Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

115 results about "Graphite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Graphite (/ˈɡræfaɪt/), archaically referred to as plumbago, is a crystalline form of the element carbon with its atoms arranged in a hexagonal structure. It occurs naturally in this form and is the most stable form of carbon under standard conditions. Under high pressures and temperatures it converts to diamond. Graphite is used in pencils and lubricants. It is a good conductor of heat and electricity. Its high conductivity makes it useful in electronic products such as electrodes, batteries, and solar panels.

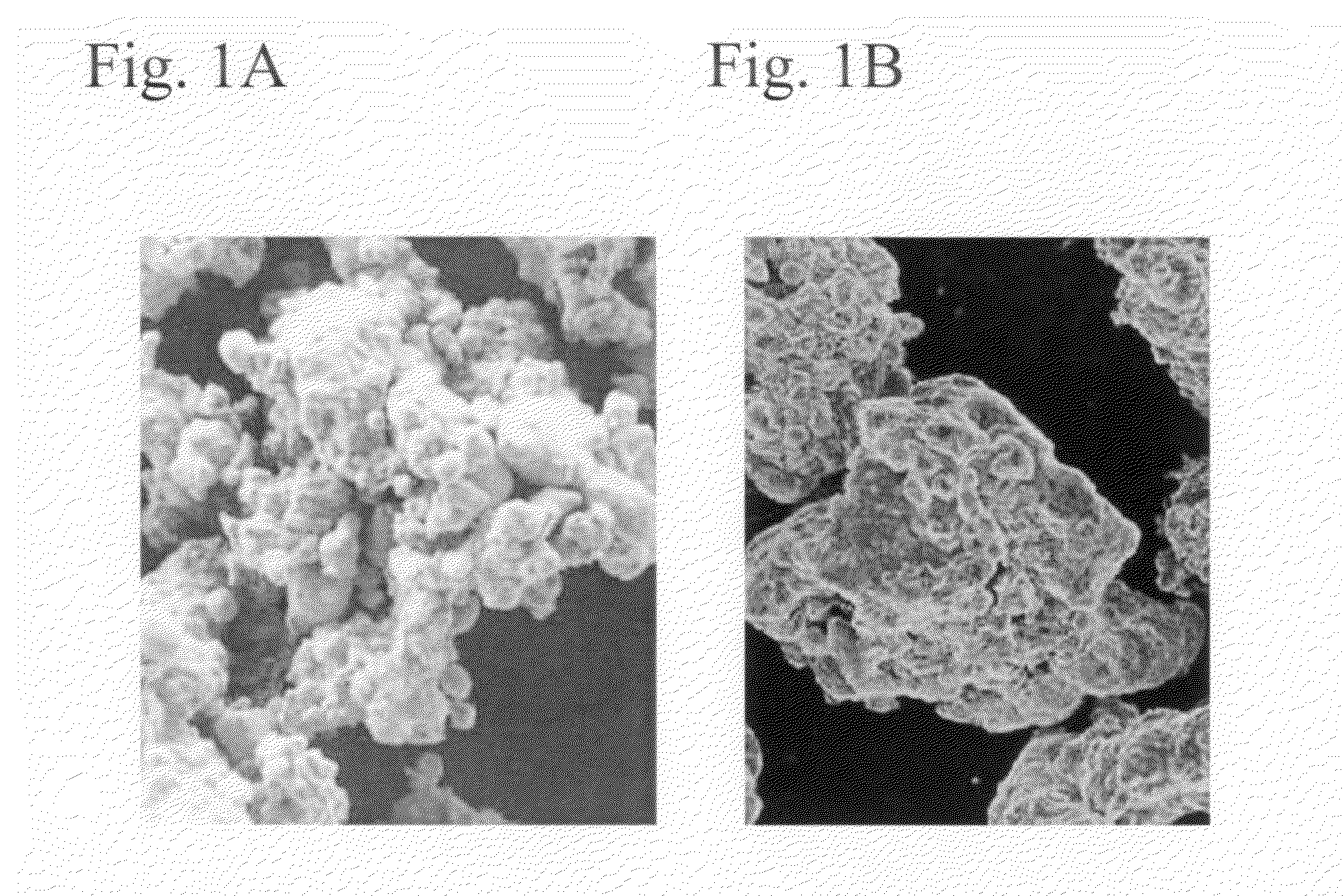

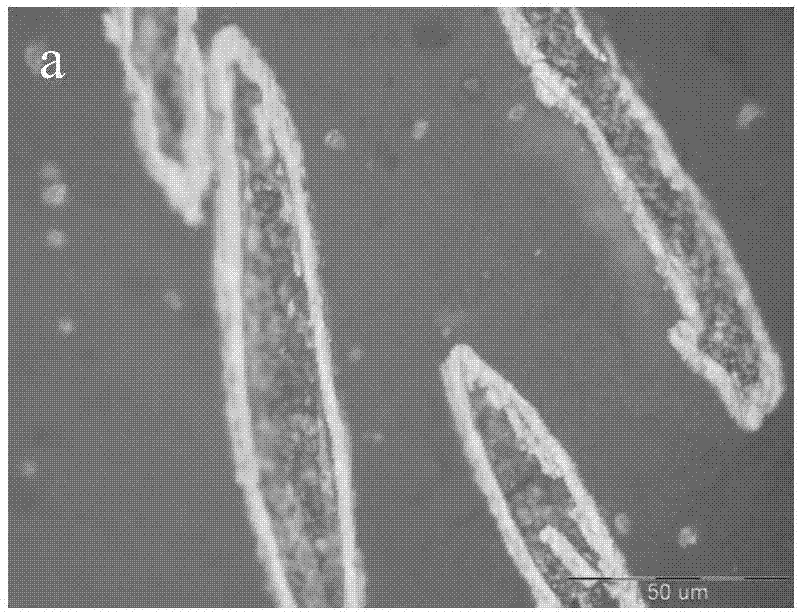

Carbon nanofibers and procedure for obtaining said nanofibers

ActiveUS20090035569A1Quality improvementGuaranteed specific surface areaMaterial nanotechnologyCarbon compoundsFiberChemical composition

The object of the present invention is carbon nanofibers mainly characterized by their high specific volume of mesopores, their high gas adsorption capacity and presenting a graphitic hollow structure. A second object of this invention is a procedure for obtaining such carbon nanofibers, which makes use of a metallic nickel catalyst and specific process furnace parameters that combined with the chemical composition of the furnace atmosphere and the fluidodynamic conditions of the gas stream inside the furnace, result in a faster growth of the carbon nanofibers and also in a higher quality of the carbon nanofibers obtained.

Owner:GRP ANTOLIN ING SA

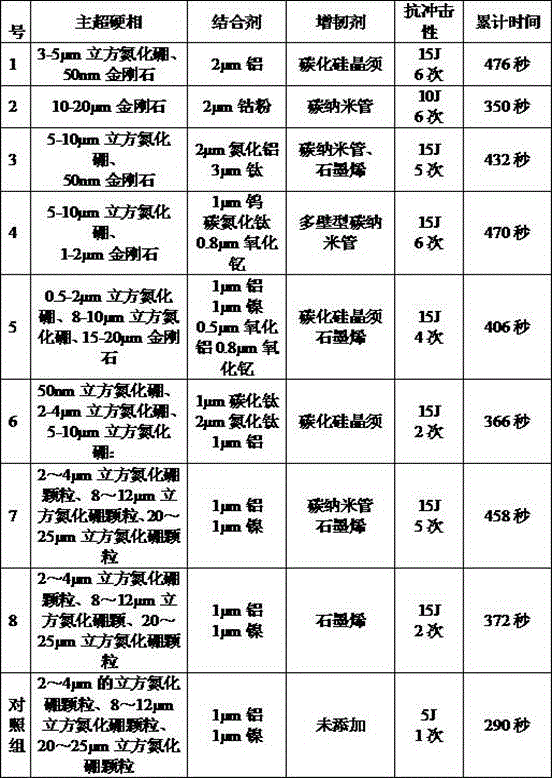

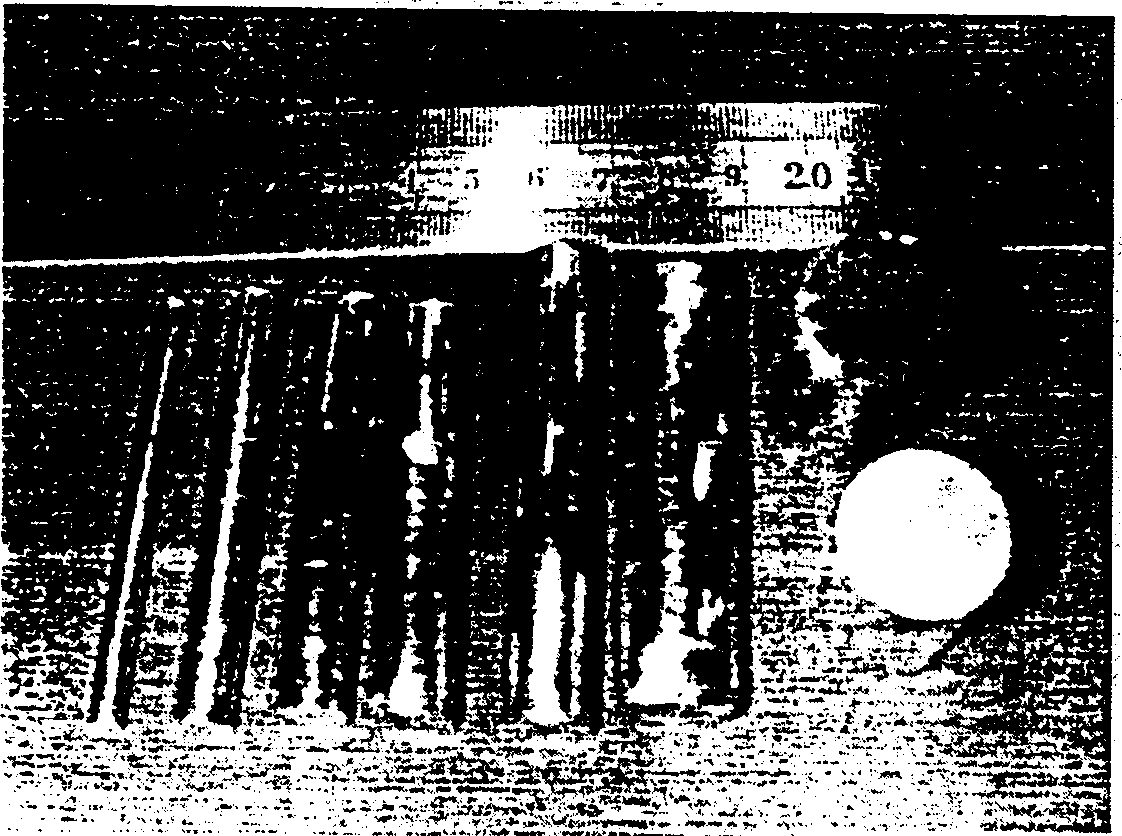

High-tenacity polycrystalline composite material, high-tenacity polycrystalline blade and preparation method of high-tenacity polycrystalline blade

InactiveCN105908041AImprove fracture toughnessImprove impact resistanceTurbinesOther manufacturing equipments/toolsCarbide siliconCarbon nanotube

Owner:FUNIK ULTRAHARD MATERIAL

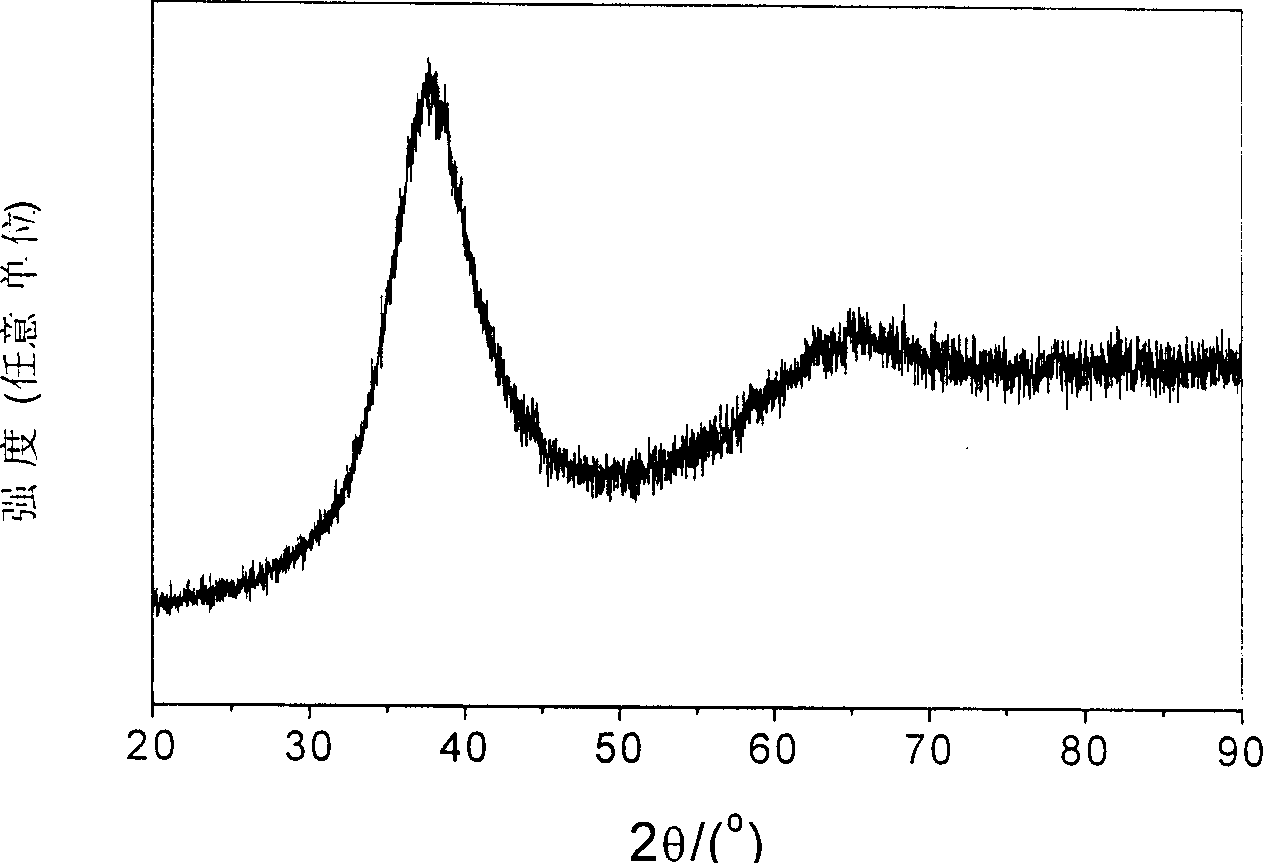

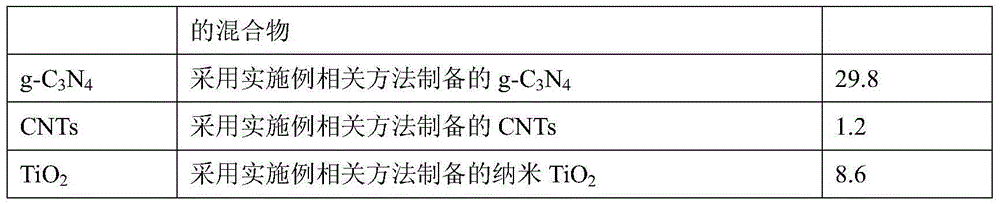

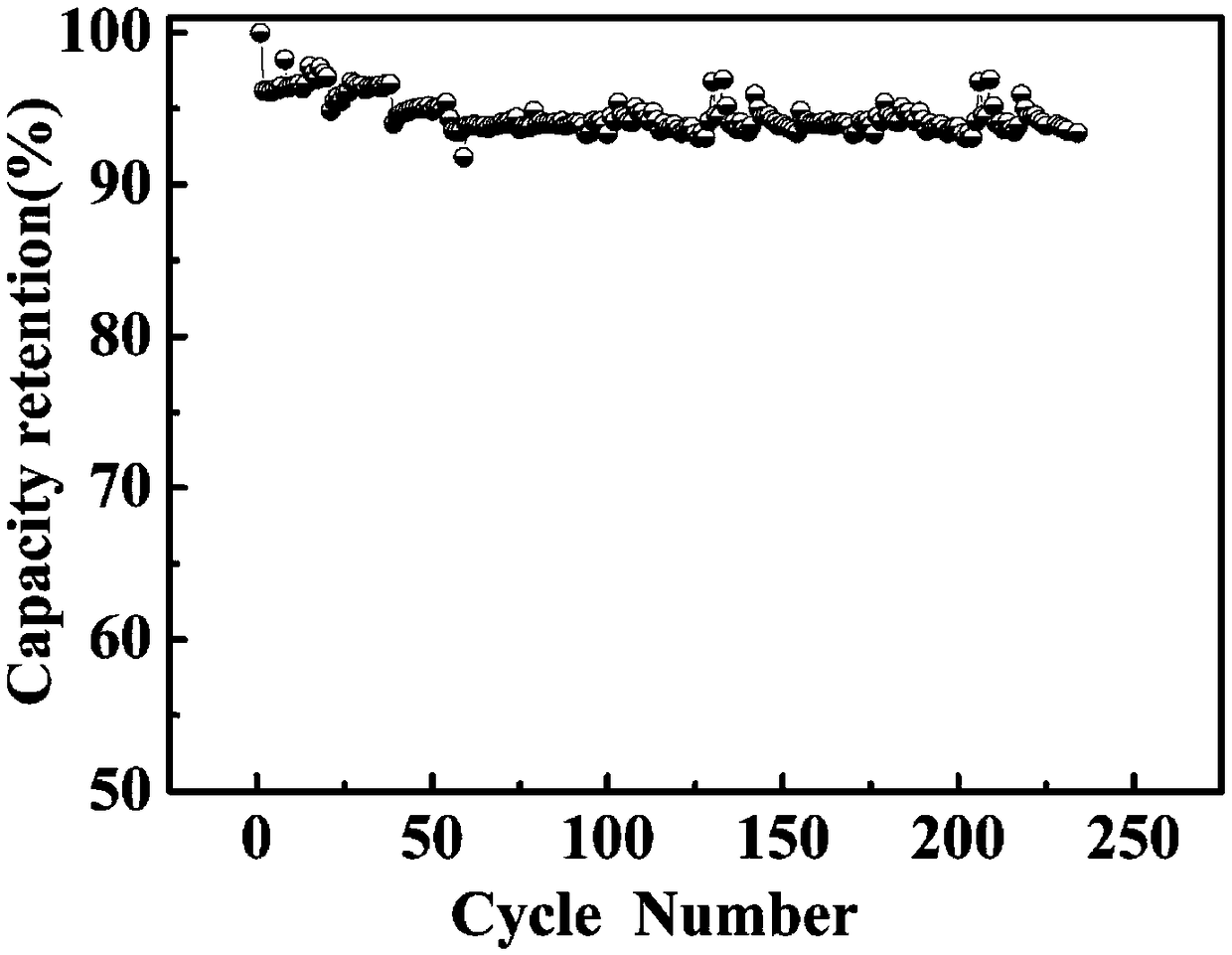

Non-aqueous solution aluminum ion secondary battery and preparation method thereof

InactiveCN104993130AGood chemical stabilityImprove thermal stabilityCell electrodesFinal product manufactureAluminum IonElectrical battery

Belonging to the technical field of batteries, the invention relates to a non-aqueous solution aluminum ion secondary battery and a preparation method thereof. The secondary battery can be widely applied in electronics, communication, electric vehicle and other fields. The aluminum ion battery provided by the invention contains a battery anode, a battery cathode, a diaphragm and an aluminum-containing non-aqueous solution electrolyte. Specifically, the cathode active material can be carbon, graphite, carbon nanotube, graphene, super carbon, WS2 and MoS2, V2O5, TiO2 and other materials having nano-layered, tubular, linear and other structures, and the anode is aluminum-containing metal or alloy. The non-aqueous solution aluminum ion secondary battery provided by the invention has the characteristics of high specific capacity, high coulomb efficiency, long service life and environmental protection, safety and reliability, stable cycle performance, and quick charging, etc.

Owner:BEIJING ALUMINUM ENERGY S&T

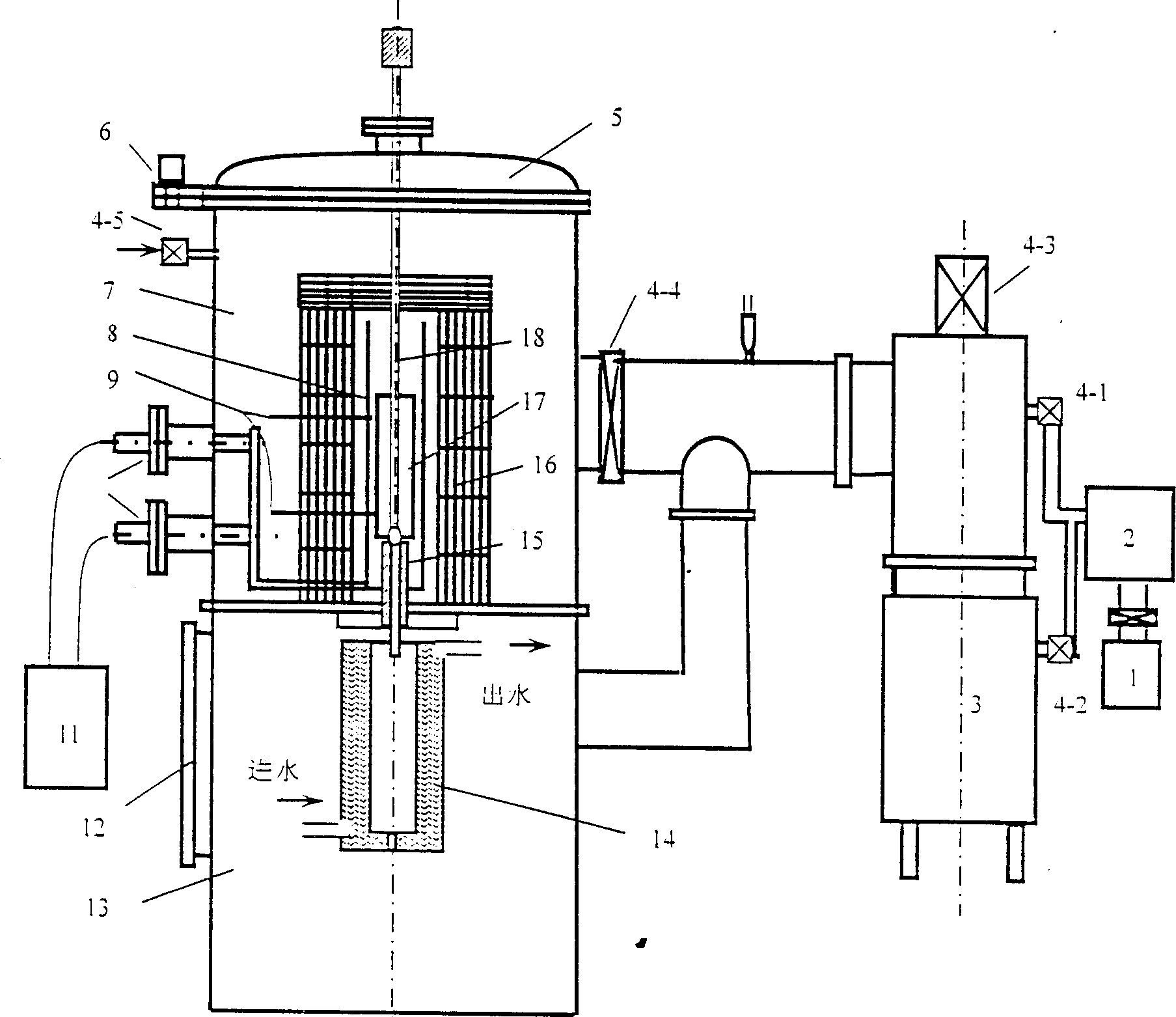

Spray casting-suction casting method and equipment for preparing large non crystal alloy

Owner:UNIV OF SCI & TECH BEIJING

Three-dimensionalgraphene composite aerogel and preparation method thereof

ActiveCN106890605ASimple methodGood lookingOther chemical processesWater contaminantsFiberChemical reaction

The invention discloses three-dimensionalgraphene composite aerogel. High-molecular material nano fiber with a biomass polysaccharide structure is compounded with oxidized graphene through a surface electrostatic-force effect, and then the composite aerogelis prepared by utilizing hydrazine hydrate reduction and a method for high-temperature pyrolysis in an inert atmosphere. The invention further discloses a preparation method of the three-dimensionalgraphene composite aerogel. The method for preparing the three-dimensionalgraphene composite aerogel is simple, easy to operate, large in specific surface area, uniform in pore size distribution and good in electrical conductivity, and the chemical reactivity is improved.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Stainless steel plate 8K mirror surface processing method

ActiveCN102962731AImprove the finishImprove anti-corrosion performancePolishing machinesFlexible-parts wheelsRough surfacePolishing

Owner:SHENYANG YUANDA ALUMINUM IND GROUP

Antistatic teflon film and preparation thereof

InactiveCN101481483ADoes not affect electrical insulationImprove mechanical propertiesOther chemical processesTetrafluoroethyleneAntistatic agent

Owner:广州市东泓氟塑料股份有限公司

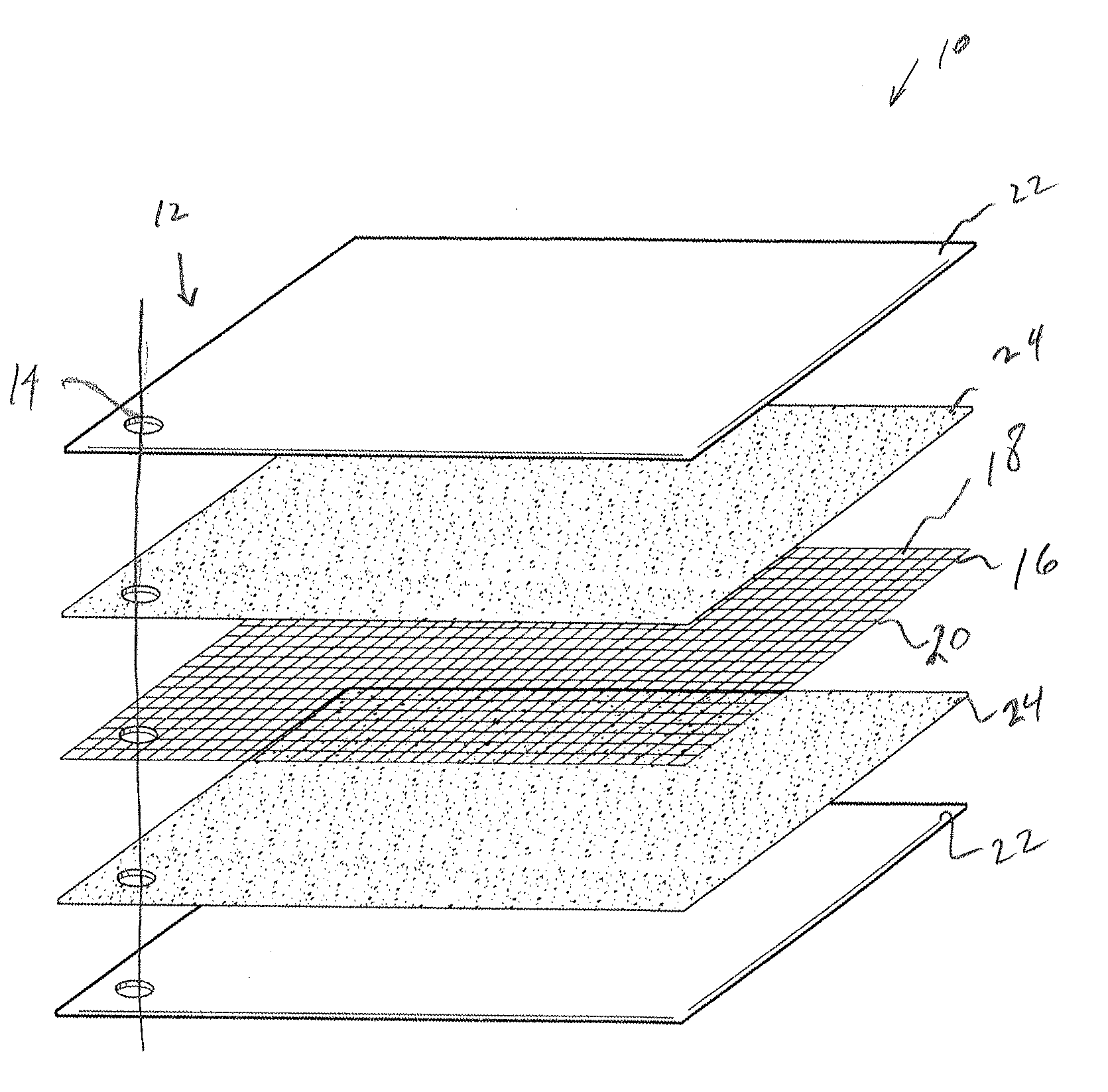

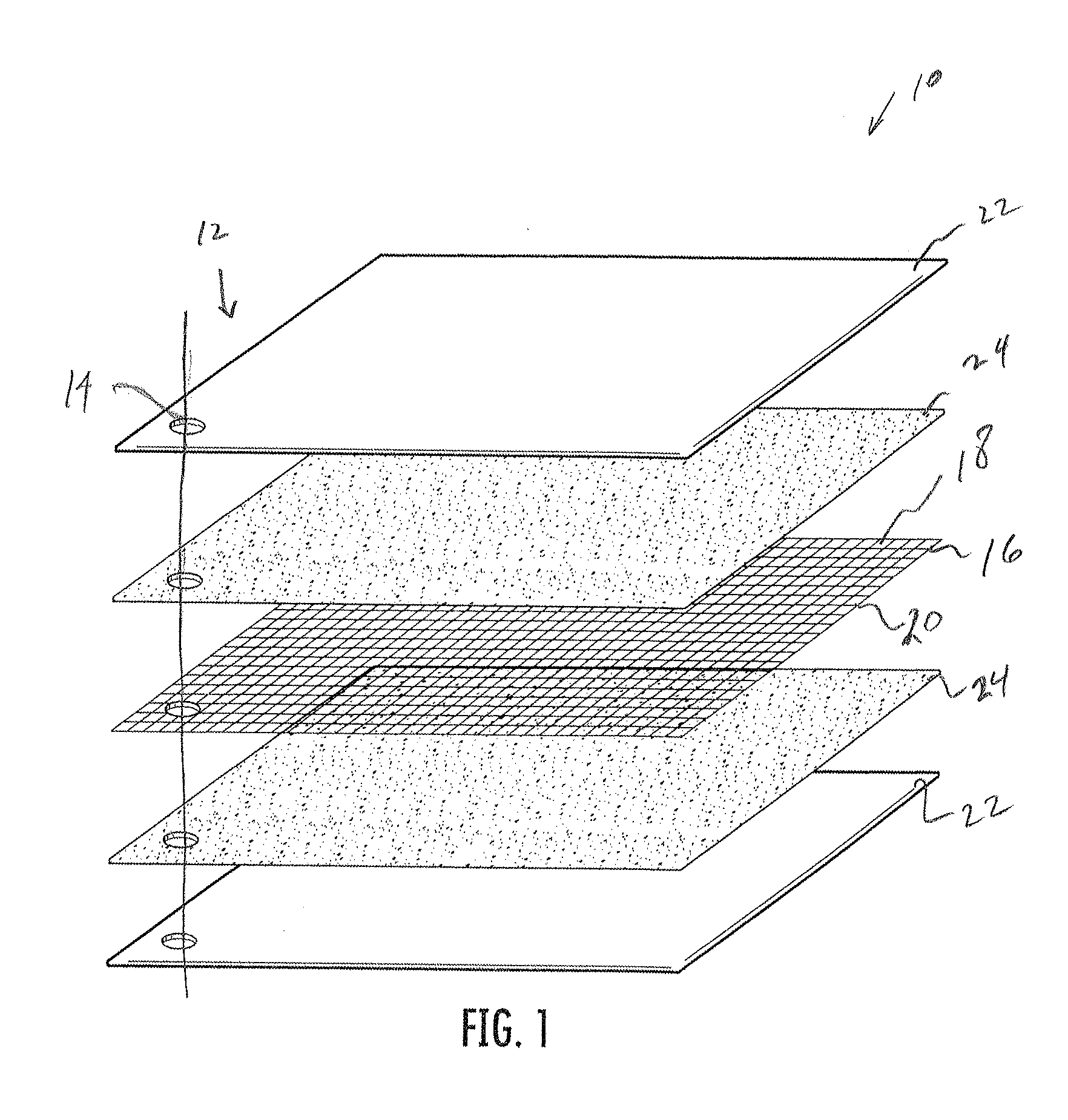

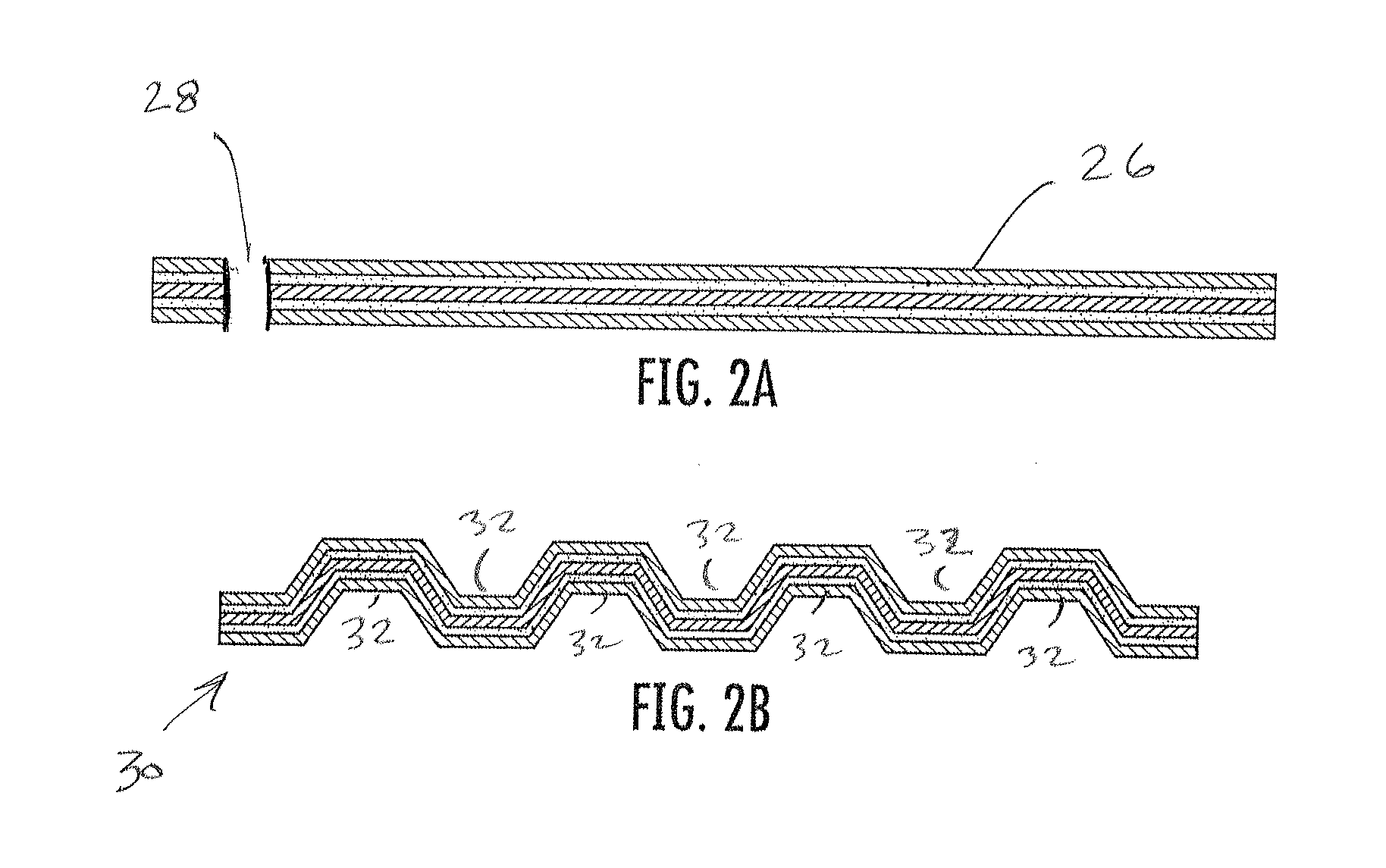

Fuel cell composite flow field element and method of forming the same

InactiveUS20110053052A1High thermalImprove conductivityElectrode manufacturing processesElectrode carriers/collectorsFuel cellsGraphite

Owner:VPJP

Anti-blockage mine ventilator

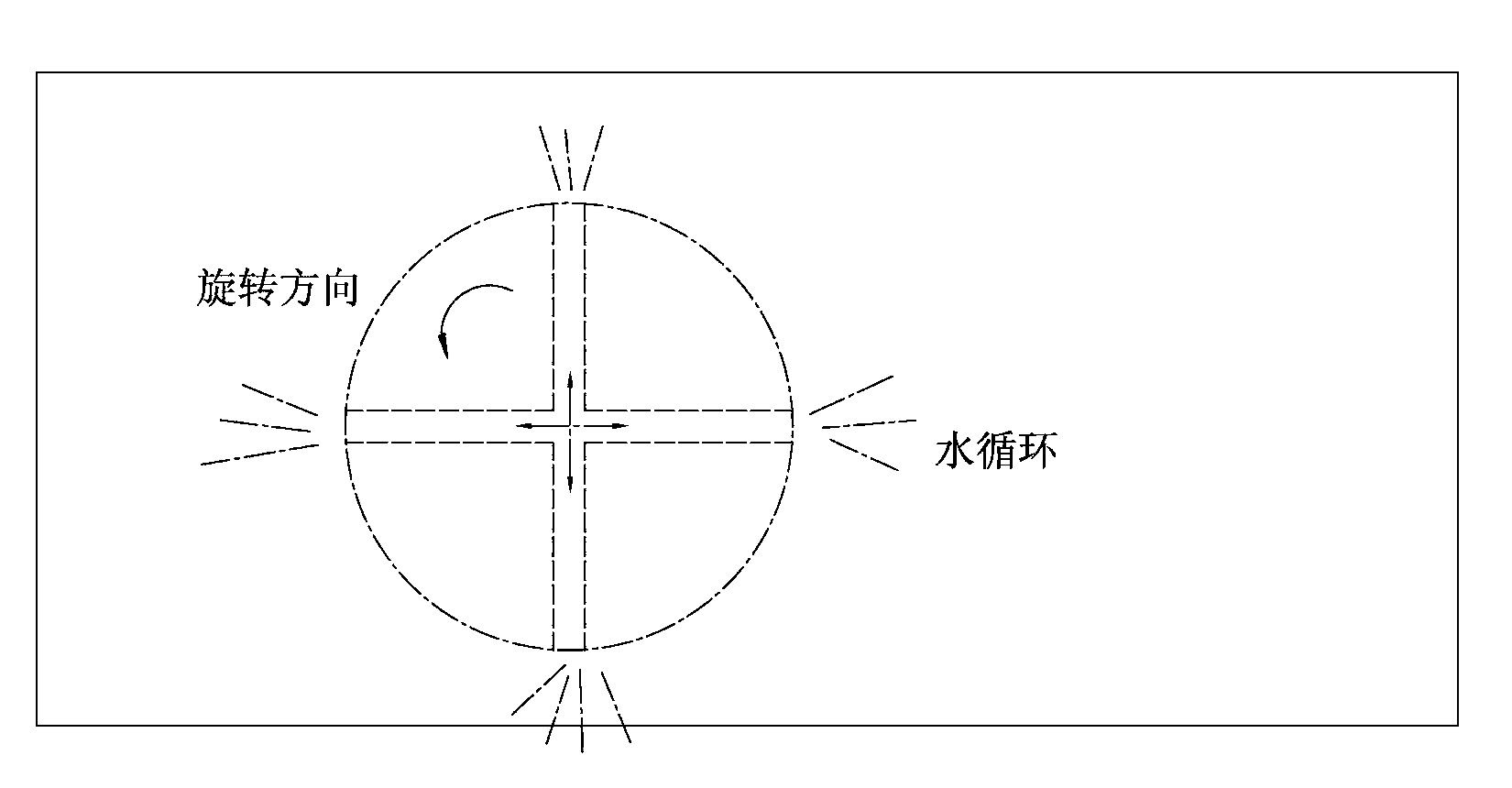

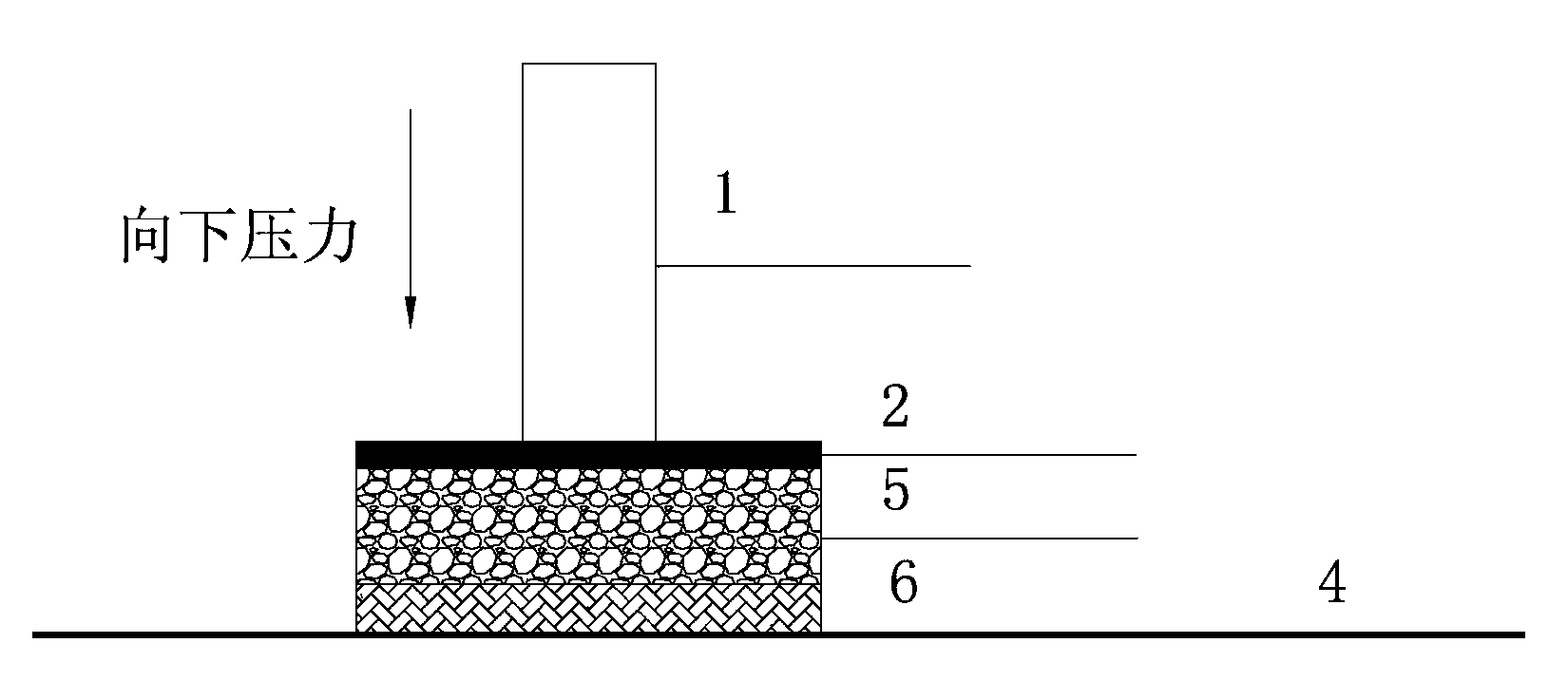

InactiveCN106122054AEasy to cleanAvoid cloggingPump componentsTunnel/mines ventillationFixed frameGraphite

The invention discloses an anti-blockage mine ventilator. The anti-blockage mine ventilator comprises a machine sleeve; a fixed frame is arranged at one end in the machine sleeve; a motor is arranged in the fixed frame; the surface of a rotating shaft of the motor is sleeved with a bearing sleeve; a blade is arranged at one end of the bearing sleeve; a connecting rod is arranged at one end of the blade; the surface of one end of the connecting rod is sleeved with a separation net; the separation net is sleeved into a fixed sleeve; and the outer side of the fixed sleeve is connected with the machine sleeve. Through mutual matched use of the connecting rod, a connecting ring, a fixed rod, a fixed plate and a cleaning brush, the anti-blockage mine ventilator achieves the advantages of conveniently cleaning the separation net, preventing blockage of the separation net, guaranteeing the ventilation efficiency and the circulation of air in mine ways and prolonging the service life of the ventilator; and the anti-blockage mine ventilator is provided with a collecting box, and a collecting cavity, a filter plate and a graphite plate are arranged in the collecting box for mutual matched use, so that the advantages of preventing flowing out of dust through wind currents and protecting the environment and the health of external workers are achieved.

Owner:WUXI HENGDA MINE MACHINERY

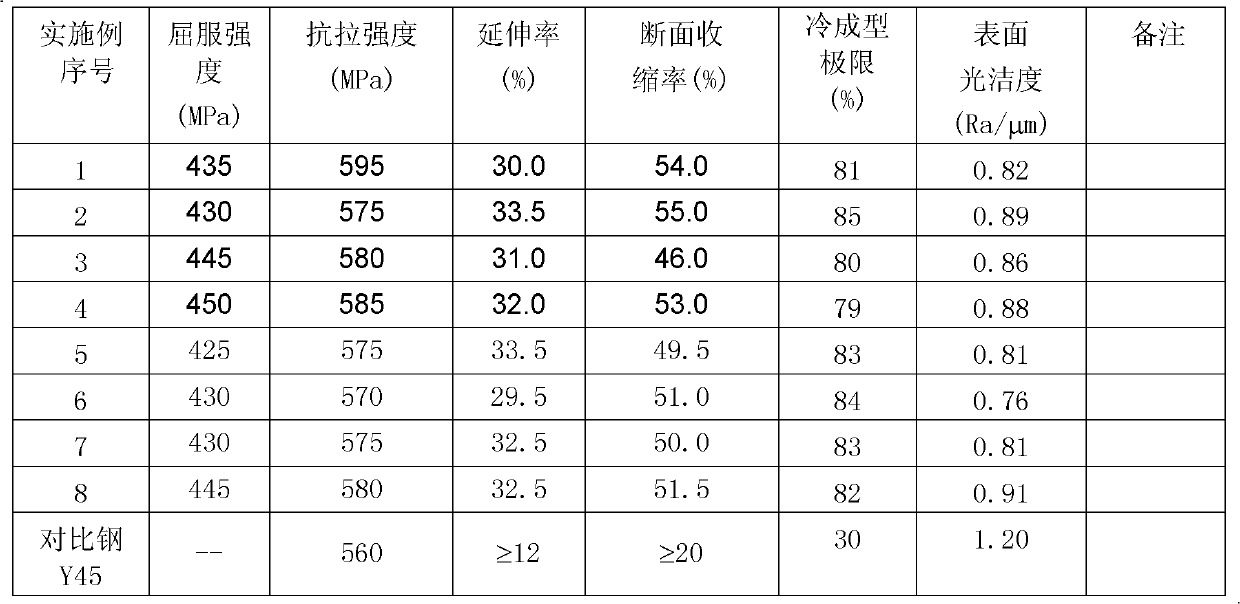

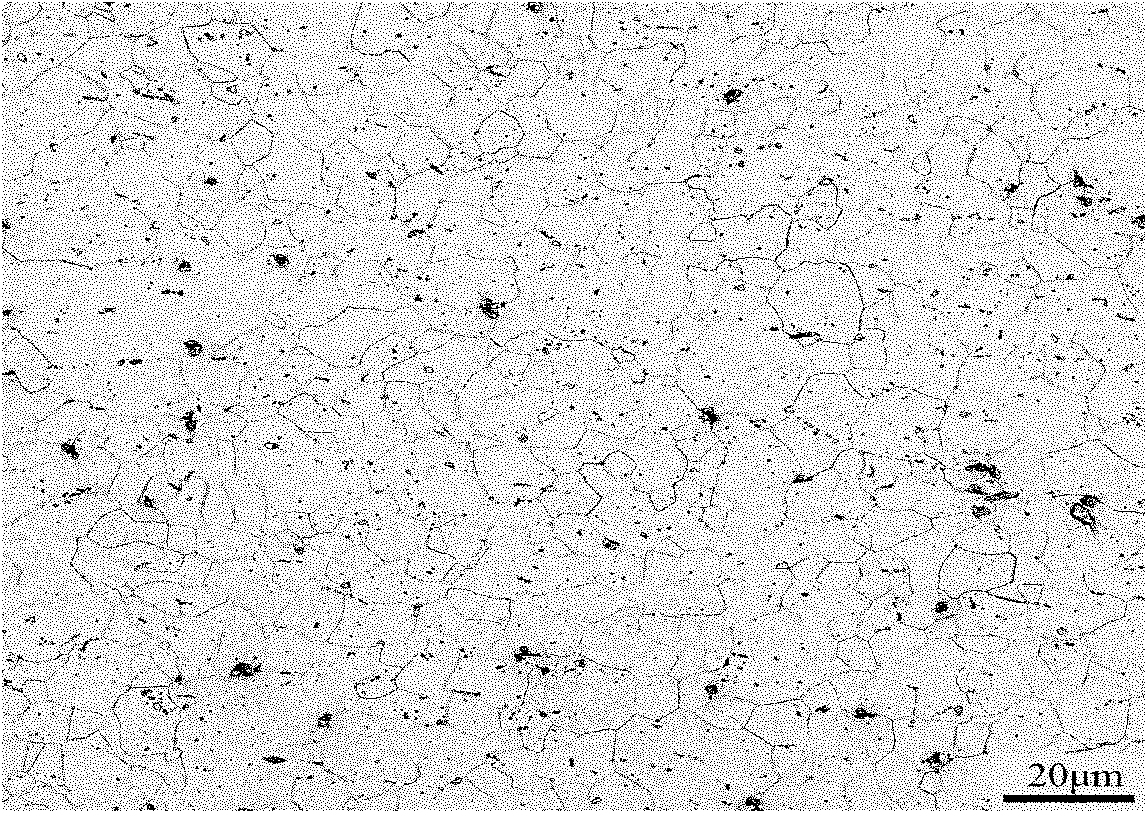

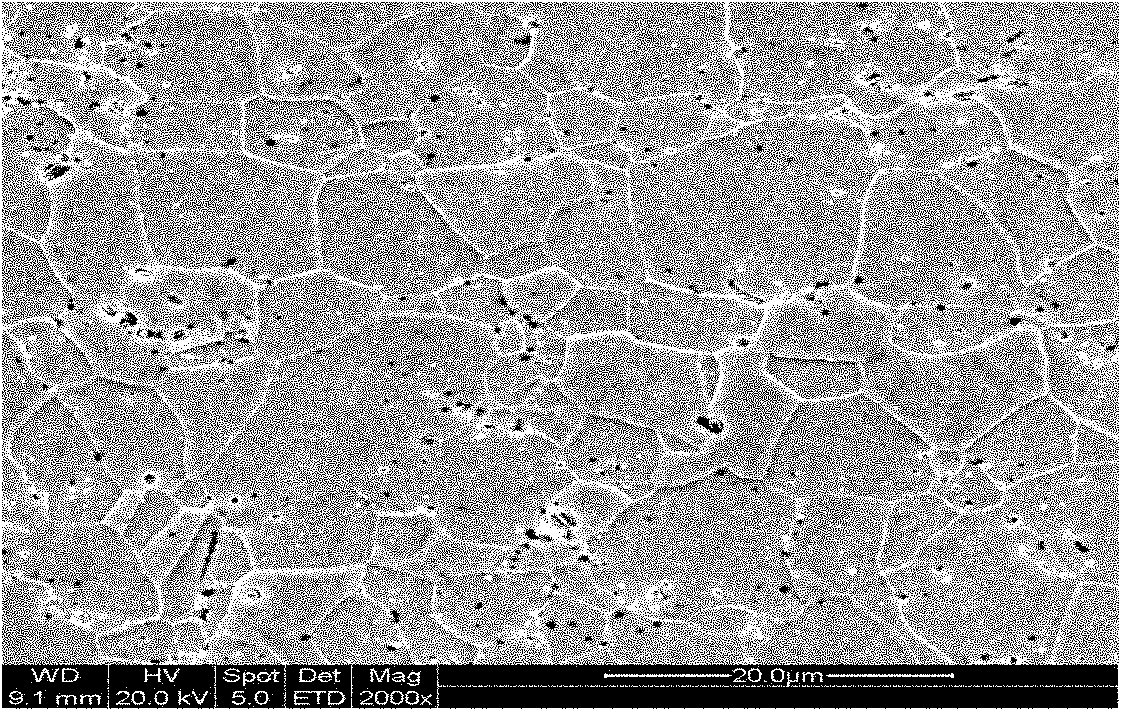

Environment-friendly high-performance graphitized free cutting steel

Owner:WUHAN IRON & STEEL (GROUP) CORP

Photocatalyst composite structure and preparation method thereof

InactiveCN104801325AImprove adsorption capacityLarge specific surface areaPhysical/chemical process catalystsHydrogen productionDecompositionCarbon nanotube

Owner:EAST CHINA UNIV OF SCI & TECH +1

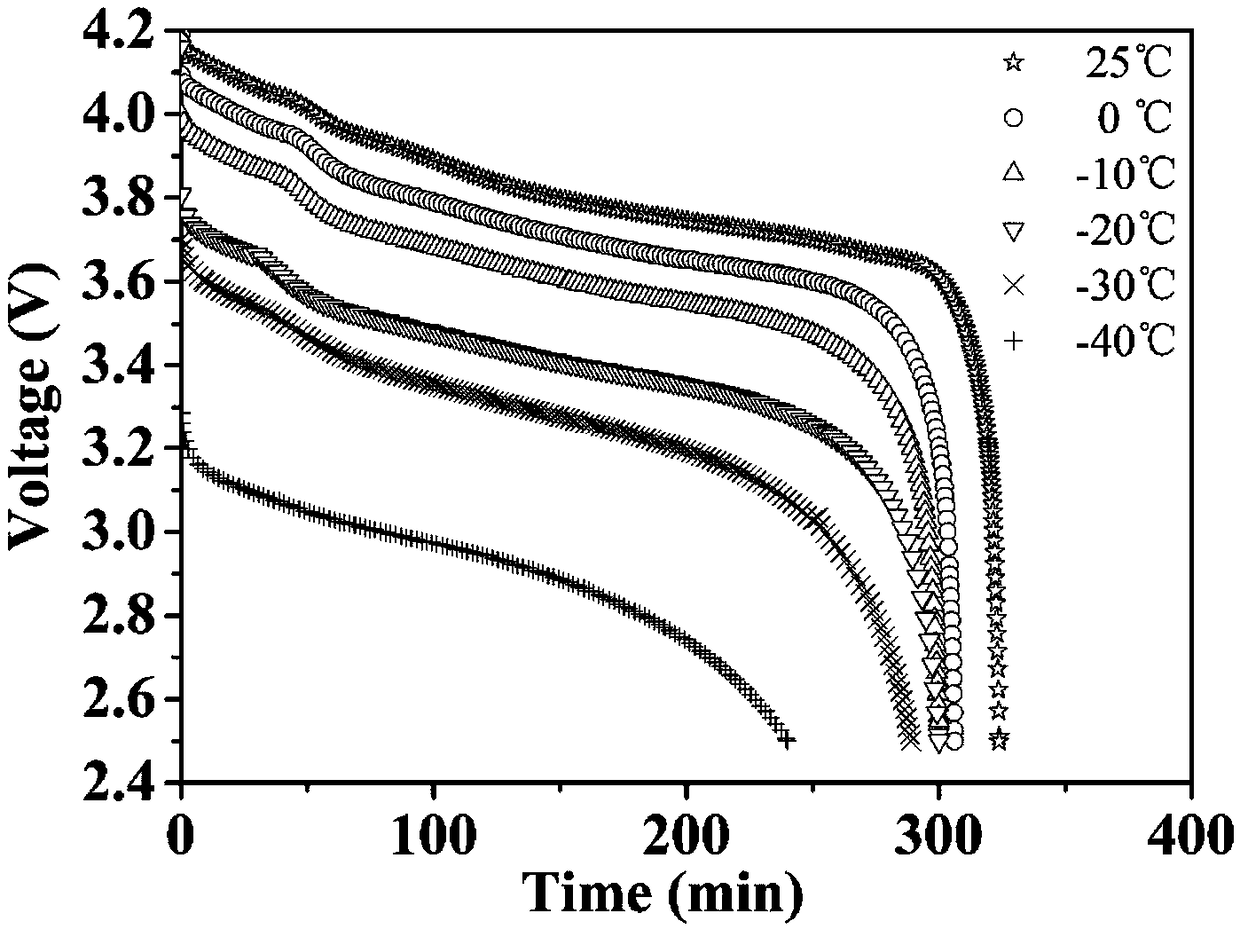

Graphite negative electrode material of low-temperature lithium ion battery and preparation method thereof

Owner:CENT SOUTH UNIV

Aqueous graphene-based electric-conducting ink and preparation method thereof

The invention relates to aqueous graphene-based electric-conducting ink, which comprises: 1-15% of an aqueous resin, 30-90% of a graphene-based composite slurry, 0.5-3% of a first auxiliary agent and5-10% of a solvent, wherein the graphene-based composite slurry comprises graphene micro-sheets, carbon nano-tubes, nano-scale superconducting carbon black, a diluent and a second auxiliary agent, anda mass ratio of the graphene to the carbon nano-tubes to the nano-scale superconducting carbon black is (3-10):(0.5-5):(0.1-4). The aqueous graphene-based electric-conducting ink of the invention isstable in performance, environmentally friendly, efficient and extremely low in resistance value, and can replace the existing solvent-based ink products on the market. The invention also relates to apreparation method of the aqueous graphene-based electric-conducting ink.

Owner:NINGBO MORSH TECH

Processing method of seed crystal with big drift angle

Owner:新乡市神舟晶体科技发展有限公司

Aluminum plastic plate flame-retardant core layer and aluminum-plastic plate

ActiveCN109111617AReduce corrosionExtended service lifeSynthetic resin layered productsMetal layered productsLow-density polyethyleneAntioxidant

Owner:台州市佳信新材料科技有限公司

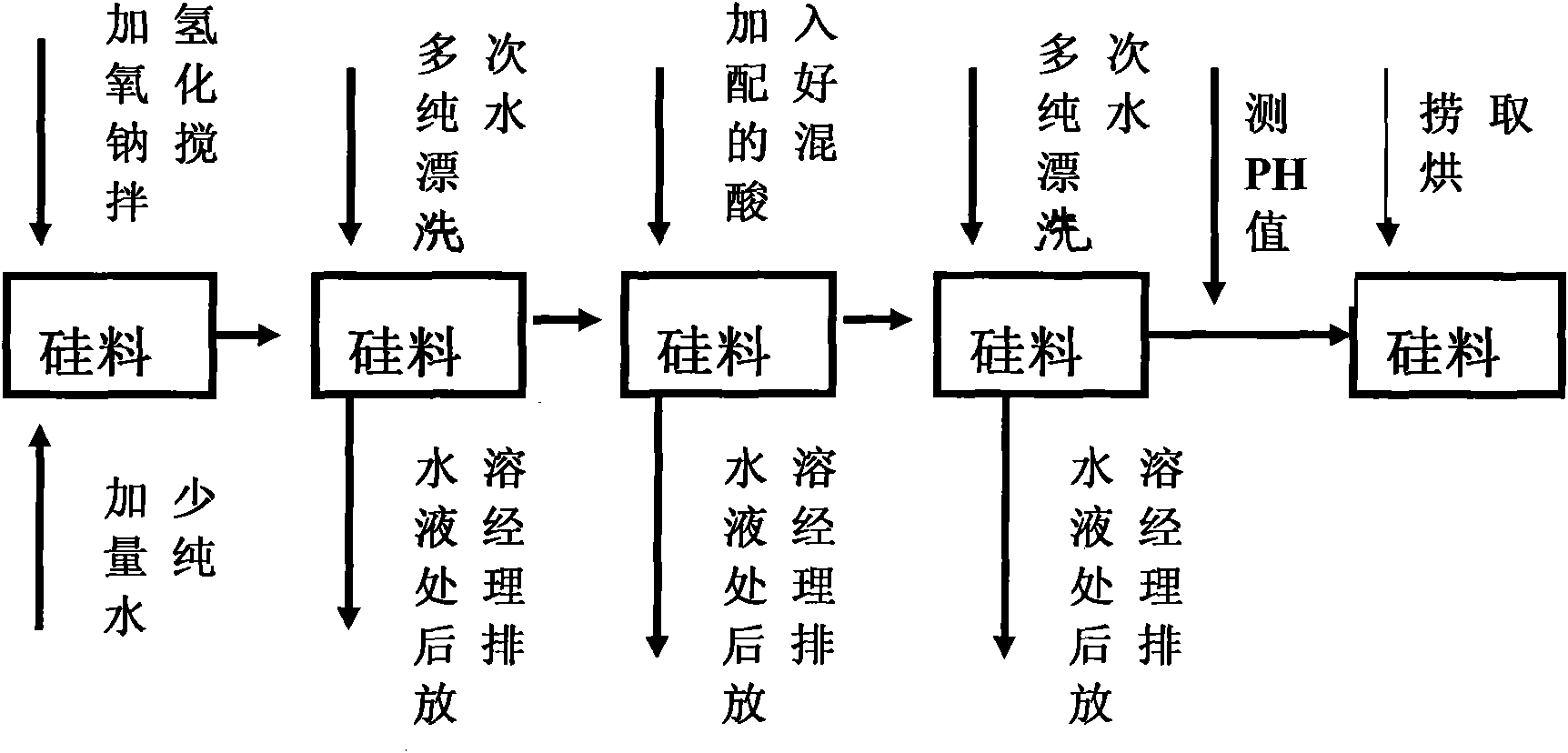

Method for cleaning graphitic silicon materials

Owner:HEFEI JINGKUN NEW ENERGY

Preparation method of paper-graphite-CoPd thin film electrode

InactiveCN103904337AImprove electroreduction performanceSolve the problem of poor cathode activityCell electrodesElectricityThin film electrode

Owner:HARBIN ENG UNIV

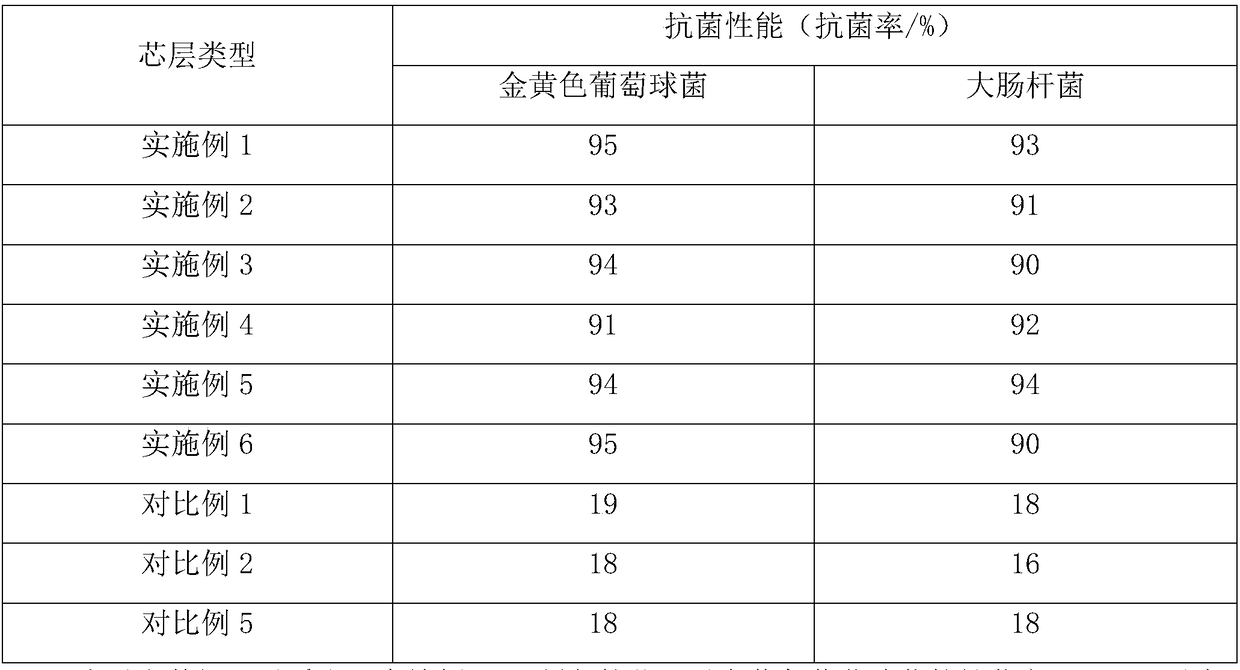

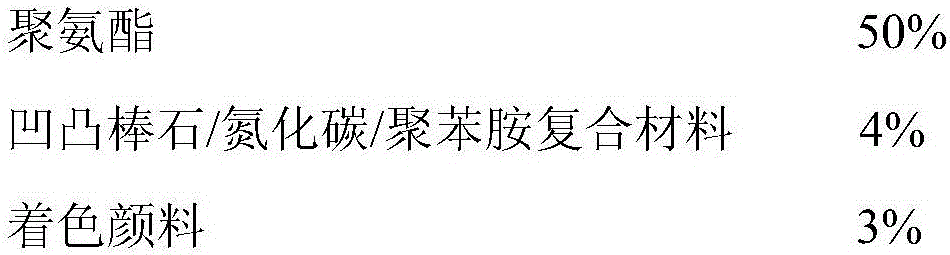

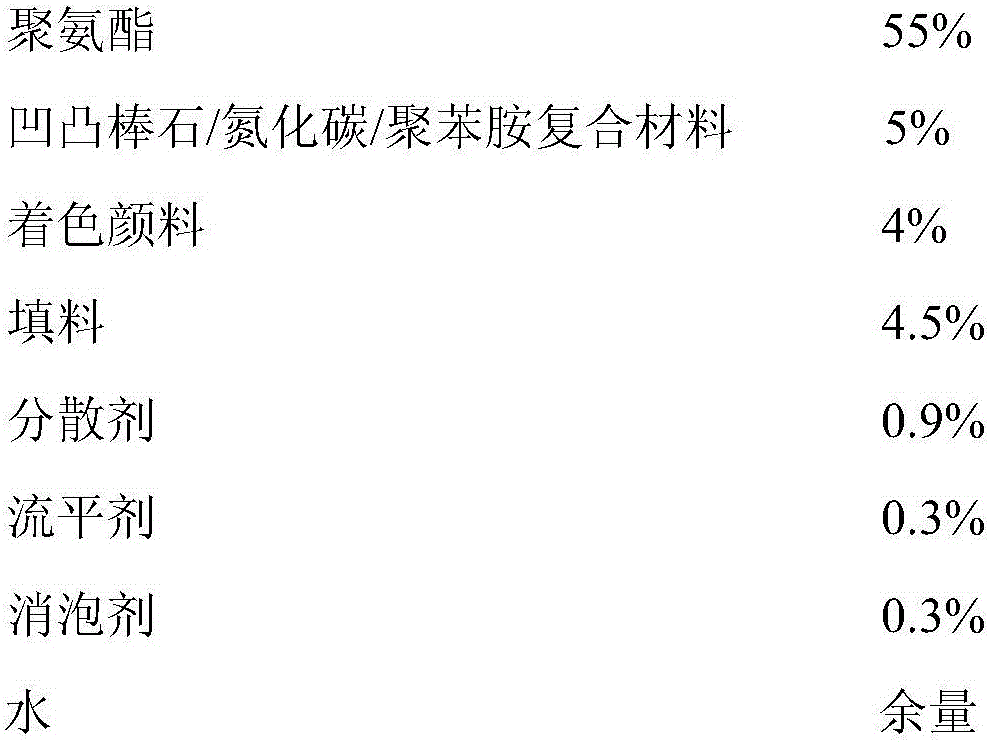

Preparation method of attapulgite-carbon nitride-polyaniline composite material and application thereof in anticorrosive paint

InactiveCN105754092AAvoid reunionReduce manufacturing costAnti-corrosive paintsPolyurea/polyurethane coatingsCarbon nitrideGraphite

Owner:CHANGZHOU UNIV

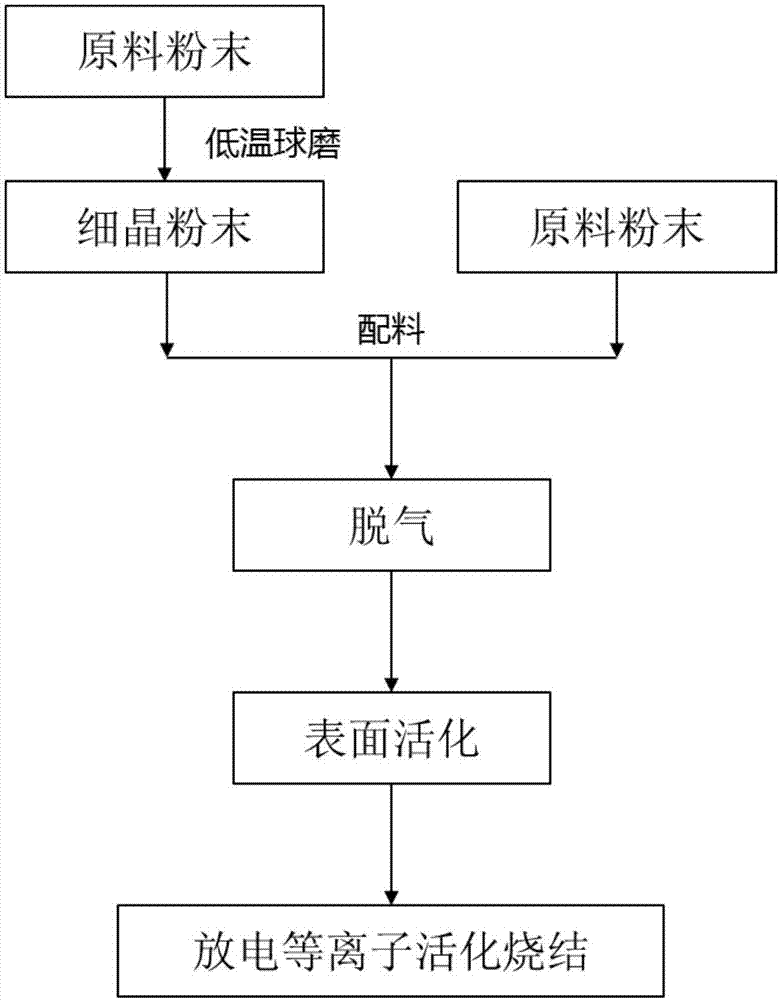

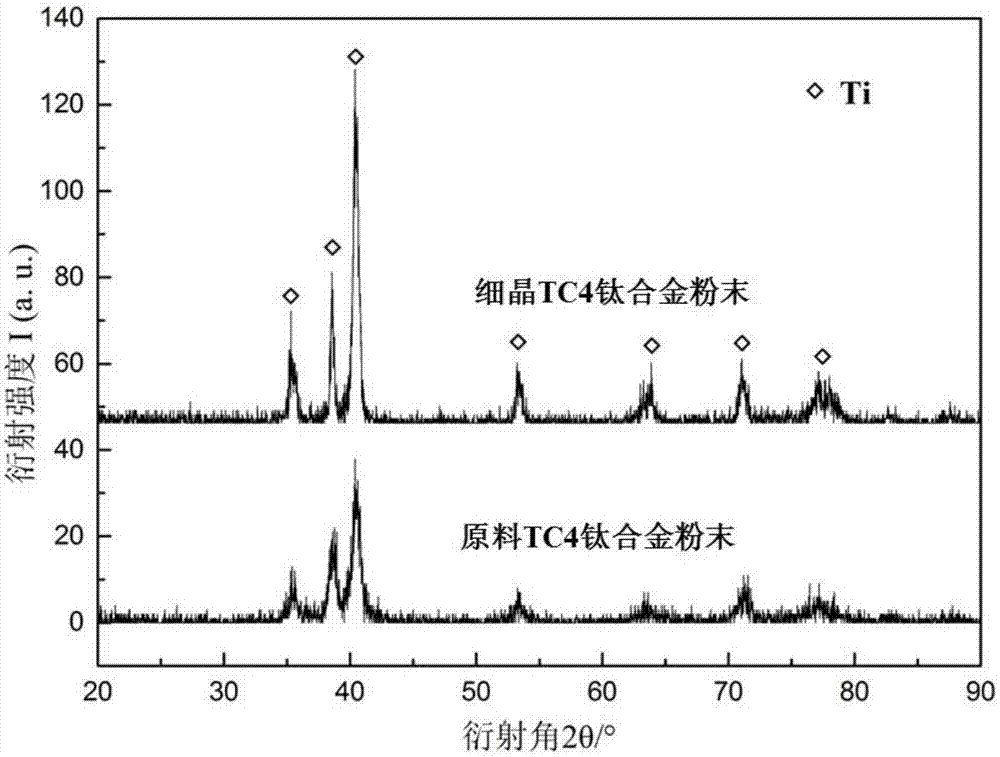

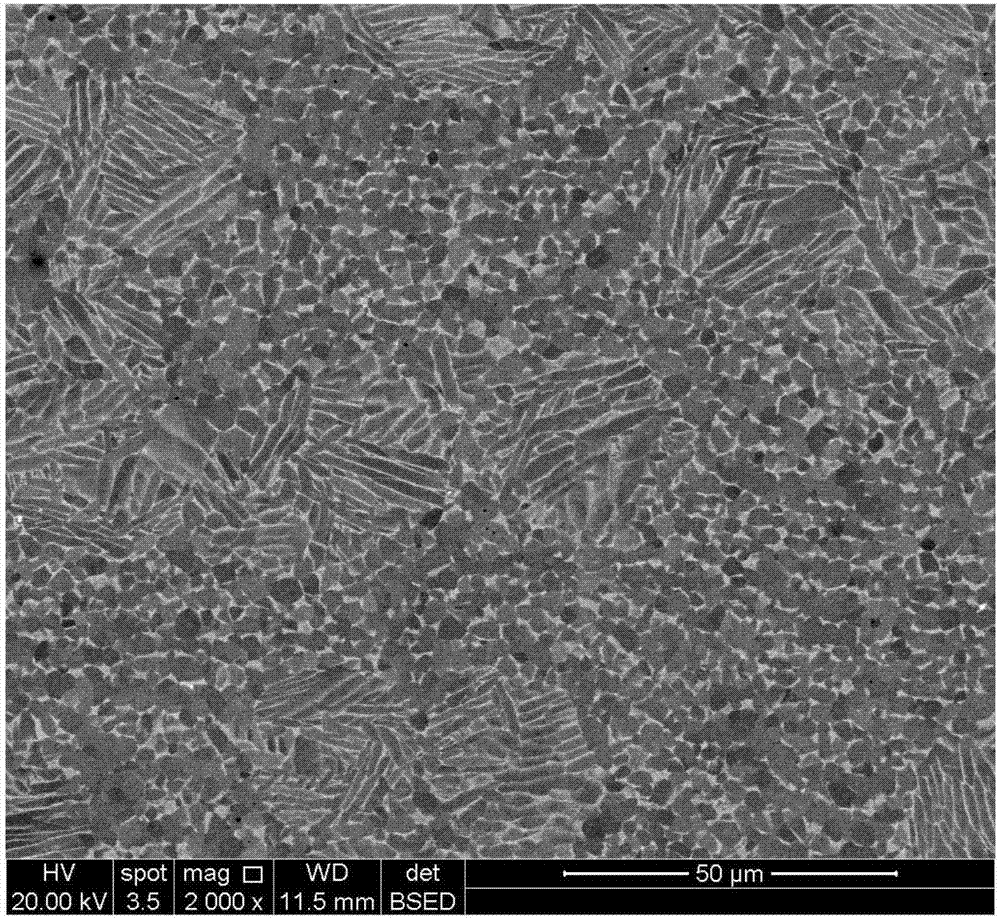

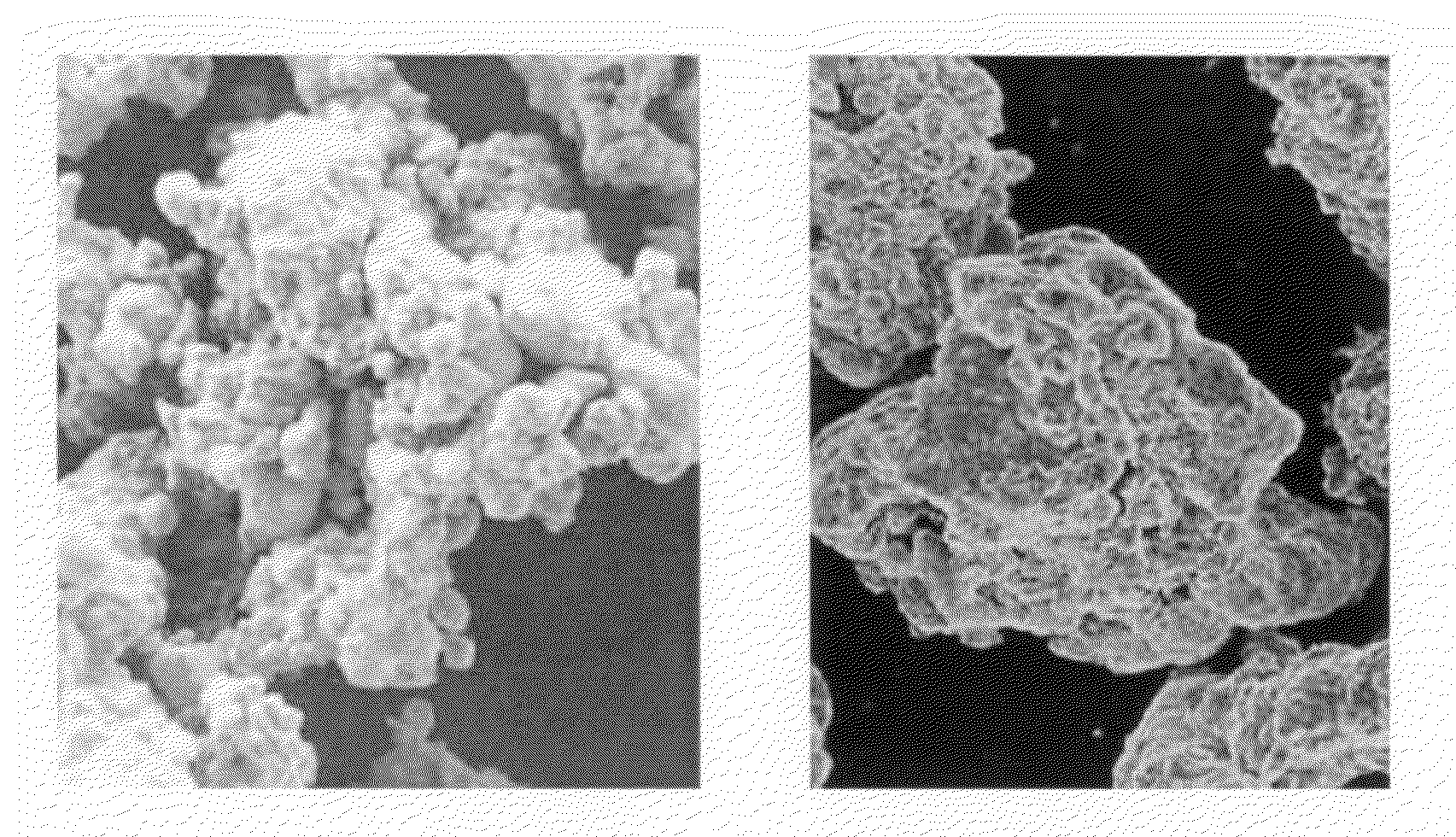

Preparation method of dual-scale titanium alloy material

Owner:WUHAN UNIV OF TECH

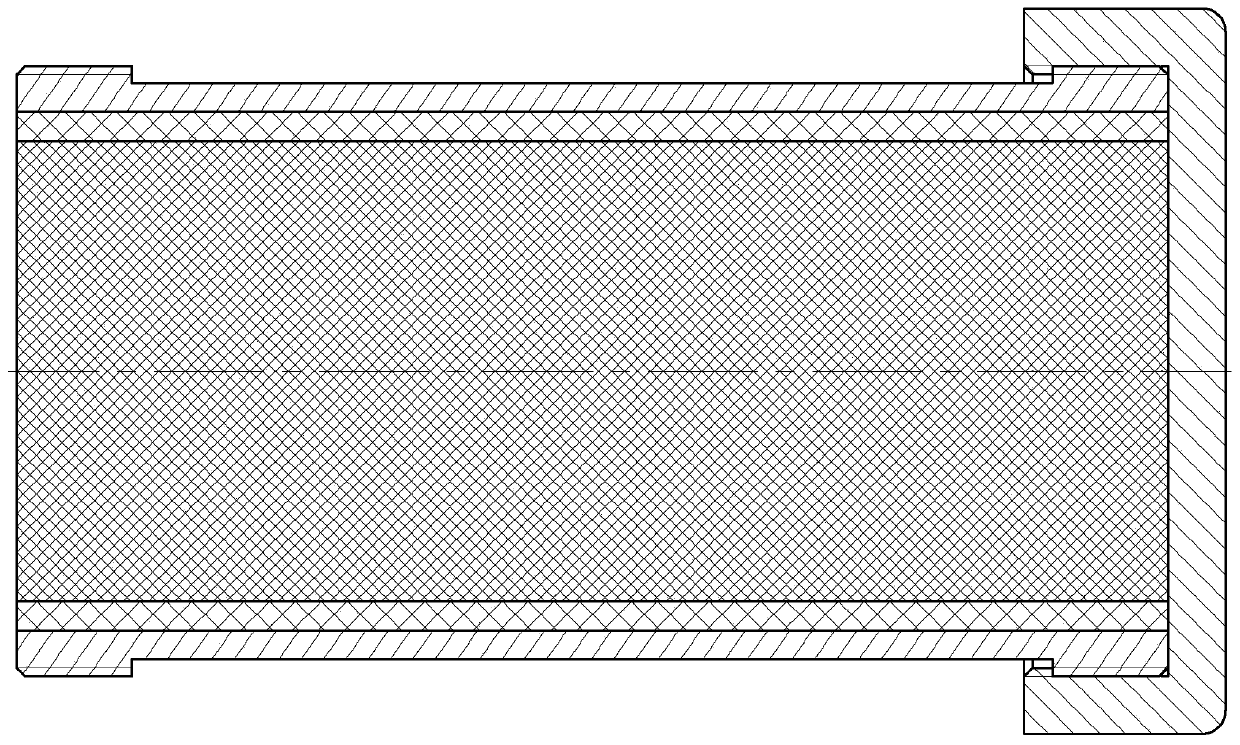

Production method for sintered valve guide

Owner:HITACHI POWDERED METALS COMPANY

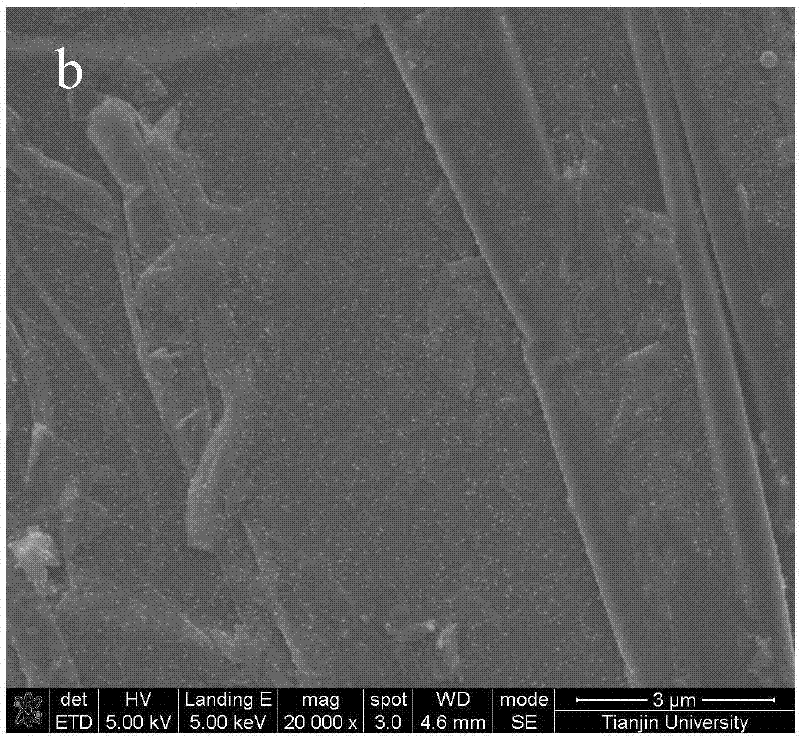

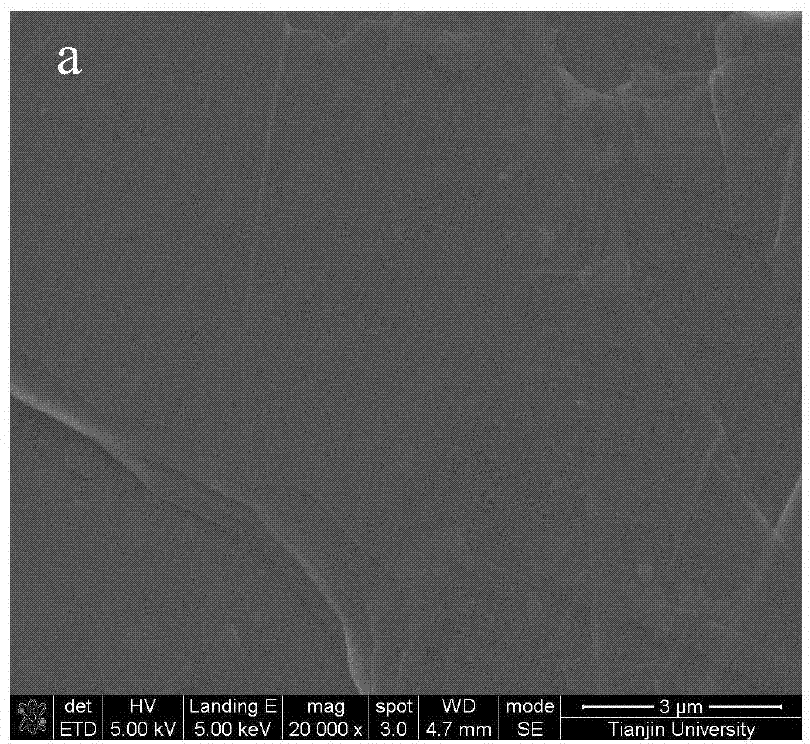

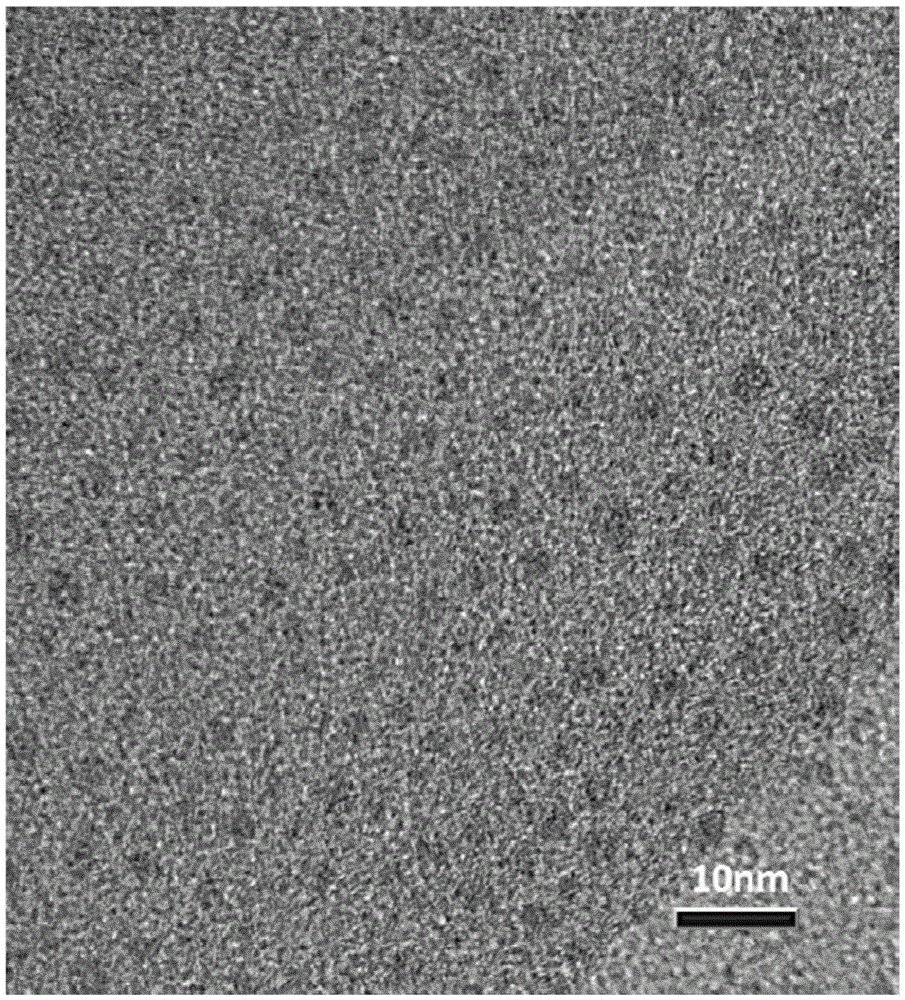

Super-clean graphene and preparation method thereof

The invention discloses super-clean graphene and a preparation method thereof. The preparation method of the super-clean graphene comprises the following steps: putting foam copper on a copper substrate, and attaching; leading carbon source gas and hydrogen to perform chemical vapor deposition; after deposition is completed, obtaining the super-clean graphene at the contact surface of the copper substrate and the foam copper. The preparation method has the advantages that the preparation method is simple and is suitable for large-scale production, the continuous clean area reaches the sub-centimeter level, and the preparation method is suitable for the fields of electronics, optics and the like.

Owner:PEKING UNIV

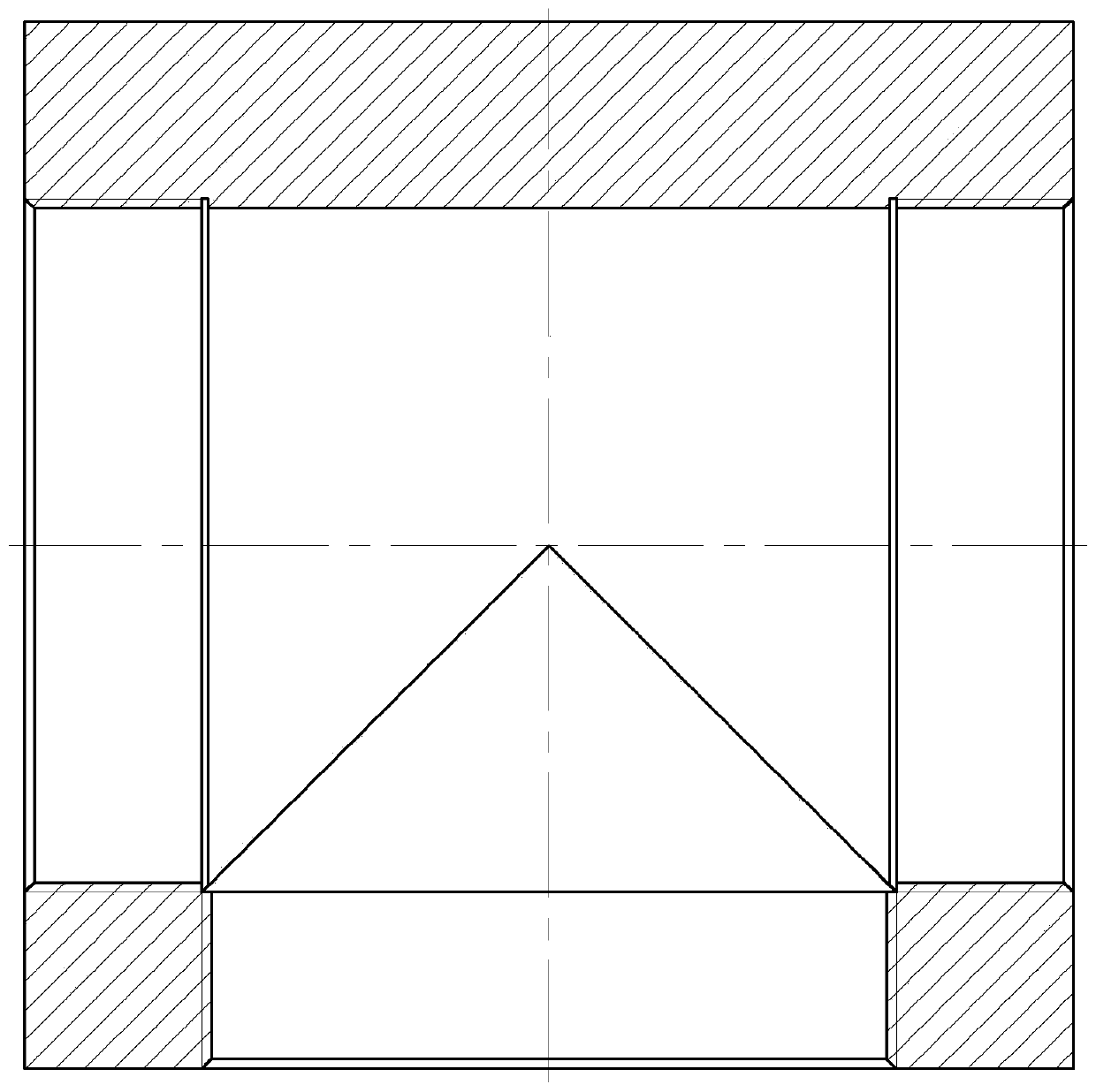

Dual-pulse solid rocket engine soft interlayer ablation test device

ActiveCN110425058ANo accelerationReal-time monitoring of flow fieldRocket engine plantsThroatCombustion

Owner:NANJING UNIV OF SCI & TECH

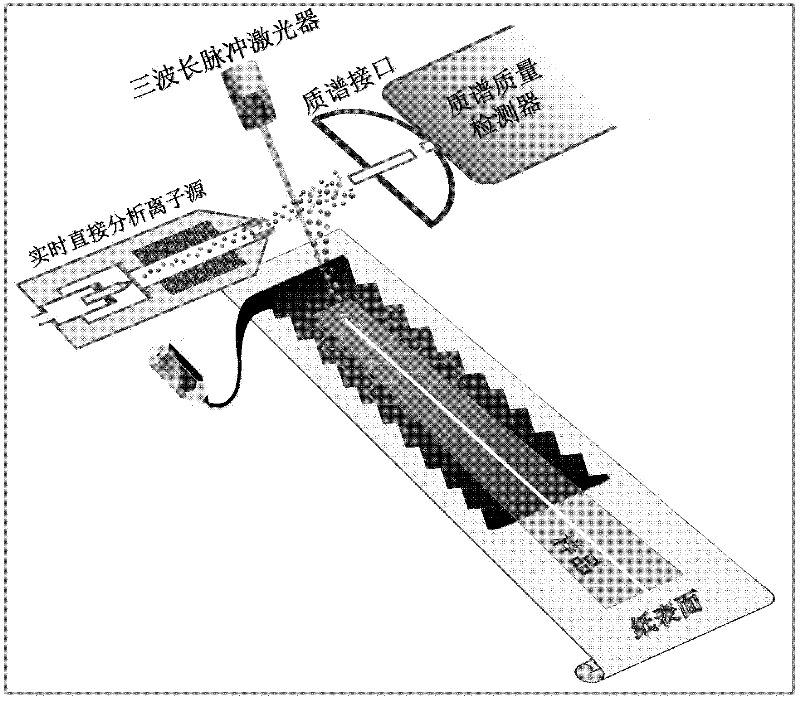

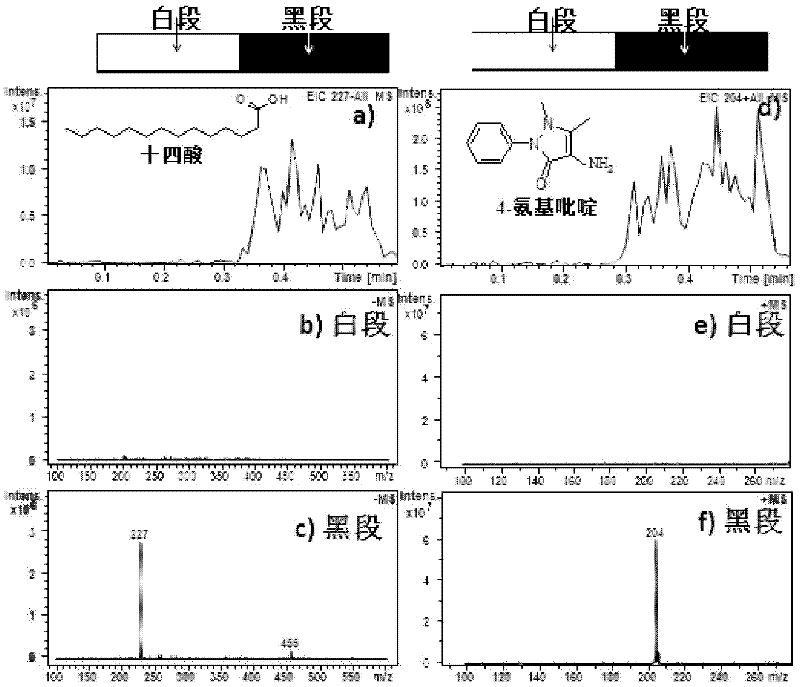

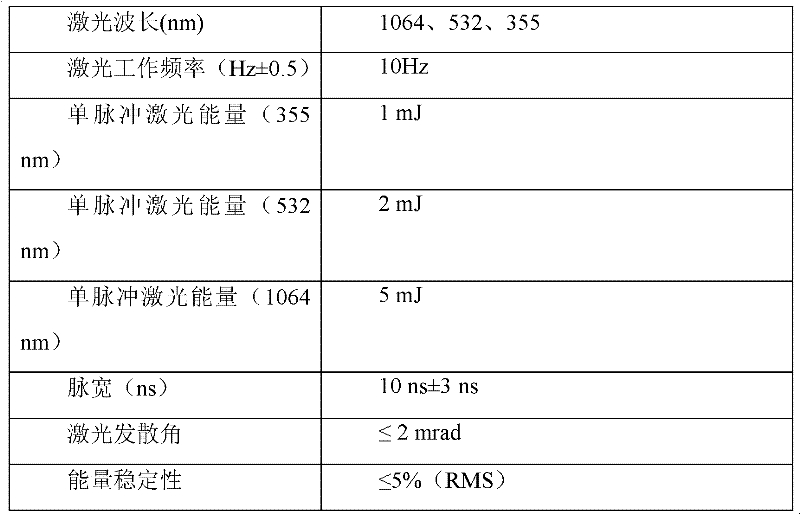

High-sensitivity detection method of normal temperature normal pressure surface assisted laser desorption mass spectrometry

InactiveCN102539515AHigh detection sensitivityUniversalMaterial analysis by electric/magnetic meansMass Spectrometry-Mass SpectrometryGraphite

Owner:PEKING UNIV

Processing method of abrasion resistant welding wire

InactiveCN105772993APrevent oxidationImprove protectionWelding/cutting media/materialsSoldering mediaArc stabilityIron powder

The invention relates to flux-cored wires, in particular to a processing method of an abrasion resistant welding wire. The processing method comprises the steps of drying microcrystalline graphite powder, aluminium powder, fluorite powder, magnesite powder, potassium carbonate powder, ferrosilicon powder, ferromanganese alloy powder and iron powder, and screening; adding the powder into a mixer for mixing; putting a cleaned and dried steel belt on a roller die, adding the mixed powder on the steel belt, and carrying out mold molding; drawing the molded welding wire to decrease the diameter; and winding the drawn wire layer by layer, and packaging the wound wire. According to the processing method, core wire powder is dried, so that the prepared abrasion resistant welding wire is not liable to have the defects of pores, press pits, even cracks, and the like, during the welding process; and during the preparation process of the abrasion resistant welding wire, the contents of carbon and aluminium are increased, so that the deoxidizing and nitrogen fixing capacities are improved, the electrical arc stability is improved, and the carbon oxidation is inhibited, and the gas overflow splashing is reduced.

Owner:LIUZHOU KAITONG NEW MATERIAL TECH CO LTD

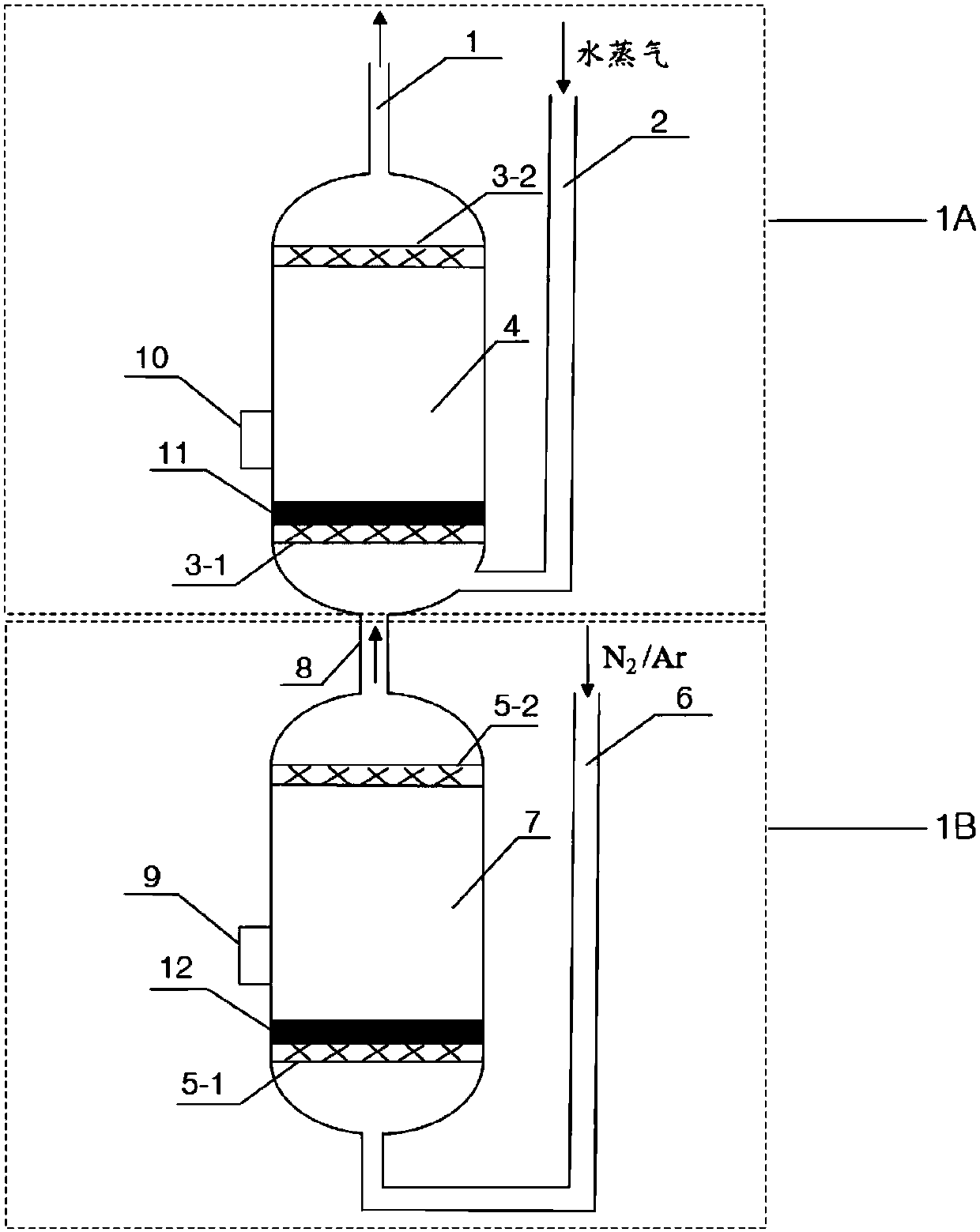

Two-section system and method for coproducing coal-based graphite and carbon nano-tubes

Owner:HUAZHONG UNIV OF SCI & TECH

Preparation method of graphite sheet surface chemical plating iron-nickel alloy layer

InactiveCN104195532AImprove bindingHigh hardnessLiquid/solution decomposition chemical coatingChemical platingGraphite

Owner:TIANJIN UNIV

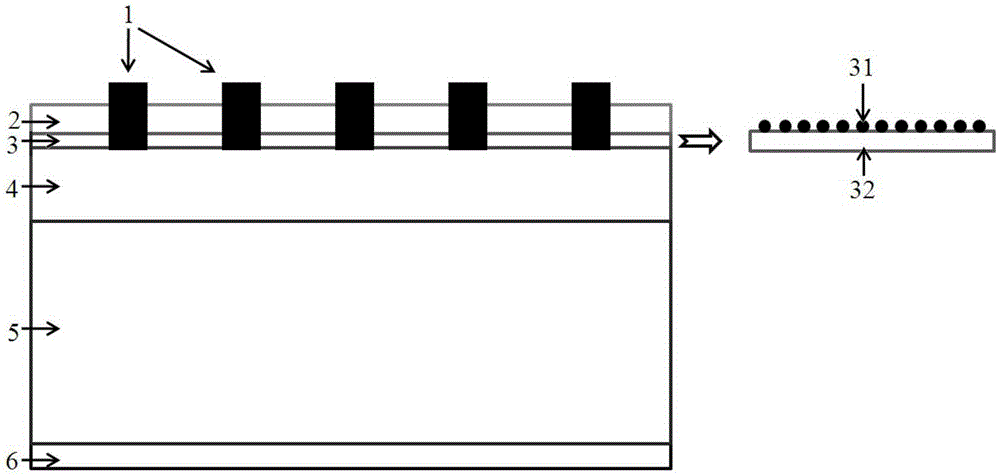

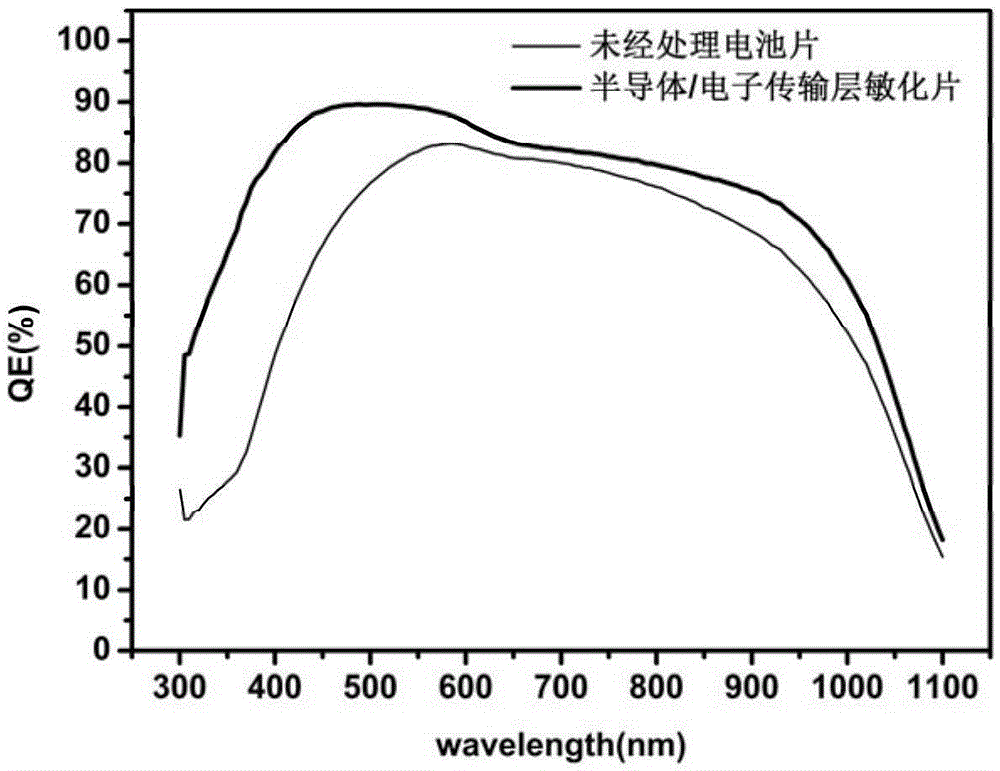

Multi-quantum well photovoltaic battery based on nanometer graphite electron transmission layer, and preparation method thereof

InactiveCN105244390AEvenly distributedGood light and heat stabilityLight-sensitive devicesFinal product manufactureElectrical batterySilicon solar cell

Owner:SHANGHAI NORMAL UNIVERSITY

Preparation method of pearlescent anti-crease waterproof moisture-permeable polyurethane synthetic leather

InactiveCN105568701AImprove wear resistanceImprove wrinkle resistanceTextiles and paperWater basedFiber

Owner:HANGZHOU FUYANG WEIWEN ENVIRONMENTAL PROTECTION TECH CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap