyst carrier for preparing lubricating oil base oil provided by the invention comprises the following steps:

[0048] (1) Preparation of molecular sieve fragment structural units:

[0049] Place the raw material molecular sieve in an acidic or alkaline solution, fully stir for 5 minutes to 60 minutes to obtain a cloudy solution A, continue to adjust the pH value of the acidic or alkaline solution to 6 to 8, and obtain a cloudy solution B containing structural units of molecular sieve fragments;

[0050] (2) Preparation of catalyst carrier:

[0051] Mechanically mix the molecular sieve, the amorphous inorganic porous material and the binder to obtain a mixed powder, then prepare the turbid solution B obtained in step (1) with additives and deionized water to form a turbid solution, add it dropwise to the mixed powder, and continue kneading Forming, homogenizing, drying and roasting to obtain the catalyst carrier.

[0052] In some embodime

Embodiment 1

[0067] In this embodiment, the molecular sieve used to make the molecular sieve fragment structural unit and the carrier is an industrial ZSM-5 molecular sieve. The amorphous inorganic porous material used is Al 2 o 3 , the additives are nitric acid and citric acid, and the binder is scallop powder.

[0068] Preparation of ZSM-5 type fragment structural unit: Take 5g of ZSM-5 type molecular sieve and place it in 10ml of 5mol / L ammonia solution, stir fully in a water bath at 30°C for 60min to obtain turbid solution A; step B: Pass turbid solution A through 1mol / L L acetic acid solution was adjusted to a pH value of 6-8 to obtain a turbid solution B containing ZSM-5 type fragment structural units.

[0069] Get ZSM-5 type molecular sieve 80g, 20g Al 2 o 3 1. Mix 5g of scallop powder in a container, mix 10g of 37% nitric acid, 4g of citric acid with turbid solution B and 40ml deionized water to make turbid solution C, add dropwise to the above-mentioned mixed powder, knead an

Embodiment 2

[0071] In this embodiment, the molecular sieve used to make the structural unit of molecular sieve fragments is NU-87 molecular sieve, and the molecular sieve used for forming the carrier is ITQ-13 molecular sieve. The amorphous inorganic porous material used is Al 2 o 3 and SiO 2 , the additives are nitric acid and sulfuric acid, and the binder is squash powder.

[0072] Preparation of NU-87 type molecular sieve fragment structural unit: take 20g of NU-87 type molecular sieve and put it in 20ml of 0.5mol / L hydrochloric acid solution, fully stir in a water bath at 30°C for 5min to obtain turbid solution A; step B: pass turbid solution A through The 3 mol / L ammonia solution was adjusted to a pH value of 6-8 to obtain a turbid solution B containing NU-87 molecular sieve fragment structural units.

[0073] Take ITQ-13 type molecular sieve as 30g, 30g Al 2 o 3 , 20g SiO2 2 Mix with 8g of scallop powder in a container, mix 3g of nitric acid and 6g of sulfuric acid with turbi

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap