Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

110results about "Drying gas arrangements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

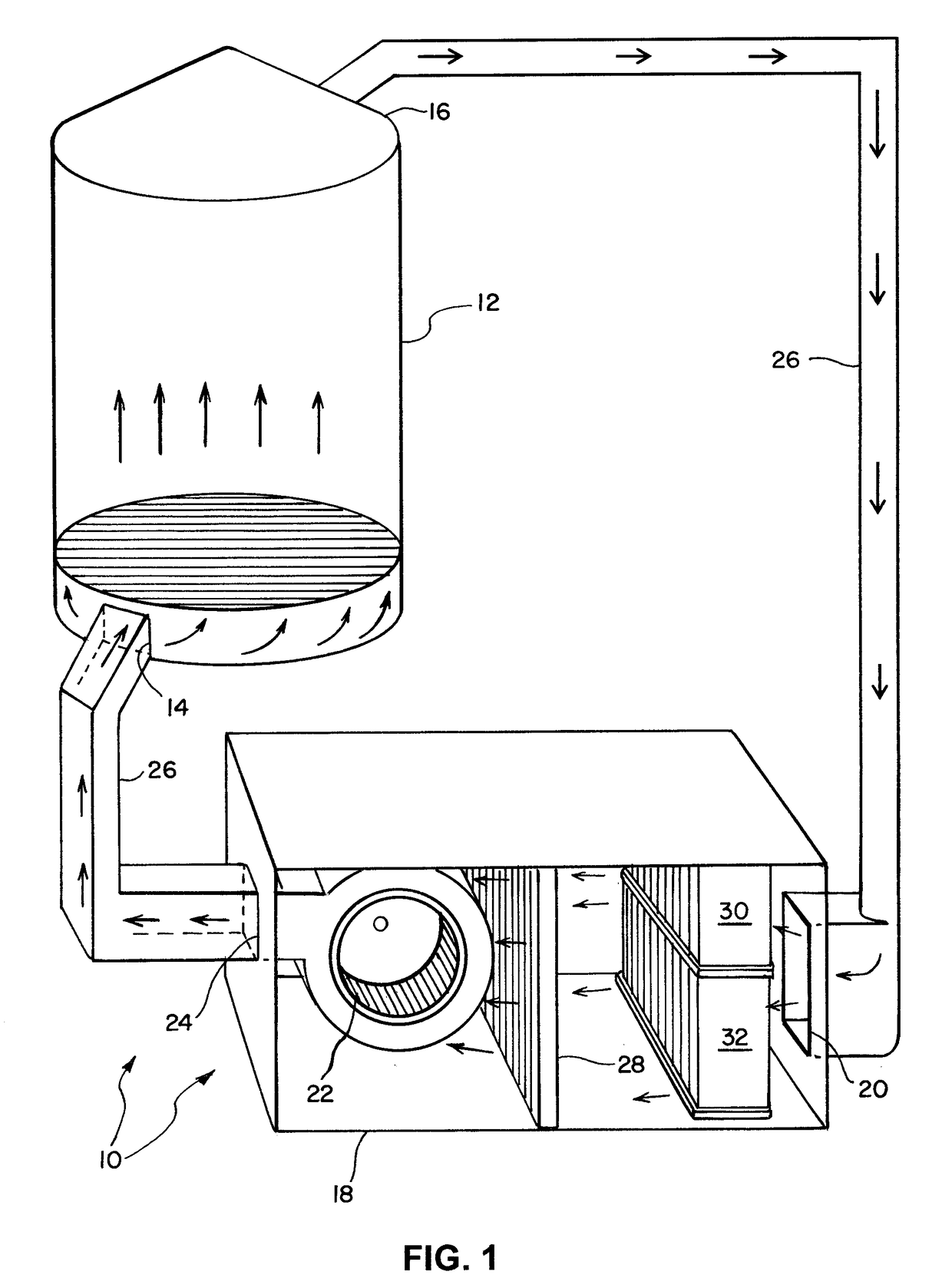

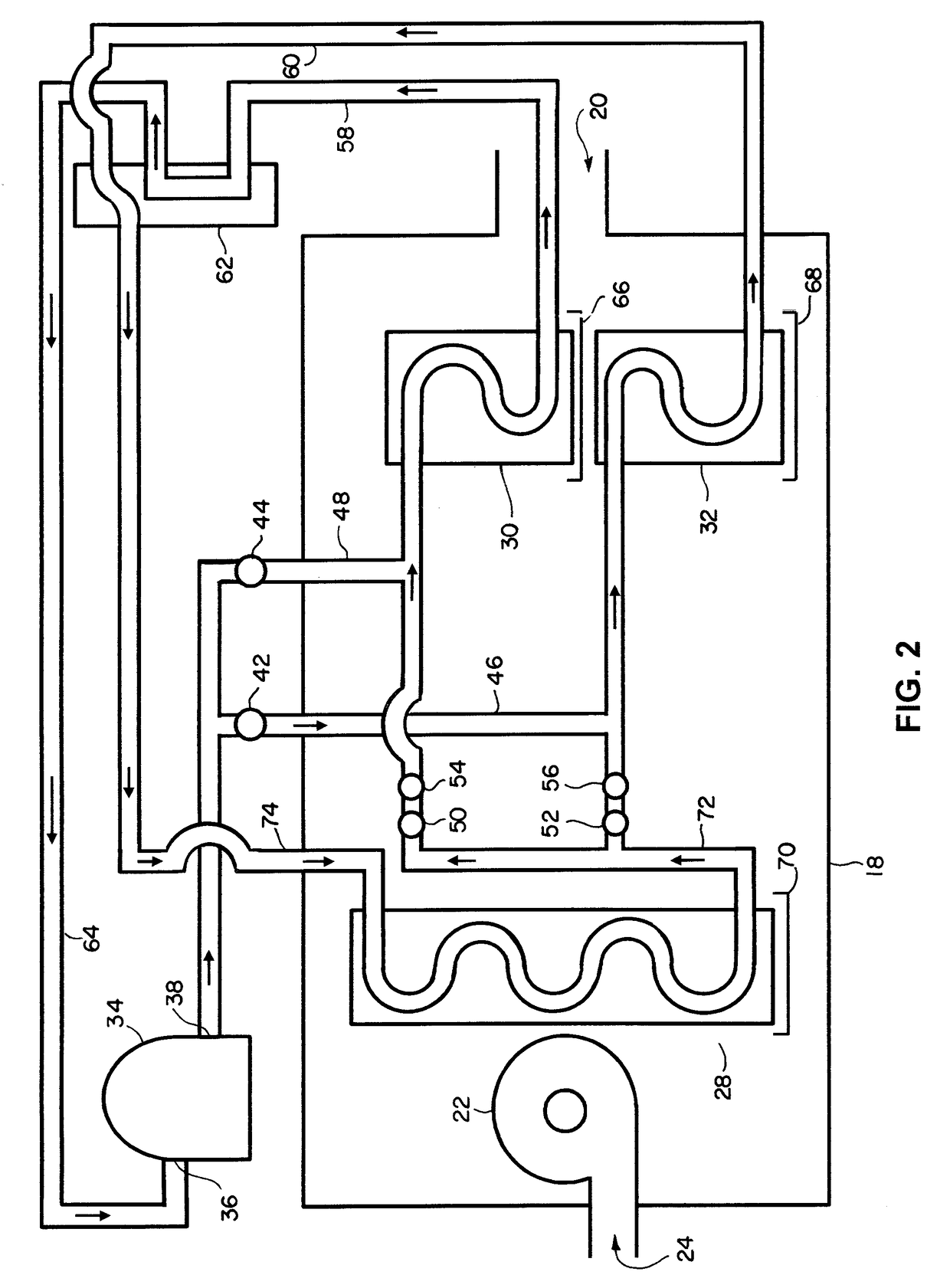

Laundry dryer/venting system interlock

InactiveUS20100000118A1Drying solid materials with heatDrying gas arrangementsAuto regulationPower flow

While a dryer is running, continuously automatically monitor operation of a dryer venting system, and continuously automatically determining if the dryer venting system is operating improperly, and if it is determined that the dryer venting system is operating improperly then automatically disabling the dryer. If the dryer starts running then automatically turning on a booster fan. Operation of booster fan is monitored by sensing the current drawn. Monitoring operation of the venting system through a first controller and automatically disabling the dryer through a second controller. Automatically turn off the booster fan if the dryer is not running. Automatically adjust operating parameters of the dryer venting system in an attempt to operate the venting system properly, and disabling the dryer if the venting system continues to operate improperly after adjustment. Check to determine if the dryer is drawing current to indicate the dryer is running.

Owner:CUBE INVESTMENTS

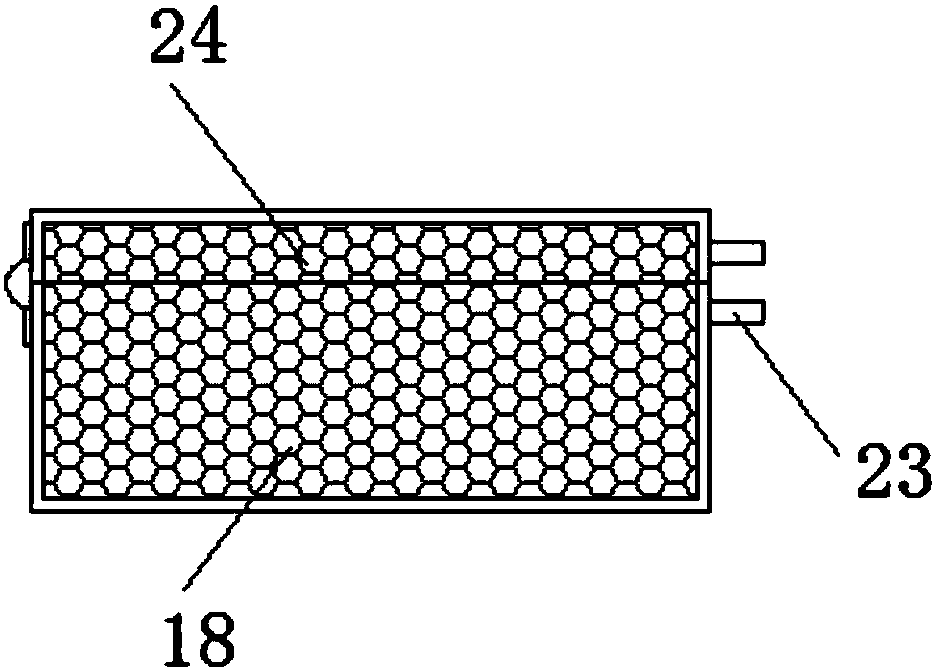

Sand screening device for bridge construction

Owner:赣州市兴顺辉科技有限公司

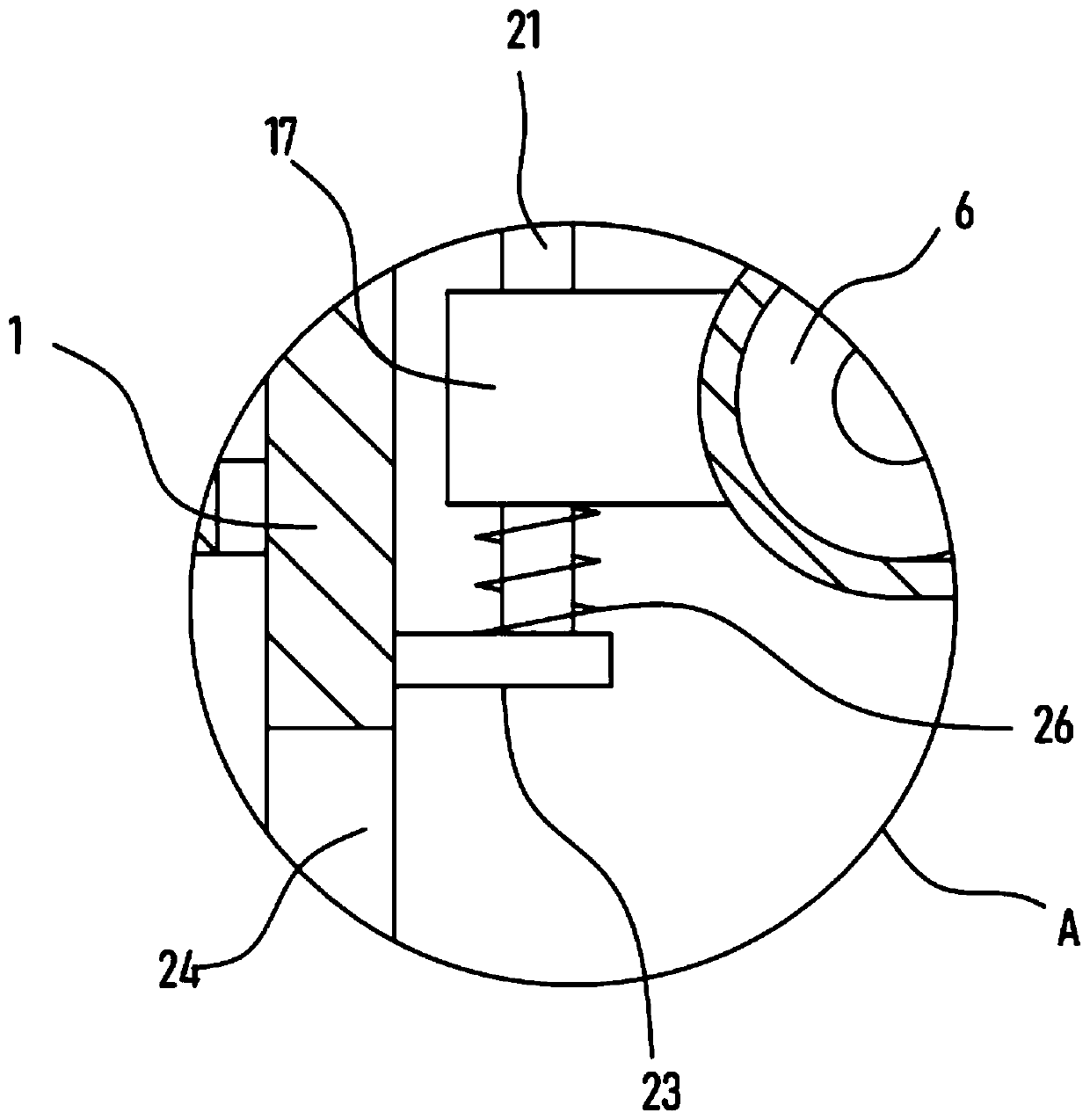

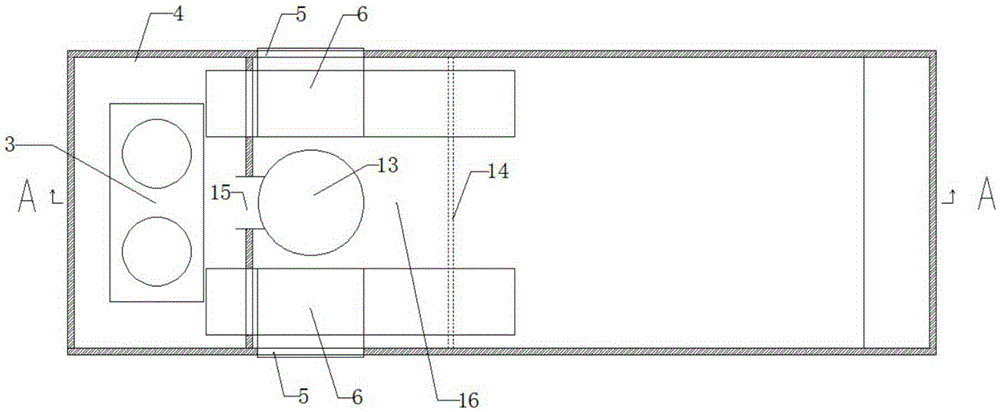

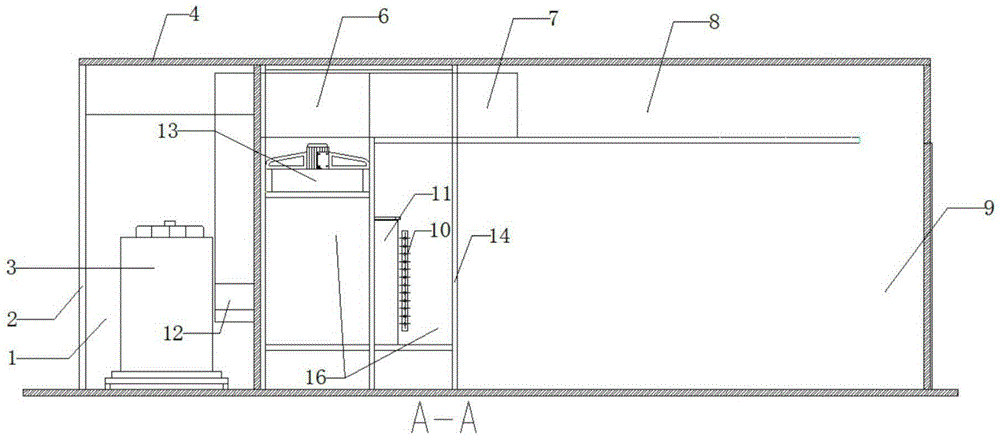

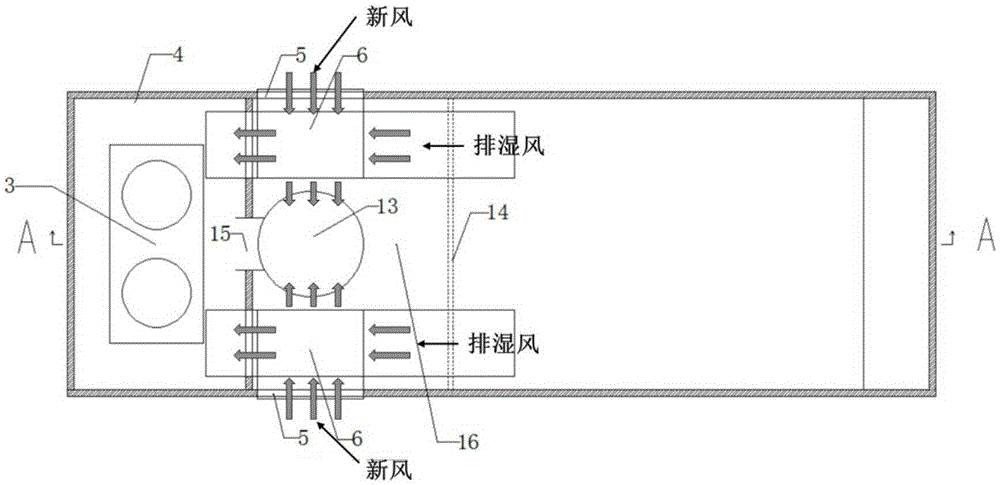

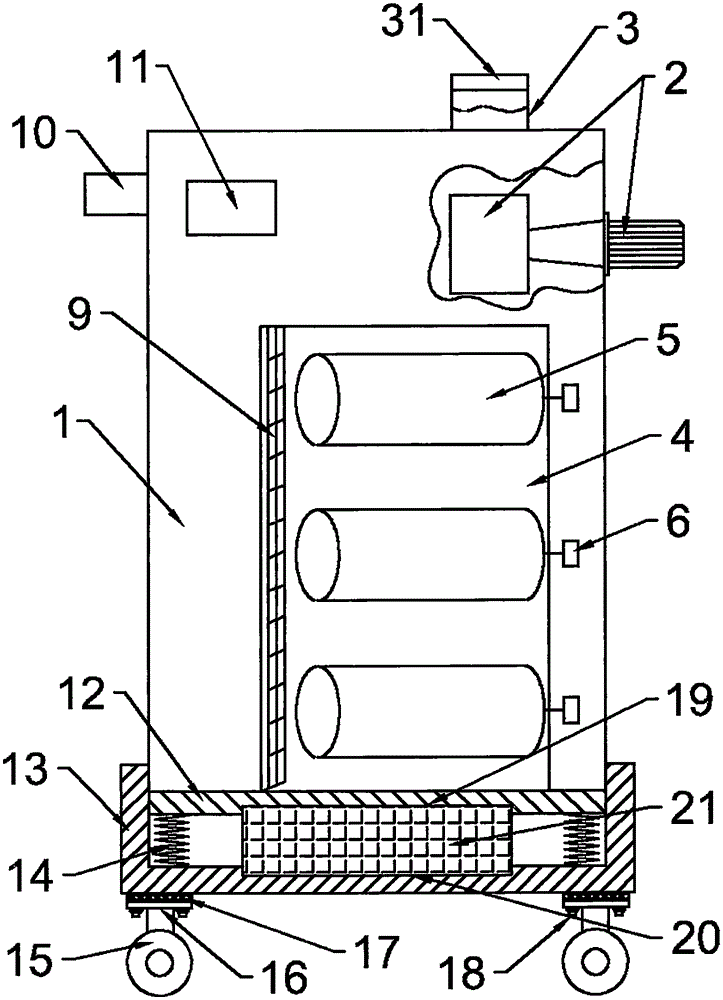

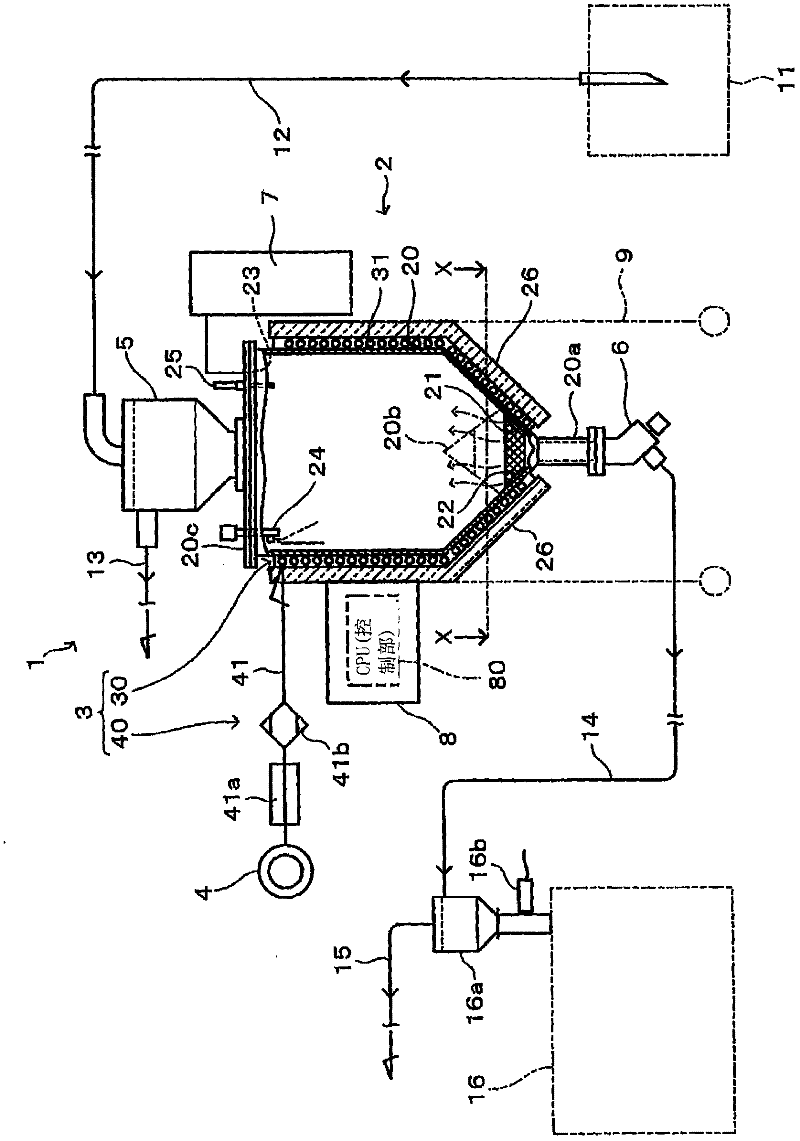

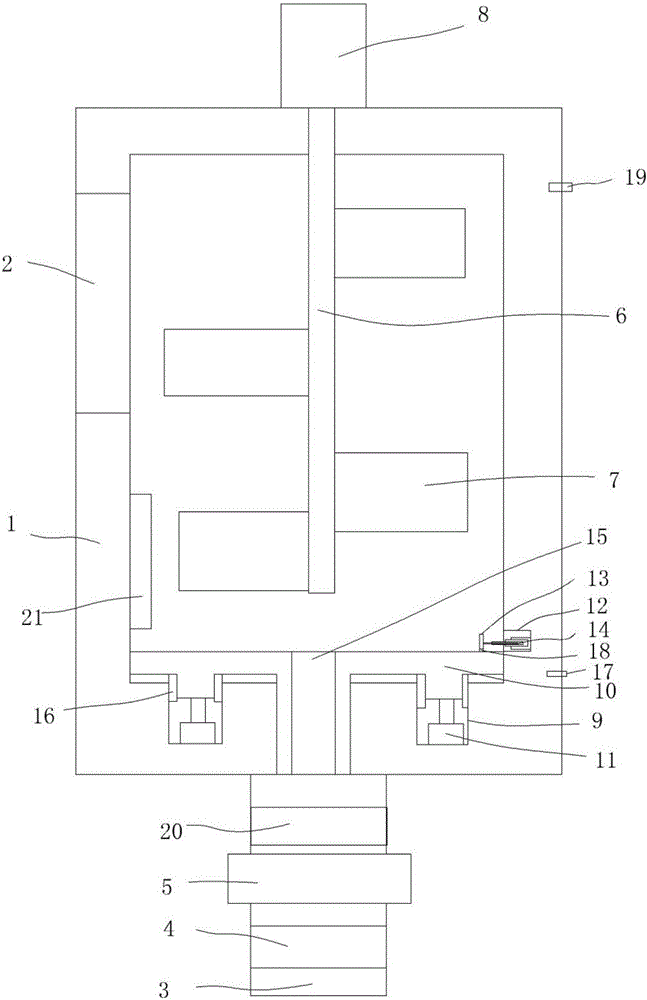

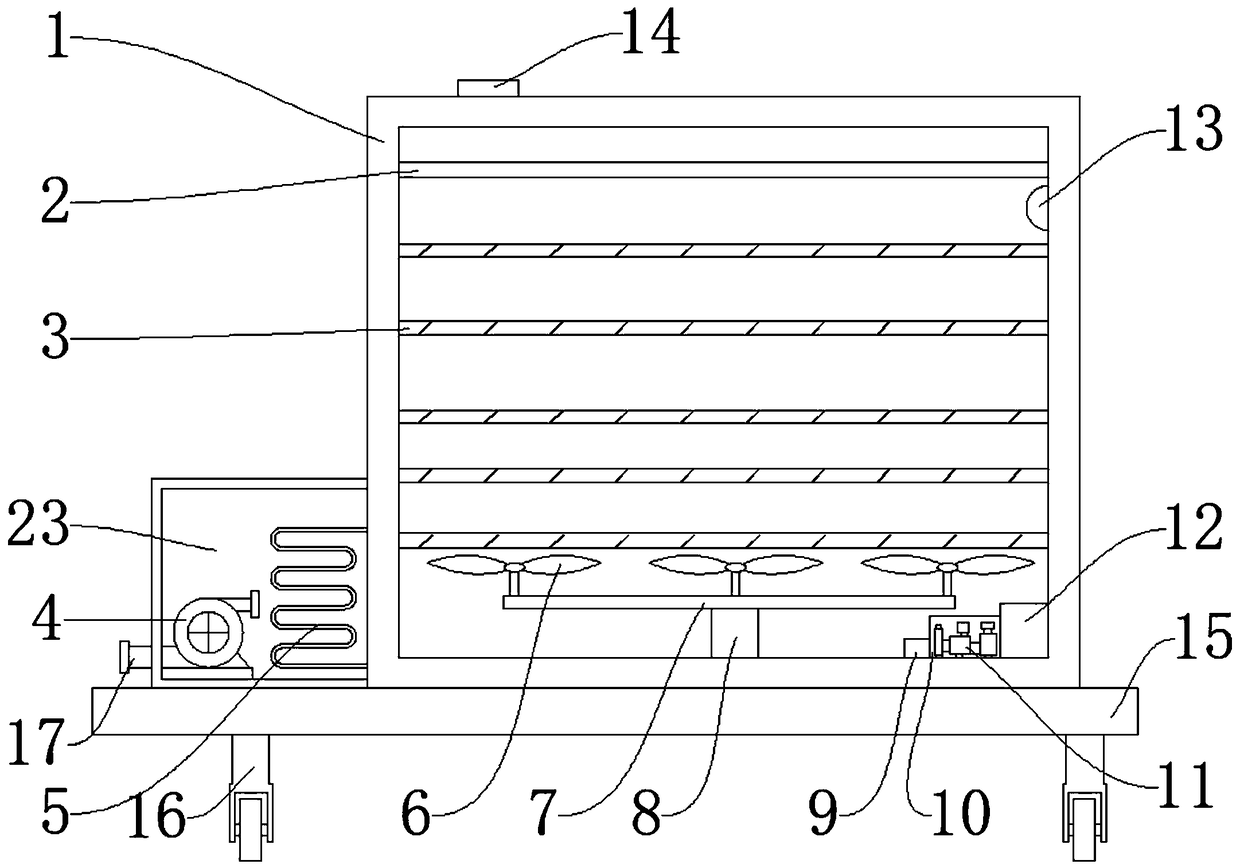

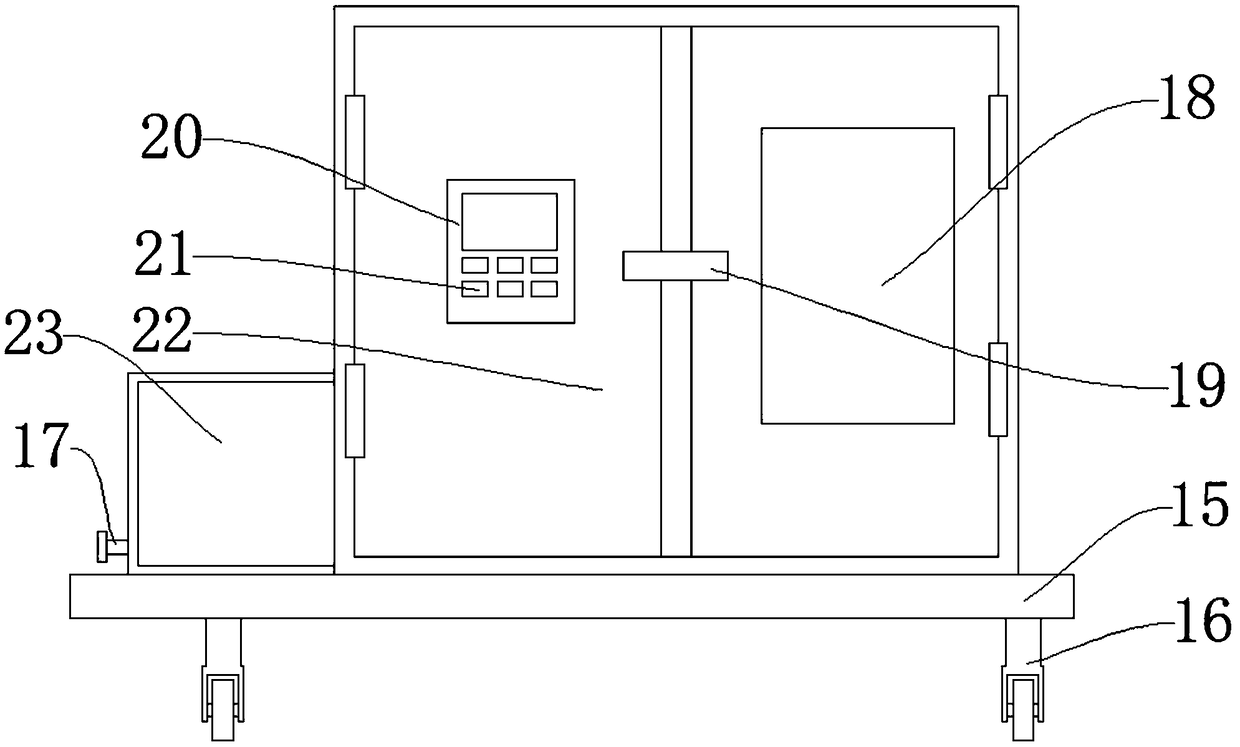

Sealed heat pump drying system

ActiveCN105258455AReduce heat lossReduce energy consumptionDrying solid materials with heatDrying gas arrangementsEngineeringFresh air

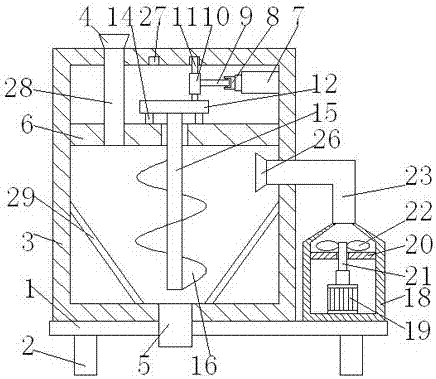

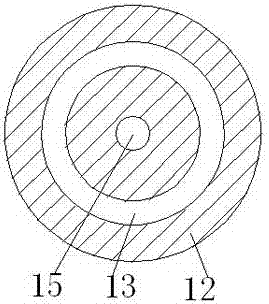

The invention relates to the field of heat pump drying systems, in particular to a sealed heat pump drying system. The sealed heat pump drying system mainly comprises a heat pump main machine room (1) which is integrally arranged with a drying room (9) and a heating room (16), a main draught fan, an air valve (15), a pair of moisture discharging cylinders (7) and a pair of fresh air valves (5). The heat pump main machine room (1) is separated from the heating room (16) through a partition plate, and an automatic door (2) is arranged on the face opposite to the partition plate. The main draught fan (13) is arranged in a heating room (16). The pair of moisture discharging cylinders (7) is symmetrically arranged on the two sides of the top in the heating room (16) respectively. The fresh air valves (5) are arranged in the positions, opposite to the main draught fan (13), of the two side walls of the heating room (16) respectively. According to the sealed heat pump drying system, a heat pump unit is separated from the outside environment, waste heat exhausted by the drying room can be fully utilized, by the heat pump unit, and the heat loss of the system when the temperature of the outside environment is low is reduced; and the source of fresh air is selected by comparing the temperature of the heat pump main machine room and the temperature of the outside environment, energy consumption of preheating the fresh air is reduced, and the energy saving effect of the system is improved.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

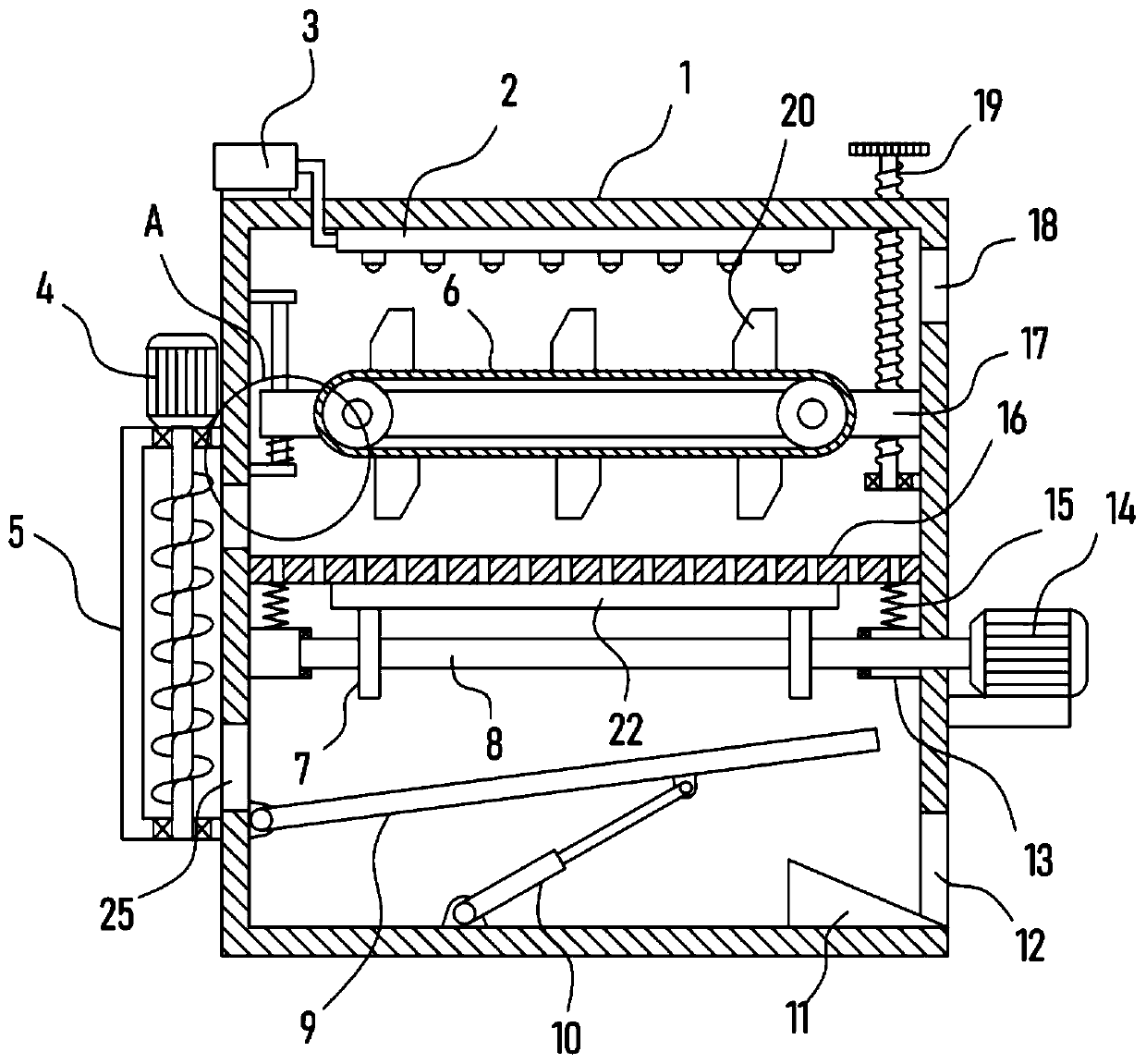

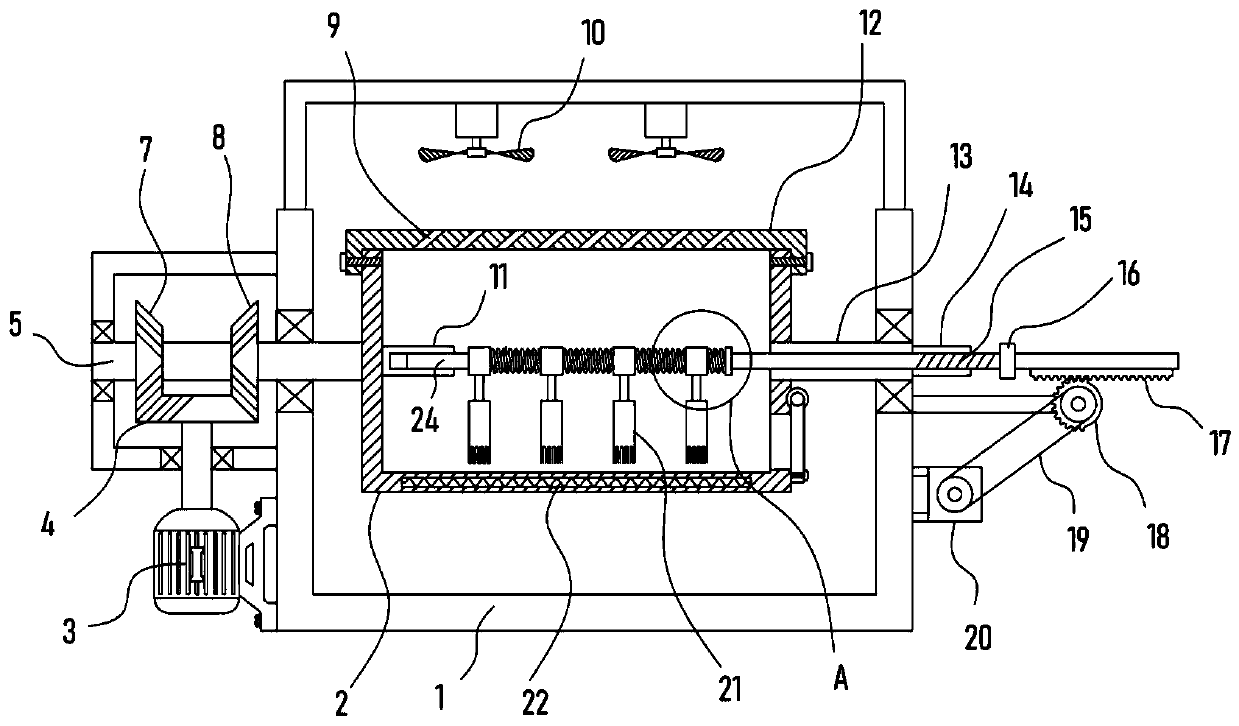

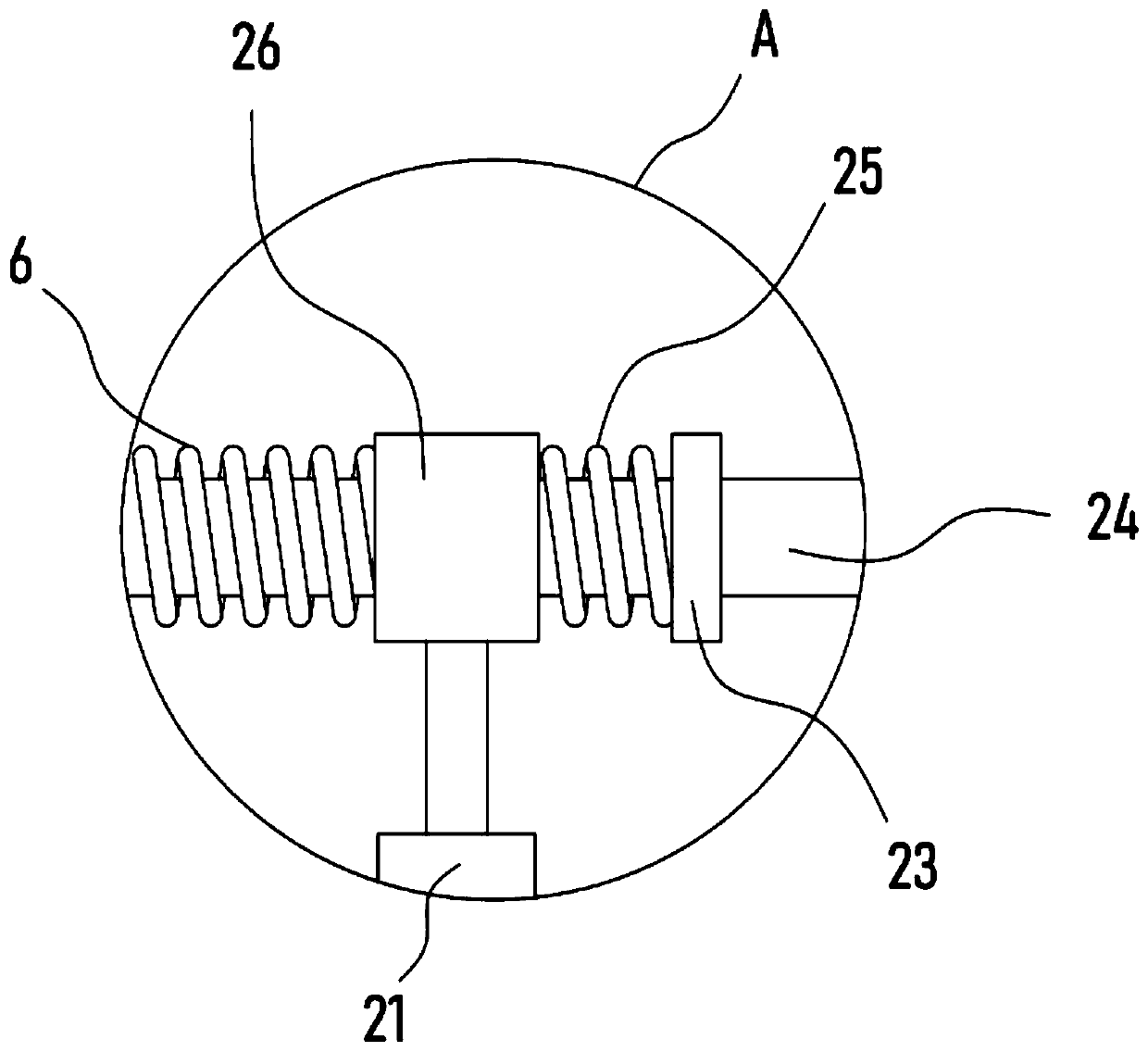

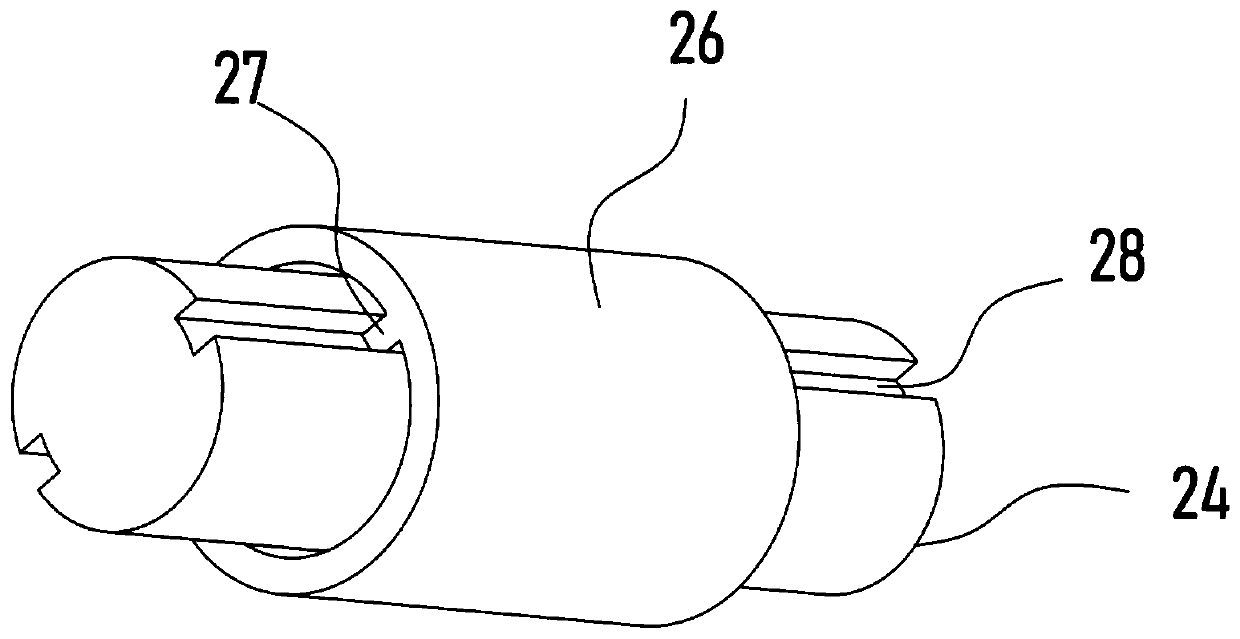

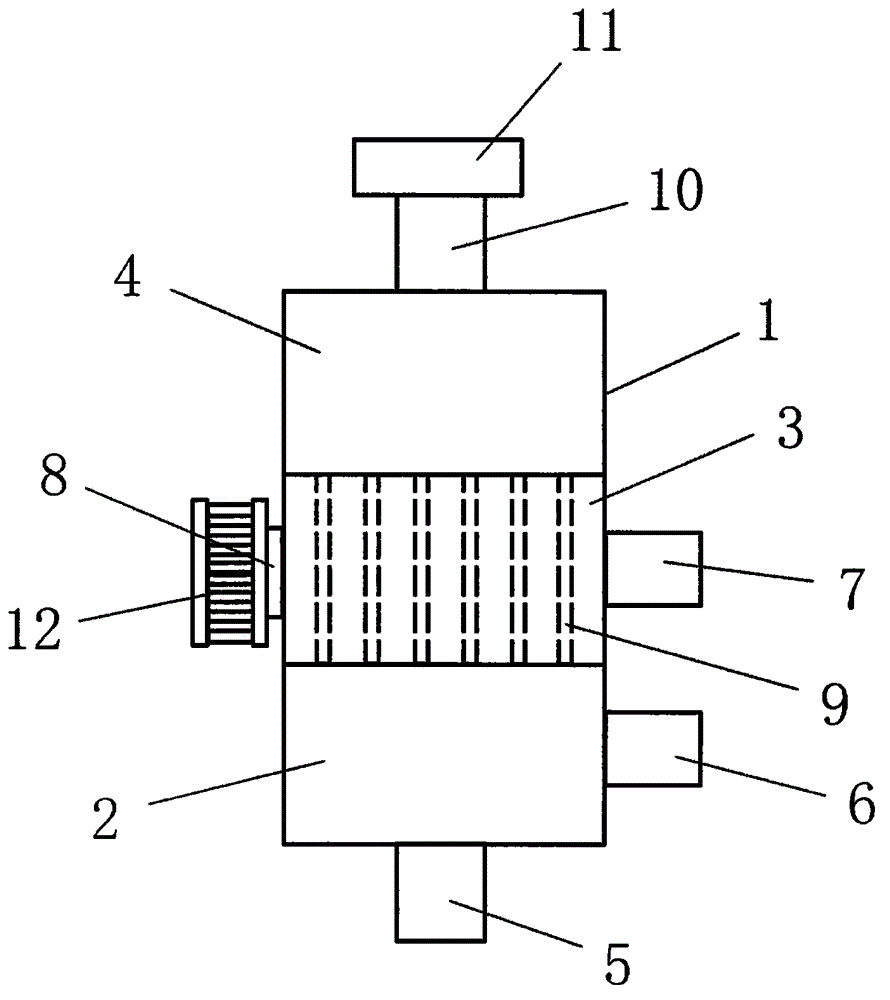

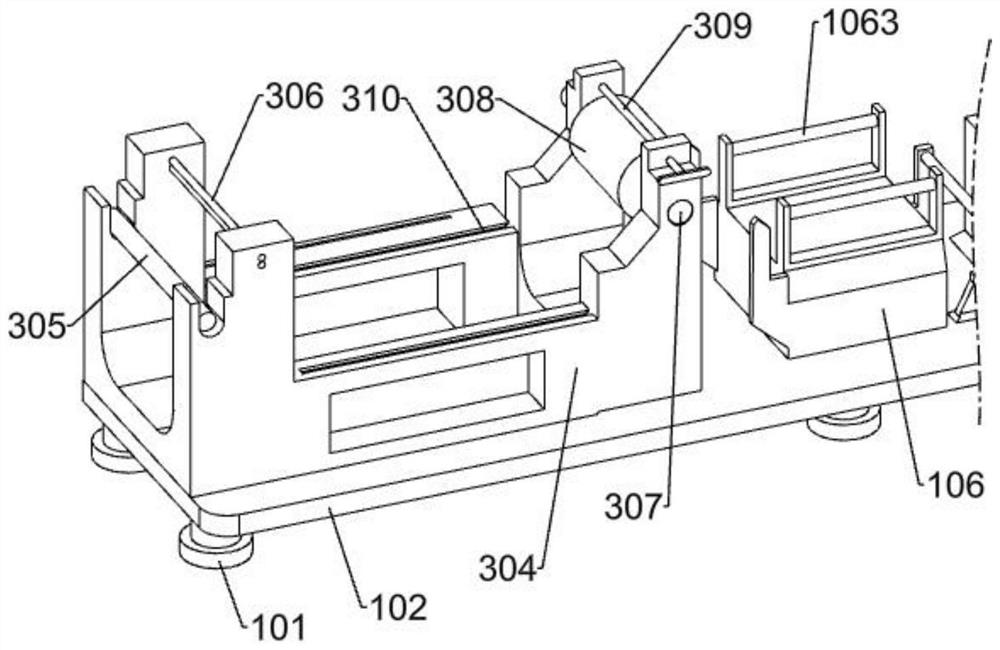

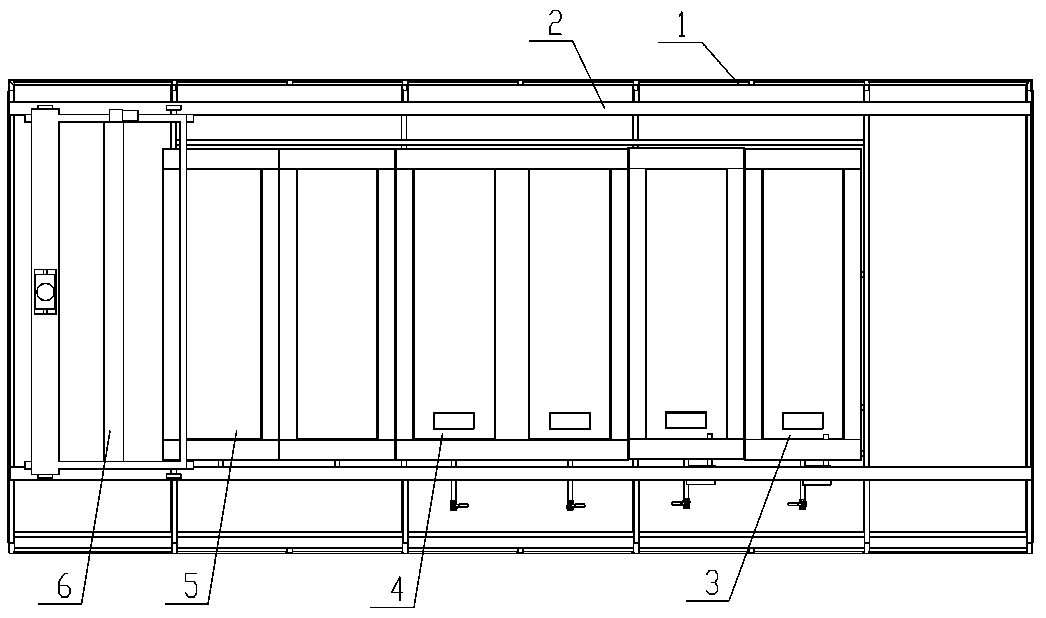

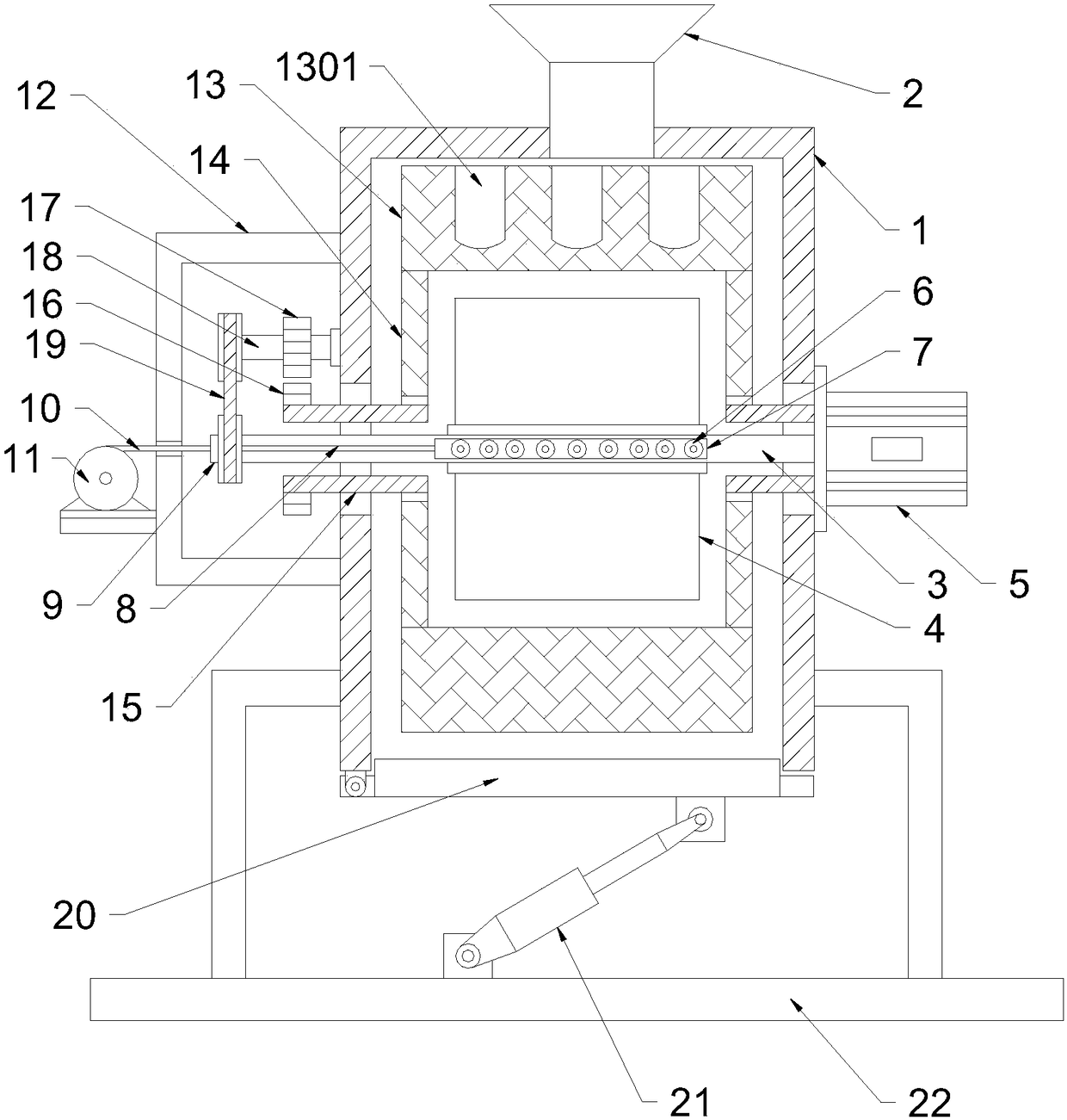

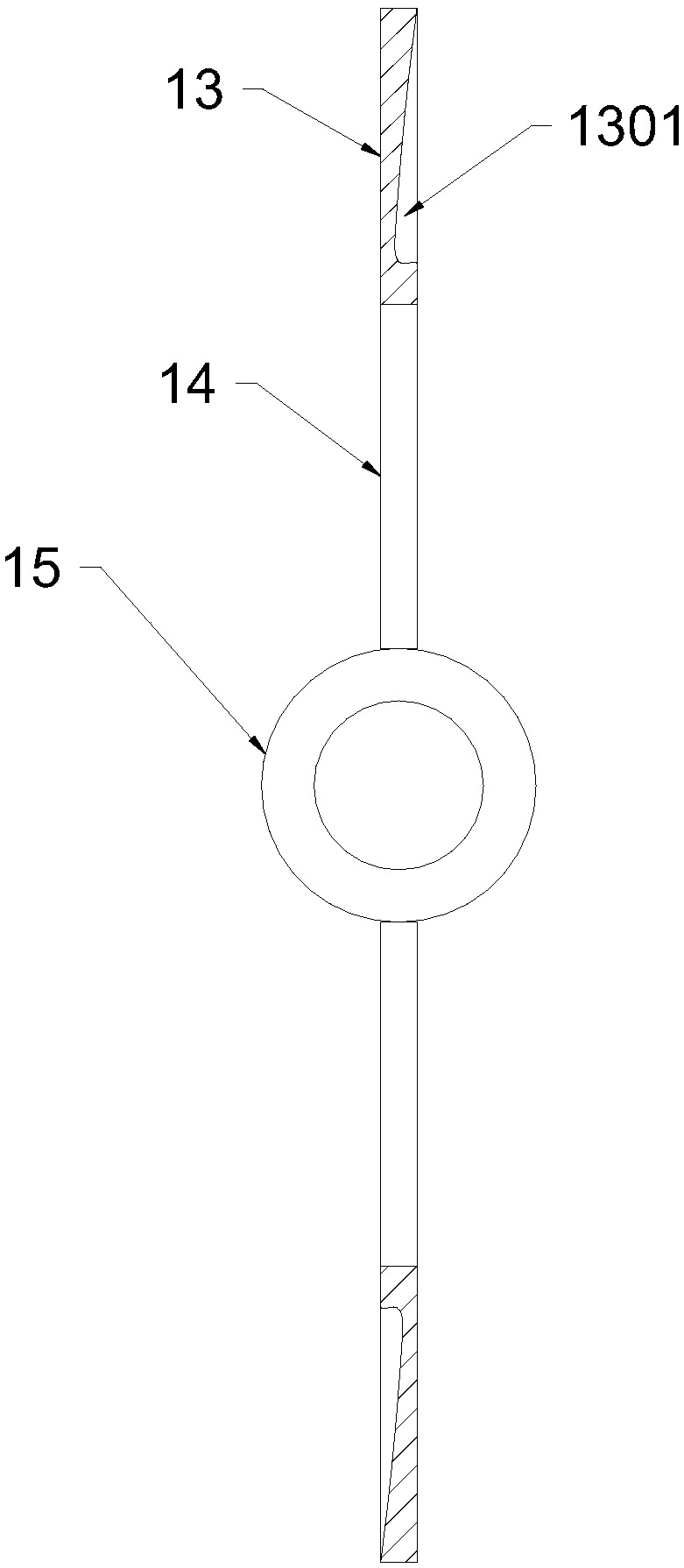

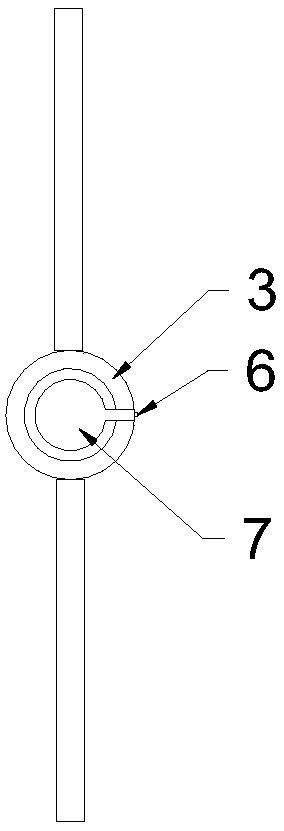

Cylinder-moving conveying type packaging bag drier

InactiveCN106564662AEasy to moveEasy to installDrying gas arrangementsDrying machines with progressive movementsEngineering

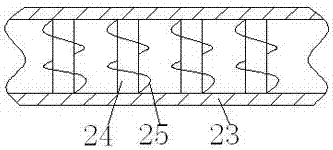

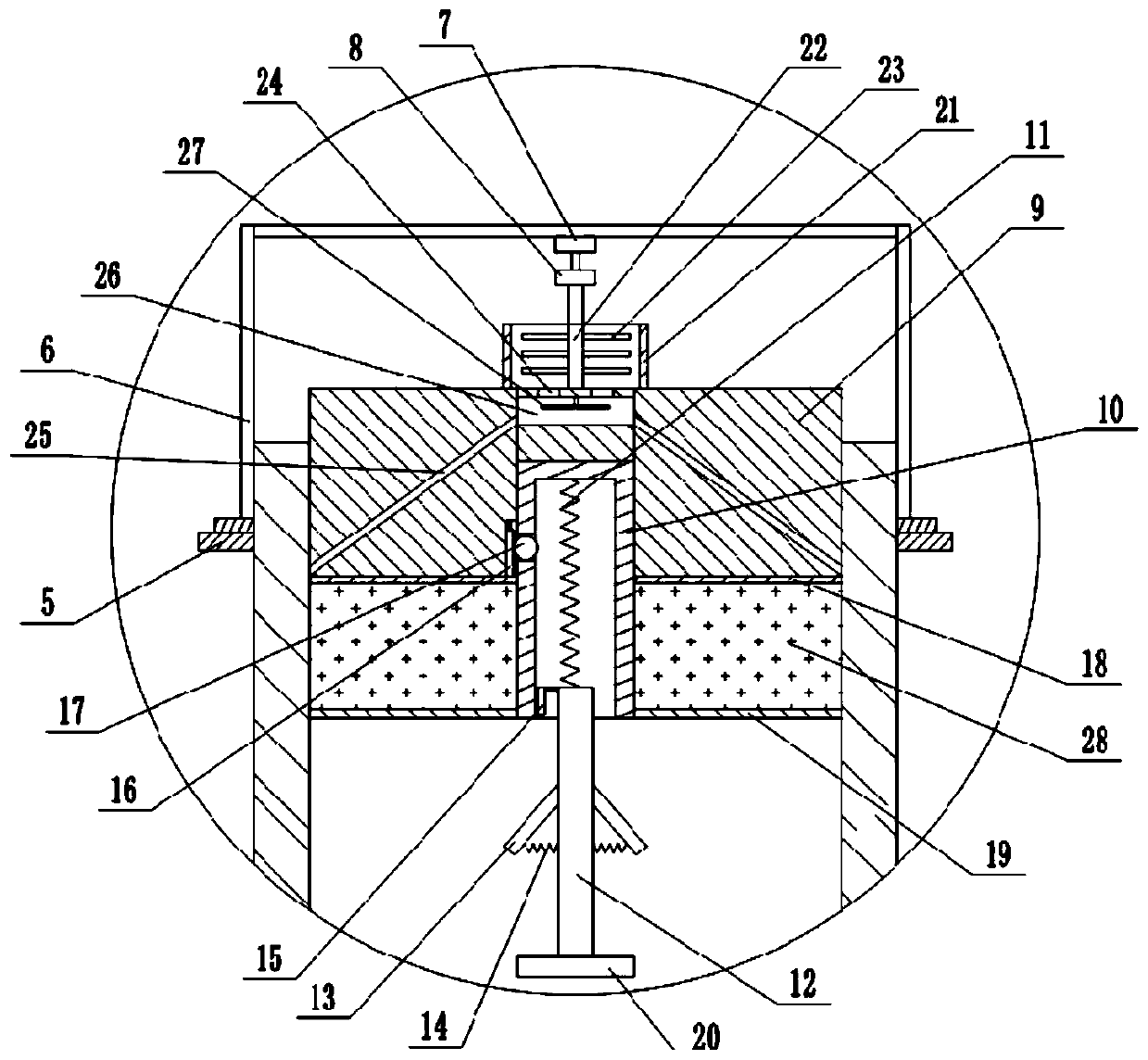

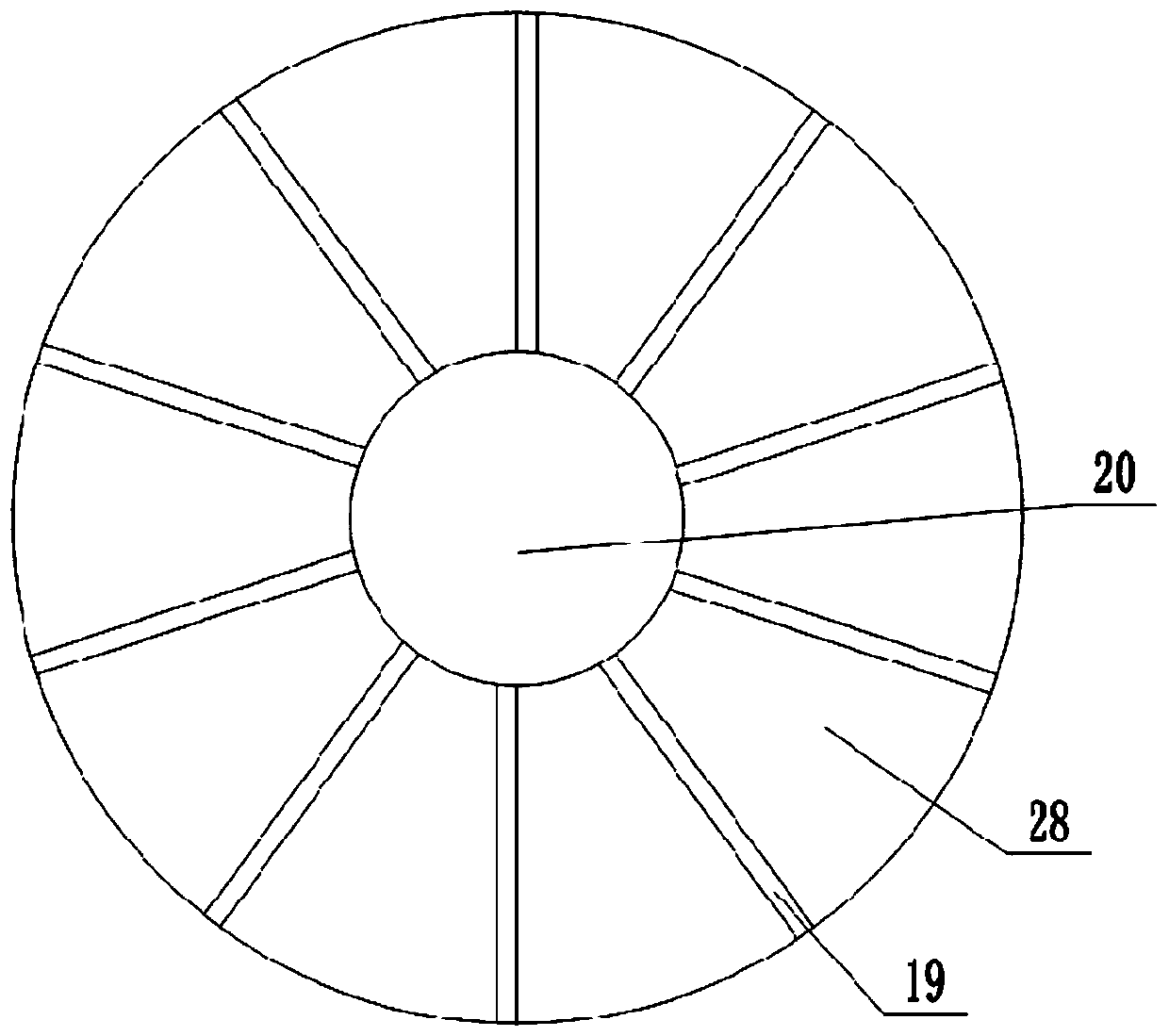

The invention discloses a cylinder-moving conveying type packaging bag drier which comprises a rack and a main board. A transverse moving through groove is formed in the middle of a top plate of the rack, rodless cylinders are fixed to the bottom face of the top plate of the rack, and guiding connection plates are fixed to sliding blocks of the rodless cylinders. Each guiding connection plate upwards stretches out of the transverse moving through groove, and an upper horizontal plate is fixed to each guiding connection plate. Guiding slide blocks are fixed to the left side and the right side of the bottom face of each upper horizontal plate, guiding rails are fixed to the left side and the right side of the top face of the top plate of the rack, sliding grooves are formed in the top faces of the guiding rails, and the guiding slide blocks are inserted into the sliding grooves. Movable connecting blocks are fixed to the left ends and the right ends of the front and back sides of the main board. The rodless cylinders push the upper horizontal plates to move rapidly and stably; meanwhile, heating pipes are fixed to the main board, the main board can move up and down to adjust the vertical positions of the heating pipes, so that heat is adjusted; and the heating pipes are fixed in an insertion mode through mounting blocks and limiting blocks, and the heating pipes are convenient to dismount and mount.

Owner:SHAOXING LITAI TEXTILE TECH CO LTD

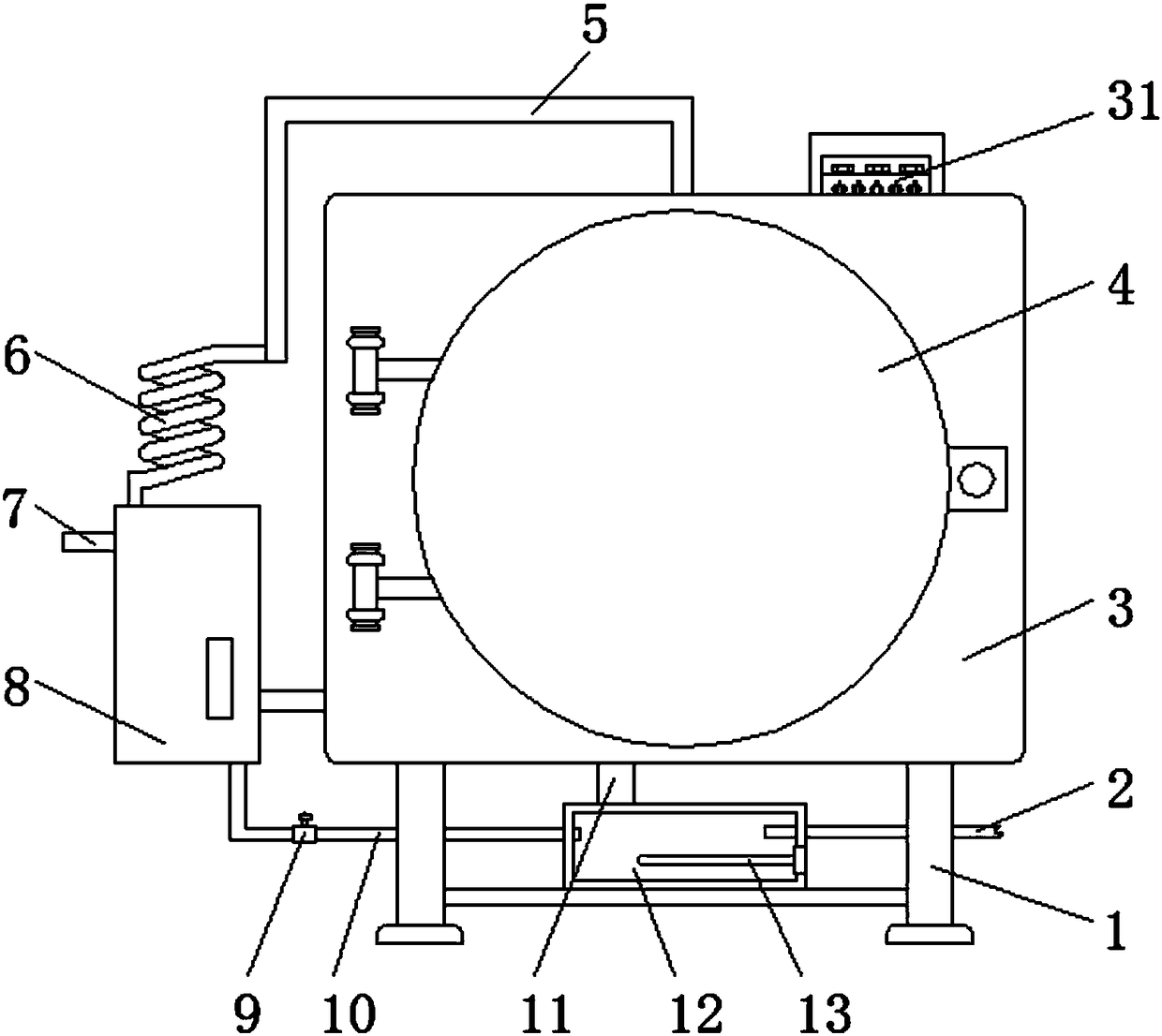

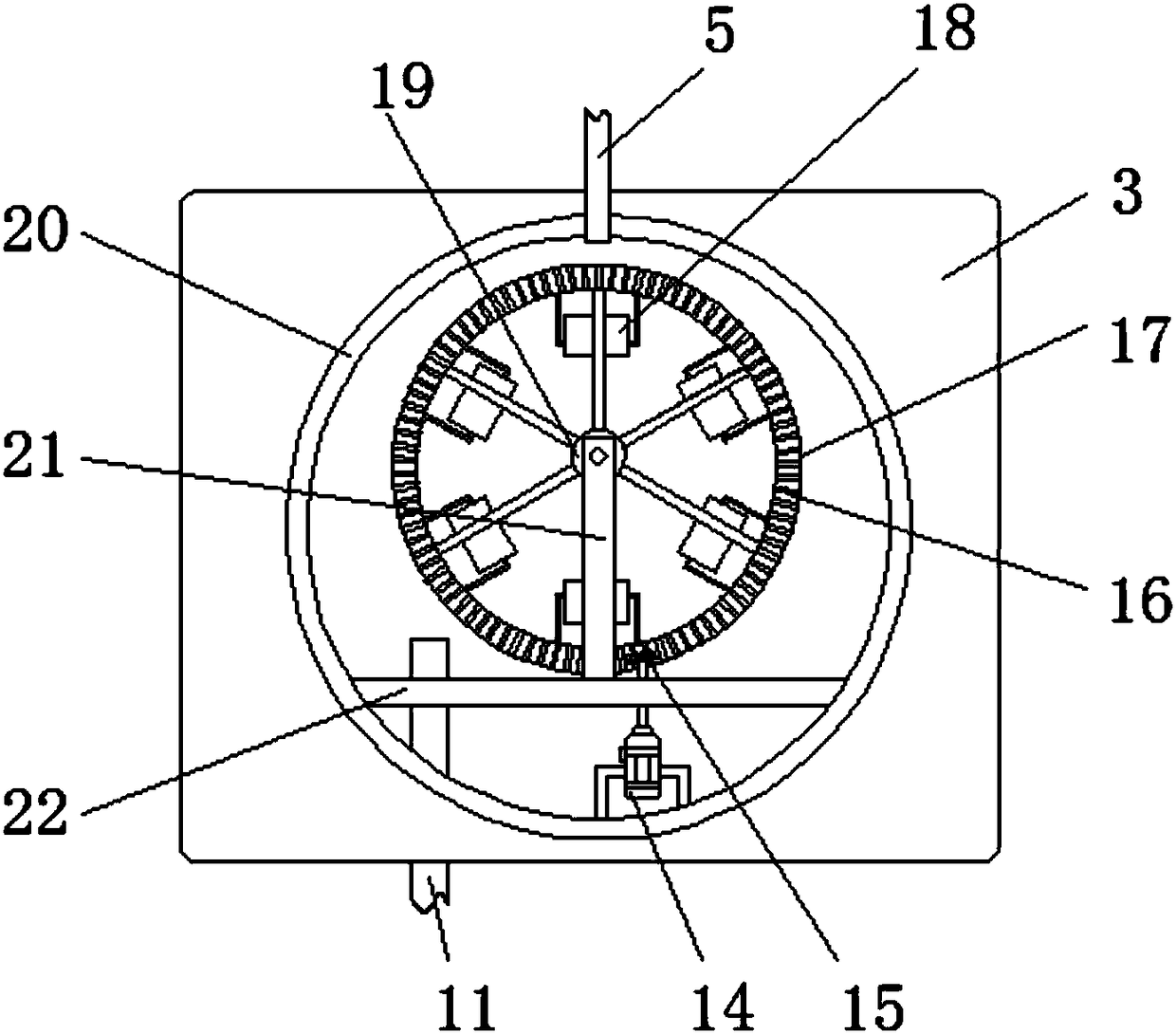

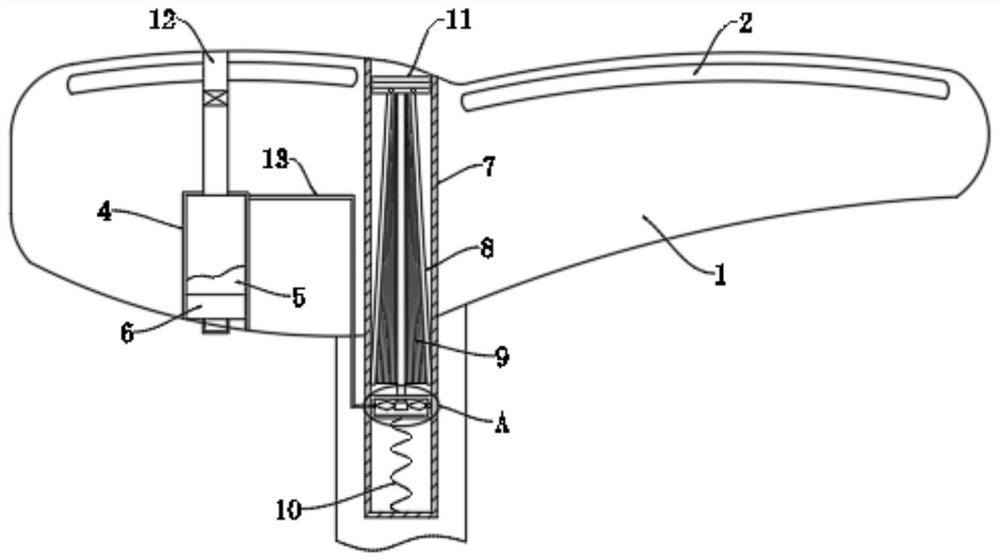

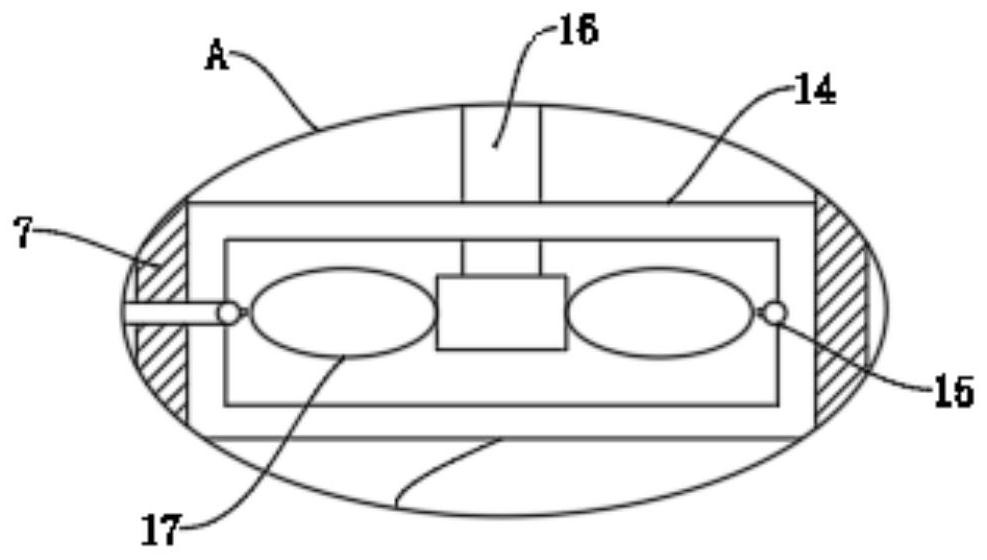

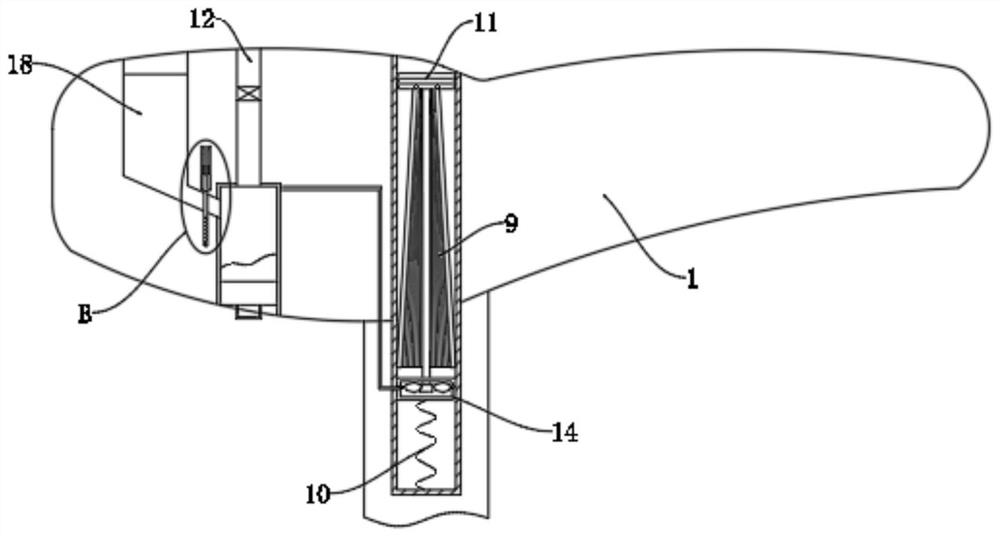

Sterilizer for medical instruments

InactiveCN108421056AReduce dosageAvoid accumulationDrying gas arrangementsLavatory sanitoryEngineeringWater vapor condensation

Owner:袁美华

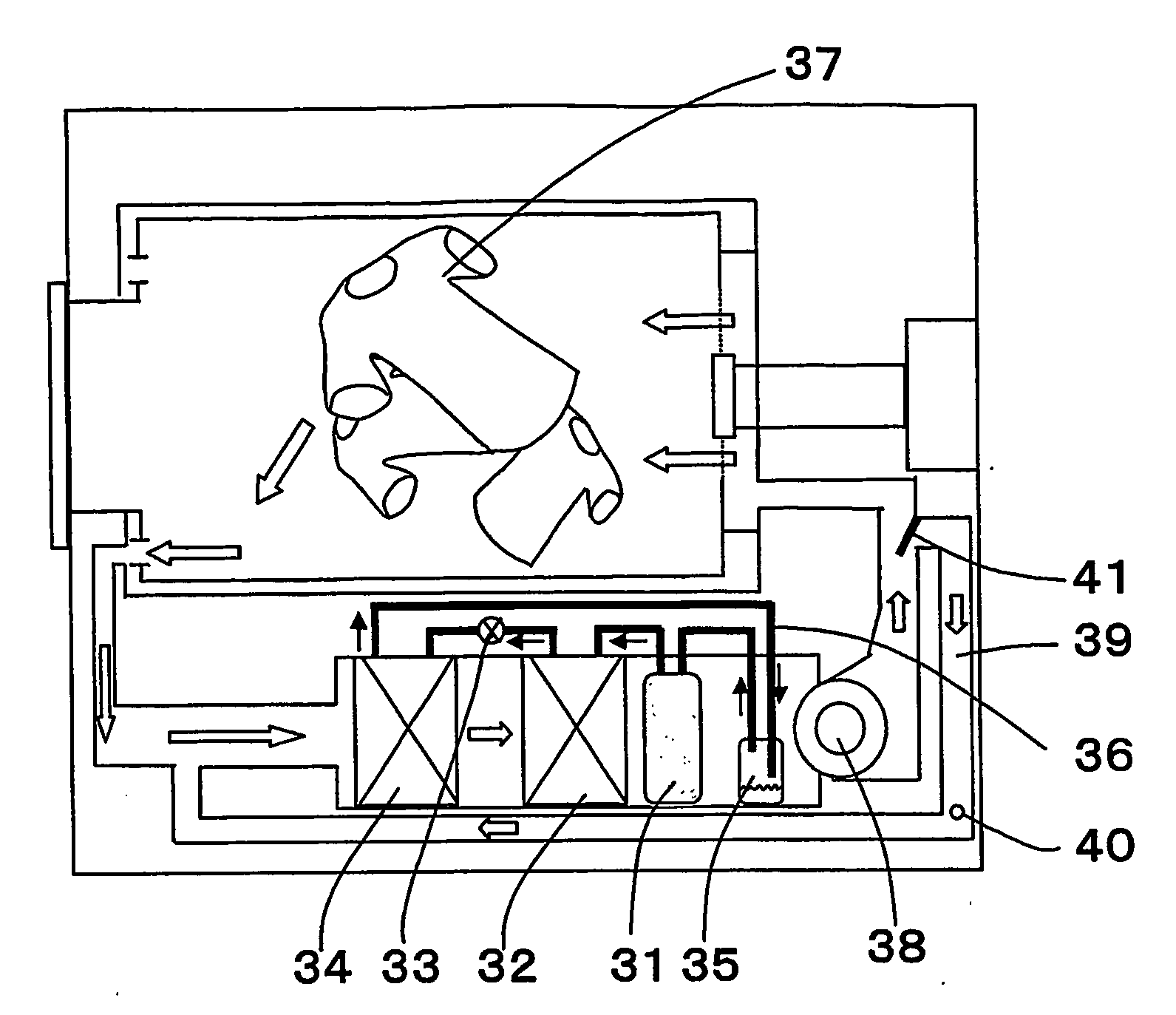

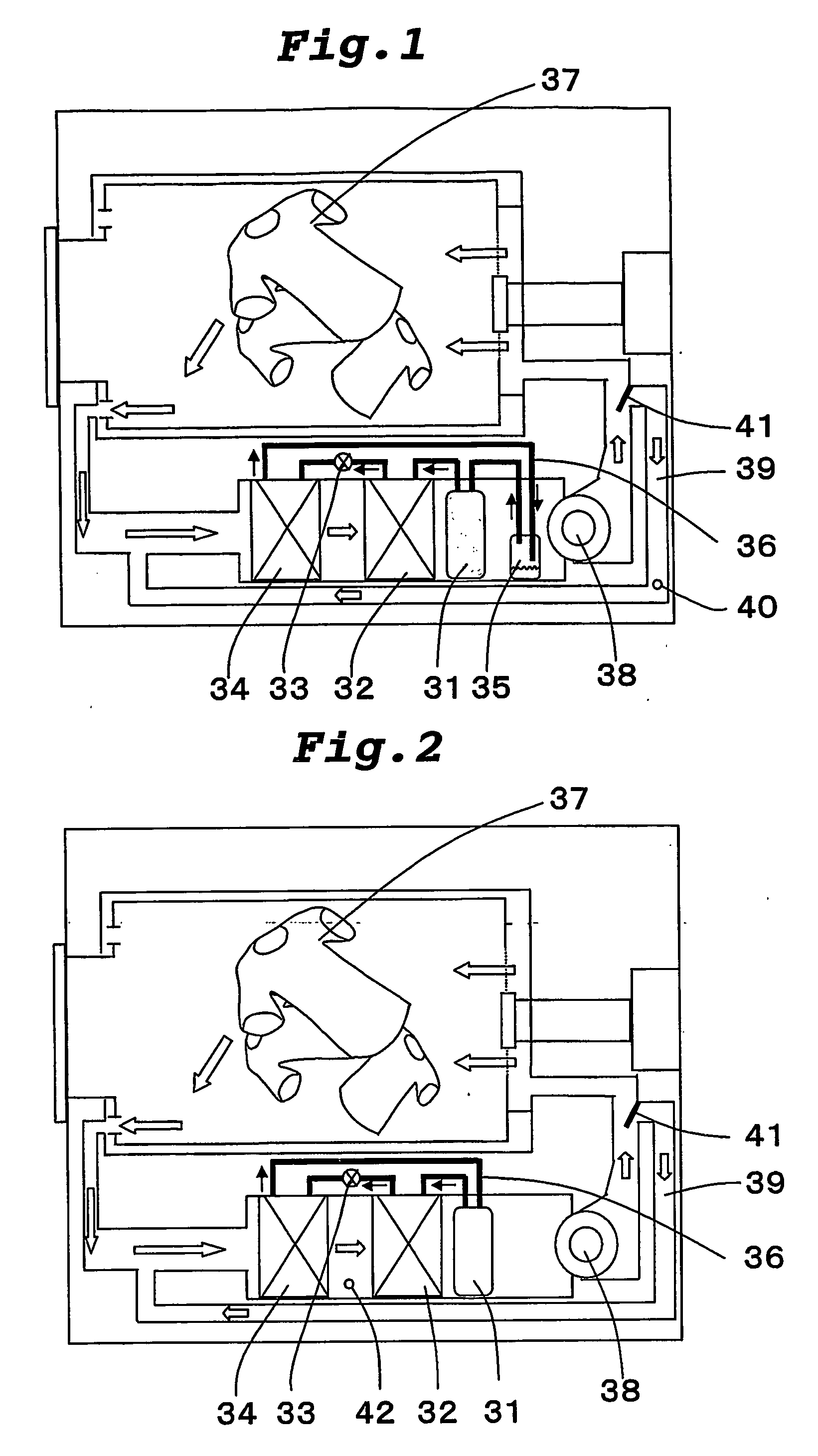

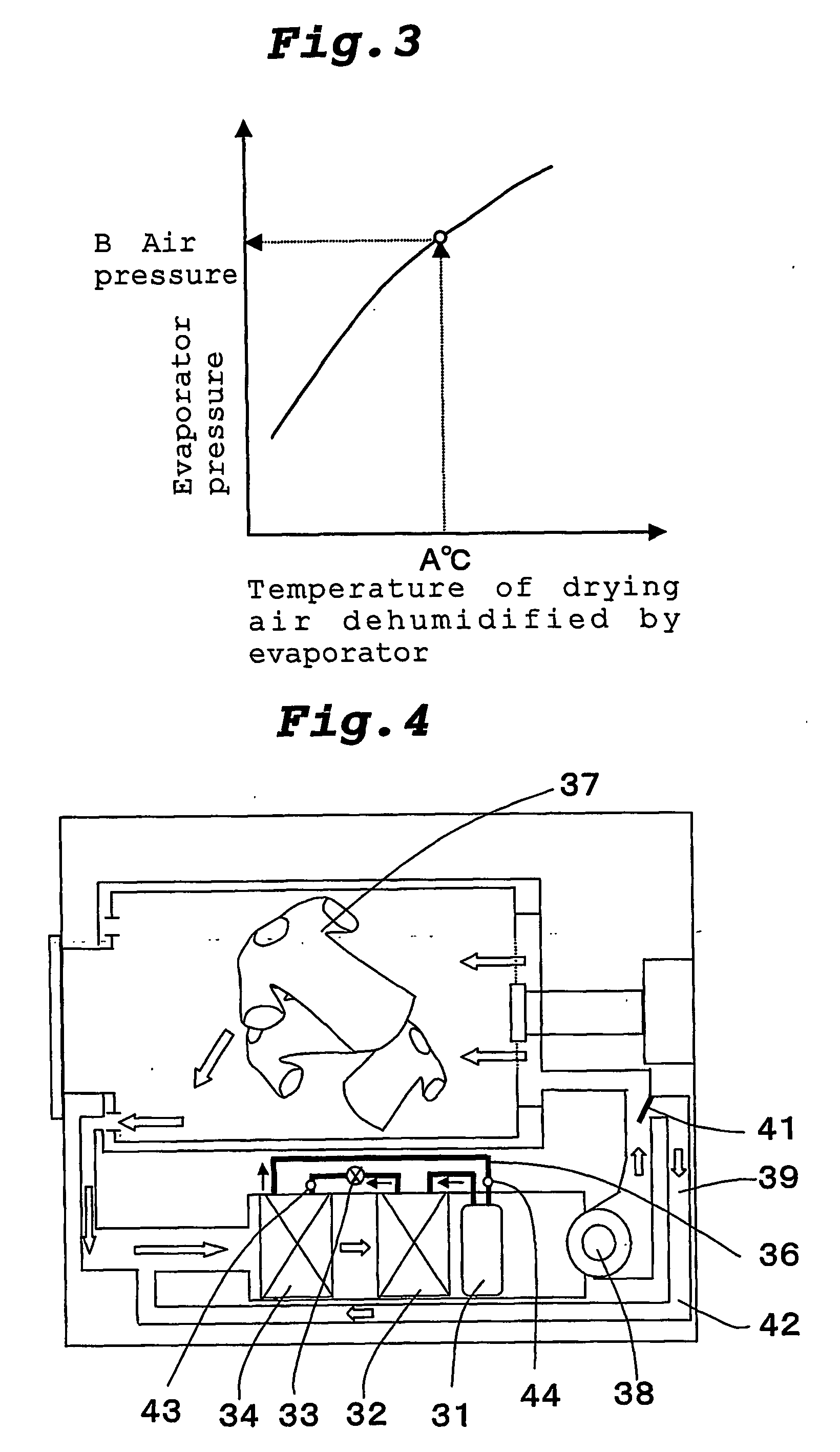

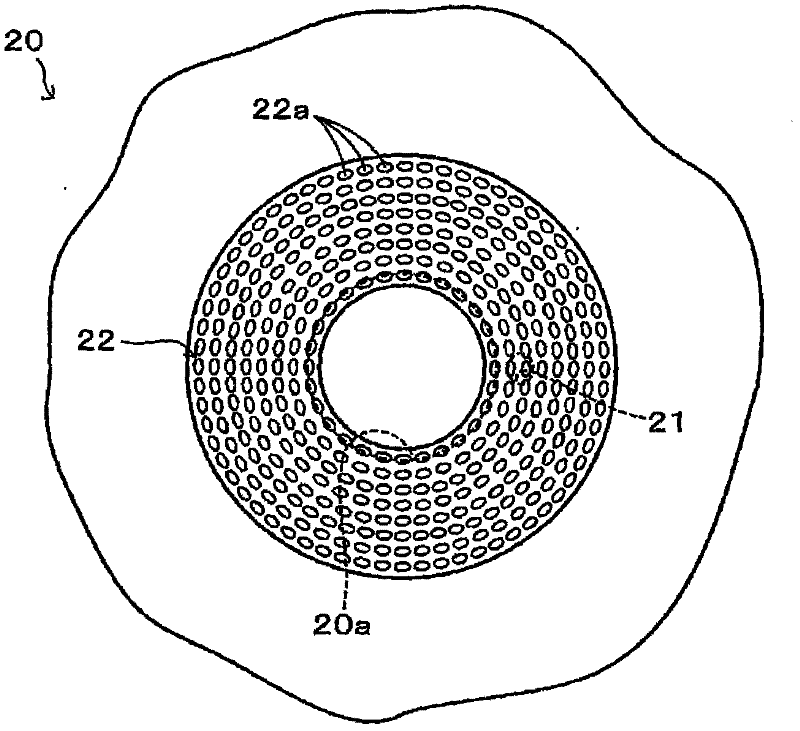

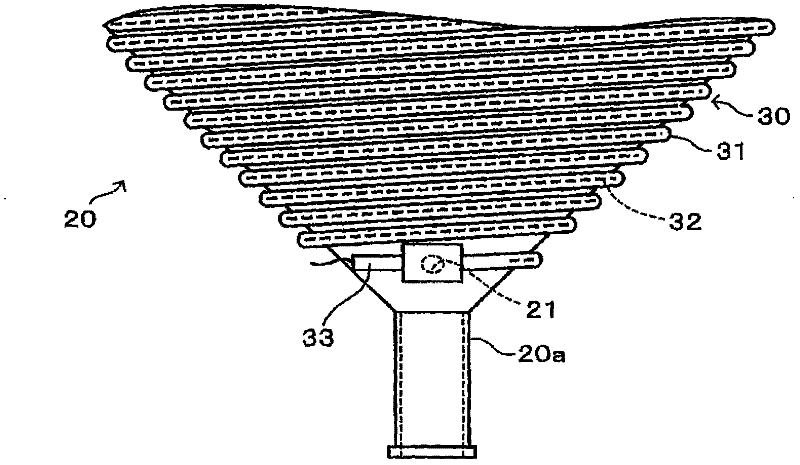

Heat pump type drying apparatus drying apparatus and drying method

InactiveUS20060179681A1Easy to operateDrying solid materials with heatDrying gas arrangementsSubject specificEvaporator

Owner:PANASONIC CORP

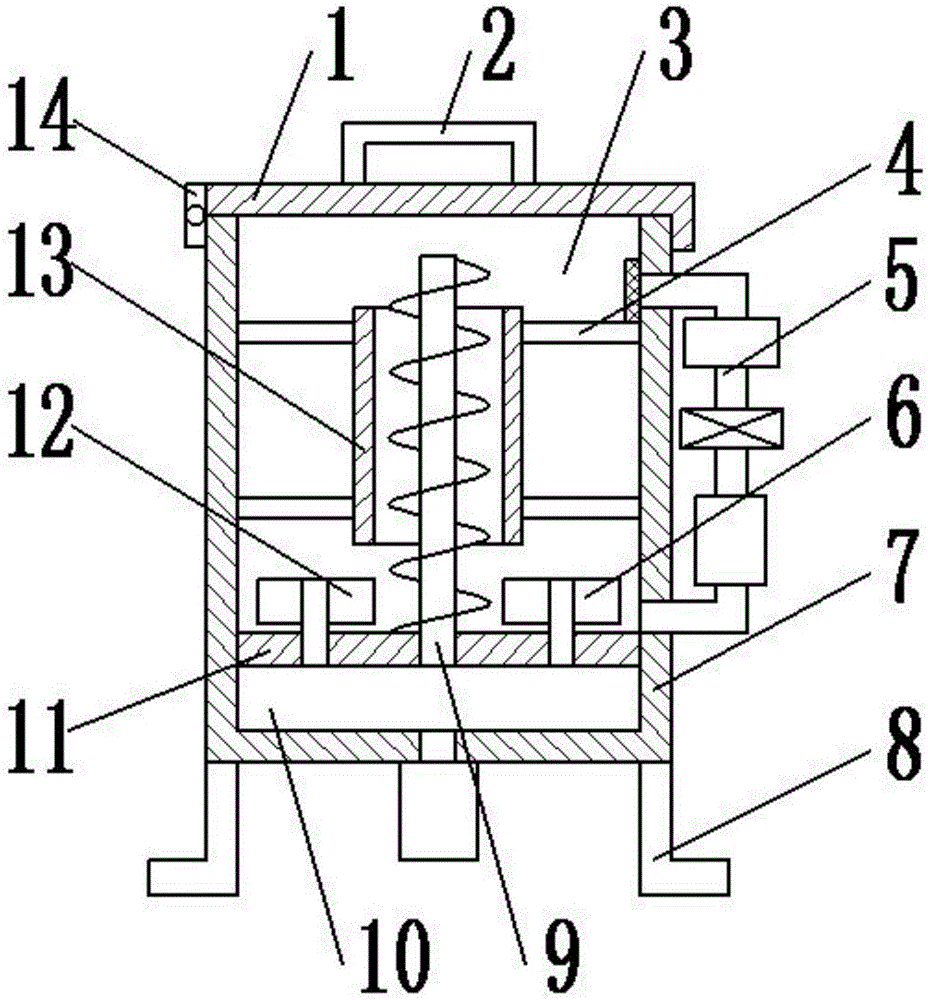

Clothing cloth drying equipment

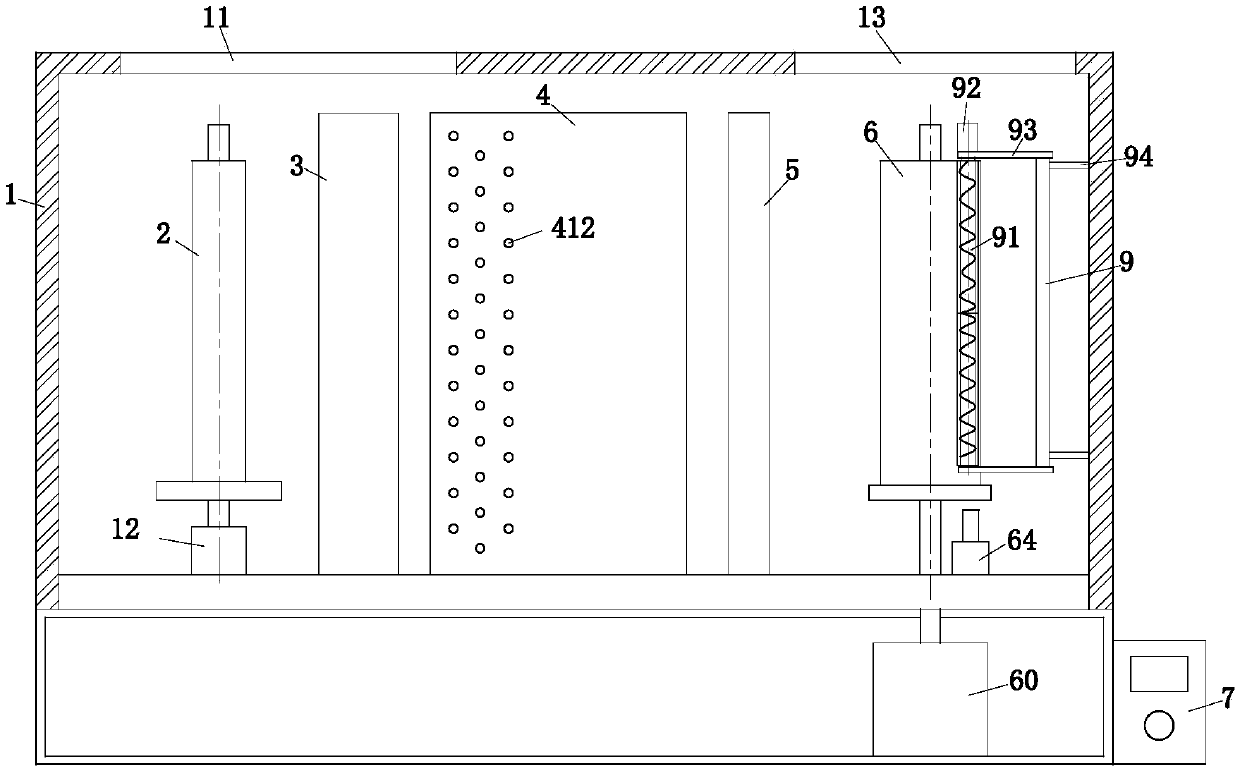

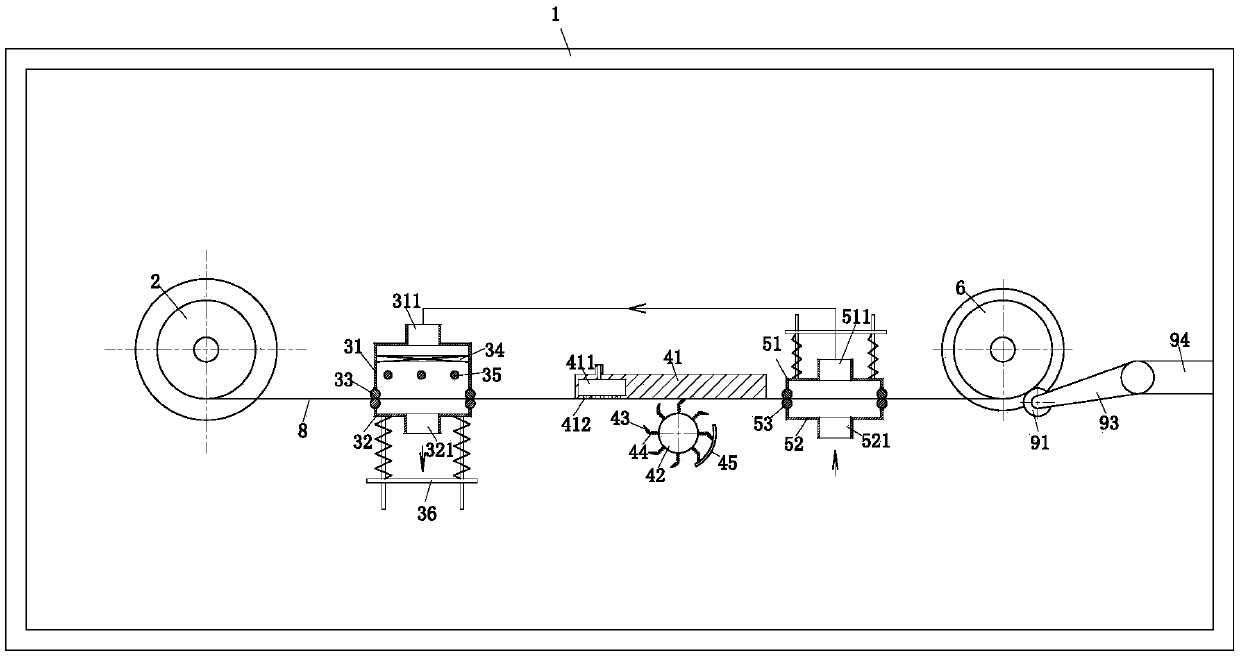

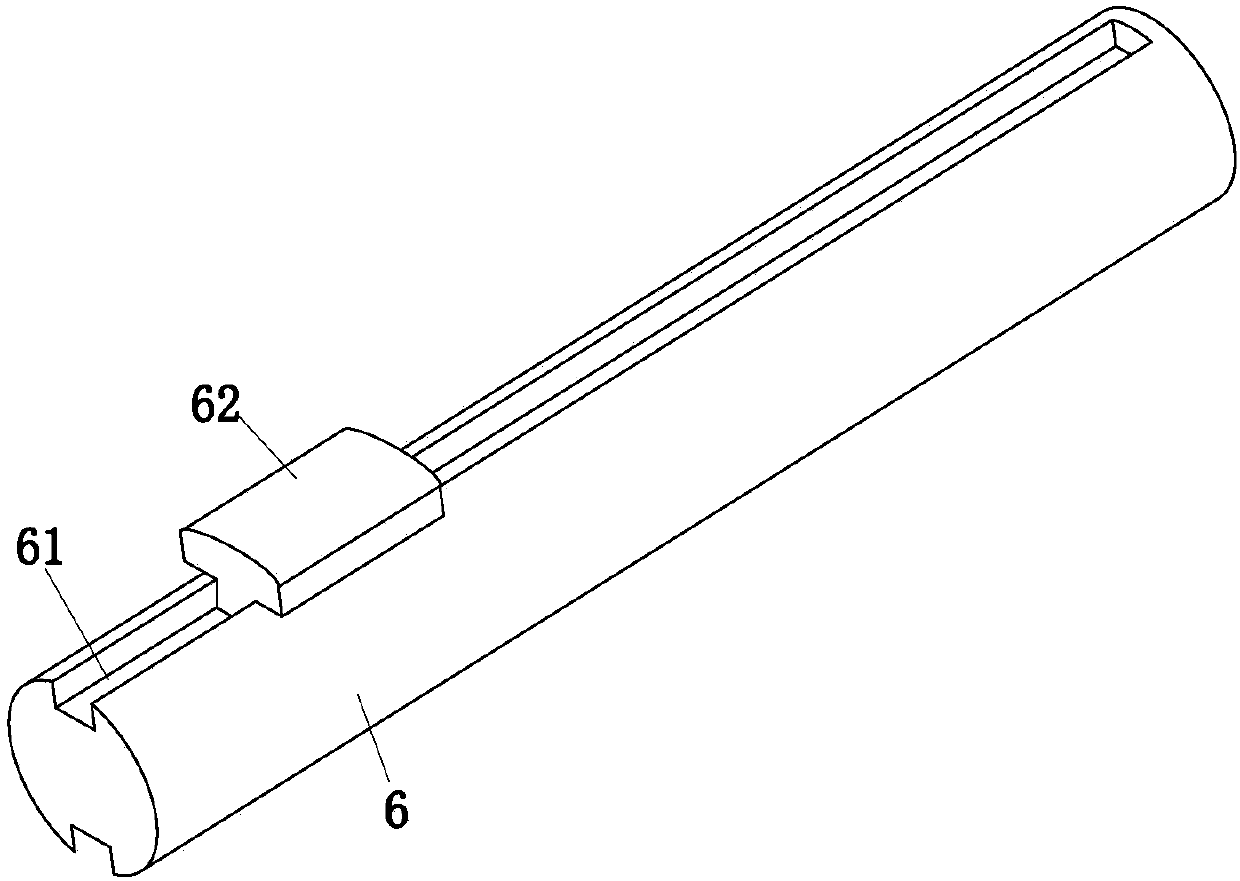

ActiveCN107677084AEasy to acceptSmall footprintDrying gas arrangementsDrying machines with progressive movementsAir dryingEnergy consumption

The invention relates to the technical field of drying equipment, in particular to clothing cloth drying equipment. The clothing cloth drying equipment comprises a box body, a discharging shaft for discharging cloths, a drying module, an ironing module, an air-drying module, a rolling shaft for rolling the cloths and a controller. The top of the left side of the box body is provided with a storinghole for storing the cloths, a damping piece mounted at the bottom of the box body is arranged under the storing hole, and the discharging shaft is vertically mounted on the damping piece. The dryingmodule is used for drying the cloths, the ironing module is used for ironing the cloths, and the air-drying module is used for air-drying the ironed cloths. The rolling shaft is located on the rightside of the air-drying module, a material taking hole for taking out the cloths is formed in the top of the box body over the rolling shaft, the rolling shaft is driven through a rolling motor, and the rolling motor is electrically connected with the controller. The clothing cloth drying equipment is mainly suitable for being used in a clothing manufacturing shop and has the characteristics that the size is small, the weight is small, the price is low, and energy consumption is little.

Owner:安徽衣信纺织科技有限公司

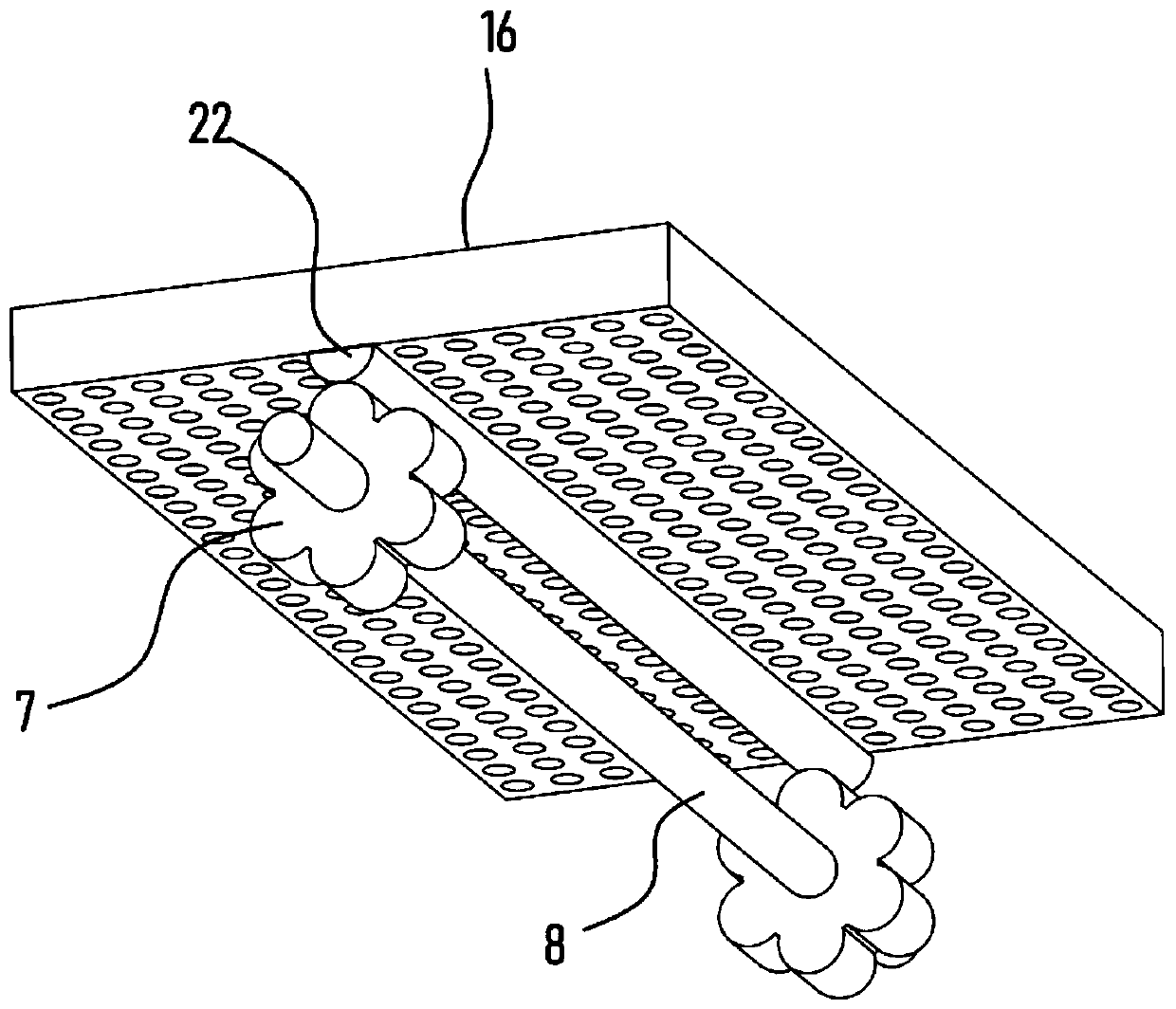

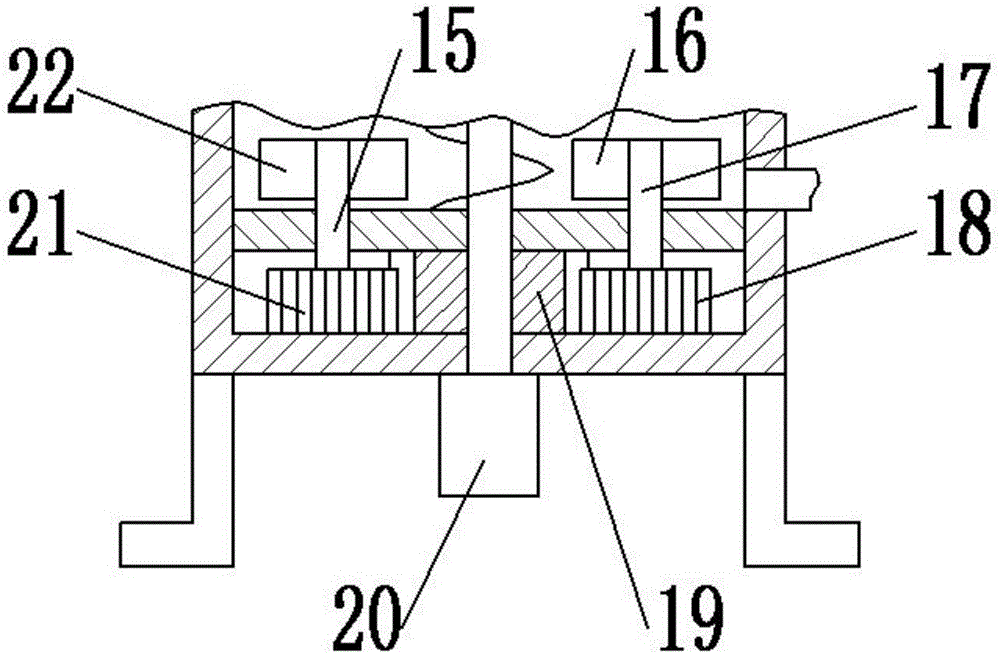

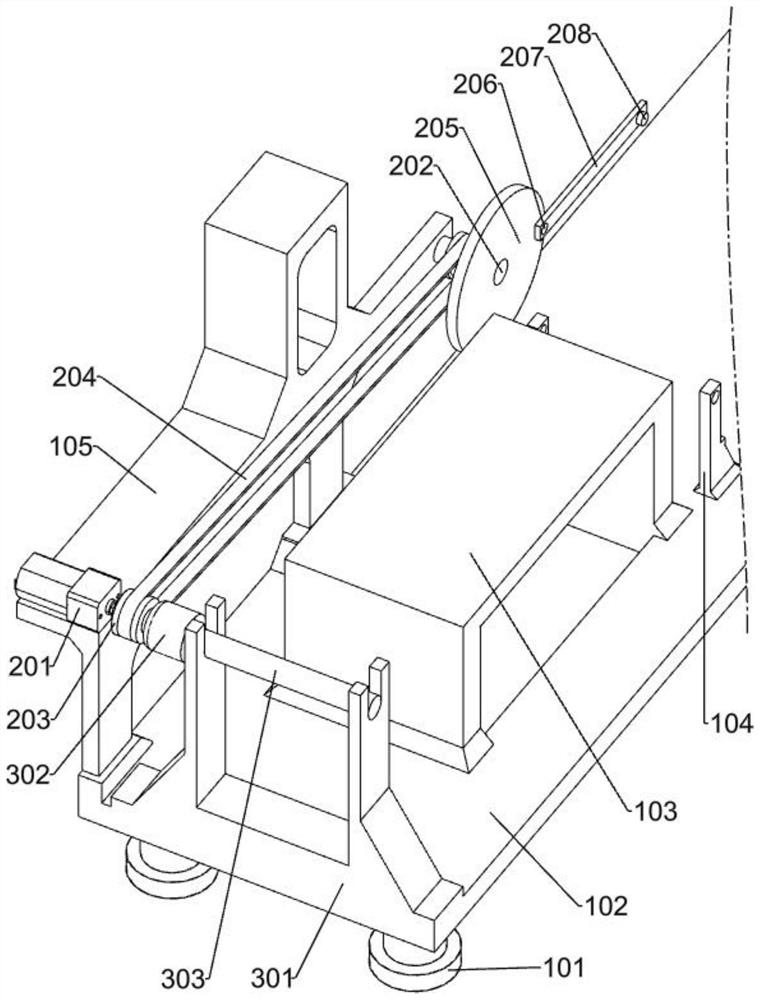

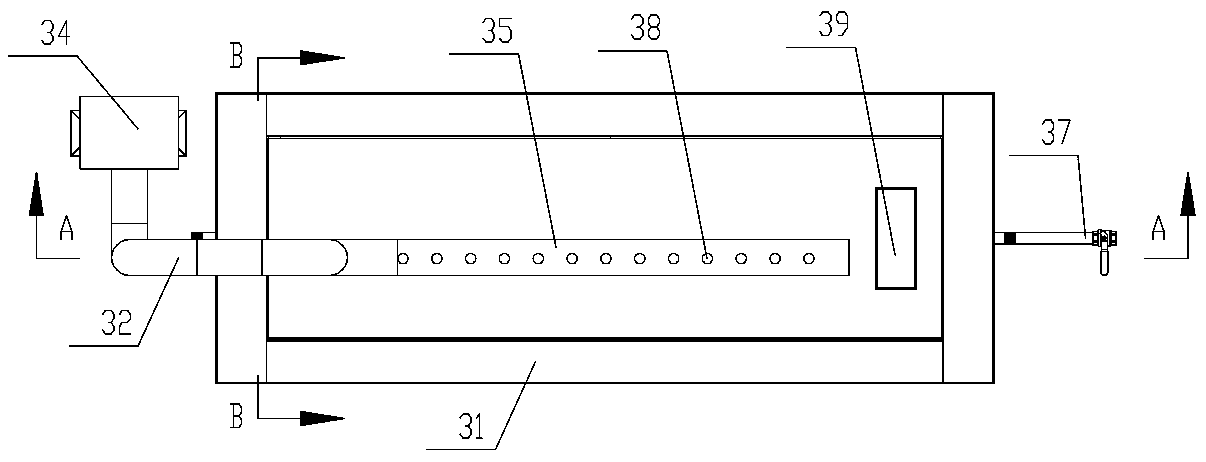

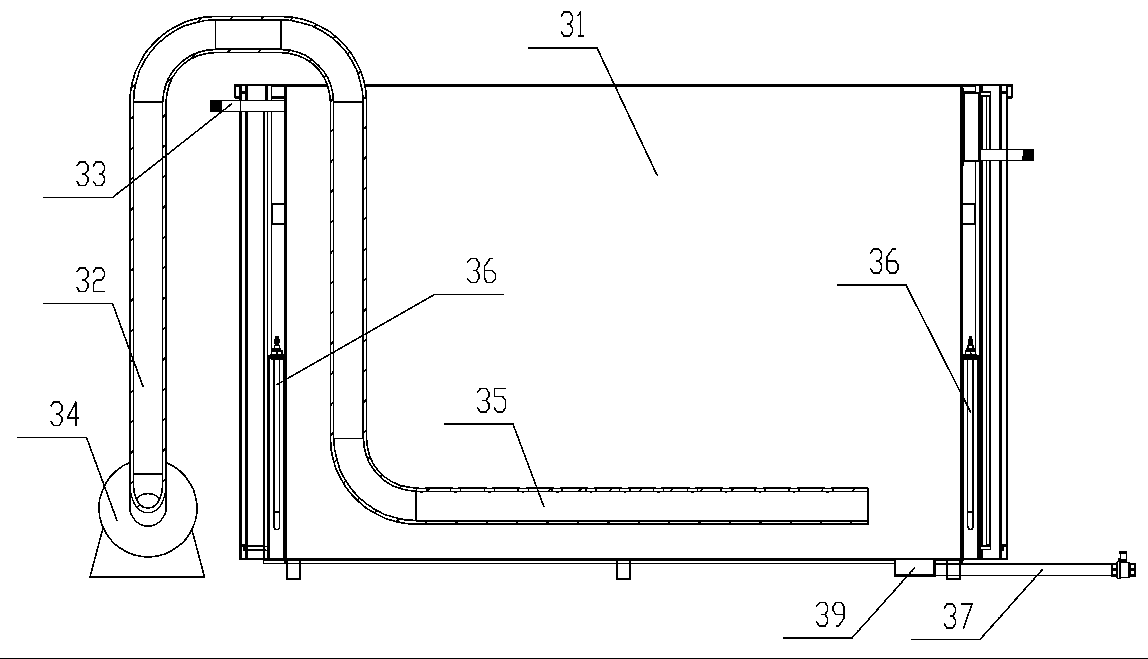

Matching drying equipment for dyeing clothing cloth

InactiveCN109654856AConvenient and fast windingFully heatedDrying gas arrangementsDrying machines with progressive movementsEngineeringCopper

The invention provides matching drying equipment for dyeing clothing cloth. The matching drying equipment comprises lower guide rollers, upper guide rollers, guide roller mounting plates, a cloth passing frame, a positioning plate and a top plate. A drying box is integrally arranged in a rectangular shape. The bottom of the drying box is provided with a water receiving tank. A group of pressing rollers driven by a motor are supported and welded to openings in the front end of the drying box. The middle of the bottom of the outer wall at the front end of the water receiving tank is provided with a drain copper ball valve in a threaded locking mode. Two electric heating fans are symmetrically locked and installed on the top plate of a hot air box. The three groups of lower guide rollers arearranged and supported at bottom positions of the left and right side walls of the drying box at equal intervals. Four electric push rods are symmetrically and vertically supported on the left side and right side of the water receiving tank. Piston rods of the four electric push rods are connected with screws of the two guide roller mounting plates in a screw locking mode. Due to the arrangement of the four positioning rods, the left-and-right swinging of the three upper guide rollers can be limited by the four positioning rods, and the piston rods of the four electric push rods are preventedfrom being broken by conveying and drawing force of cloth.

Owner:FO SHAN SHI TAO LIAN RAN ZHENG DING XING YOU XIAN GONG SI

Drug drying box

Owner:姚莲琴

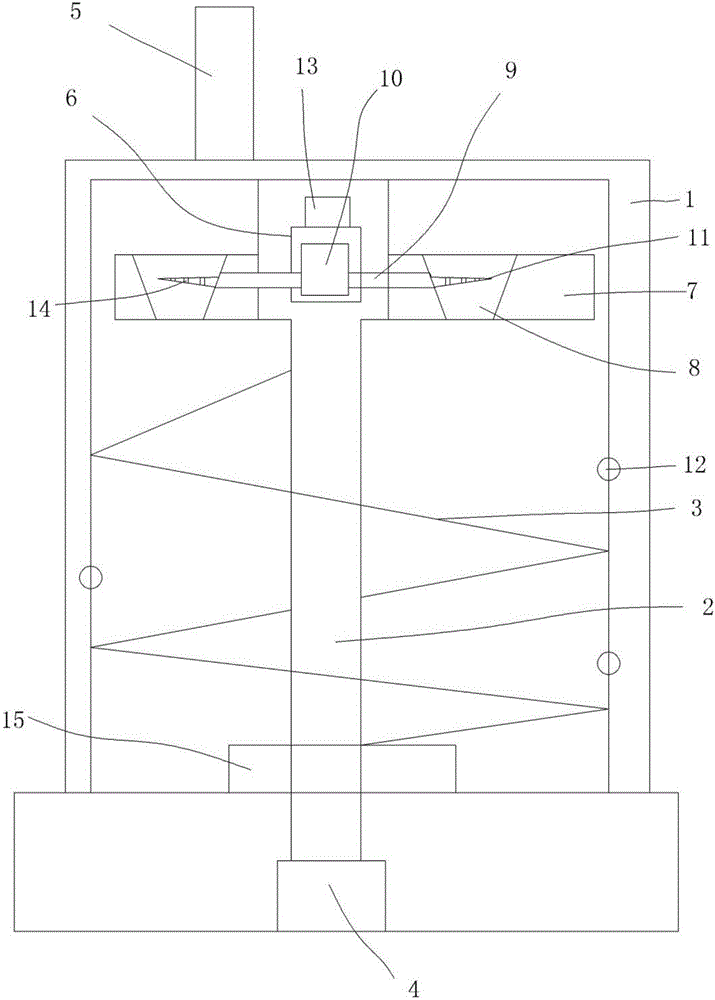

Drying device of particle material

Owner:MATSUI MFG

Heat recycling type efficient medicinal material drying device

ActiveCN106382808ADrying gas arrangementsDrying chambers/containersPulp and paper industryAir blower

Owner:深圳市惠普生科技发展有限公司

Ceramic glaze drying device

ActiveCN110044137APromote shakingFull heating effectDrying solid materials with heatDrying gas arrangementsWater vaporDrive shaft

Owner:GUANGDONG VOCATIONAL & TECHNICAL COLLEGE

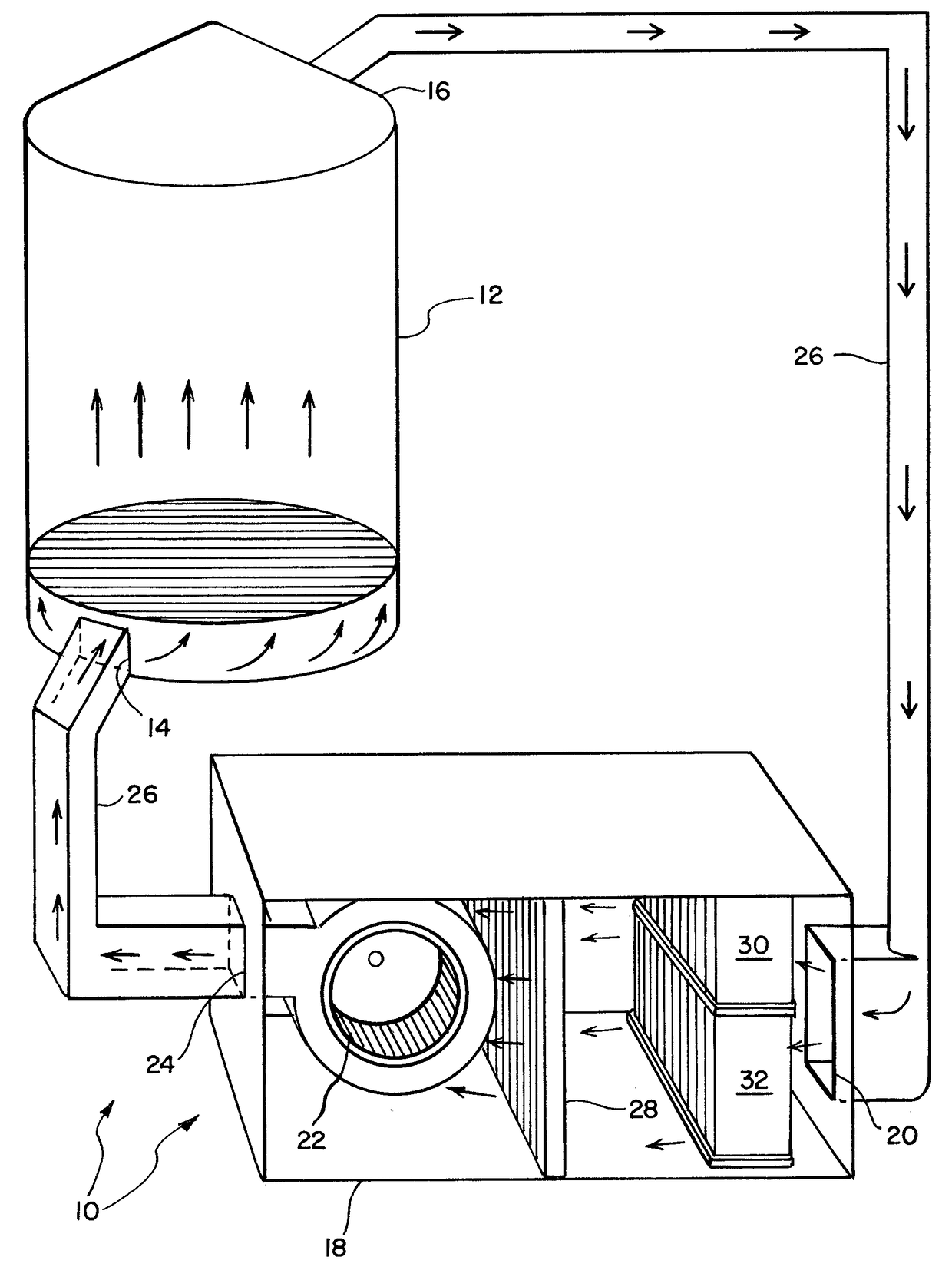

Crop drying system

ActiveUS20170115061A1Increase the ambient temperatureQuantity minimizationFruit and vegetables preservationGas treatmentClosed loopMoisture

Owner:LOEBACH DAVID R

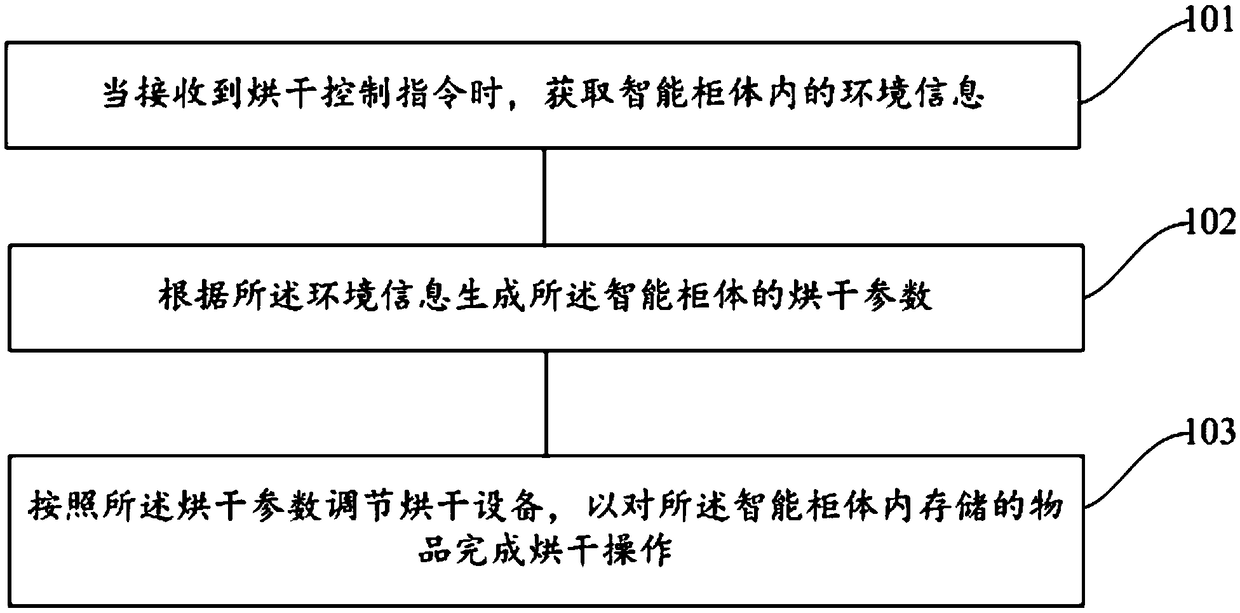

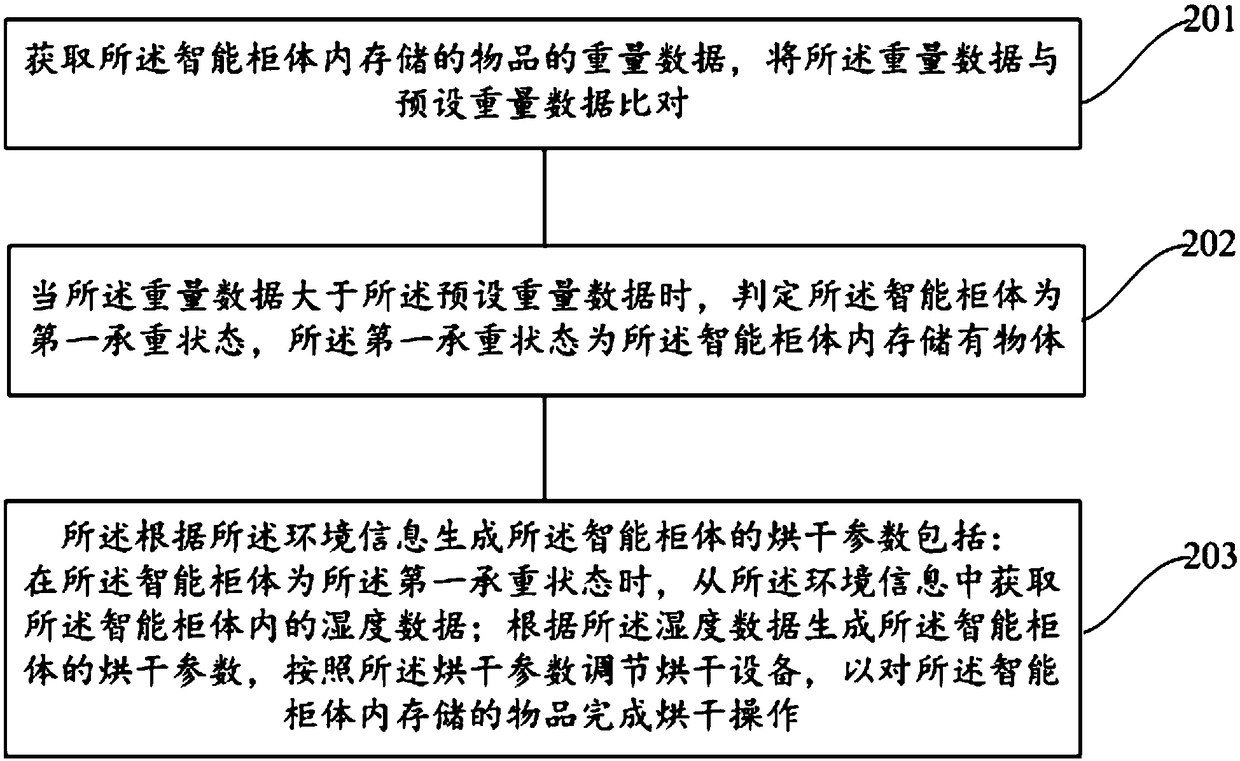

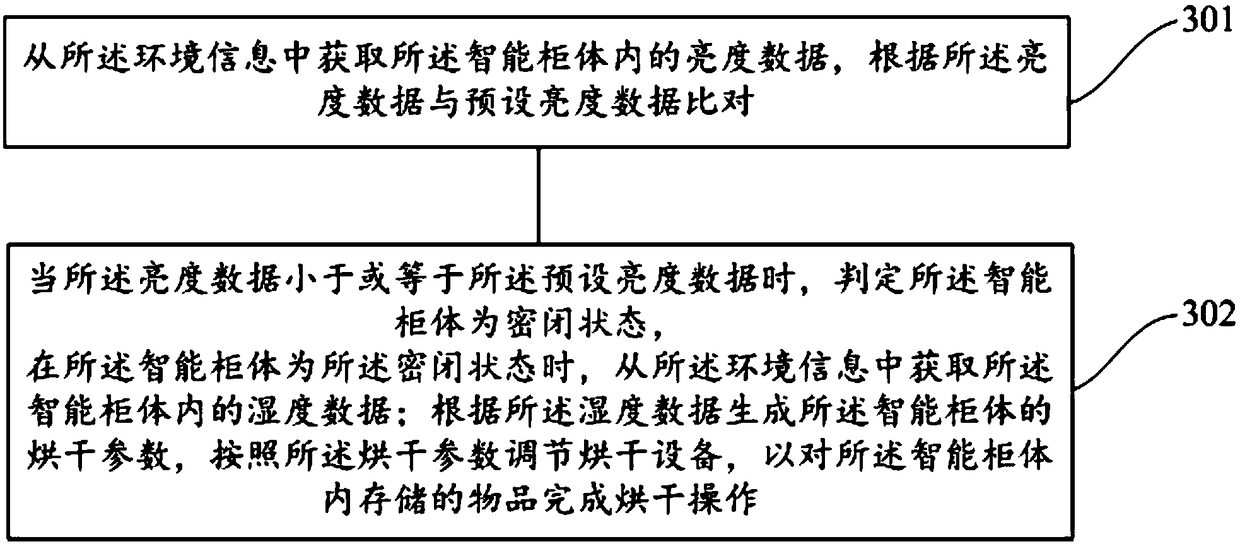

Drying method, computer readable storage medium and intelligent shoe cabinet

Owner:SHENZHEN ORLANT INTELLIGENT CONTROL SYST CO LTD

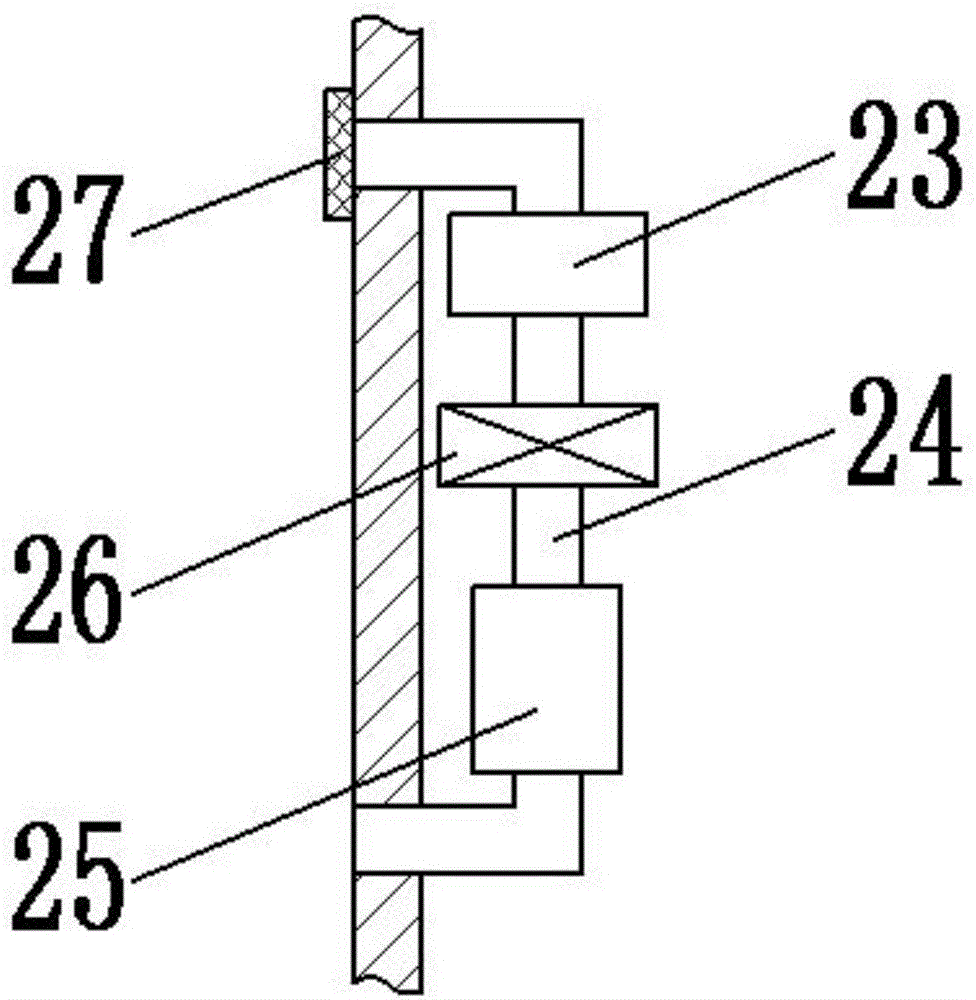

Oven energy economizer

InactiveCN104390477AAchieve recyclingExtended stayDrying gas arrangementsWaste heat treatmentTraffic volumeProcess engineering

The invention discloses an oven energy economizer. The oven energy economizer comprises a box body, wherein a heat recovery bin, an energy conservation bin and a waste gas bin are arranged in the box body, two hot air inlets are respectively formed in the bottom and the side wall of the heat recovery bin, a hot air outlet is formed in one side wall of the energy conservation bin, a fresh air inlet is formed in the other side wall of the energy conservation bin, a heat absorbing tube is arranged in the energy conservation bin, a waste gas outlet is formed in the top of the waste gas bin, and the waste gas outlet is connected with an air draft device adjustable in flow. Compared with the prior art, the oven energy economizer collects hot air discharged by an oven, mixes the hot air with fresh air so as to obtain mixing air, and then recycles the mixing air into the oven, and thereby reduces heating electric quantity of a heater, saves energy, protects environment, and is practical, convenient and quick to install, low in cost and simple to operate.

Owner:孙大华

Open type absorption heat pump-MVR technology coupled closed cycle drying system

ActiveCN111947443AReduce trafficReduce the risk of entrainmentEnergy efficient heating/coolingClimate change adaptationThermodynamicsEngineering

The invention discloses an open type absorption heat pump-MVR technology coupled closed cycle drying system which comprises an open type absorption heat pump system and a mechanical compression heat pump cycle system. An outlet of a mechanical heat pump compressor is divided into two paths, one path is in pipeline connection with a hot channel inlet of a heat removal device through a hot channel of a condenser, and the other path is in pipeline connection with the hot channel inlet of the heat removal device through a 2# heat and mass exchanger; and a hot channel outlet of the heat removal device is connected with an expansion valve through a pipeline, an outlet of the expansion valve is divided into two paths, one path is in pipeline connection with an inlet of the mechanical heat pump compressor through a 1# heat and mass exchanger, the other path is in pipeline connection with the inlet of the mechanical heat pump compressor through a cold channel of an evaporator, and a mechanicalcompression type heat pump cycle system is formed. According to the open type absorption heat pump-MVR technology coupled closed cycle drying system, absorbed heat is used for regenerating a dilute solution through the mechanical compression type heat pump cycle system, regenerated steam is used for heating dry gas after the grade of the regenerated steam is improved through an MVR technology; andby means of the open type absorption heat pump-MVR technology coupled closed cycle drying system, a large amount of latent heat in damp and hot gas exhausted by a dryer can be reasonably utilized.

Owner:ZHEJIANG UNIV OF TECH +1

Wood board drying equipment

InactiveCN107976046AImprove drying efficiencyFully contactedDrying gas arrangementsDrying machines with progressive movementsControl systemEngineering

Owner:广西桂林林博士家具有限公司

Efficient drying machine for spinning

ActiveCN112696902AAutomatic deliveryDry thoroughlyDrying gas arrangementsDrying machines with progressive movementsSpinningWorkbench

Owner:新疆金大禹环境科技有限公司

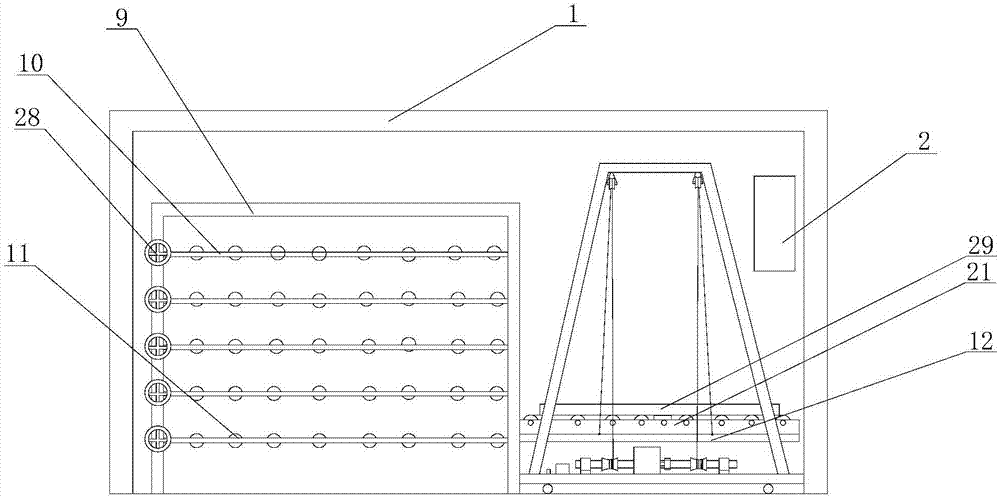

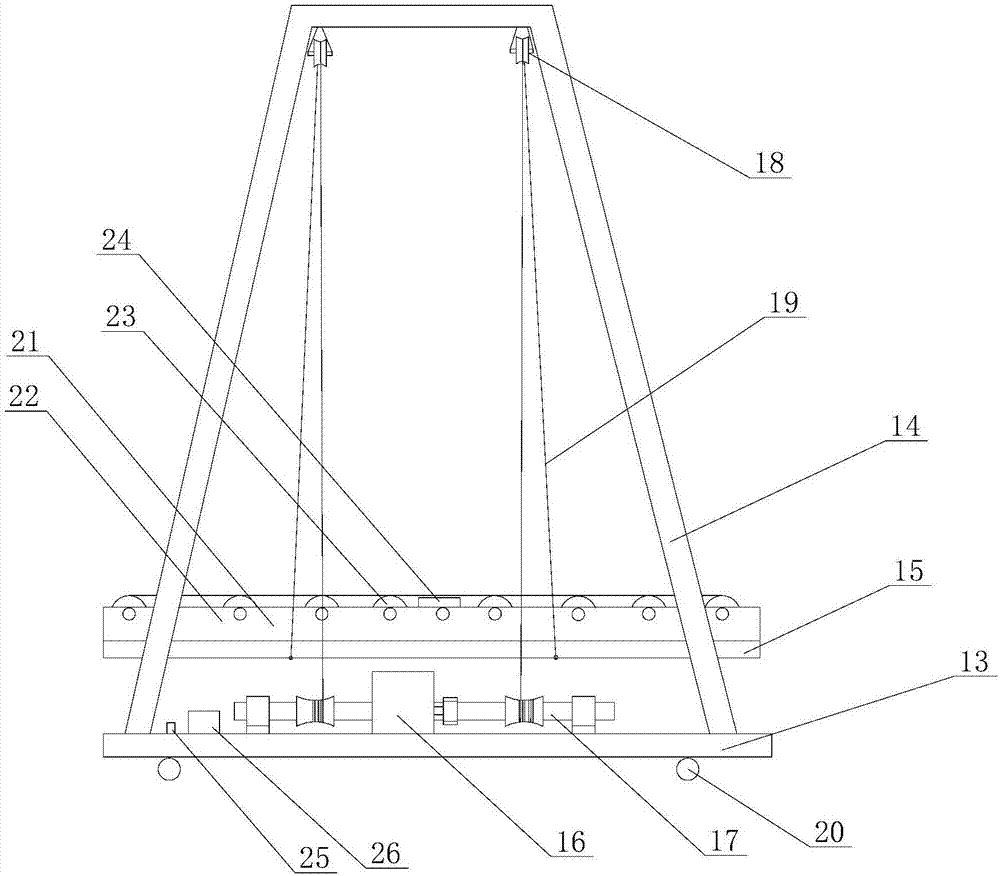

Cleaning system used for metal mask plate

PendingCN109382365AReduce volatilityEasy to fixDrying gas arrangementsDirt cleaningEngineeringMechanical engineering

The invention relates to the technical field of metal mask plates, in particular to a cleaning system used for a metal mask plate. The system includes a closed workshop, a row of cleaning tanks are placed on the floor in a workshop, and dewatering tanks are installed at the back ends of the cleaning tanks. The system is characterized in that two longitudinal beams are installed above the cleaningtanks in the workshop, two longitudinal beams are provided with mechanical arms, the cleaning system further includes a lifting appliance used for loading the metal mask plate, and the mechanical armscan lift or horizontally move the lifting appliance. The cleaning tanks include bubble cleaning tanks and alcohol cleaning tanks. The cleaning efficiency is higher, the cleaning effect is better, theoperation cost is lower, and the system is suitable for improvement of an existing metal mask plate cleaning machine.

Owner:湖北浚山光电有限公司

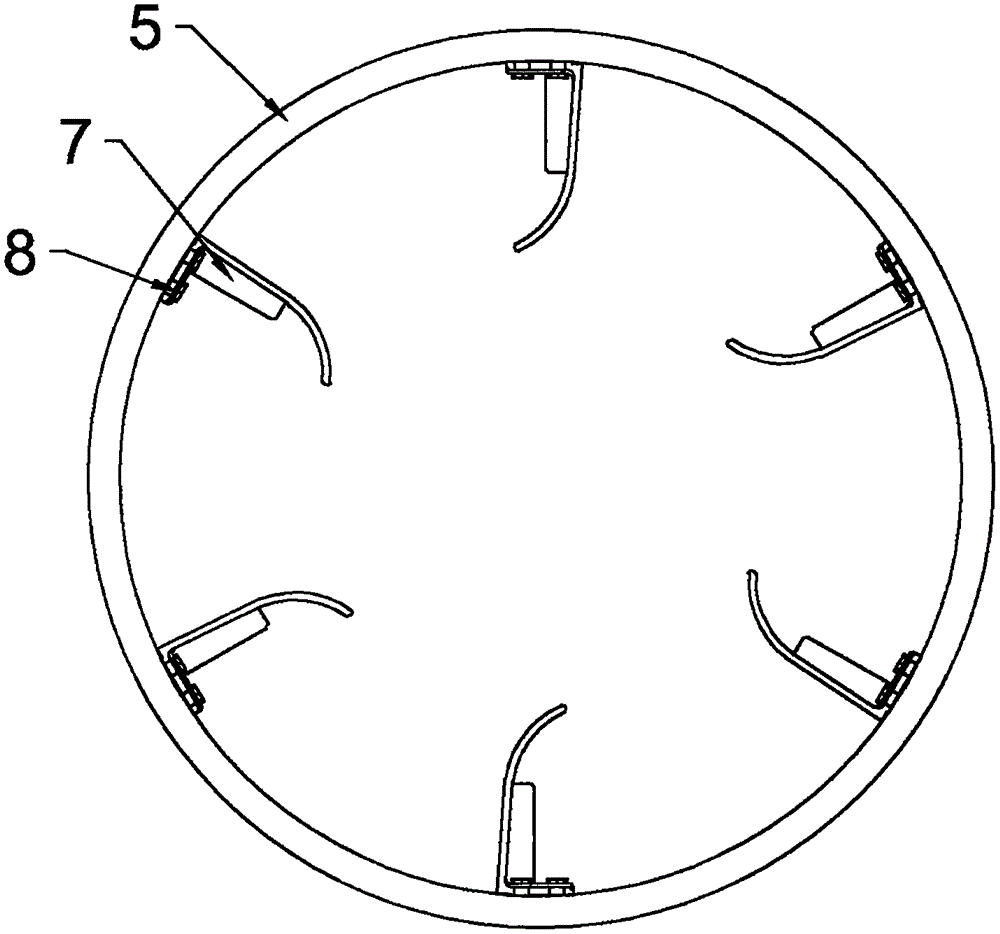

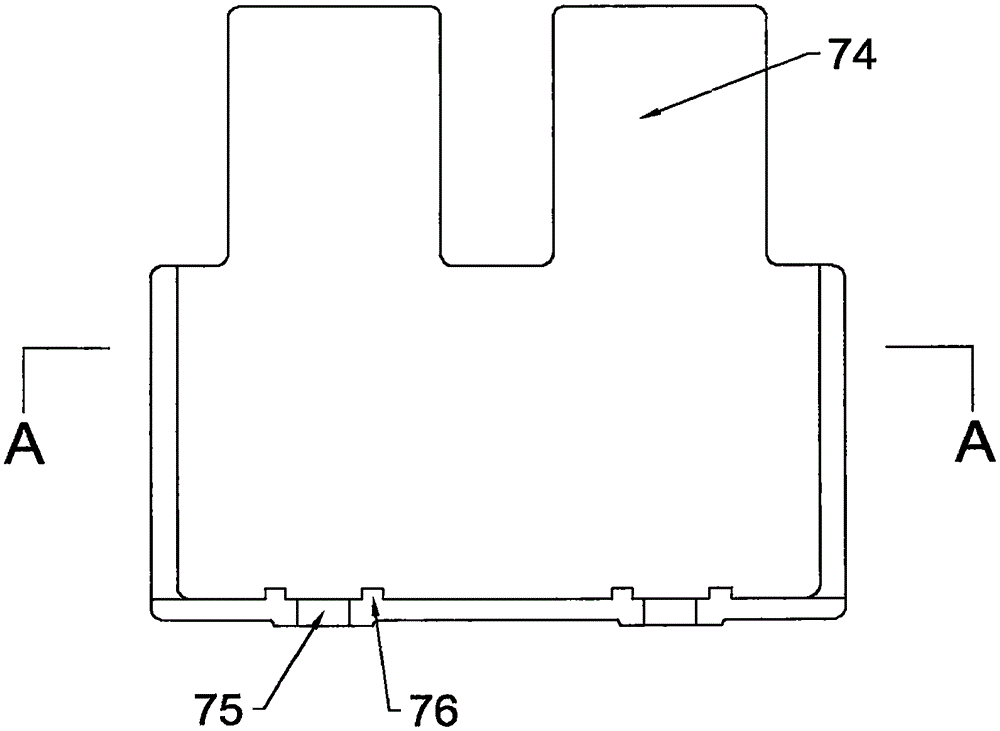

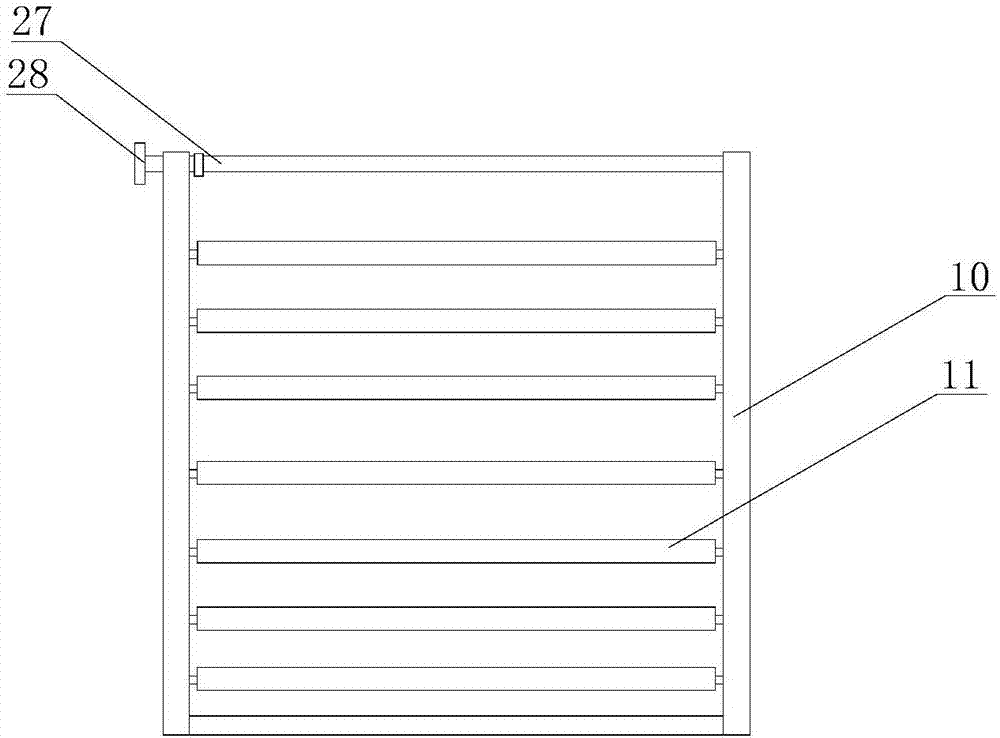

Textile drying box

InactiveCN108826912AImprove drying efficiencyEvenly heatedDrying solid materials without heatDrying gas arrangementsEngineeringSliding contact

The invention discloses a textile drying box, comprising a box body, wherein a plurality of exhaust holes are formed in the top of the box body, a multi-layer drying frame and a heating main pipe forproviding heat for the drying frame are arranged in the axial direction of the box body, and the multi-layer drying frame is driven by a rotating shaft to rotate; the drying rack comprises supportingnets fixedly sleeving the rotating shaft, the edges of the supporting nets are in sliding contact with the inner wall of the box body, a plurality of agitating blocks are arranged on each supporting net in a sliding contact manner, the agitating blocks are arranged in a ring shape around the rotating shaft, one ends of the agitating blocks are fixedly connected with the inner wall of the box body,and the same sides of the agitating blocks are smooth arc surfaces. Compared with the prior art, the supporting nets are driven by the rotating shaft to rotate, and the supporting nets and the agitating blocks cooperate with each other, so that the textile fabric is continuously rolled and agitated in the drying process, and the fabric on the supporting nets is heated uniformly, thereby improvingthe drying efficiency of the textile fabric.

Owner:HUBEI FUXING TEXTILE CO LTD

Drying device for food processing

InactiveCN111879073AHigh speedFully heatedDrying gas arrangementsDrying solid materialsElectric machineProcess engineering

The invention discloses a drying device for food processing, relates to the technical field of food processing, and mainly aims to solve the problem that existing raw materials are easy to accumulate.The drying device comprises a box body and a drying unit, a plurality of electric heating elements are installed on the two side walls of the box body, the drying unit comprises a dispersing assemblyused for dispersing materials and an air spraying assembly used for spraying hot air for drying, and the dispersing assembly comprises a supporting net, a first motor, a disc and a driving rod; the air spraying assembly comprises an air heater, a hollow rotating shaft, a driving mechanism used for driving the hollow rotating shaft to rotate, a hard air pipe, a sliding sleeve and a sliding block,the dispersing assembly is mounted, the supporting net is rapidly pulled outwards through the rapid return characteristic, raw materials on the supporting net are made to fly off upwards at a high speed and are fully and evenly heated, and the drying efficiency is improved; and the air spraying assembly is arranged, upward cyclone is formed, the drying effect is good, the air spraying angle is continuously changed, the drying range is enlarged, and the efficiency is improved.

Owner:马迎锋

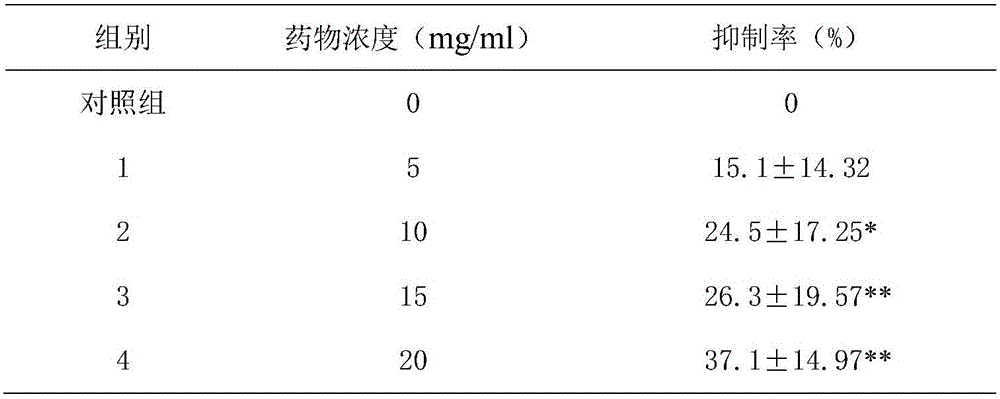

Capsules capable of activating blood and stopping pains and preparation method of capsules

InactiveCN106074658AIncreased yield of ferulic acidSimple structureHeavy metal active ingredientsHydroxy compound active ingredientsAlcohol contentGround beetle

Owner:南京多宝生物科技有限公司

Medicinal material dendrobe drying device

InactiveCN109282586AFully contactedReduce volumeDrying gas arrangementsDrying solid materialsEngineeringAir heating

Owner:NANJING ZHENGKUAN MEDICAL TECH

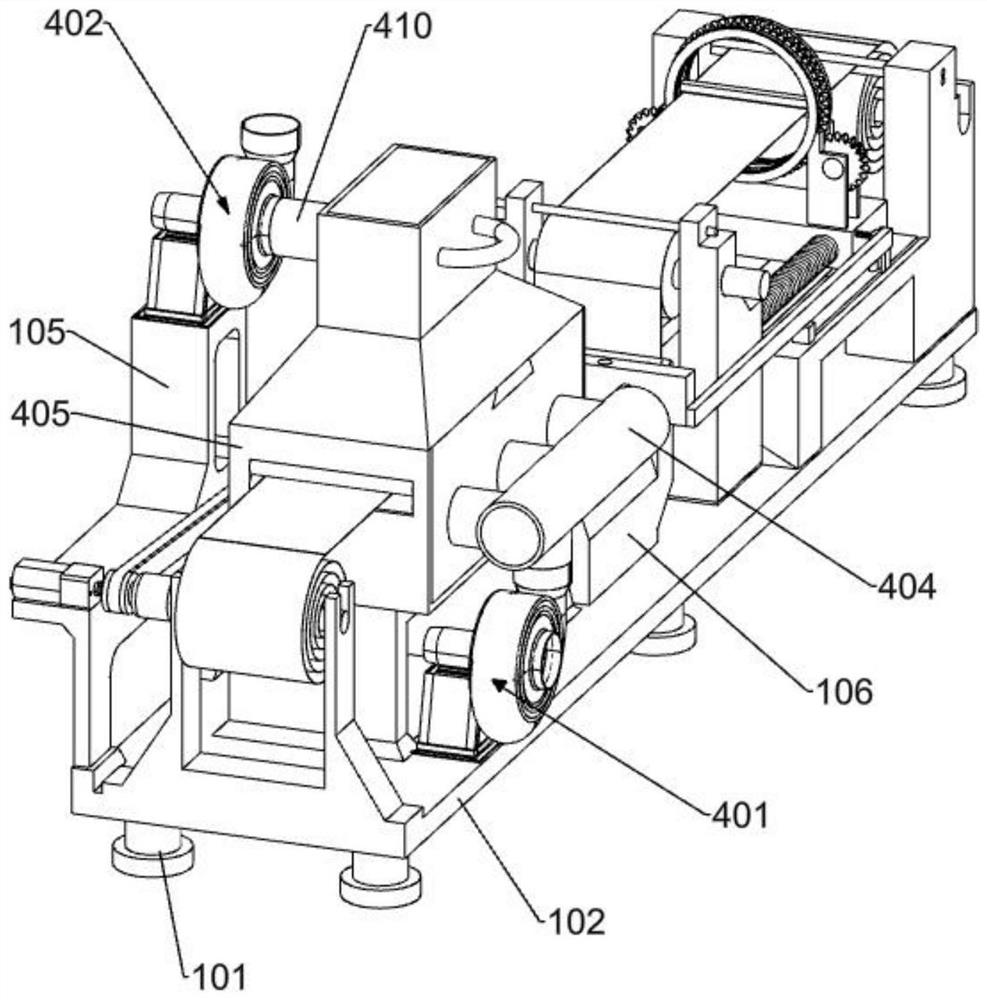

Textile cleaning and drying integrated machine

InactiveCN108035102AReduce cost inputEasy to integrateMechanical cleaningPressure cleaningAgricultural engineeringProcessing cost

The invention discloses a textile cleaning and drying integrated machine and relates to the technical field of textile processing equipment. The textile cleaning and drying integrated machine includesa box body, a filtering mechanism, a lifting mechanism, a material guiding mechanism, a water inlet pipe, a water outlet pipe, a partition plate, a long hole, strip-shaped holes, mounting plates, bearings, rotating shafts, mounting holes, connecting rods, motors, bobbins, a hot air fan, a three-way pipe, air outlet pipes, air exhaust pipes, a box door and a water tank. The middle of the front face of the box body is movably connected to the box door through hinges, and the water tank is fixedly installed in the inner bottom wall of the box body. According to the textile cleaning and drying integrated machine, the box body can be divided into two spaces for cleaning and drying through the partition plate fixedly connected in the box body, the cleaning and drying operation in the same machine can be conducted, the integration degree is high, the processing cost of the machine can be effectively saved, and accordingly the cost input of manufacturers is reduced.

Owner:SHAOXING KEQIAO CHENGXIN PRECISION CASTING CO LTD

Feed uniform stirring device with drying function

Owner:自贡正邦农牧科技有限公司

Rainproof seat of shared bicycle

Owner:邳州市景鹏创业投资有限公司

Pearl cleaning and drying device

InactiveCN107051952AEasy to pourConvenient whereaboutsDrying gas arrangementsCleaning using liquidsControl valvesRotating hinge

Owner:龚俏枚

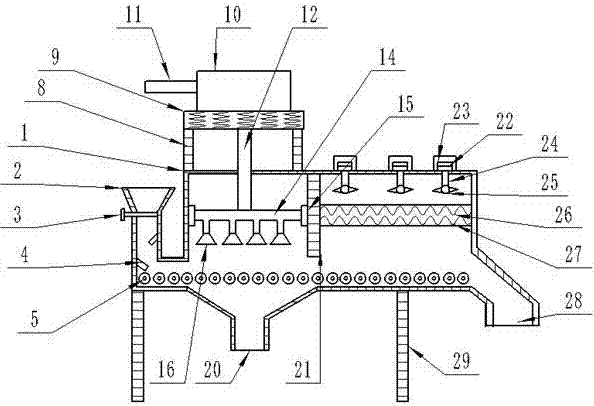

Efficient alloy baking device and baking method thereof

The invention discloses an efficient alloy baking device and a baking method thereof in the field of alloy baking. The efficient alloy baking device comprises a hot-blast stove, the hot-blast stove isconnected with an air inducing mechanism through a hot-blast pipeline, a temperature adjusting mechanism is further arranged between the air inducing mechanism and the hot-blast stove, the air inducing mechanism is connected with a baking bin, and the baking bin is arranged on a rack. The hot-blast stove is arranged on one side of the rack, a weighing and discharging mechanism is arranged below the baking bin, the baking bin is further provided with a feeding mechanism in a matched mode, and the hot-blast stove is controlled by an intelligent detection control system. The hot-blast stove andthe baking bin are of a separated structure, coal gas can be fully combusted, carbon monoxide poisoning accidents are avoided, safety measures are complete, the hot-blast stove is controlled by the intelligent detection control system, the hot-blast stove and the baking bin can be monitored in real time, and the heat energy utilization efficiency is greatly improved through the air inducing mechanism and the temperature adjusting mechanism. The efficient alloy baking device and the baking method thereof can be used for iron alloy baking.

Owner:JIANGSU EURASIA ENVIRONMENTAL PROTECTION TECH CO LTD

Crop uniform drying device

InactiveCN108007128ASolve the problem of not having uniform dryingDry evenlyDrying gas arrangementsDrying machines with non-progressive movementsEngineeringDrying time

Owner:王腾蛟

Fluid pressure detection device

InactiveCN111426422AKeep dryPlay a drying roleHollow article cleaningDrying gas arrangementsElectric machineryEngineering

Owner:CHONGQING UNIV OF ARTS & SCI

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap