Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

25 results about "Waste gas" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Healthcare workers in a variety of settings can be exposed to the anesthetic gases that are released or leak out during medical procedures. These gases and vapours are known as waste anesthetic gases (WAGs).

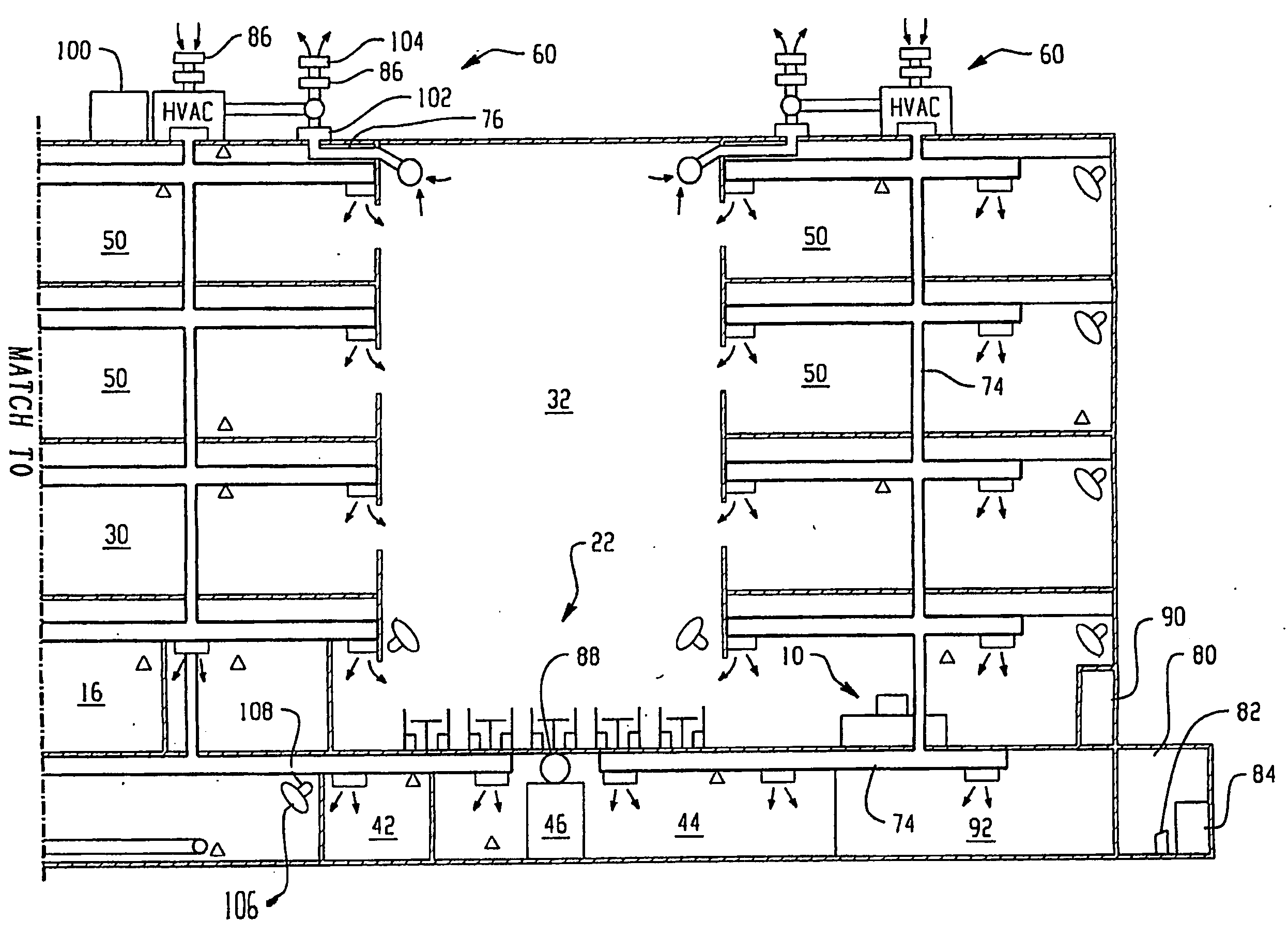

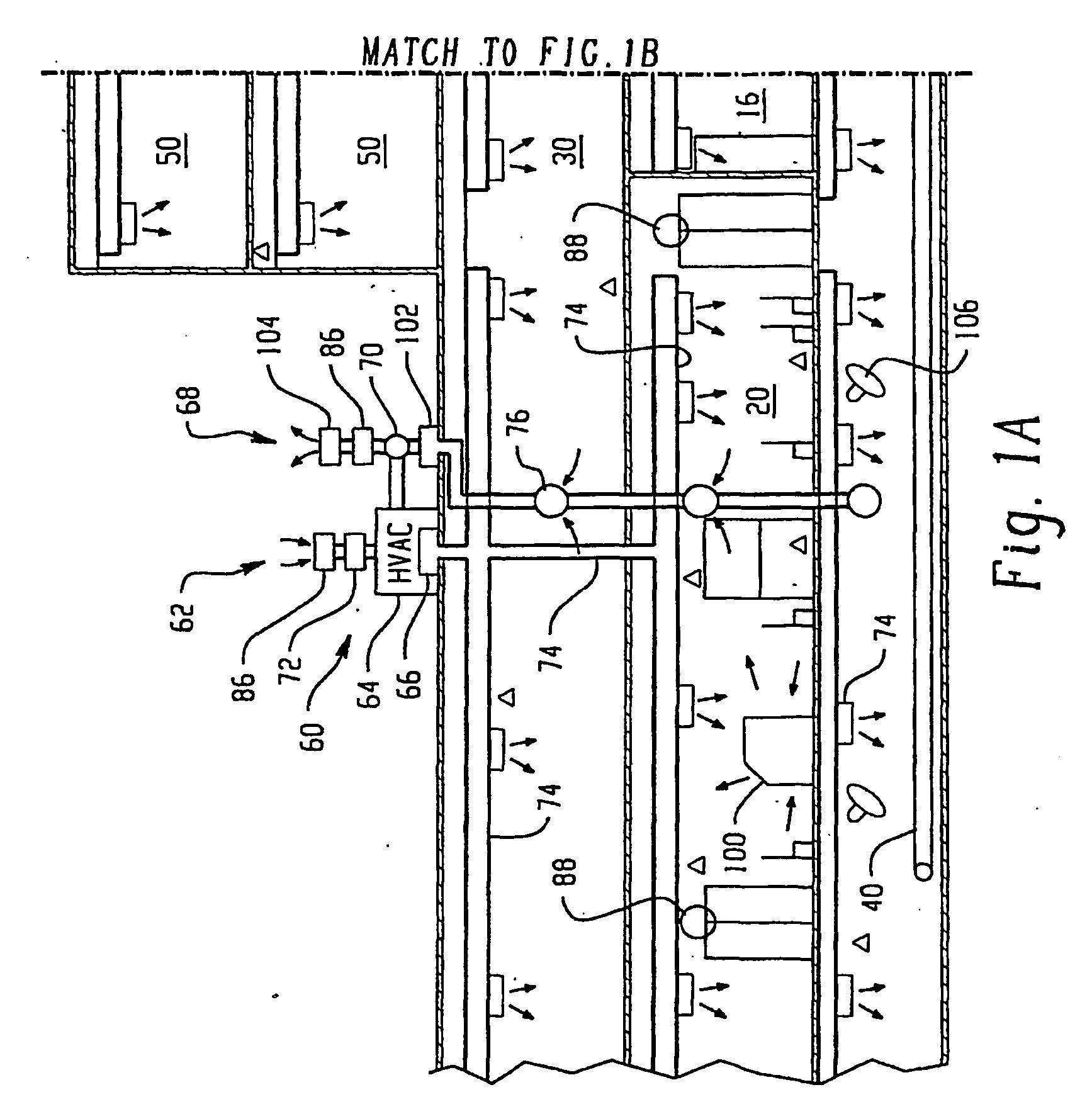

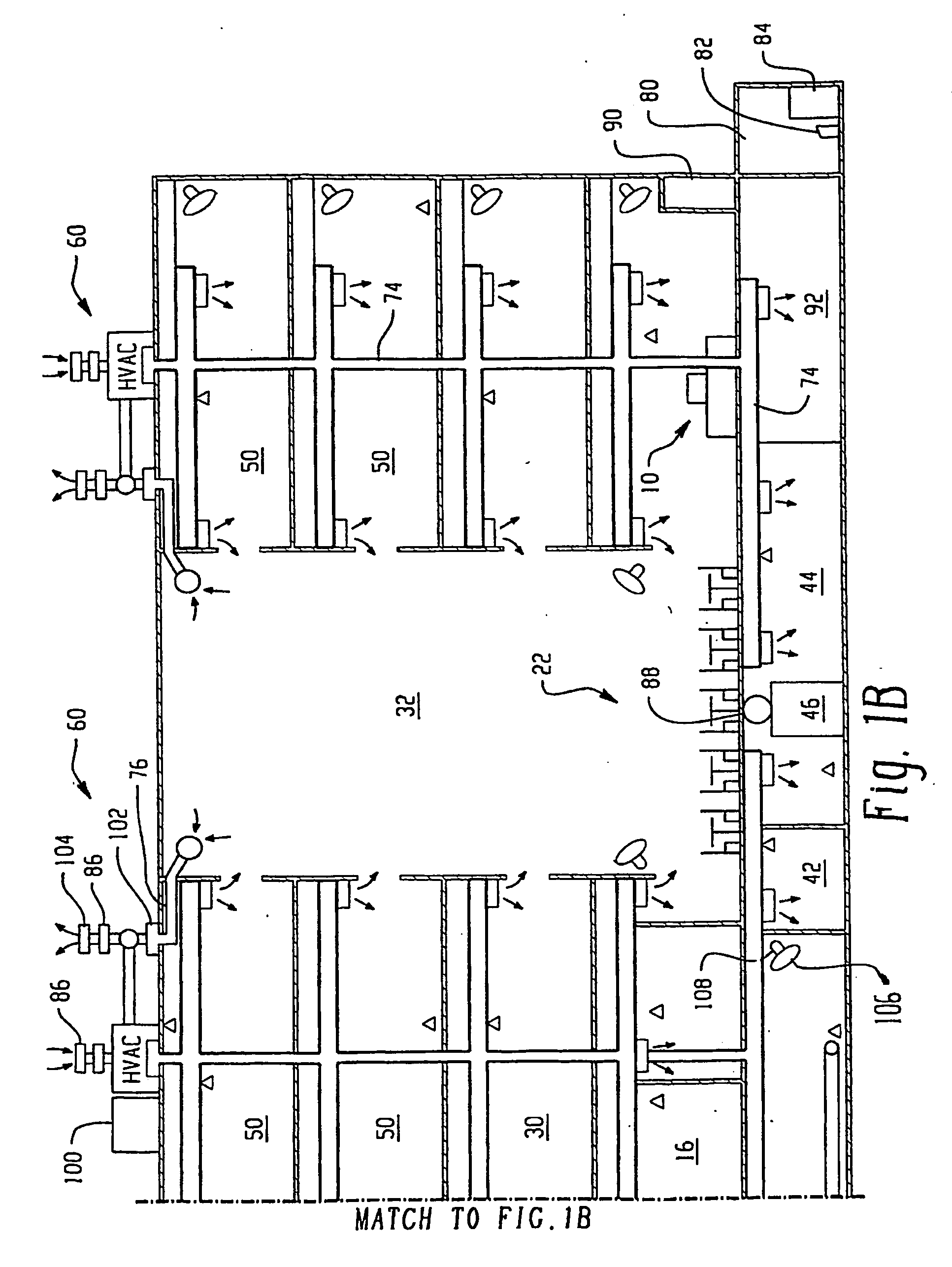

Integrated control and distribution system for the decontamination of large volume convoluted configuration spaces

ActiveUS20070140893A1Big spaceQuick implementationComponent separationSynthetic resin layered productsDistribution systemProcess engineering

Owner:STERIS CORP

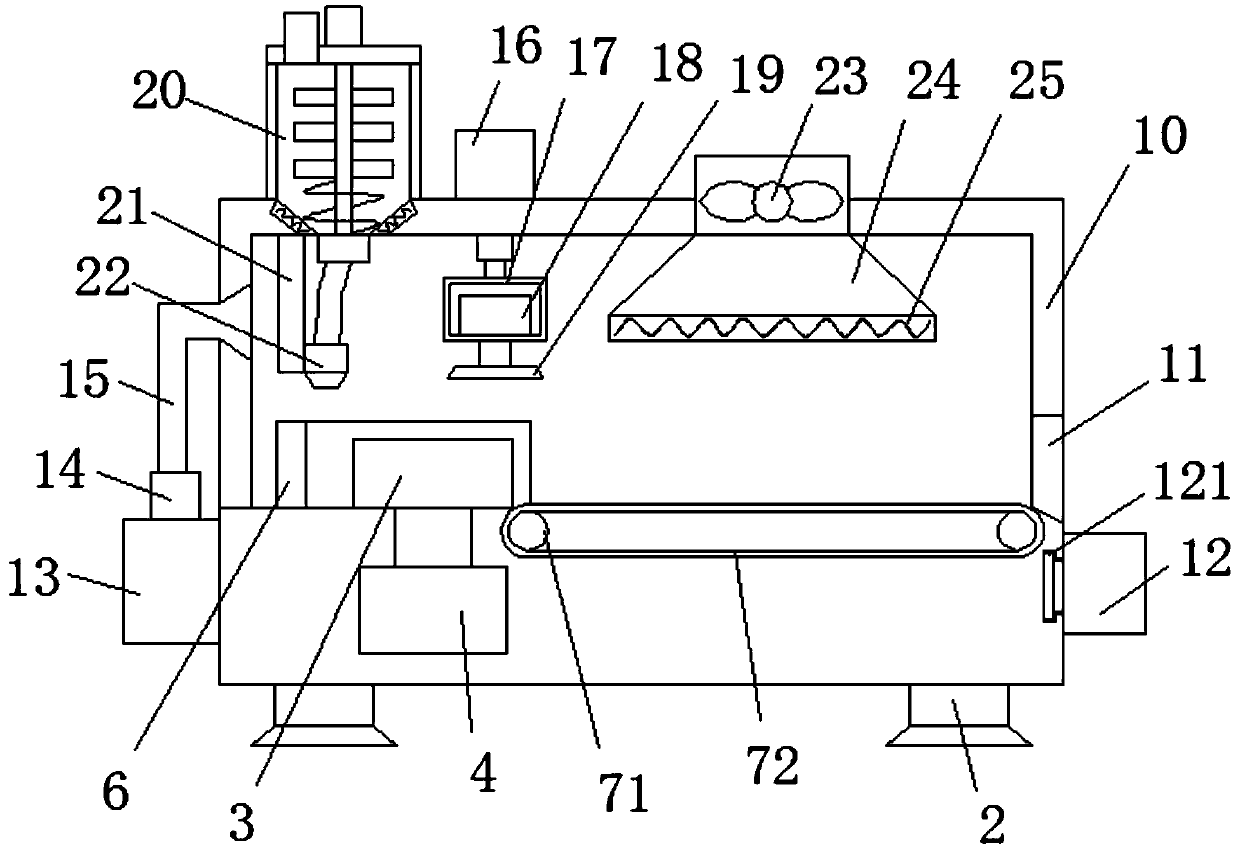

Automatic circular metal plate spray coating device

PendingCN111215268AEasy to sendConveying with different conveying directions facilitatesSpray boothsElectric machineSpray coating

Owner:JILIN UNIV

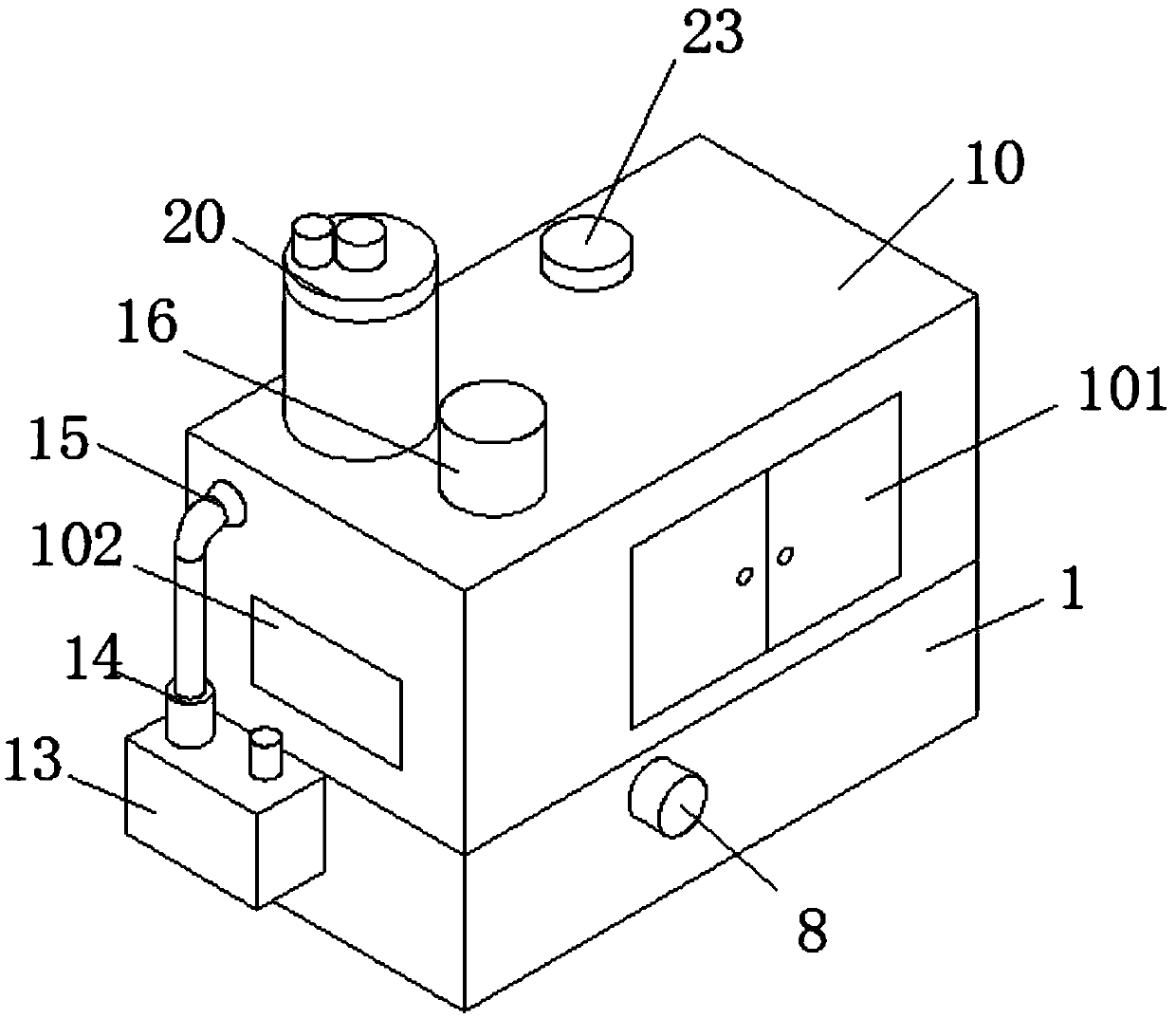

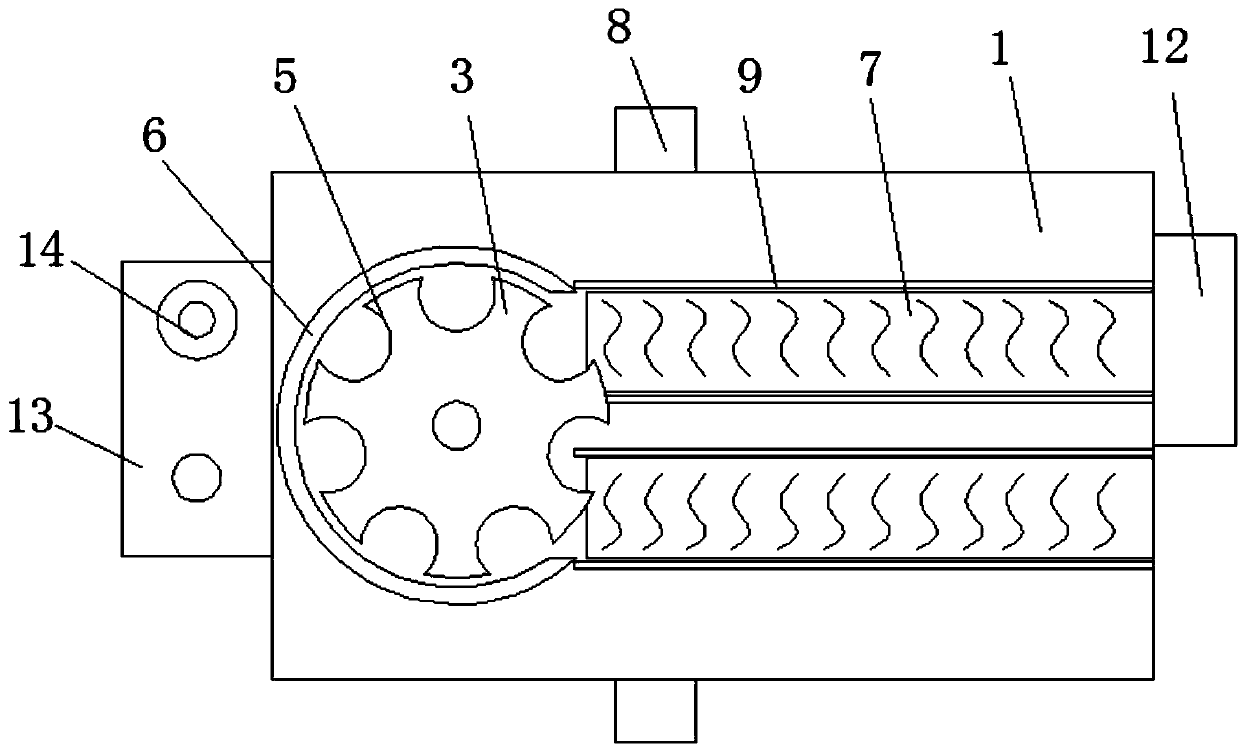

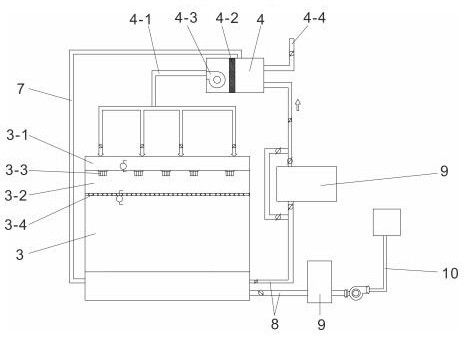

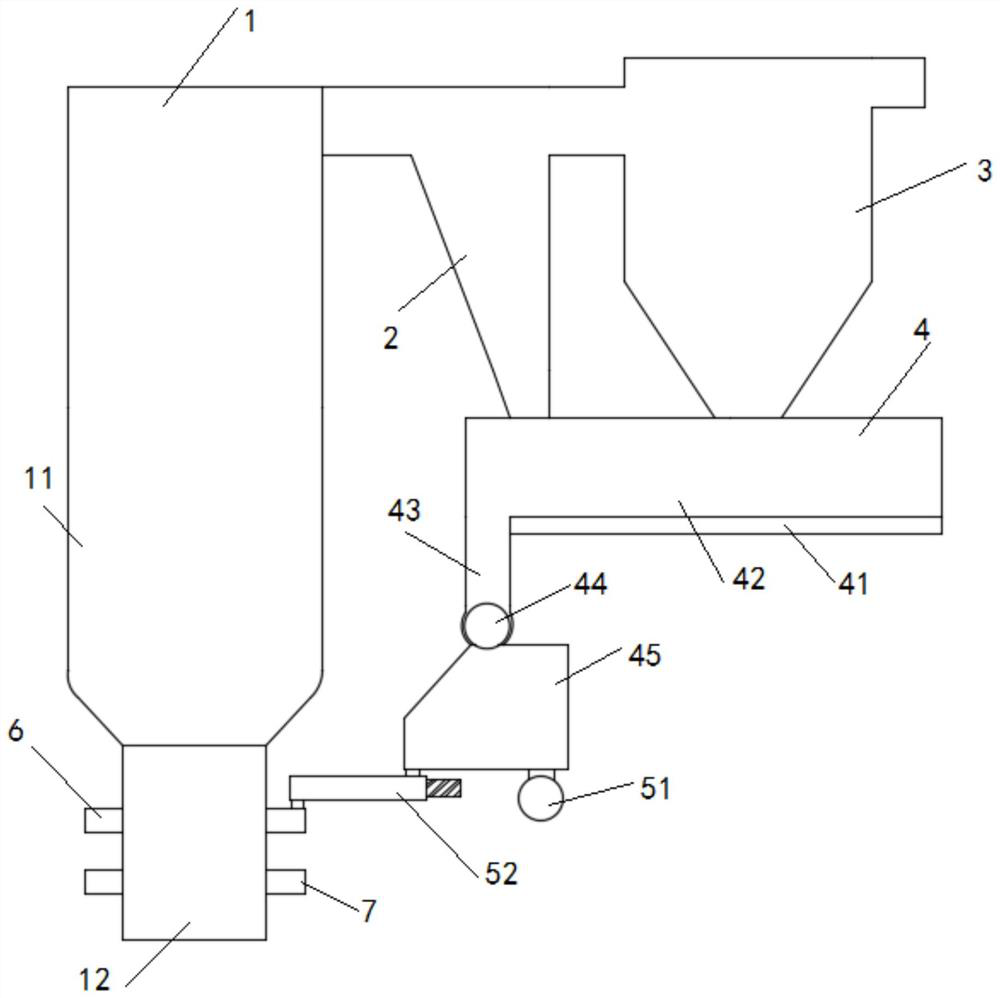

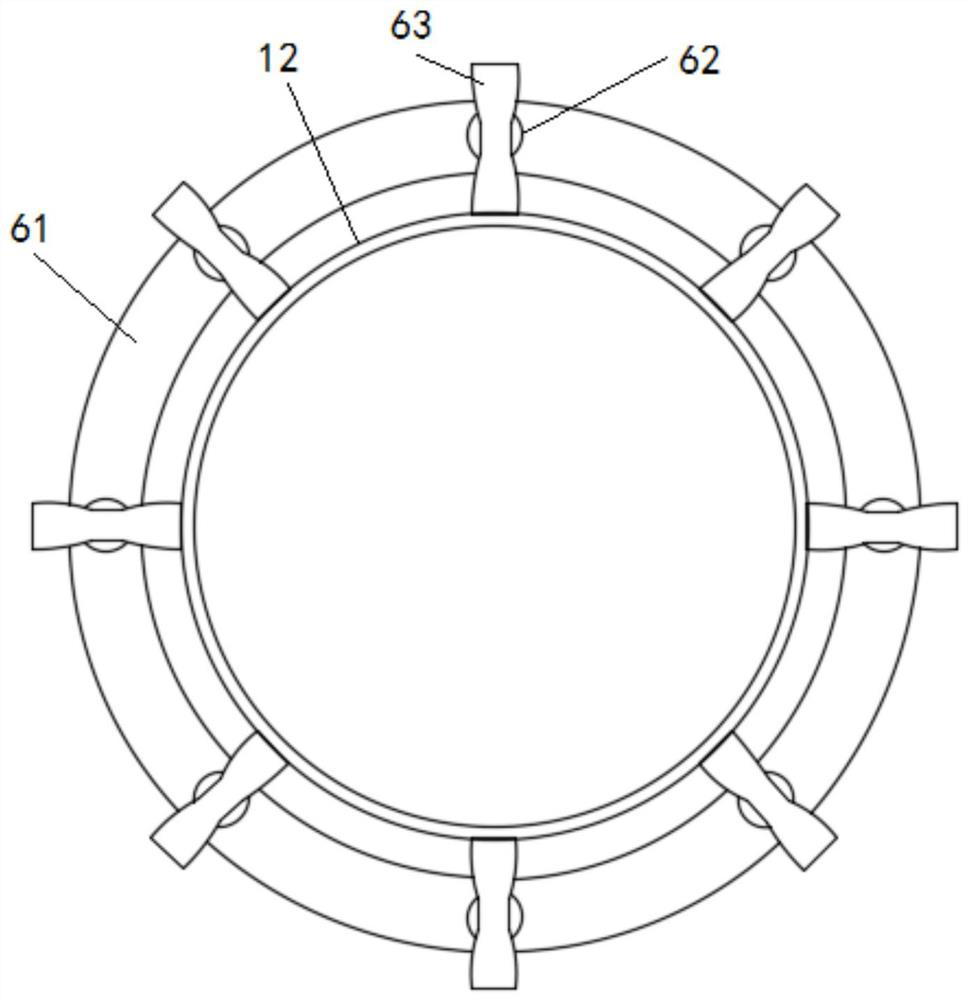

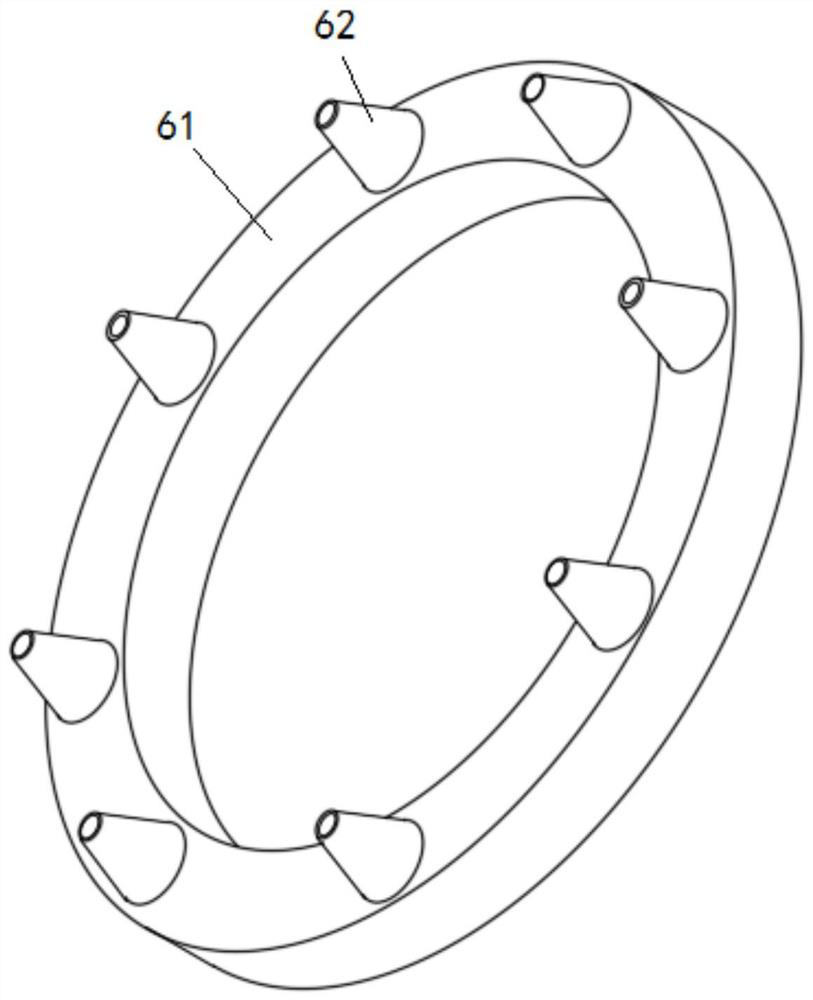

Waste gas neutralization treatment device for thermal power plant

InactiveCN114307598AReduce manufacturing costSave the hassle of steering switchingLighting and heating apparatusHollow article cleaningPower stationEnvironmental engineering

The invention discloses a waste gas neutralization treatment device for a thermal power plant, relates to the technical field of waste gas treatment equipment, and solves the problems that most of existing waste gas treatment equipment needs to be additionally matched with a cleaning assembly for a smoke exhaust mechanism such as a chimney, an original spraying assembly cannot be used for internal cleaning, and the manufacturing cost of the equipment cannot be reduced. The waste gas neutralization treatment device for the thermal power plant comprises a chimney, the chimney is of a circular structure, a settlement cover is welded to the bottom of the chimney, a discharge pipe is welded and communicated to the bottom of the settlement cover, four vertical supporting shafts are symmetrically welded to the bottom of the chimney, and an annular base is welded and fixed to the bottoms of the four vertical supporting shafts; and two electric push rods are symmetrically mounted on the top end sections of the two vertical supporting fulcrum shafts which are in bilateral symmetry in a hanging and supporting mode, and a baffle is locked and fixed to the bottoms of the two electric push rods. The trouble that six vertical water spraying pipes are subjected to steering switching through manual driving operation can be omitted, and use is convenient, labor-saving and rapid.

Owner:杜苏月

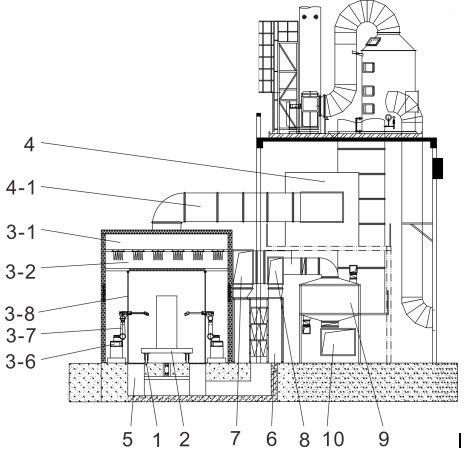

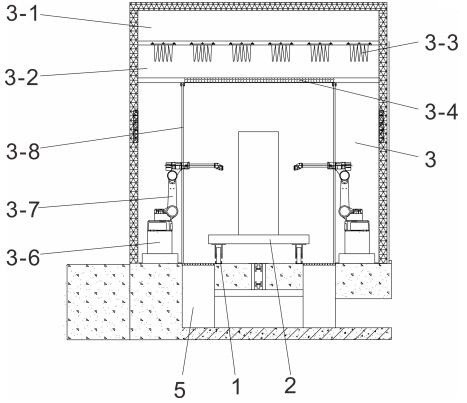

Paint spraying and drying integrated room for robot operation

Owner:苏州金迈驰航空智能科技有限公司

Anode intermittent exhaust method for anode closed proton exchange membrane fuel cell

The invention provides an anode intermittent exhaust method for an anode closed proton exchange membrane fuel cell. A humidification treatment program is set during an exhaust operation, and a protonexchange membrane is subjected to humidification treatment before exhaust gas is discharged. According to the method, by monitoring the voltage in system operation and closing a plurality of valves, the problems of repeated water loss and absorption of a membrane electrode during the intermittent exhaust process of the anode closed proton exchange membrane fuel cell are solved, and the problem ofslow recovery after an excessive voltage drop during the exhaust process is solved.

Owner:GREE ELECTRIC APPLIANCE INC OF ZHUHAI

Environment-friendly waste gas detection device

InactiveCN110672798AEasy to installThe test result is accurateMaterial analysisEnvironmental engineeringIntegrated design

Owner:榆林市榆阳区昱茂农业科技有限公司

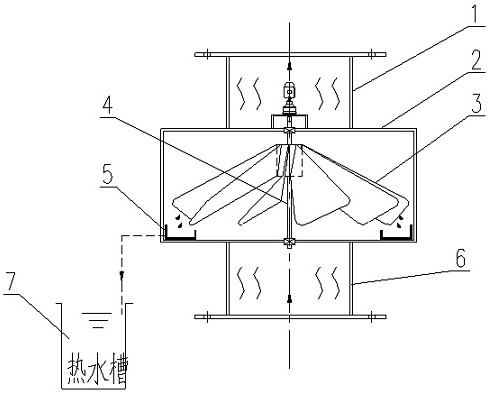

Online wet and hot water vapor recovery device for electroplating treatment

InactiveCN113398714AReduce heating energy consumptionCapture implementationCellsGas treatmentWater vaporEnvironmental engineering

Owner:中航长沙设计研究院有限公司

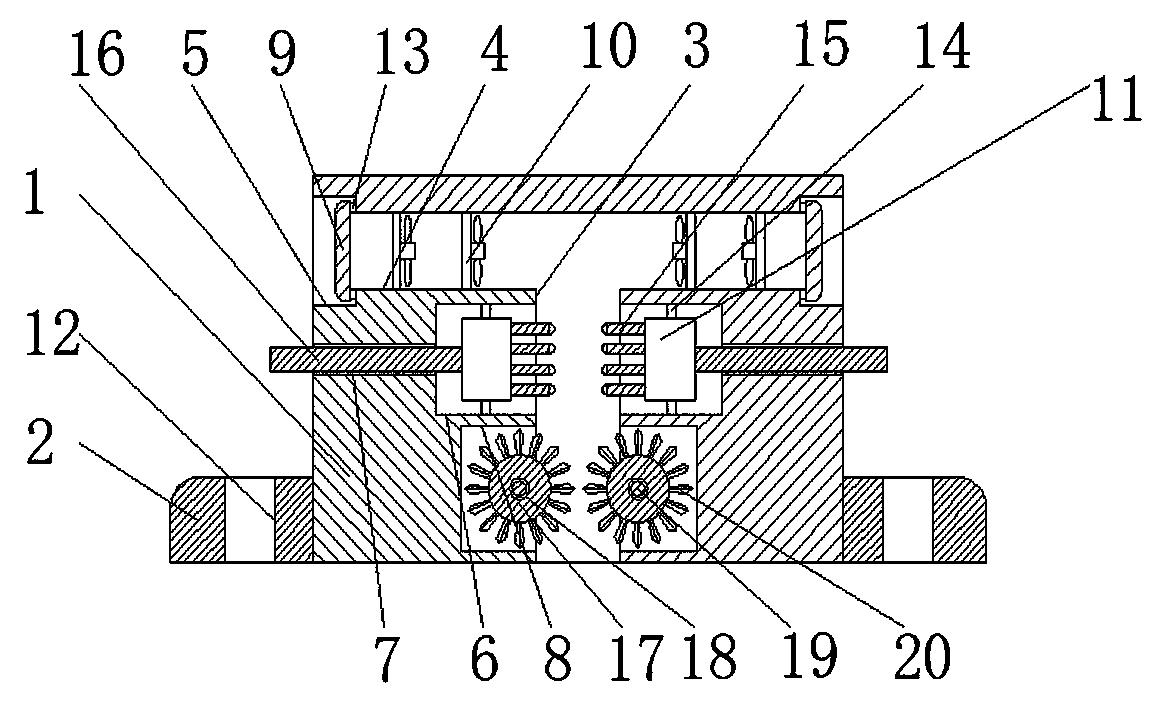

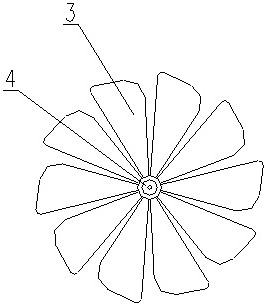

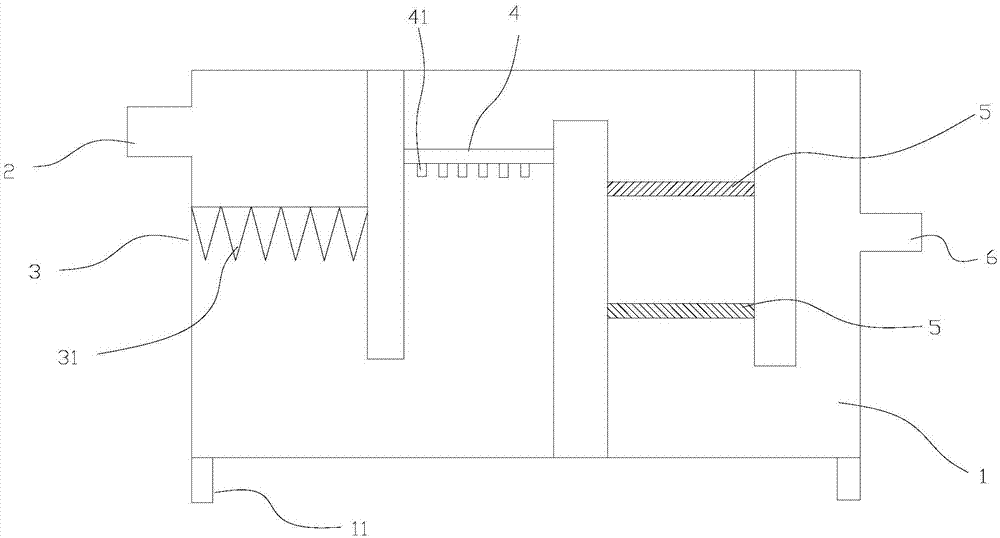

Incineration waste gas treatment device based on planetary gear transmission principle

InactiveCN111408252AGuaranteed one-way flowPrevent backflowGas treatmentDispersed particle separationGear wheelEnvironmental engineering

The invention relates to the technical field of environmental protection. The invention further discloses an incineration waste gas treatment device based on the planetary gear transmission principle.The device comprises a treatment tank, and an air inlet is fixedly connected to the outer part of the treatment tank; the interior of the air inlet is movably connected with a rotating ring; a fan plate is movably connected to the interior of the rotating ring; reset springs are movably connected to the outer part of the fan plate; a convex block is movably connected to the outer part of the fanplate; a rotating block is movably connected to the interior of the treatment tank; an air cavity is formed in the rotating block; a net plate is movably connected to the outer part of the rotating block; a spiral plate is movably connected to the upper part of the net plate; through cooperative use of the air inlet, the rotating ring, the fan plate, the reset spring and a protruding block, it isguaranteed that waste gas at the air inlet is adsorbed, one-way flowing of the waste gas is guaranteed through rotation of the fan plate, waste gas backflow is effectively prevented, air pollution caused by waste gas backflow leakage is avoided, and the waste gas treatment efficiency is effectively improved.

Owner:陈秀凤

Efficient waste gas purification all-in-one machine utilizing photo-oxidation catalysis and activated carbon adsorption

InactiveCN111686578AFree from pollutionHuman health protectionGas treatmentParticulatesUltraviolet lights

Owner:湖南沃工环境科技有限公司

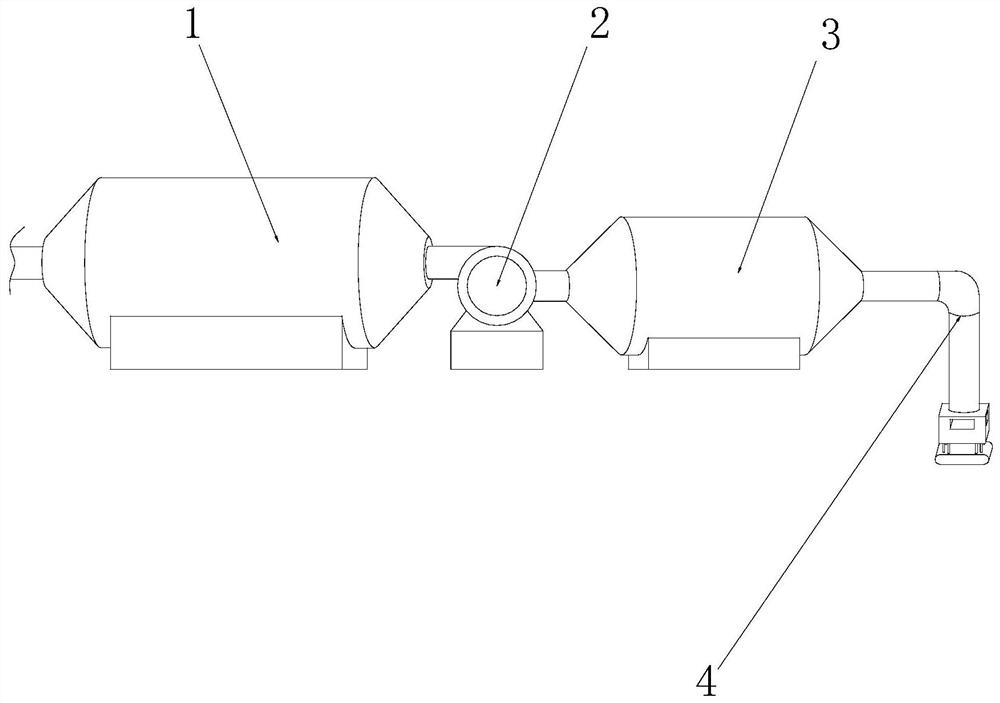

Device and method for catalytically degrading VOCs (Volatile Organic Chemicals) by low-temperature plasma in cooperation with ultraviolet light

InactiveCN111467954AAvoid dischargeAvoid destructionGas treatmentDispersed particle separationUltraviolet lightsEnvironmental engineering

The invention discloses a device and a method for catalytically degrading VOCs (Volatile Organic Chemicals) by cooperation of low-temperature plasma and ultraviolet light, and belongs to the technicalfield of organic waste gas treatment. The device comprises a pretreatment purifier, a gas flow control mechanism and a plasma purifier, which are connected in sequence, the plasma purifier comprisesa plasma reaction tube and an ultraviolet lamp, and the plasma reaction tube comprises a first section tube, a second section tube, a third section tube and a fourth section tube, which are connectedin sequence. The method comprises the following steps: S1, introducing VOCs waste gas into a pretreatment purification chamber, and removing particulate matters in the waste gas by a filter screen; S2, detecting the flow value of the pretreated VOCs waste gas, and judging whether the flow value is higher than a preset flow threshold value or not; and S3, setting an output voltage according to theflow value of the VOCs waste gas, and turning on a high-voltage power supply and an ultraviolet lamp to generate plasma in a plasma tube. The provided device and the method have the characteristics ofhigh automation degree and high VOCs catalytic degradation efficiency.

Owner:SUZHOU JINYAOMIAO ENVIRONMENTAL TECH CO LTD

Process for treating tail gas containing acetone and triethylamine

InactiveCN112295368APromote absorptionHigh recovery rateDispersed particle separationActivated carbonPhysical chemistry

Owner:山东利士得生物科技有限公司

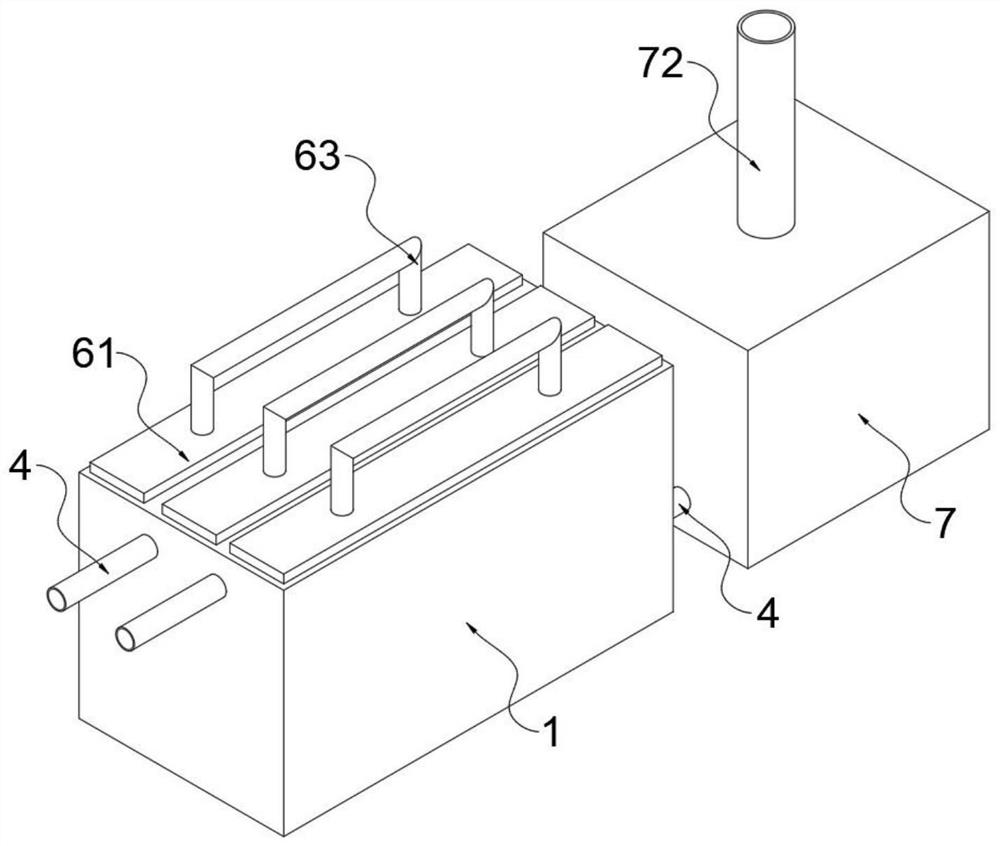

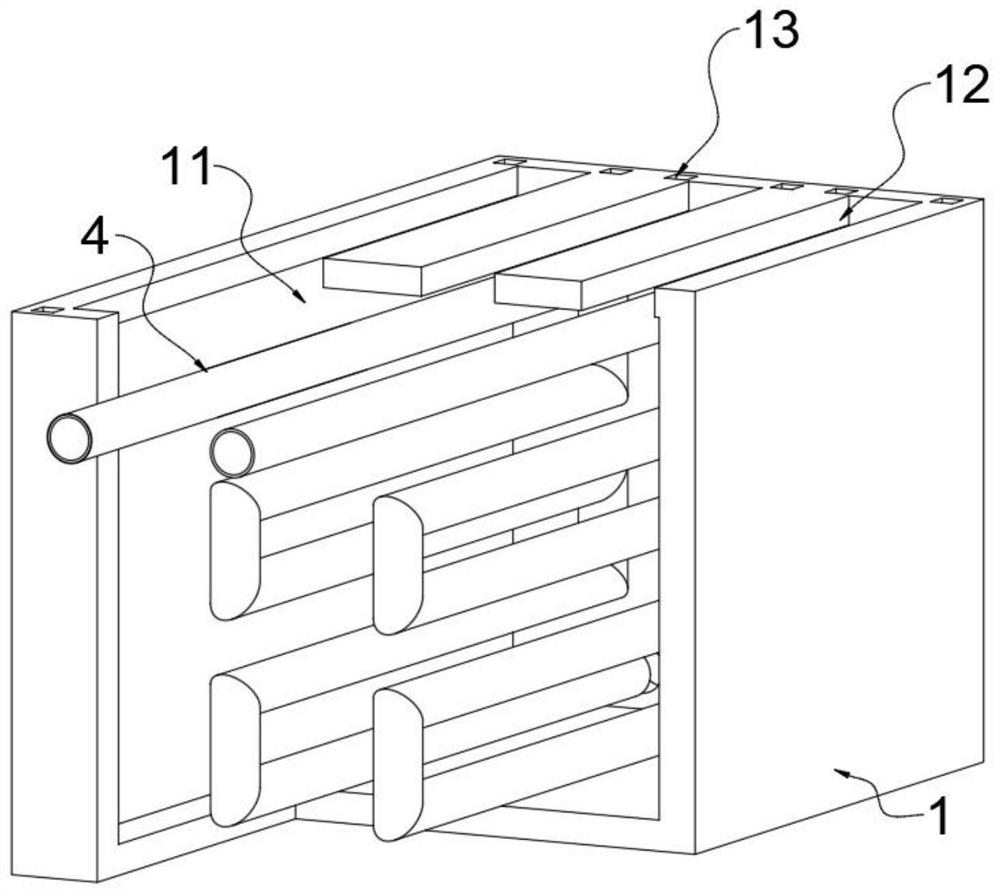

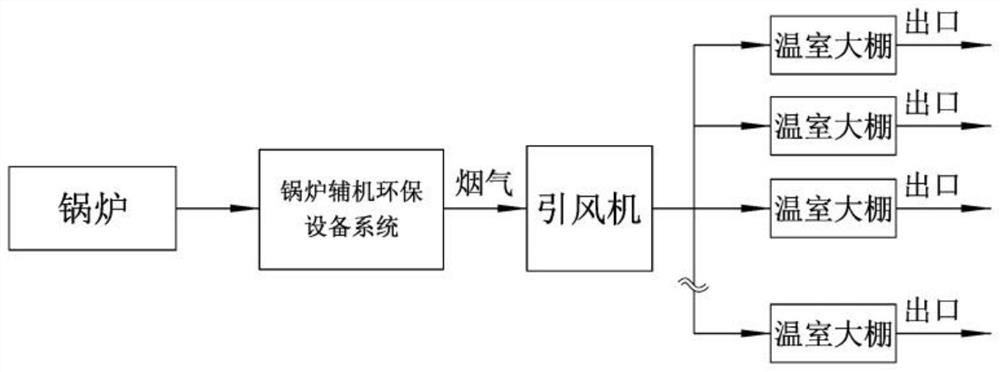

Carbon neutralization combined cycle device

PendingCN113251432AShortened growth periodGrow fastSolar heating energyClimate change adaptationFlue gasGreenhouse

Owner:HUNAN HUIFENG ENVIRONMENTAL PROTECTION TECH DEV CO LTD

Kitchen waste gas treatment device

InactiveCN107376610AEasy to handleSimple structureCombination devicesGas treatmentTreatment effectSmall footprint

Owner:张粉银

Waste gas slag-removal device for industrial furnace

InactiveCN106925069AHas the advantage of slag removalAvoid harmCombination devicesSlagEnvironmental engineering

The invention discloses a waste gas slag-removal device for an industrial furnace. The device of the invention comprises a pedestal. The top of the pedestal is successively and fixedly connected to an industrial furnace body and a filter tank from the left to the right. The right side of the industrial furnace is communicated with a first connecting pipe, the right side of which is communicated with the filter tank. The right side of the filter tank is communicated with a gas outlet pipe. A blower fan is fixedly connected to the top of the right side of the filter tank. An input end of the blower fan is communicated with the gas outlet pipe. With the arrangement of the filter tank, the first connecting pipe, the gas outlet pipe, the blower fan, a hollow block, nozzles, a filter screen, an escape net, a water pump, a water tank, a second connecting pipe, a water pipe and a controller, the problem that existing industrial furnaces cannot treat slag generated in industrial furnace waste-gas is solved. The waste gas slag-removal device for an industrial furnace has the advantage of slag removal, avoids harm of slag generated in waste gas to the environment, and protects the body health of users.

Owner:CHANGXING DINGNUO ELECTROMECHANICAL CO LTD

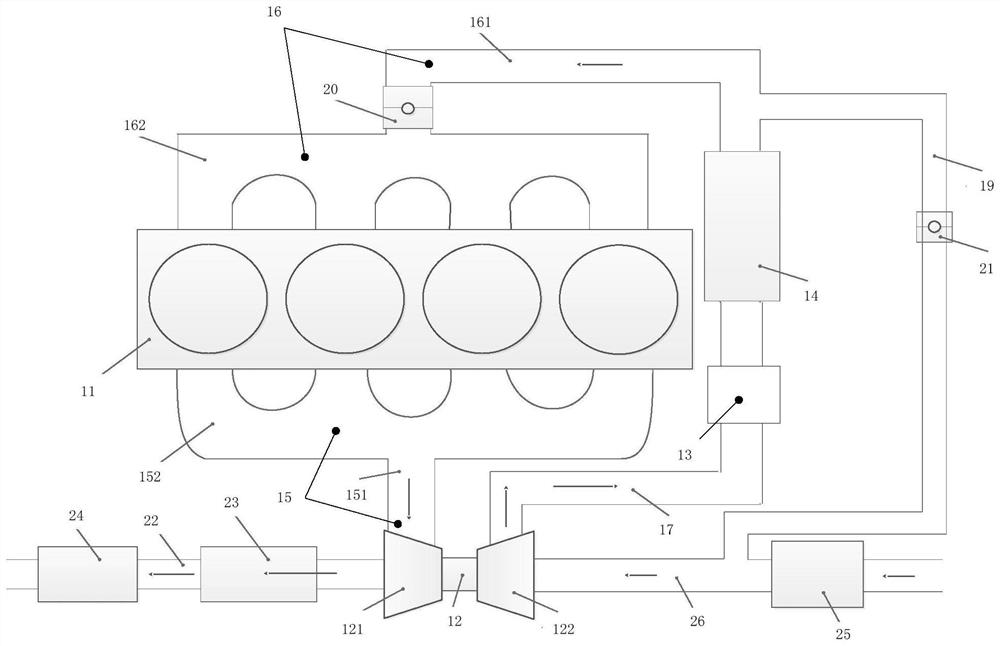

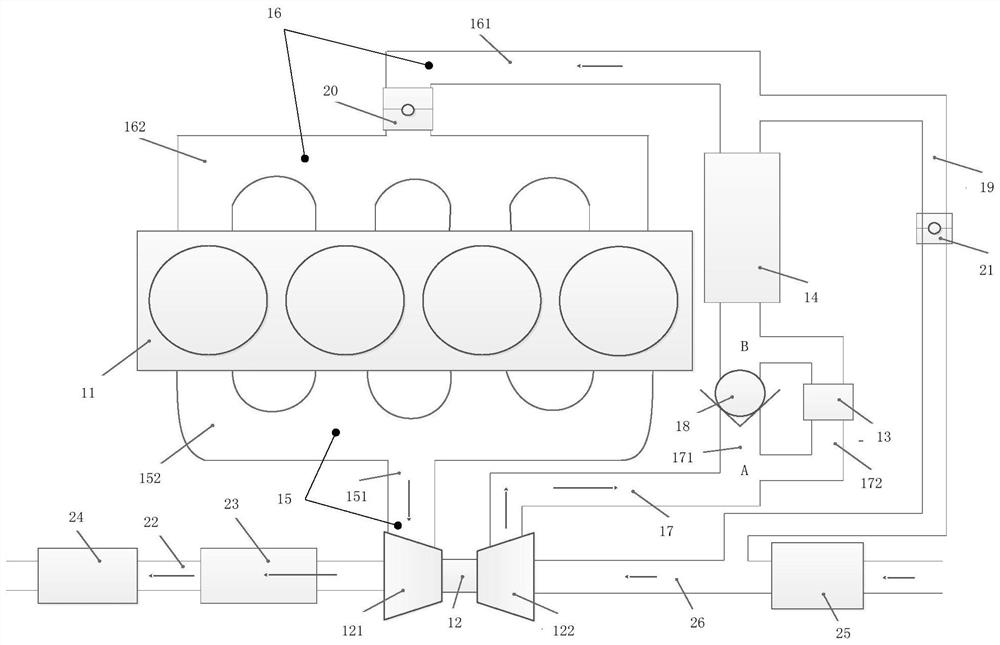

Double-supercharging system

InactiveCN112240238AAvoid hysteresisFast torque responseInternal combustion piston enginesAir compressionTurbocharger

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

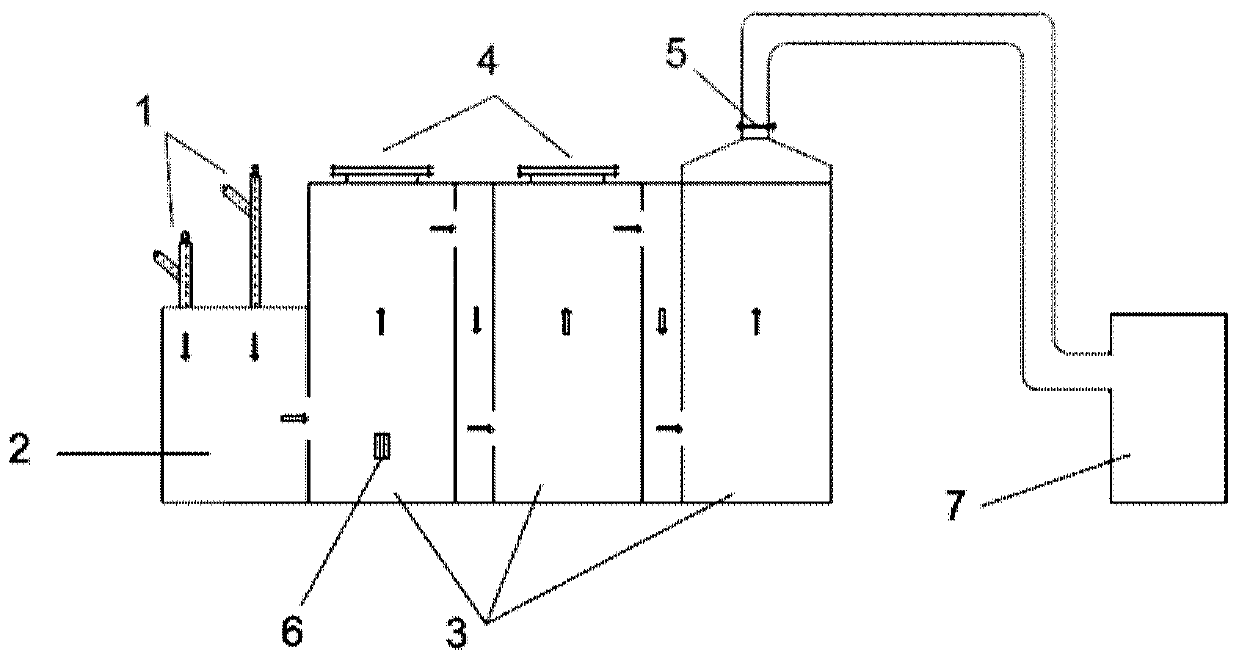

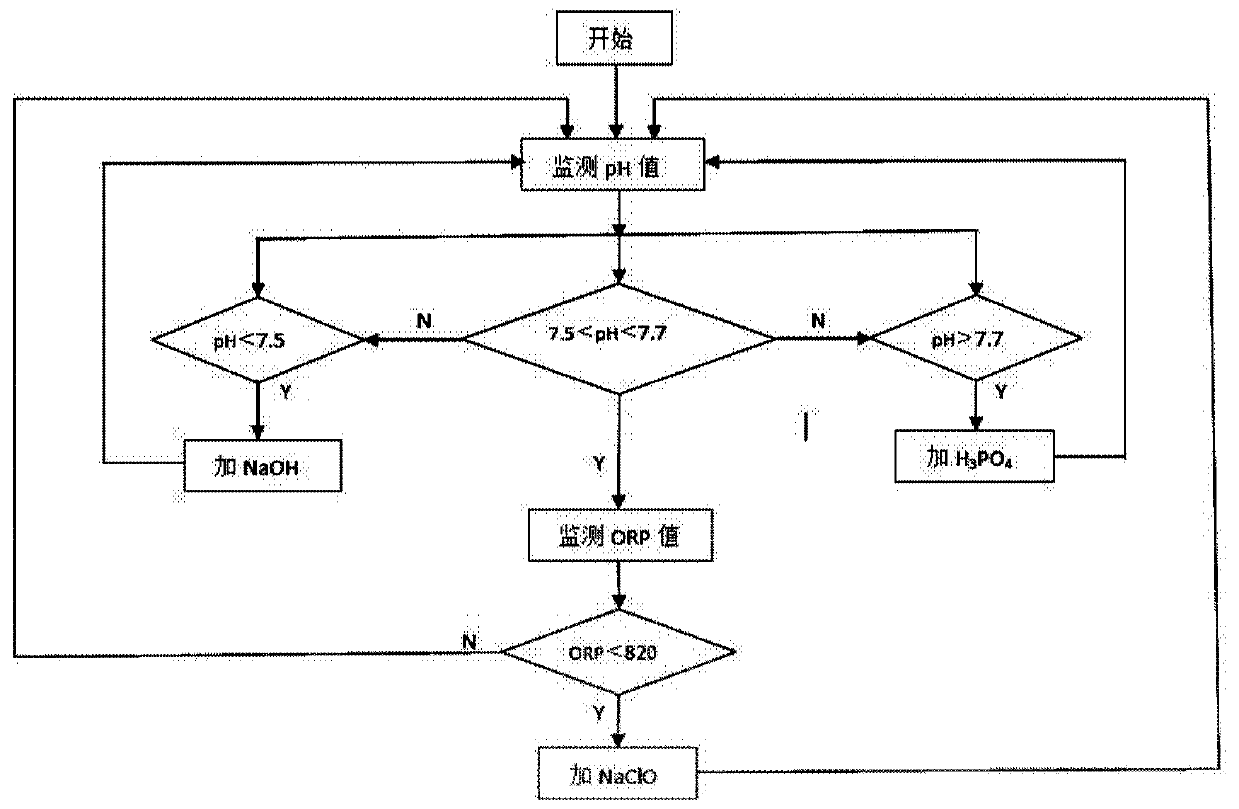

Ammonia-nitrogen electrolysis tail gas treatment system

InactiveCN107670473AReduce fugitiveReduce odorGas treatmentDispersed particle separationElectrolysisAcid substances

The invention provides an ammonia-nitrogen electrolysis tail gas treatment system. The ammonia-nitrogen electrolysis tail gas treatment system has the advantages that a first washing tower and a second washing tower are connected with the rear of a tail gas emission opening of an electrolytic tank, and peculiar smell of ammonia-nitrogen waste gas emitted from the electrolytic tank can be reduced by reducing chemicals at the first washing tower; dissipation smell of ammonia gas under the condition of high PH (potential of hydrogen) values can be removed by acidic materials such as sulfuric acidor hydrochloric acid in the second washing tower, accordingly, peculiar smell of electrolyzed tail gas can be reduced, and dissipation of the ammonia gas can be decreased; a PH value of washing liquid of the first washing tower keeps higher than 8 in procedures for reducing the smell of the gas by the aid of the reducing chemicals, and the usage amount of reducing agents can be effectively reduced.

Owner:CONCORD TECH CO LTD

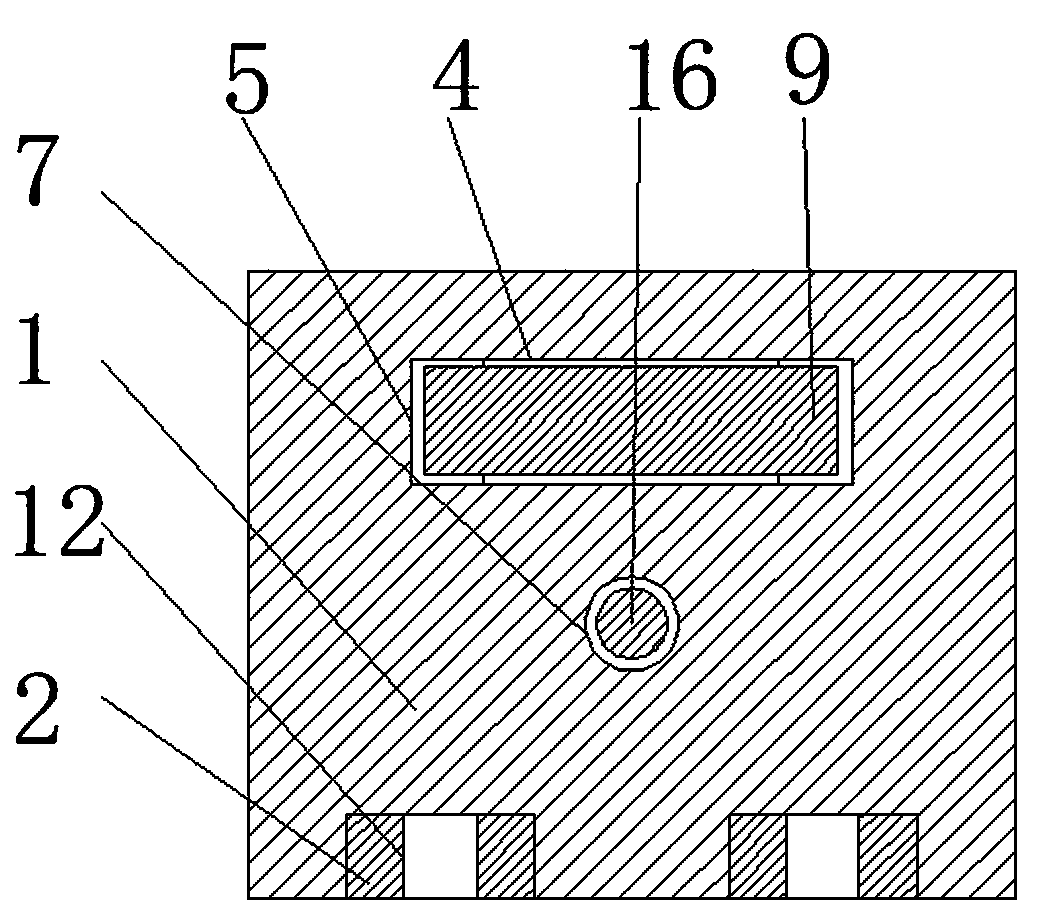

Industrial waste gas treatment device

InactiveCN109092027AQuality improvementImprove processing qualityDispersed particle separationEnvironmental engineeringDrive motor

The invention discloses an industrial waste gas treatment device. The device comprises a connecting pipeline part and a waste gas treatment part, wherein a gas inlet and a gas outlet are arranged at the connecting pipeline part, a main pipeline is arranged on the right side of the gas inlet, a plurality of branch pipelines are arranged below the main pipeline, switching valves are arranged on thebranch pipelines, a first waste gas treatment chamber, a second waste gas treatment chamber and a third waste gas treatment chamber are sequentially arranged on the right side of the branch pipelines,drive motors are arranged in the first waste gas treatment chamber, the second waste gas treatment chamber and the third waste gas treatment chamber, rotating rods are arranged below the drive motors, rotating paddles are arranged below the rotating rods, and heating layers are arranged at bottoms of the first waste gas treatment chamber, the second waste gas treatment chamber and the third wastegas treatment chamber. By the aid of structures such as the switching valves, the rotating paddles and the heating layers, the waste gas treatment quality is improved in multiple ways such as changeof the treatment process, heating and stirring, and use in production is facilitated.

Owner:JIANGYIN CITY CHECKING FIXTURE CO LTD

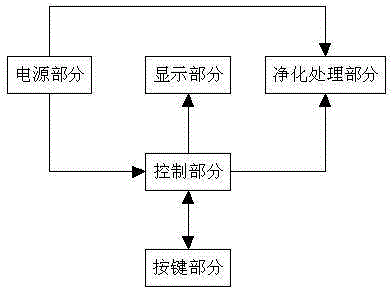

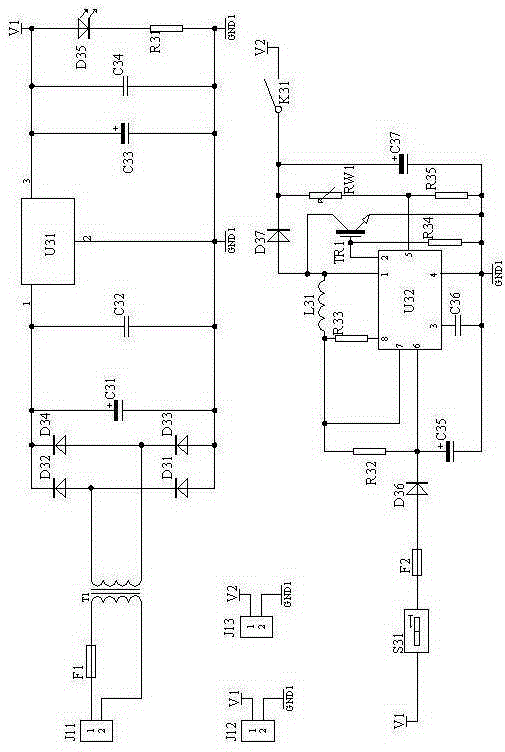

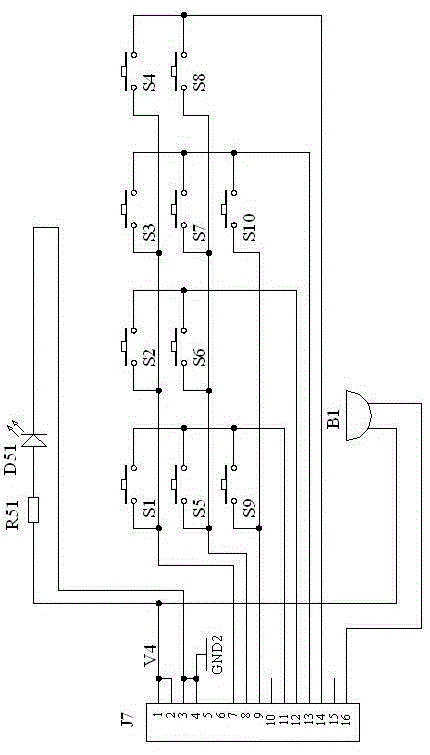

Power adjustable ultrasonic wave flue dust purification apparatus

ActiveCN104857794AReal-time monitoring of working environment temperatureReal-time temperature monitoringDispersed particle separationThermodynamicsHemt circuits

Owner:谷春刚

Exhaust gas treatment device of metal organic chemical vapor deposition apparatus and application of exhaust gas treatment device

PendingCN110339673APrevent leakageNo cloggingDispersed particle separationEngineeringChemical vapor deposition

Owner:DR TECH CO LTD YIXING JIANGSU

PNCR denitration optimization system based on big data

ActiveCN112933952AEasy to handleFully contactedDispersed particle separationMaterial analysis by electric/magnetic meansProcess engineeringEnvironmental engineering

The invention provides a PNCR denitration optimization system based on big data. The optimization system comprises a detection device, a sensing device, a control device, an early warning device, a sampling device, an adjusting device and a processor, the detection device is configured to detect reducing agent parameters in a reaction chamber; the sensing device is configured to sense a reducing agent; the control device is configured to control the triggering time of the reducing agent; the early warning device is configured to carry out early warning on parameters in the reaction cavity, and carry out early warning operation in cooperation with data response of the detection device and the sensing device; the sampling device is configured to collect the reaction effect of the reaction cavity; and the adjusting device is configured to adjust the mixing condition of the reducing agent. Oxygen is driven in a contact cavity, so that the exhaust speed is reduced in the constant output process of waste gas in a container, the contact between the reducing agent and the waste gas is further enhanced, and it is guaranteed that the treatment efficiency of the waste gas is improved.

Owner:DONGGUAN KEWEI ENVIRONMENTAL POWER CO LTD

Waste gas treatment device

InactiveCN112337304AEasy to handleImprove processing efficiencyGas treatmentDispersed particle separationActivated carbonFiltration

The invention relates to the technical field of waste gas treatment devices, in particular to a waste gas treatment device. The device is provided with a first-stage treatment assembly and a second-stage treatment assembly; the first-stage treatment assembly is communicated with the second-stage treatment assembly through a pipeline; the first-stage treatment assembly comprises a shunting phase filtering area, a UV photo-oxidation catalytic area and a photo-oxidation catalytic area; the shunting phase filtering area, the UV photo-oxygen catalytic area and the photo-oxygen catalytic area are communicated in sequence; the second-stage treatment assembly comprises a shunting rough filtration area, an isolation adsorption area and an activated carbon adsorption area; the shunting rough filtration area, the isolation adsorption area and the activated carbon adsorption area are communicated in sequence; one side of the first-stage treatment assembly is communicated with an air outlet pipe; and one side of the in second-stage treatment assembly is communicated with an exhaust pipe. The waste gas treatment device is simple in structure, capable of rapidly and effectively treating waste gas, high in waste gas treatment efficiency, capable of reducing harm of the waste gas to the environment and effectively protecting the environment and convenient to wide popularization and use.

Owner:HUZHOU HONGYUE ELECTRONIC DEVICE FACTORY

CFB semi-dry desulfurization system

PendingCN114011216ASmall specific surface areaEvenly combinedGas treatmentElectrostatic separationFlue gasProcess engineering

Owner:SHANYING INT HLDG CO LTD

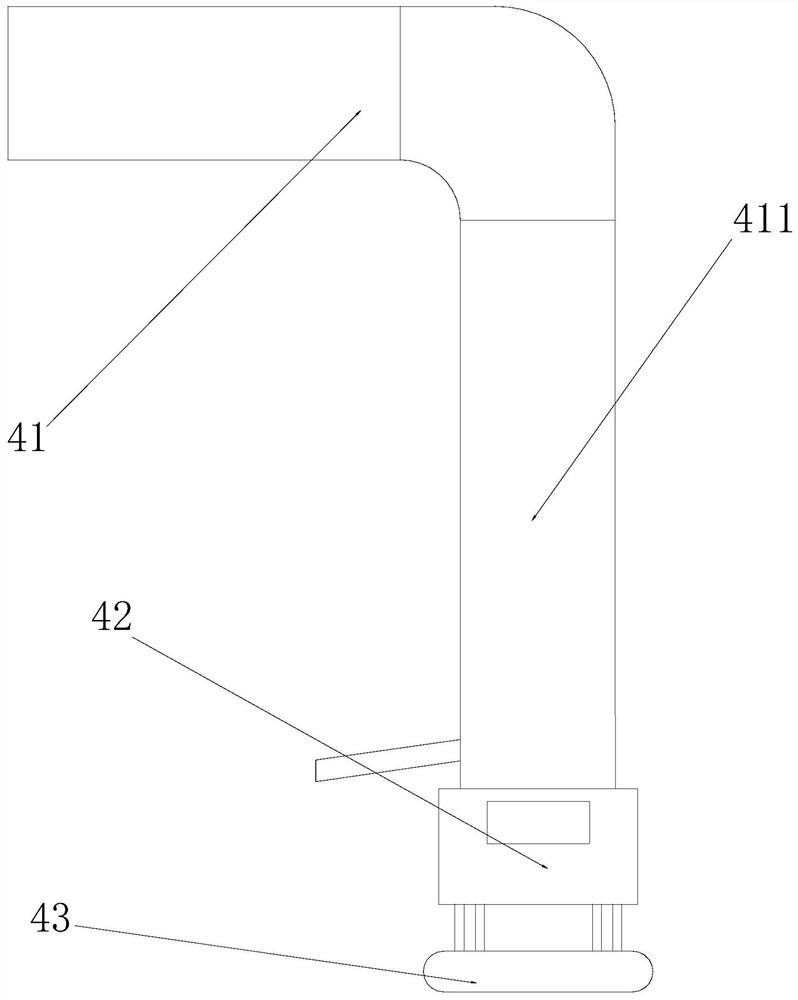

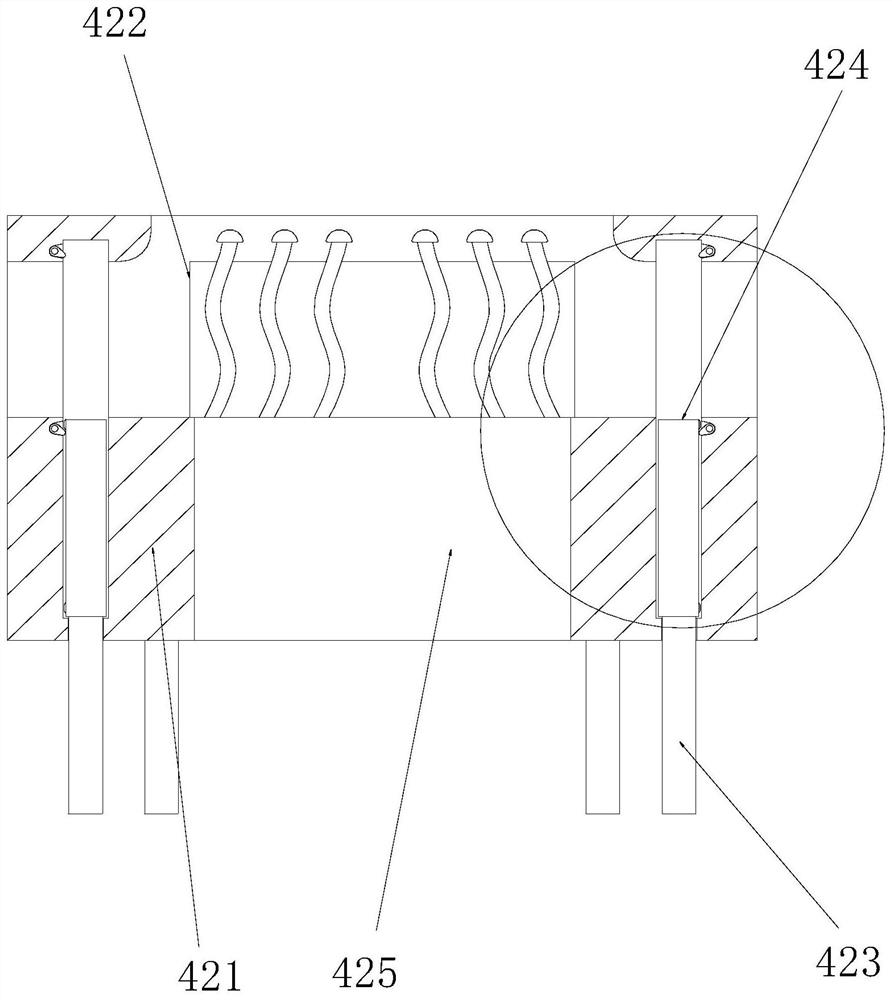

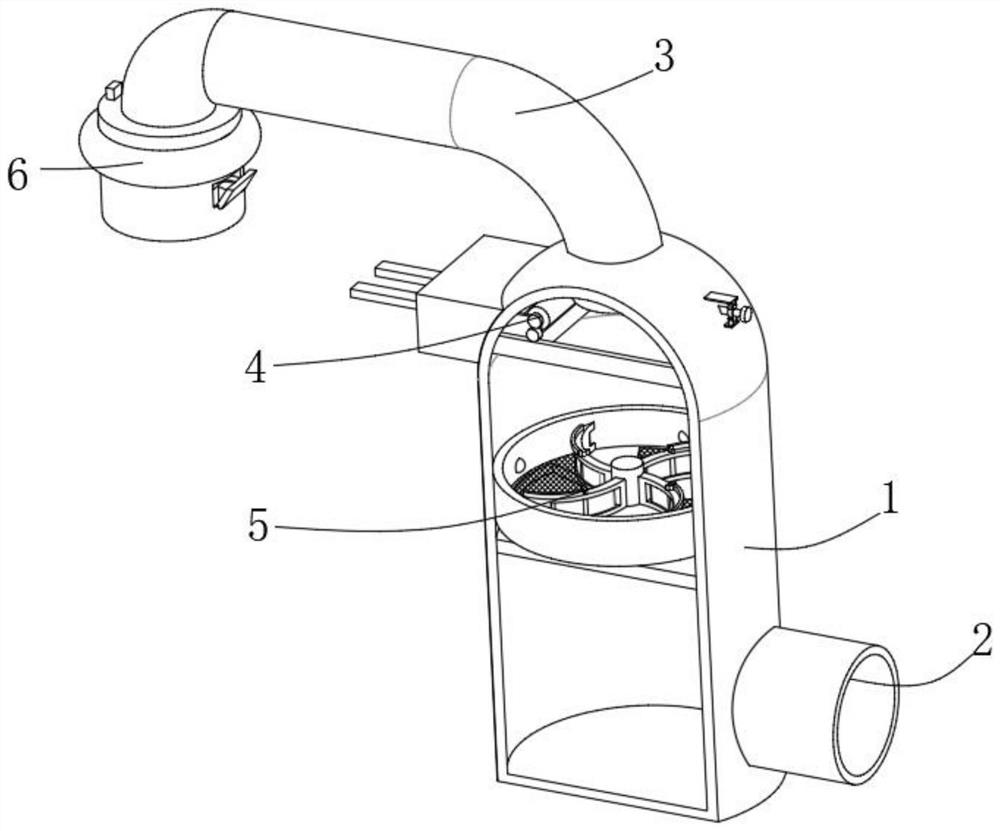

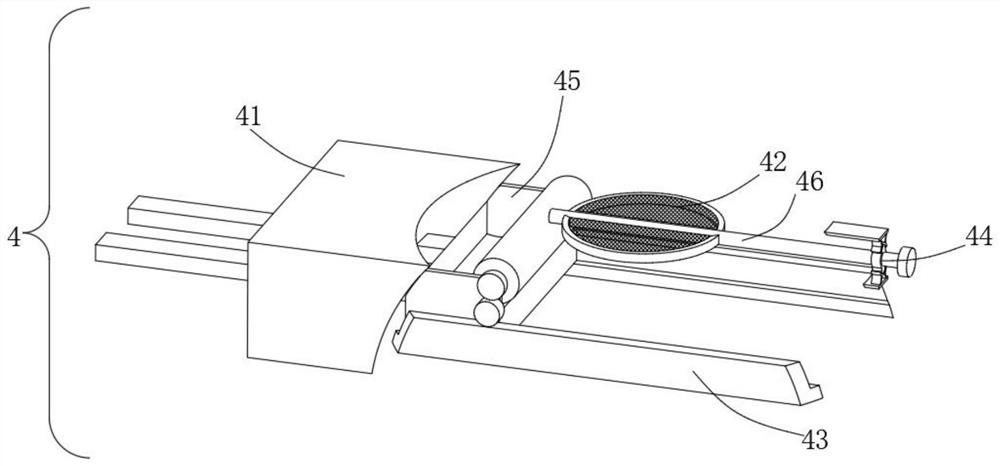

Domestic deepening processor for wet garbage under water tank and control method thereof

PendingCN112726753AEasy to separateImprove decomposition efficiencyDomestic plumbingStationary filtering element filtersProcess engineeringEnvironmental engineering

The invention discloses a domestic deepening processor for wet garbage under a water tank and a control method thereof. The domestic deepening processor comprises a shell, and a shredding device, a solid-liquid separation device, a stirring device and a waste gas treatment device which are arranged in the shell and connected in sequence, the shredding device shreds wet garbage into particles and discharges the particles to the solid-liquid separation device, the solid-liquid separation device is used for separating wet garbage and discharging separated solid particles to the stirring device and liquid at the same time; and the stirring device stirs the solid particles and then performs fermentation, and the waste gas treatment device purifies waste gas generated in the stirring and fermentation process. The shredding device shreds wet garbage into particles, solid-liquid separation is facilitated, and the separation efficiency is improved; the inlet of the shredding device is directly connected with the outfall of the water tank, so that the space is saved, and the odor generation probability is reduced; and the solid outlet of the solid-liquid separation device is connected to the stirring device, and the liquid outlet is connected to a drainage pipeline, so that the space deployment is more reasonable, and the whole machine is more attractive and easy to store.

Owner:INTRADIN HUZHOU HARDWARE CO LTD

High-concentration organic malodorous waste gas treatment machine for municipal sewage treatment plant

InactiveCN113457360APrevent intrusionAvoid damageGas treatmentDispersed particle separationMunicipal sewageWaste water treatment plant

Owner:吴贤华

Waste gas treatment equipment for incinerator

PendingCN114768410AIncrease contact areaImprove the effect of reaction filteringDispersed particle filtrationTransportation and packagingElectric machineProcess engineering

Owner:谭瑞平

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap