Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

8 results about "Oil can" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An oil can (oilcan or oiler) is a can that holds oil (usually motor oil) for lubricating machines. An oil can can also be used to fill oil-based lanterns. An occupation, referred to as an oiler, can use an oil can (among other tools) to lubricate machinery.

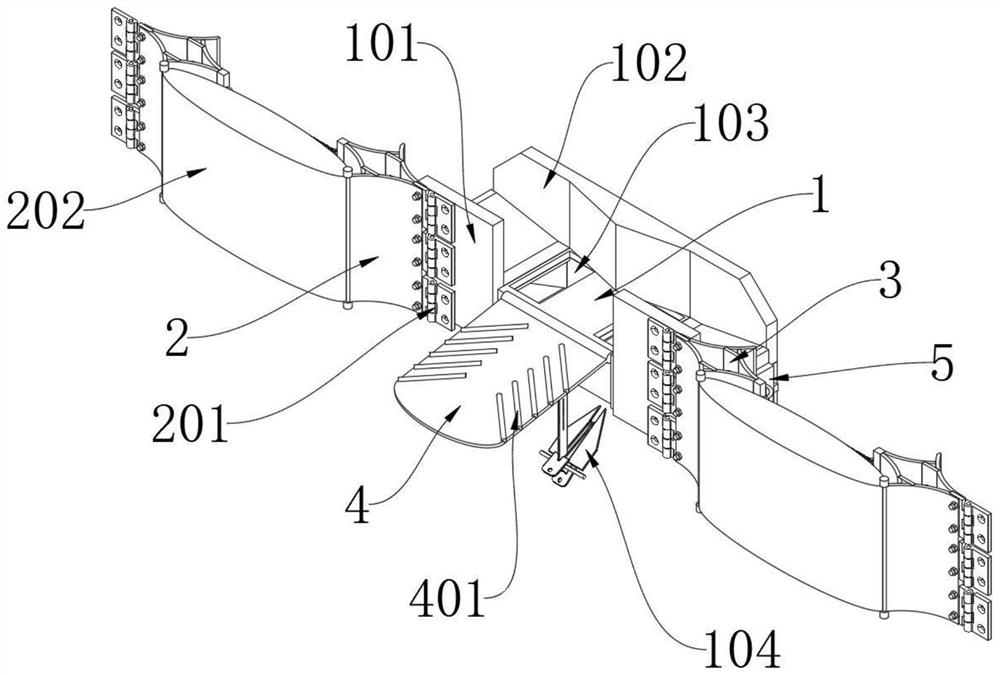

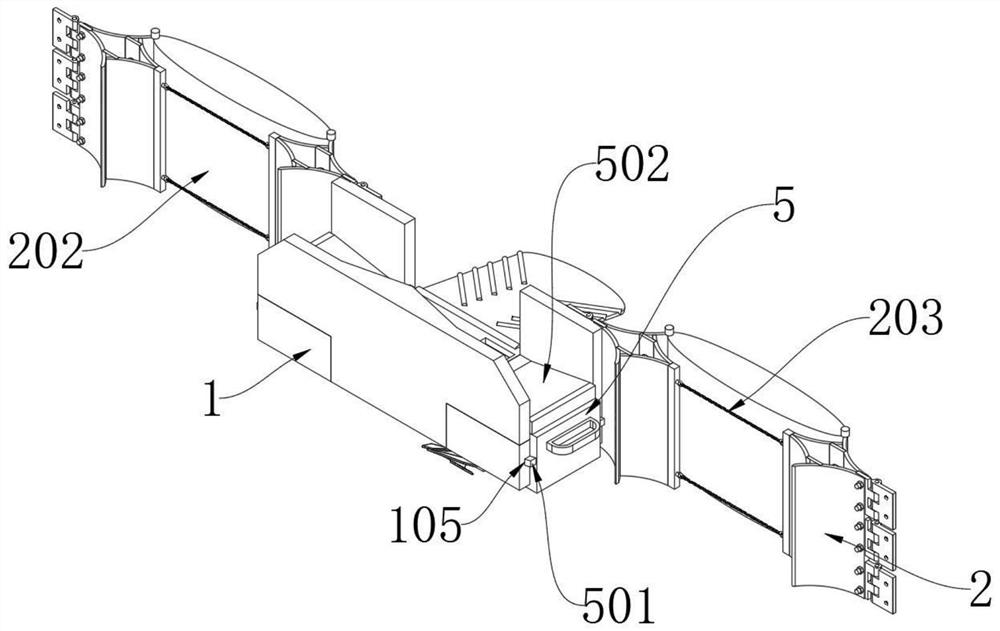

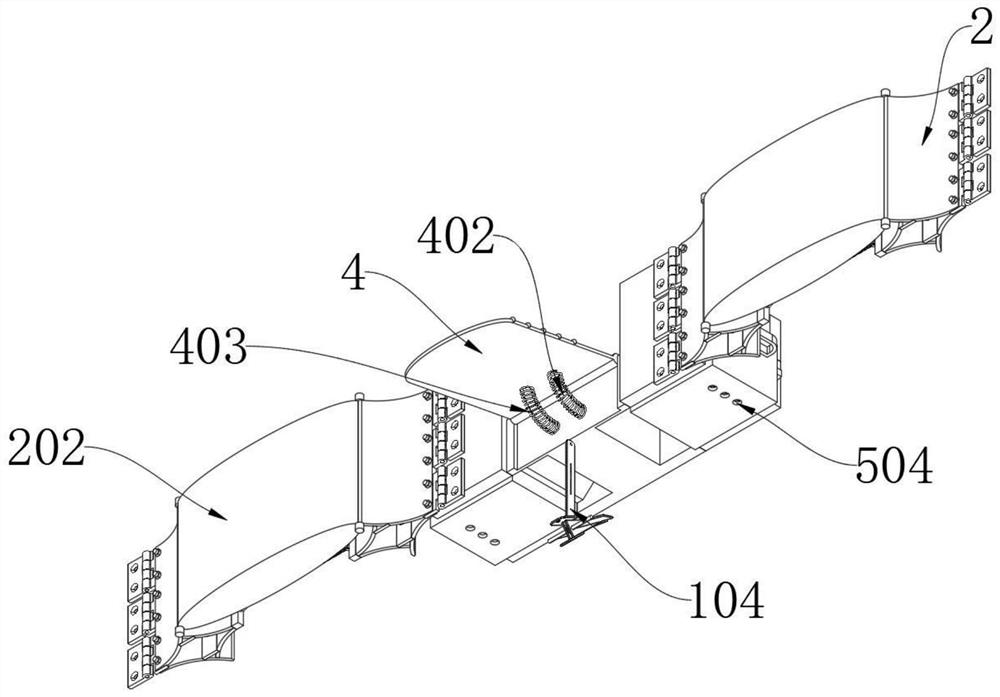

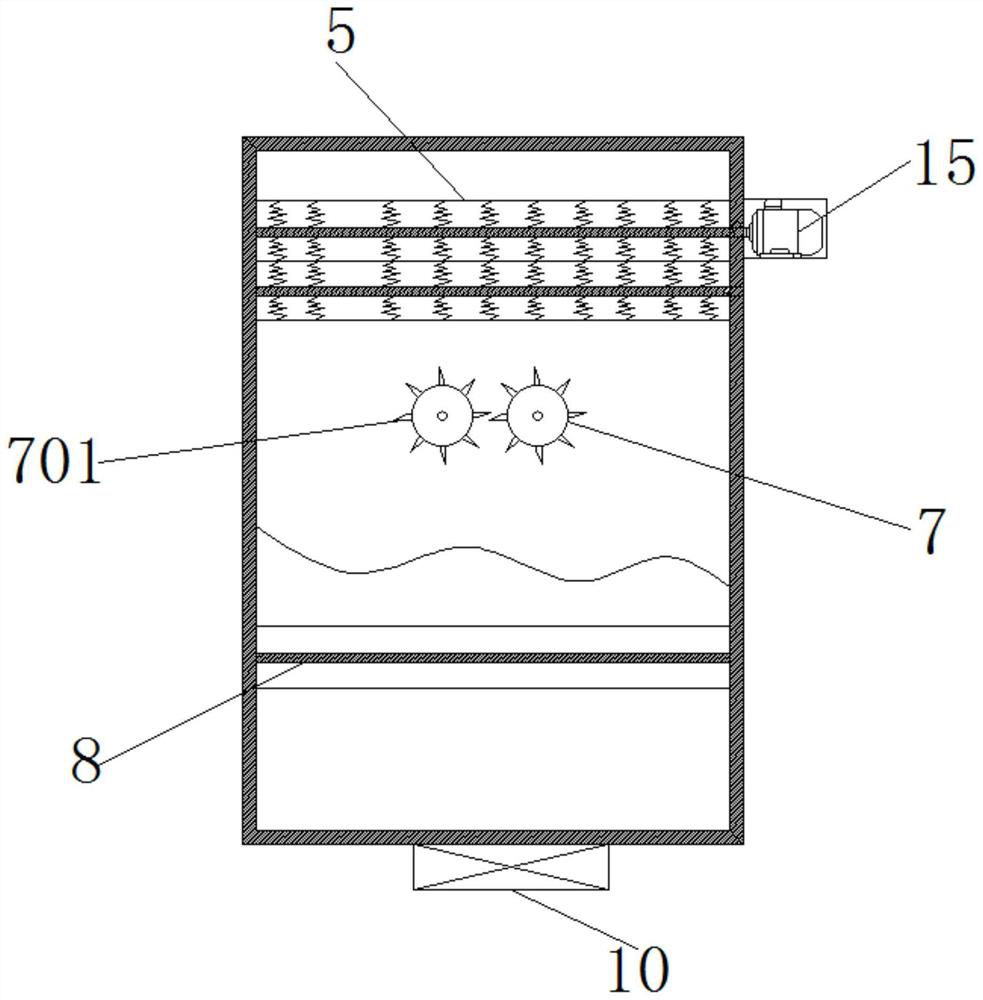

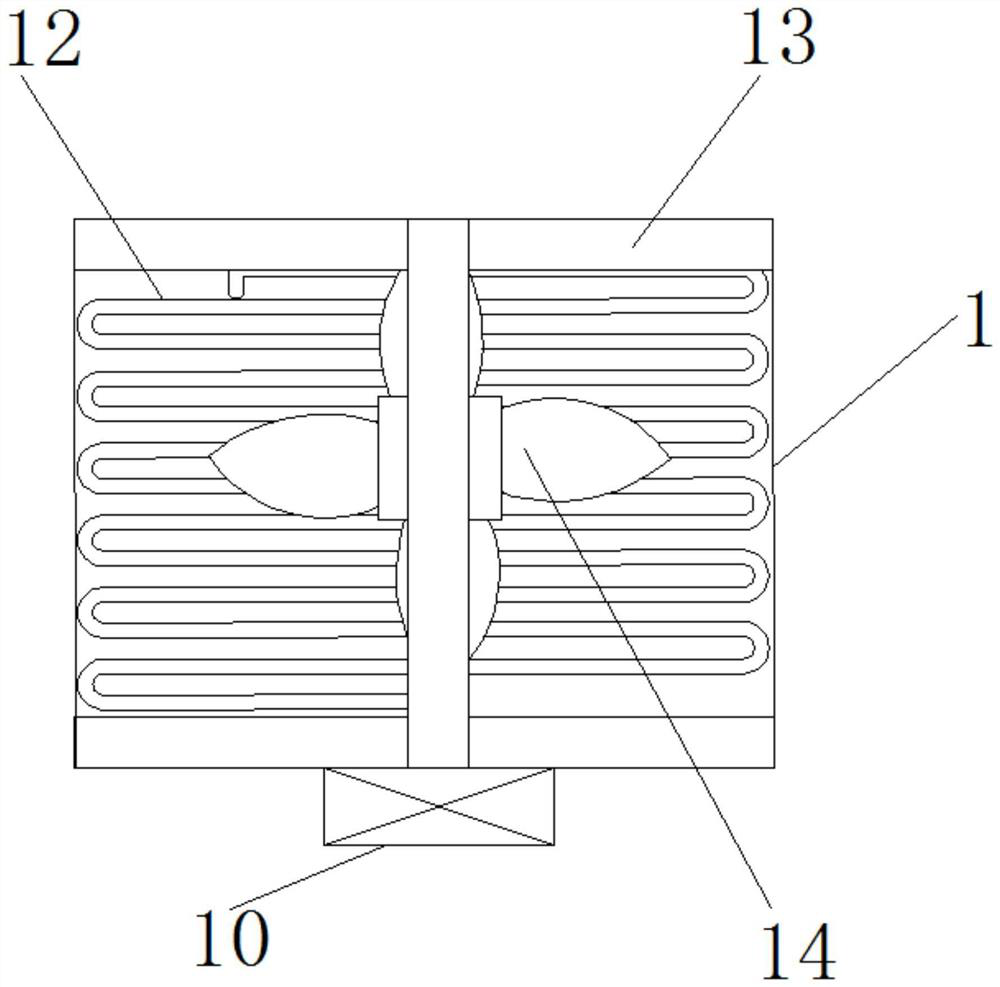

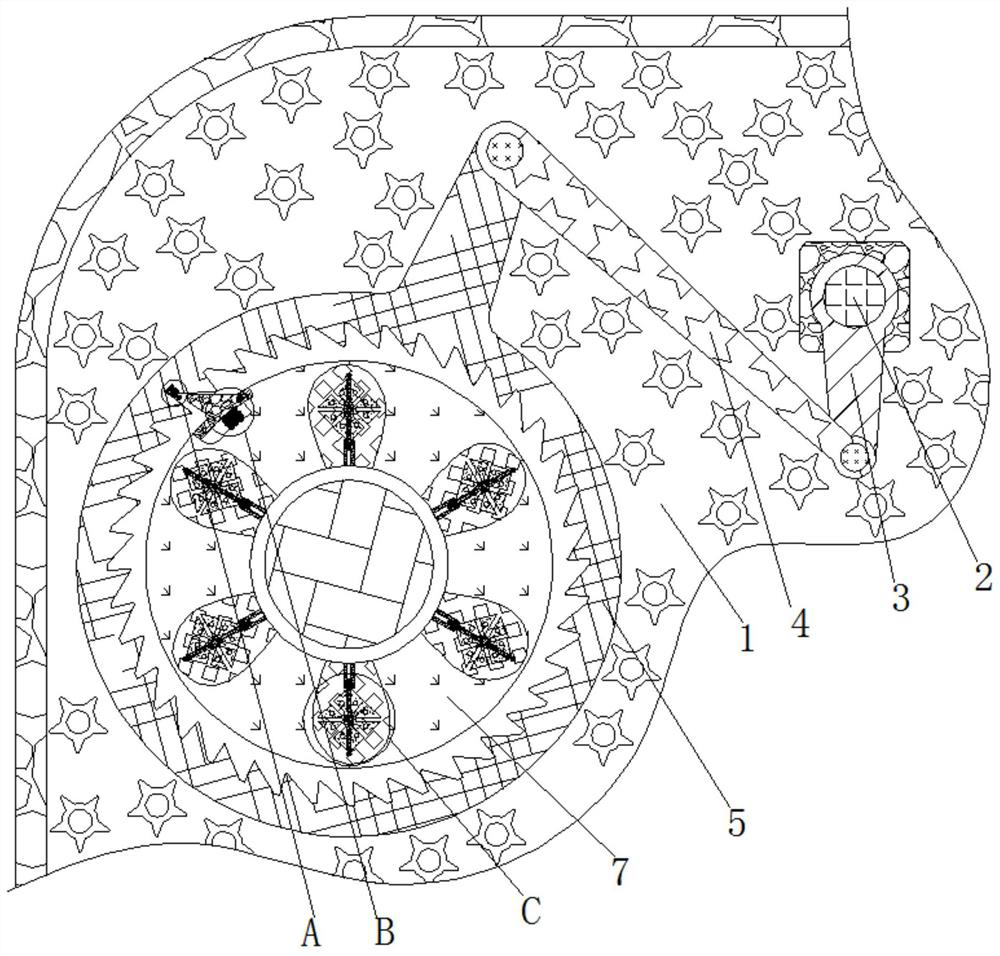

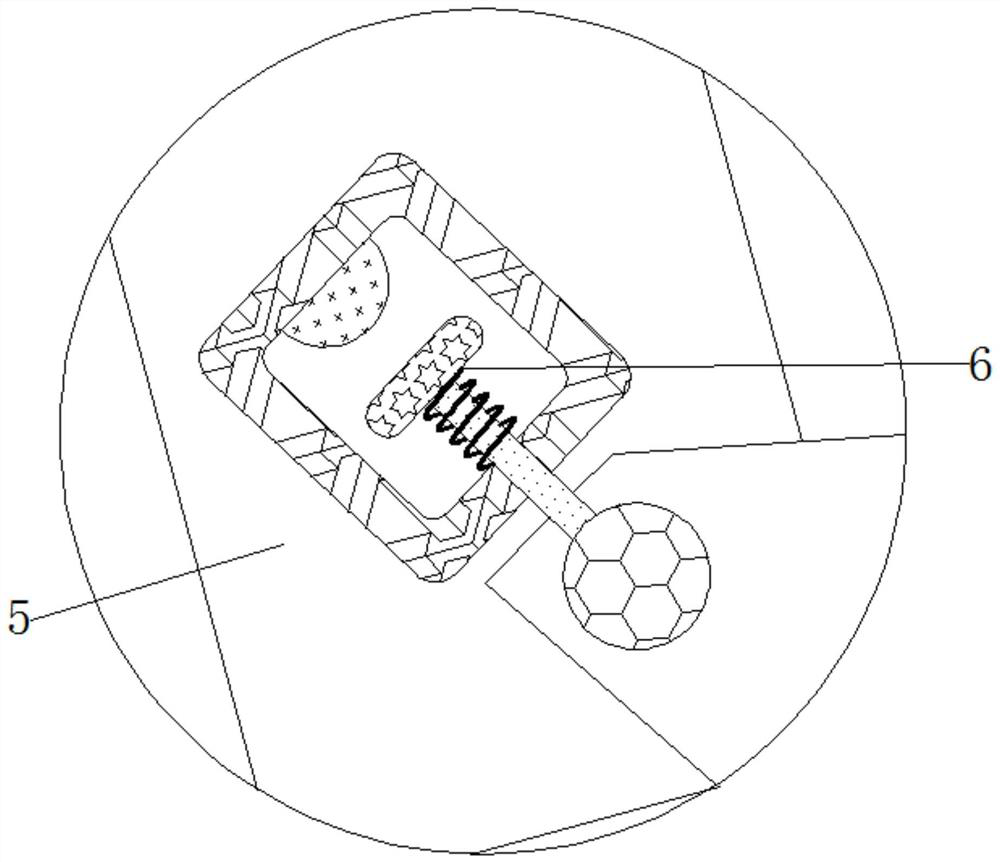

Dirty oil blocking device based on marine environmental protection engineering

InactiveCN111778943AEasy to collect and processEffective ability to bear impactWater cleaningGeneral water supply conservationOil canSea waves

Owner:任春连

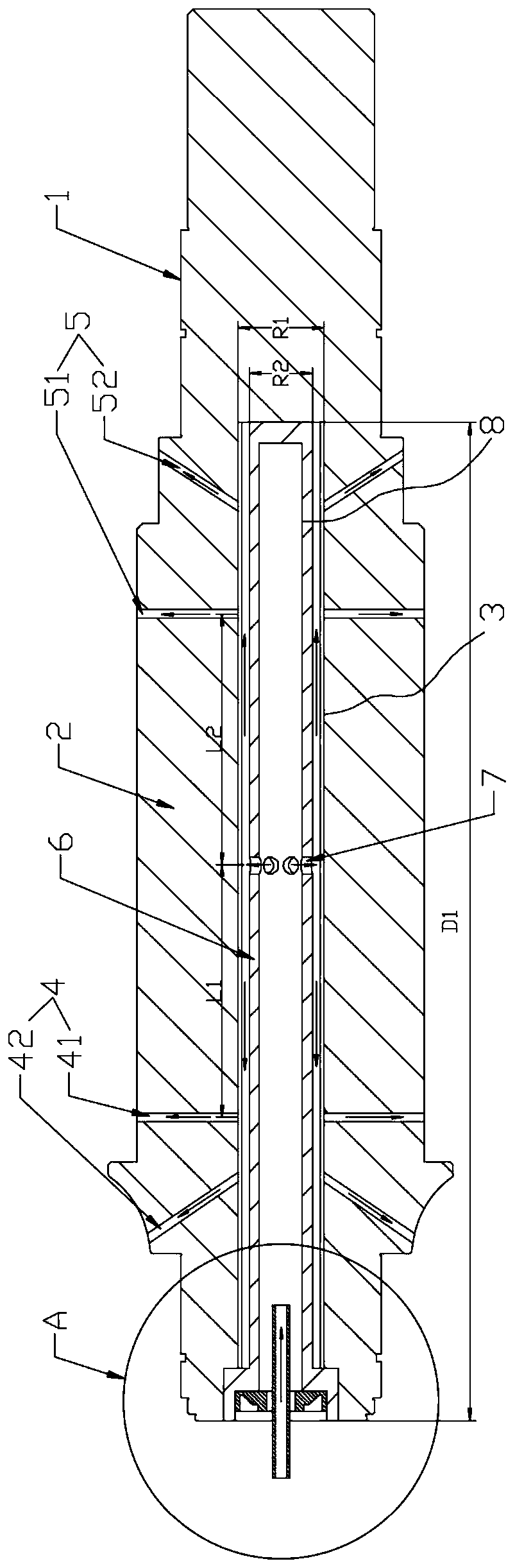

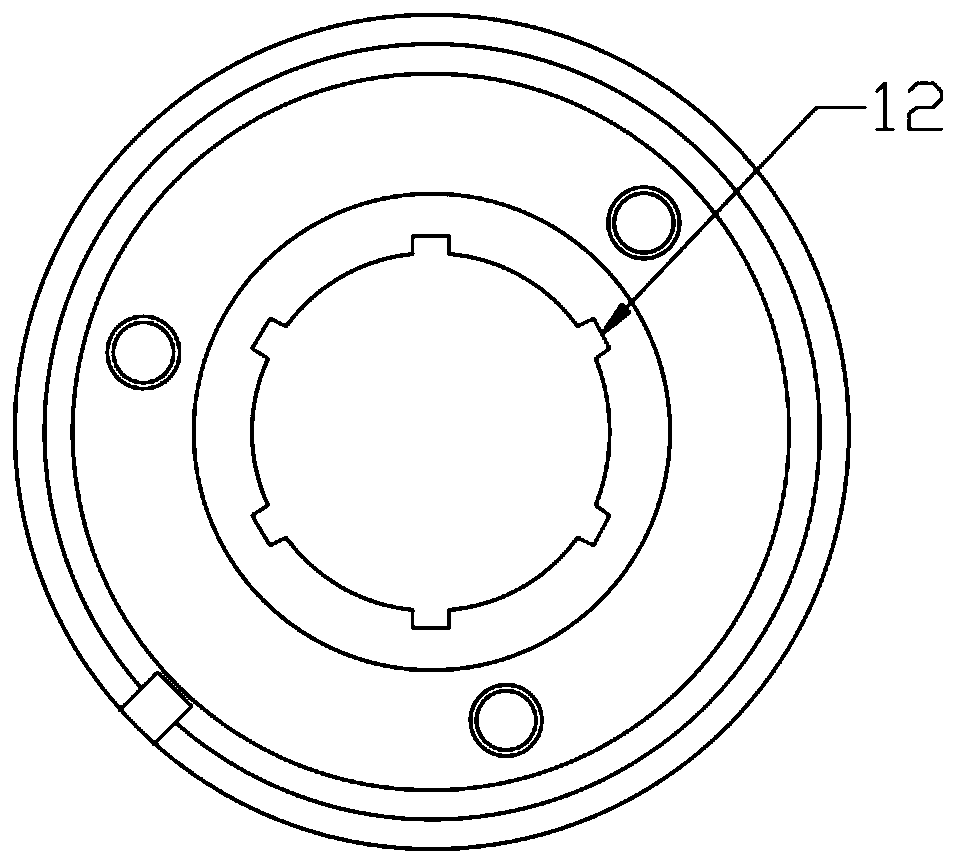

Hollow shaft sealing ring, hollow shaft, rotor structure, motor and electric vehicle

ActiveCN111564927APrevent leakageGuaranteed connectivityEngine sealsPiston ringsOil canElectric machinery

Owner:GREE ELECTRIC APPLIANCES INC

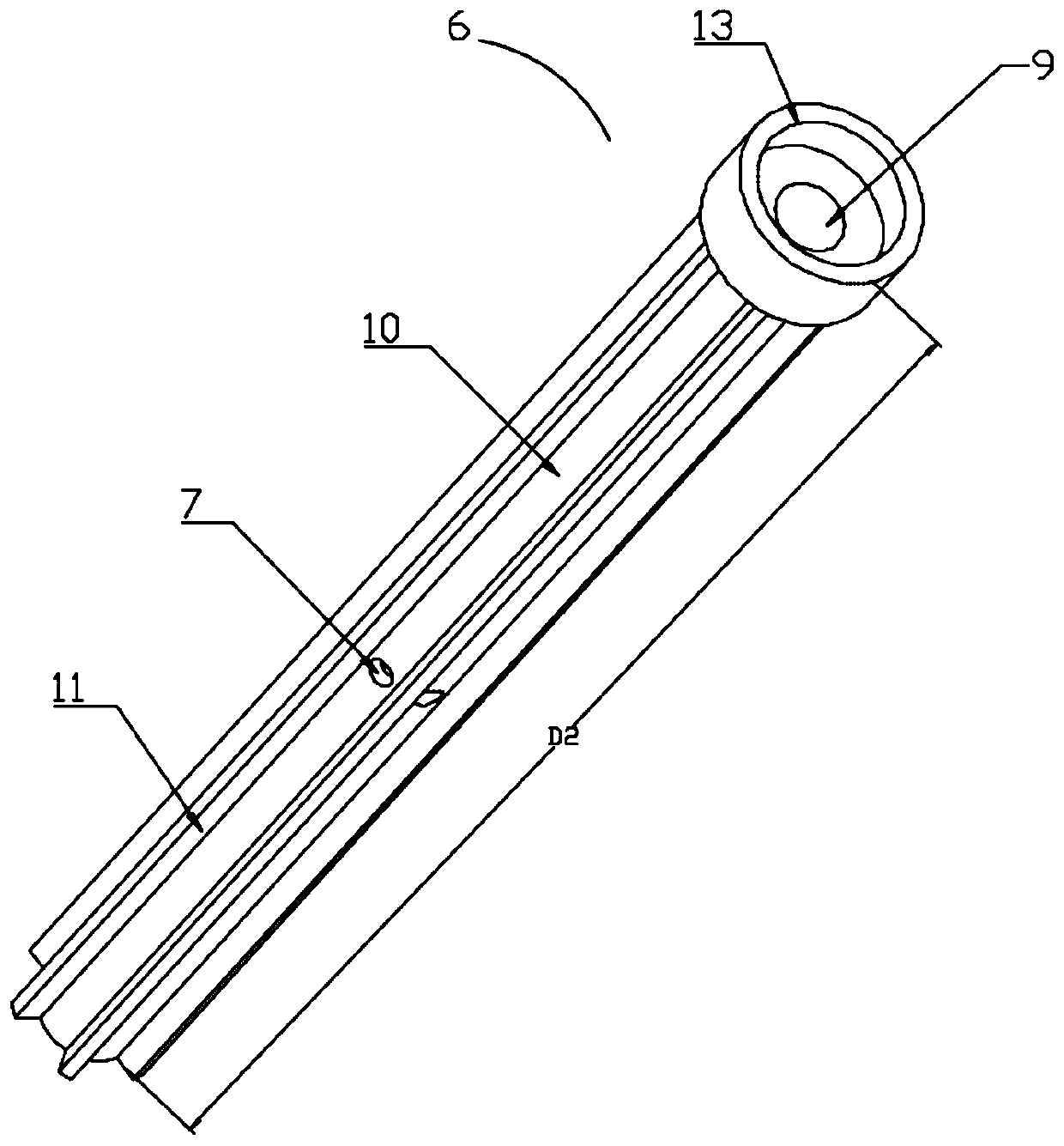

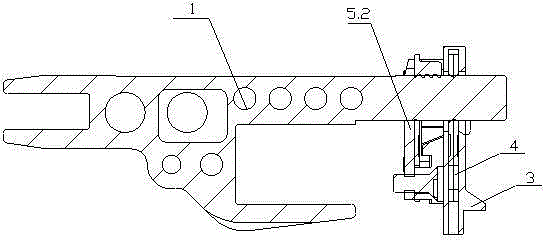

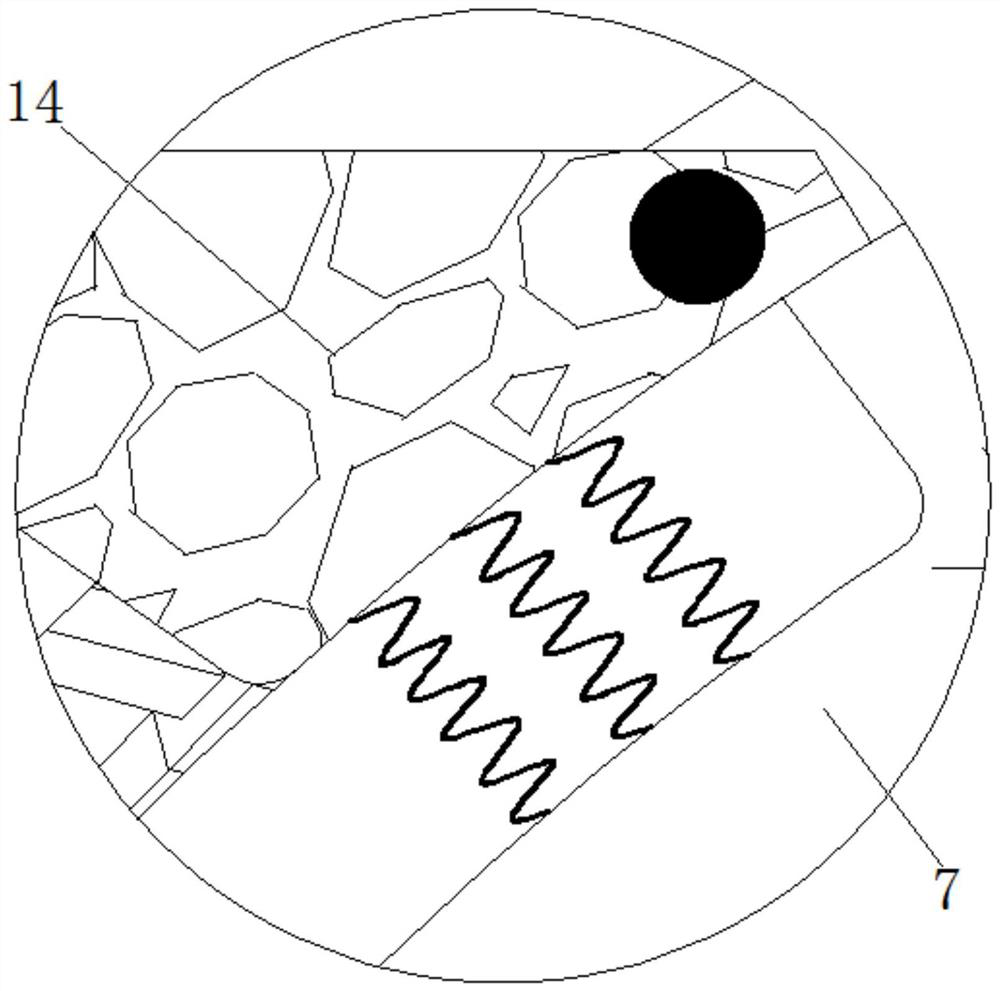

Oil leakage preventing device of feed dog rack of sewing machine

InactiveCN105420952AGood oil resistanceOil scraping effect is goodLubrication/cooling devicesOil canReturn function

Owner:JACK SEWING MASCH CO LTD

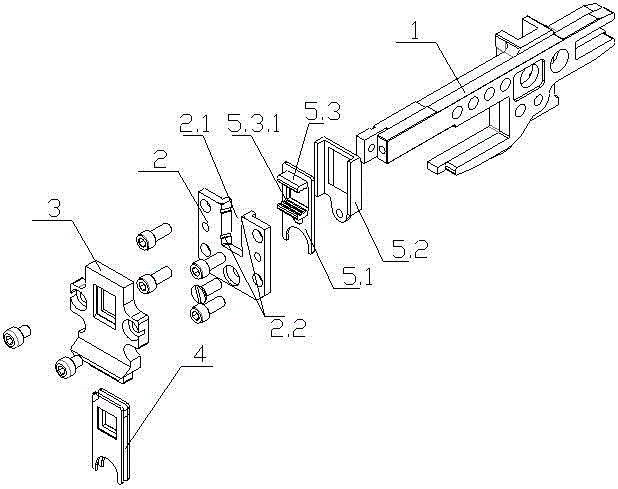

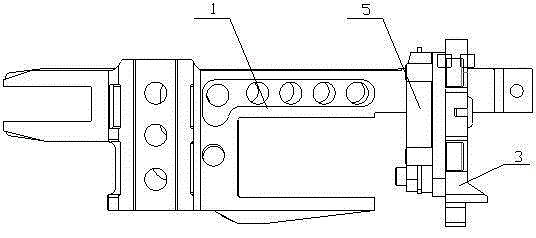

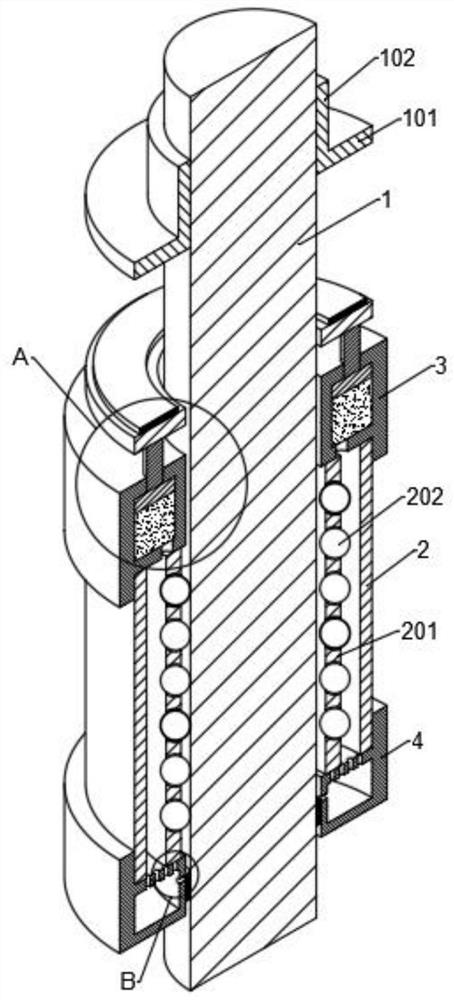

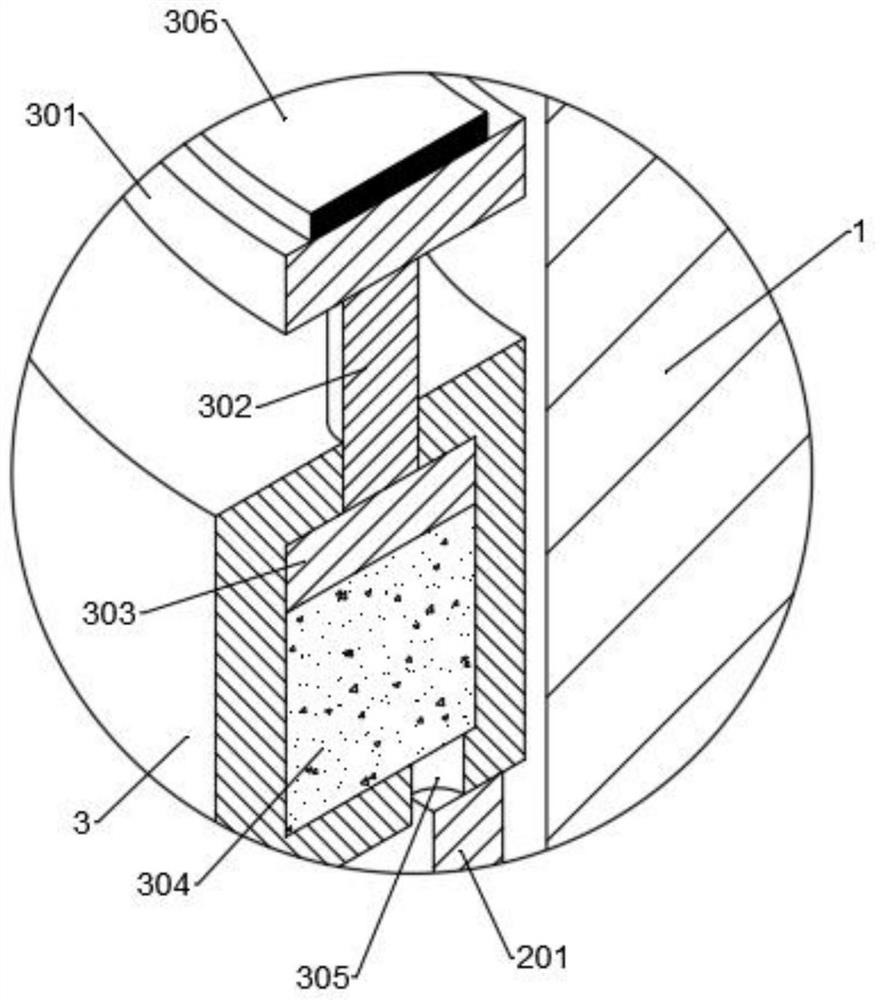

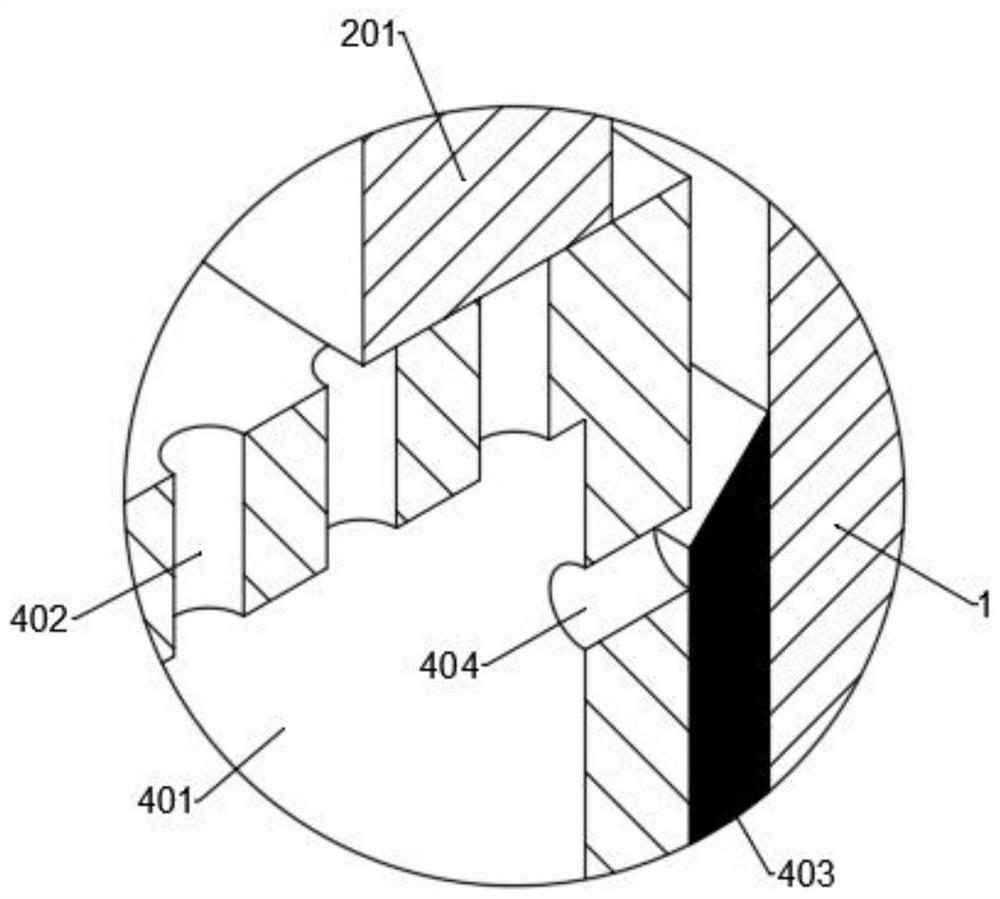

Miniature ball bushing guide assembly

Owner:东莞市创宇模具配件有限公司

Welded body open type turnbuckle

InactiveCN111271348AThe fixing method is simple and firmThe fixing method is simple and labor-savingSecuring devicesEngine lubricationOil canEngineering

Owner:江苏兴洋船舶设备制造有限公司

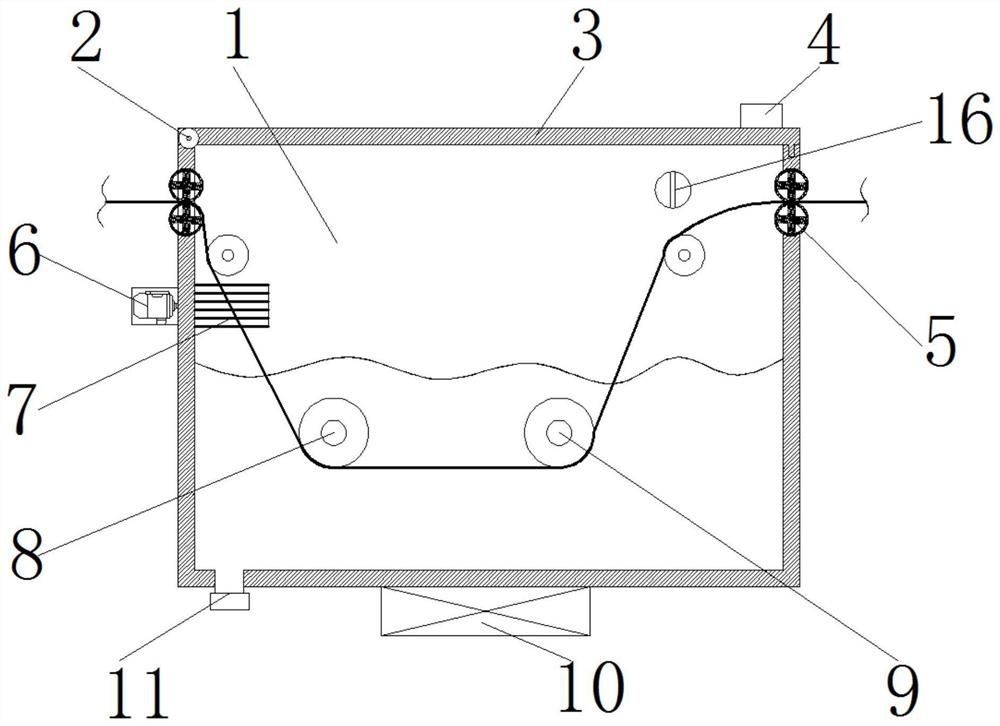

Oil stain isolation device facilitating oil stain collection and used for flat wire production

PendingCN112941764AAnnealed thoroughlyPrevent take outTextile treatment machine arrangementsLiquid/gas/vapor removal by scrapingOil canRotational axis

Owner:句容建荣汽配有限公司

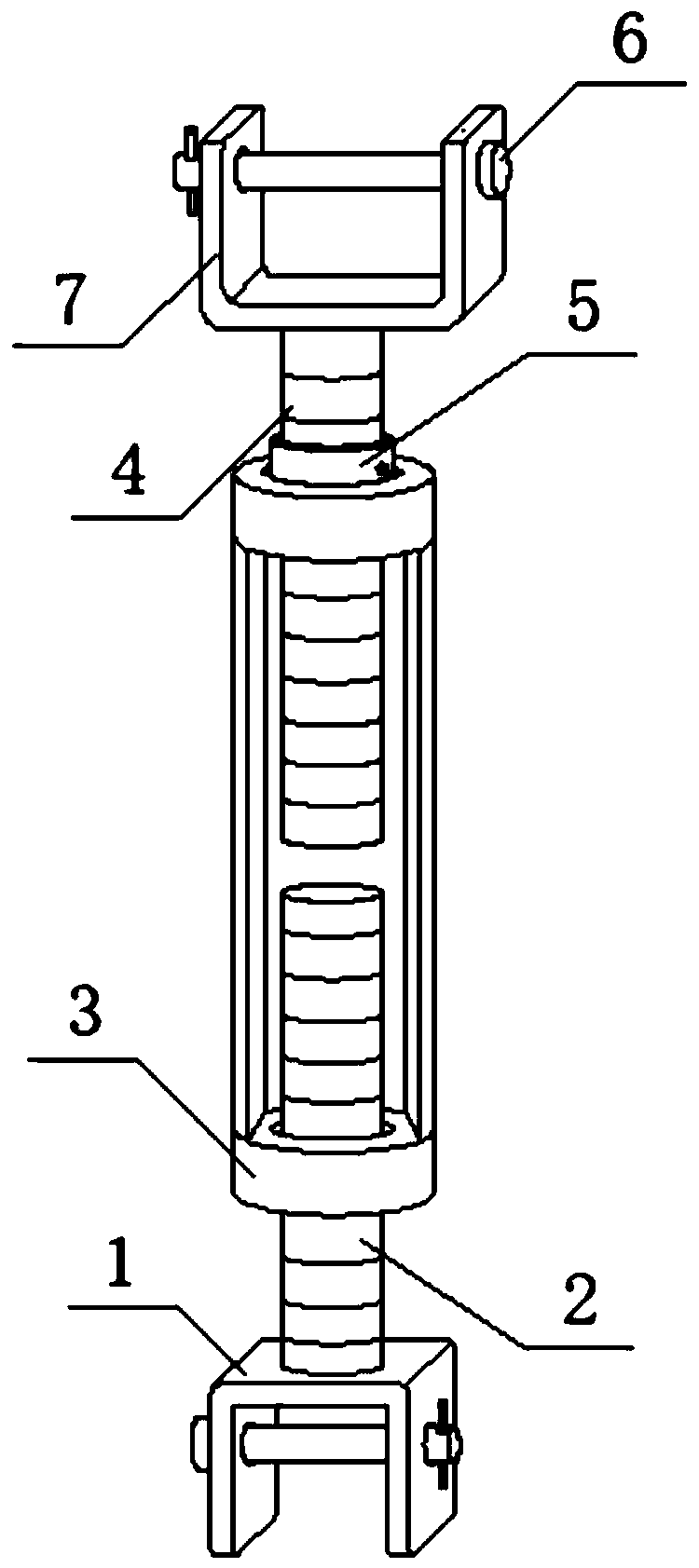

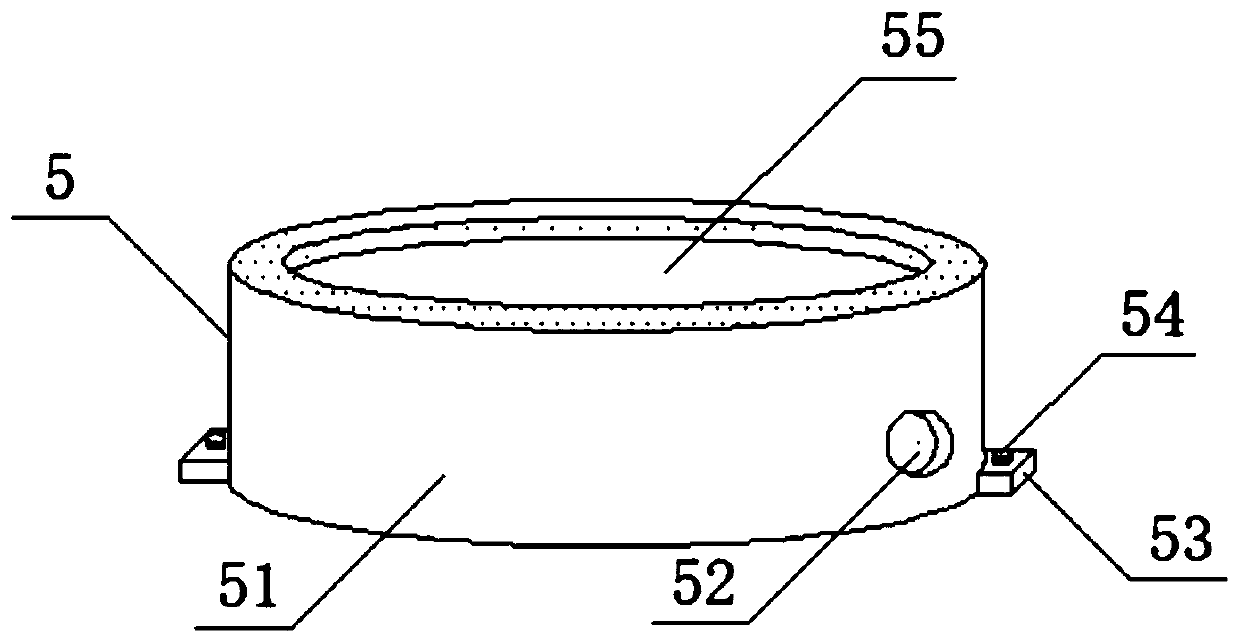

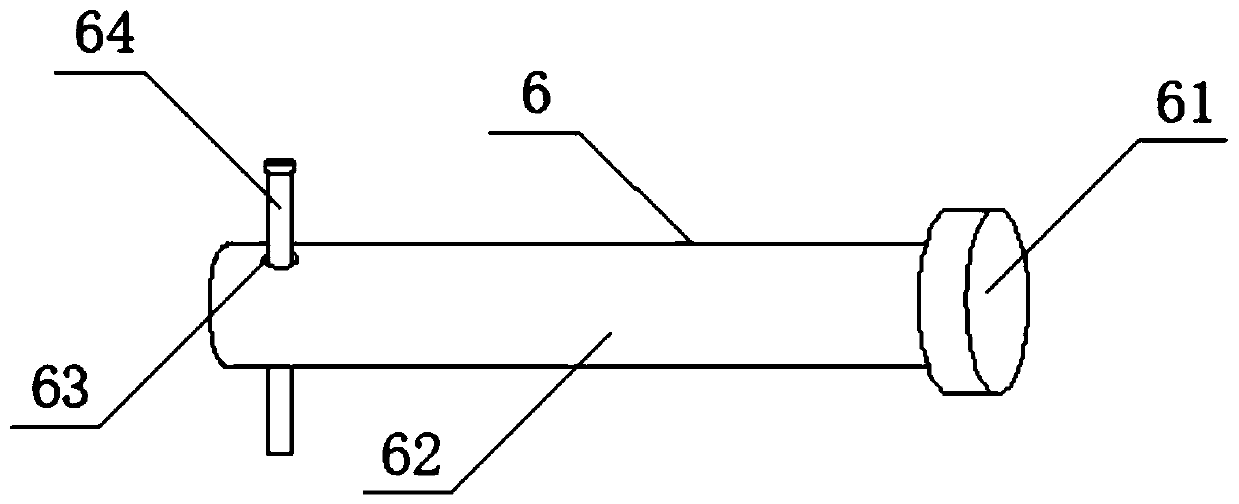

Bearing auxiliary oiling device for mine ventilator

Owner:佛山繁微星工业设计有限公司

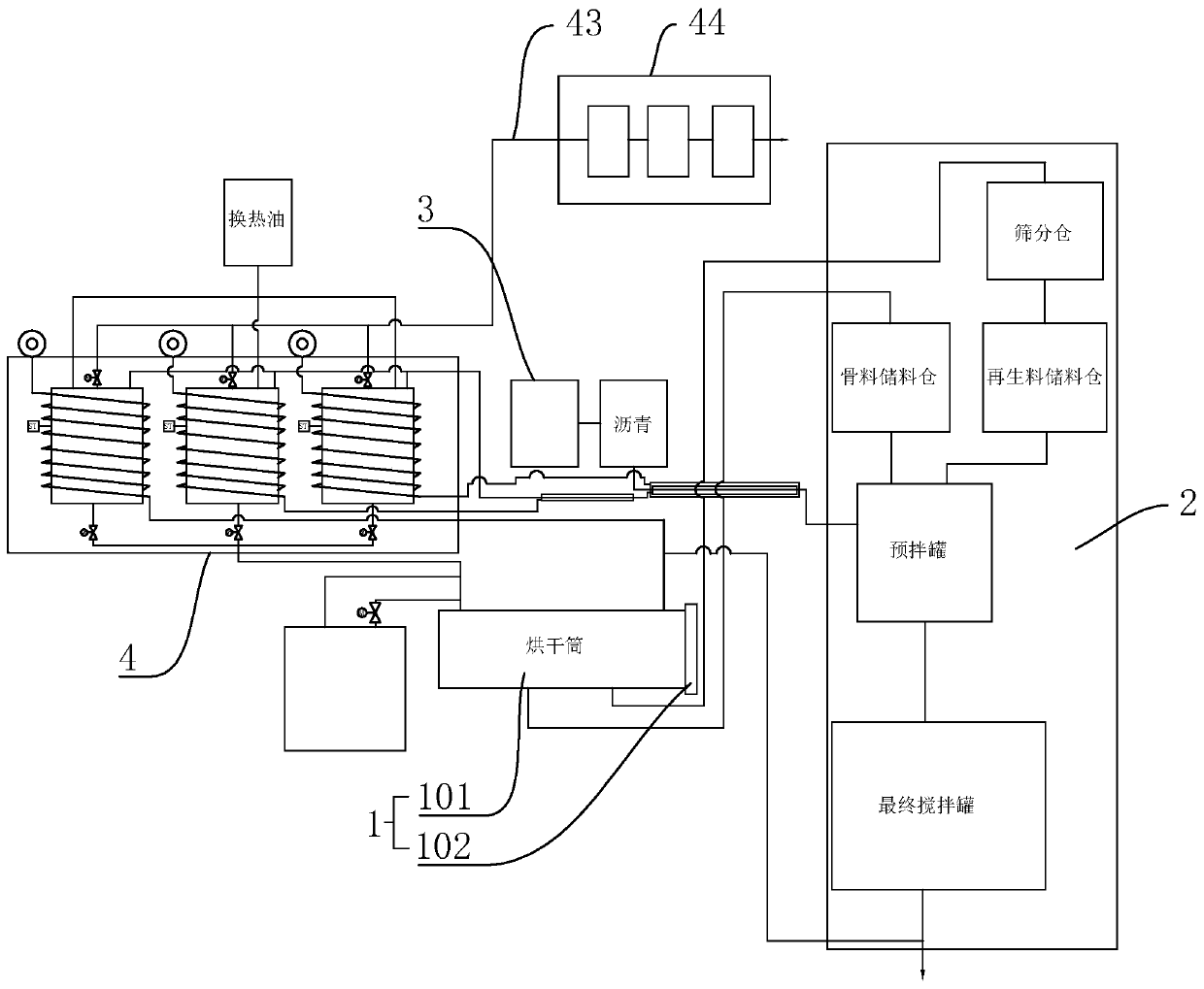

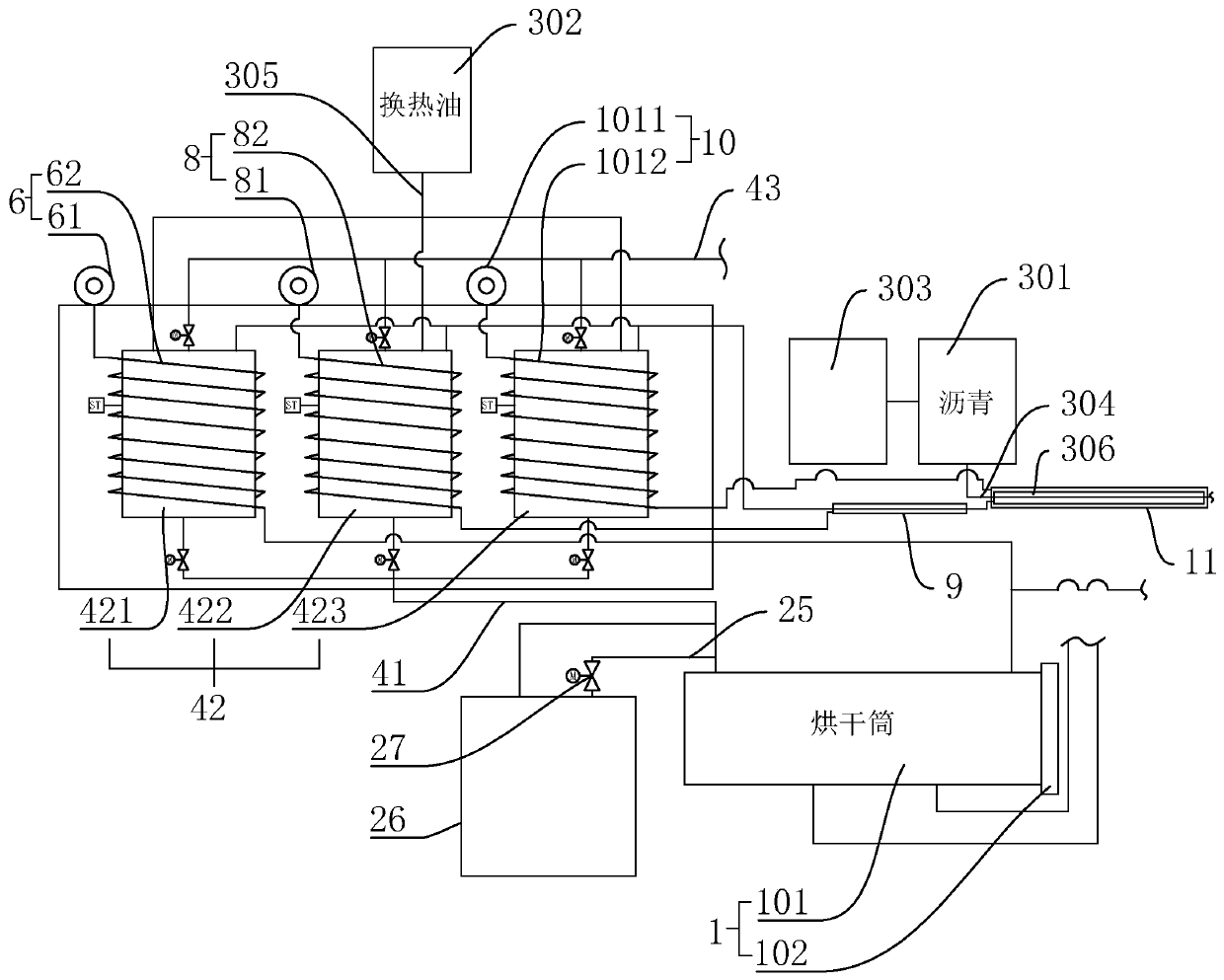

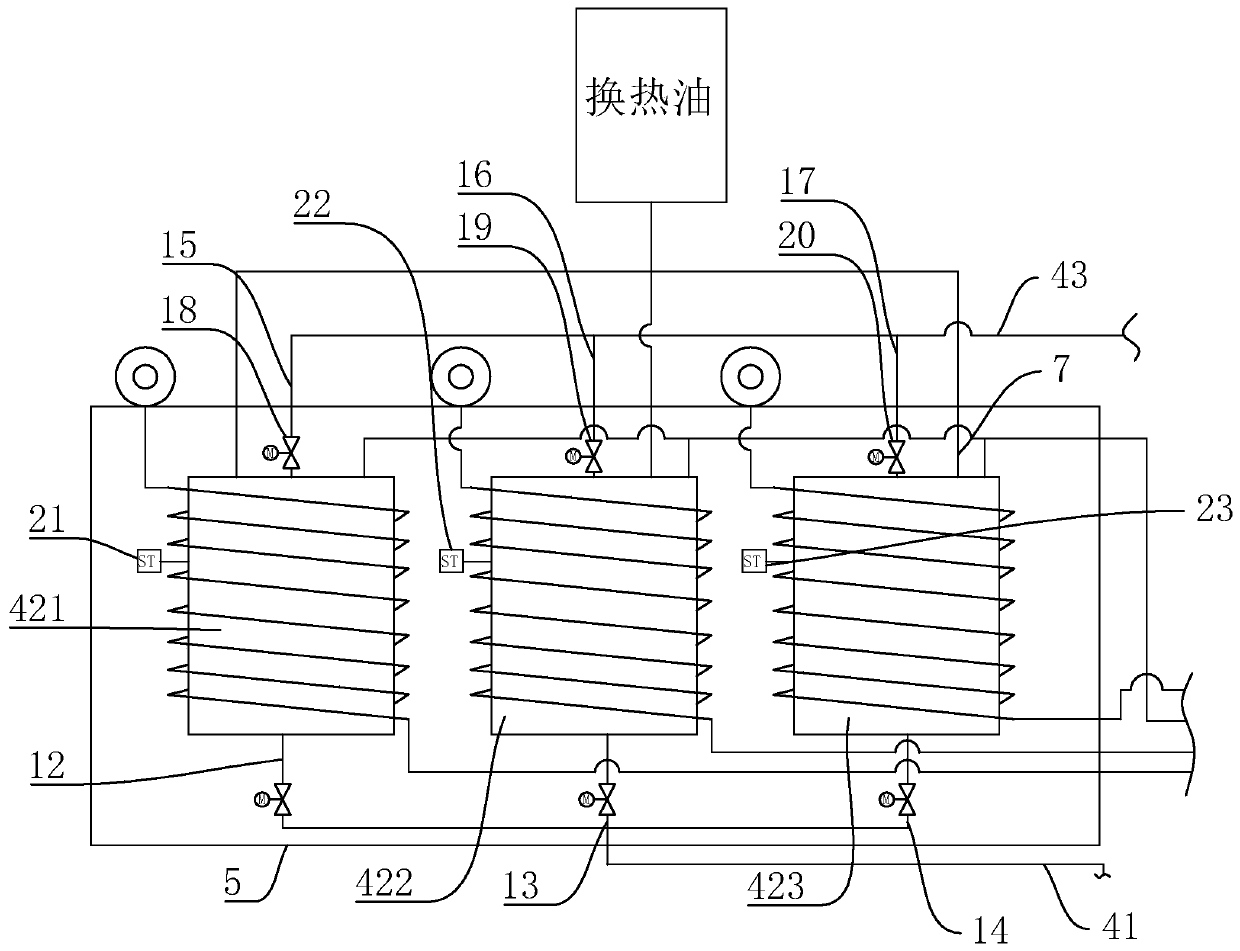

Flue gas heat energy recycling system applied in production process of bituminous concrete

InactiveCN111578743ATake advantage ofAvoid wastingHeat storage plantsDrying gas arrangementsOil canThermodynamics

Owner:江苏盛达飞建筑材料有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap