Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

25 results about "Porosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Porosity or void fraction is a measure of the void (i.e. "empty") spaces in a material, and is a fraction of the volume of voids over the total volume, between 0 and 1, or as a percentage between 0% and 100%. Strictly speaking, some tests measure the "accessible void", the total amount of void space accessible from the surface (cf. closed-cell foam). There are many ways to test porosity in a substance or part, such as industrial CT scanning. The term porosity is used in multiple fields including pharmaceutics, ceramics, metallurgy, materials, manufacturing, hydrology, earth sciences, soil mechanics and engineering.

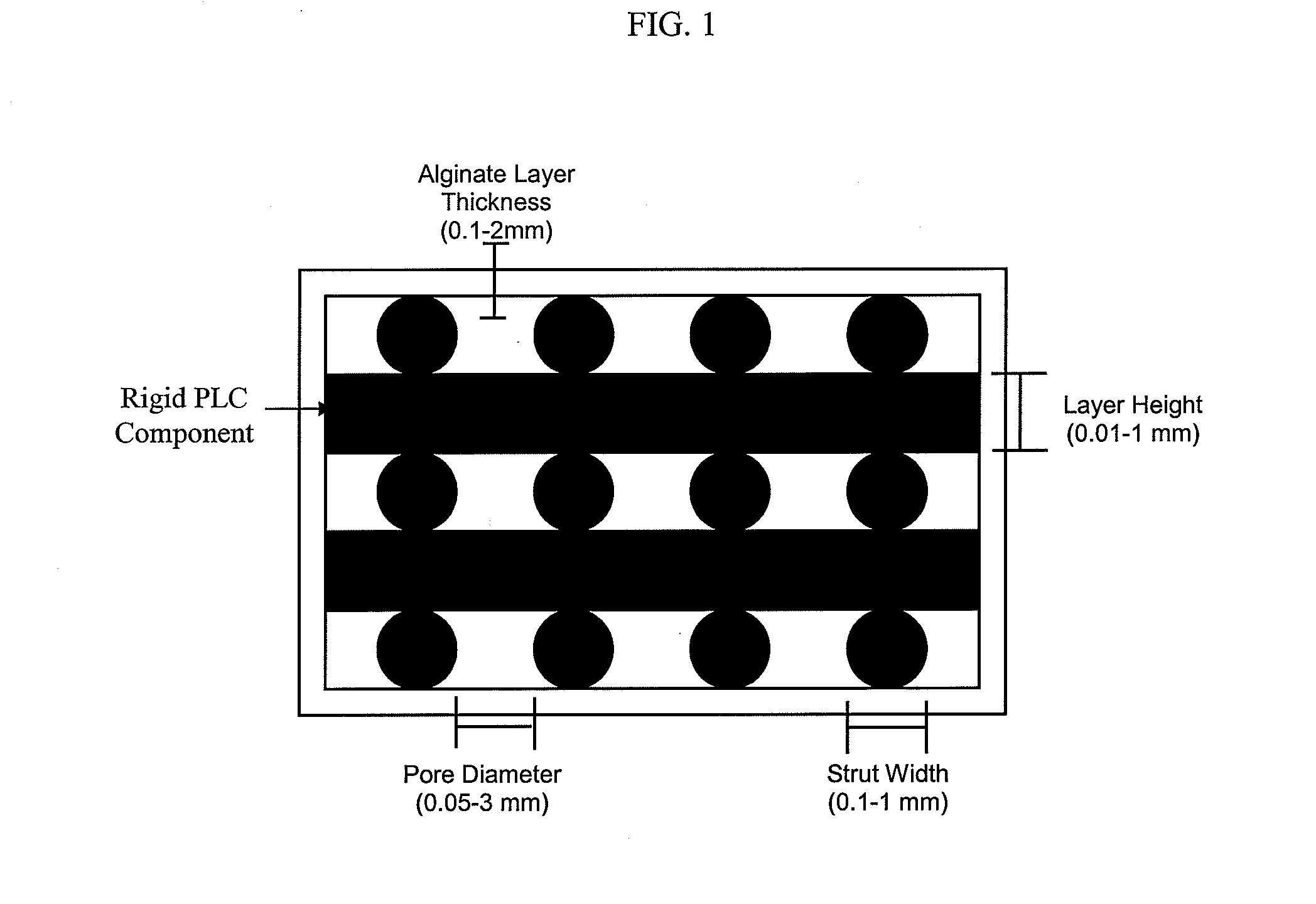

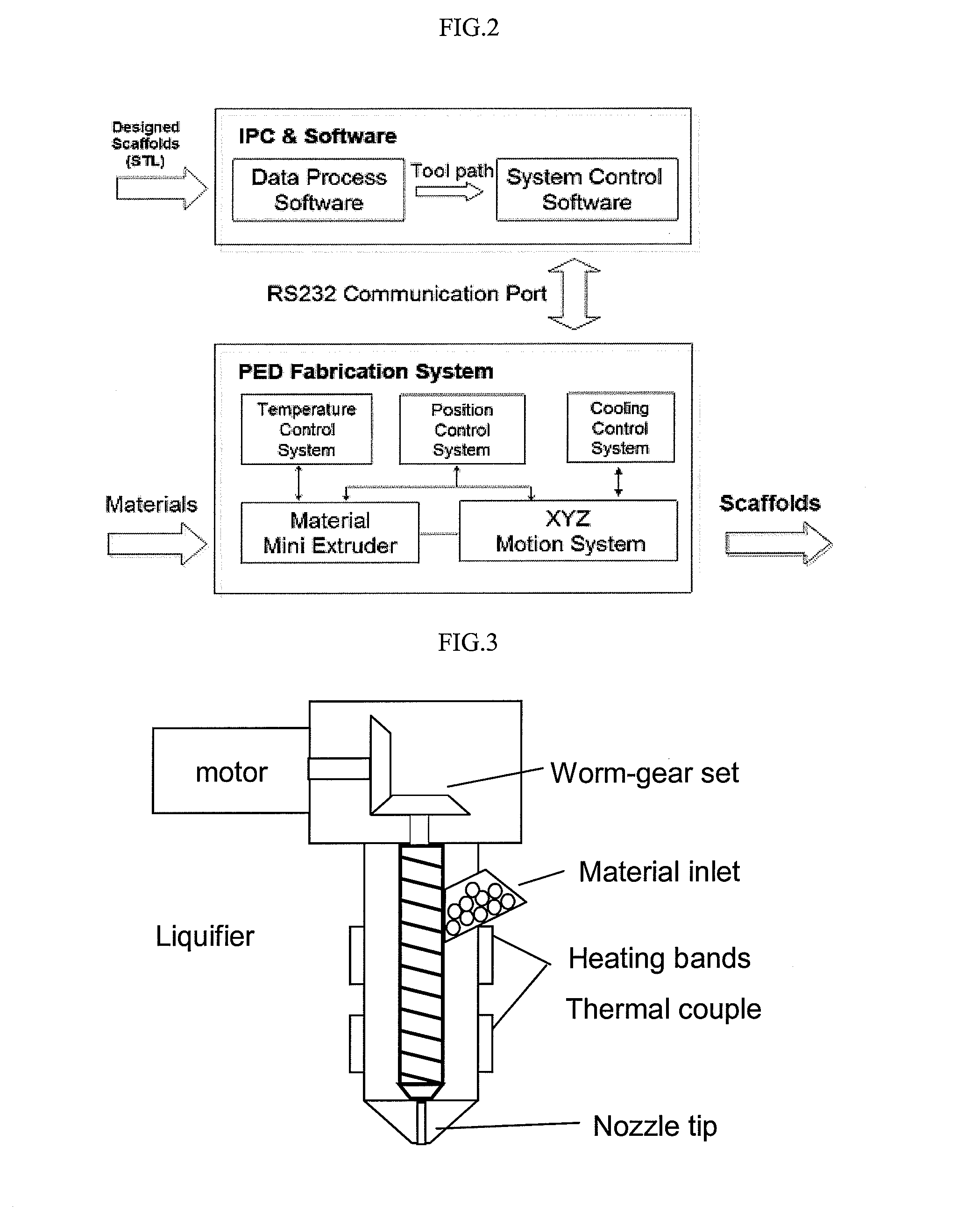

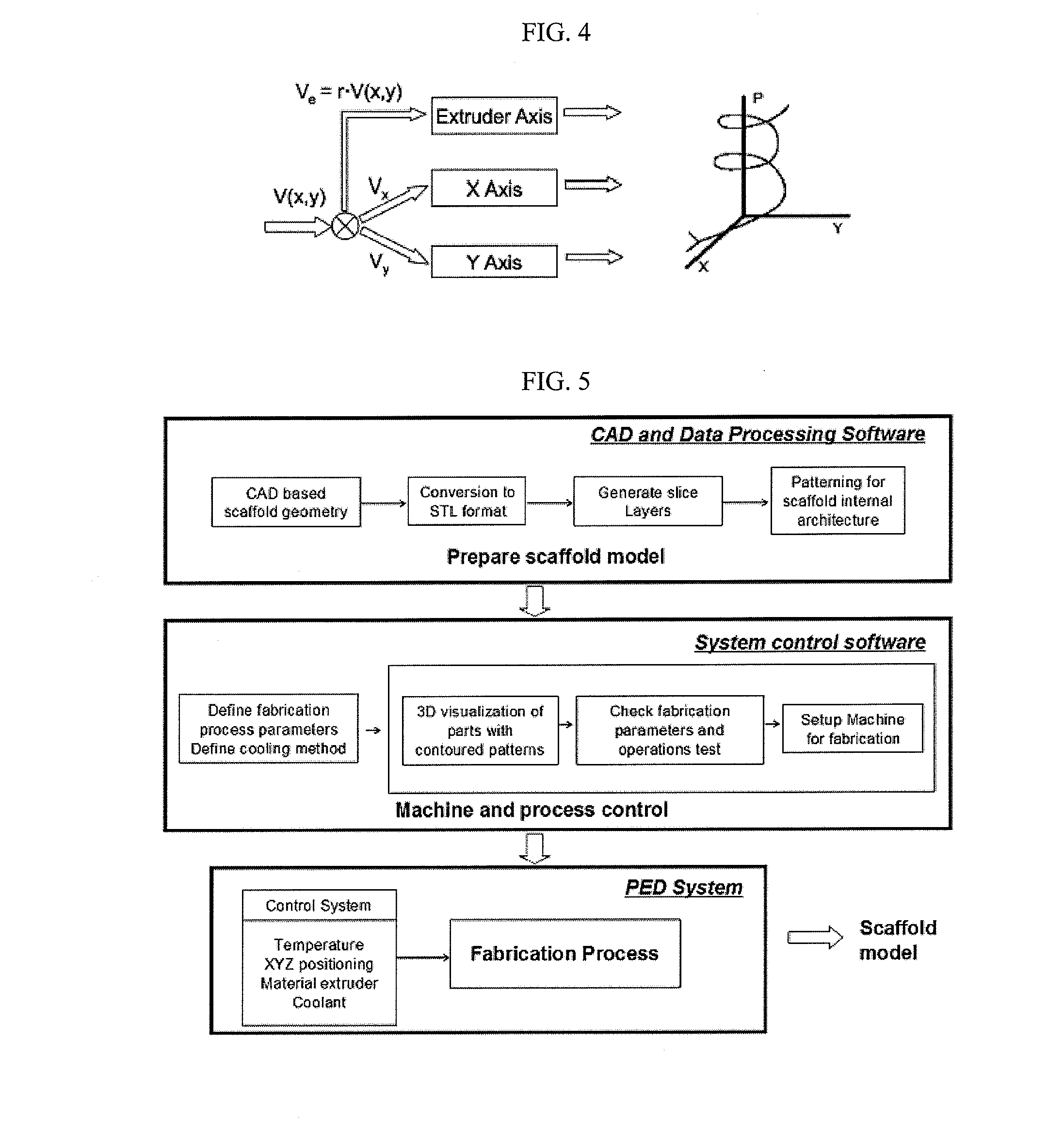

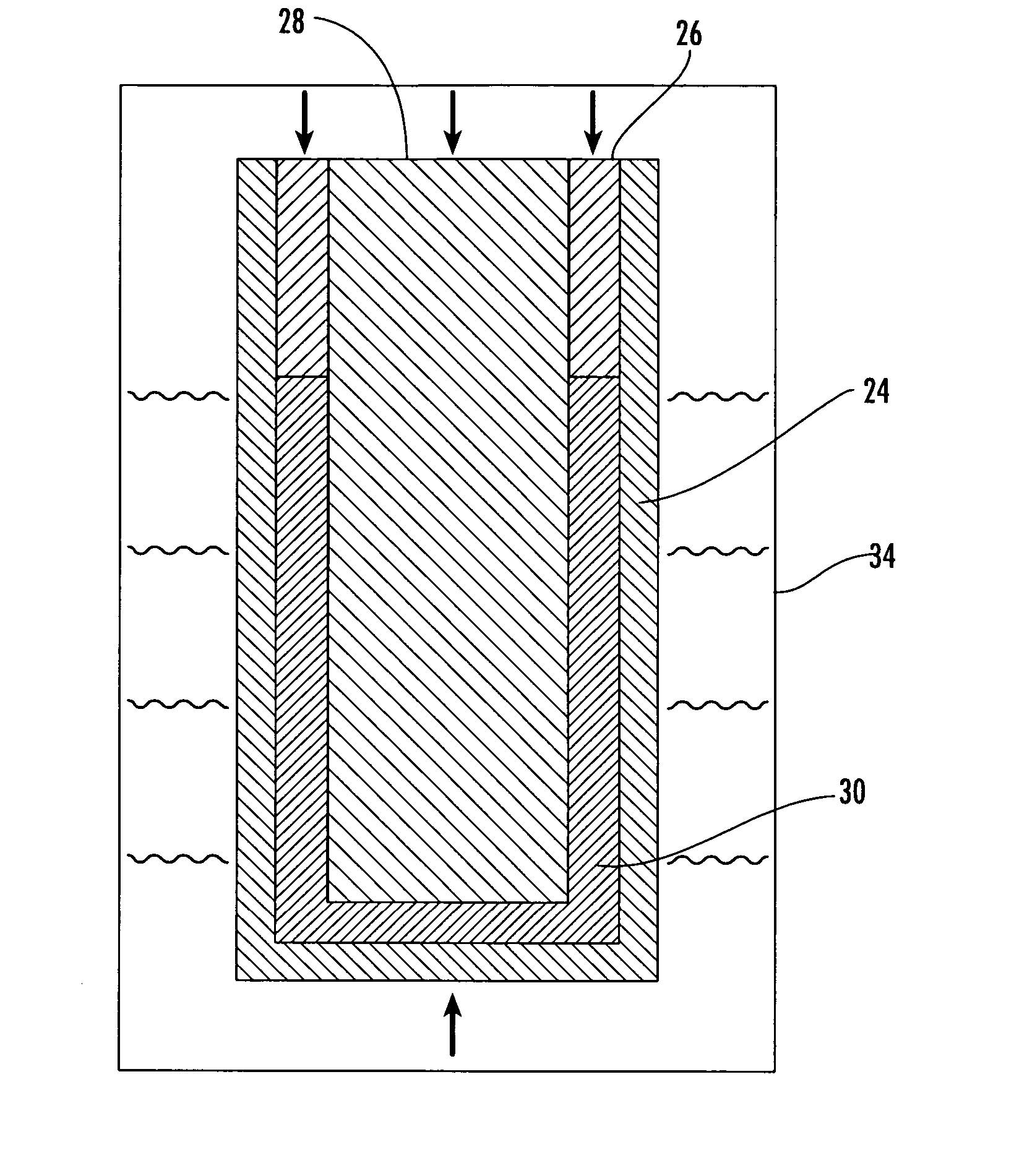

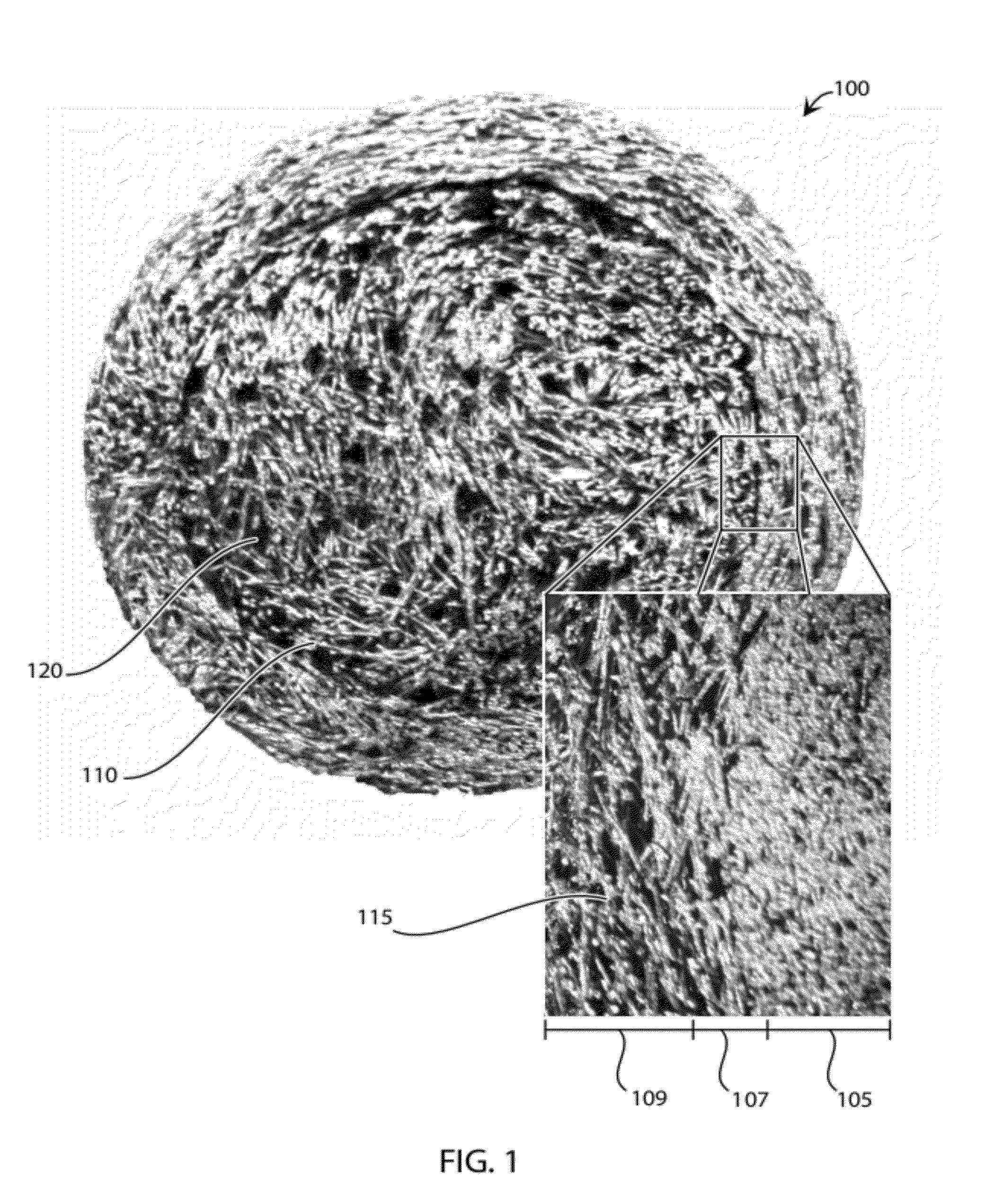

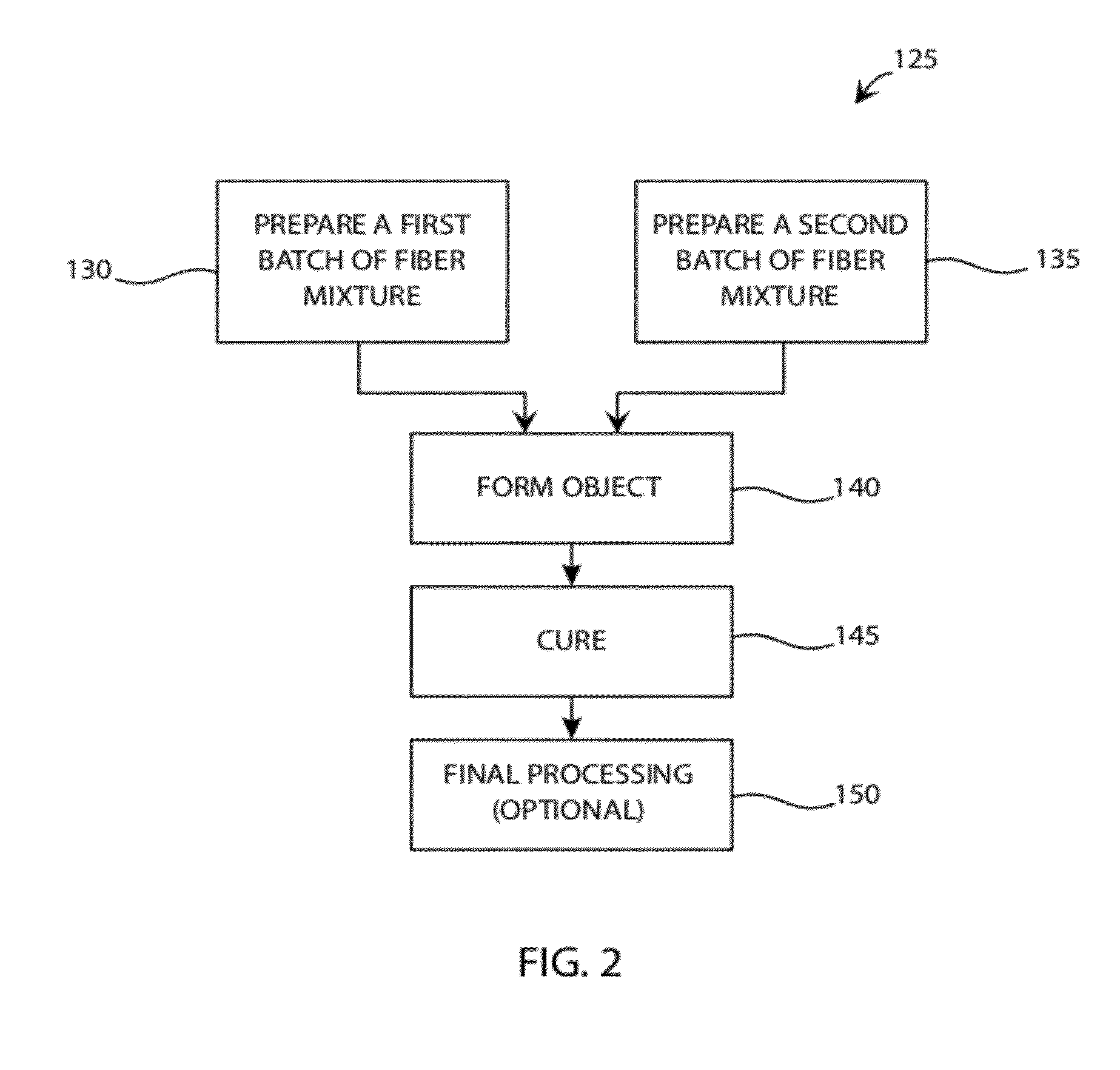

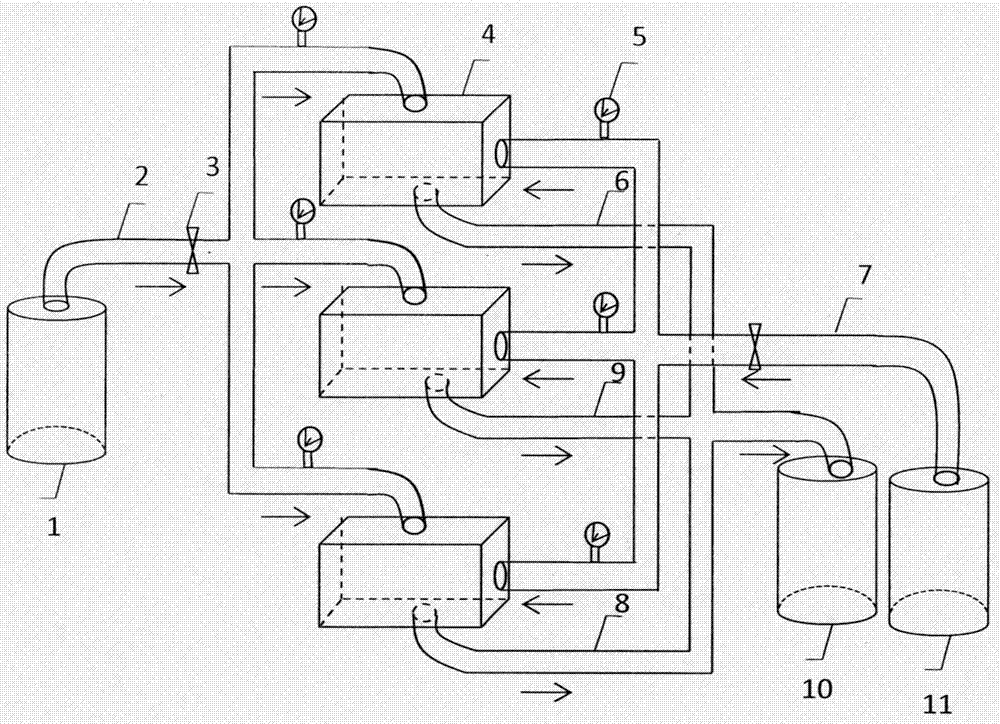

Super-sparger microcarrier beads and precision extrusion deposited poly-epsilon-caprolactone structures for biological applications

Owner:DARLING ANDREW +3

Method for making molecular sieves and novel molecular sieve compositions

Owner:ABB LUMMUS GLOBAL INC

Technique for producing energy-saving sintering brick by silt

InactiveCN101265077AHigh porosityImprove thermal insulationCeramic materials productionClaywaresPorosityBrick

Owner:XIAN RES & DESIGN INST OF WALL & ROOF MATERIALS CO LTD

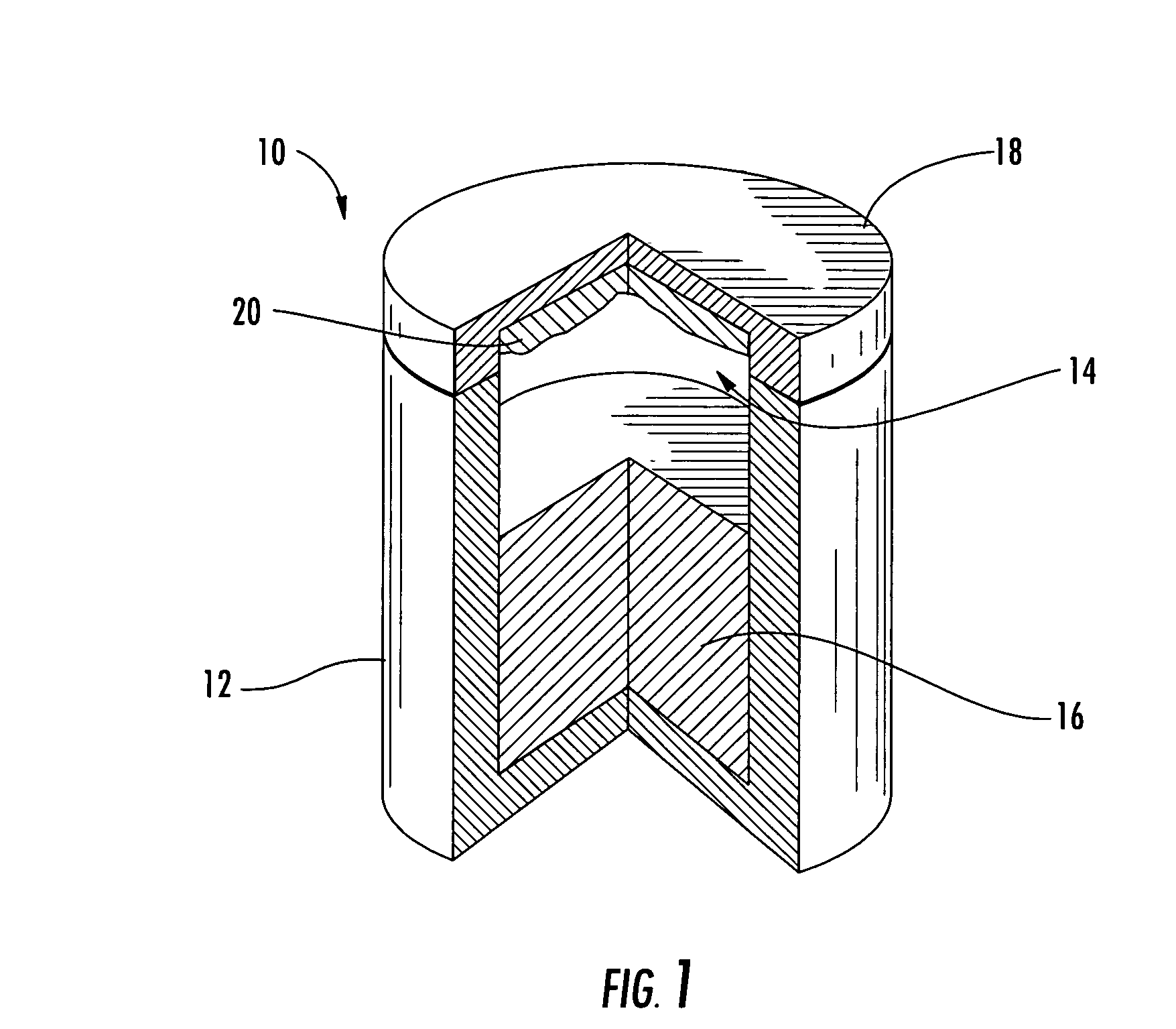

Dense, shaped articles constructed of a refractory material and methods of preparing such articles

ActiveUS20060280640A1High utilization yieldUniform material propertiesPolycrystalline material growthCeramic shaping apparatusPorosityCrucible

Owner:NORTH CAROLINA STATE UNIV +6

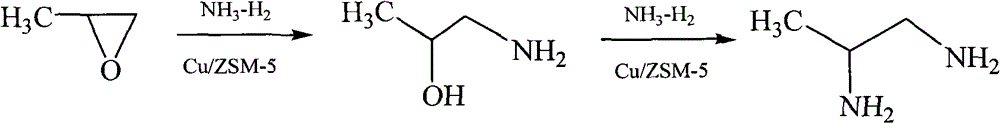

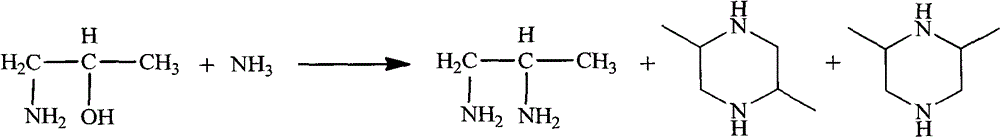

Coproduction method of 1, 2-propanediamine and dimethyl piperazine

InactiveCN102718661AReduce consumptionLow costOrganic compound preparationAmino compound preparationPorosityContact time

Owner:XIAN MODERN CHEM RES INST

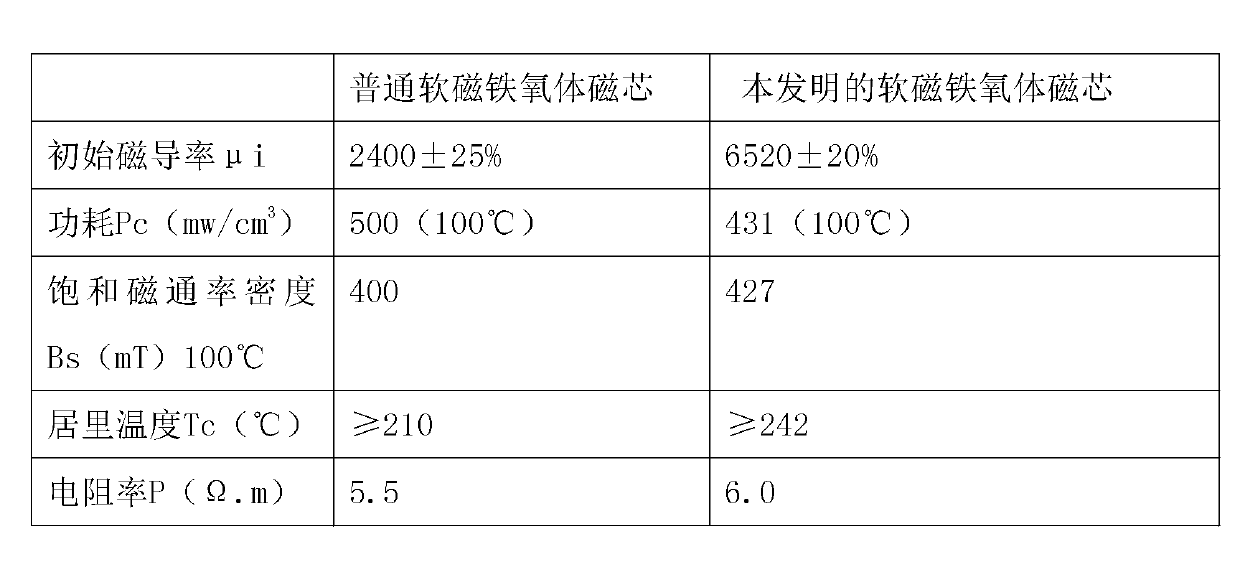

Preparation method of MnZn (Manganese-Zinc) soft magnetic ferrite material containing modified nanoscale titanium dioxide

Owner:浙江大通磁业科技有限公司

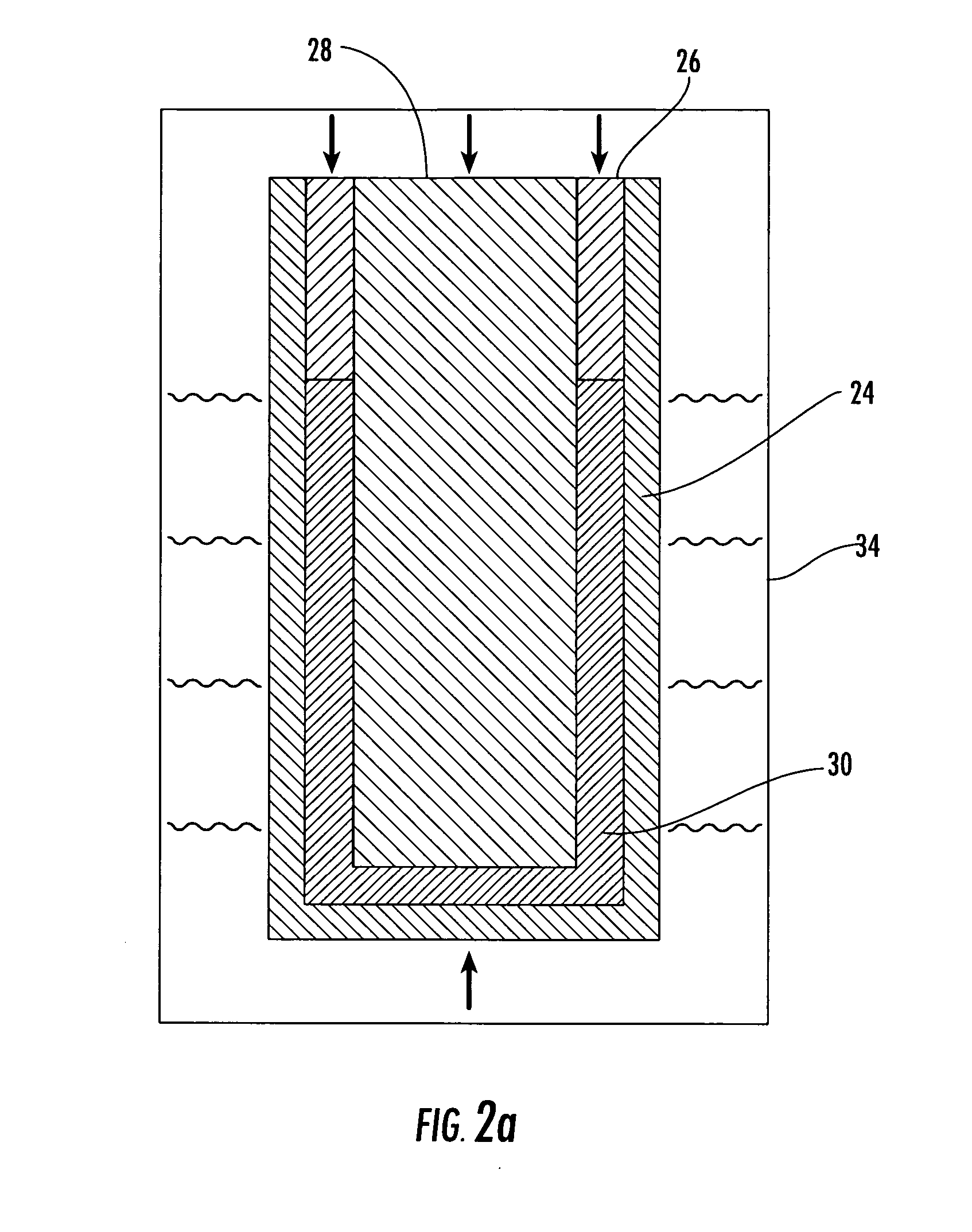

Fine die cast metallic parts

InactiveUS20050087320A1Minimize amount of gasGreat dimensionPorosityDie casting

A finished molded metal part is produced by an injection molding system includes a feeder in which a metal is melted and a first chamber into which a desired amount of melted metal is introduced. The molded metal parts can have extremely fine dimensions, small thicknesses, and indented or protruding surface features that are molded with such low porosity that no further milling / finishing operation is required before the part is used in its finished state.

Owner:TAKATA CORPORATION

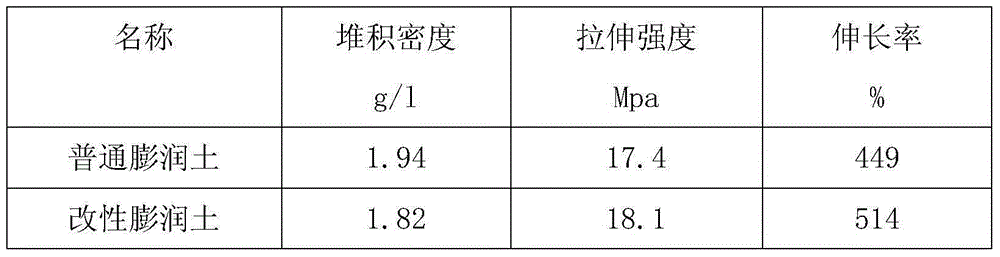

Porous modified bentonite with foaming effect and preparation method thereof

InactiveCN105126779APorousReasonable formulaOther chemical processesAlkali metal oxides/hydroxidesPorositySodium Bentonite

Owner:安徽雪城超细碳酸钙有限公司

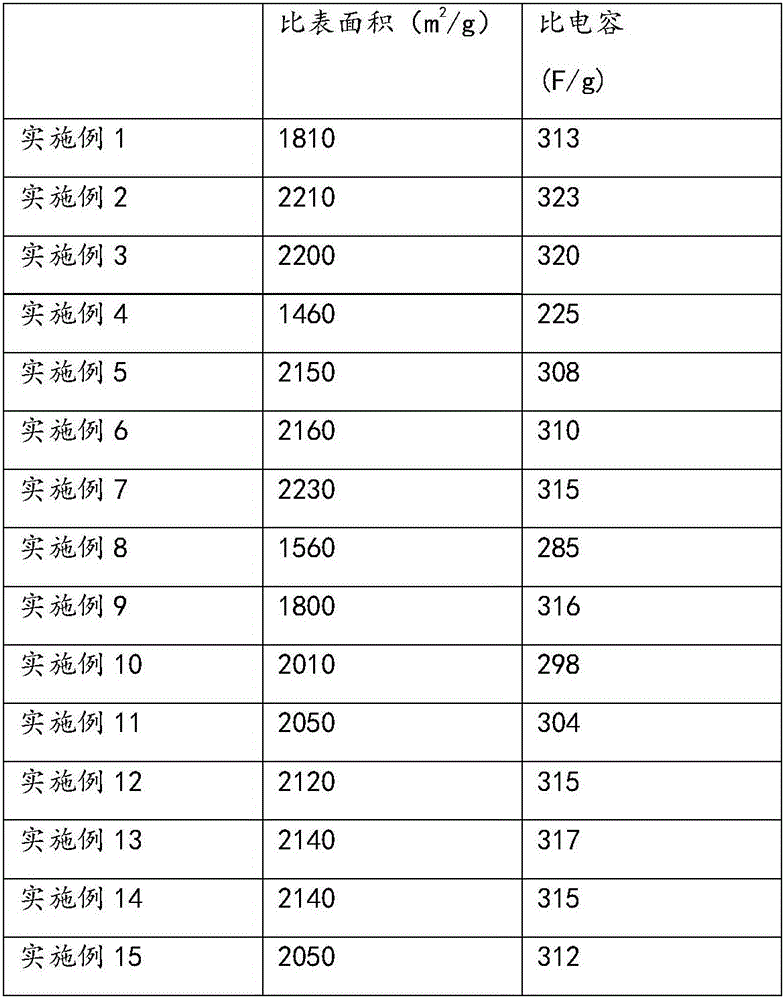

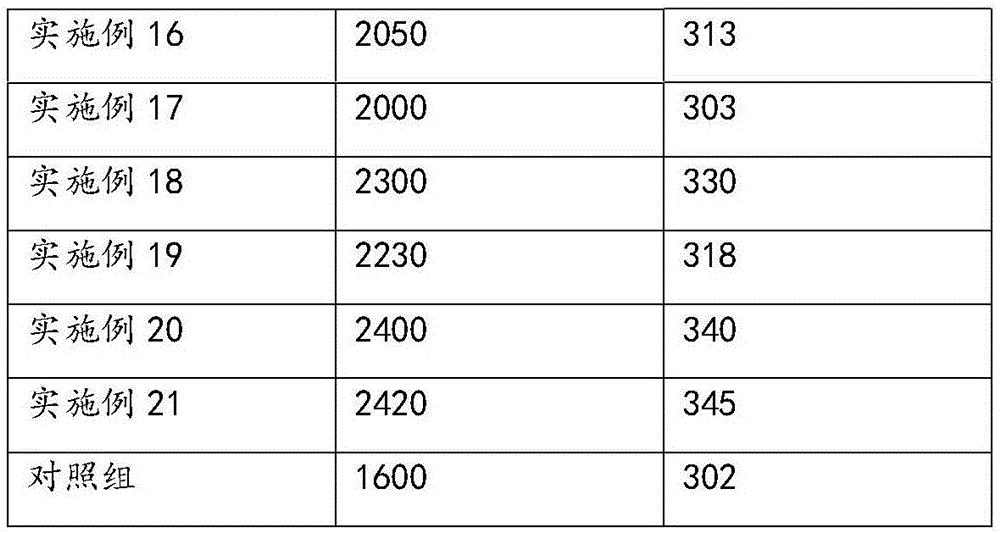

Graphene-based hierarchical pore capacitor carbon and preparation method thereof as well as capacitor

InactiveCN106467299ACurl suppressionSuppress stackingHybrid capacitor electrodesGrapheneCross-linkPorosity

Owner:山东圣泉新能源科技有限公司

Method for making coated filter cloth through wet process

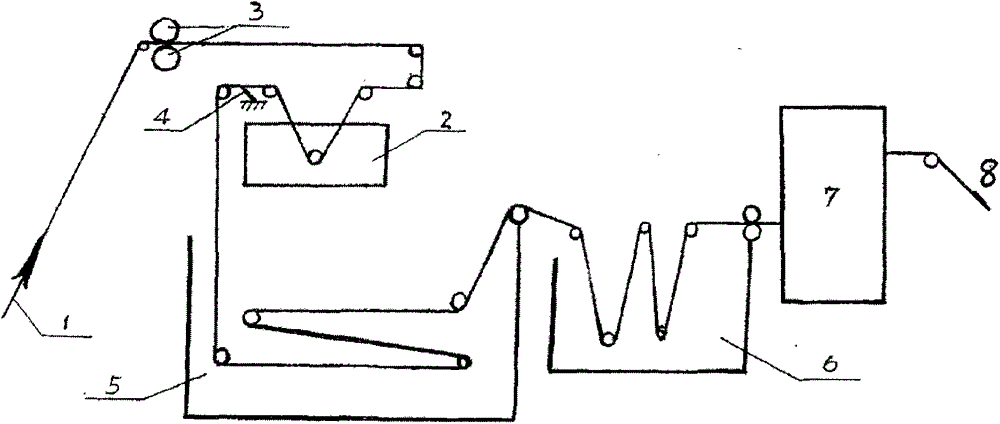

InactiveCN103952914AHigh porosityHigh Solids RetentionFibre treatmentFiltration separationPorosityYarn

Owner:刘冠利

Foaming-ceramic heat insulating board and preparing method thereof

InactiveCN105503238ALow thermal conductivityHigh compressive and flexural strengthCeramicwarePorosityPotassium

Owner:韩功篑

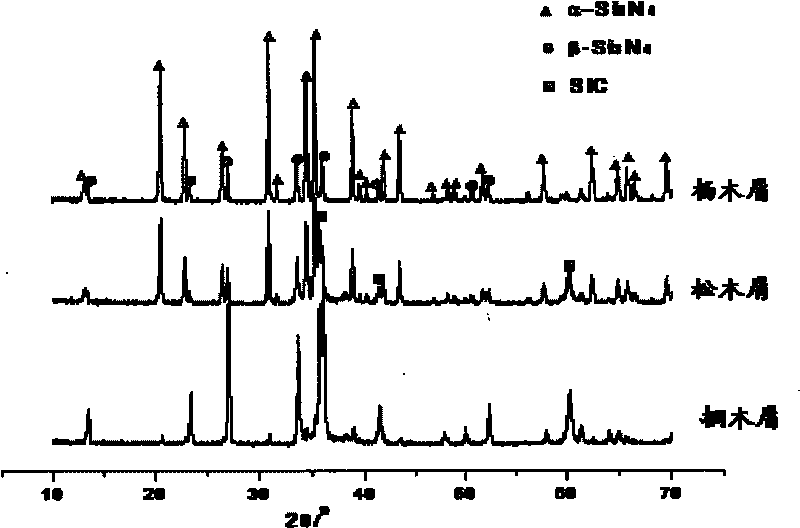

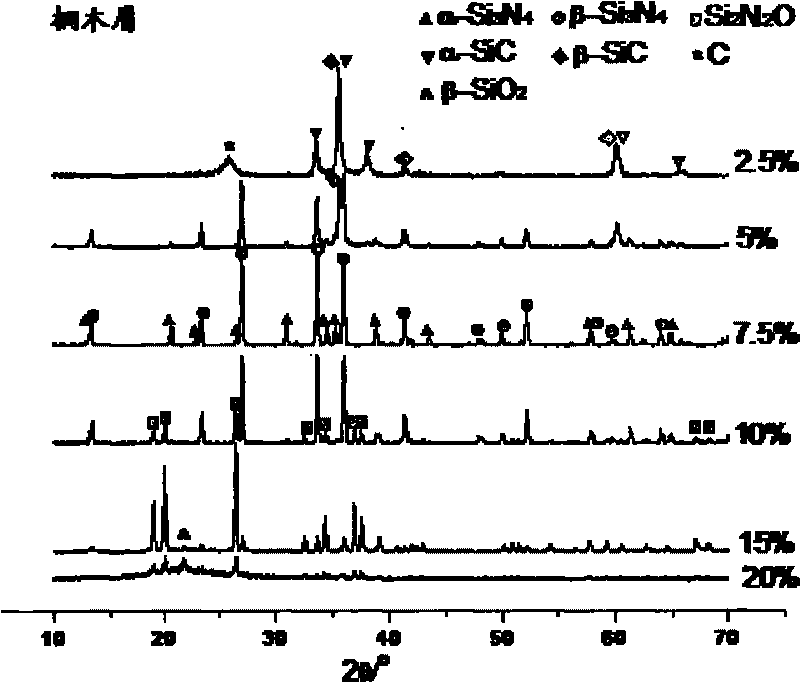

Method for preparing silicon nitride powder with saw dust

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

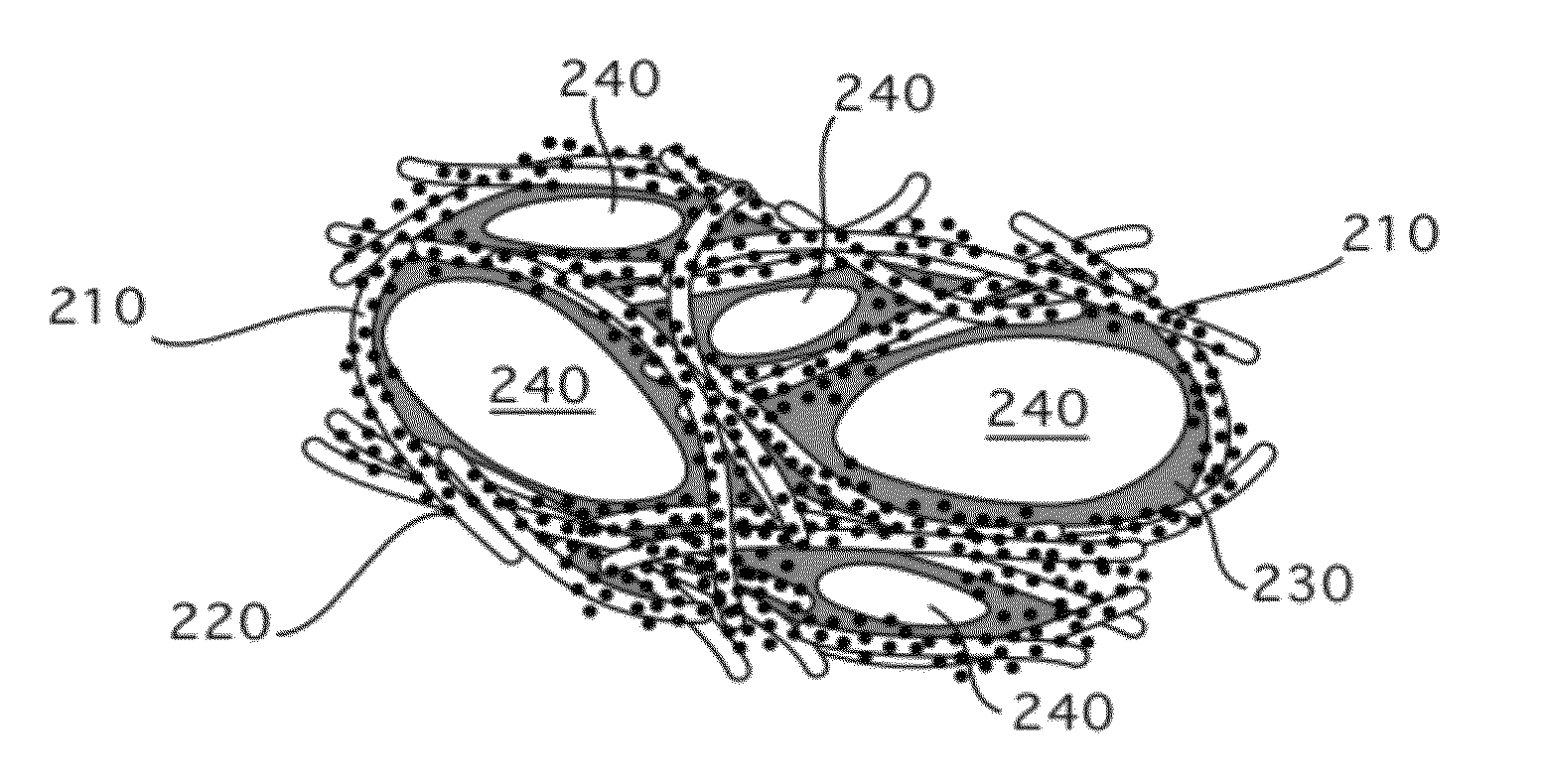

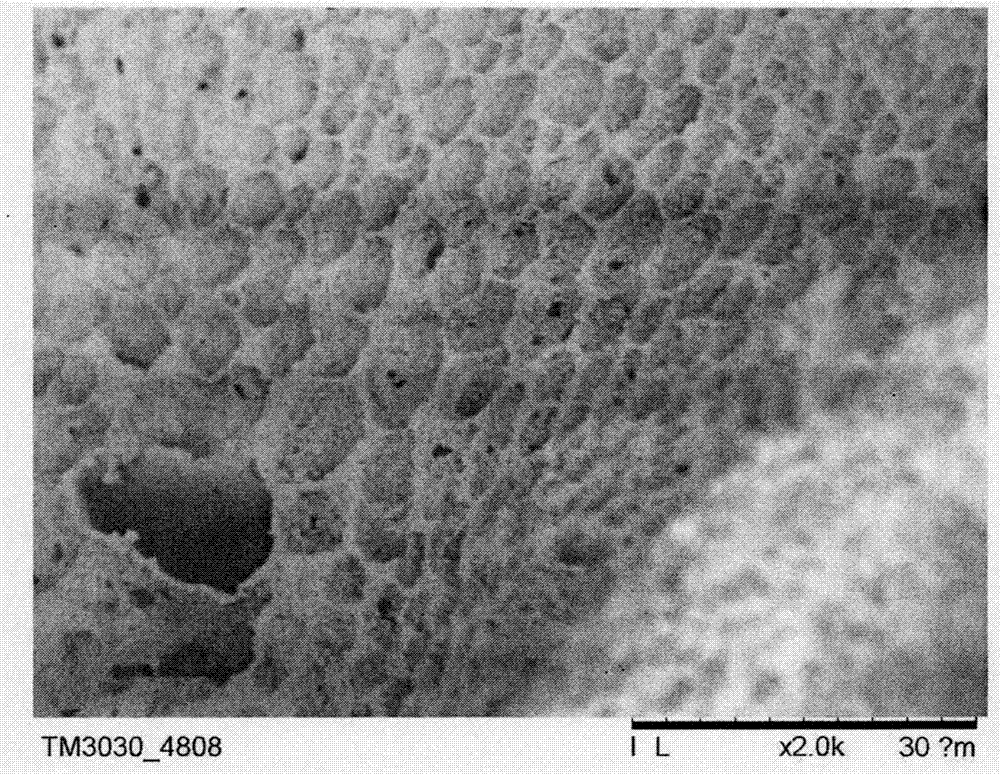

Devices and Methods for Tissue Engineering

Owner:BIO2 TECH

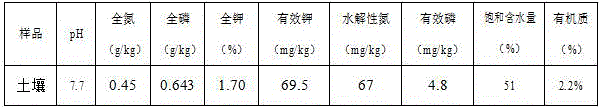

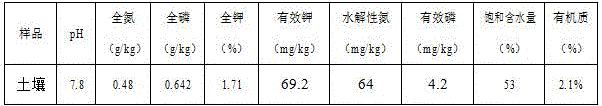

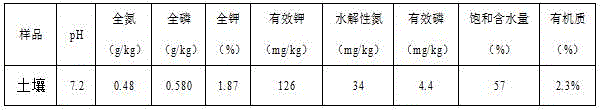

Planting red soil improving method

InactiveCN106332570AIncrease stickinessHigh porosityCalcareous fertilisersExcrement fertilisersPorosityAdditive ingredient

Owner:YUNNAN ACAD OF FORESTRY

Preparation method for preparing nylon porous material on large scale

ActiveCN107353634ALarge specific surface areaWith insulationOther chemical processesWater/sewage treatment by sorptionPorositySodium bicarbonate

Owner:TIANJIN POLYTECHNIC UNIV

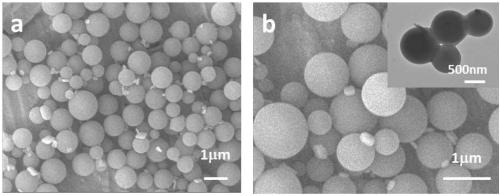

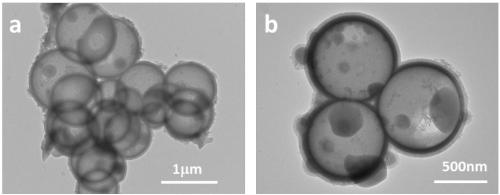

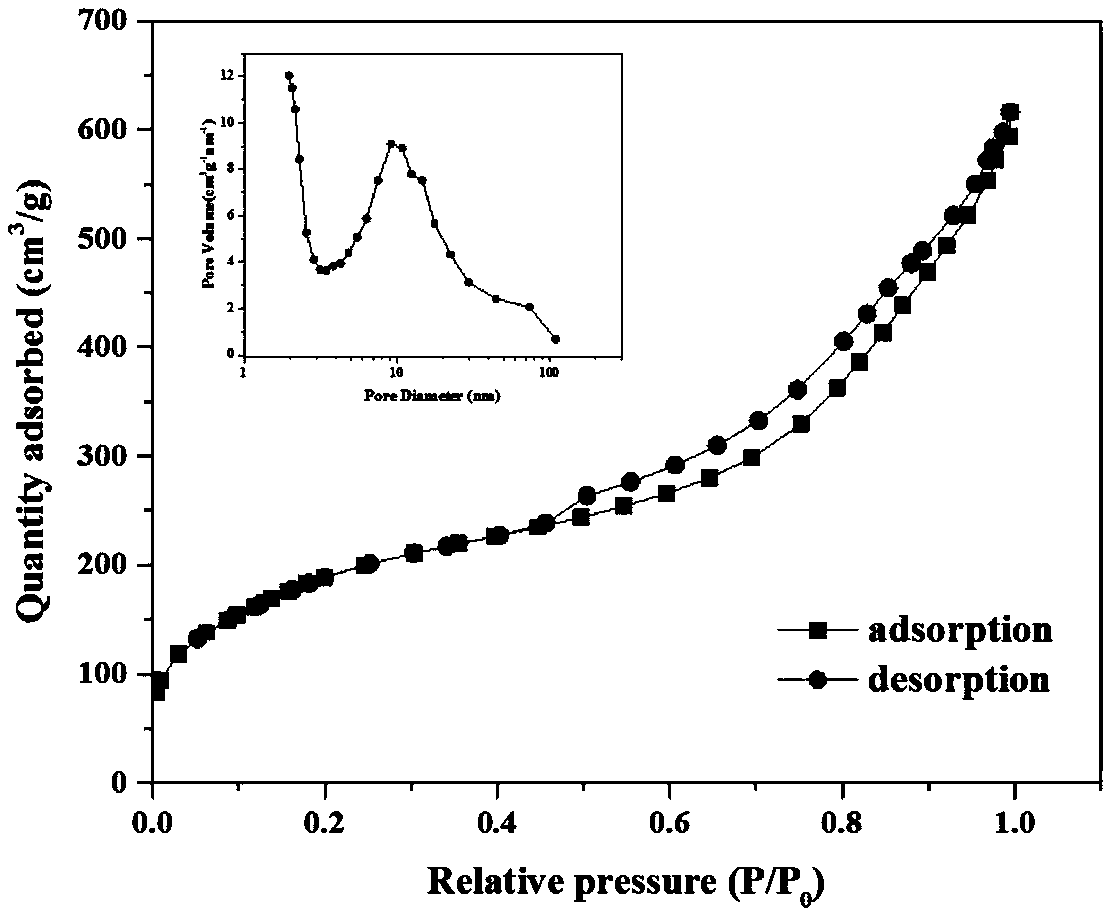

Composite microsphere with radial fibrous mesoporous shell layer/hollow nuclear layer structure and preparation method of composite microsphere

ActiveCN109647297AGood spherical shapeNarrow particle size distributionMicroballoon preparationMicrocapsule preparationPorosityMicrosphere

Owner:ETERNAL SPECIALTY MATERIALS ZHUHAI CO LTD

Multiwall carbon nanotube cement-based composite material and preparation method thereof

The invention relates to a multiwall carbon nanotube cement-based composite material and a preparation method thereof. The composite material is prepared from the following raw materials in parts by weight: 0.4 to 0.7 part of surfactant, 10 to 20 parts of ethanol, 0.05 to 0.15 part of multiwall carbon nanotubes, 1.5 to 1.8 parts of nano silicon dioxide, 100 parts of cement gelling material, 10 to20 parts of silica fume, 300 to 400 parts of standard sand, and 40 to 60 parts of water. The multiwall carbon nanotube is added into the cement-based composite material, so that the composite materialis low in porosity, small in average aperture, and compact in structure, thereby improving the mechanical performance of the material. By virtue of determination, the pressure resistant strength is increased by 11.6 to 20.99 percent, so that the service life of a building is effectively prolonged. The method disclosed by the invention is simple and easy in operation, controllable in cost, capableof solving the agglomeration problem of the multiwall carbon nanotube, and capable of preventing the secondary agglomeration of the multiwall carbon nanotube in the cement-based composite material. In the current construction process of smart cities and green cities, the multiwall carbon nanotube cement-based composite material have wide market prospect and application value.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

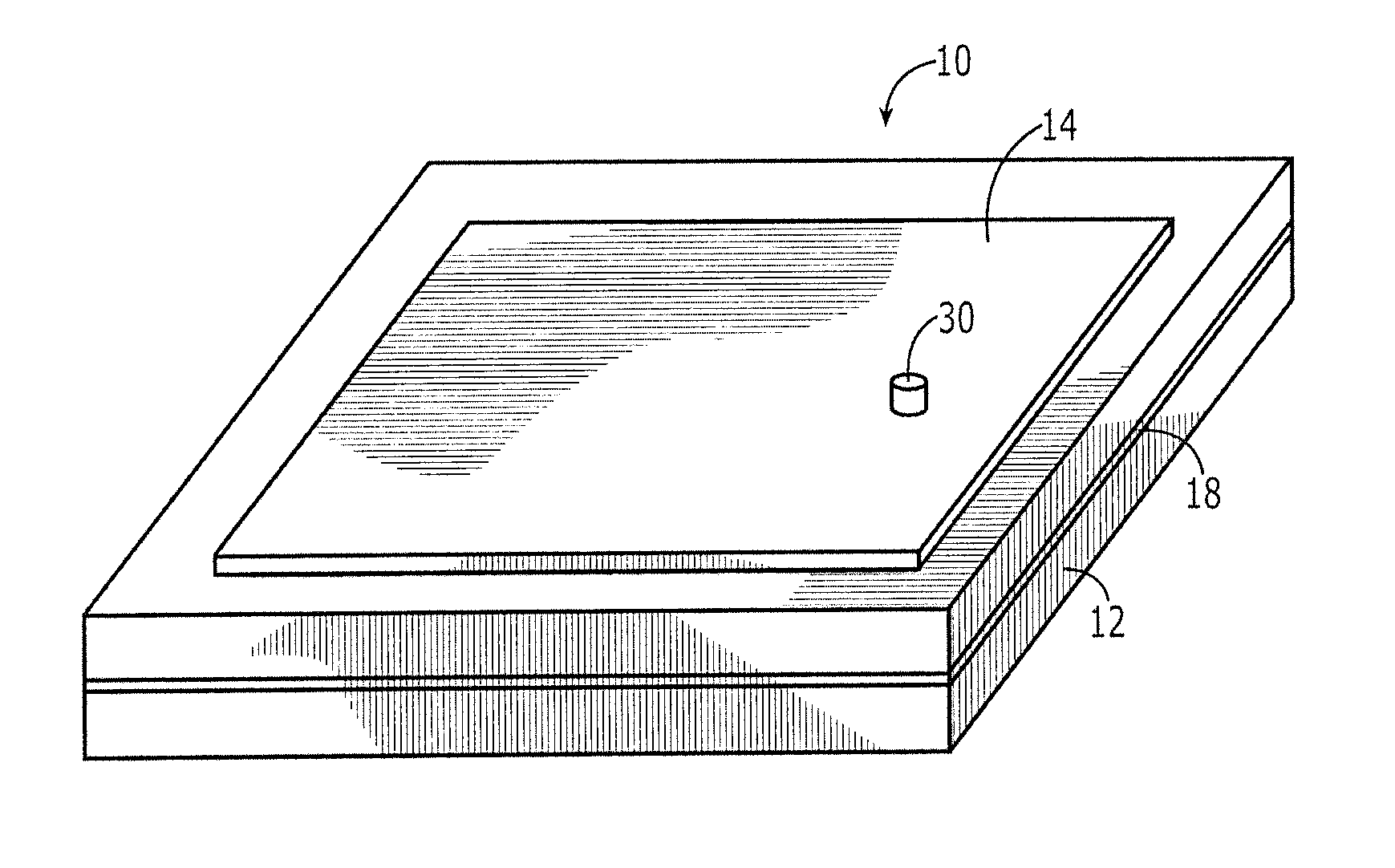

Preparation method of silicon dioxide antireflection film

The invention discloses a preparation method of a silicon dioxide antireflection film. The preparation method comprises the following steps of preparing a clear sol by using raw materials like a silicon compound, a solvent, a suppressor, deionized water and acid catalyst under an acidic condition through a sol-gel method; stirring and adding aqueous ammonia and ethyl acetate into the clear sol, and reacting for 0.5-24 hours in a 40-100DEG C constant temperature backflow condition, so as to prepare milky white silicon dioxide sol, wherein the milky white silicon dioxide sol contains 2-10 mass percent of silicon compound, 60-90 mass percent of solvent and 1-40 mass percent of water; and applying the milky white silicon dioxide sol onto a substrate with the surface treated, so as to obtain acoating. The silicon dioxide antireflection coating prepared by the method has higher air porosity and lower refractive index, and has much better antireflection effect while maintaining the frictionresistance. The preparation method is low in production cost, slightly affects surrounding environment, and is suitable for large-scale production and application of industry.

Owner:HUNAN XINGWEI NEW MATERIAL CO LTD

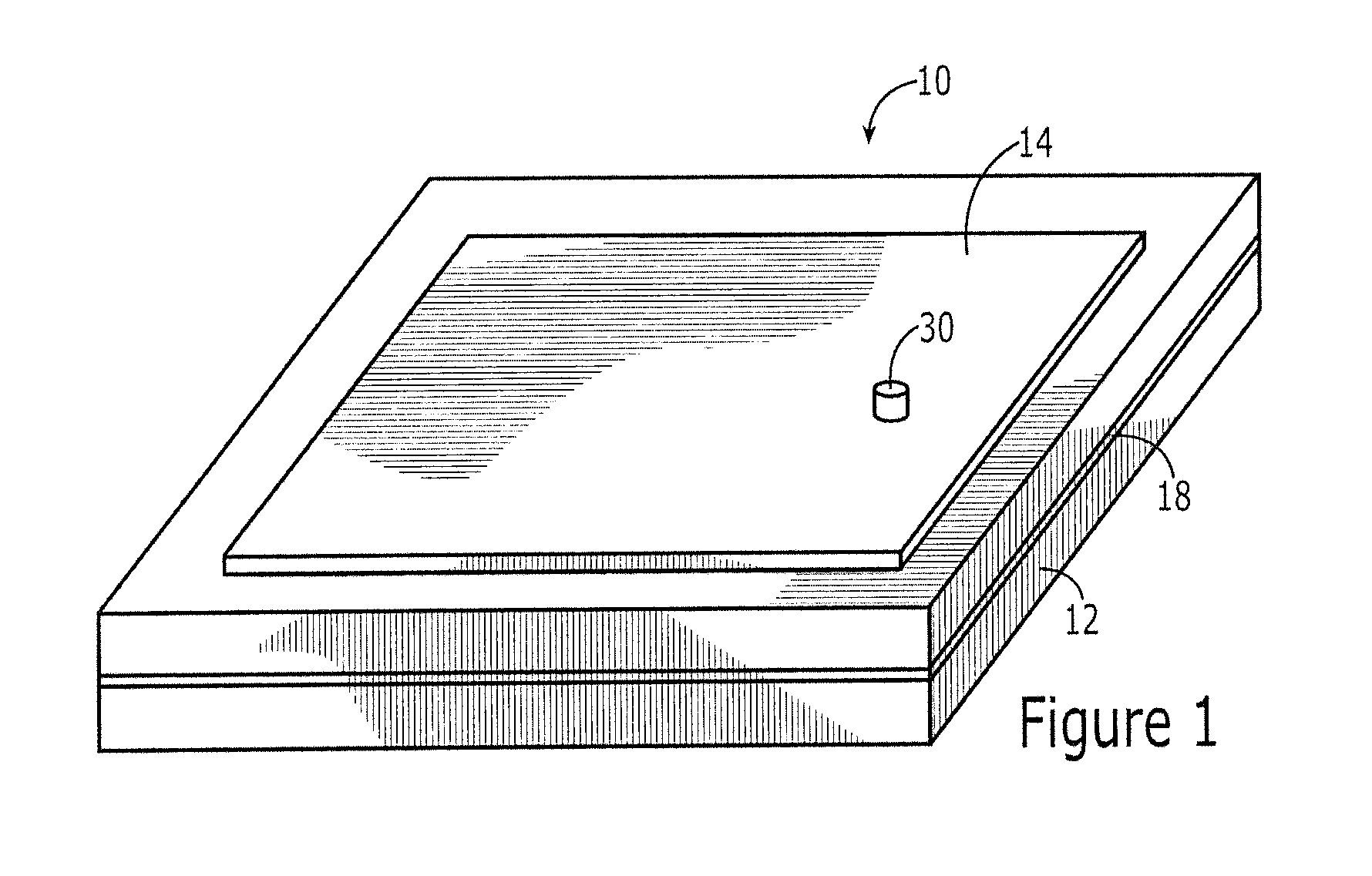

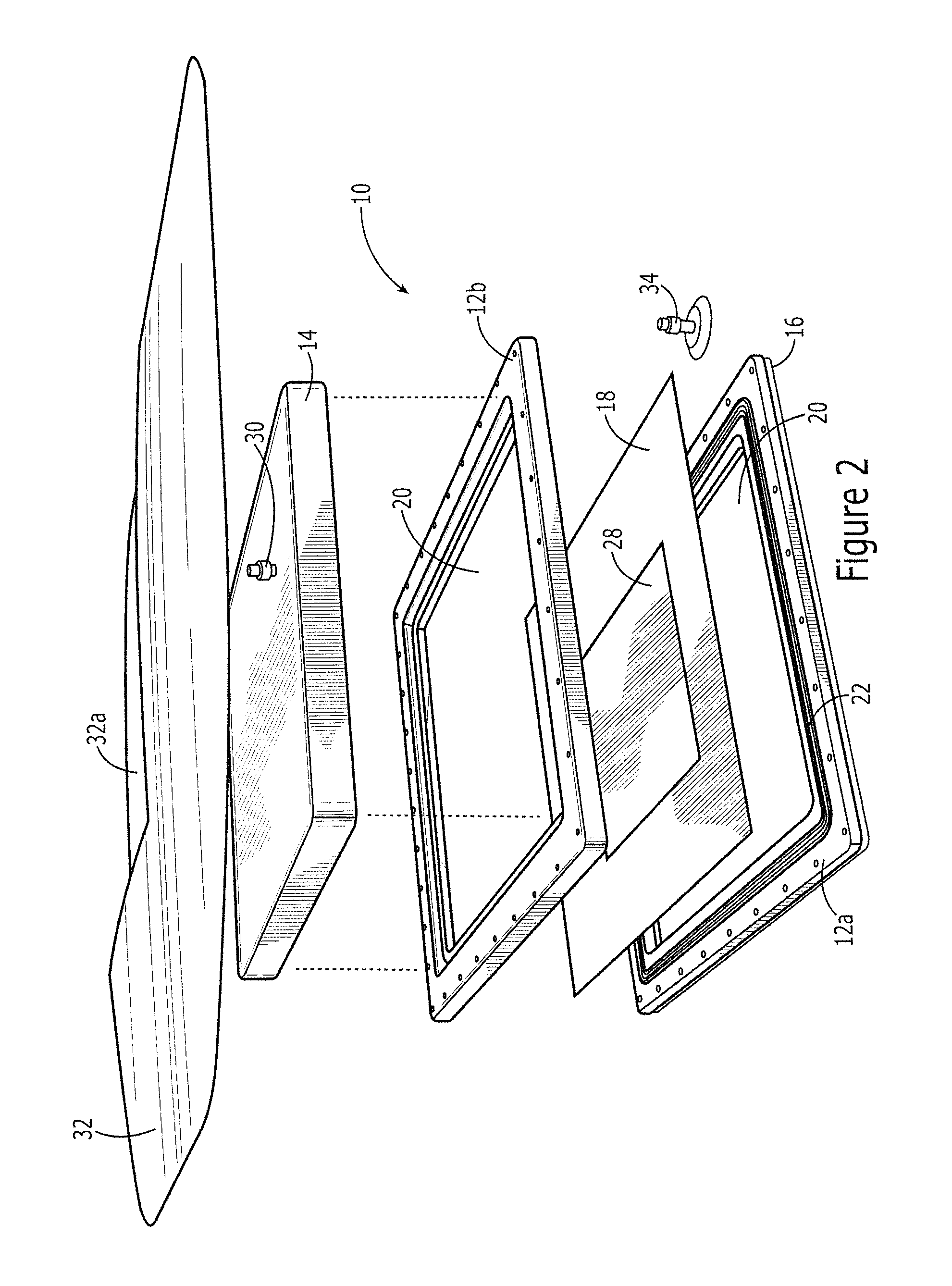

Installation tool and associated method for applying a patch to a surface

Owner:THE BOEING CO

Preparation method of refining agent for smelting fly ash doped aluminum alloy

The invention discloses a preparation method of a refining agent for smelting a fly ash doped aluminum alloy. The refining agent is prepared from the following raw materials in parts by weight: 6-8 parts of potassium chloride, 4-6 parts of tree ash, 6-8 parts of slag, 7-9 parts of mountain flour, 6-8 parts of zinc oxide, 3-5 parts of calcium fluoride, 3-5 parts of sodium nitrate, 5-8 parts of slag, 8-10 parts of sodium fluosilicate, 3-5 parts of sodium sulfate, 5-8 parts of aluminum chloride, 3-5 parts of potassium carbonate, 8-10 parts of sepiolite, 5-8 parts of NaBF4, 3-5 parts of sodium chloride, 5-8 parts of calcium carbonate, 8-10 parts of Na2TiF68 and 5-8 parts of NaF. The refining agent disclosed by the invention is used for treating to obtain a high-quality molten aluminum alloy; the molten aluminum alloy can be used for casting production and the rate of finished products is obviously improved; particularly, the porosity in a cast is reduced by 1-2 degrees and is effectively controlled; pores are not formed on the surface of the cast, oxide inclusion is obviously reduced and the oxide inclusion is about grade 2; and the mechanical property of the cast is obviously improved.

Owner:王俊霞

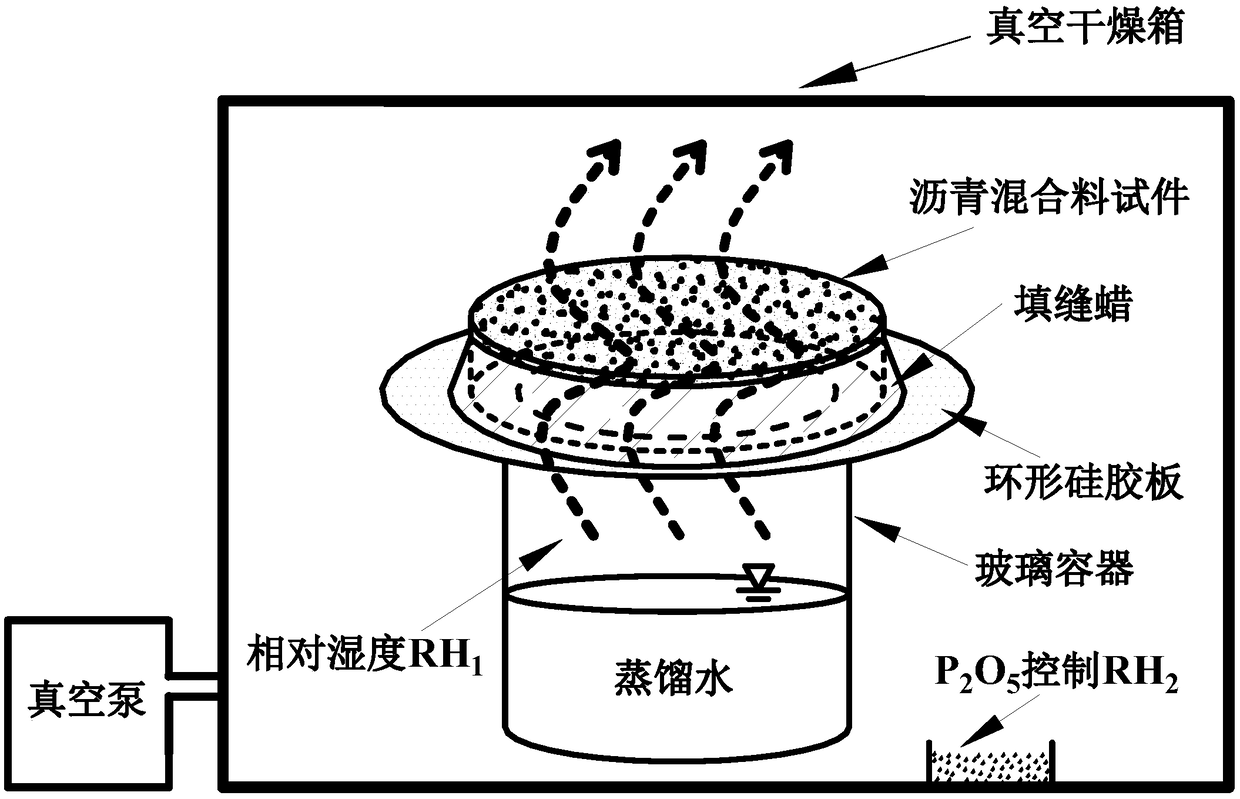

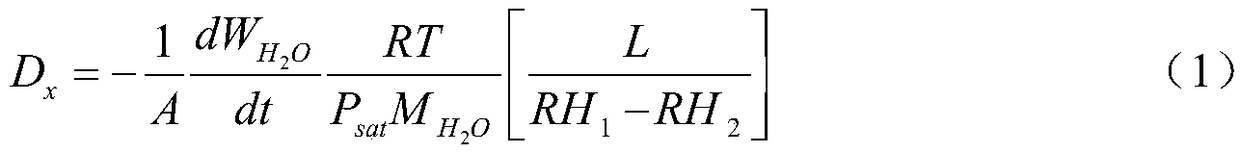

A method for detecting the penetration type water vapor diffusion coefficient of a large-thickness low-porosity asphalt mixture

ActiveCN108776084ARealize humidity gradient driveIncrease humiditySurface/boundary effectPorosityWater vapor

Owner:WUHAN UNIV OF TECH

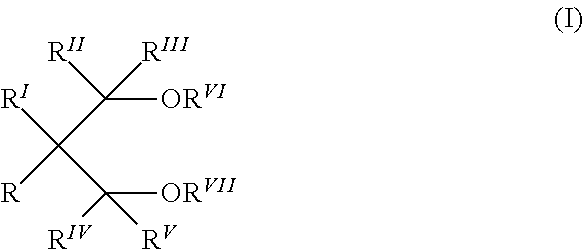

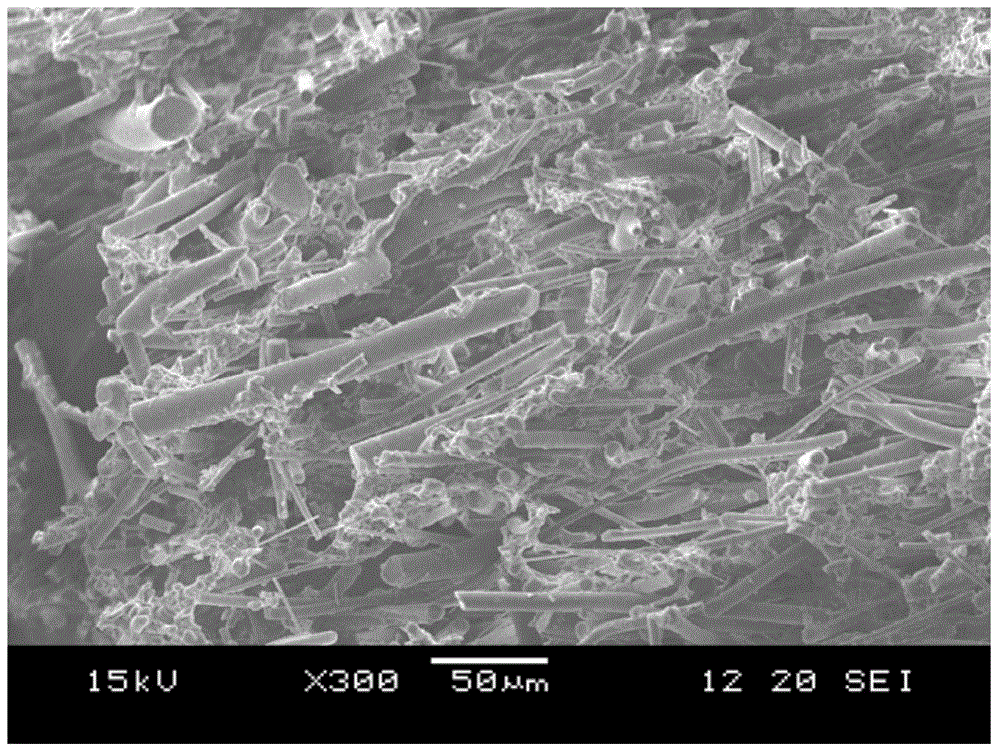

Catalyst components for the polymerization of olefins

InactiveUS20180230247A1PorosityElectron donor

Owner:BASSELL POLIOLEFINE ITAL SRL

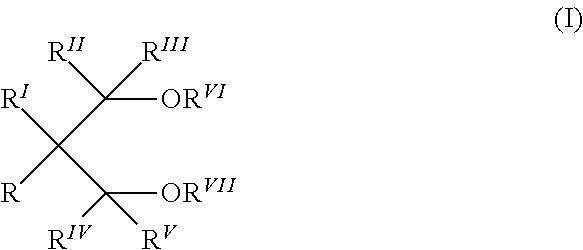

Preparation method of oil-water separation membrane

The invention discloses a preparation method of an oil-water separation membrane, and belongs to the technical field of environmental protection. According to the method, wood stone fiber is mixedintopolyvinylidene chloride melt in a suitable temperature condition, and lignin reaches glassy state, is softened and flows under high pressure; nanofiber sponge is prepared from resin soaked activatedstone pulp; sea-foam stone powder in the activated stone pulp belongs to a magnesium-enriched silicate compound, can magnesium hydroxide crystal and ammonium phosphate under the action of ammonia gasand phosphoric acid, not only ensures that oil absorption sponge has high porosity, but also ensures that the oil absorption sponge has certain flame retardant property; firstly scale has a bionic hydrophobic structure, and a separation membrane structure with a hydrophobic exterior; finally during the process of copper film plating, the internal surface area of fiber fabric is greatly increased through activation of phosphoric acid, and a plurality of active centers are formed in the surface of the fiber fabric; granule suspension oil and dissolved oil liquid can be easily absorbed into interiors of pores, so that damage to the inner surface of the fiber sponge is weakened when the inner surface is scoured by liquid, and the oil-water separation membrane has a wide application prospect.

Owner:FOSHAN LINGXIE ENVIRONMENTAL PROTECTION TECH CO LTD

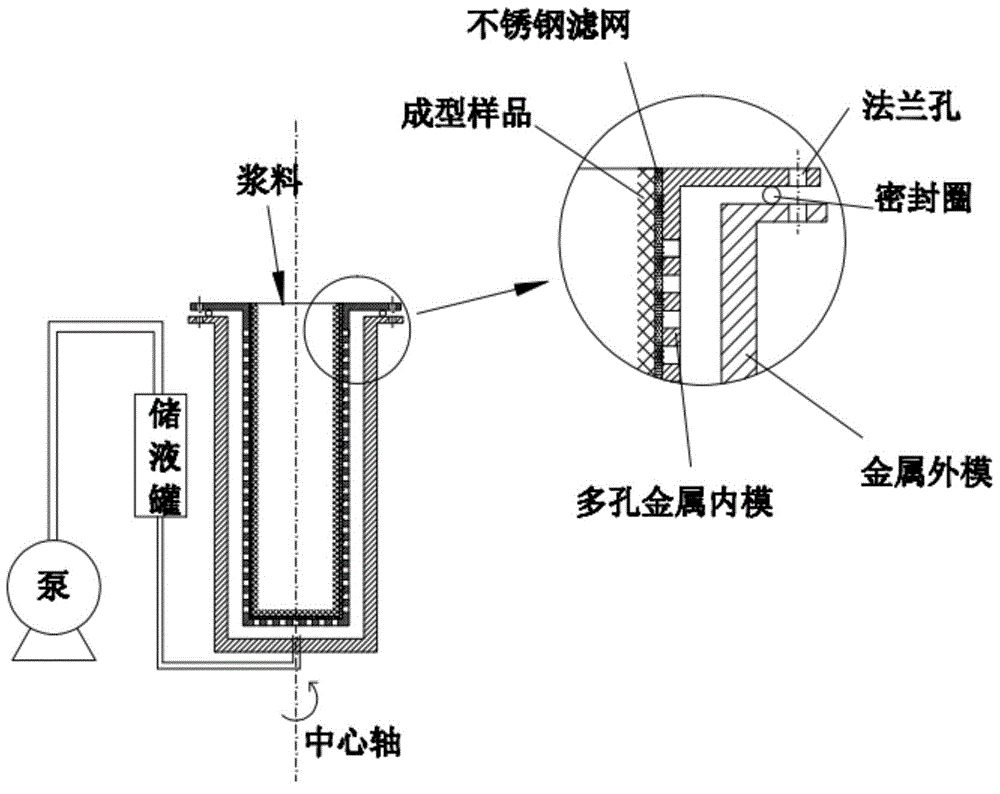

Gas-solid separation ceramic material and preparation method thereof

Owner:NANJING UNIV OF TECH

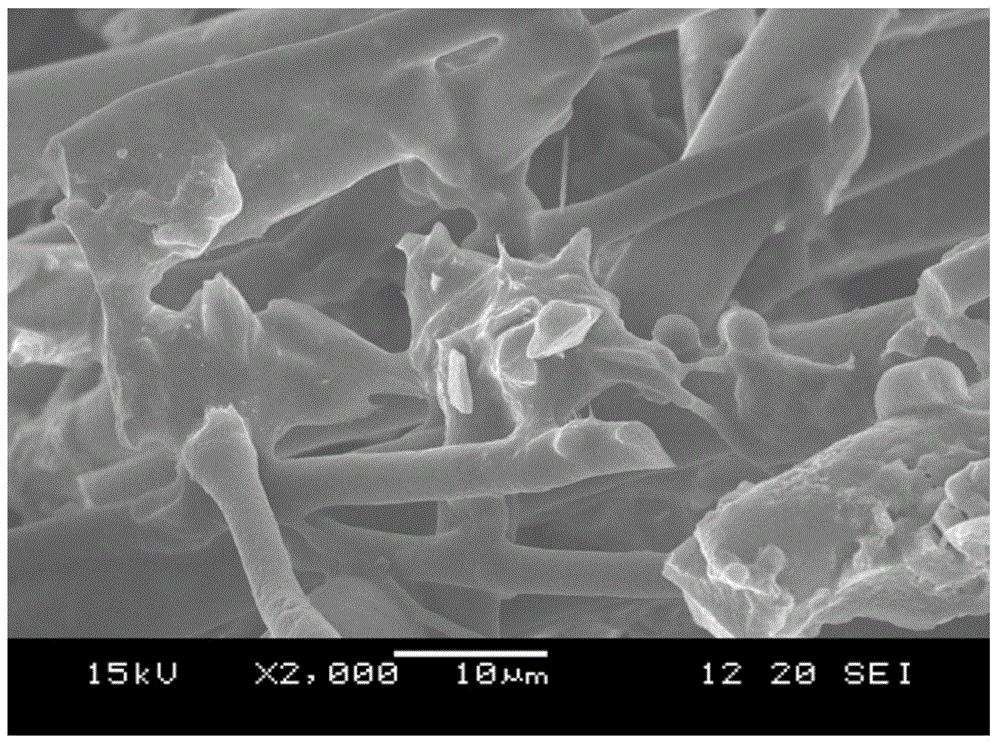

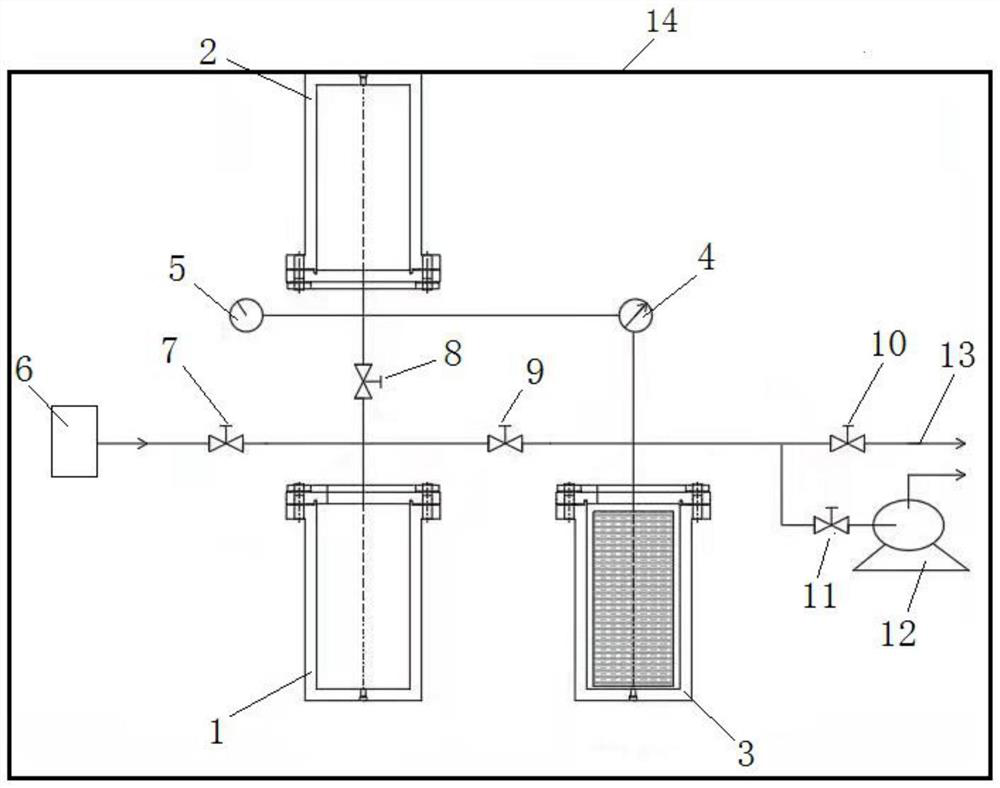

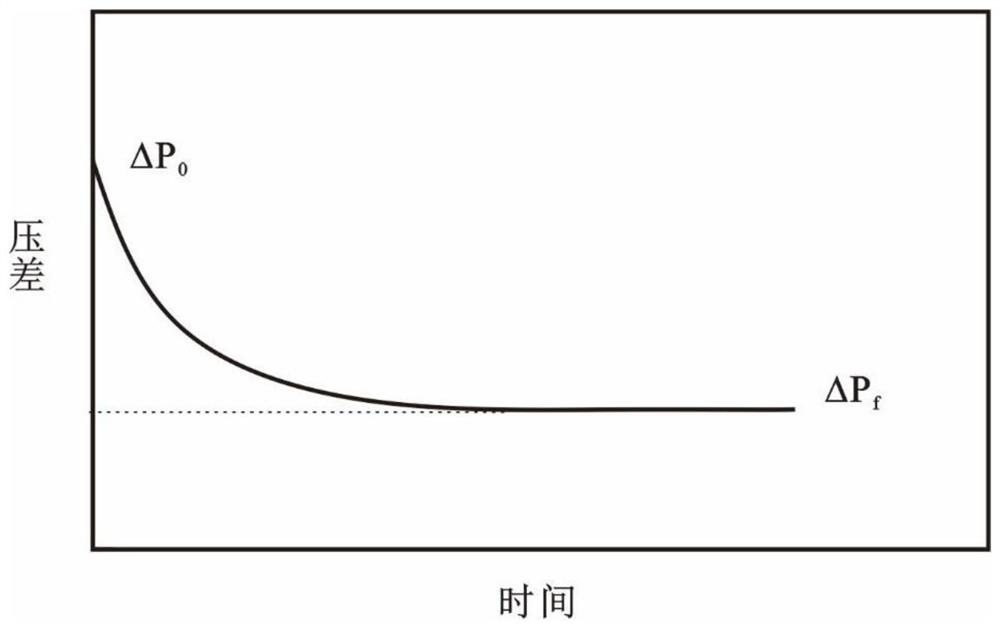

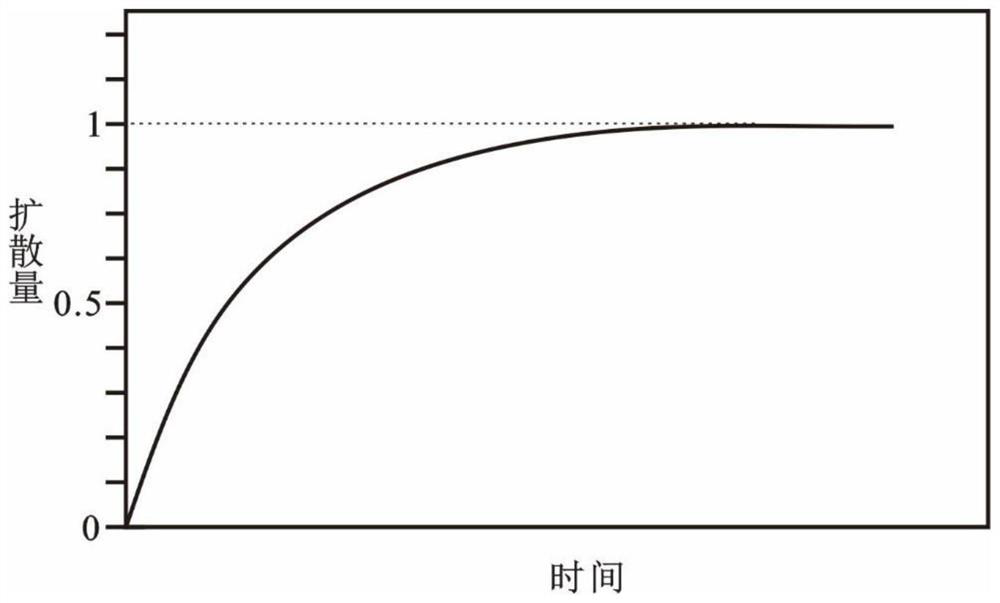

High-pressure helium shale porosity testing device and method

ActiveCN114047105AGet the amount of diffusionGet timeEarth material testingPermeability/surface area analysisTemperature controlPorosity

Owner:NORTHEAST GASOLINEEUM UNIV

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap