Method for preparing three-dimensional porous bioactive glass

A bioactive glass, three-dimensional porous technology, applied in tissue regeneration, medical science, prosthesis, etc., to achieve excellent adsorption performance and improve the effect of sustained release of drugs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

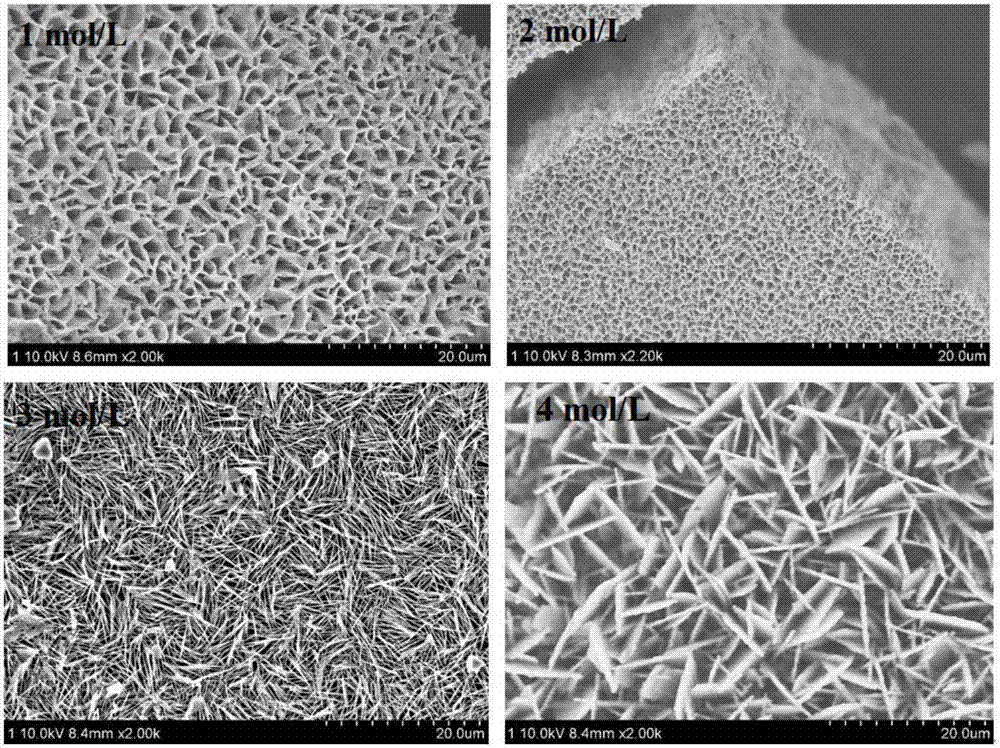

[0023] figure 1 Shown are the morphology changes of porous silicate nanosheets at different NaOH concentrations. When the NaOH concentration is 1mol / L, a uniform and ordered array of silicate nanosheets is formed on the conductive surface of the glass. The size of the silicate nanosheets is about 500nm, and the adjacent nanosheets are closely adjacent to each other, forming a channel with a size of about 400 nm, and the large-area nanosheets are closely arranged to form a porous silicate nanosheet array. When the NaOH concentration is 2mol / L, a uniform and orderly array of silicate nanosheets is still formed on the glass. At this time, the size of the silicate nanosheets is reduced to about 200nm, and the adjacent silicate nanosheets They are closely connected with each other to form pores with a size of about 100nm, and the large-area nanosheets are closely arranged to form a porous silicate nanosheet array; with the increasing concentration of NaOH, the size of the silicate

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap