Ash bucket feeding equipment for thermal power plant

A technology for thermal power plants and feeding equipment, which is applied in the direction of conveyors, conveyor objects, conveyor control devices, etc., and can solve problems such as the inability of the feeding equipment to prevent leakage, the low efficiency of vibrating motor ash loosening, and the reduction of the service life of the ash hopper. , to avoid the continuous increase in the amount of dust, avoid the reduction of service life, and ensure the effect of health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

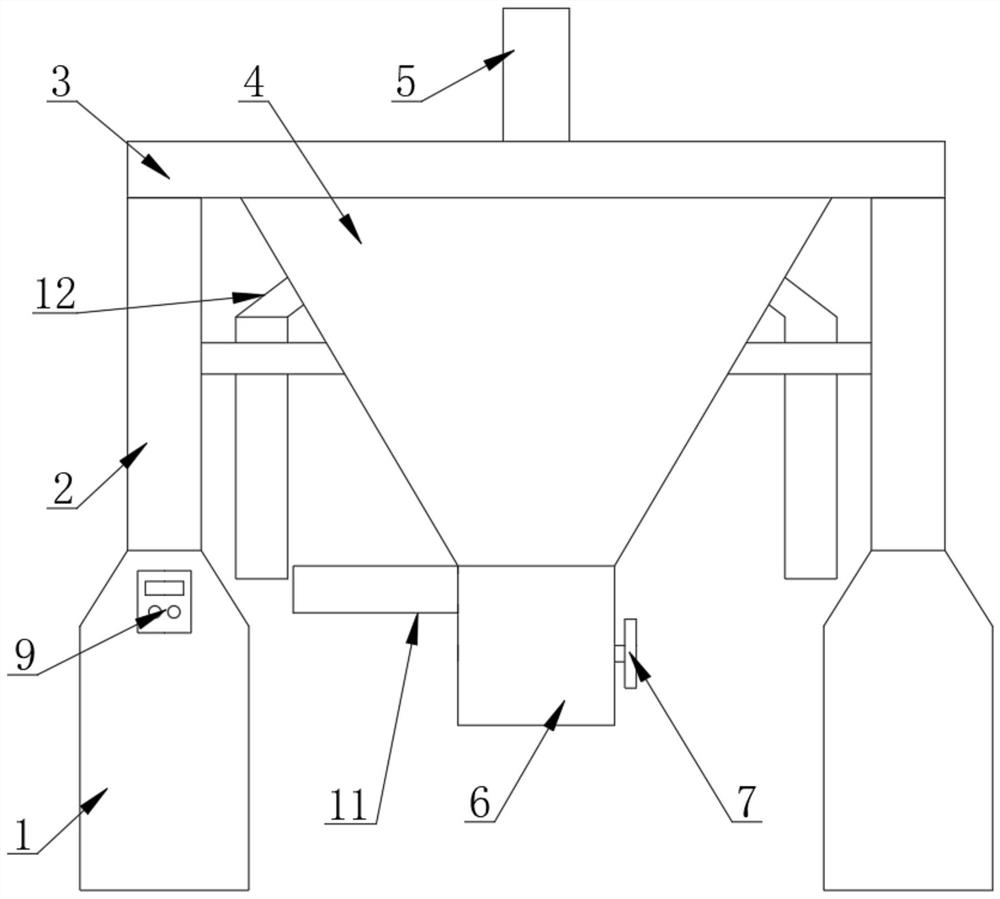

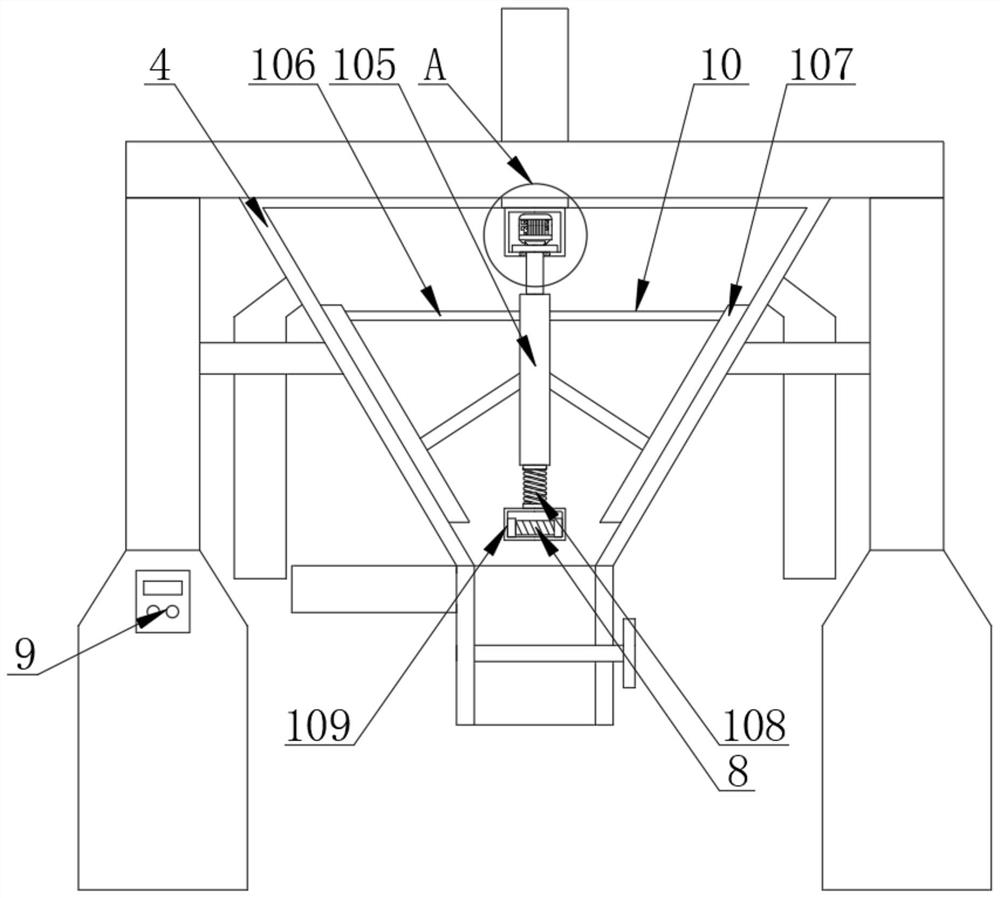

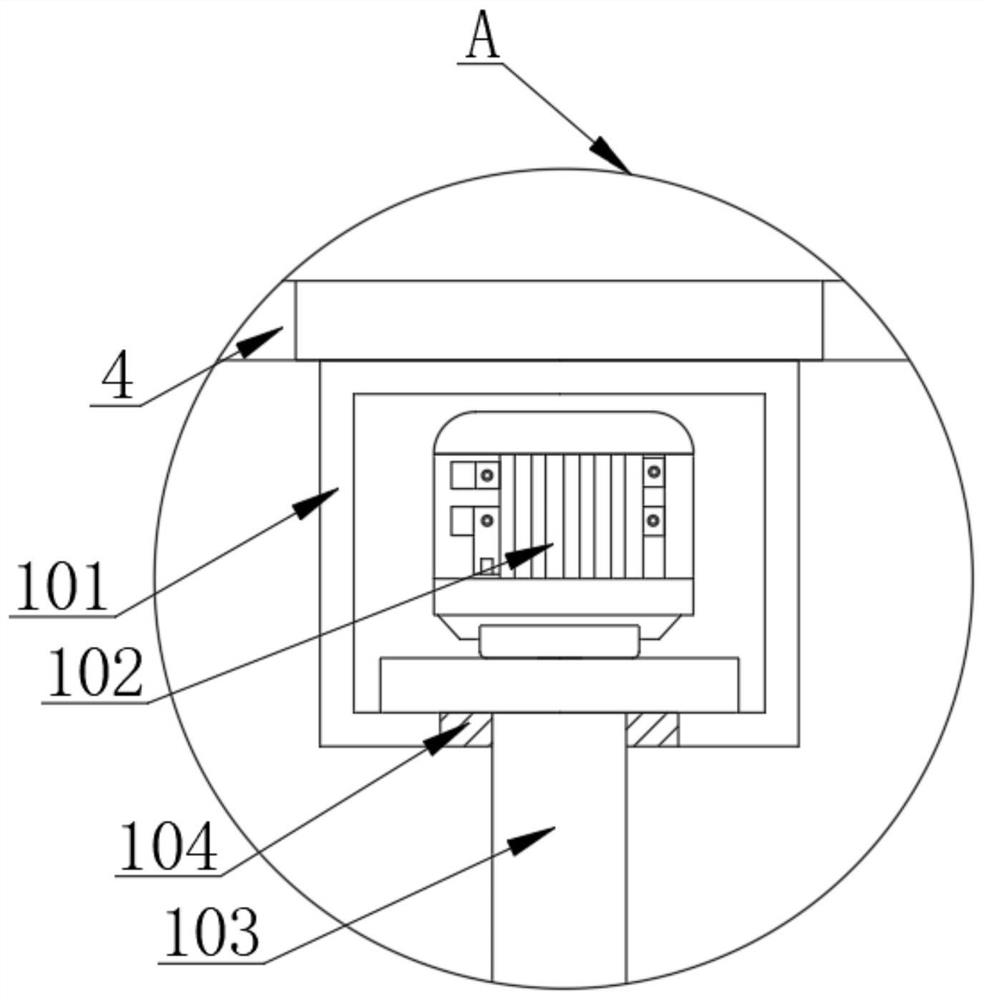

[0030] as attached figure 1 to attach Figure 8 An embodiment of the present invention provides an ash hopper feeding device for a thermal power plant, including a base 1 and a vibrating motor 8, a support column 2 is fixedly installed on the top of the base 1, and a support plate is fixedly installed on the top of the support column 2 3. An ash hopper 4 is fixedly installed on the bottom of the support plate 3, an ash inlet pipe 5 is fixedly connected to the top of the ash hopper 4, and an ash outlet pipe 6 is fixedly connected to the bottom of the ash hopper 4, and the ash outlet pipe 6 is fixedly connected to the bottom of the ash hopper 4. A valve 7 is movably installed on one side of the pipe 6, a control panel 9 is detachably installed on the front o

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap