Oil leakage preventing device of feed dog rack of sewing machine

A technology for preventing oil leakage and sewing machines. It is applied in the direction of sewing machine components, sewing equipment, lubrication/cooling devices, etc. It can solve the problem of large contact area between the oil seal and the guide rail, the oil cannot be completely scraped off, and the oil leakage of the bracket cannot be completely solved. problem, to achieve a better oil scraping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

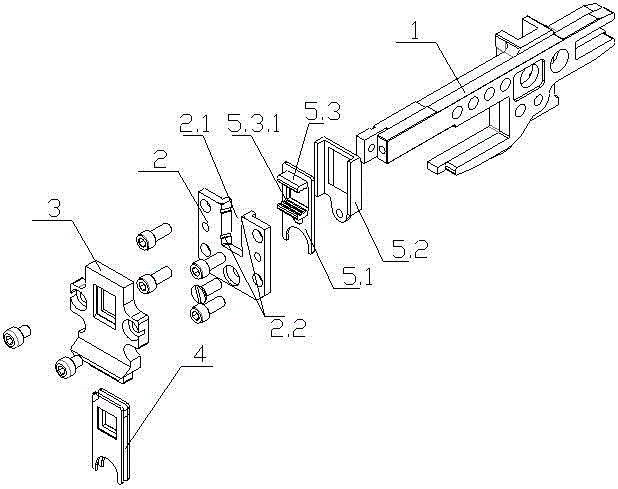

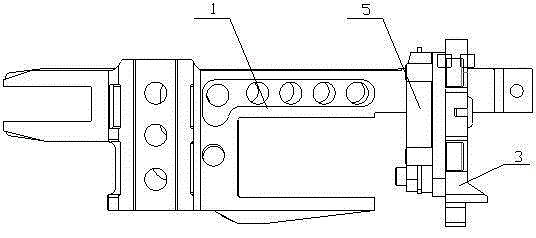

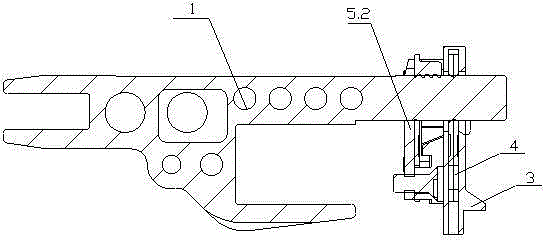

[0023] refer to Figure 1 to Figure 3 The embodiment of the oil leakage prevention device for the tooth frame of the sewing machine of the present invention will be further described.

[0024] In the prior art bracket oil leakage prevention device, only an oil blocking mechanism is arranged on the outer side of the bracket, and there is only one oil prevention measure, and the oil prevention effect is poor. Therefore, the present invention designs two oil-proof mechanisms. The specific structure is as follows. An oil leakage prevention device for a sewing machine bracket 1 includes a bracket 1, a bracket guide 2, an oil baffle 3, and an oil seal 4. The oil seal 4 is assembled in the oil baffle 3, and the bracket 1 It is slidably fitted on the bracket rail 2, the bracket 1 runs through the oil seal 4, and also includes an inner oil-proof assembly 5, the bracket guide 2 is located on the inner side of the oil baffle 3, and the inner oil-proof assembly 5 is located on the inner sid

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap