Integrated core drilling machine for single-cylinder double-acting tower crane

A core drilling rig and double-acting technology, applied in drilling equipment, earthwork drilling, drilling equipment and methods, etc., can solve the problems of high cost of dismantling towers, relocation, and assembly, and achieve the effect of facilitating relocation and transportation and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

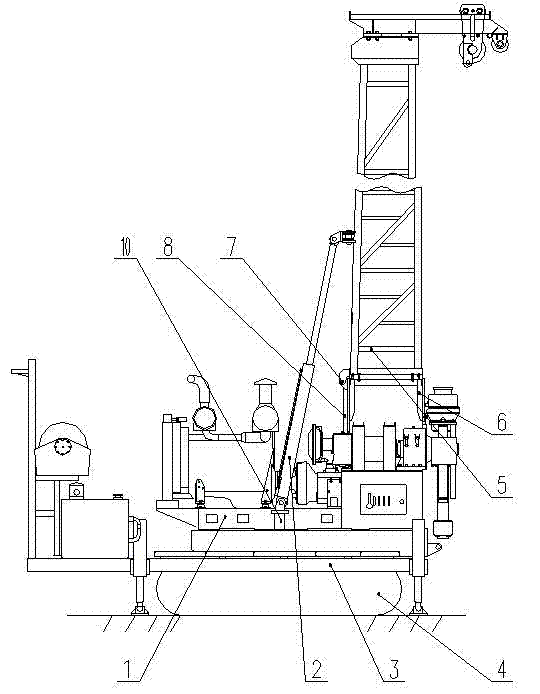

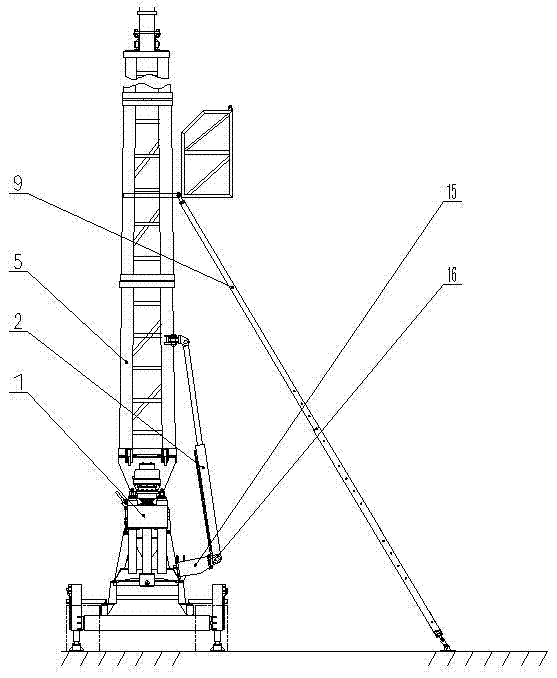

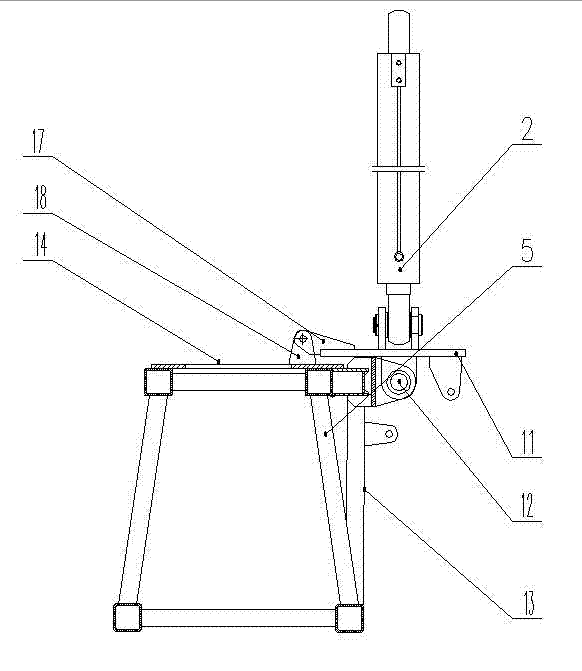

[0013] A single-cylinder double-acting tower crane integrated core drilling rig, comprising a core drilling rig 1, a drilling tower and a tower lifting cylinder 2, the core drilling rig 1 is mounted on a base 3, and a crawler body 4 is provided on the lower part of the base 3, and the drilling tower includes The tower body 5 and the drilling tower rotating seat 6 are connected by the lifting tower hinge shaft 7 and the fastening mechanism between the tower body 5 and the drilling tower rotating seat 6, and the drilling tower fixing seat 8 is arranged on the front frame of the core drilling machine 1 , the drilling tower rotating seat 6 is connected to the drilling tower fixing seat 8 through the horizontally arranged rotating shaft, the upper end of the lifting cylinder 2 is connected to the tower body 5, and the lower end of the lifting cylinder 2 is connected to the lifting support on the base 3 10 is connected, and a turning plate 11 is provided at the joint between the tower l

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap