Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

12 results about "Sliding contact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sliding Contact¶. The sliding contact is a special type of contact which allows dispacement tangential to the contact surface but no relative movement along the normal direction.

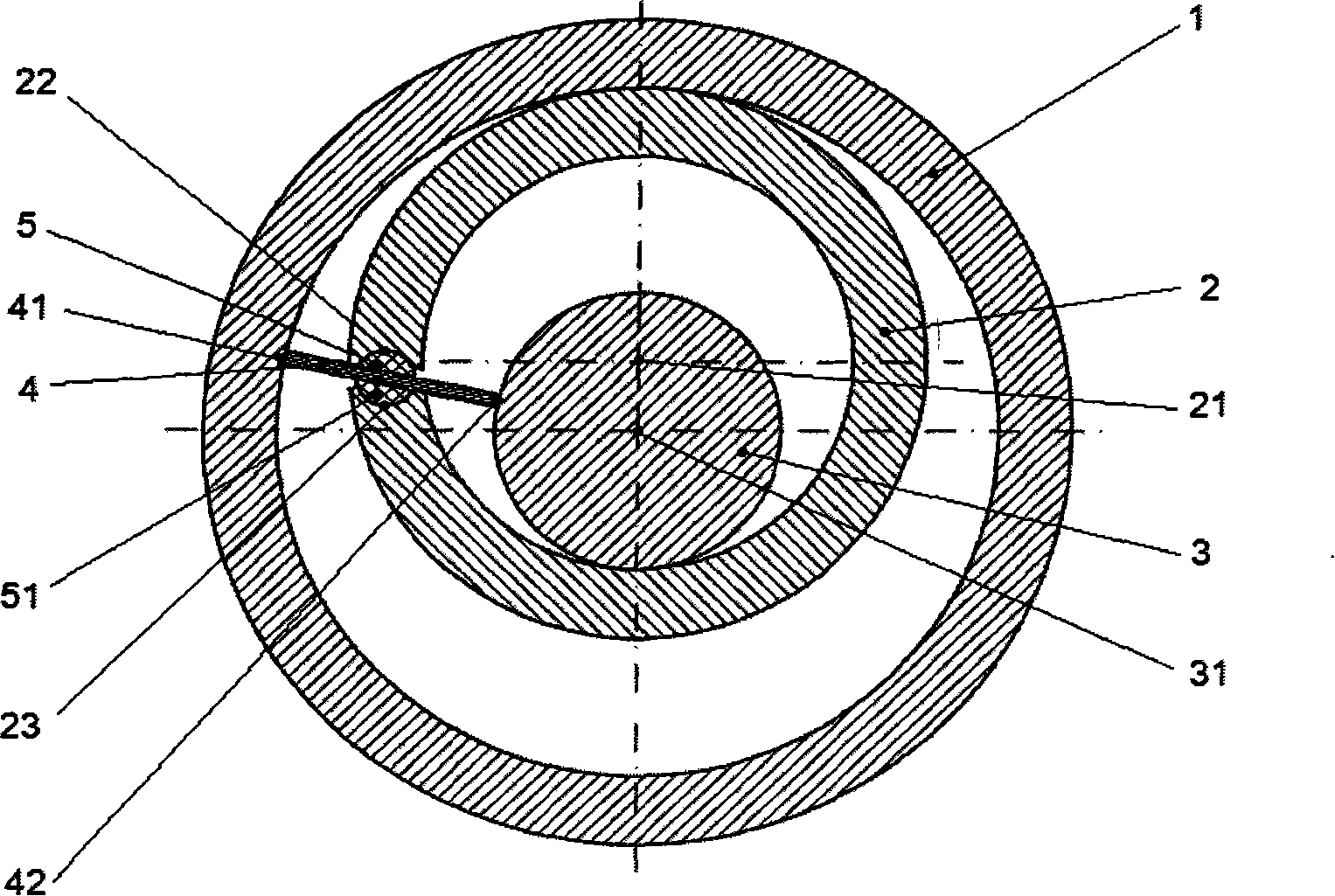

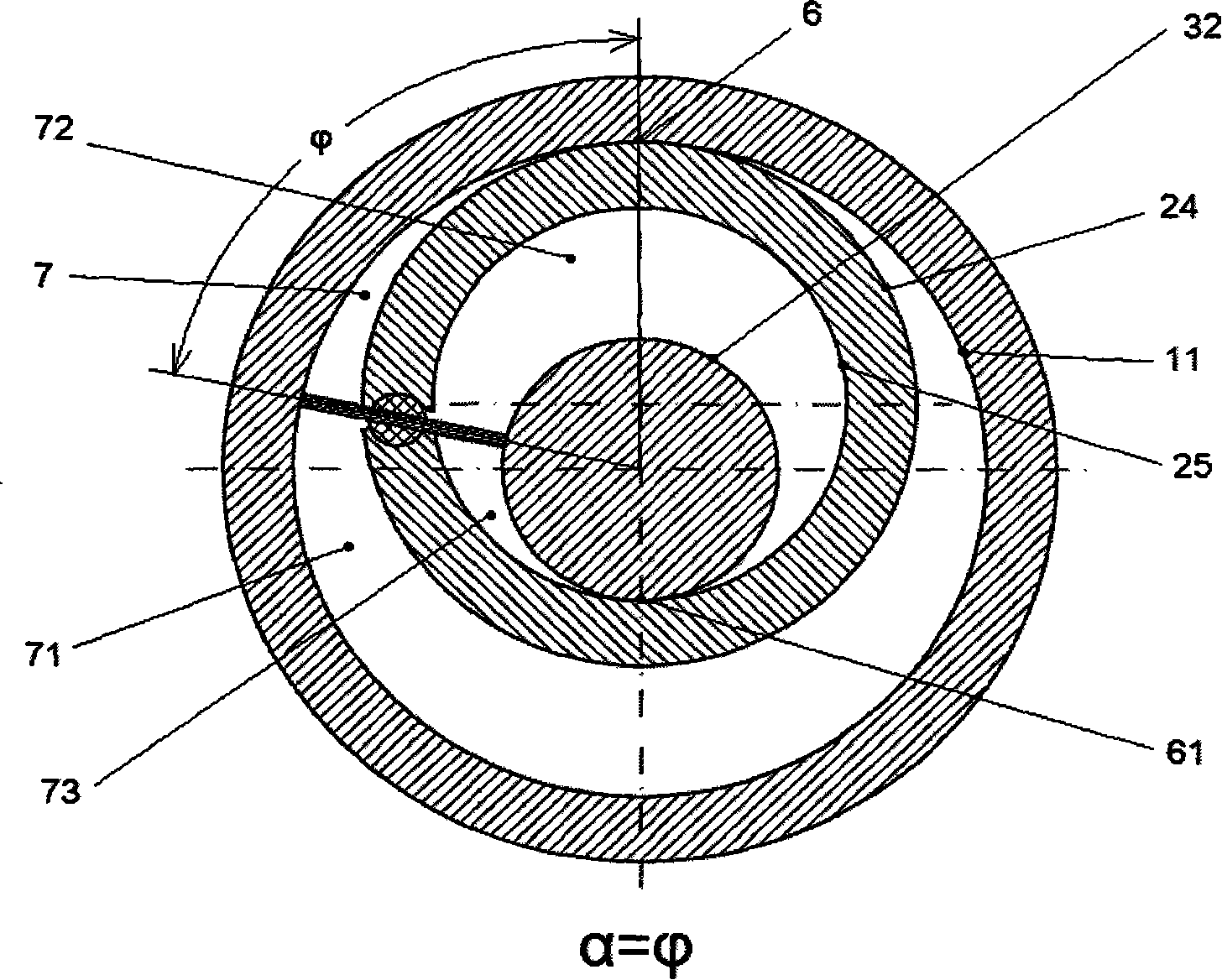

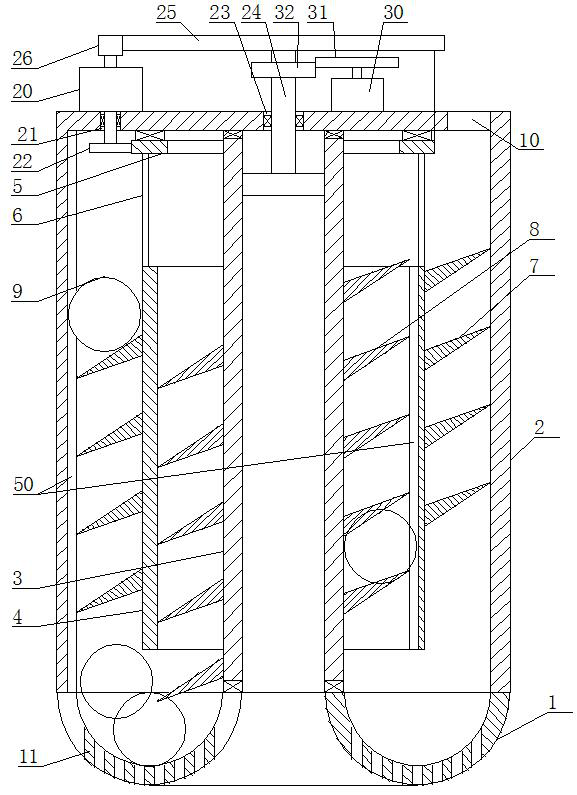

Rotary type fluid machine transfiguration mechanism

InactiveCN101251106AStop invalid flowSolve the liquid hammer problemRotary piston pumpsRotary piston liquid enginesSlide plateEngineering

Owner:贲铭鑫

Anaesthetic-concentration-adjustable device

The invention provides an anaesthetic-concentration-adjustable device. The device comprises a base; two horizontal pipes distributed up and down are arranged above the base; the horizontal pipe on thelower side is fixedly connected with the base; the two horizontal pipes are fixedly connected; annular partition plates which are symmetrical from side to side are arranged on the middle parts of thehorizontal pipes respectively; the inner side of each annular partition plate and the inner periphery of the corresponding horizontal pipe form a gas storage cavity; the interiors of the annular partition plates are fixedly connected with the gas inlet ends of first one-way valves respectively; first pistons are respectively arranged on the left sides and right sides of the interiors of the horizontal pipes; the inner side of each first piston, the outer side of the corresponding annular partition plate, and the inner periphery of the corresponding horizontal pipe form a gas inlet cavity; thegas inlet cavities and the gas storage cavities are communicated through the first one-way valves; the outer periphery of each first piston is respectively matched with the inner wall of the corresponding horizontal pipe in a sliding contact way; first through holes are respectively formed in the middles of the outer sides of the first pistons. The anaesthetic-concentration-adjustable device is ingenious in design and convenient in use and operation, and can continuously mix anesthetic gas and loaded gas in small batches; the mixing is more uniform; waste caused by residues after mixing of alarge quantity of anesthetic gas is avoided.

Owner:肖锦亮 +2

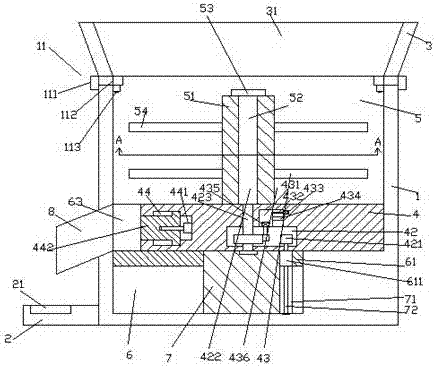

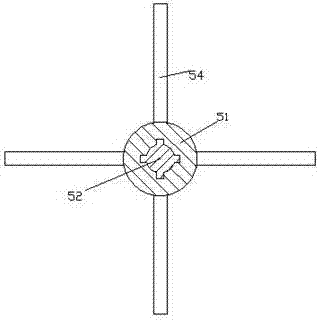

Textile drying box

InactiveCN108826912AImprove drying efficiencyEvenly heatedDrying solid materials without heatDrying gas arrangementsEngineeringSliding contact

The invention discloses a textile drying box, comprising a box body, wherein a plurality of exhaust holes are formed in the top of the box body, a multi-layer drying frame and a heating main pipe forproviding heat for the drying frame are arranged in the axial direction of the box body, and the multi-layer drying frame is driven by a rotating shaft to rotate; the drying rack comprises supportingnets fixedly sleeving the rotating shaft, the edges of the supporting nets are in sliding contact with the inner wall of the box body, a plurality of agitating blocks are arranged on each supporting net in a sliding contact manner, the agitating blocks are arranged in a ring shape around the rotating shaft, one ends of the agitating blocks are fixedly connected with the inner wall of the box body,and the same sides of the agitating blocks are smooth arc surfaces. Compared with the prior art, the supporting nets are driven by the rotating shaft to rotate, and the supporting nets and the agitating blocks cooperate with each other, so that the textile fabric is continuously rolled and agitated in the drying process, and the fabric on the supporting nets is heated uniformly, thereby improvingthe drying efficiency of the textile fabric.

Owner:HUBEI FUXING TEXTILE CO LTD

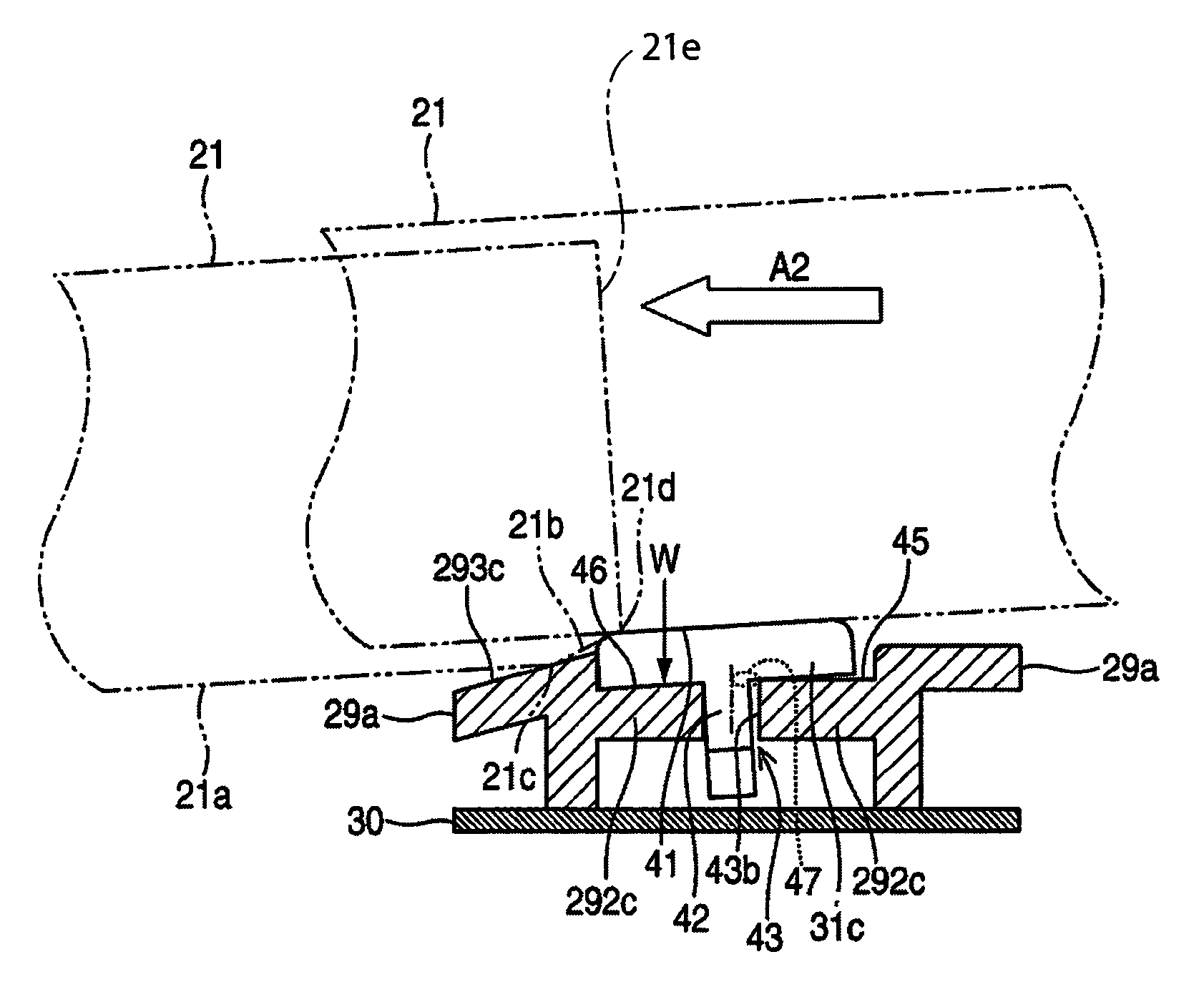

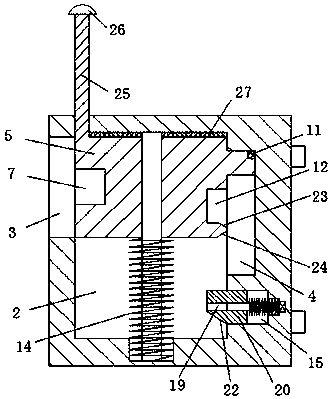

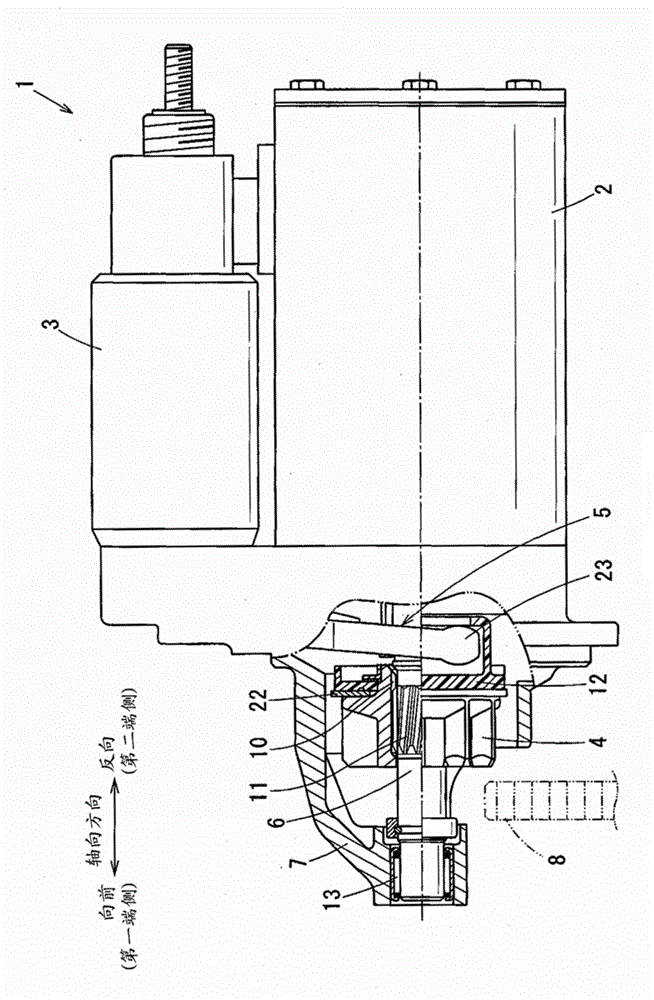

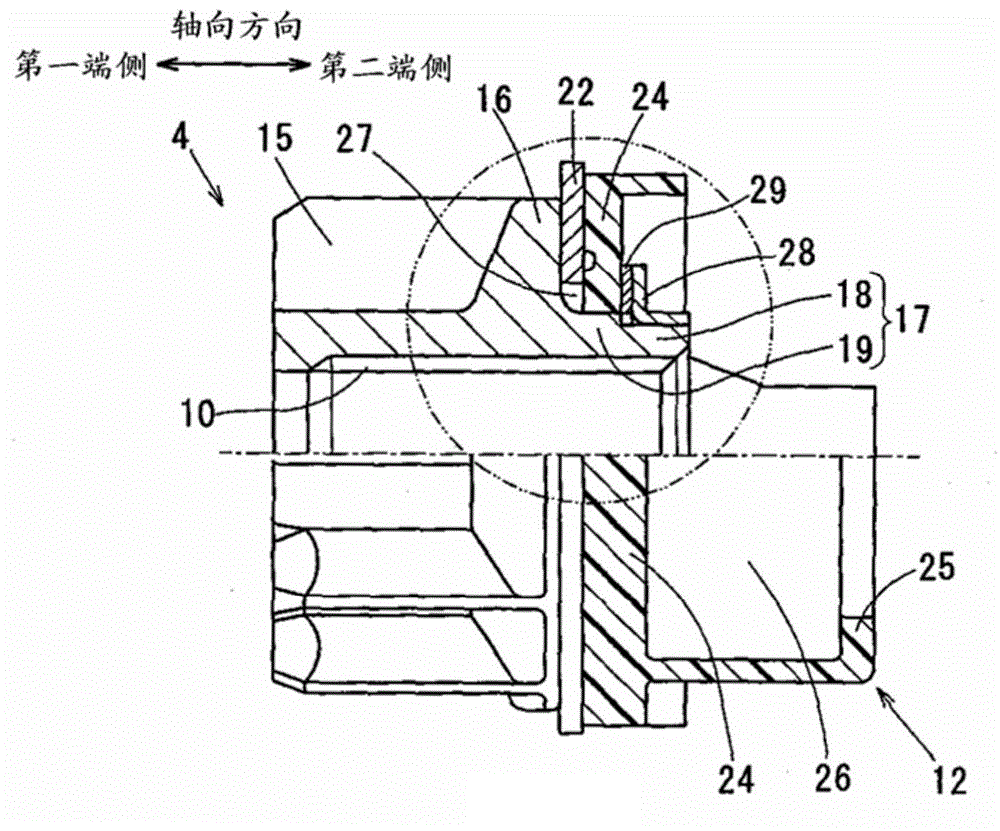

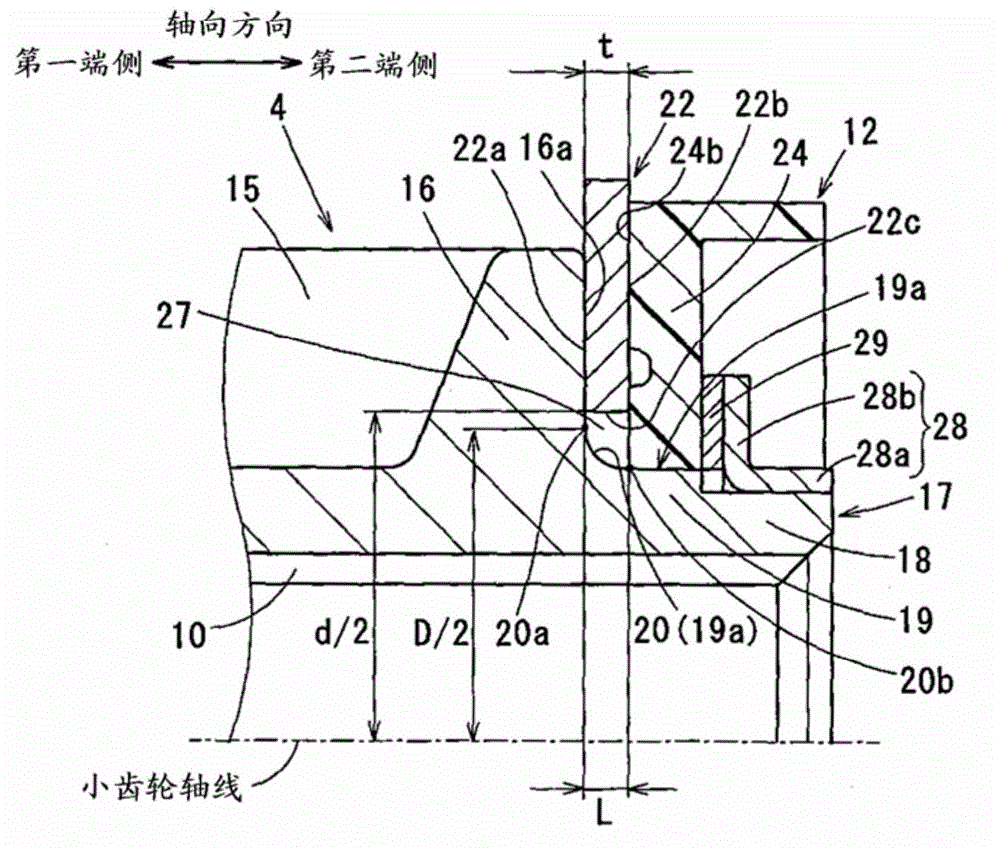

Friction bonding structure and pump device

InactiveUS20130064601A1Sealing arrangements for enginesRotary piston pumpsEngineeringSliding contact

An annular groove is formed at an open end of a motor case, and a sliding contact projection, which is in an annular plate-shape and corresponding to the annular groove, is formed on a cover. A bottom of the annular groove and the sliding contact projection rotate relative to each other while being in sliding contact with each other to form an annular friction bonded portion therebetween. Wall portions of the annular groove are arranged at such positions as to be concentric with the friction bonded portion. Thus, a storage portion that stores burrs produced at the friction bonded portion is formed. A plurality of protrusions that protrude radially outward is formed on the sliding contact projection over all around. The storage portion is partitioned in the circumferential direction by using the protrusions as partitioning elements.

Owner:JTEKT CORP

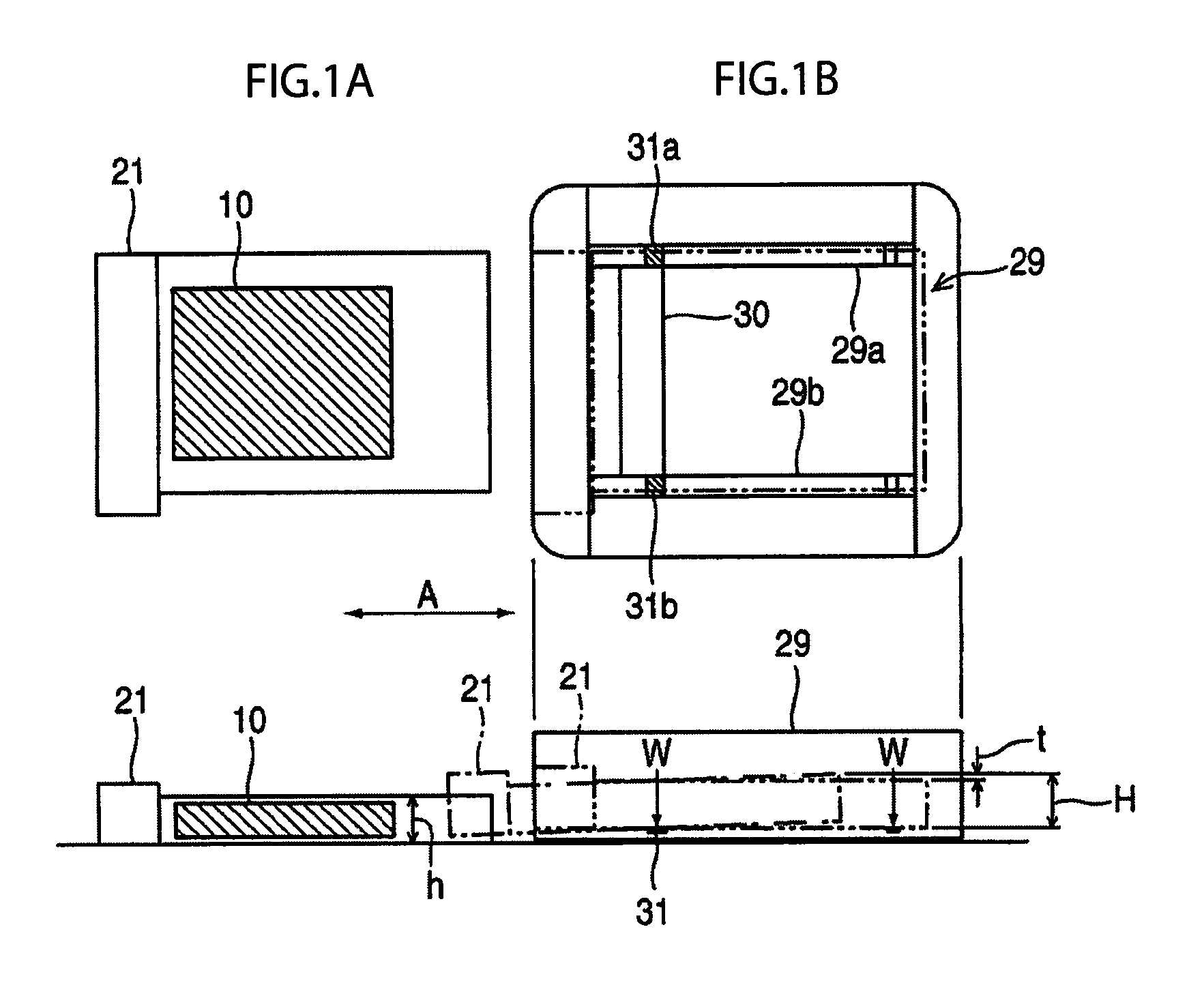

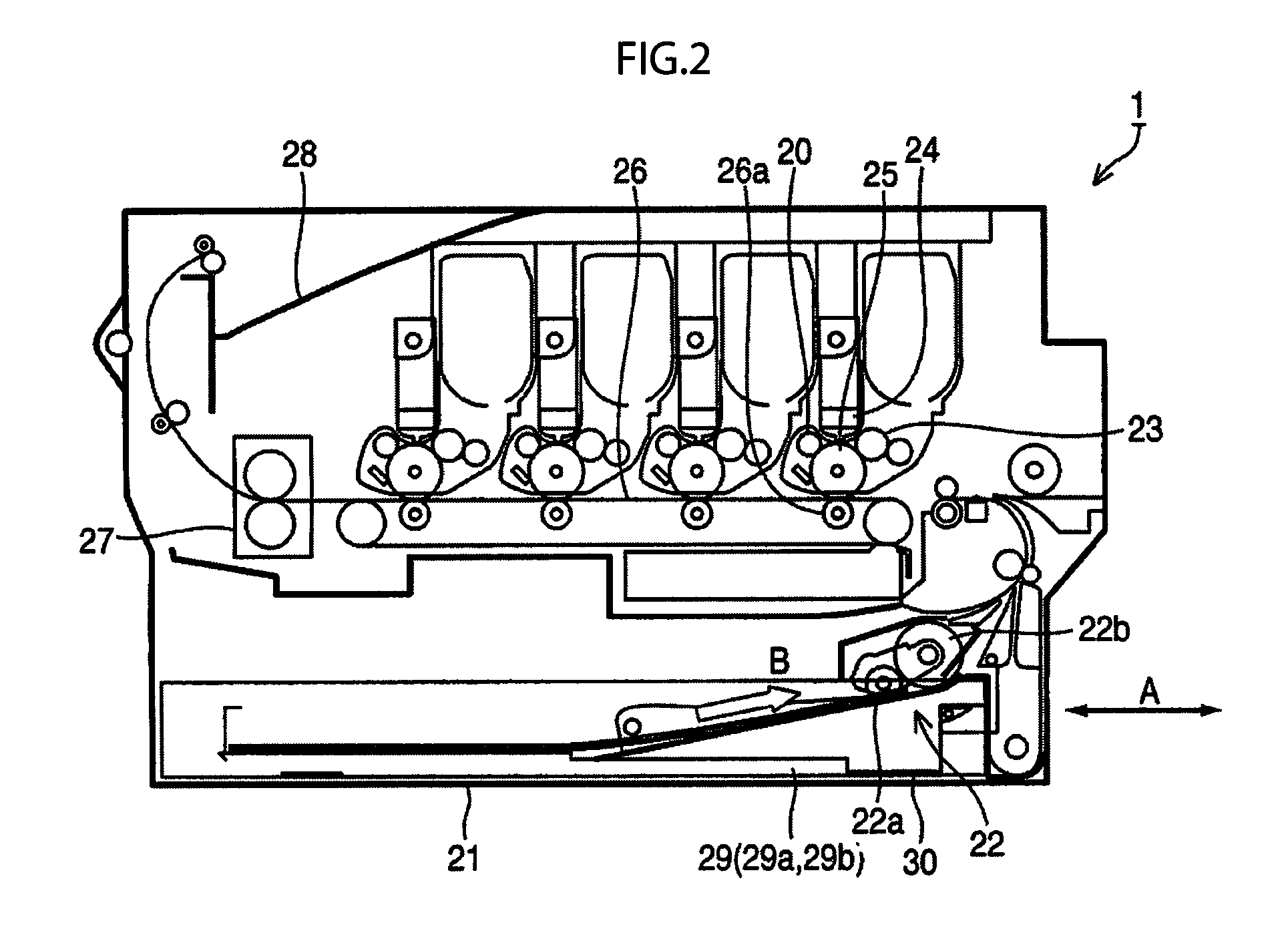

Media cassette housing system and image formation apparatus

InactiveUS20130049292A1Reduce friction and wearElectrographic process apparatusOther printing apparatusMagnetic tapeImage formation

Owner:OKI DATA CORP

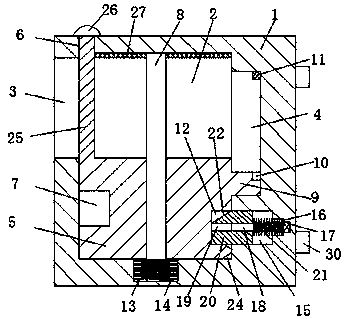

Injection mould device with spray nozzle self-centering device

The invention discloses an injection mould with a spray nozzle self-centering device. The injection mould with the spray nozzle self-centering device comprises a fixed mould, a moving mould, a mould line cavity, a flow distribution plate and a spray nozzle device, wherein the spray nozzle self-centering device is arranged at the upper end of the spray nozzle device; the spray nozzle self-centering device comprises a connecting part, a protective ring, and a guide ring part which are arranged outside a spray nozzle main body from the top to the bottom; and the spray nozzle main body is fixed to the bottom surface of the flow distribution plate axially through the connecting part by the protective ring. By rotating the guide ring part forwards or reversely, a first central guide surface and a second central guide surface are matched and then are separated to finish the self-centering of the spray nozzle device and keep the centers of related components aligned. A radial sliding clearance is formed between the protective ring and the connecting part to counteract horizontal movement of the protective ring caused by thermal expansion of the flow distribution plate, wherein the bottom surfaces of the protective ring and the connecting part are in sliding contact, so that the spray nozzle main body cannot be influenced by the thermal expansion and deformation and a centering state is remained.

Owner:HOTSYS CO LTD

Bridge construction equipment

Owner:黄铁

Catalyst extrusion molding machine convenient to maintain

Owner:ZIBO QIMAO CATALYST

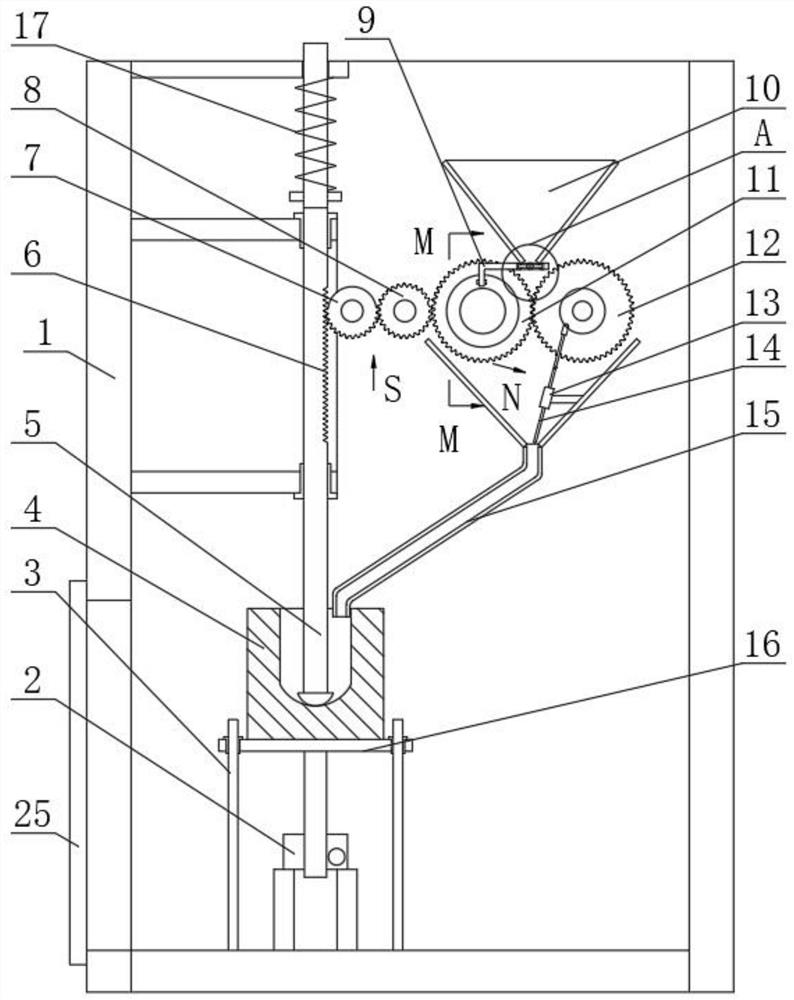

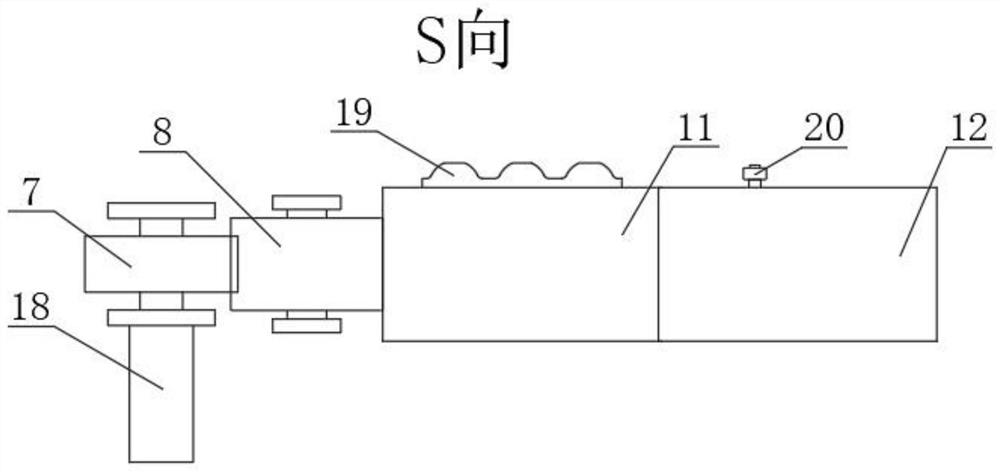

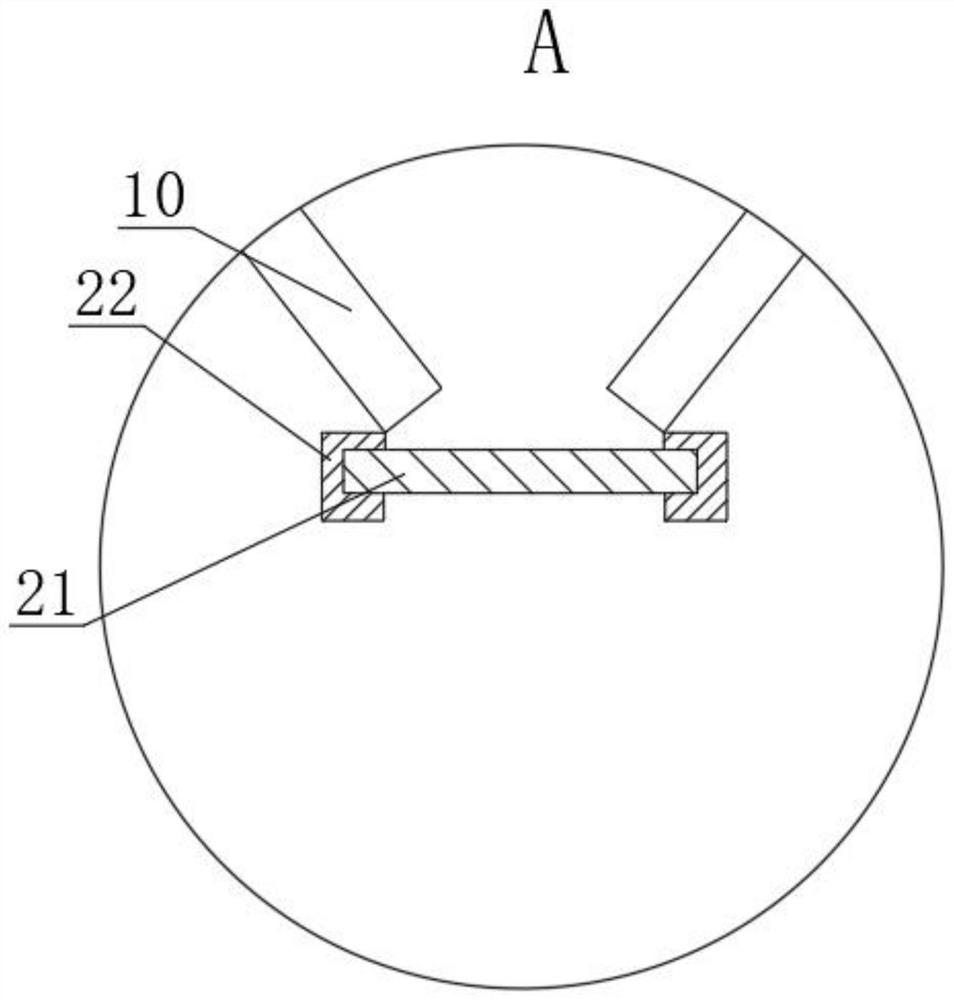

Agricultural straw smashing device

Owner:叶丛杰

Intermittent feeding type tablet grinding device and using method thereof

InactiveCN113019526ARealize the pounding workRealize intermittent feedingGrain treatmentsStructural engineeringDrive motor

Owner:周欢欢

Starter

Owner:DENSO CORP

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap