Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

133 results about "Petroleum engineering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Petroleum engineering is a field of engineering concerned with the activities related to the production of hydrocarbons, which can be either crude oil or natural gas. Exploration and production are deemed to fall within the upstream sector of the oil and gas industry. Exploration, by earth scientists, and petroleum engineering are the oil and gas industry's two main subsurface disciplines, which focus on maximizing economic recovery of hydrocarbons from subsurface reservoirs. Petroleum geology and geophysics focus on provision of a static description of the hydrocarbon reservoir rock, while petroleum engineering focuses on estimation of the recoverable volume of this resource using a detailed understanding of the physical behavior of oil, water and gas within porous rock at very high pressure.

Method for evaluation of hydrocarbon content of shale

InactiveUS20120312090A1Easy to exportSeismology for water-loggingBorehole/well accessoriesKerogenPyrite

The invention relates to the evaluation of hydrocarbon gas or liquid deposits, or condensate, in a shale formation. From relatively few log inputs, together with assumed or estimated or known values for density or porosity of kerogen, a single mathematical process involving the solution of a number of simultaneous equations, provides a value for both kerogen volume and total porosity. Additional checks and balances may be used to provide corrections to the result, for example based on pyrite volume or water saturation.

Owner:CONOCOPHILLIPS CO

Lubricating oil special for motorcycle engine and preparing method thereof

ActiveCN104031729AExtended service lifeThe steps are simple and environmentally friendlyLubricant compositionAntioxidantViscosity index

The invention discloses a lubricating oil special for a motorcycle engine, and belongs to the technical field of lubricating oil. The lubricating oil is obtained through a reaction carried out on 80 parts to 90 parts of base oil, 2 parts to 5 parts of abrasion resistance agents, 5 parts to 10 parts of corrosion resistance agents, 2 parts to 5 parts of cleaning factors, 5 parts to 15 parts of antioxidant, 1 part to 3 parts of metal deactivator and 8 parts to 12 parts of viscosity modifier. The base oil is composed of 30 parts to 40 parts of PAO and 40 parts to 50 parts of naphthenic base oil. The cleaning factors are any one of metal-based sodium or metal-based calcium or metal-based magnesium. The invention further discloses a preparing method of the lubricating oil. According to the lubricating oil special for the motorcycle engine, the cost of the base oil is controlled, and the better viscosity index and the high abrasion resistance performance can be ensured at the same time; viscous black carbon mud particles wrapped on engine parts can be effectively removed through matched addition of auxiliaries, the service life of the engine is prolonged, the equipment maintenance cost is reduced, and the clean abrasion protection mode is provided for the motorcycle engine. The preparing method of the lubricating oil is simple in steps, environmentally friendly, and easy to implement.

Owner:BAOJIE LUBRICATING OIL ZHENJIANG CO LTD

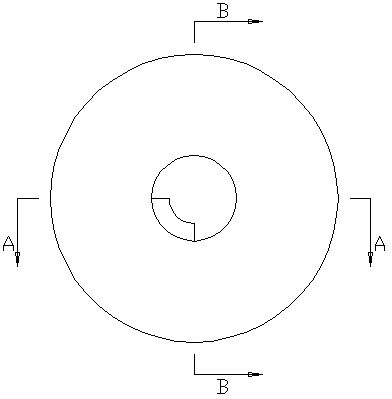

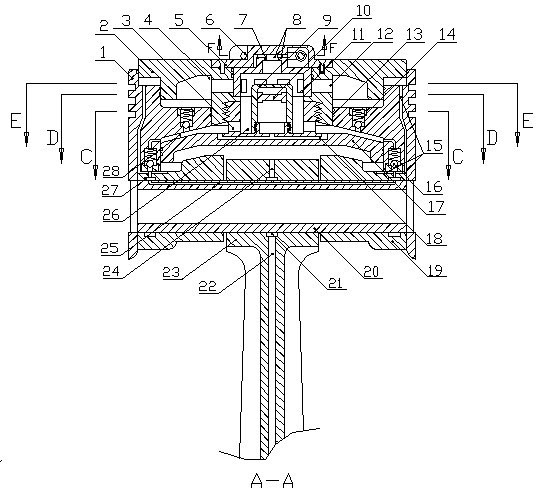

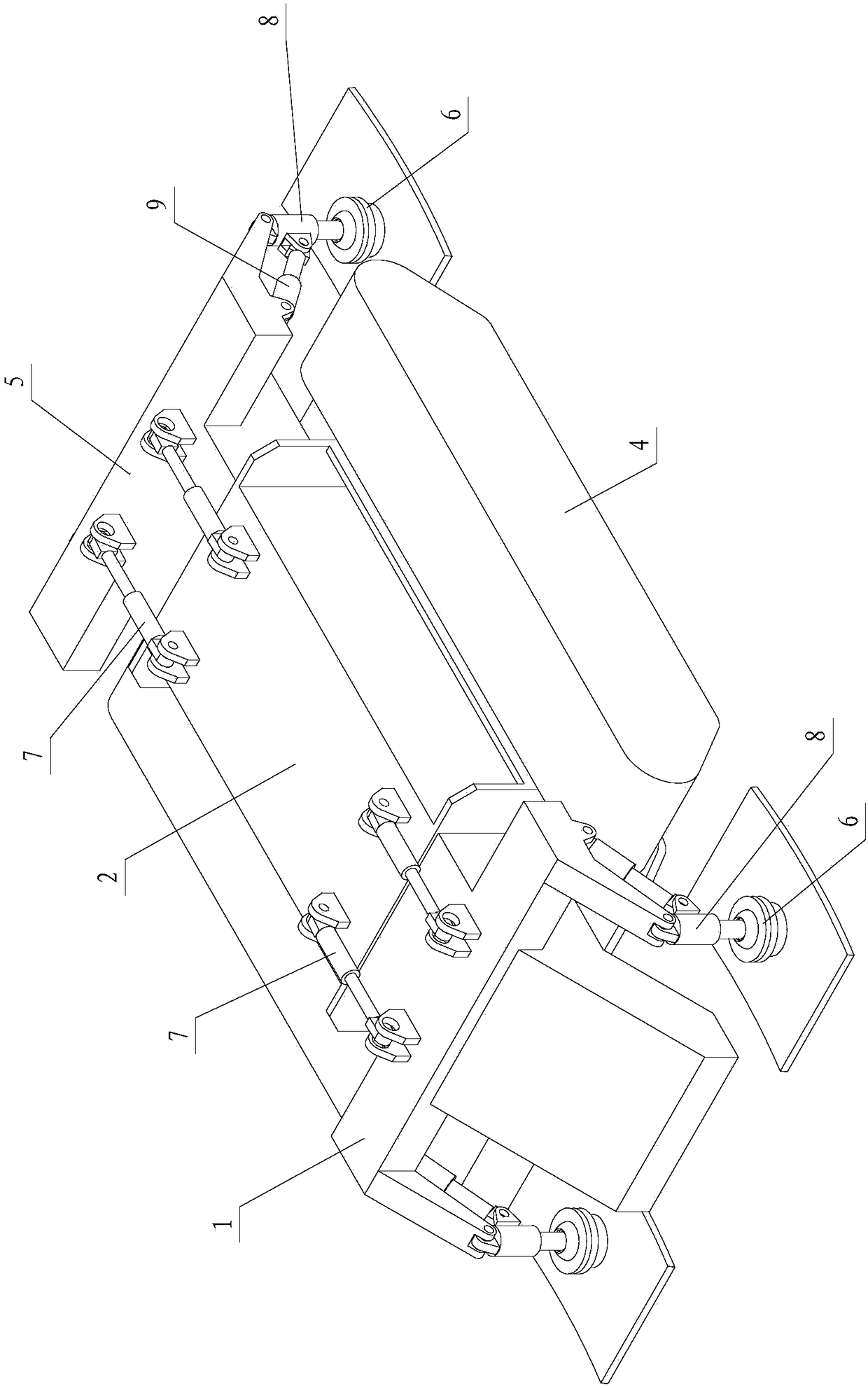

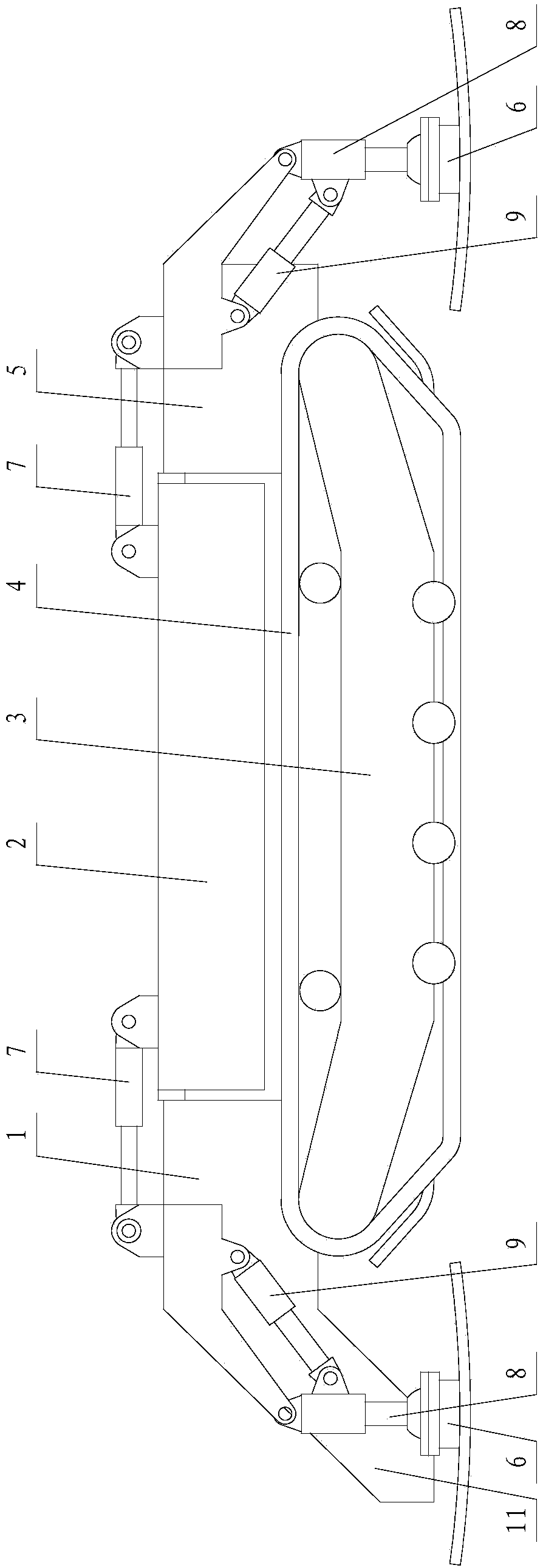

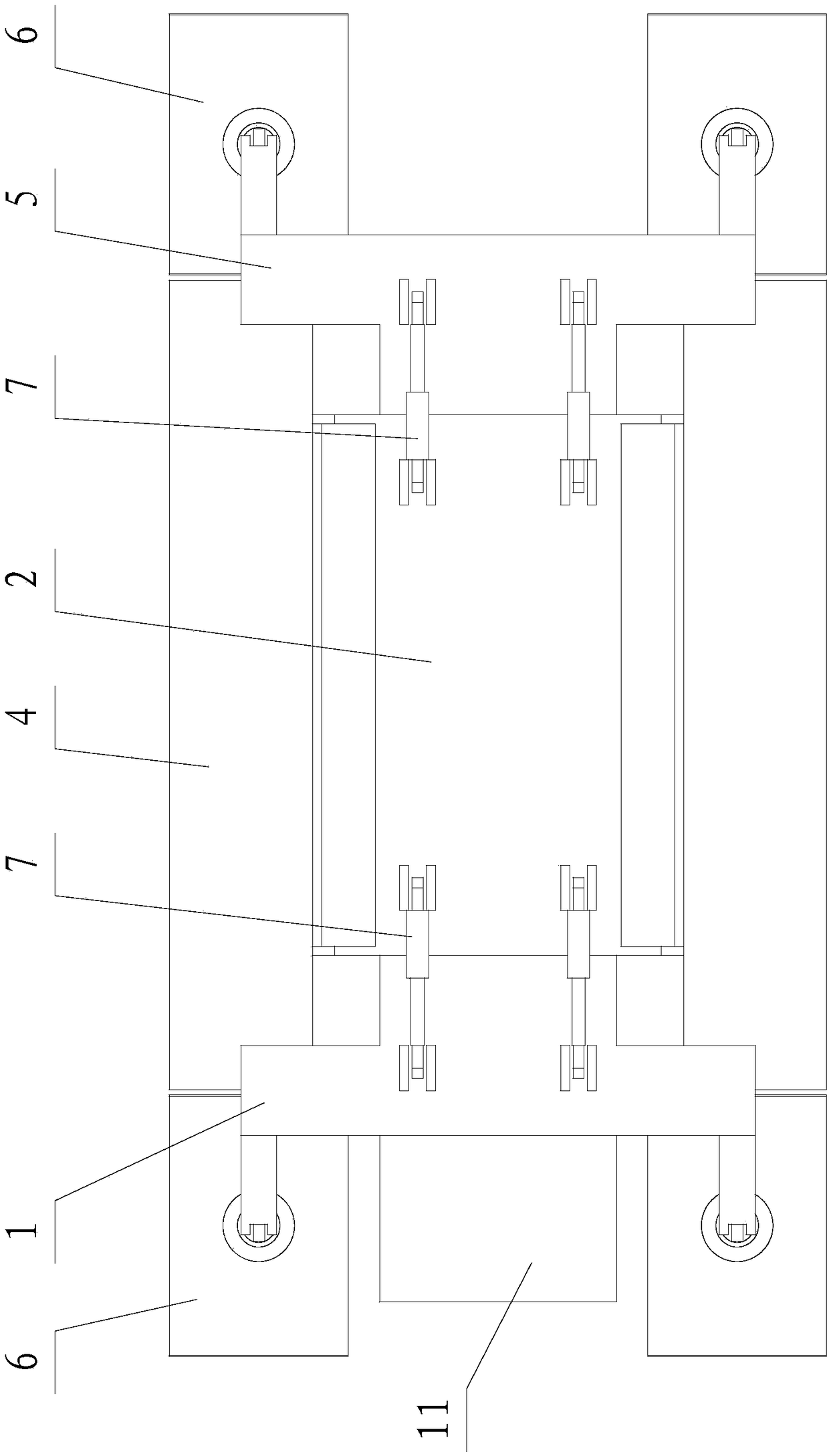

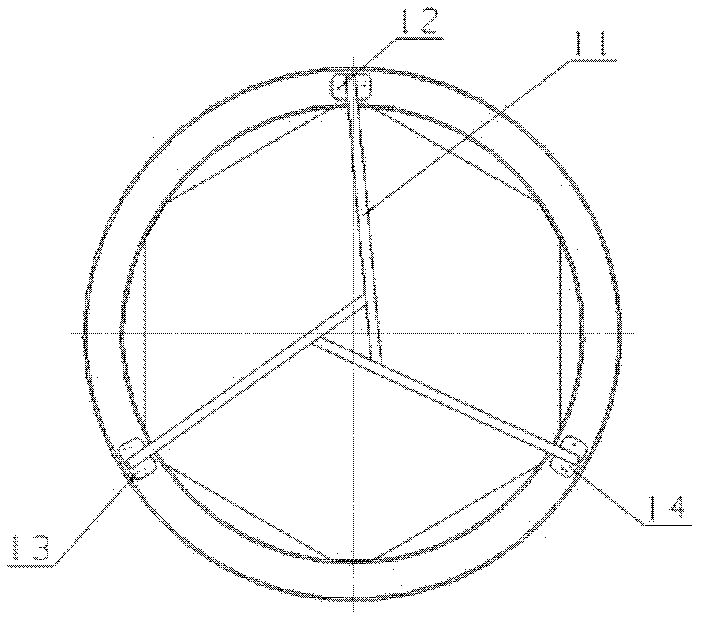

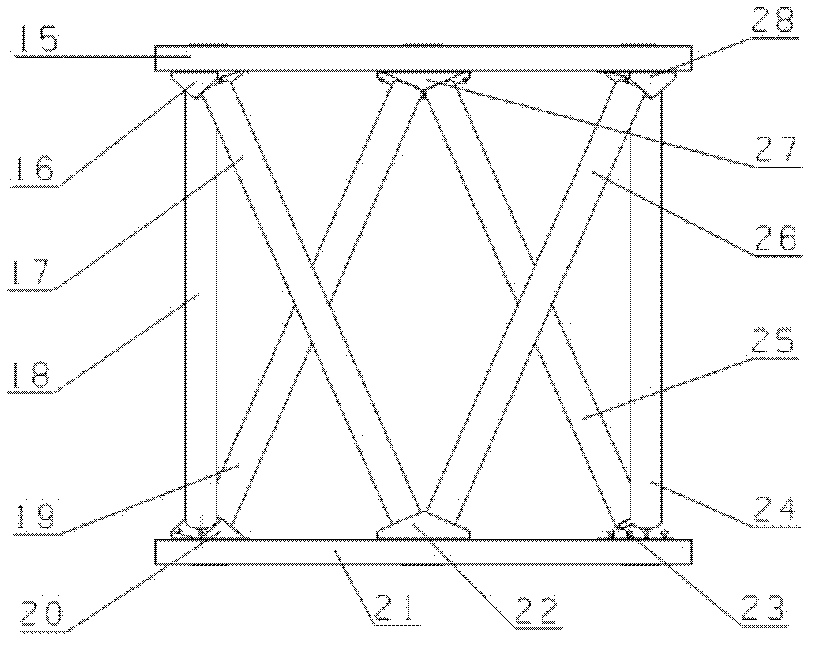

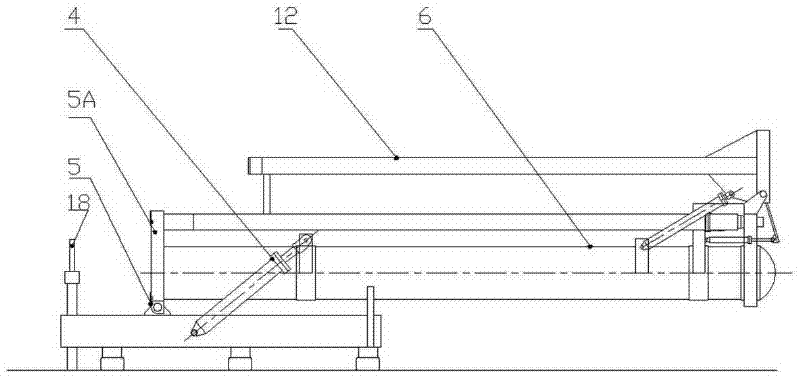

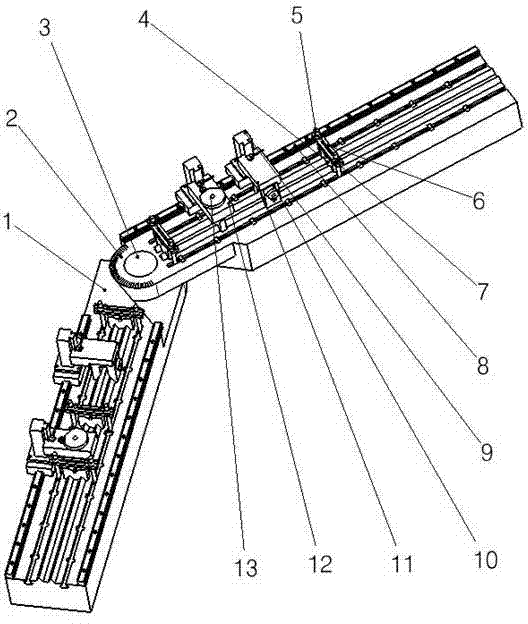

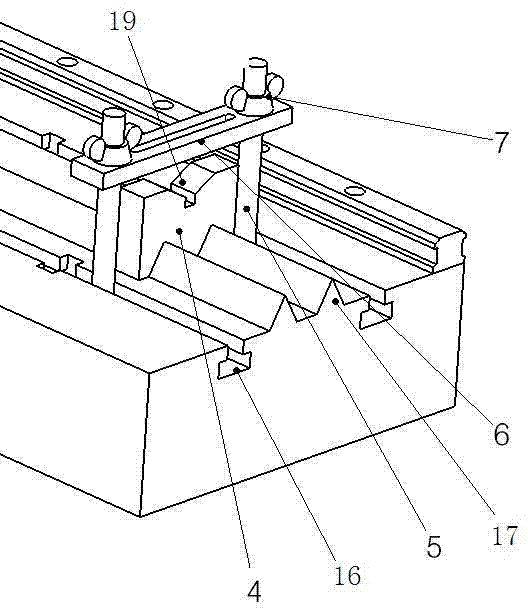

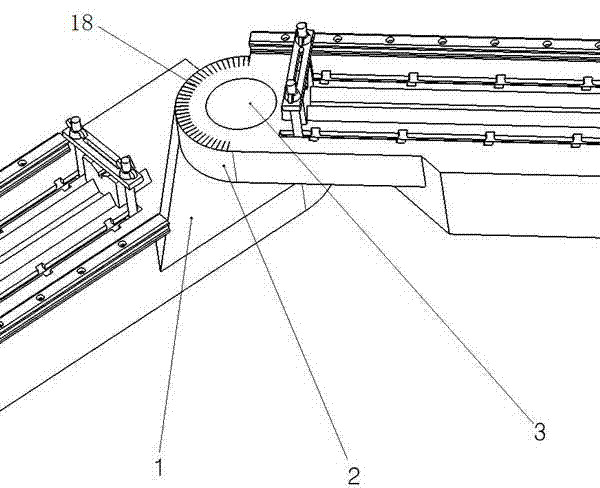

Single-hole geological radar automatic drilling rig arranged at cutter head center of tunneling machine

ActiveCN103696780ASo as not to damageHigh degree of automationTunnelsAutomatic control for drillingBorehole radarSpherical joint

The invention discloses a single-hole geological radar automatic drilling rig arranged at the cutter head center of a tunneling machine. The single-hole geological radar automatic drilling rig comprises an equipment entrance and exit hole, a rapid drilling machine, a borehole geological radar detection device and a carrying device, wherein the equipment entrance and exit hole is located at the cutter head center of the tunneling machine, the rapid drilling machine for the synchronous operation of tunneling and drilling and the borehole geological radar detection device are arranged in the hole, the carrying device comprises a carrying device support and an initiative angle adjusting device for adjusting an included angle between a drill bit of the rapid drilling machine or a borehole radar antenna hydraulic expansion link and the rotating axis of a cutter head of the tunneling machine, and the rapid drilling machine and the borehole geological radar detection device move relative to the device support, and the carrying device support is connected to the cutter head of the tunneling machine by a spherical joint for an equipment entrance and exit pipeline. The single-hole geological radar automatic drilling rig has the beneficial effects that the synchronous operation of tunneling and drilling can be realized, and the included angle between the eccentric casing drilling bit or the borehole radar antenna hydraulic expansion link and the rotating axis of the cutter head of the tunneling machine is adjusted.

Owner:SHANDONG UNIV

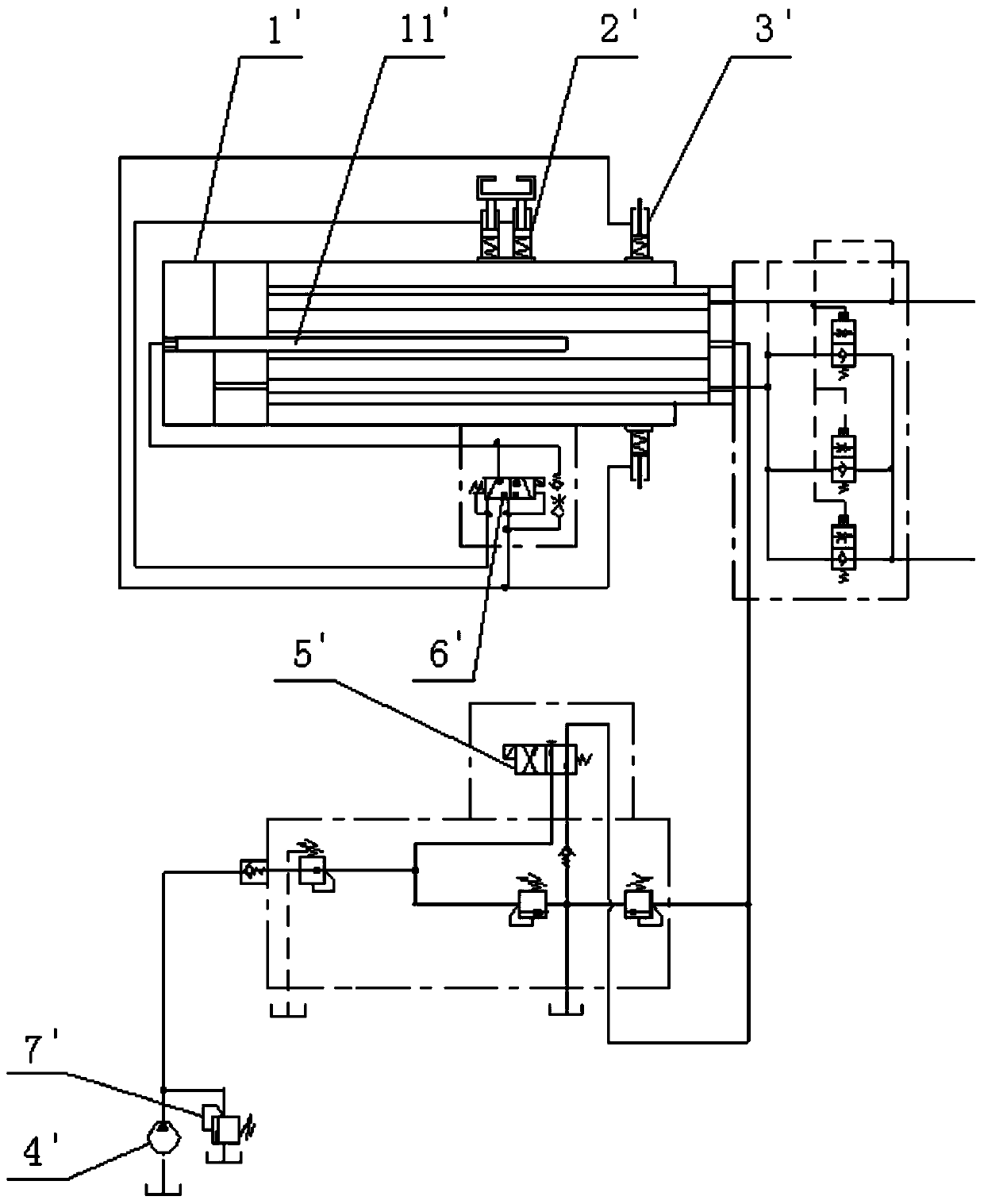

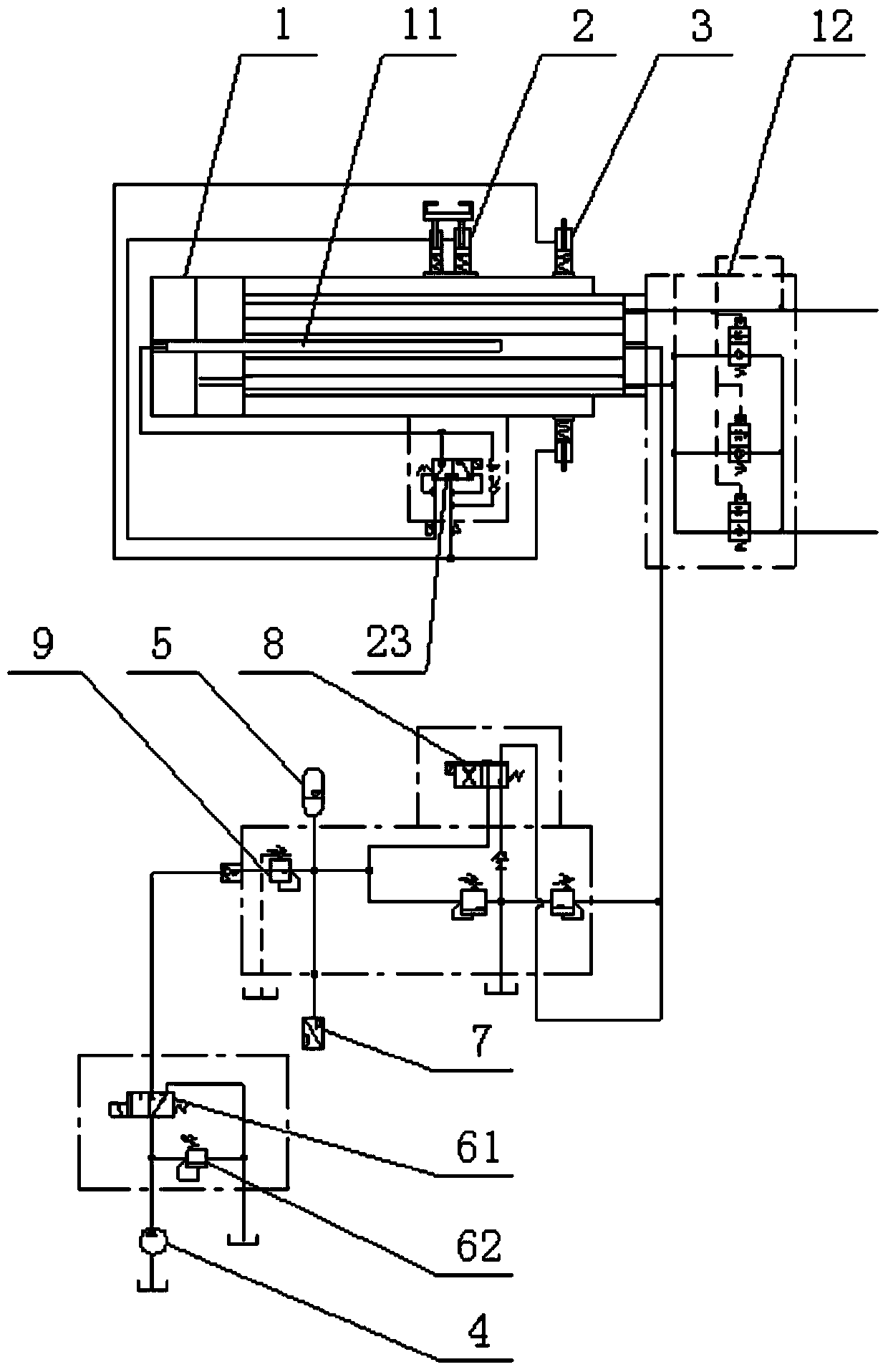

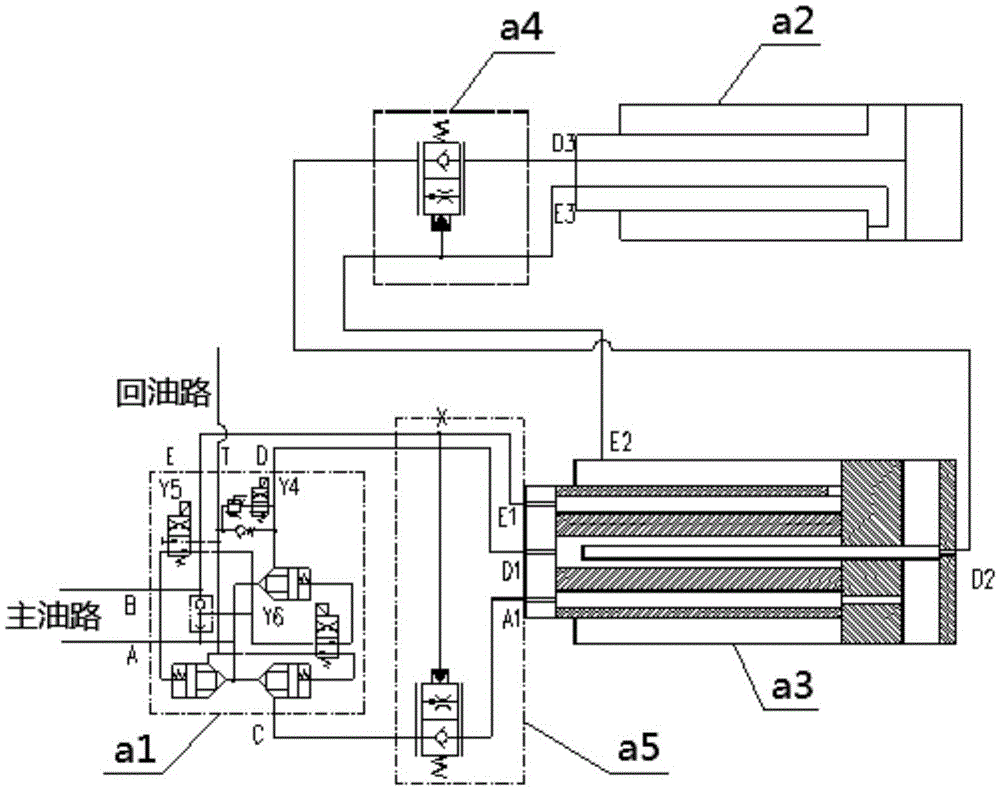

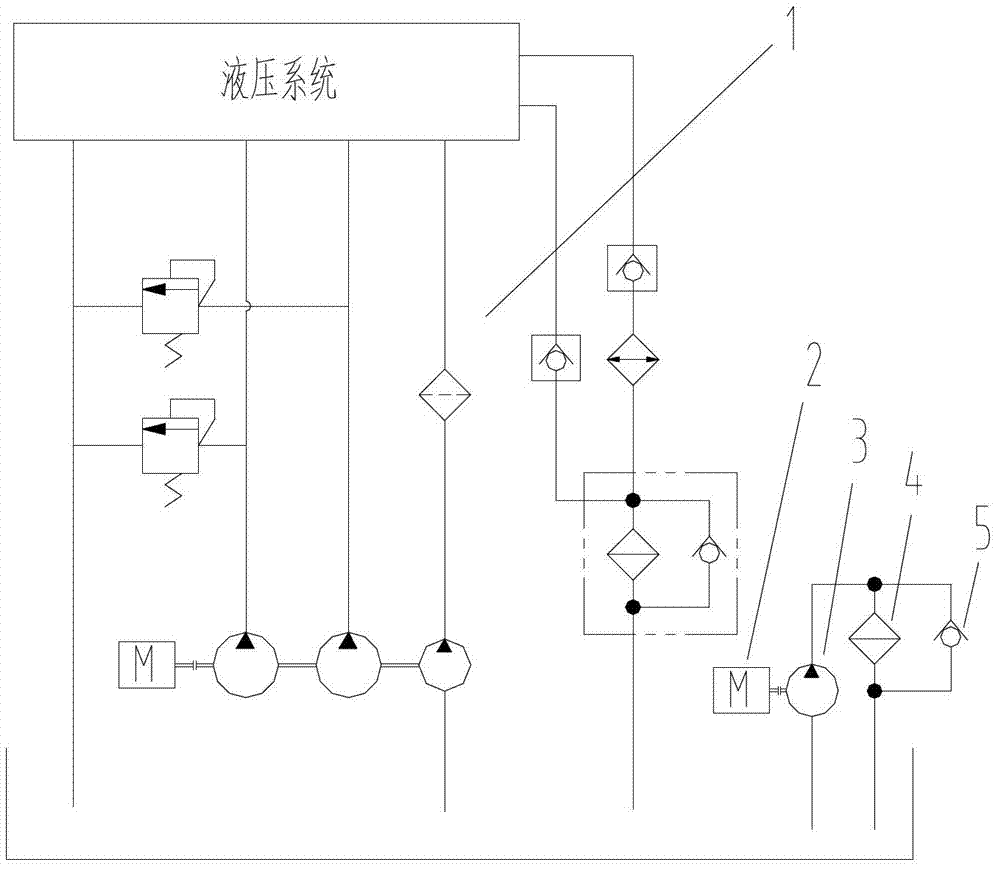

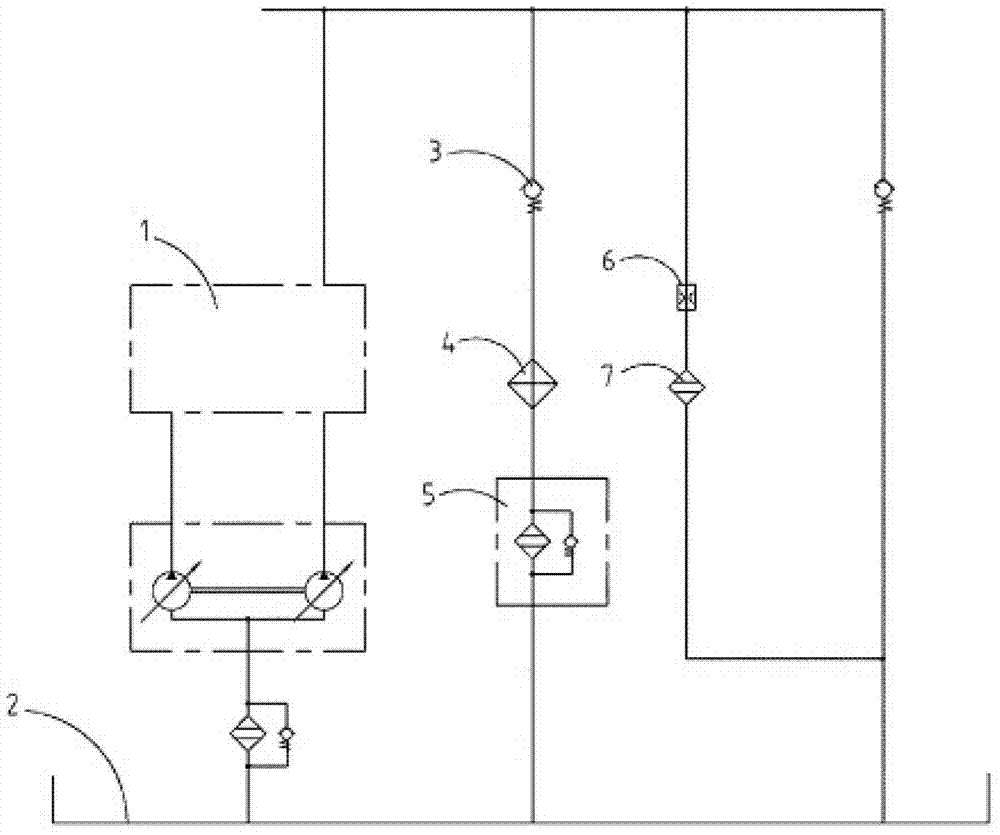

Hydraulic system and control method of single-cylinder pin type telescopic arm and crane

ActiveCN103438034AReduce temperature riseNo overflow lossServomotorsCranesSystem pressurePetroleum engineering

Owner:XUZHOU HEAVY MASCH CO LTD

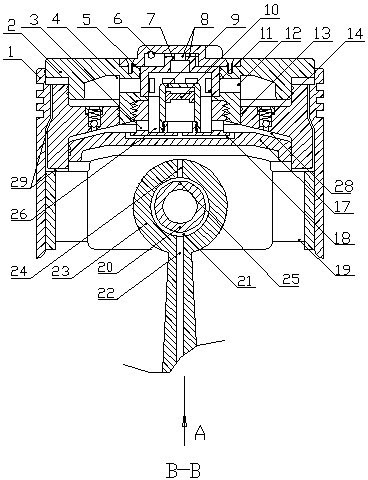

Adaptive variable compression engine piston

ActiveCN102330617ANo significant volume changeActual replacement installationEngine controllersMachines/enginesCombustionCheck valve

Owner:安徽格太信控科技有限公司

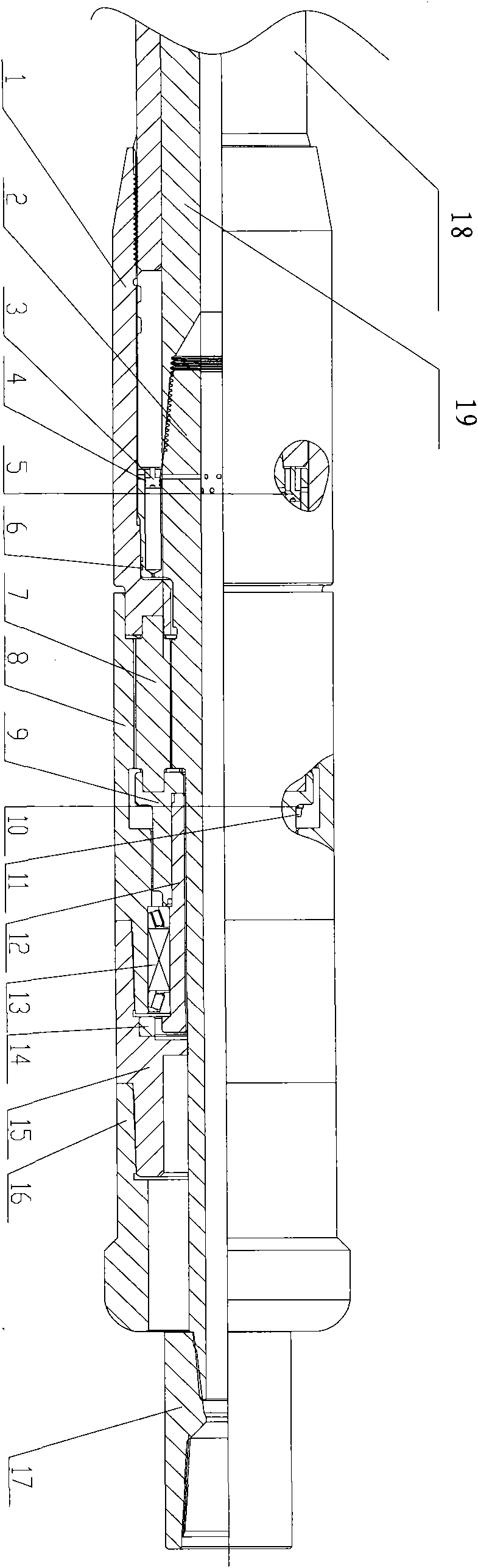

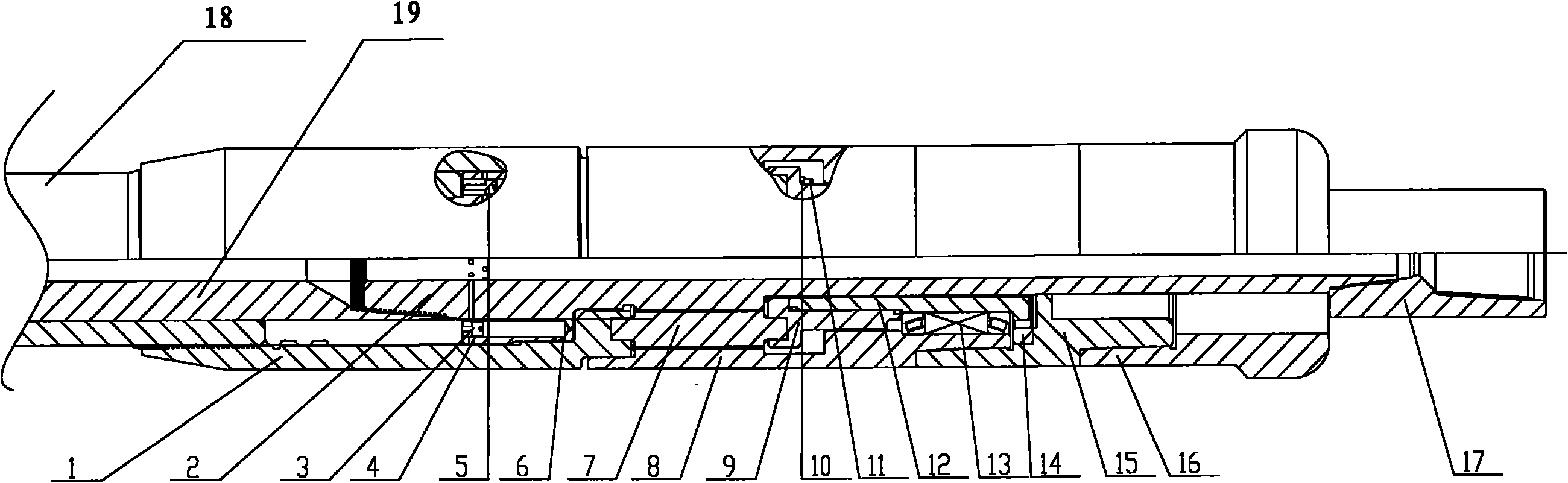

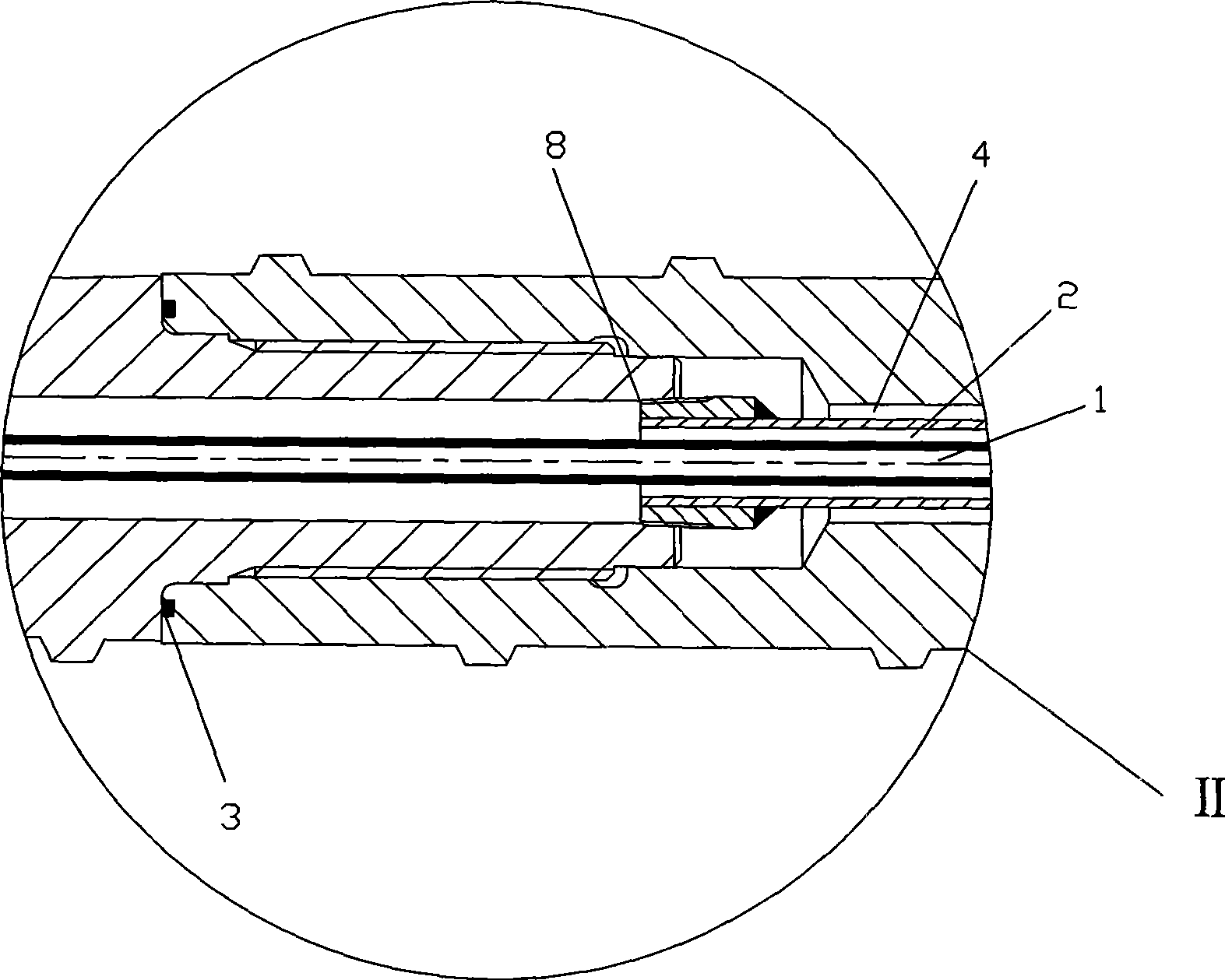

Anti-pressure anti-torsion high-strength V-groove self-cleaning sand-proof screen pipe

The invention discloses a pressure and torsion resistance high-strength V groove self-cleaning anti-sand sieve tube which belongs to a petroleum exploitation mechanical anti-sand device. A coupling is connected with a base tube; the base tube is provided with a round through hole along the axial direction; a filter component is fixed in the round through hole on the base tube; the outer diameter of the base tube is provided with a protective tube. The filter component of the invention is welded on the base tube, and then a protective cover is welded on the filter component; next, the filter component is connected with the coupling and access to the lower end of a petroleum pipe to produce the petroleum. In the anti-sand sieve tube of the invention, the filter component with a V groove filter element consisting of a plurality of circular rings with V-shaped gaps is fixed on the tube wall of the base tube, so as to overcome the defects of low strength, high processing difficulty, high cost, etc. Fine sand can be discharged as the petroleum through elastic and vermicular filtering crack and spacing, so that the sand filtering procedure keeps self-cleaning; in this way, the gap size can mostly meet the petroleum production requirements.

Owner:詹其国

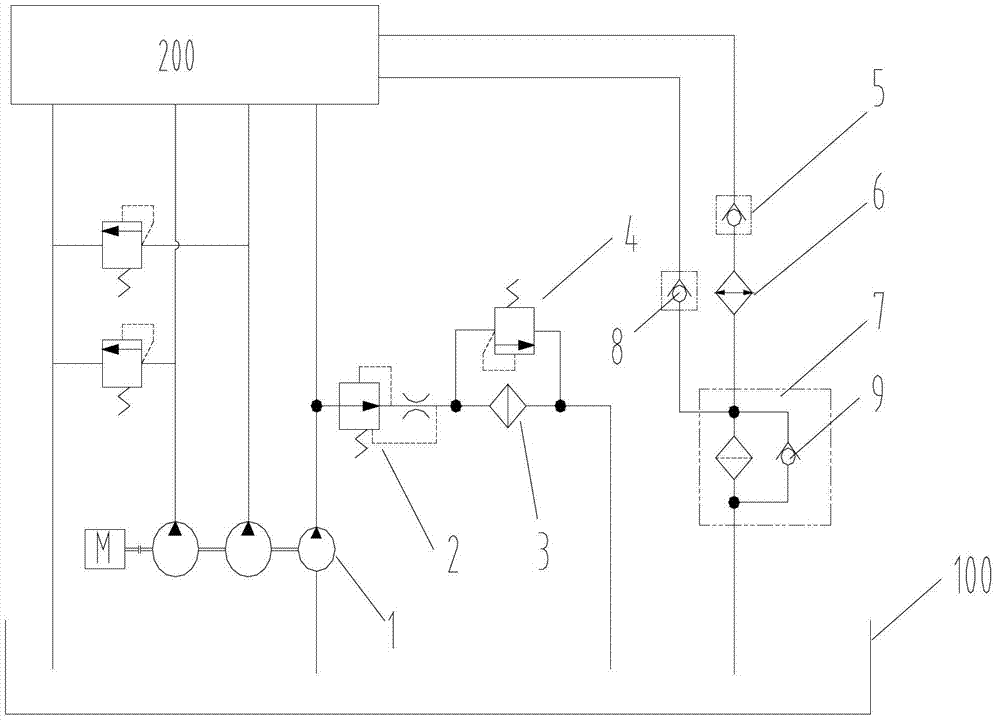

Telescopic control valve, multi-stage telescopic hydraulic system and hoist jib telescopic hydraulic control system

ActiveCN105545853AEasy to controlAchieve conductionServomotor componentsCranesControl valvesPetroleum engineering

Owner:XUZHOU HEAVY MASCH CO LTD

Full oil base drilling fluid with high dynamic shear force ratio

ActiveCN103146365AHigh ratio of dynamic plasticImprove rheologyDrilling compositionBase oilPotentiator

The invention discloses full oil base drilling fluid with high dynamic shear force ratio. The full oil base drilling fluid comprises base oil and other ingredients on the basis of the volume of the base oil: 1.5-2.5% of main emulsifying agent, 0.5-1.0% of auxiliary emulsifying agent, 0.8-1.0% of reverse wetting agent, 0.8-1.0% of shearing potentiator, 0.3-0.5% of thermoplastic flow type regulating agent, 2.0-3.0% of calcium oxide, 1.0-3.0% of organic soil, 1.5-2.0% of fluid loss additive and weighting material, and due to the addition amount of the weighting material, the density of the full oil base drilling fluid is 0.89-2.50g / cm<3>. The addition amount of the organic soil in the full oil base drilling fluid system is reduced by 1.0-3.0% through adding the thermoplastic fluid type regulating agent, the dynamic shear force ratio of the system is obviously improved and can achieve more than 0.45, the rheological property of the system can be improved, the comprehensive properties can be improved, and the production cost can be saved.

Owner:CHINA NAT PETROLEUM CORP +1

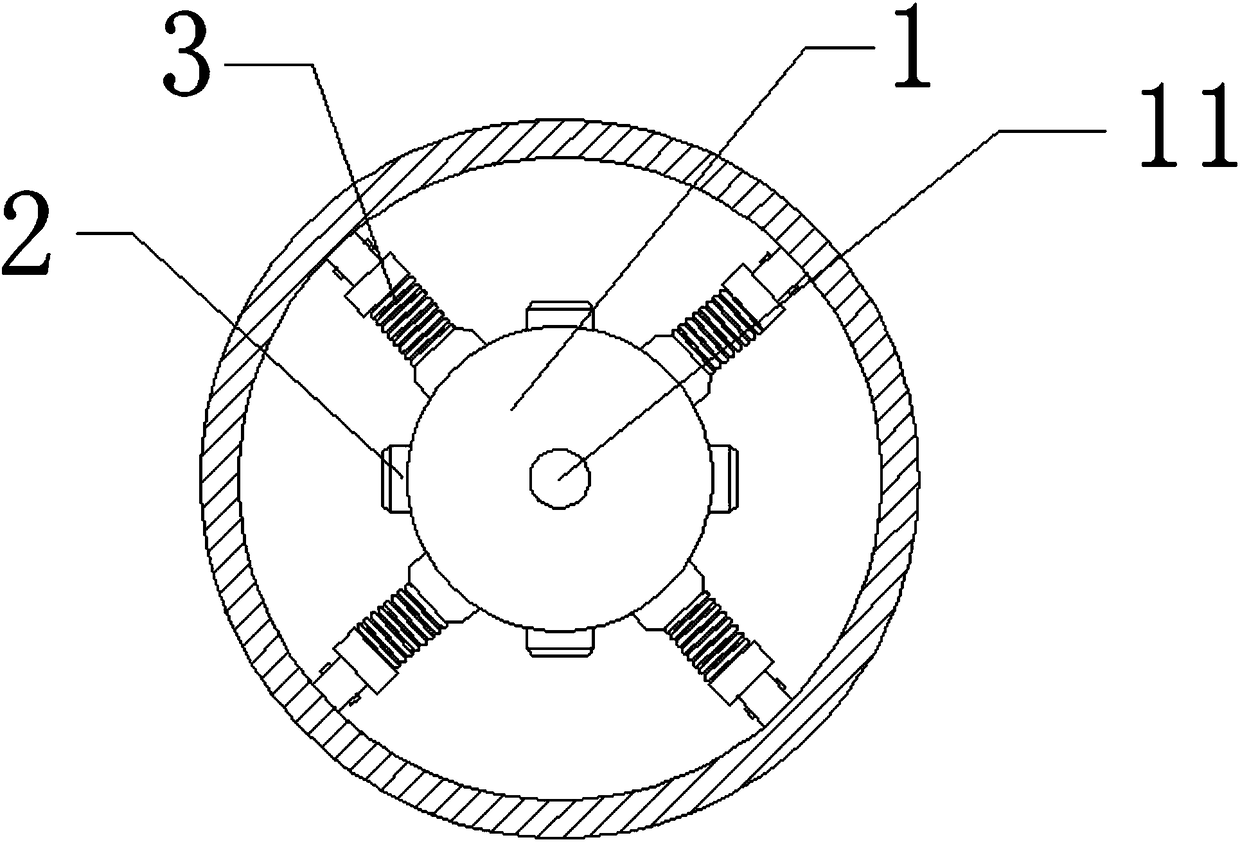

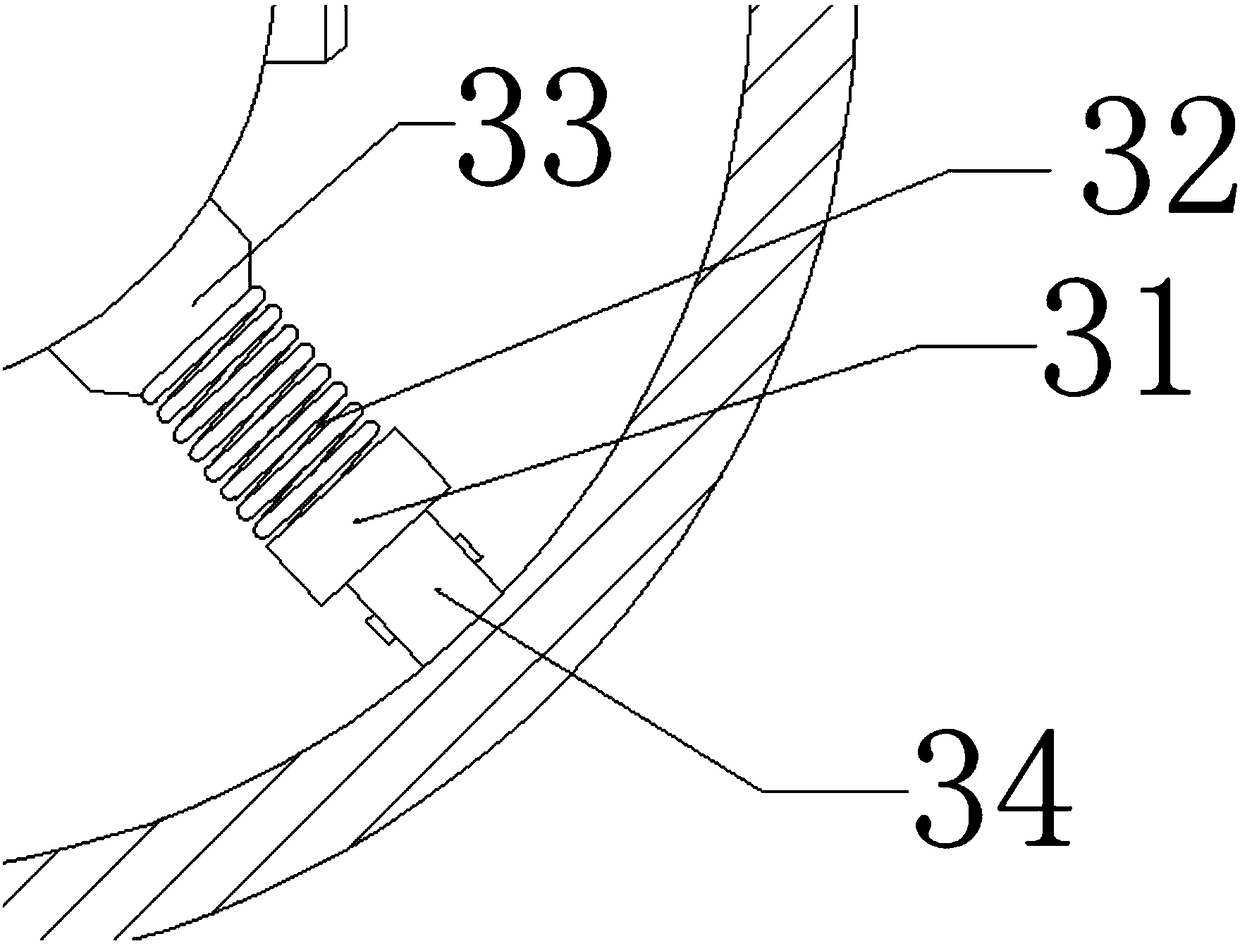

Planetary drill bit assembly for balancing reactive torque of drilling equipment in well drilling

ActiveCN101871328AImprove stabilityIncreased directional control capabilitiesDrilling rodsDirectional drillingWell drillingDrive shaft

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

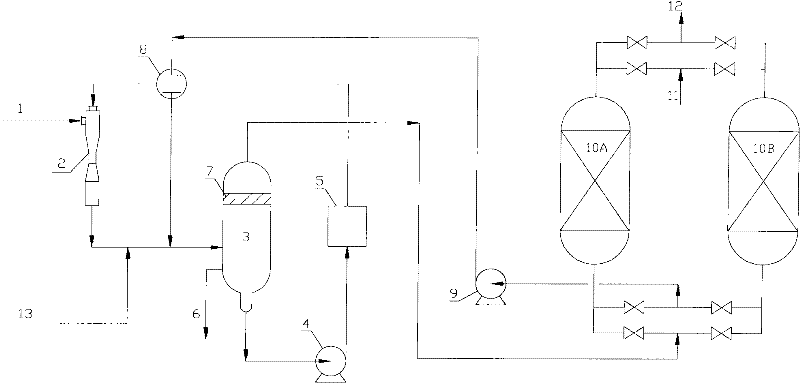

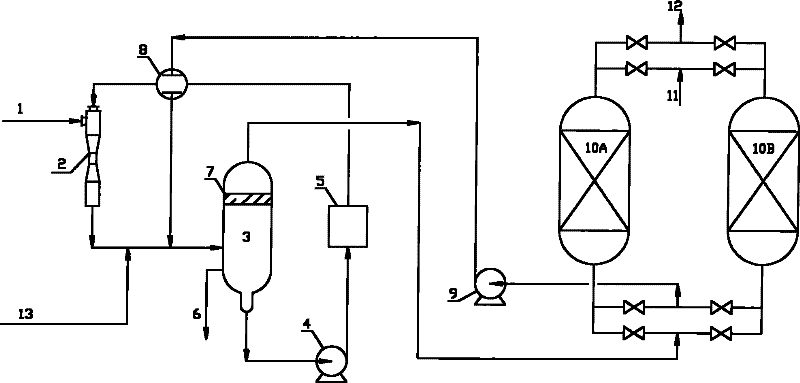

Method for controlling temperature of crude oil for emulsion of rolling mill and control device

InactiveCN101575044AUniform temperatureImprove the heating effectTank wagonsTemperature controlEmulsion

The invention relates to a method for controlling temperature of crude oil for emulsion of a rolling mill and a control device. The method comprises the steps of: arranging a heating device on the outer part of a crude oil tank; adopting a circulation heating pump arranged at the tail of the crude oil tank to transfer crude oil to a heat exchanger for heat exchange; simultaneously adopting a temperature controller on the crude oil tank to control the on and off of the heating device; and transferring crude oil to the top of the crude oil tank for outer circulation heating so as to keep the temperature of crude oil inside the crude oil tank at a preset value. A control device comprises the heating device consisting of the circulation heating pump and the heat exchanger, the temperature controller, a steam control valve, a steam trap and pipelines connecting the components, wherein the circulation heating pump is arranged at the tail of the crude oil tank, the heat exchanger is arranged on the side of the crude oil tank and the temperature controller is arranged on the crude oil tank. The invention has the advantages of good heating effect, equal crude oil temperature, high temperature-control property and precision, simple and convenient operation process, non-steam entering the crude oil and non-impact on crude oil quality.

Owner:BAOSTEEL ENG & TECH GRP

Submarine mining vehicle walking chassis and self-rescue method thereof

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

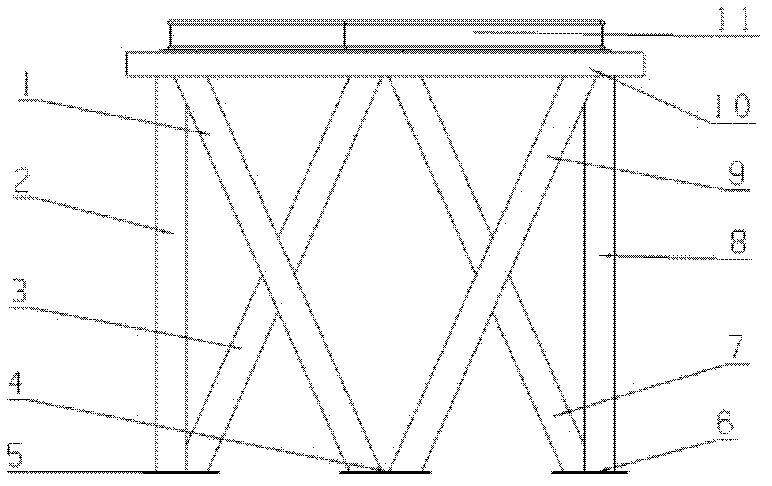

Ring-shaped carbon fiber truss support structure of coaxial three-reflector spatial optical system

Owner:CHANGGUANG SATELLITE TECH CO LTD

Piezomagnetic turbine loss type reinforced concrete strain sensor and piezomagnetic stain meter thereof

InactiveCN101806577AHigh sensitivityImprove stabilityForce measurement by measuring magnetic property varationFluid pressure measurement by electric/magnetic elementsObservational errorCantilevered beam

The invention discloses a piezomagnetic turbine loss type reinforced concrete strain sensor, and is characterized in that a piezomagnetic turbine loss effect is used as a sensing mechanism to manufacture a piezomagnetic turbine loss type reinforced concrete strain sensor and a piezomagnetic stain meter thereof for measuring surface strain, inner strain and steel bar strain. The sensor is designed with a mechanics model and a deformation structure of a combined cantilever beam or a cantilever curved beam with two elastic free ends. The invention uses a seamless connection technology of whole manufacturing and conical hole connection and a component separation signal processing method. Compared with the prior art, the invention has the characteristics of high sensitivity, good stability, small measuring error, strong reliability, simple structure, low cost and convenient use; and the invention has wide application prospect.

Owner:何思龙

Surface drilling device for flocked cloth

InactiveCN107097292AHigh degree of automation integrationIncrease productivityLiquid surface applicatorsCoatingsDrill bitPetroleum engineering

The invention discloses a surface drilling device for flocked cloth. The surface drilling device comprises a base and a movable drilling assembly arranged at the upper end of the base, wherein a fixture is inserted into a fixture fixed groove; the flocked cloth needing to drill is clamped on a sliding panel; the sliding panel is controlled by a servo motor to move leftwards and rightwards; successively, the movable drilling assembly moves by a control shaft fixed base of the servo motor; a drilling head is controlled by a lifting air cylinder to move downwards; and the drilling head is controlled by the motor to rotate to carry out drilling. The surface drilling device for the flocked cloth is high in automatic integration degree, is beneficial for improving production efficiency, and greatly reduces defective rate; meanwhile, by adopting a multi-shaft drilling way, the surface drilling device for the flocked cloth greatly improves the adjustability of the device, and is beneficial for improving the drilling efficiency.

Owner:JIASHAN SHENGLAISI CASHMERE

Power driven system and oil pumping unit applying same

InactiveCN102192199AReduce volumeSave energyFluid removalFluid-pressure actuatorsDrivetrainClosed loop

Owner:杨崇恩

Method for recovering oil gas and device

InactiveCN102441309AImprove purification effectReduce the temperatureDispersed particle separationVapor condensationRecovery methodGas emissions

Owner:CHINA PETROLEUM & CHEM CORP +1

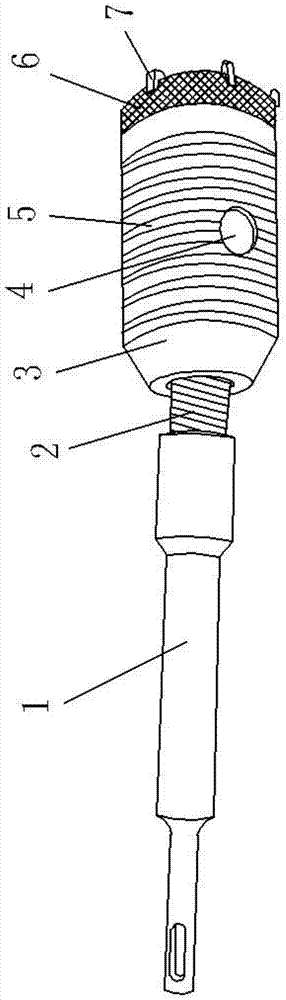

Drill bit of hollow drill and manufacturing method thereof

InactiveCN103752907AAnti-corrosionWith cleanTransportation and packagingTool adaptersWear resistantDrill bit

Owner:宁波神钻工具有限公司

Linear compressor and lubricating oil pump thereof

InactiveUS20060257275A1Reduce frictionIncreased durabilityPositive displacement pump componentsWorking fluid for enginesLinear compressorReciprocating motion

Disclosed herein are a linear compressor and a lubricating oil pump thereof. The lubricating oil pump comprises a lubricating oil cylinder integrally formed in a frame that supports a compression unit, a lubricating oil piston mounted to be reciprocated inside the lubricating oil cylinder to resonate with the compression unit, and a lubricating oil cylinder protector to prevent generation of friction between the lubricating oil cylinder and the lubricating oil piston. With this configuration, it is possible to improve the durability of the lubricating oil cylinder and to simplify or omit additional processing of the lubricating oil piston.

Owner:LG ELECTRONICS INC

Cylindrical part bending angle measuring and horizontal and vertical surface drilling jig

InactiveCN103692251APrecise positioningConvenient bending angle measurementMeasurement/indication equipmentsPositioning apparatusHorizontal and verticalDrill

Owner:SHENYANG AEROSPACE UNIVERSITY

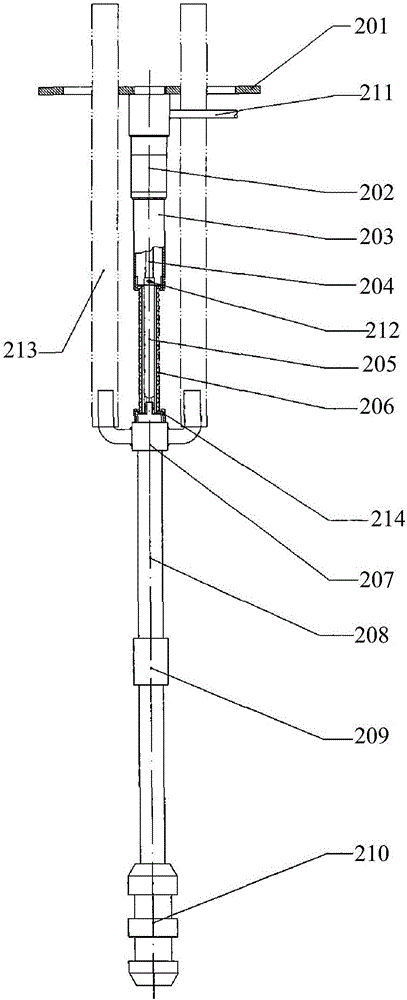

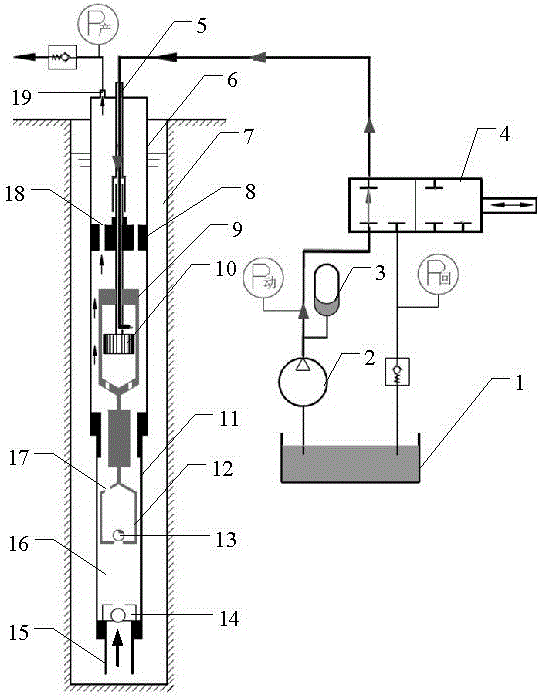

Material delivery pipe mechanism for bottom-mounted power drill rod

The invention belongs to the technical field of building, and relates to a material delivery pipe mechanism for a bottom-mounted power drill rod. The material delivery pipe mechanism comprises a drill rod and a length adjusting rod. A power mechanism is disposed between the drill rod and the length adjusting rod; the power mechanism is in driving connection with the drill rod, and is capable of driving the drill rod to rotate circumferentially. A delivery passage is formed within the drill rod, and a discharge hole is formed in the bottom of the drill rod and is communicated with the delivery passage. A slurry delivery pipe is disposed in the length adjusting rod, and extends into the power mechanism. A slurry delivery connecting pipe is disposed on the outer wall of the power mechanism, and one end of the slurry delivery connecting pipe is detachably connected to the slurry delivery pipe, while the other end of the slurry delivery connecting pipe is detachably connected to the delivery passage. The invention provides a delivery pipe mechanism capable of realizing bottom-mounted power of the drill rod, thereby guaranteeing that material can be delivered to the drill rod when power for the drill rod is mounted at bottom so as to obtain a high-strength cement soil mixing pile; no disturbance is produced for the power structure; and reliable and stable work is achieved.

Owner:ZHEJIANG ZHAODI TECH CO LTD

Hydraulic oil filtration system and hydraulic shovel

ActiveCN103174704ASoil-shifting machines/dredgersFluid-pressure actuator componentsControl systemFiltration

Owner:ZOOMLION HEAVY IND CO LTD

Screw rod of EPE/EPS single-screw rod foam extrusion machine with constant temperature oil for cooling forepart inner wall

InactiveCN101480841AIncrease elasticitySatisfy the processing technology requirements of subsection coolingFoaming agentReturn channel

Owner:罗承绪

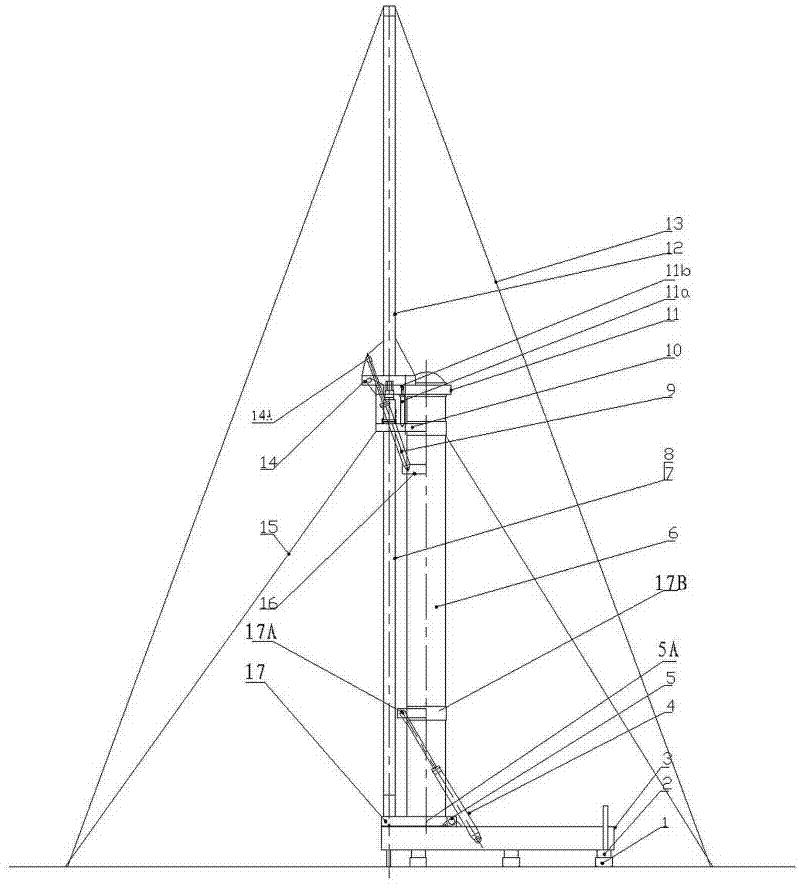

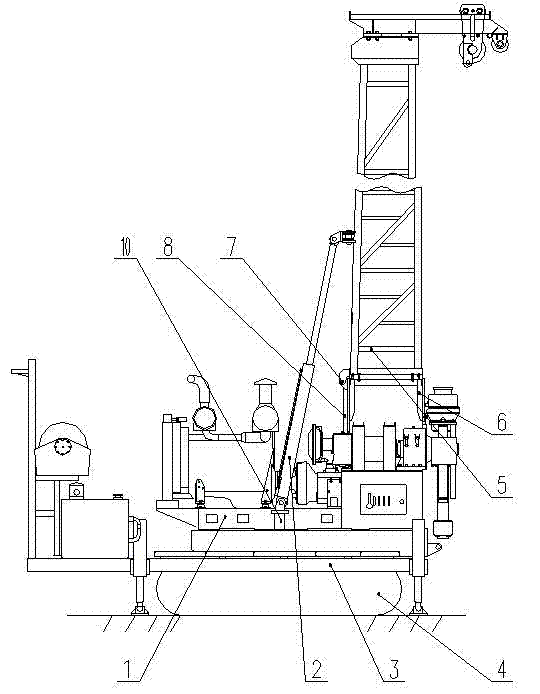

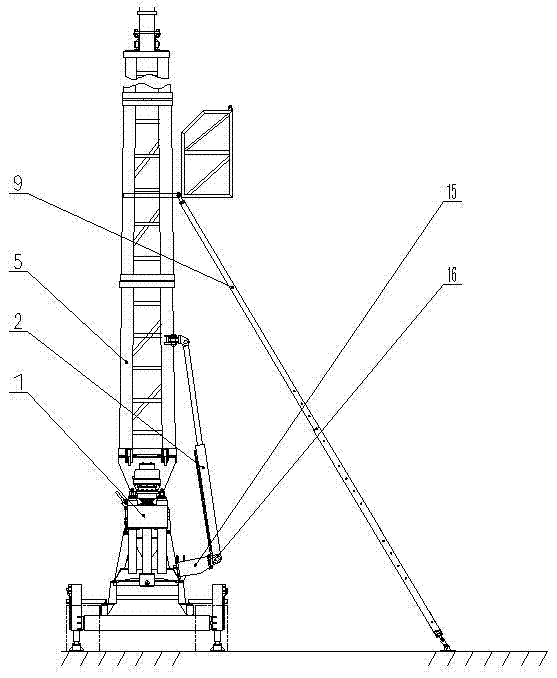

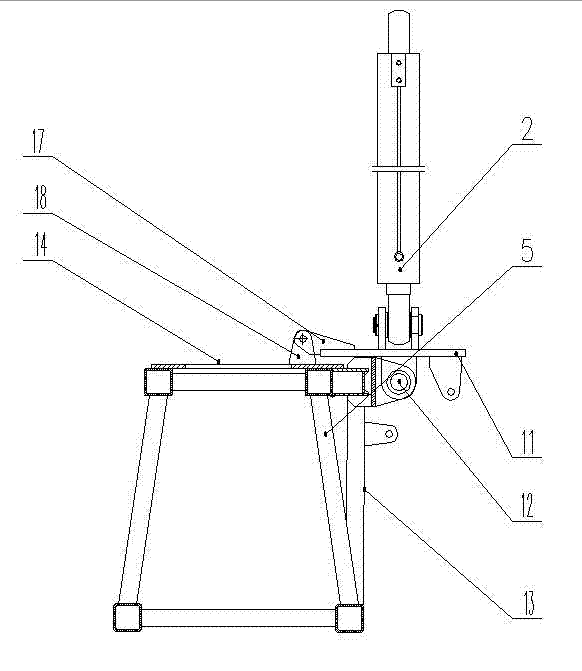

Multifunctional rotary drilling rig

InactiveCN103147689ALower purchase costImprove work efficiencyEarth drilling toolsDerricks/mastsFoundation engineeringWinch

The invention relates to a multifunctional rotary drilling rig and belongs to the field of foundation engineering construction equipment. The multifunctional rotary drilling rig comprises a chassis, an upper wagon mounted on the chassis, a diagonal bracing oil cylinder mounted on the upper wagon and a mast, wherein the mast is connected with a winch box and the diagonal bracing oil cylinder; the winch box is fixed at the front end of the upper wagon; a guide device is mounted at the tail end of the mast; and a soil remover is arranged above the guide device and also arranged on the mast. The multifunctional rotary drilling rig integrates functions of a rotary drilling rig, a CFG (Cement Flyash Gravel Pile) drilling rig and a screw pressure soil squeezing and filling pile drilling rig, and realizes multiple functions and construction by multiple construction methods; the cost for purchasing the drilling rig is saved; and the working efficiency is improved.

Owner:SHANDONG XINGUO HEAVY MASCH TECH CO LTD

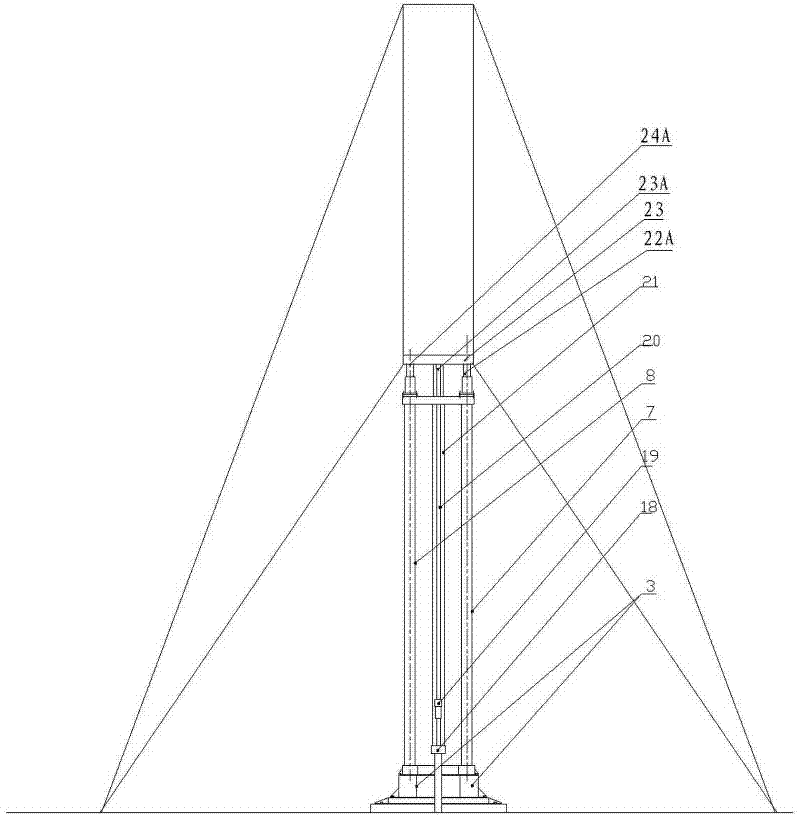

Integrated core drilling machine for single-cylinder double-acting tower crane

ActiveCN102777124AImprove efficiencyRealize single-cylinder double-actingDerricks/mastsDrilling machines and methodsLocking mechanismTower crane

Owner:H H DRILL TECH DRILLING MACHINERY CO LTD

Design method for quasi dual-lead conical worms and worm gears

InactiveCN102797829ASmooth transmissionImprove transmission efficiencyPortable liftingGearing elementsNatural toothOffset distance

The invention discloses a design method for quasi dual-lead conical worms and worm gears. The method comprises the steps as follows: 1. designing natural tooth profile angle alpha for a quasi dual-lead conical worm; 2. designing an approximate tooth profile angle betab1 in an outer engaging surface section Q-Q and an approximate tooth profile angle betab1' in an inner engaging surface section Q'-Q'; 3. designing a taper angle theta for the quasi dual-lead conical worm; 4. designing the lead of the quasi dual-lead conical worm; 5. designing the installation center distance from the quasi dual-lead conical worm to the worm gear; 6. designing the inner and outer engaging parameters of the quasi dual-lead conical worm; 7. testing and verifying the transmission ratio and the lead of the quasi dual-lead conical worm; 8. designing the tooth depth of the quasi dual-lead conical worm; 9. designing the threaded part of the quasi dual-lead conical worm; 10. designing the radial parameter of the quasi dual-lead conical worm; 11. designing the tooth thickness of the quasi dual-lead conical worm; 12. designing the installation offset distance of the quasi dual-lead conical worm; 13. designing the installation height of the quasi dual-lead conical worm; 14. designing the geometrical parameters of the worm gear; 15. analyzing errors; and 16. carrying out accurate design.

Owner:JILIN UNIV

Pipeline oil stain cleaning device

Owner:四川天人能源科技有限公司

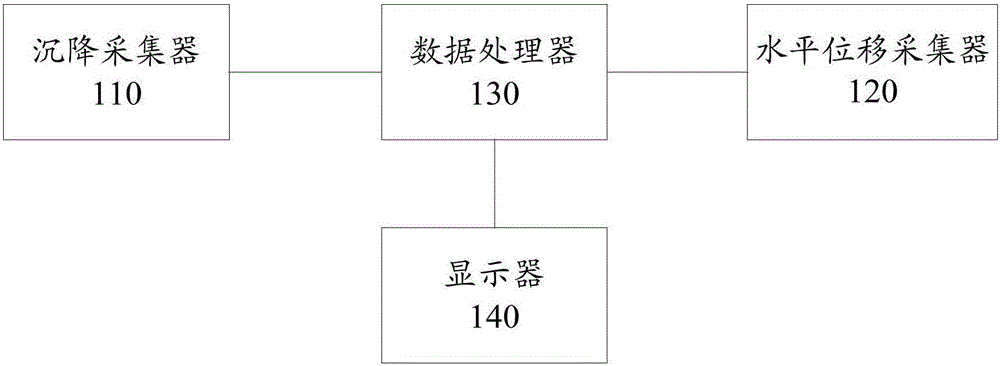

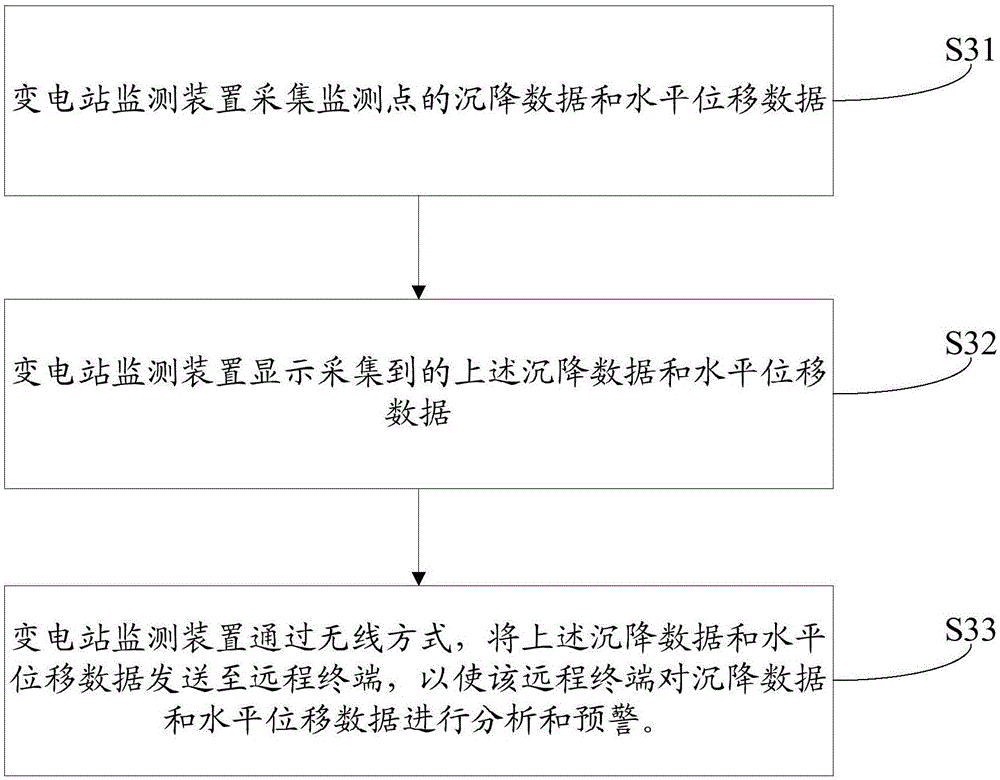

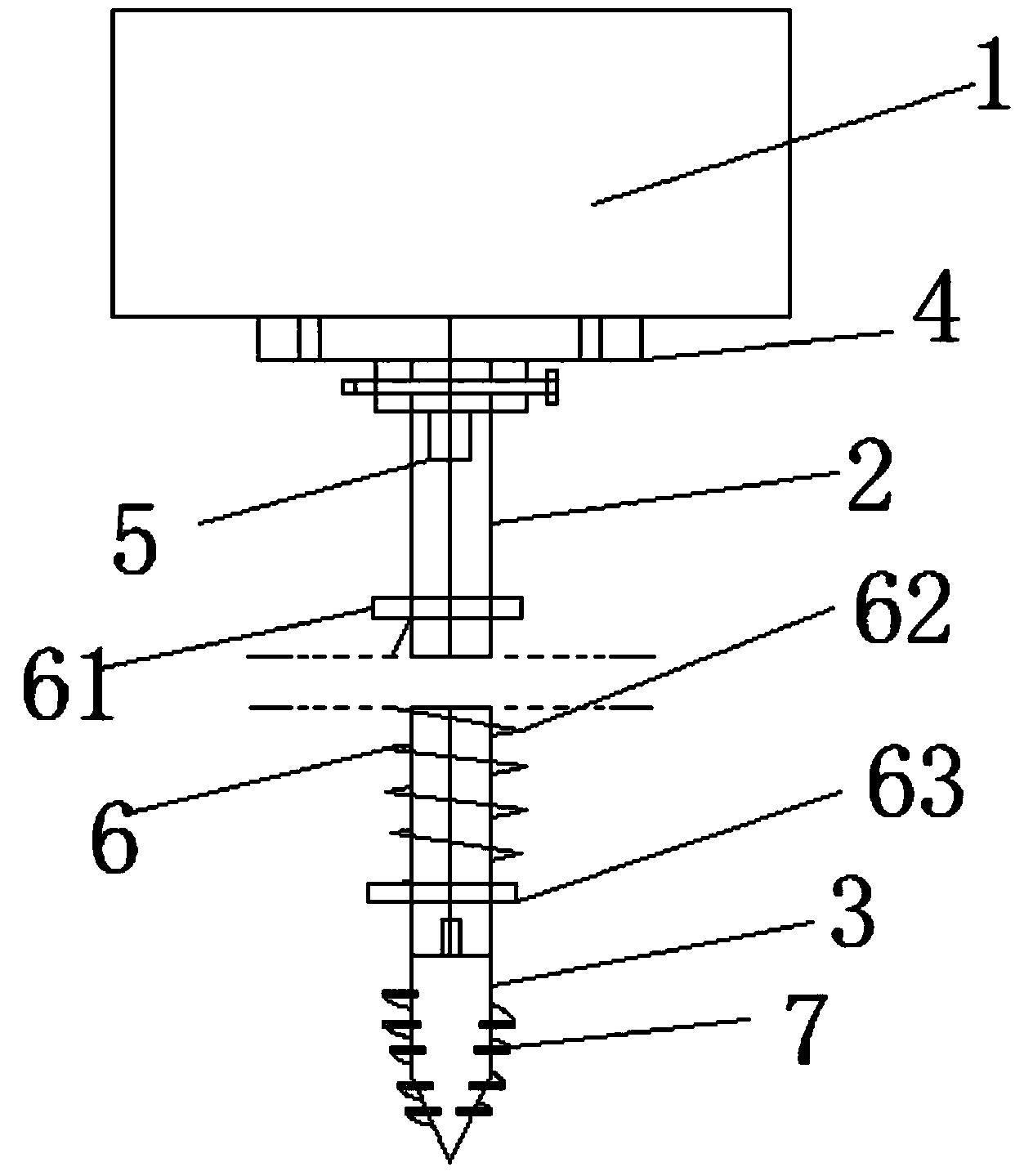

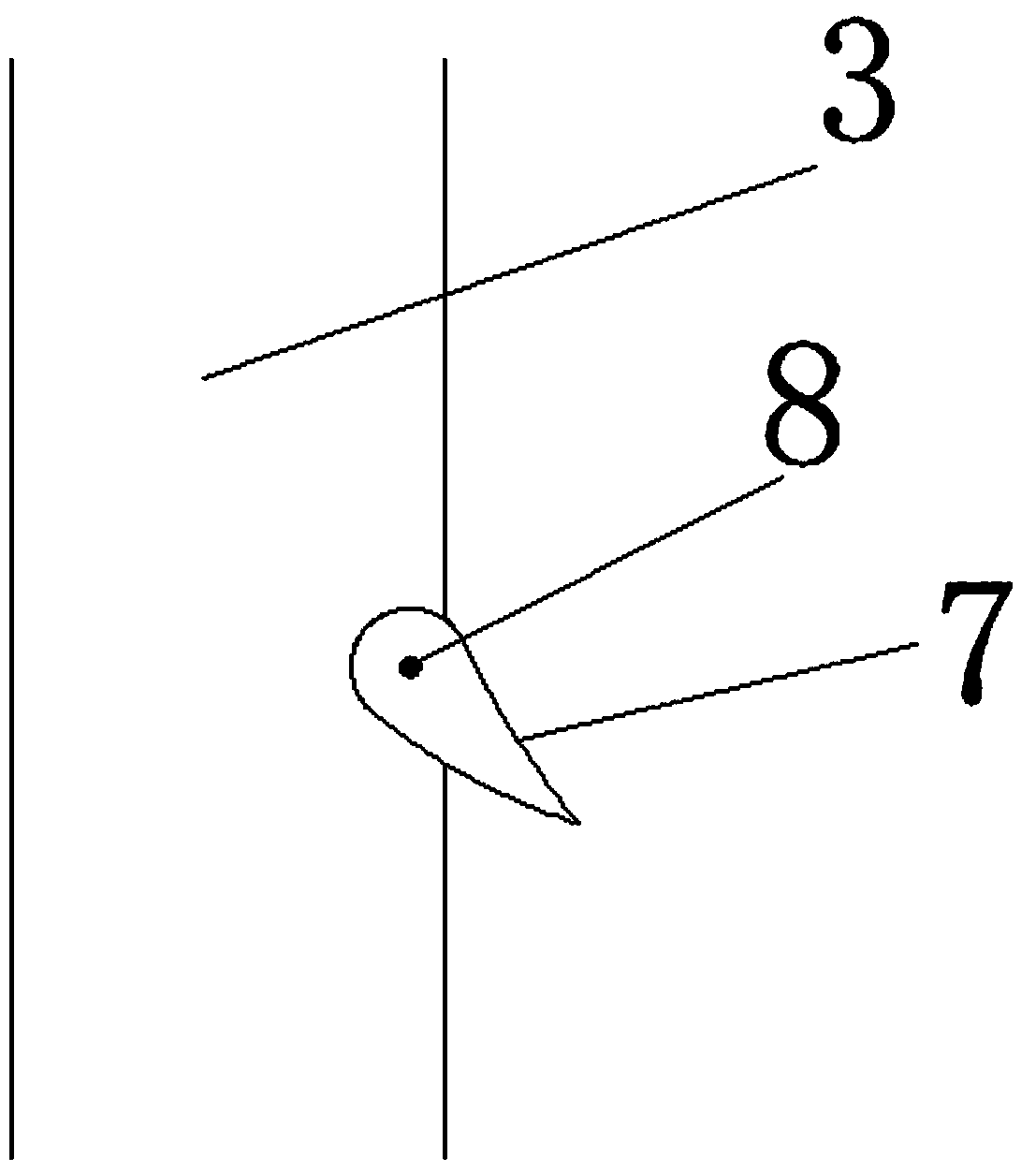

Transformer substation monitoring device, method and system

InactiveCN106546219AReal-time acquisitionAccurate collectionUsing electrical meansHeight/levelling measurementTransformerElectric power system

Owner:JUANCHENG POWER SUPPLY CO STATE GRID SHANDONG ELECTRIC POWER CO

Engineering drilling device

InactiveCN104165024AEasy to operatePlay a buffer roleReciprocating drilling machinesConstructionsEconomic benefitsPetroleum engineering

Owner:JIANGSU ENG EXPLORATION & SURVEYING INST

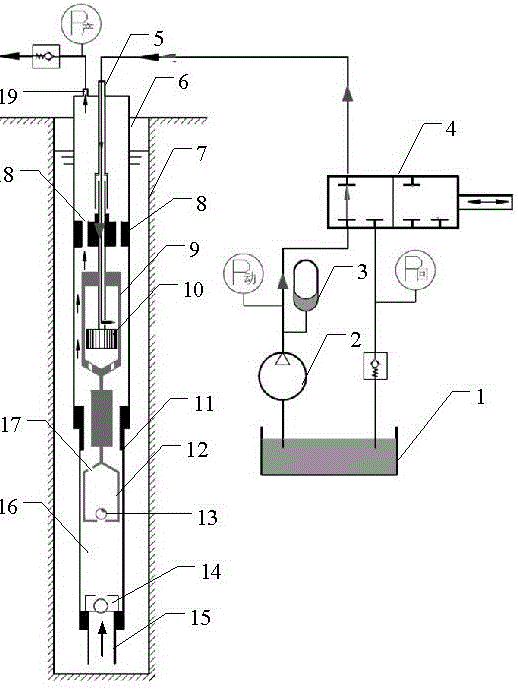

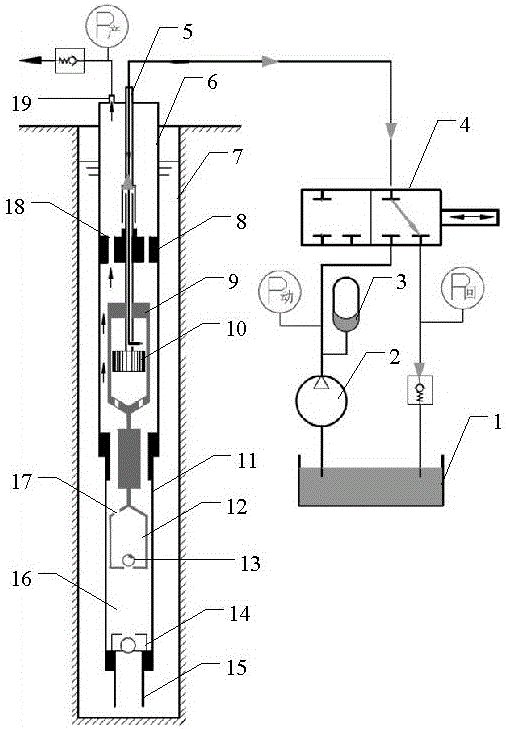

Novel anti-eccentric wear hydraulic oil extraction device

InactiveCN105041629ANo loadShort schedule of activitiesOperating means/releasing devices for valvesFlexible member pumpsLiquid storage tankPower equipment

Owner:盐城市佳鑫石化机械制造有限公司

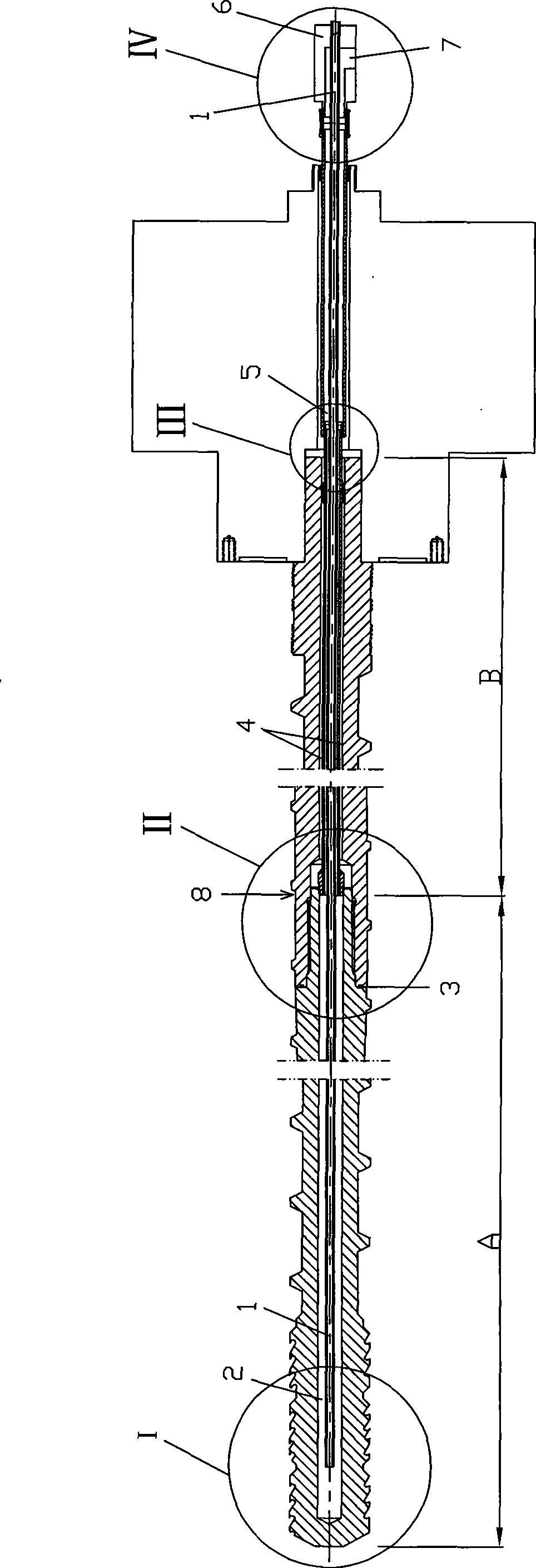

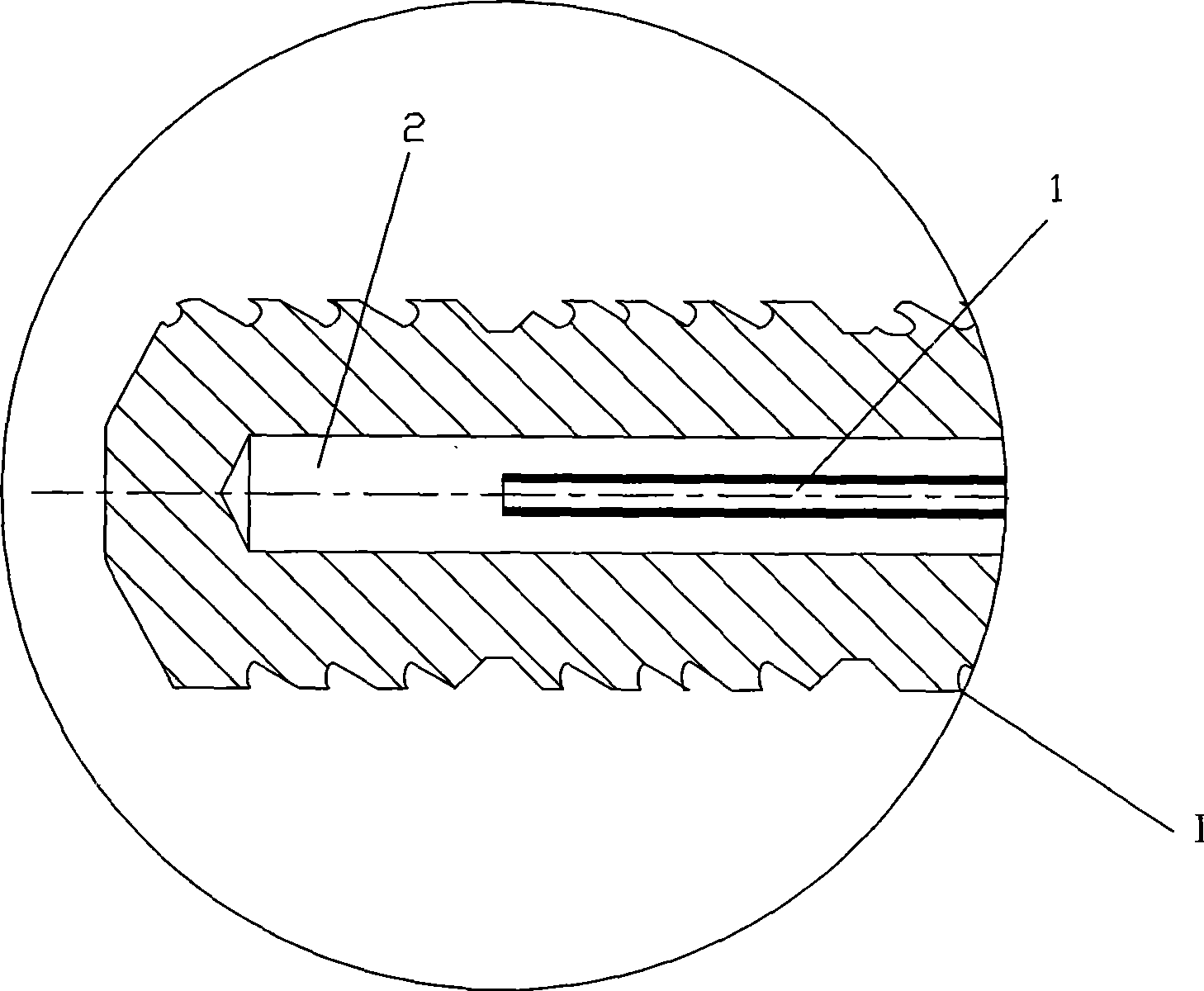

Core sectional rod and rotary drilling rig drilling rod including same

ActiveCN104612597AChange the force structureLow failure rateDrilling rodsDrilling casingsFailure ratePetroleum engineering

The invention provides a core section rod. The core section rod comprises a core section rod pipe body and a drilling tool connector arranged under the core section rod pipe body, wherein the drilling tool connector comprises a rectangular head portion, a connection portion and a boss portion located between the rectangular head portion and the connection portion; the boss portion is clamped between a bearing plate and a spring stop; the spring stop is connected with the core section rod pipe body and connected with the bearing plate through multiple driving keys. According to the core sectional rod, the connection mode of welding the drilling tool connector to the core section rod pipe body directly is changed, and the forced structure of the drilling tool connector is changed through the clamping of the boss portion of the drilling tool connector between the spring stop and the bearing plate. Accordingly, the forced pressure can reach the bearing plate position of the drilling tool connector without passing the wear area of the drilling tool connector and torque is also divided into two directions, so that the failure rate of a drilling rod is reduced and the service life of the drilling rod is prolonged. Moreover, a rotary drilling rig drilling rod with the core sectional rod is also provided.

Owner:SHANGHAI ZOOMLION HEAVY IND PILING MACHINERYCO +1

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap