Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

25 results about "Silicate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In chemistry, a silicate is any member of a family of anions consisting of silicon and oxygen, usually with the general formula [SiO₄₋ₓ]ₙ, where 0 ≤ x < 2. The family includes orthosilicate SiO⁴⁻₄ (x = 0), metasilicate SiO²⁻₃ (x = 1), and pyrosilicate Si₂O⁶⁻₇ (x = 0.5, n = 2). The name is also used for any salt of such anions, such as sodium metasilicate; or any ester containing the corresponding chemical group, such as tetramethyl orthosilicate.

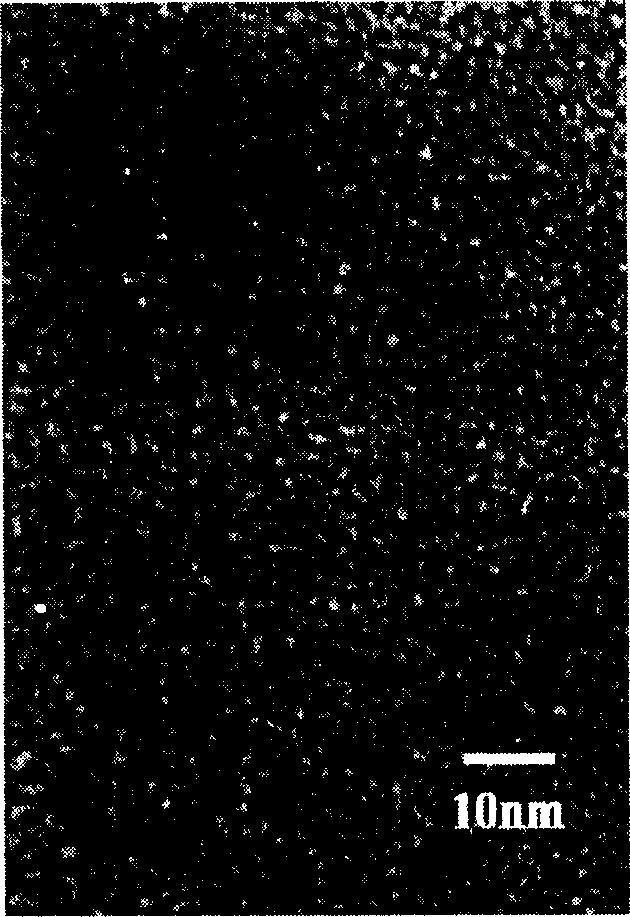

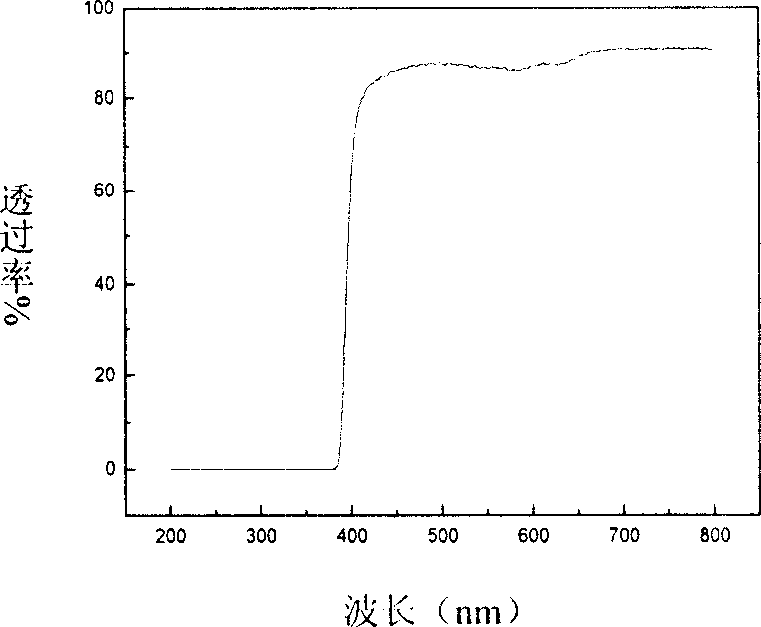

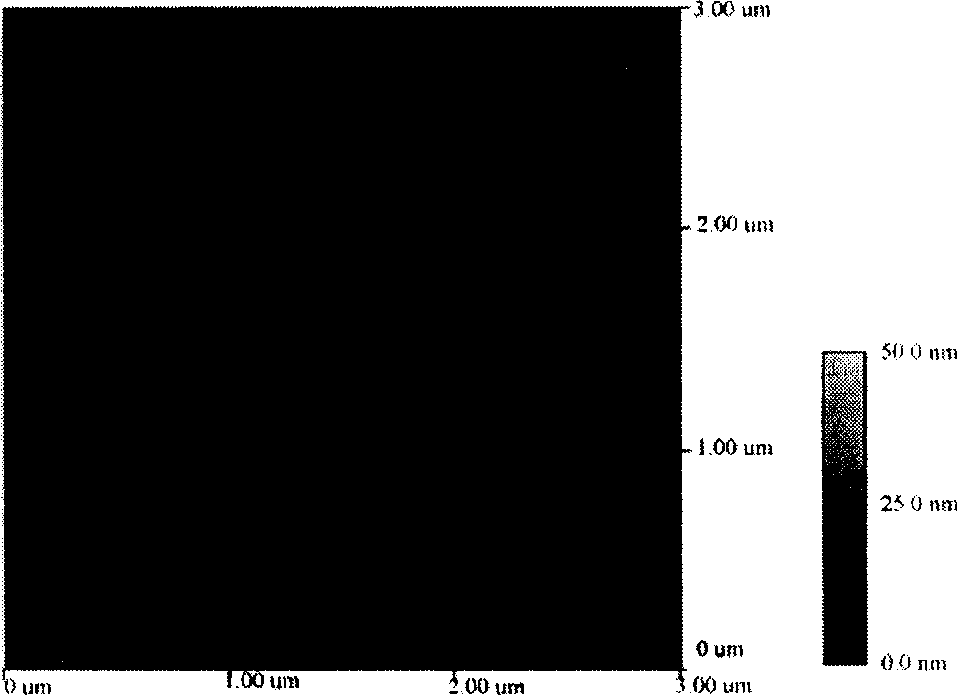

High strength organic / inorganic nano composite transparent film layer materials and method for preparing same

InactiveCN1699488AHigh refractive indexHigh transparencyCoatingsOptical elementsComposite filmRefractive index

Owner:JILIN UNIV

Negative electrode active material for non-aqueous electrolyte secondary batteries and non-aqueous electrolyte secondary battery using negative electrode active material

InactiveUS20150221950A1Improve efficiencyImprove propertiesNegative electrodesNon-aqueous electrolyte accumulator electrodesCharge dischargeNon aqueous electrolytes

In a non-aqueous electrolyte secondary battery using SiOX as a negative electrode active material, it is an object to improve initial charge-discharge efficiency and cycle properties. Provided is a negative electrode active material containing particles made of SiOX containing a lithium silicate phase, 50% to 100% of the surface of each particle made of SiOX being covered by carbon. The proportion of the number of moles of the lithium silicate phase to the number of moles of the particles made of SiOX is 0.5 mole percent to 25 mole percent. The average primary particle size of the particles made of SiOX is 1 μm to 15 μm.

Owner:SANYO ELECTRIC CO LTD

Green total organic carbon steel scale and corrosion inhibitor for circulating cooling water system

InactiveCN102351328AEasy to makeEasy to useScale removal and water softeningEutrophicationCarboxylic acid

The invention discloses a green total organic carbon steel scale and corrosion inhibitor for a circulating cooling water system, which comprises a scale inhibitor and a corrosion inhibitor, wherein the scale inhibitor comprises one or more of hydrolyzed polymaleic anhydride, polyacrylic acid, polymethacrylic acid, acrylic acid / hydroxypropyl acrylate copolymer, acrylic acid / hydroxypropyl acrylate / methyl acrylate terpolymer and acrylic acid / 2-acrylamido-2-methylpropane sulfonic acid copolymer; and the corrosion inhibitor comprises oxalic acid or oxalate, alpha-hydroxycarboxylic acid or salt thereof and silicate. The scale and corrosion inhibitor has excellent scale inhibition and corrosion inhibition performance, and belongs to a completely phosphorus-free metal-free environment-friendly total organic composition. Discharged waste water treated by the composition can not cause eutrophication pollution to the environment.

Owner:TIANJIN HEGUANG ELECTRICAL & MECHANICAL EQUIP CO LTD

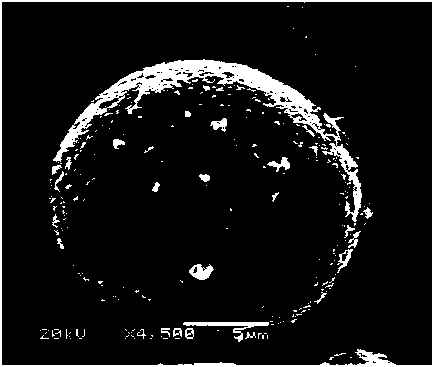

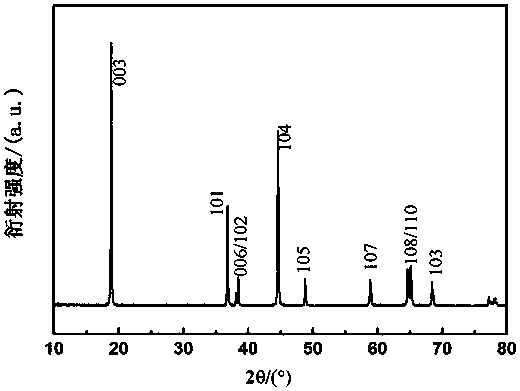

Lithium silicate-coated Ni-Co lithium aluminate positive electrode material and preparation method thereof

InactiveCN107910539AImprove cycle stabilityImprove high rate discharge performanceCell electrodesSecondary cellsLithium aluminateSilicon dioxide

Owner:CENT SOUTH UNIV

Dry-mixed pre-mixed mortar prepared by alkali activated slag cement, and preparation method thereof

Owner:JIANGSU NIGAO SCI & TECH +1

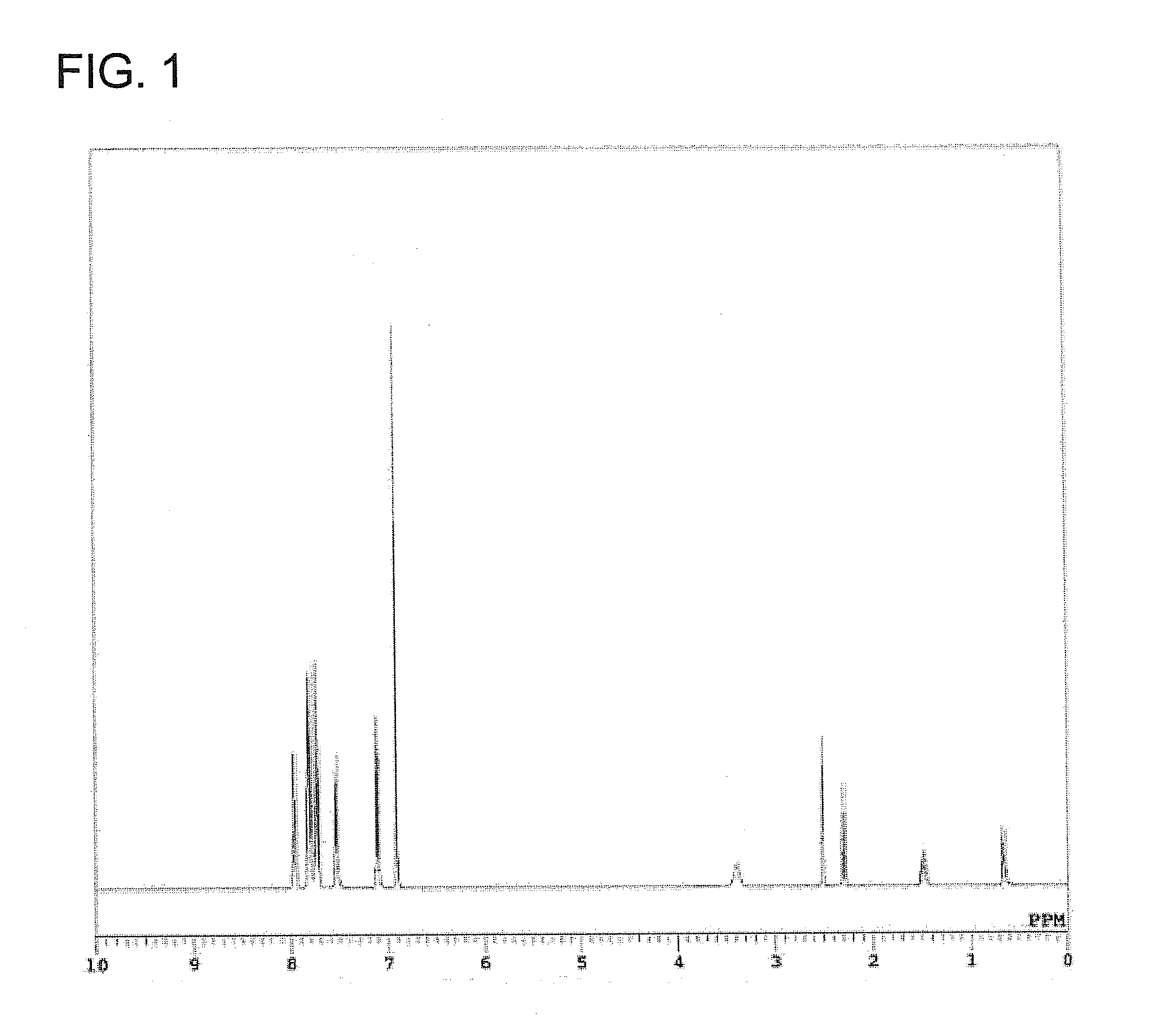

Process for producing latent catalyst and epoxy resin composition

InactiveUS20090234080A1High yieldGood fluidityOrganic-compounds/hydrides/coordination-complexes catalystsEpoxyPhosphonium

Owner:SUMITOMO BAKELITE CO LTD

Alkali metal ion source with moderate rate of ion release and methods of forming

ActiveUS20140345348A1Inhibition formationSafely raisedCalcareous fertilisersMagnesium fertilisersCalcium hydroxideAlkaline earth metal

An alkali metal ion source with a moderate rate of release of the ion (e.g. potassium) is formed by a method that includes: 1) combining an particulate ore that contains at least one of an alkali metal ion-bearing framework silicate (e.g. syenite ore) with at least one of an oxide and hydroxide of at least one of an alkali metal and alkaline earth metal such as calcium hydroxide; 2) milling the mixture of these two components optionally, with water, optionally, milling the dry components separately and blended thereafter, optionally, with water; 3) forming a mixture by adding water to the solid mixture after milling, if water was not added before milling; 4) exposing the mixture to an elevated temperature and pressure to form a gel that includes silica and the alkali metal of the framework silicate.

Owner:MASSACHUSETTS INST OF TECH

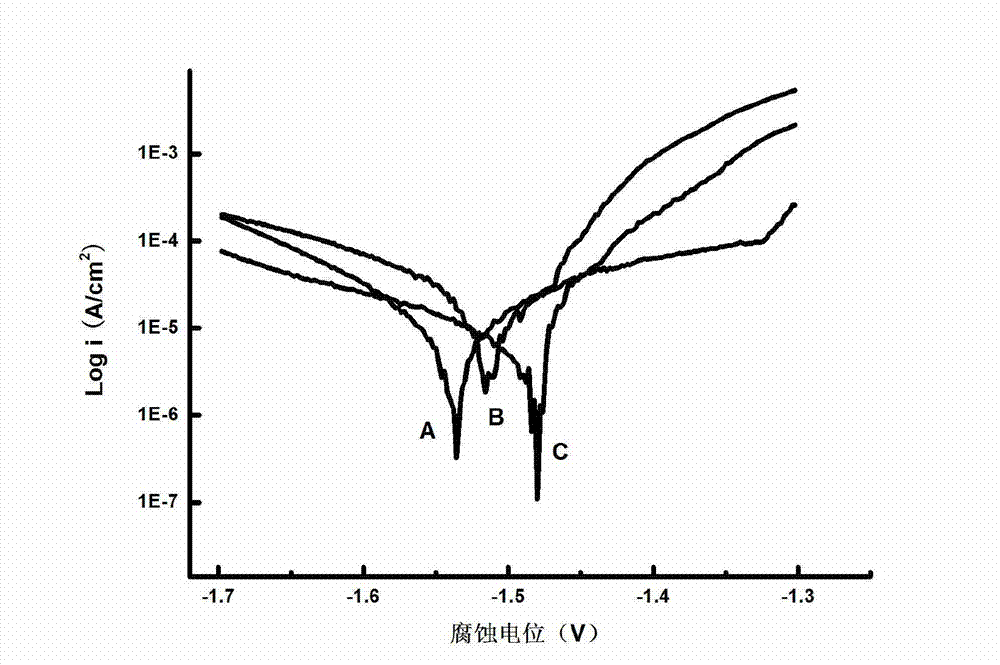

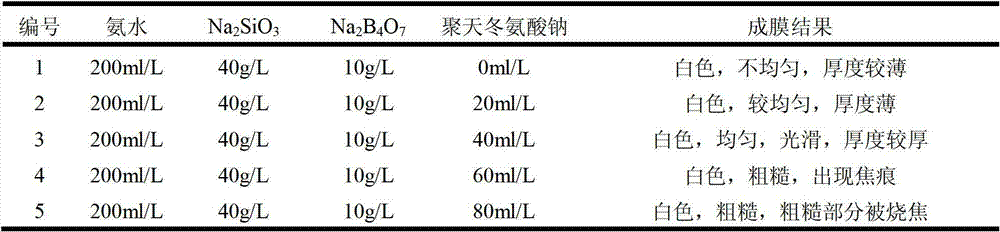

Electrolyte used for magnesium alloy anode oxidation treatment and treatment method

ActiveCN102828218AImprove corrosion resistanceStable temperatureAnodisationElectrolytic agentOxidative treatment

Owner:戚威臣

Microwave enhancement of the segregation roast

Owner:CATO RES CORP

Integral utilization treatment method for aerating concrete waste material

InactiveCN101215110AHigh activityImprove performanceSolid waste managementCeramicwareBall millGypsum

Owner:HOHAI UNIV

Method for preparing three-dimensional porous bioactive glass

InactiveCN107129157AEasy to makeFast preparationTissue regenerationProsthesisMolecular sieveNatural bone

Owner:ZHEJIANG SCI-TECH UNIV

Environment-friendly ceramic coating material for water faucet

InactiveCN106189561ACorrosion resistantWear-resistantAnti-corrosive paintsCarbon fibersPolybutylene terephthalate

Owner:朱燕华

Honeycomb denitration catalyst with water resistance and preparation method therefor

InactiveCN105413678AHigh mechanical strengthExtended service lifeGas treatmentDispersed particle separationPtru catalystFlue gas

Owner:ANHUI YUANCHEN ENVIRONMENTAL PROTECTION SCI & TECH

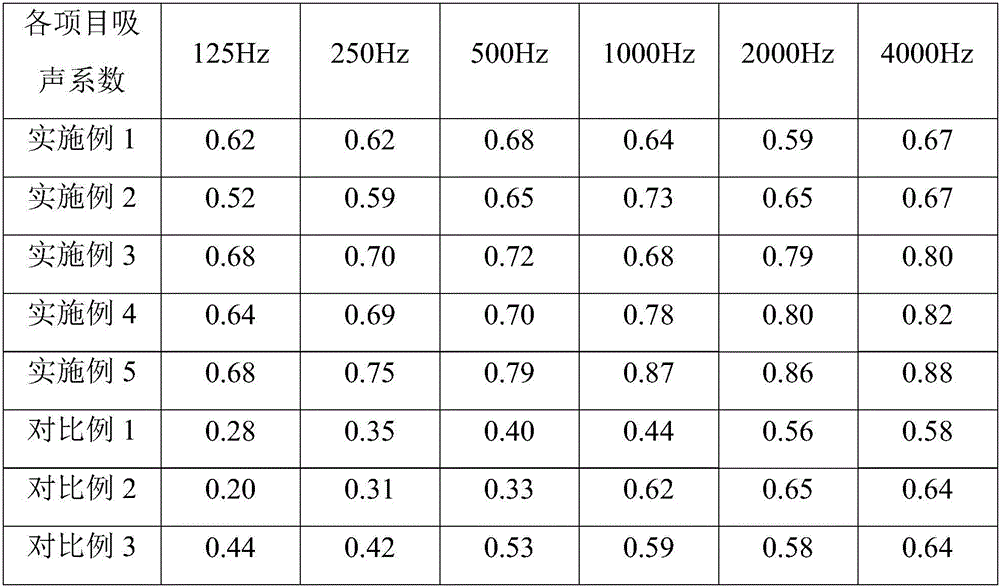

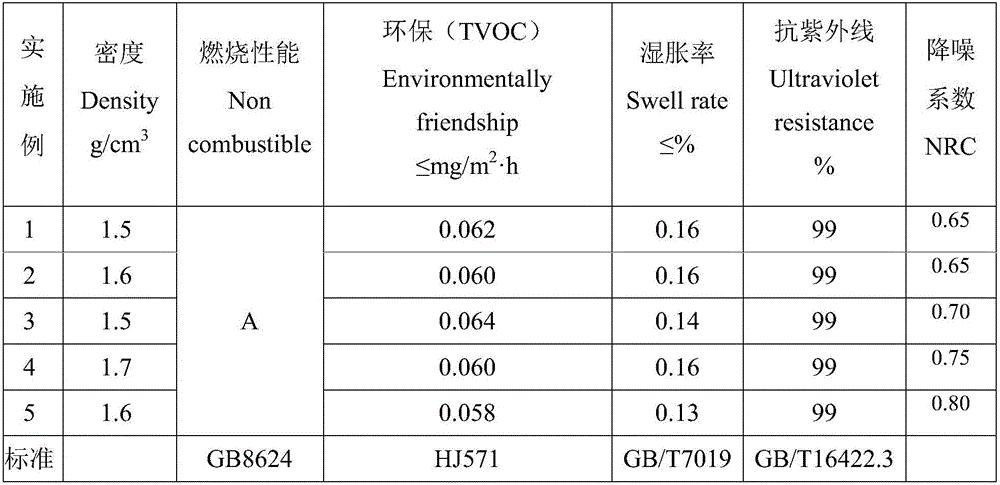

Ultra-fine fly ash light self-insulation wall plate and manufacturing method thereof

InactiveCN107780590ALow refractorinessReduce weightCeramic shaping plantsBuilding componentsAir separationUltra fine

Owner:SHANXI HUATONG LANTIAN ENVIRONMENTAL PROTECTION

Ultrawhite stoneware and production process

Owner:SHENYANG SHUNXIN CERAMIC

Method for concentrating platinum and palladium from platinum-palladium flotation concentrates

InactiveCN108722675AHigh precious metal contentHigh enrichment ratioFlotationMass ratioPt element

Owner:GUANGDONG INST OF RARE METALS

Sewage treatment agent and preparation method thereof

InactiveCN110422916AGood flocculation effectSmall frictional resistanceWater/sewage treatment by magnetic/electric fieldsWater/sewage treatment by flocculation/precipitationSodium BentoniteMicroparticle

Owner:合肥华威药业有限公司

Plastering adhesive cement for external wall surface

Owner:重庆琨森建筑材料有限公司

Acidic lithium slag-Portland cement-silica fume composite cementing material and preparation method thereof

ActiveCN110877970AImprove flexural performanceAccurate control of densityCeramicwareFoaming agentSludge

The invention discloses an acidic lithium slag-Portland cement-silica fume composite cementing material. The composite cementing material comprises Portland cement, acidic lithium slag, silica fume, agraphene material, iron tailings and a light filler. The invention further discloses a preparation method of the composite cementing material. The preparation method comprises the following steps: taking and uniformly mixing fly ash, 15-25 parts by weight of sludge, oyster shell powder, clay, water and fusible foaming particles, granulating the obtained mixture, and firing the granulated mixtureto obtain the light filler; mixing the Portland cement with silica fume, and grinding the obtained mixture to obtain a first ground product; respectively grinding the acidic lithium slag, the graphenematerial and the iron tailings; mixing the first ground product, the acidic lithium slag powder, the graphene powder and the iron tailing powder to obtain a second ground product; and uniformly mixing the second ground product with the light filler to obtain the finished cementing material product. A foaming agent is not used, the density of the material is controlled by utilizing the light filler, and the material density can be accurately controlled, so that the quality of the finished product is improved.

Owner:HUNAN LVSHENG TECH DEV CO LTD

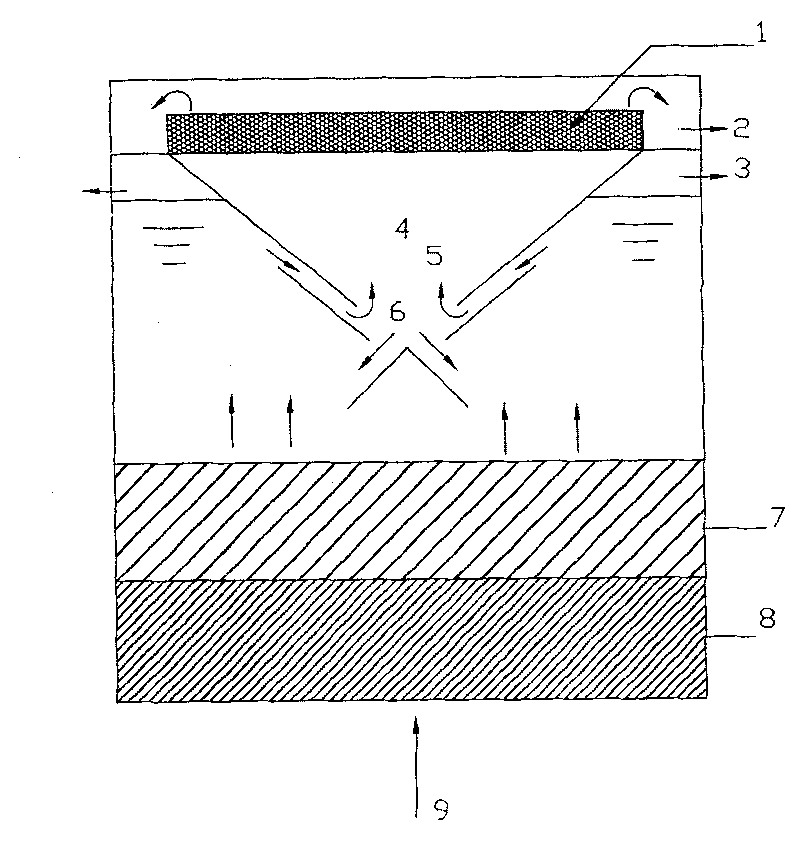

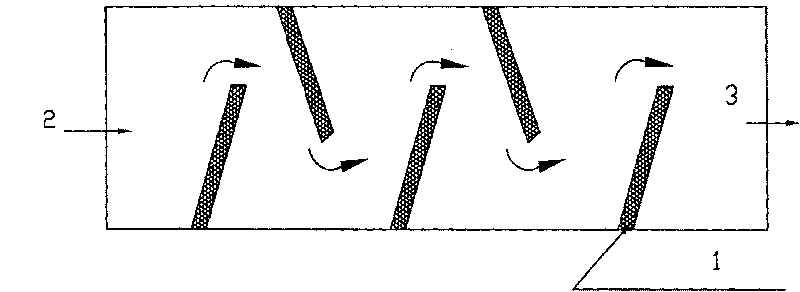

Profile control and plug removal integrated operation system and method for polymer flooding and injection well

PendingCN114810002AAvoid secondary damageIncrease the amount of suction and deblocking working fluidCleaning apparatusFluid removalWater floodingIntegrated operations

The invention discloses a profile control and plug removal integrated operation system and method for a polymer flooding and injection well, and belongs to the technical field of profile control and plug removal of a polymer injection well in the petroleum drilling and production technology. The method comprises the following steps: manufacturing an artificial high-permeability core and a low-permeability core, evacuating saturated water and saturated oil from the high-permeability core and the low-permeability core, connecting the high-permeability core and the low-permeability core in parallel to form a model for simulating intra-layer and inter-layer heterogeneity of an oil reservoir, performing constant-speed water flooding, injecting a polymer solution into the parallel model at a constant speed, and performing subsequent water flooding until the water content is 90%; the calcium chloride, the spacer fluid and the sodium silicate solution are alternately injected into the parallel model for multiple rounds under constant pressure P profile control, and contact and react in the high-permeability layer to finally generate the silicate gel profile control agent; according to constant-pressure P plug removal, plug removal working liquid is injected into the parallel models, and the models are closed for 12-36 h; and injecting water into the parallel model under the constant-pressure P follow-up water drive, and performing follow-up water drive until the water content reaches 90%.

Owner:CNOOC TIANJIN BRANCH

Heat-resisting anti-burning sticking coating and preparation method

InactiveCN102690598AImprove insulation effectLow thermal conductivityCoatingsGas phasePhosphoric acid

The invention relates to a heat-resisting anti-burning sticking coating and a preparation method. The heat-resisting anti-burning sticking coating is prepared by using ethyl silicate, fluosilicic acid, silicone acrylic emulsion, phosphoric acid, potassium titanate whisker, graphite, molybdenum disulfide, cerium fluoride and gas-phase silicon dioxide. The preparation method comprises the following steps of: firstly, taking ethyl silicate and placing into a reaction kettle, stirring, and then slowly adding an aqueous solution of fluosilicic acid, thereby forming an inorganic film forming matter A; uniformly mixing the silicone acrylic emulsion, potassium titanate whisker, graphite, molybdenum disulfide, cerium fluoride and gas-phase silicon dioxide, thereby forming a component B; and adding a defined amount of water for mixing the inorganic film forming matter A, the component B and phosphoric acid, and then stirring uniformly, thereby obtaining the heat-resisting anti-burning sticking coating. A heat-insulating coating provided by the invention has stronger heat-insulating and cold-insulating functions; the highest heat-insulating temperature can reach about 1300 DEG C; the lowest cold-insulating temperature can reach -60 DEG C; the heat-resisting anti-burning sticking coating completely meets the heat-insulating demands of various heating equipment and various low-temperature facilities; and the properties in other aspects are excellent.

Owner:TIANCHANG YINHU PAINT

Composite immobilized enzyme material for repairing polluted water source and its preparing process

InactiveCN1986789BReduce resistanceThe geometric specific surface area is largeOn/in inorganic carrierBiological water/sewage treatmentWater sourceSewage

Owner:江苏晨翔环境科技股份有限公司

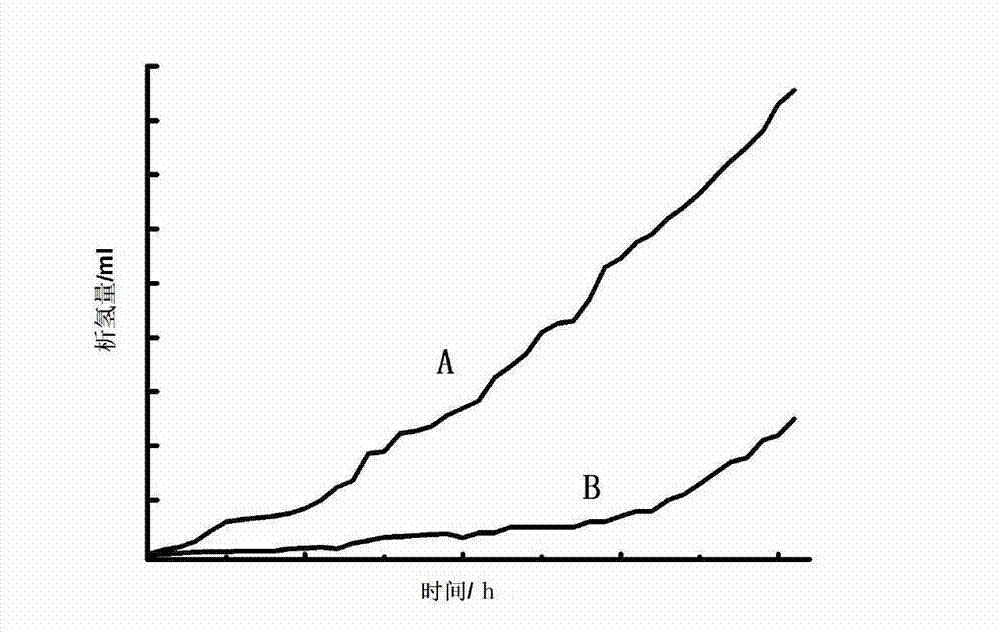

UO2-containing beryllium silicate glass, and radioactive waste liquid treatment method

ActiveCN103613274ARegular Performance GuaranteedImprove stabilityRadioactive decontaminationRare-earth elementExtremely good

Owner:LIYANG TECH DEV CENT

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap