Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

24 results about "Brush" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A brush or carbon brush is an electrical contact which conducts current between stationary wires and moving parts, most commonly in a rotating shaft. Typical applications include electric motors, alternators and electric generators.

Steam device and operation and use method thereof

PendingCN111472156ANormal use workIncrease flexibilityBatteries circuit arrangementsIroning apparatusThermodynamicsLiquid medium

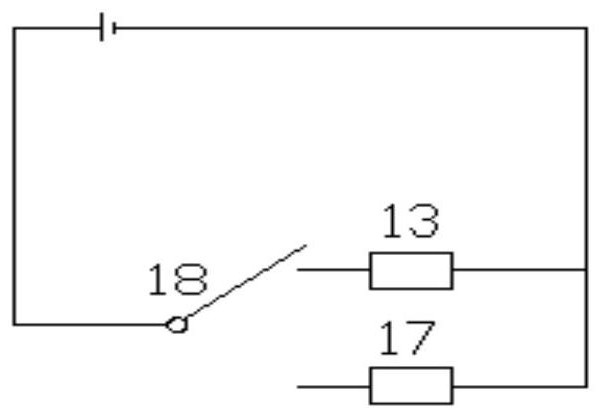

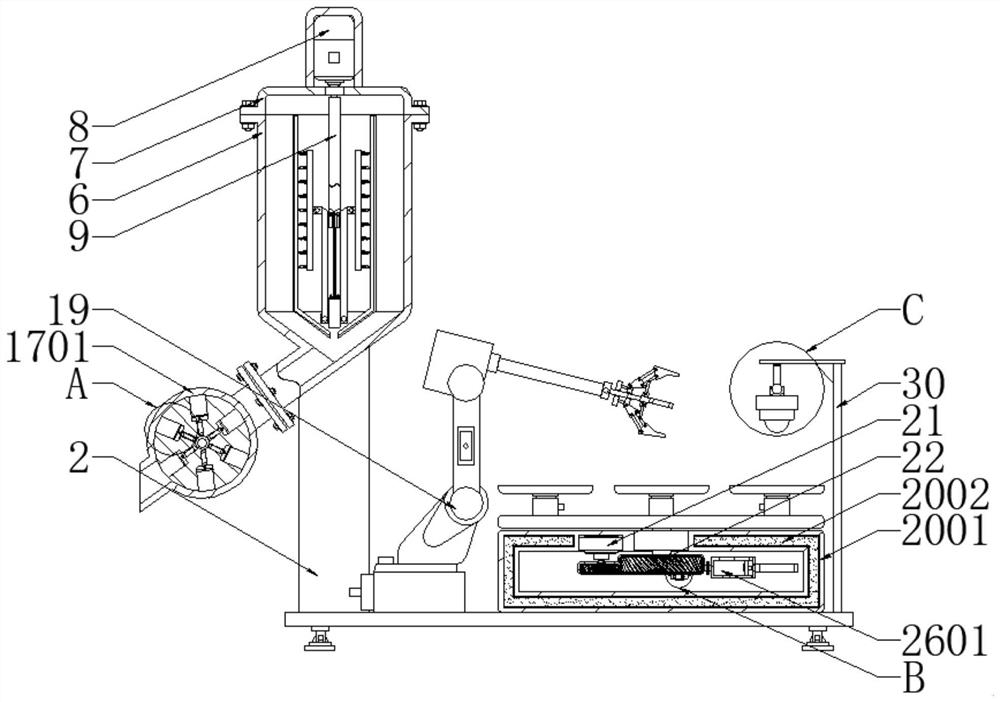

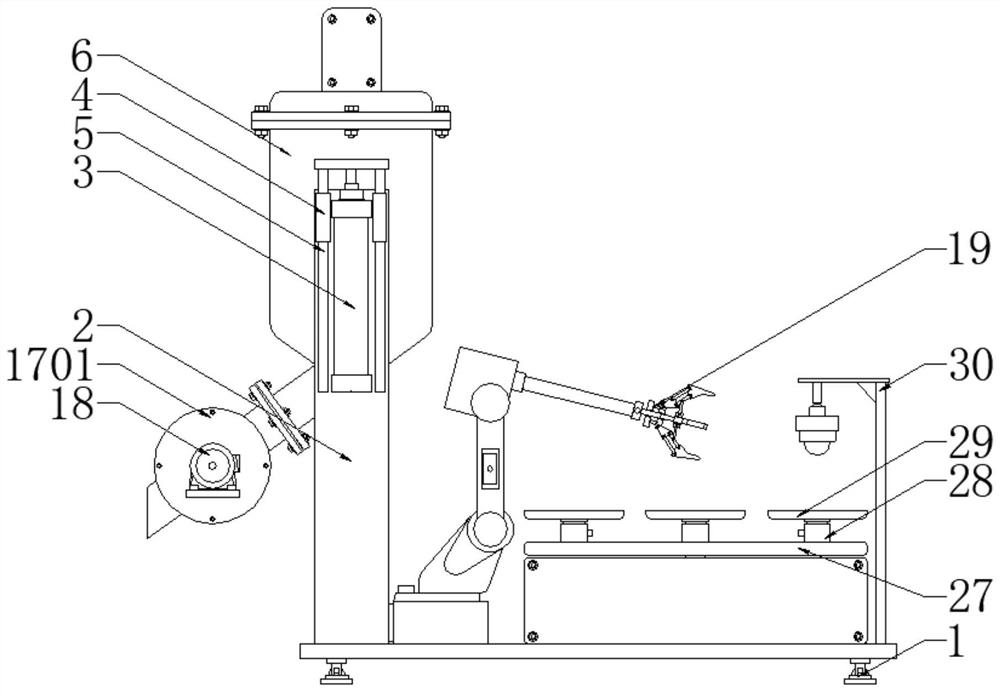

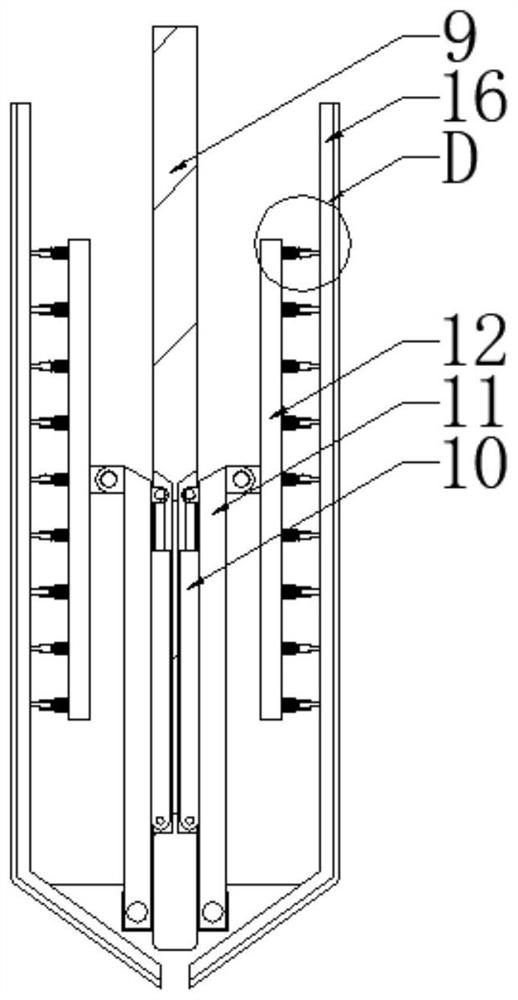

The invention discloses a steam device and an operation and use method thereof. The method comprises the steps that a steam brush and a power supply seat are connected; the power supply seat suppliespower to a steam generator in the steam brush and heats the steam generator; meanwhile, a lithium battery in the steam brush is charged through the power supply seat; an indicating lamp indicates thatthe steam generator reaches prese temperature; the steam brush is taken off from the power supply seat and disconnected with the power supply seat; and a switch element on the steam brush is closed,power is supplied to a water pump in the steam brush through the lithium battery, a liquid medium is conveyed into the steam generator through the water pump, and the liquid medium is heated into steam through the steam generator. Due to the fact that the lithium battery is arranged in the steam brush, after the steam generator is heated to certain temperature, the steam brush can be divorced fromdependence on electric supply to complete normal use work, and the use flexibility is improved.

Owner:CUORI ELECTRICAL APPLIANCES GRP

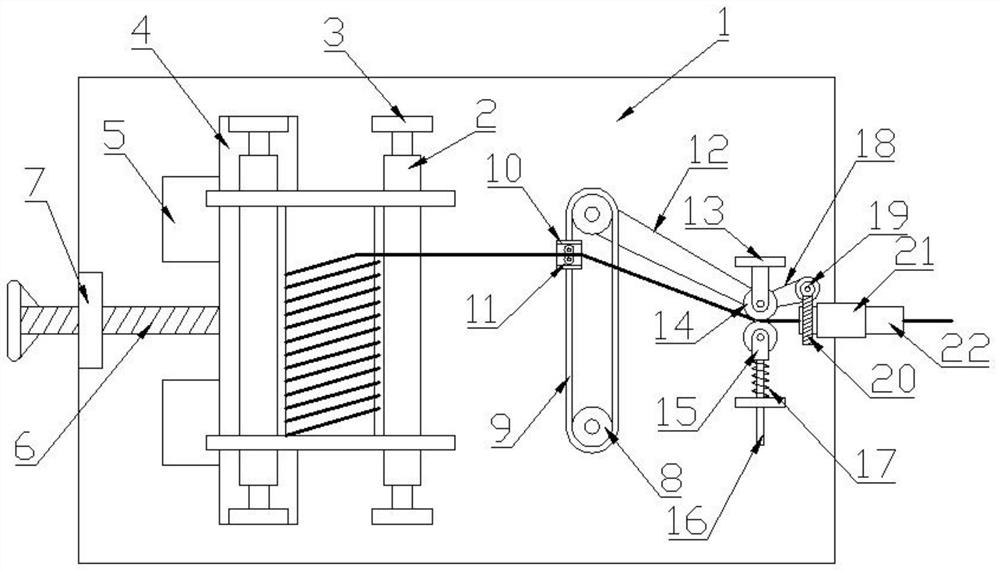

Rolling type electric power equipment electric leakage troubleshooting device and troubleshooting method thereof

ActiveCN112415428AConvenient interspersedGuarantee sufficiencyShort-circuit testingMeasurement instrument housingFiberElectric power equipment

Owner:鄂州电力勘察设计院有限责任公司

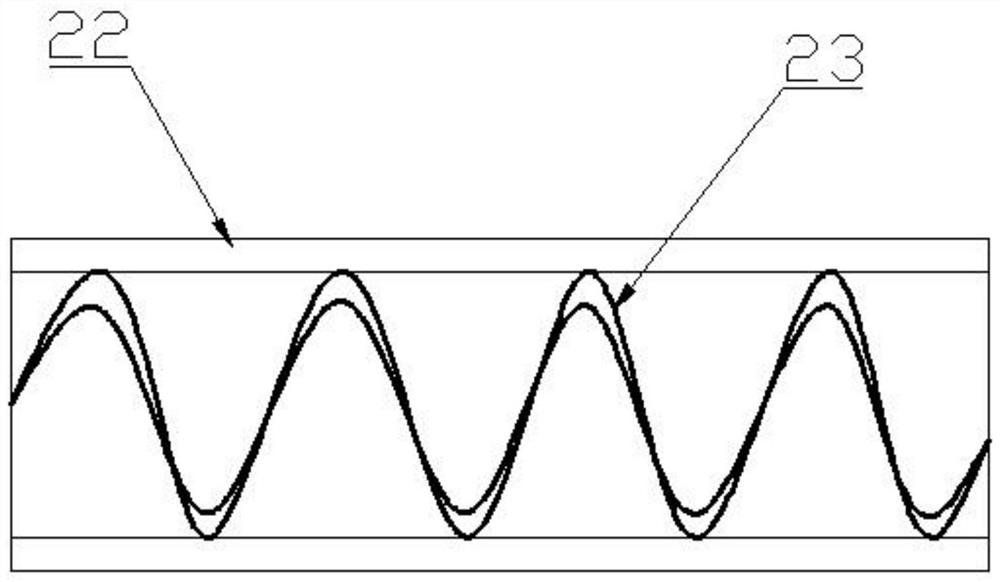

Demoulding structure used for producing brush strip of dust collector

A demoulding structure used for producing a brush strip of a dust collector comprises a fixing board, a bearing pedestal and a sliding block which are sequentially arranged from front to back; a bearing is installed inside the bearing pedestal; a cylindrical cavity is arranged in the bearing in a penetrating mode; the front end of the cavity extends out of the fixing board; the rear end of the cavity is fixedly connected with the sliding block; an ejection block is arranged behind the sliding block and forwards provided with an ejection rod used for ejecting the brush strip of the dust collector; the front end of the ejection rod extends into the cavity; the cavity is sleeved with a roller; the roller is provided with a spiral groove matched with the brush strip of the dust collector; the fixing board is provided with a guide block matched with the spiral groove; and the sliding block is moved backwards, the roller drives the cavity to move backwards spirally, and the ejection rod ejects the brush strip of the dust collector out of the cavity. Through cooperation of the spiral groove in the roller and the guide block, the spiral demoulding structure is formed, the brush strip of the dust collector is rapidly and completely released from a mould, the mold manufacturing cost is lower, the demoulding speed is higher, and the production efficiency is higher.

Owner:NINGBO HENGHE PRECISION INDUSTRY CO LTD

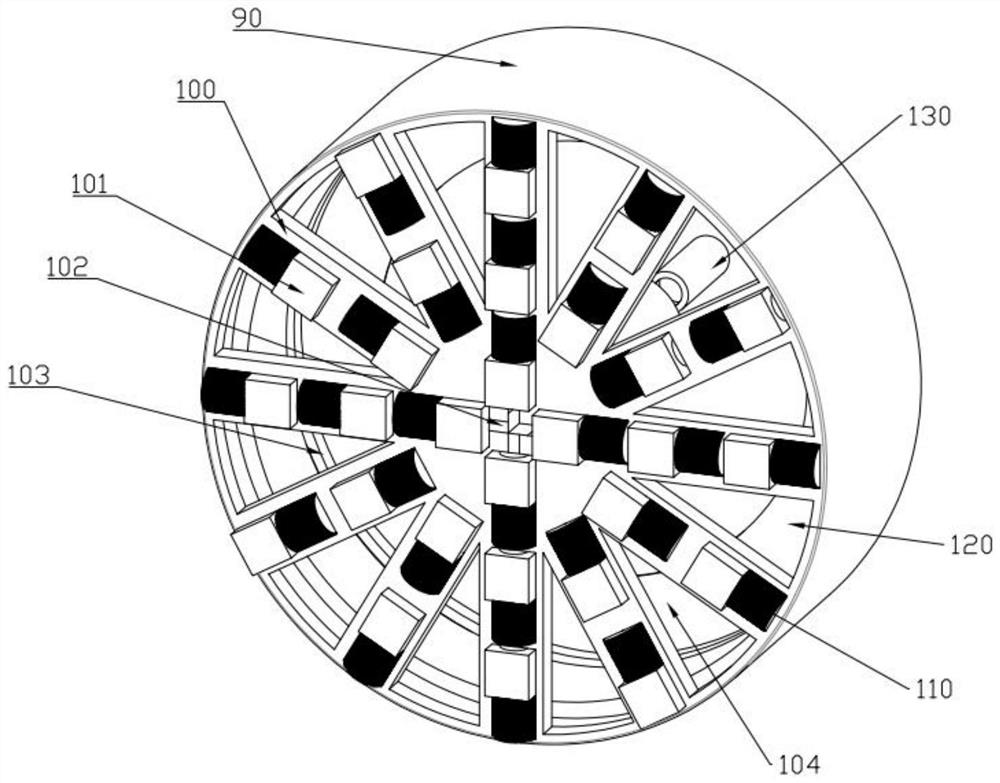

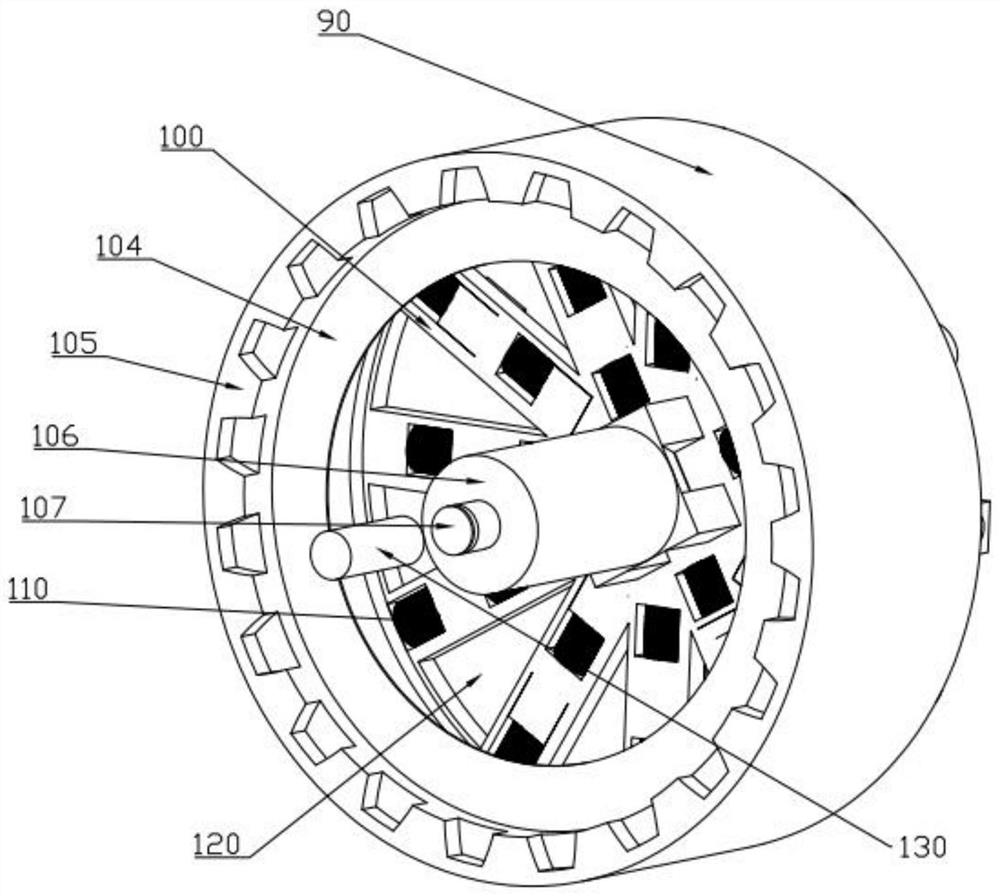

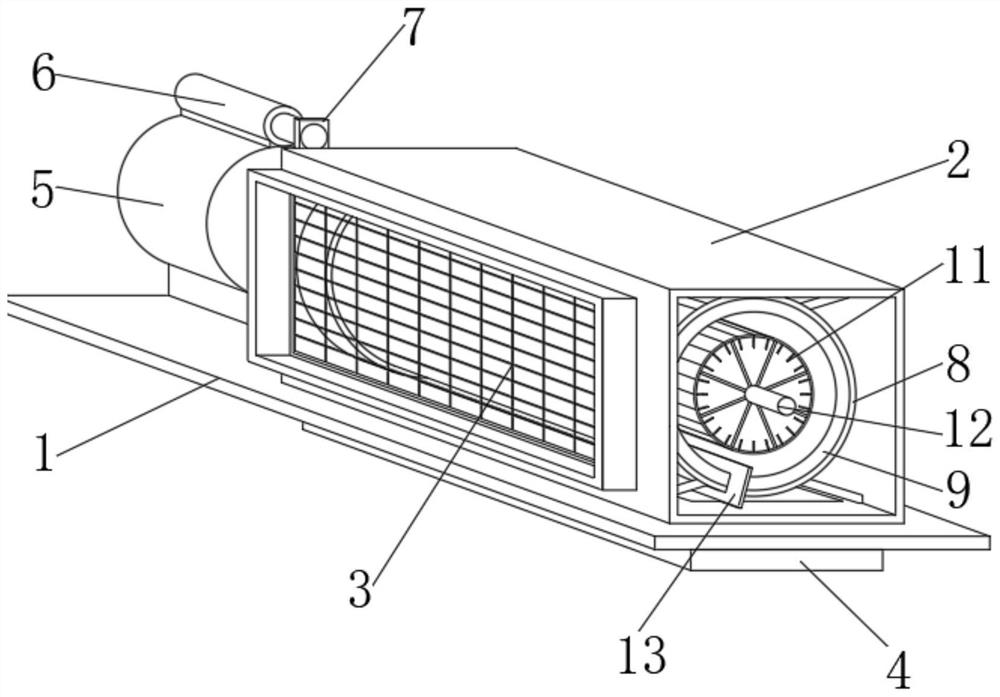

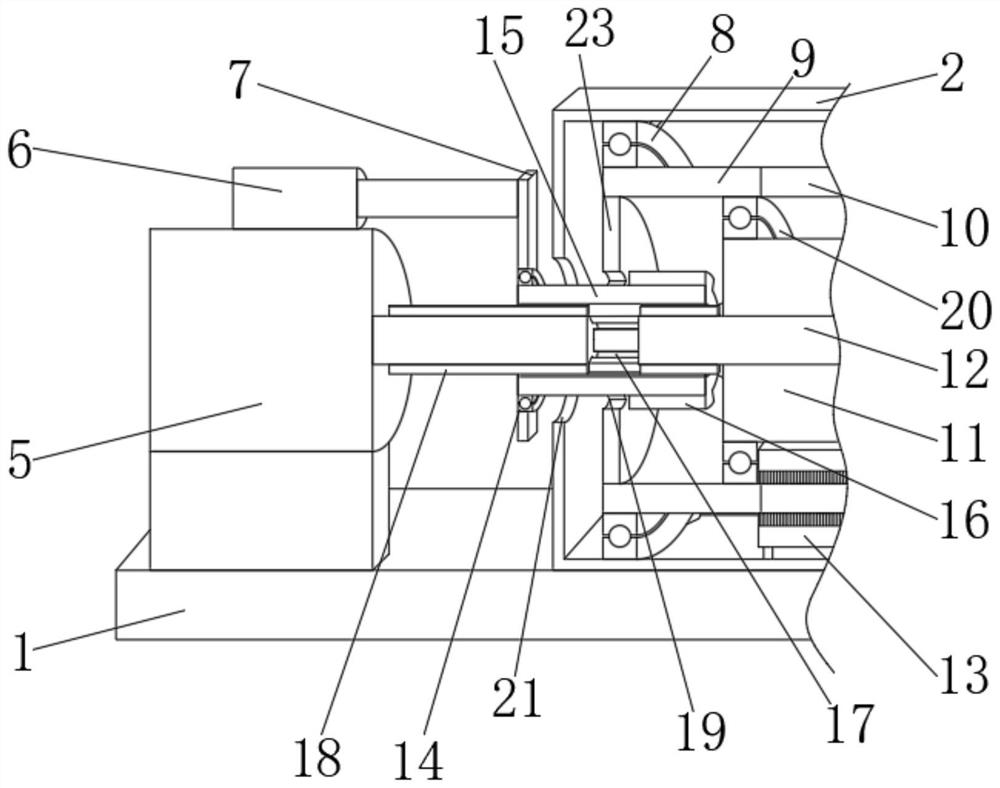

Pipe jacking machine cutter head with cage type hob cutting device

PendingCN112593967AReduce adhesionExtended service lifeTunnelsStructural engineeringMechanical drive

Owner:安徽唐兴装备科技股份有限公司

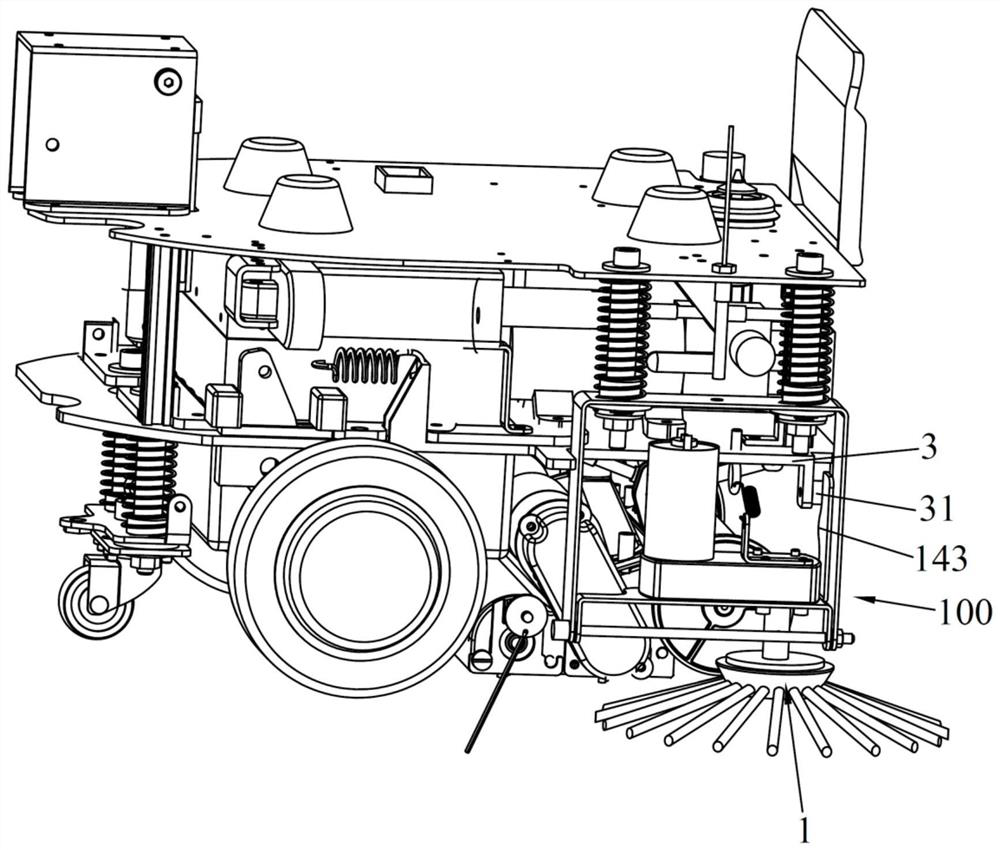

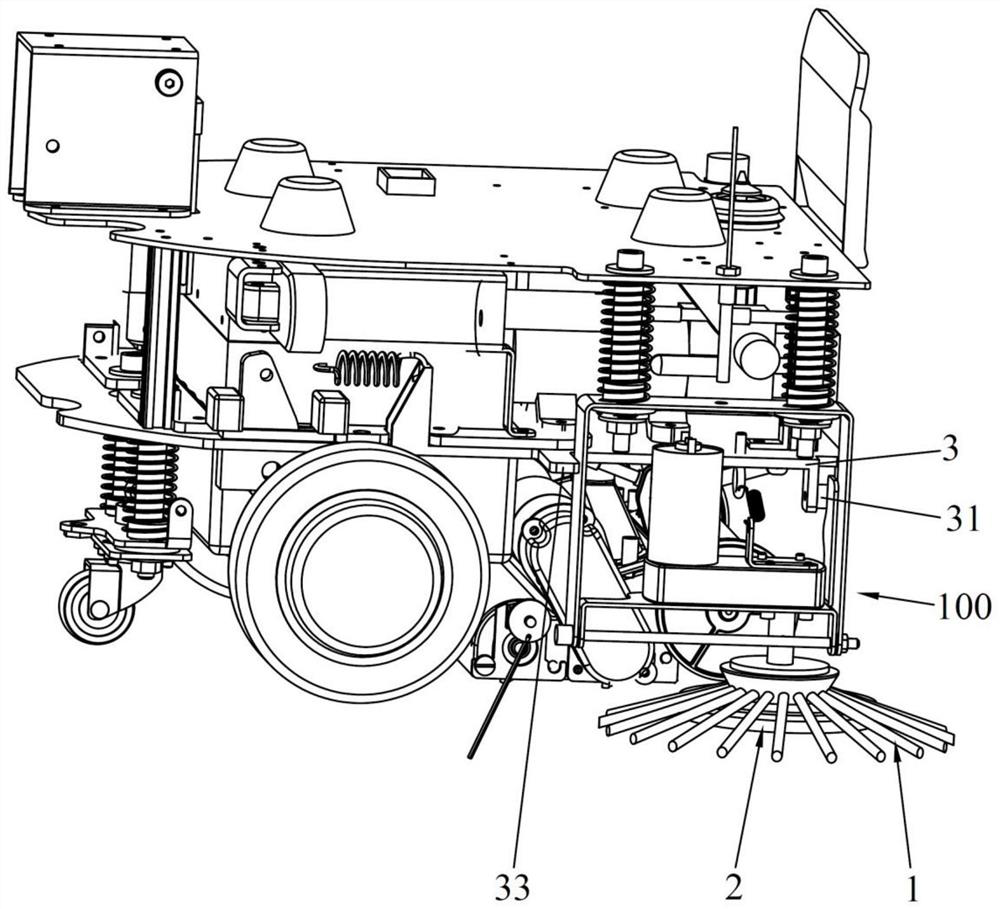

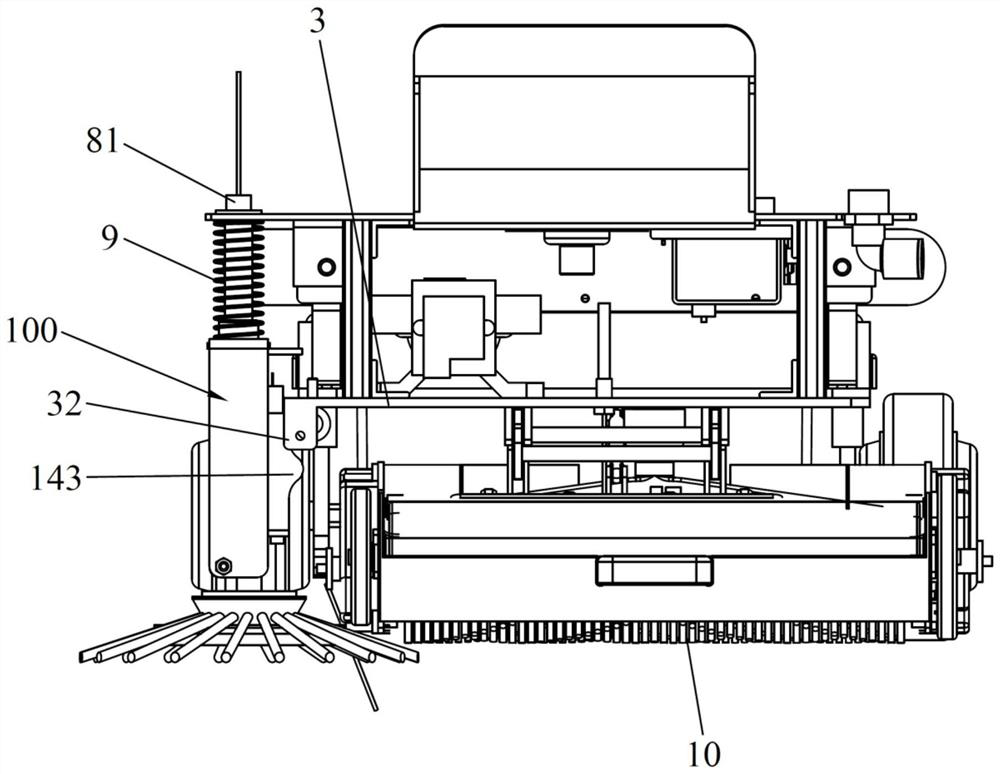

Side brush module and cleaning robot

Owner:SHANGHAI GAOXIAN AUTOMATION TECH

Cable take-up and pay-off device for communication engineering

Owner:安徽莱特实业集团有限公司

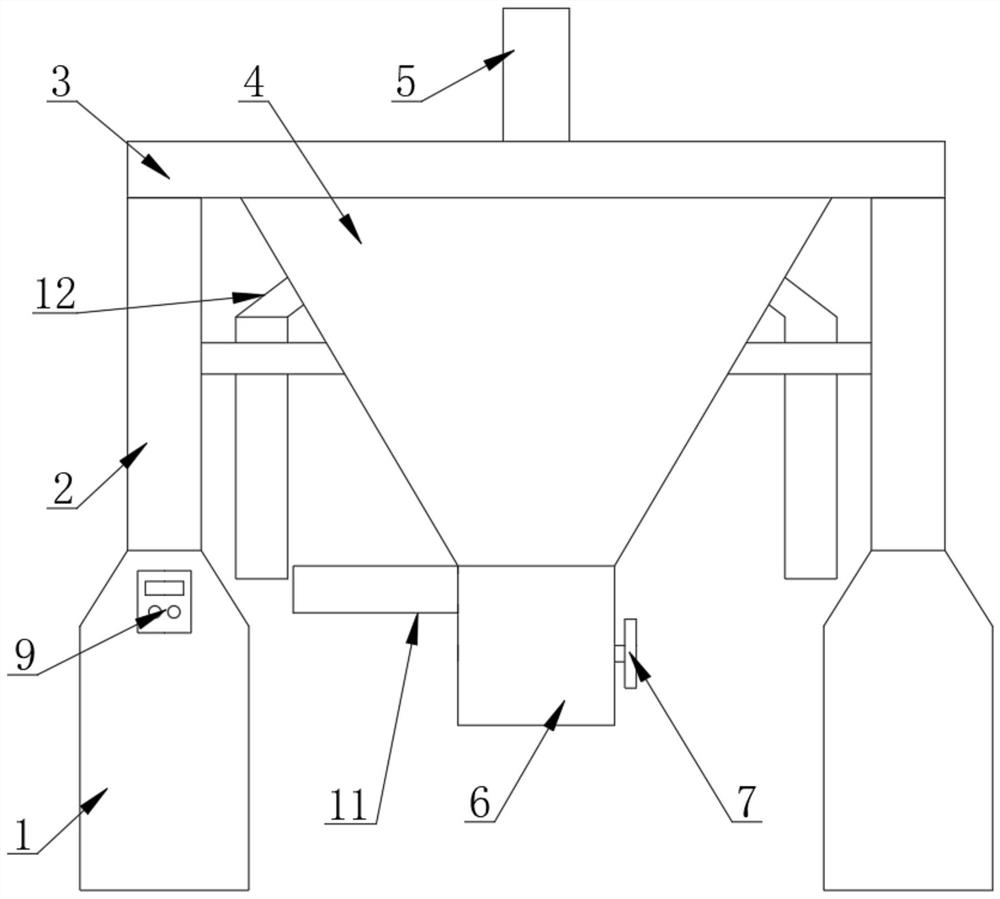

Ash bucket feeding equipment for thermal power plant

InactiveCN112938405AReduced service lifePrevent leakageConveyorsHollow article cleaningPower stationElectric machine

Owner:DATANG HUAIBEI POWER PLANT

Improved PVC particle material cleaning device

InactiveCN111391174APrevent fallingGuaranteed cleanlinessCleaning using toolsCleaning using liquidsElectric machineStructural engineering

The invention relates to the technical field of cleaning devices and discloses an improved PVC particle material cleaning device. The improved PVC particle material cleaning device comprises a box; amaterial inlet is formed in the top of the box; two cleaning rollers are rotationally connected into the box; cleaning brushes which are uniformly distributed are fixedly connected to the two cleaningrollers correspondingly; one ends of the backs of the two cleaning rollers penetrate through and extend to the back surface of the box; gears are arranged at one ends of the back surfaces of the twocleaning rollers in a sleeving mode; the two gears are engaged with each other; a motor is fixedly connected with the back surface of the box; one end of the back of the left cleaning roller is fixedly connected with a motor output shaft; a first filtering plate is hinged to the left side of the interior of the box; the right side of the first filtering plate is slideably connected with the box; and a vibrating motor is fixedly connected to the bottom of the first filtering plate. The improved PVC particle material cleaning device is easy to operate and high in cleaning efficiency, meanwhile PVC particle materials can be air-dried, and time and labor are saved.

Owner:GAOYOU YAPU PLASTIC IND CO LTD

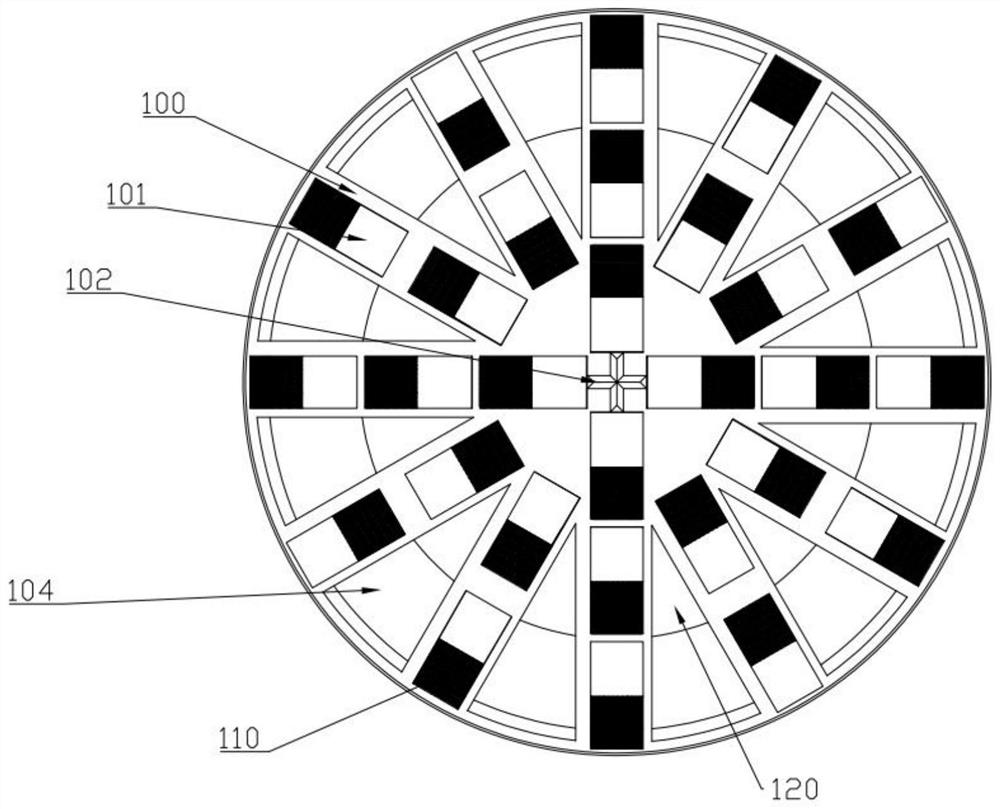

Mixed-excitation synchronous motor with tripolar combination

InactiveCN104638862ASimple structureShort magnetic circuitMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsSynchronous motorElectric machine

The invention discloses a mixed-excitation synchronous motor with a tripolar combination, and belongs to the technical field of motors. The mixed-excitation synchronous motor comprises a case (1), a stator core (2), armature windings (3), a rotor core (4), a permanent magnetic pole (5), ferromagnetic poles (6), exciting windings (7) and a rotating shaft (8). The armature windings are distributed in stator core grooves, and poles of the armature windings are identical to poles of rotors in number. According to the tripolar combination of the rotor core, the permanent magnetic pole is arranged in the middle, and the ferromagnetic poles are arranged on two sides. The exciting windings are placed in grooves on two sides of the tripolar combination, and the number of poles of each exciting winding is one third of that of the poles of the rotors. During motor operation, the exciting windings can be powered by an excitation system with or without a brush; wide range adjustment of a magnetic field of the motor can be achieved only by excitation capacity which is about one third of excitation capacity of a common synchronous motor. Compared with the prior art, the mixed-excitation synchronous motor has the advantages of simple structure, few permanent magnetic material consumption, high motor efficiency, high magnetic field adjustment capability and capability of adapting to wide range operation speed requirements.

Owner:黄劭刚

Medical instrument cleaning device

InactiveCN112893207AEasy to cleanEasy to sterilize and dryDrying gas arrangementsCleaning using toolsElectric machineEngineering

The invention relates to the technical field of medical instruments, in particular to a medical instrument cleaning device. The medical instrument cleaning device comprises a machine body and a cleaning box arranged in the machine body, a water collecting tank is arranged below the cleaning box, a plurality of damping seats are installed below the water collecting tank, a sliding rod and a cleaning table are slidably installed on the upper surface of the water collecting tank, a double-output-shaft motor is fixedly installed on the upper surface of the machine body, the output end of the double-output-shaft motor is connected with a rotating shaft, the rotating shaft is connected with a bevel gear set, the bevel gear set is connected with a stirring shaft, a plurality of side rods are fixedly installed on the side face of the stirring shaft, the side rods are rotationally connected with magnetic rods, and the magnetic rods are fixedly connected with fixed sliding rods. By arranging the magnetic rod and a rolling brush rod, a stirring rod can be driven by the double-output-shaft motor to rotate, and meanwhile, a second electromagnetic block is controlled to be electrified.

Owner:李越强

Electric power metering cabinet ventilation device

InactiveCN112993814ASpeed up circulationAffect the accuracy of useBatteries circuit arrangementsSubstation/switching arrangement cooling/ventilationElectric machineryEngineering

Owner:王欣

Automatic material taking and discharging mechanism of metal powder injection molding machine

ActiveCN114570928AEfficient cleaning structureWith structureSubsonic/sonic/ultrasonic wave measurementPlastic recyclingEngineeringMachine

Owner:扬州钰能精密机械科技有限公司

Rolling brush assembly and coating robot with same

PendingCN114457979AUniform dischargeImprove work efficiencyBuilding constructionsBrushMaterials science

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

Grinding and polishing device and method based on glass machining

ActiveCN113696004AChange heightReduce the difficulty of manual cleaningGrinding carriagesRevolution surface grinding machinesPolishingEngineering

Owner:湖北浠玻实业有限公司

Corner treatment device used for track gasket machining

PendingCN113492345AEnsure safetyAchieve a clean finishGrinding drivesGrinding machinesElectric machineGear wheel

Owner:JIANGSU JINYANG MACHINERY

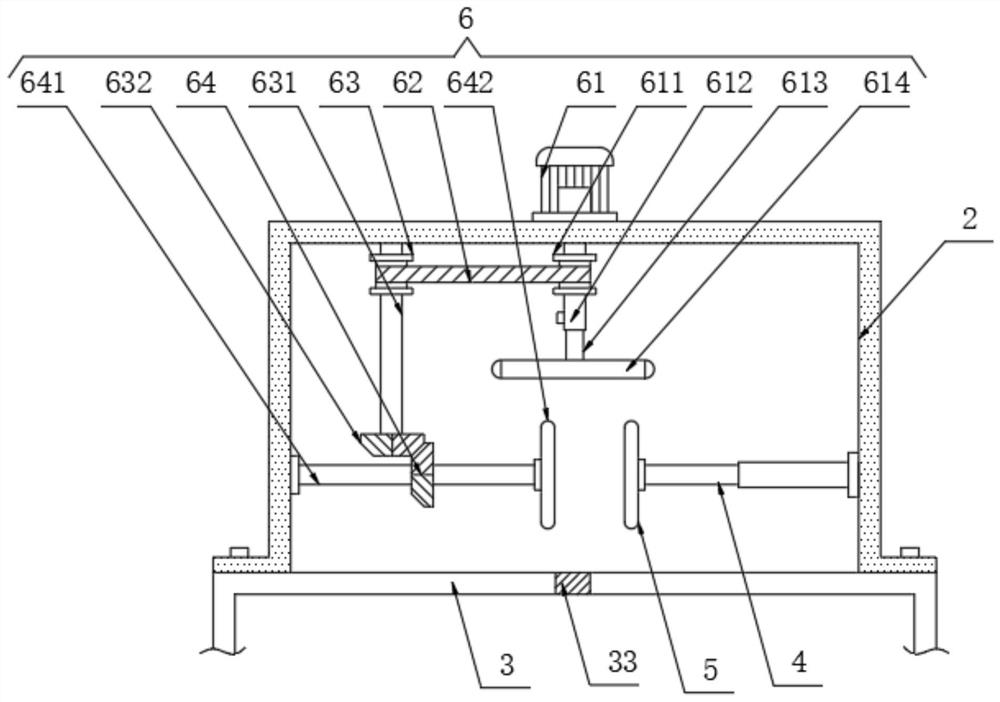

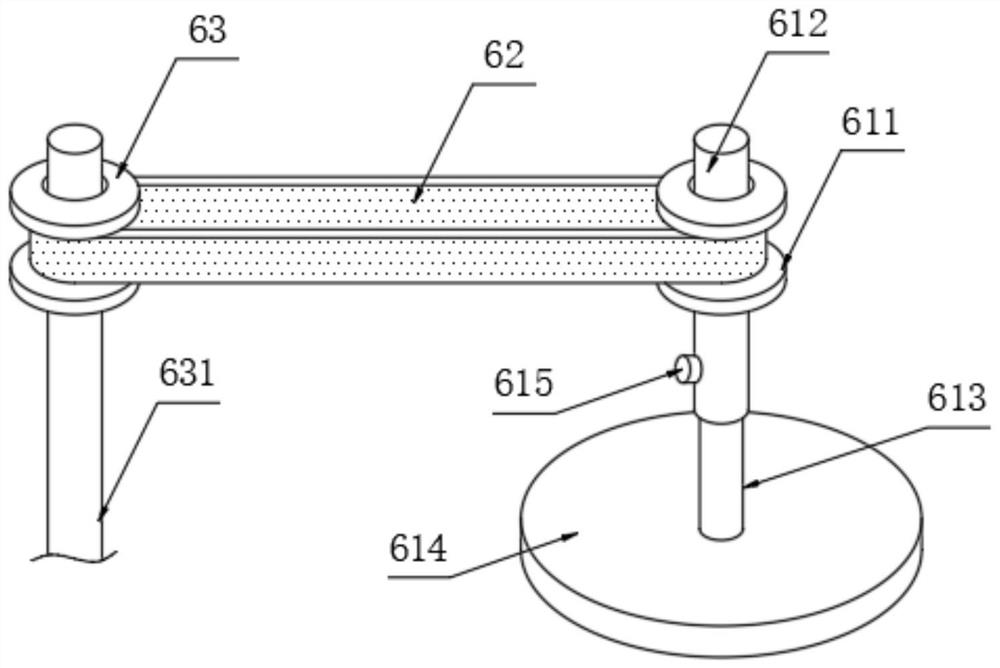

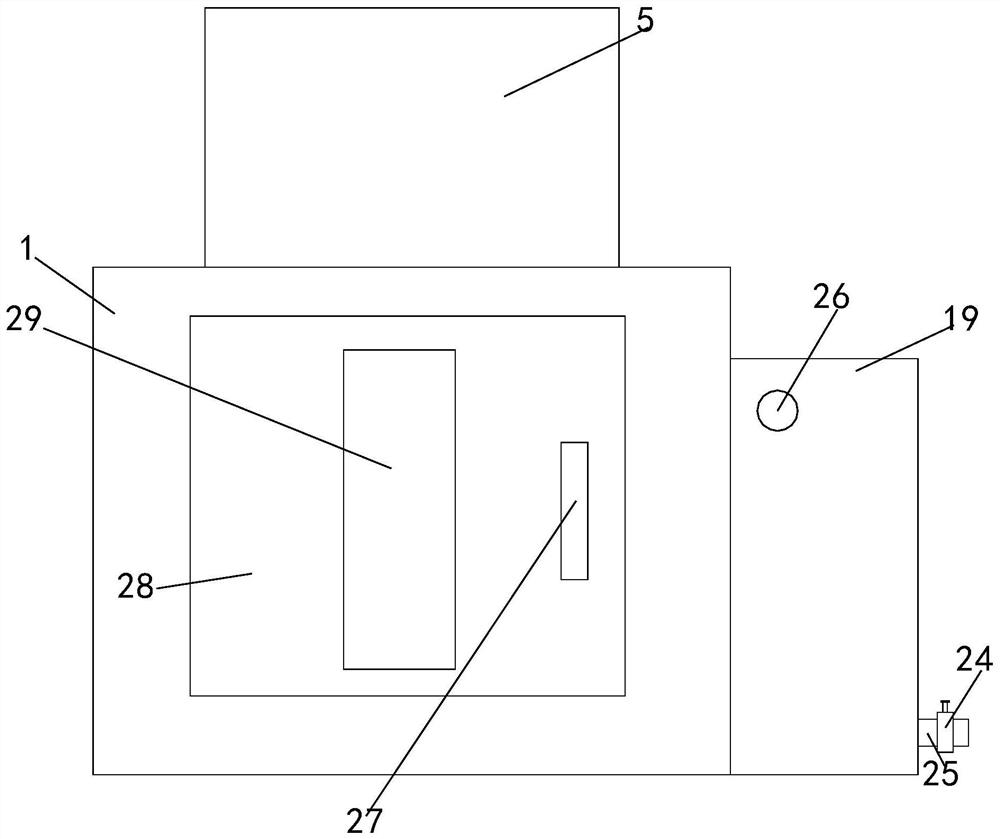

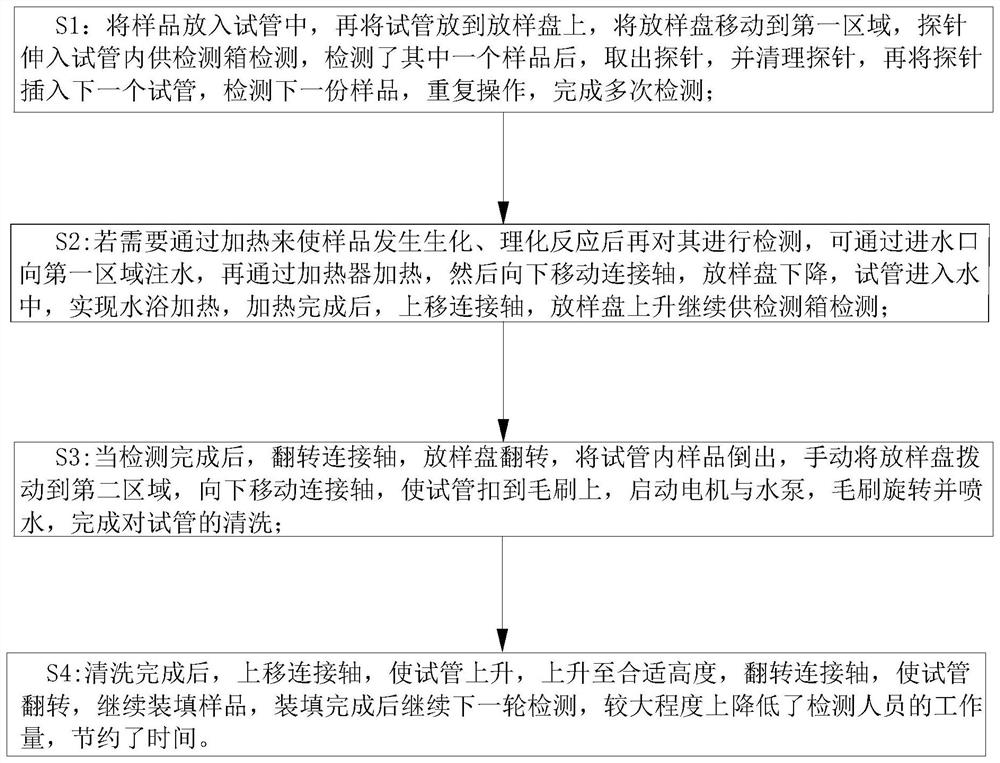

Food safety detection equipment and detection method thereof

PendingCN114062619ALabor savingTimely inputPreparing sample for investigationCleaning using toolsFood safetyWater flow

Owner:刘雨莎

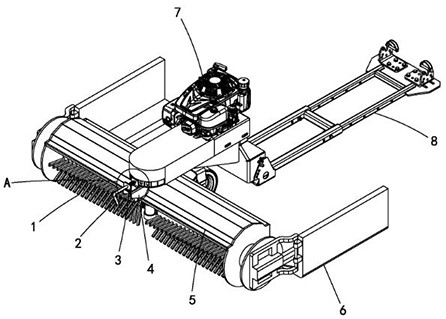

Aloft glass cleaning device

PendingCN105852742AEasy to cleanImprove efficiencyAutomatic obstacle detectionTravelling automatic controlSignal processing circuitsControl signal

The invention discloses an aloft glass cleaning device. The aloft glass cleaning device comprises a remote controller and a cleaner; the remote controller provides a control function for an operator and transmits control signals to the cleaner wirelessly; the cleaner comprises a bottom plate, centrifuges, wheels, cleaning cloth, brushes and a control circuit. The centrifuges are arranged on one side of the bottom plate, and the wheels are arranged on the bottom plate; the brushes and the cleaning cloth are arranged on the same side of the centrifuges on the bottom plate; the control circuit comprises a central signal processing circuit, a signal receiving circuit, a wheel control circuit, a brush control circuit and a centrifuge control circuit, and the signal receiving circuit, the wheel control circuit, the brush control circuit and the centrifuge control circuit are connected with the central signal processing circuit. The signal receiving circuit is in wireless communication with the remote controller and sends received control signals to the central signal processing circuit, and the central signal processing circuit controls action of the wheels, the brushes and the centrifuges according to the control signals through the wheel control circuit, the brush control circuit and the centrifuge control circuit respectively. The aloft glass cleaning device has advantages of high safety, high reliability, low operation cost, high operability and high controllability.

Owner:XIAMEN UNIV OF TECH

Automatic dust cleaning device

Owner:常州卡夫特机械有限公司

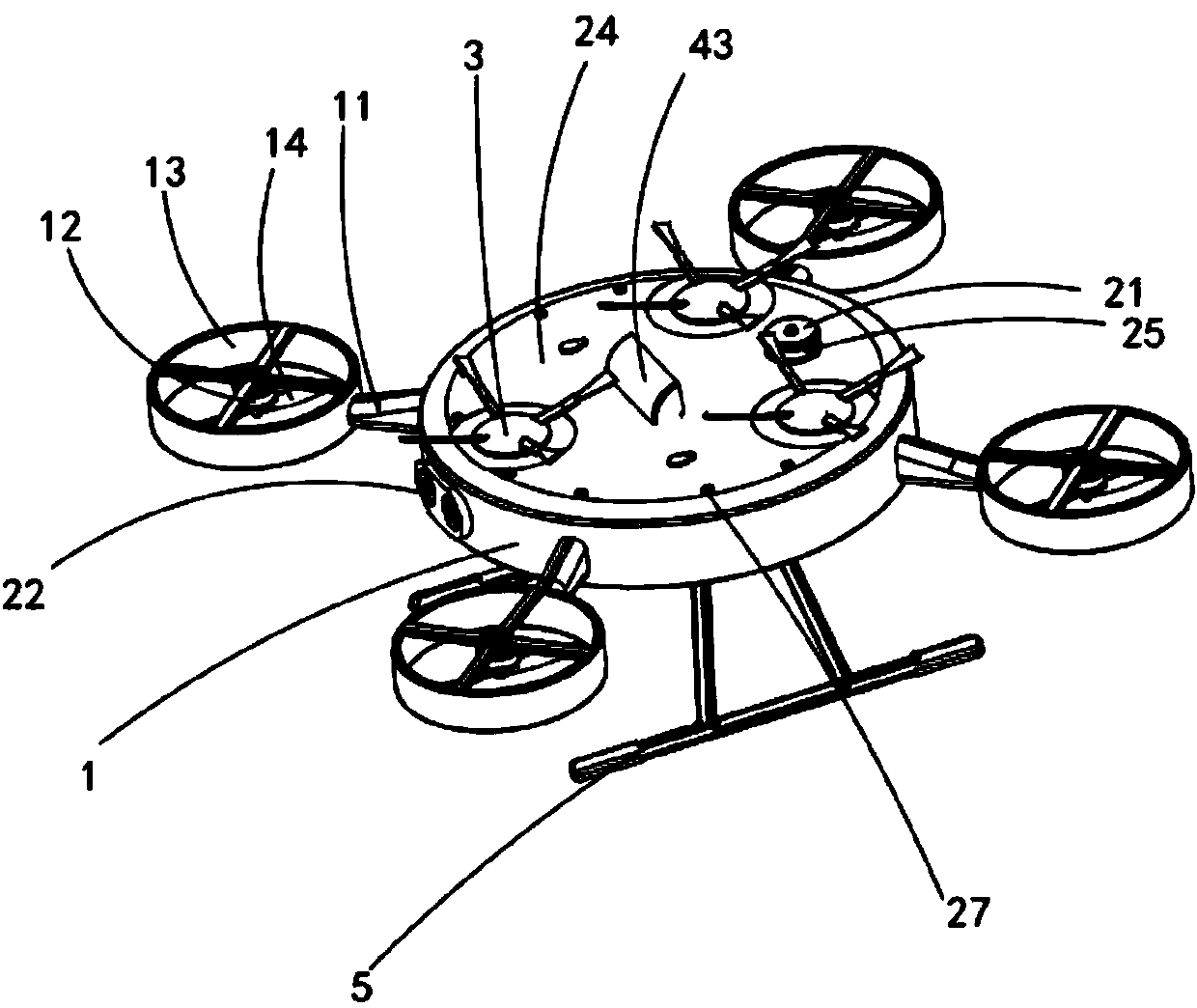

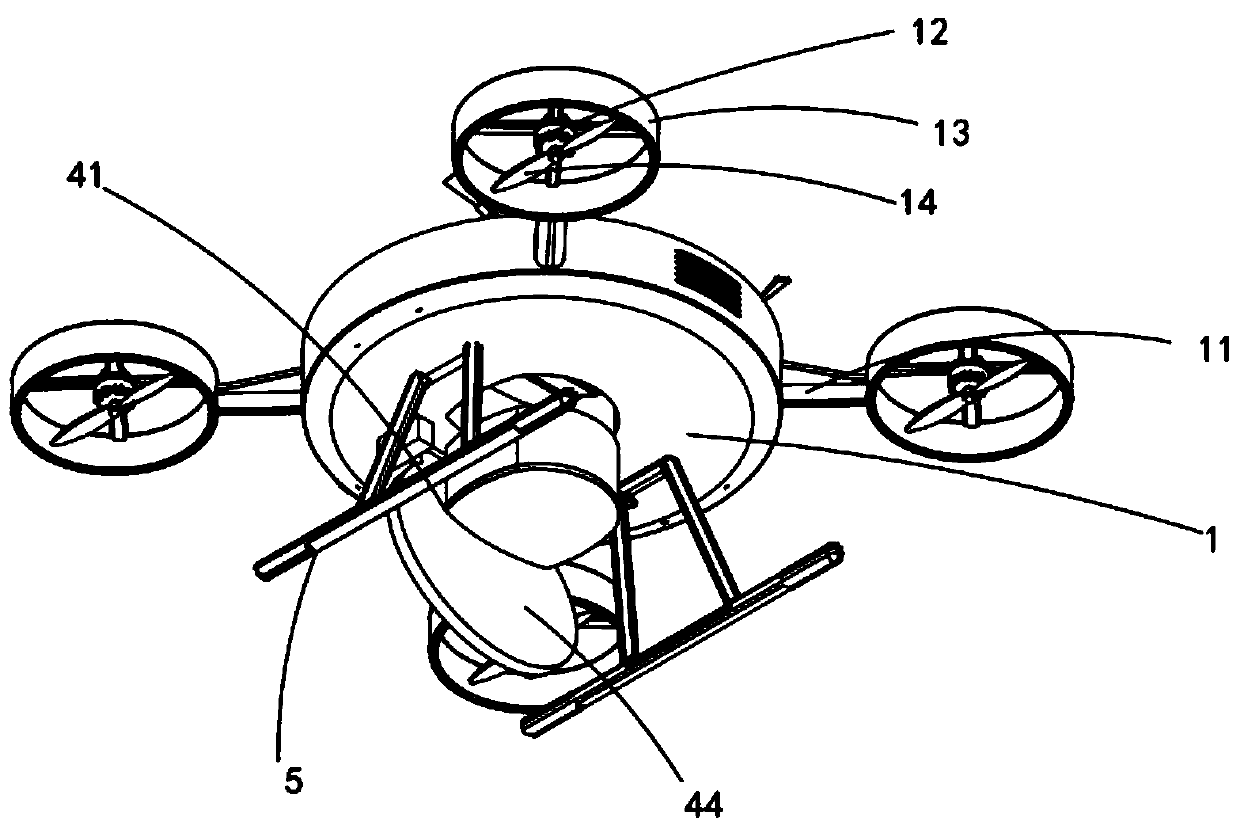

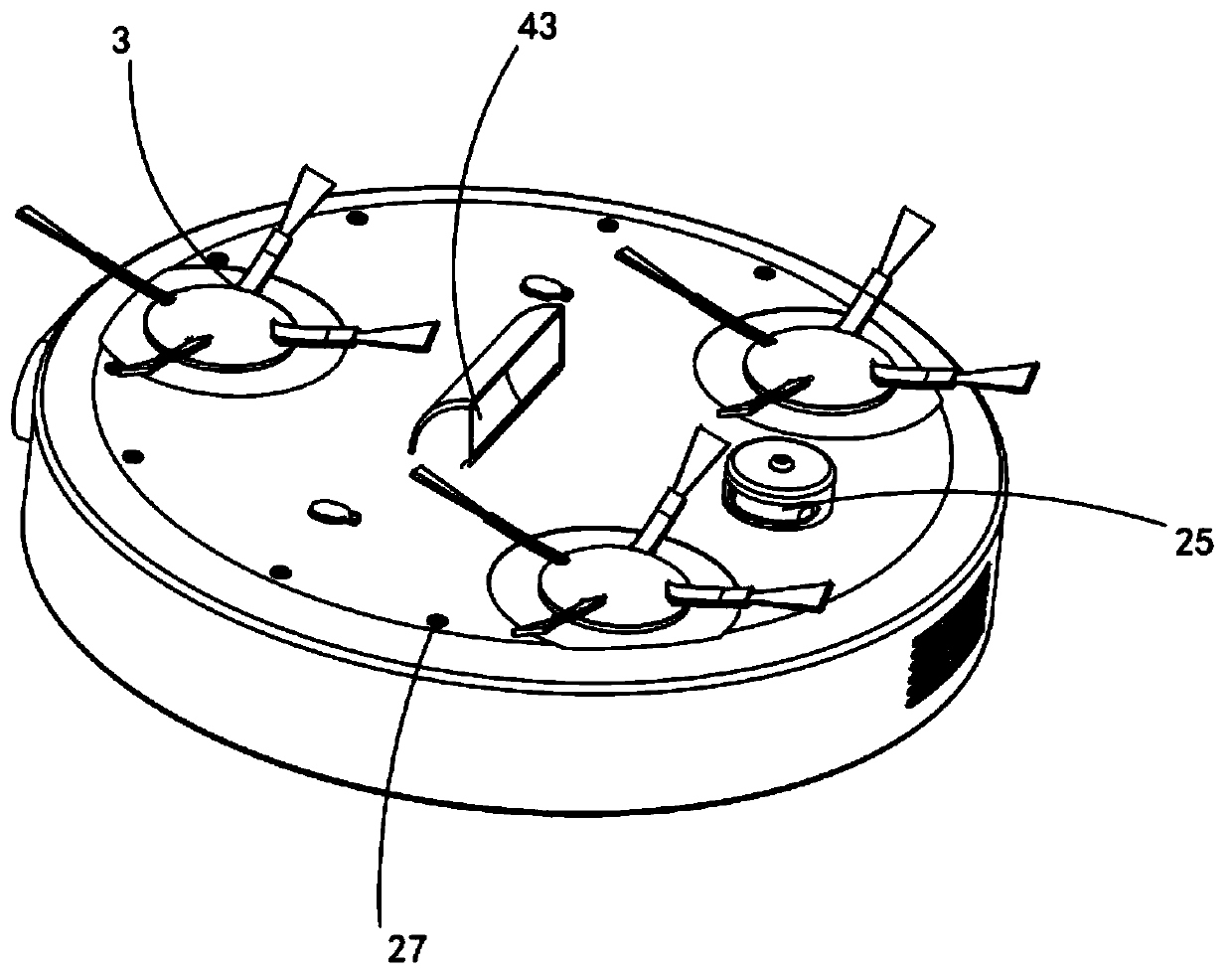

Unmanned aerial vehicle ceiling cleaning device

PendingCN110946527AImprove efficiencyExpand the cleanable areaCarpet cleanersFloor cleanersBrushless motorsUncrewed vehicle

Owner:GUANGXI UNIV

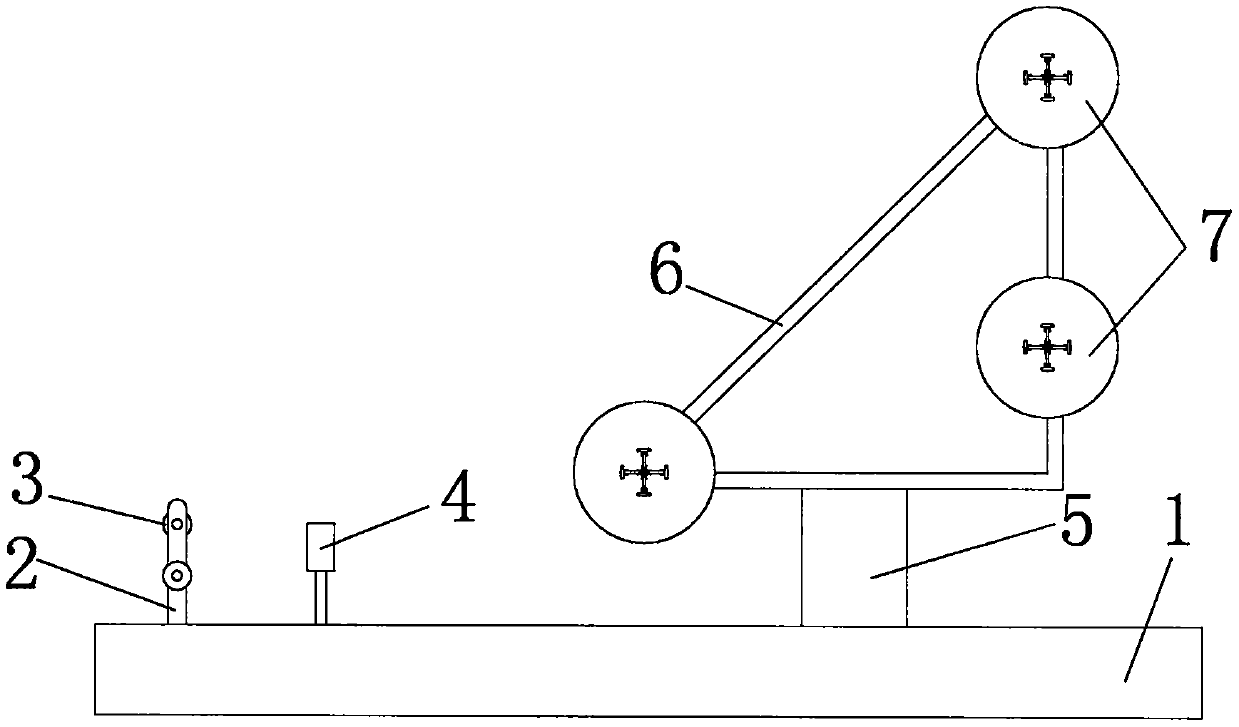

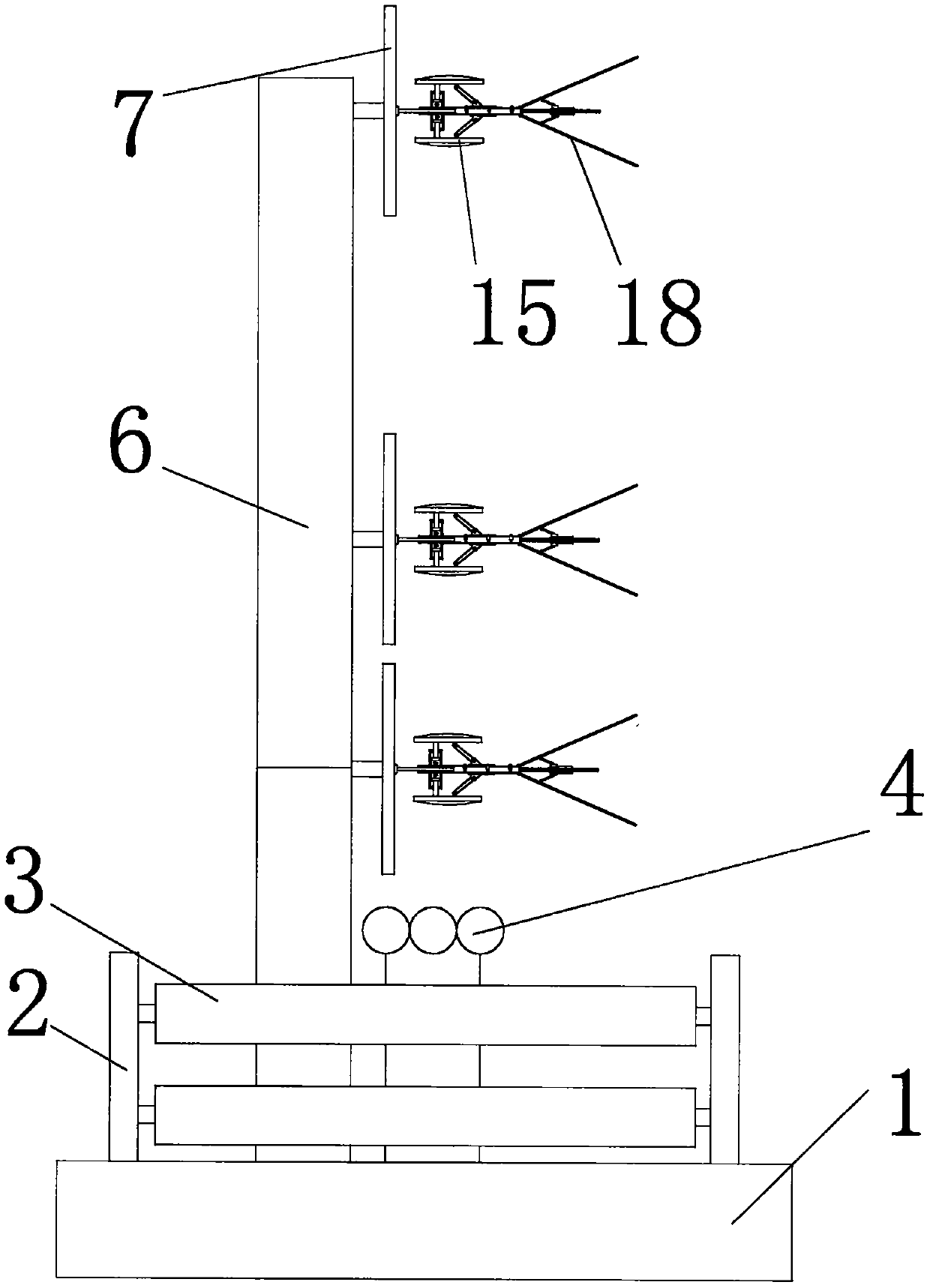

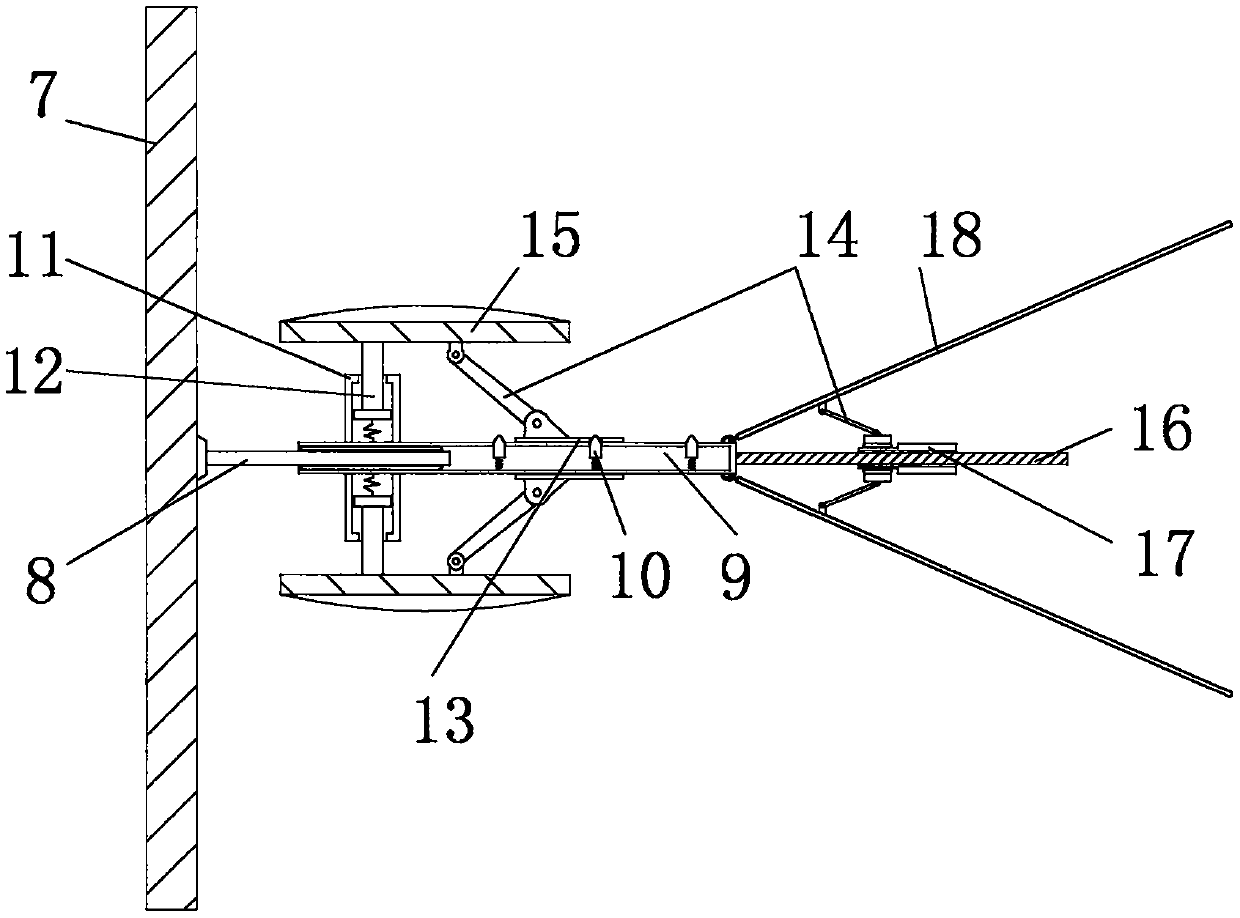

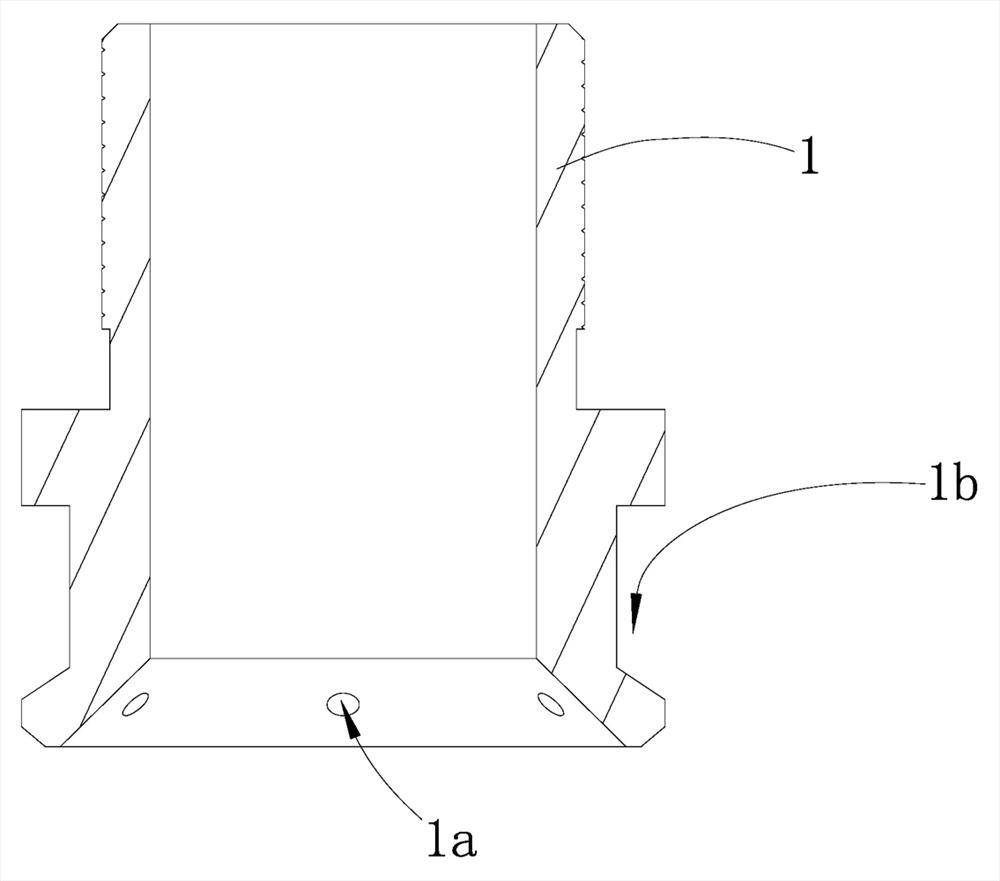

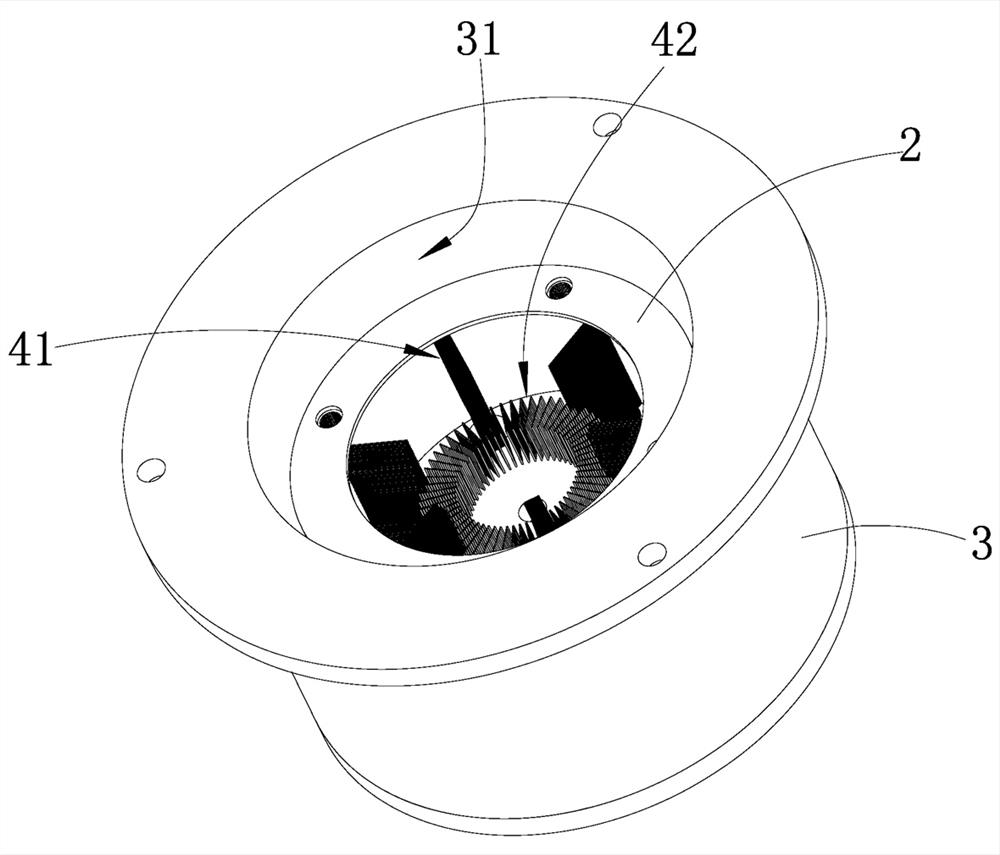

Wire unwinding device and wire unwinding method for weak current cable construction

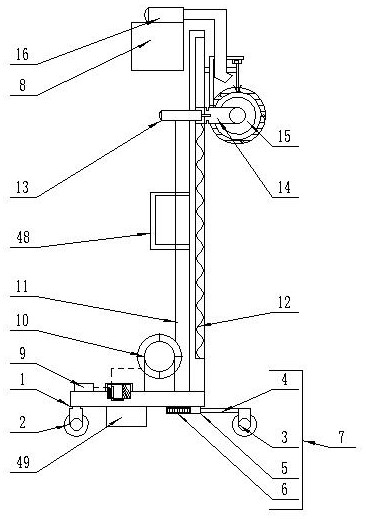

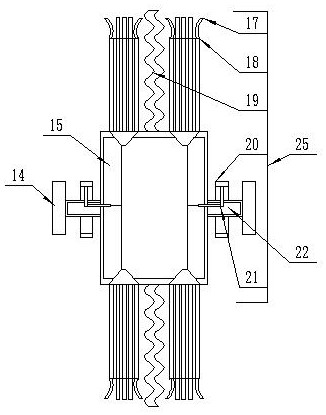

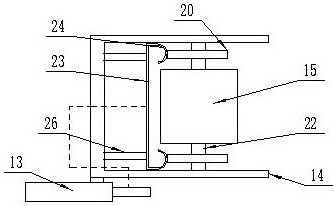

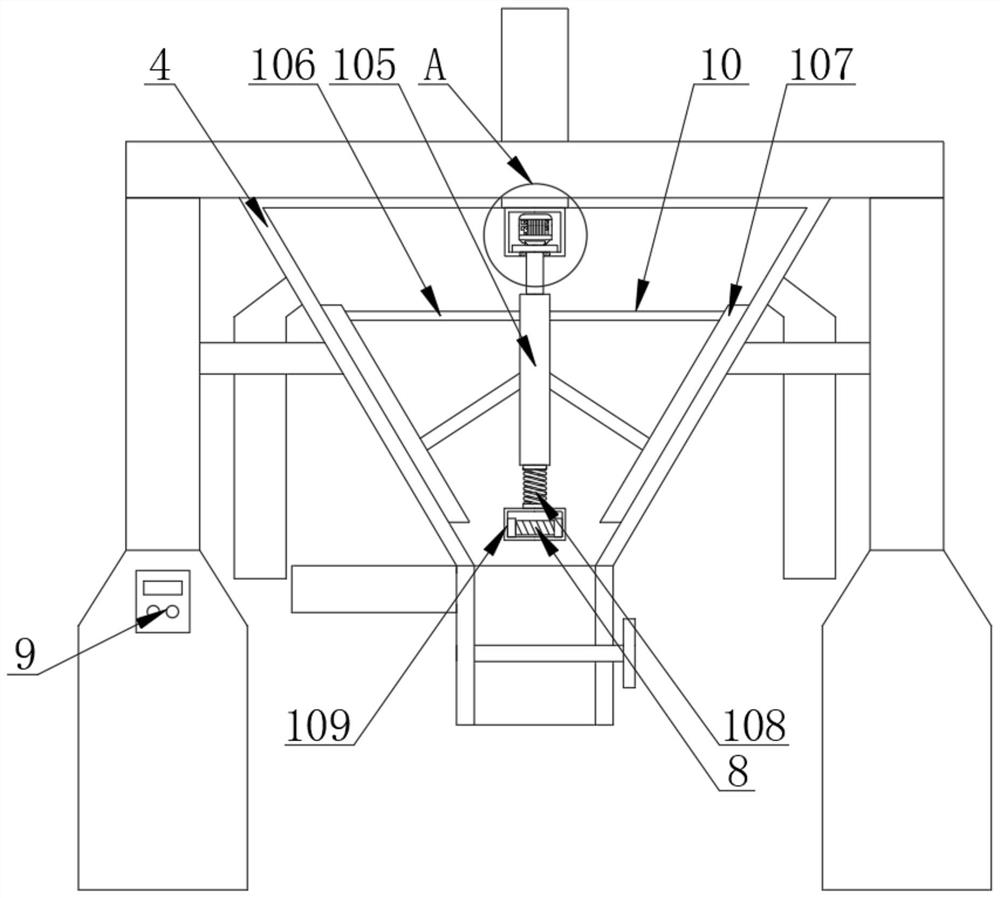

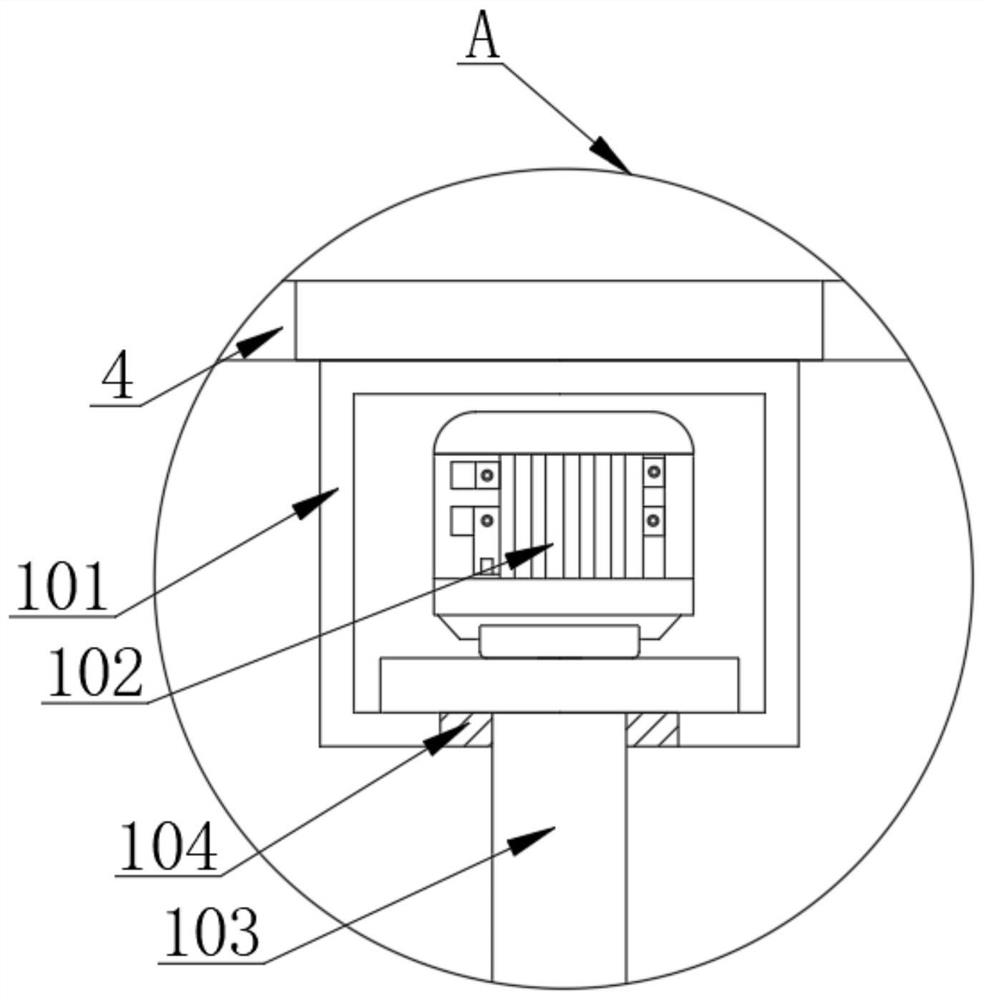

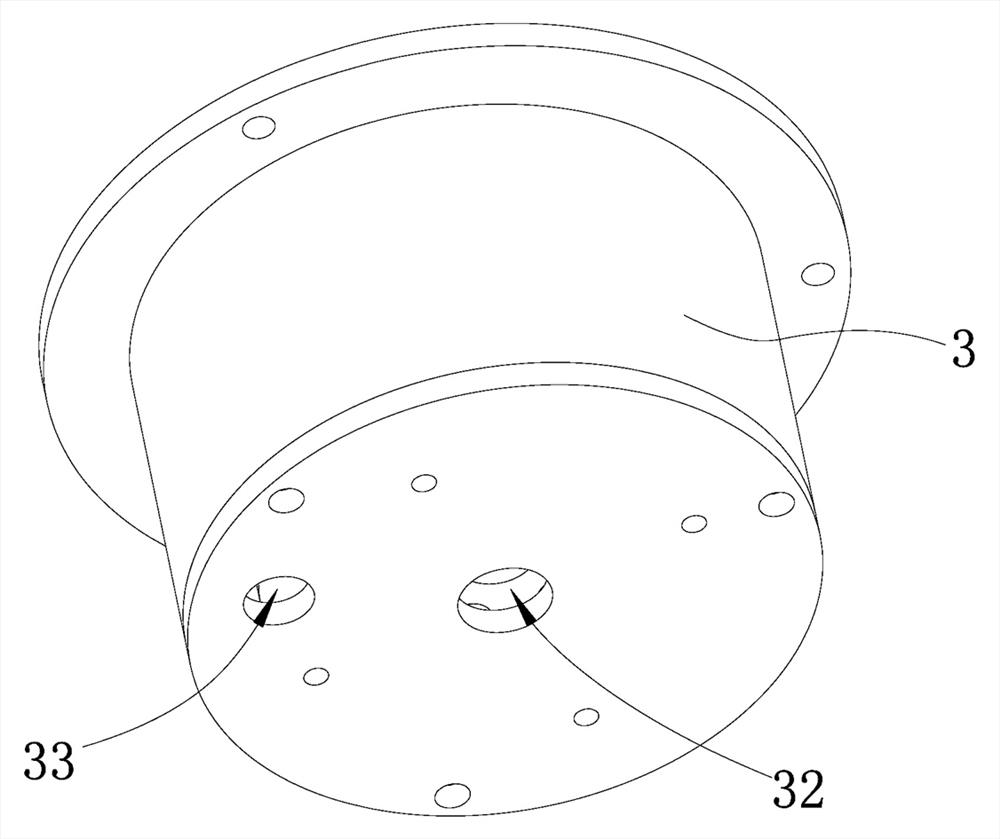

The invention discloses a wire unwinding device and a wire unwinding method for weak current cable construction. The wire unwinding device comprises a supporting base, wherein rotating shaft rods arewelded to the edge of the top of the supporting base, the outer walls of the rotating shafts rod are sleeved with roller brushes correspondingly, a wire combiner is fixedly installed at the position,on the side of the rotating shaft rods, of the top of the supporting base, wheel discs are fixedly installed on the side of a triangular support, horizontal rotating shafts are installed in centers ofthe wheel discs through bearings correspondingly, the outer walls of the horizontal rotating shafts are sleeved with rotating shaft sleeves correspondingly, sleeves are fixedly installed on the outerwalls of the sides of the rotating shaft sleeves correspondingly, supporting rods are embedded into the sleeves correspondingly, threaded rods are fixedly installed at the ends of the rotating shaftsleeves correspondingly, and the outer walls of the threaded rods are in threaded connection with threaded sleeves correspondingly. According to the wire unwinding device for the weak current cable construction, cables of different sizes can be arranged more conveniently, the functionality of the device is enhanced, the cleaning capacity of surfaces of the cables is improved, and the surfaces of the cables are not prone to being damaged.

Owner:鼎腾(天津)科技发展有限公司

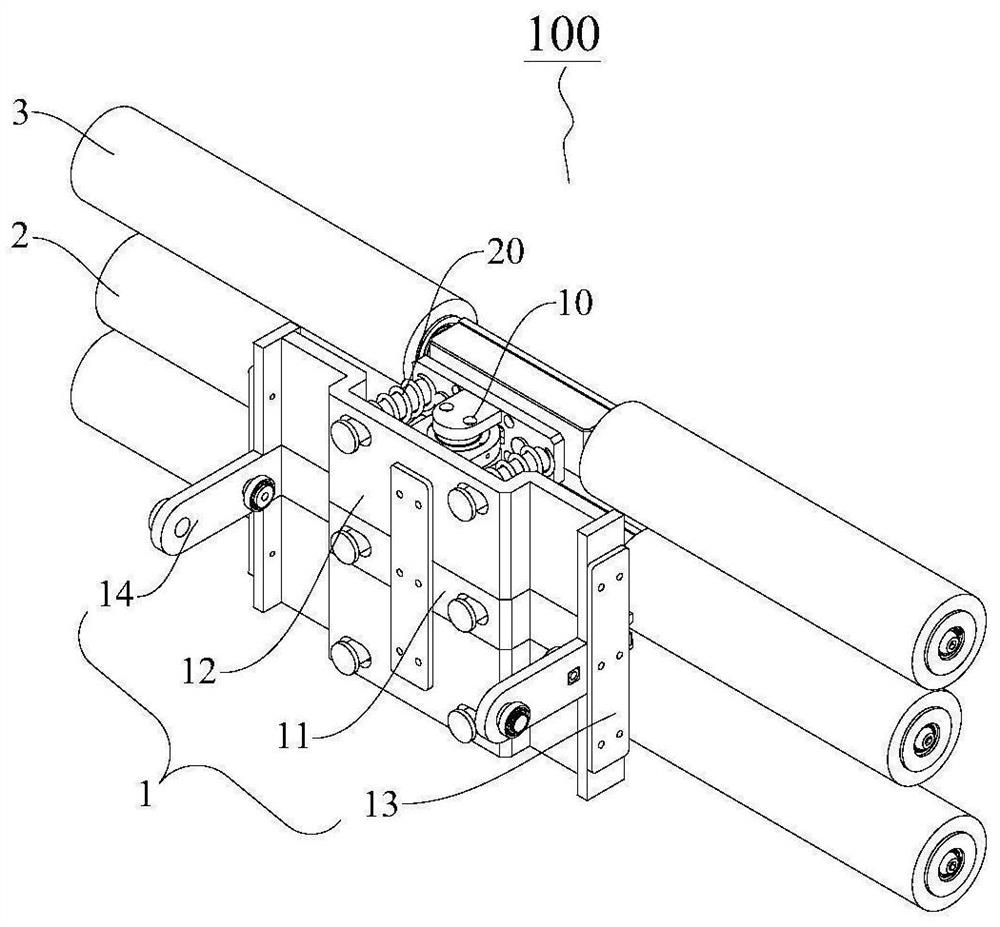

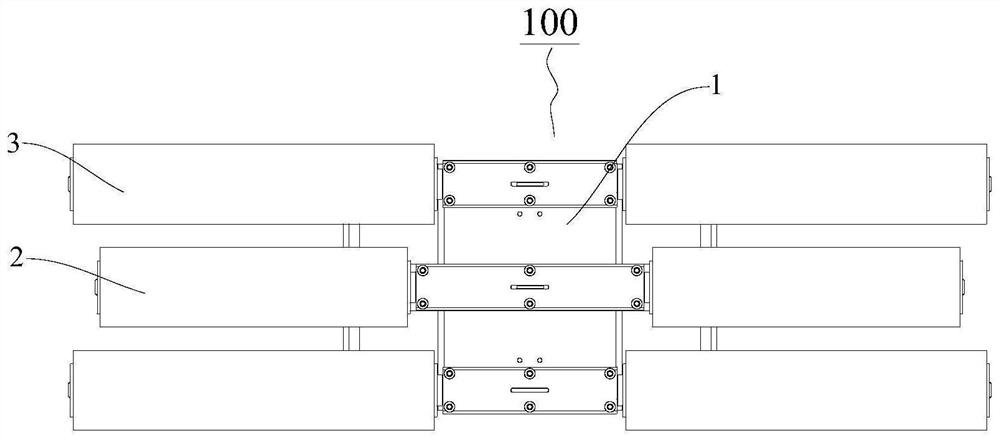

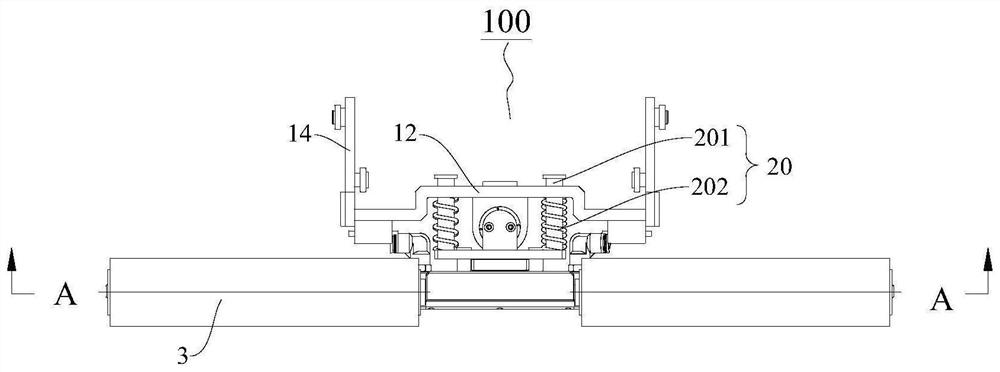

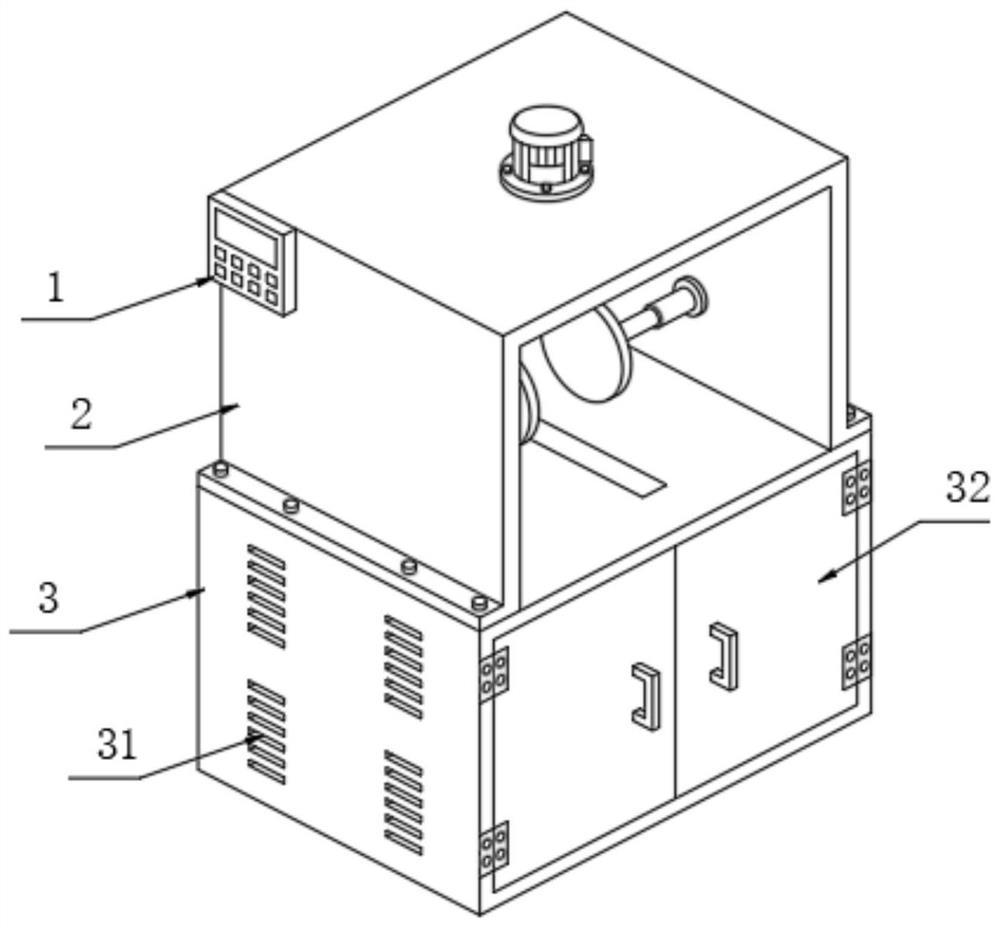

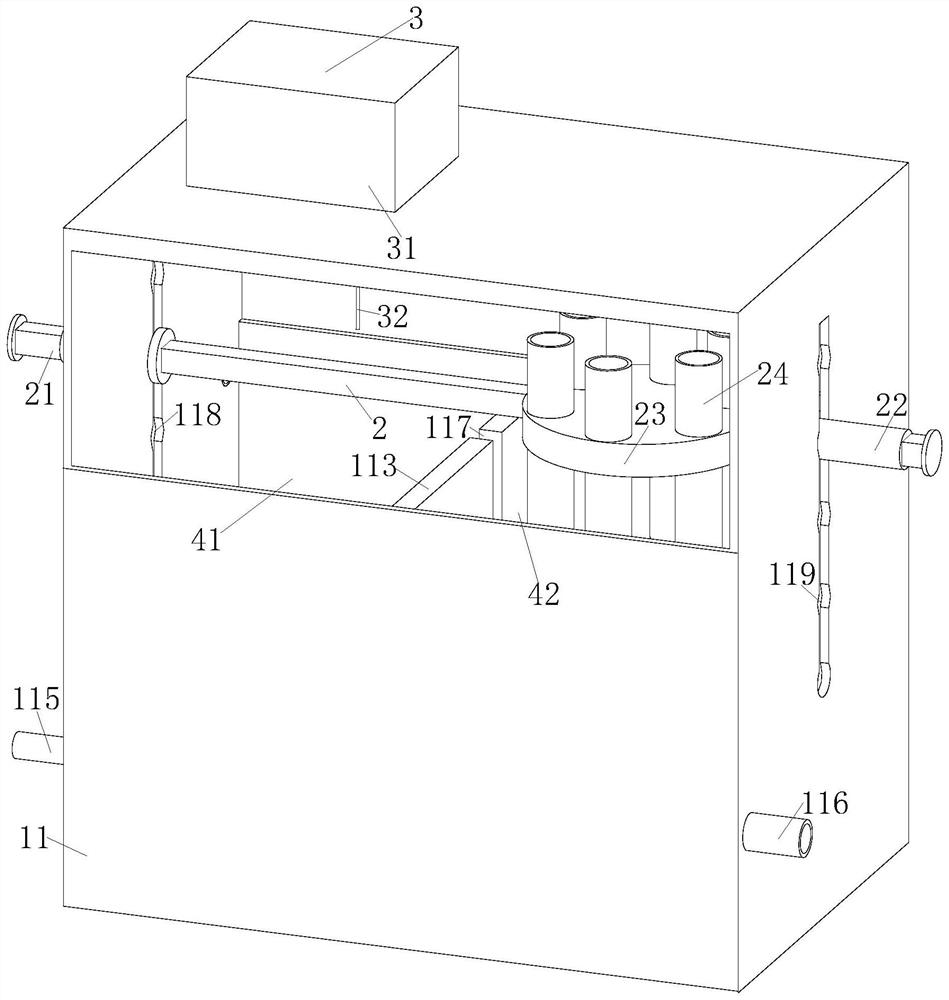

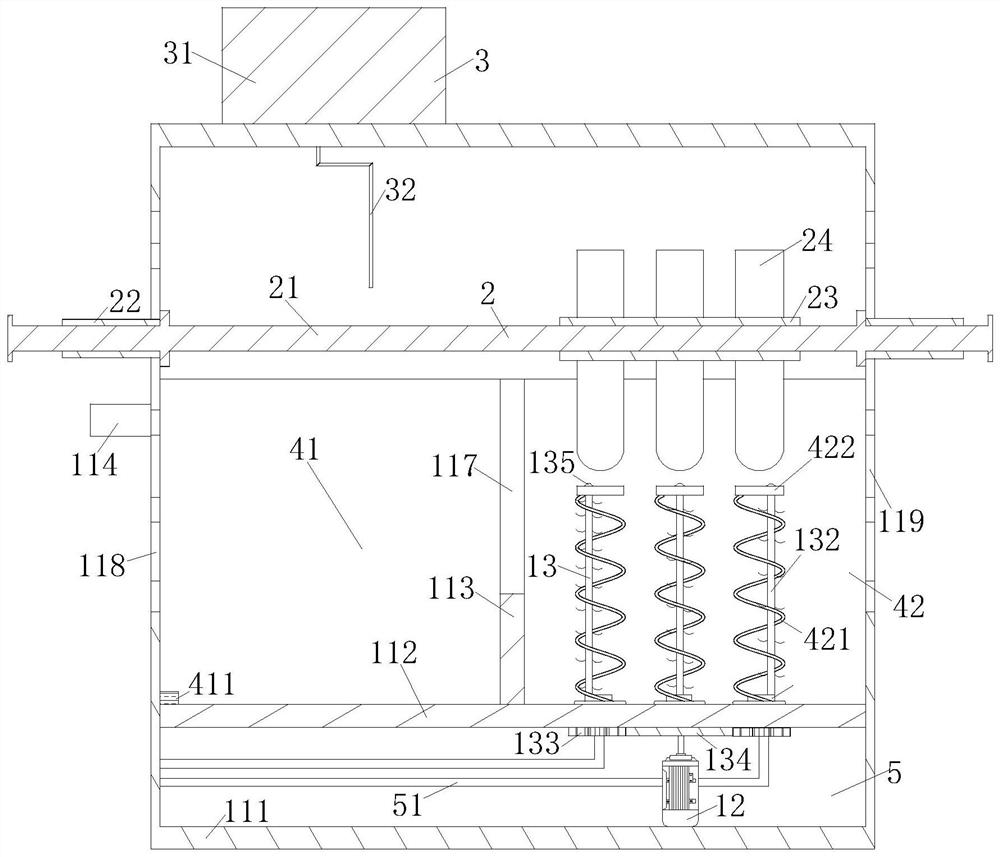

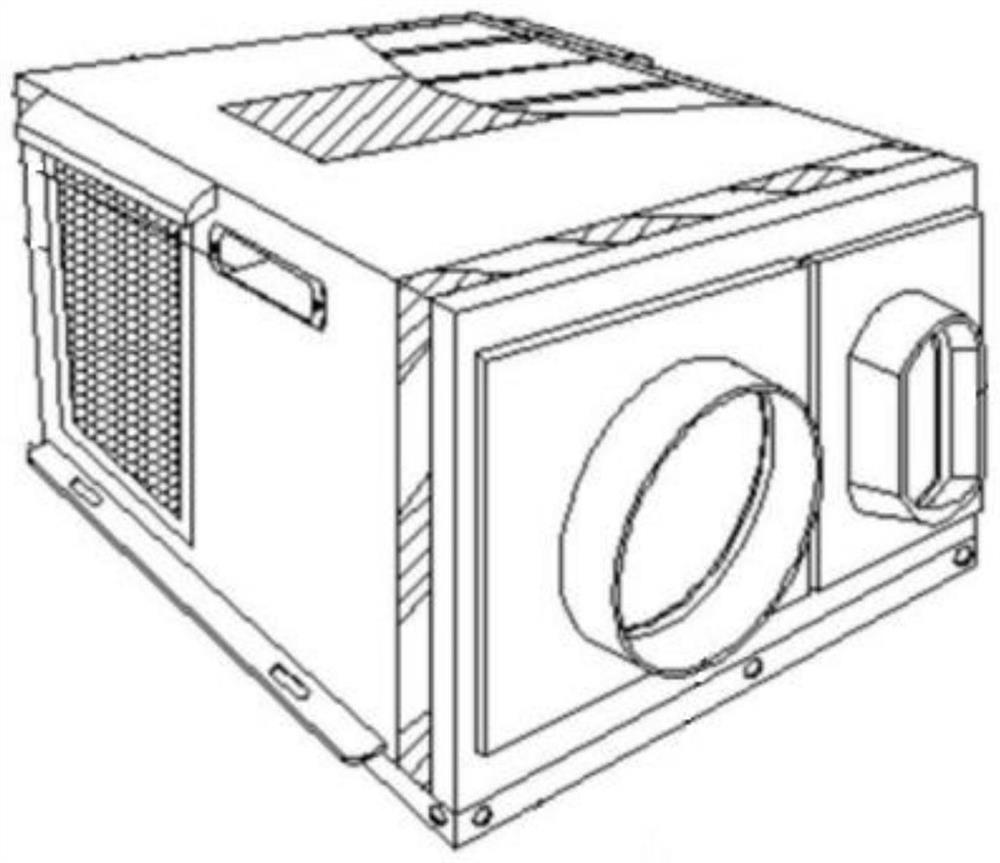

Belt rolling brush scraper cleaning device

The invention provides a belt rolling brush scraping plate cleaning device which comprises an upper box body, a lower box body and a control box, the upper box body is fixedly connected to the upper portion of the lower box body, an electric rolling brush is installed in the upper box body, a belt inlet and a belt outlet are formed in the front side edge and the rear side edge of the upper box body respectively, a scraping plate machine assembly is installed in the lower box body, and the control box is connected with the control box. And the electric rolling brush is in control connection with the control box. By arranging the upper box body and the electric rolling brush, dust can be removed from the belt in a relatively closed environment in the upper box body, so that dust raising is avoided, and meanwhile, damage to the belt caused by a hard scraper can also be avoided; and by arranging the lower box body and the scraper assembly, dust of the upper box body can be received and scraped away, and therefore the effect of removing the dust is achieved.

Owner:BIG PAWER ELECTRICAL TECH XIANGYANG

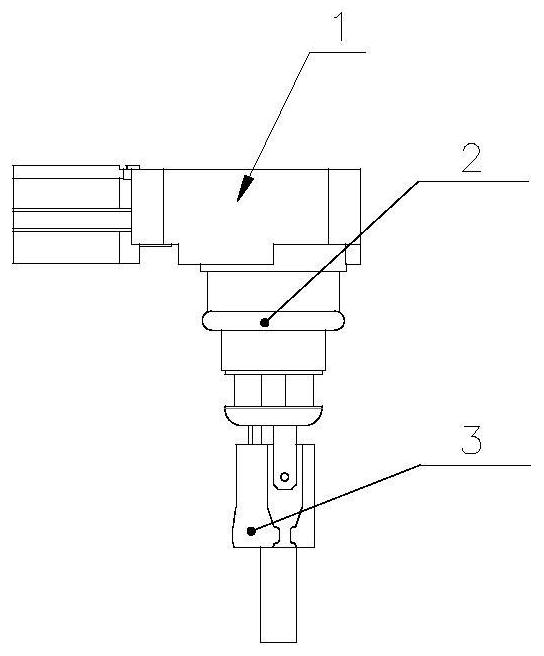

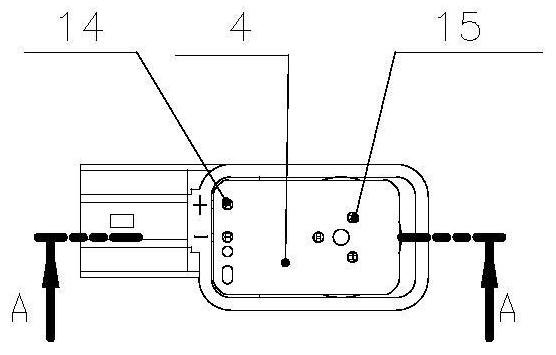

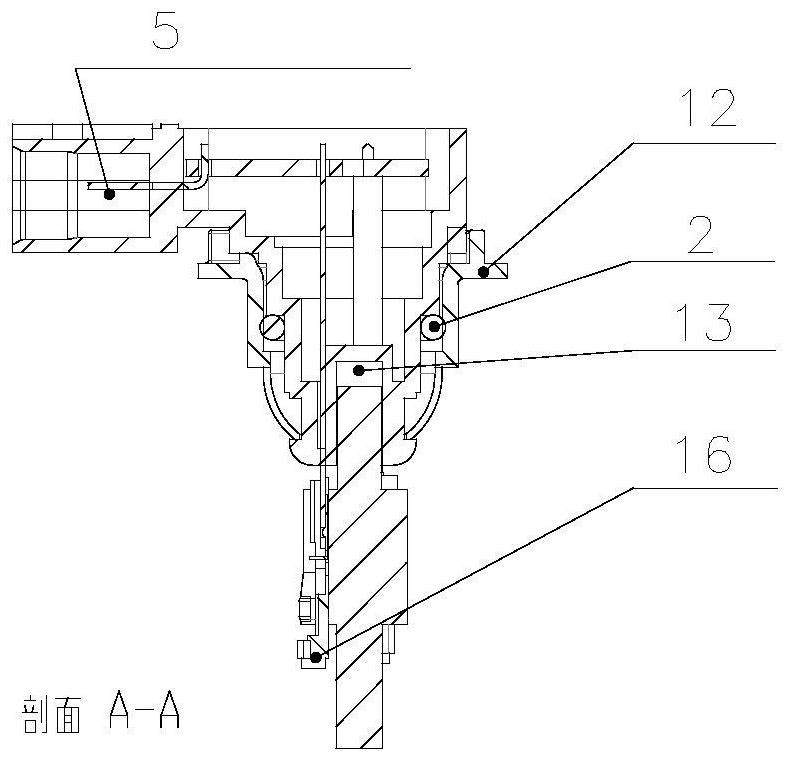

Wiping mechanism for polyurethane foaming mixing head

PendingCN112643960AImprove cleaning efficiencyReasonable structureCleaning using toolsPolymer scienceElectric machinery

Owner:蚌埠中正聚氨酯发泡设备有限公司

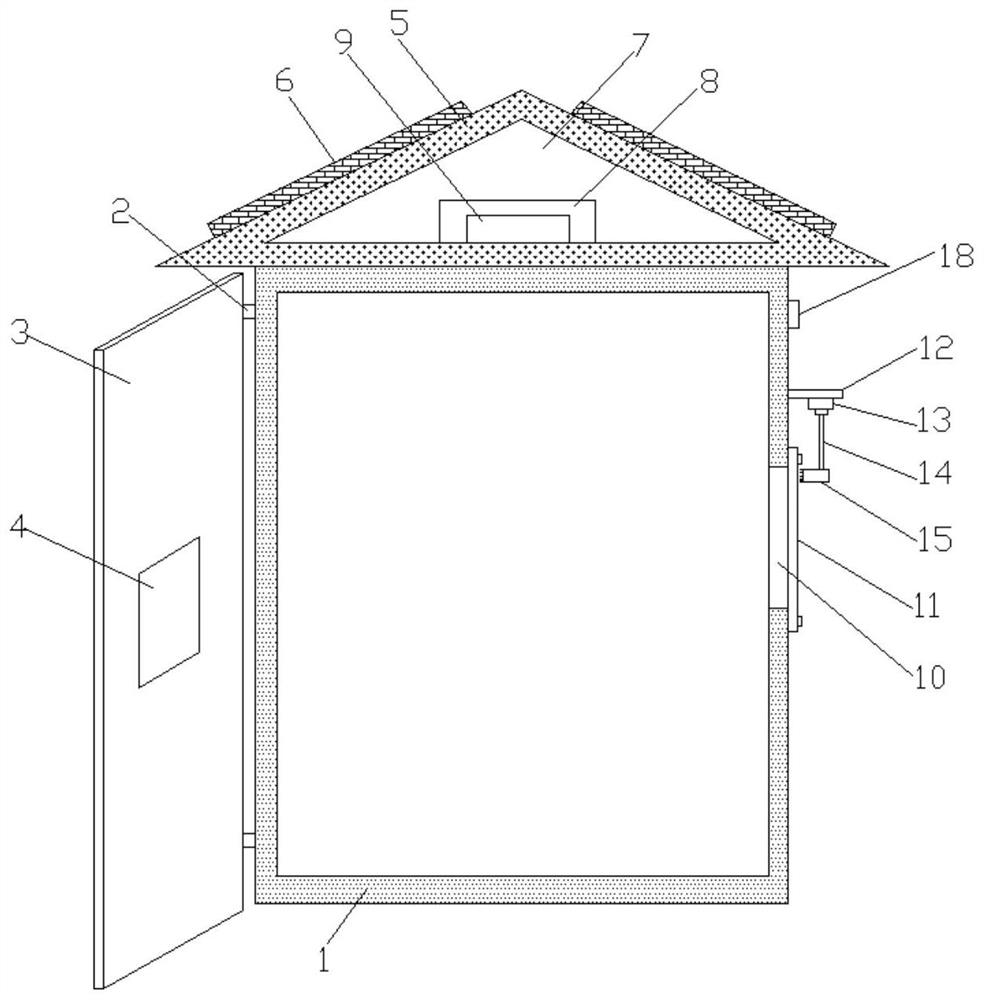

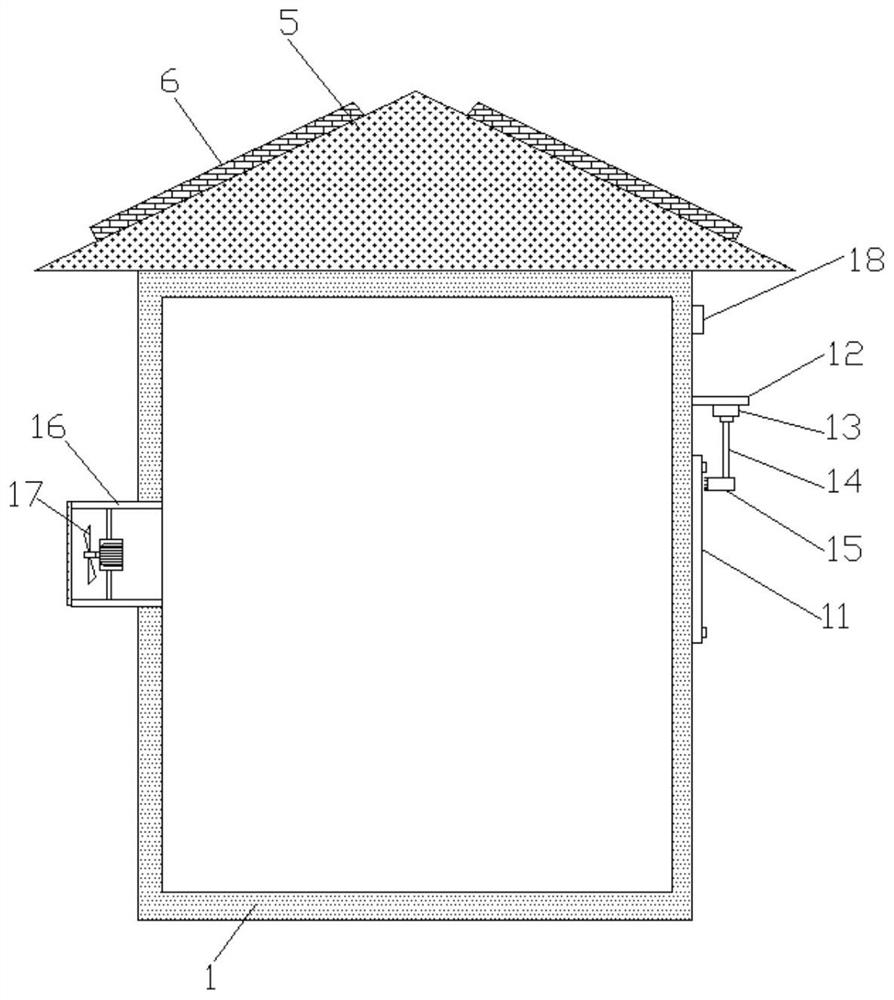

Ventilation equipment for elevator

ActiveCN114353226AAvoid pollutionSmooth transmissionMechanical apparatusLighting and heating apparatusElectric machineryStructural engineering

Owner:安徽舒马克电梯股份有限公司

Independent driver for brushless pump assembly

PendingCN113949194AEasy to installRealize seamless upgradeAssociation with control/drive circuitsSupports/enclosures/casingsBrushless motorsElectric machine

Owner:CHONGQING PINGSHAN TK CARBURETOR CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap