Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4 results about "Industrial furnace" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The purpose of an industrial furnace is to attain a higher processing temperature in comparison to open-air systems, as well as the efficiency gains of a closed system. Industrial furnaces typically deal with temperatures higher than 400 degrees Celsius.

Waste gas slag-removal device for industrial furnace

InactiveCN106925069AHas the advantage of slag removalAvoid harmCombination devicesSlagEnvironmental engineering

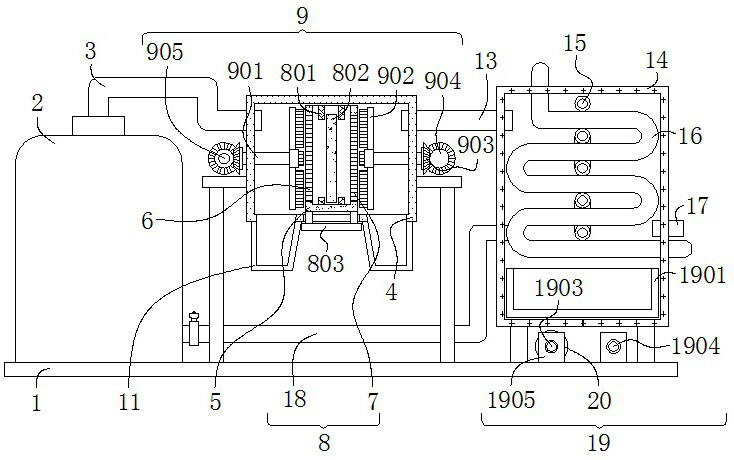

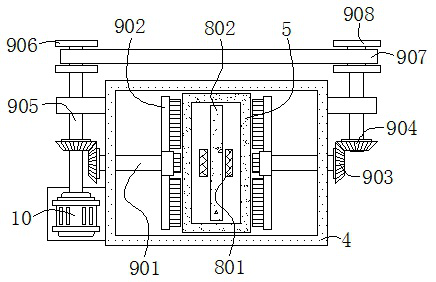

The invention discloses a waste gas slag-removal device for an industrial furnace. The device of the invention comprises a pedestal. The top of the pedestal is successively and fixedly connected to an industrial furnace body and a filter tank from the left to the right. The right side of the industrial furnace is communicated with a first connecting pipe, the right side of which is communicated with the filter tank. The right side of the filter tank is communicated with a gas outlet pipe. A blower fan is fixedly connected to the top of the right side of the filter tank. An input end of the blower fan is communicated with the gas outlet pipe. With the arrangement of the filter tank, the first connecting pipe, the gas outlet pipe, the blower fan, a hollow block, nozzles, a filter screen, an escape net, a water pump, a water tank, a second connecting pipe, a water pipe and a controller, the problem that existing industrial furnaces cannot treat slag generated in industrial furnace waste-gas is solved. The waste gas slag-removal device for an industrial furnace has the advantage of slag removal, avoids harm of slag generated in waste gas to the environment, and protects the body health of users.

Owner:CHANGXING DINGNUO ELECTROMECHANICAL CO LTD

Hot flue gas treatment device and treatment method for industrial furnace

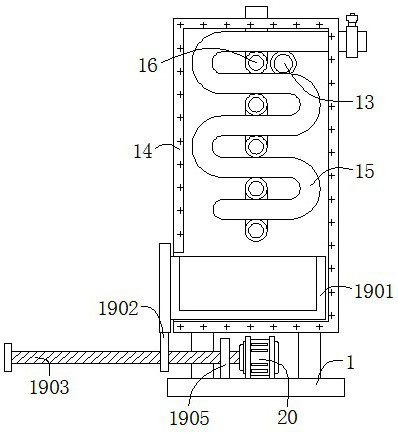

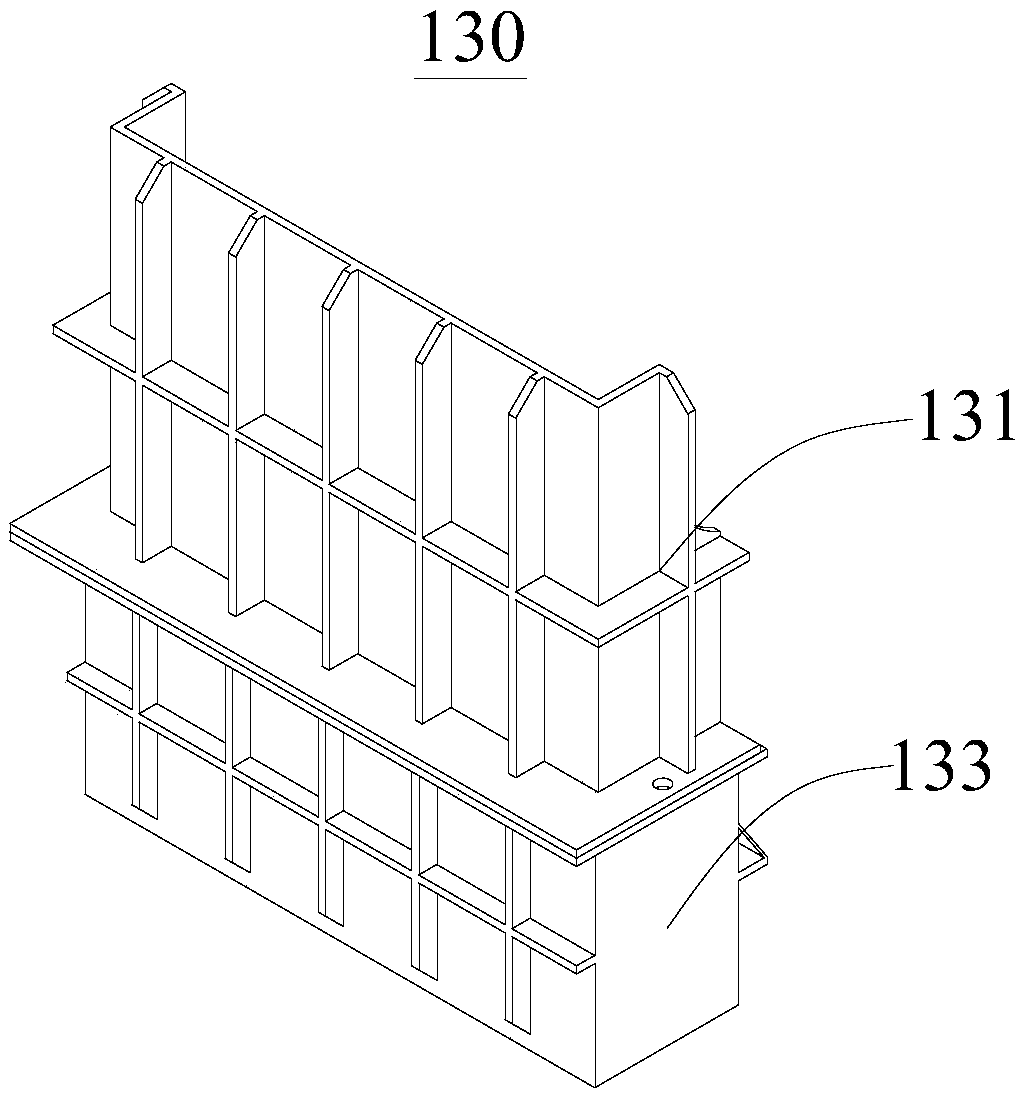

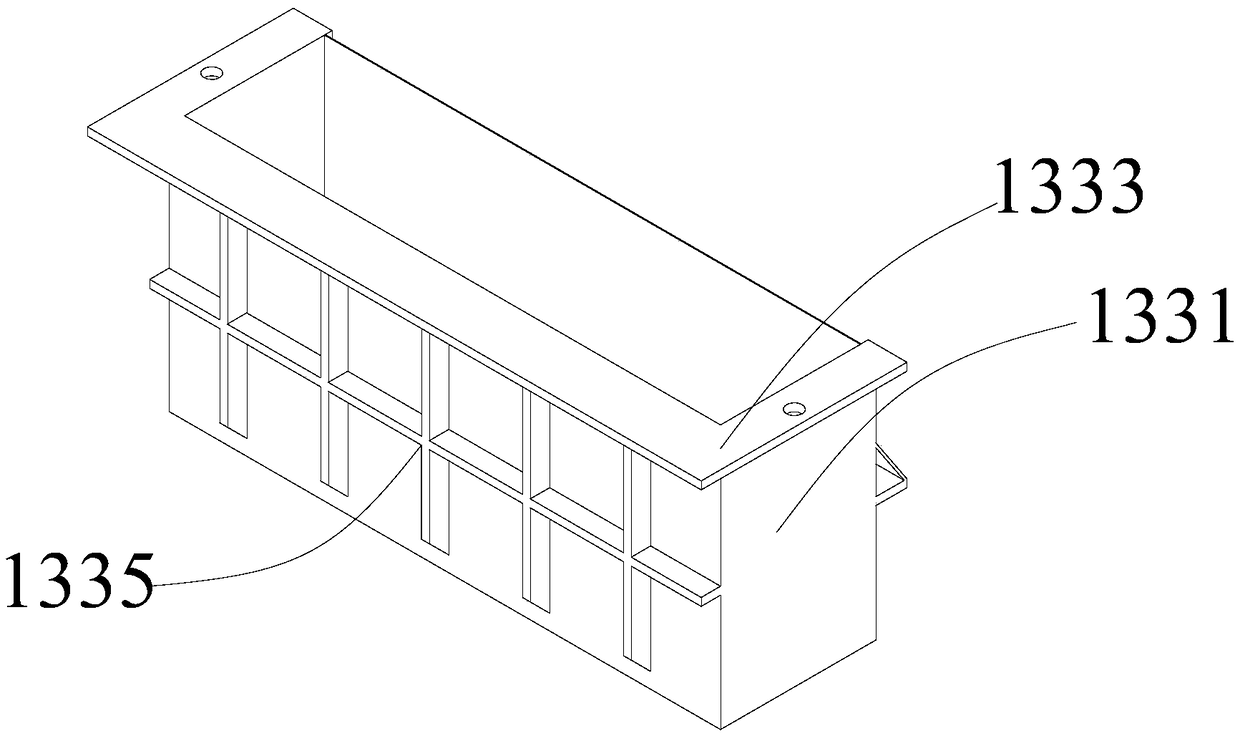

PendingCN114543539AEasy to cleanAvoid cloggingGas treatmentTransportation and packagingThermodynamicsFlue gas

Owner:陕西备晟科技有限公司

Salt bath furnace blanking device and salt bath heating furnace

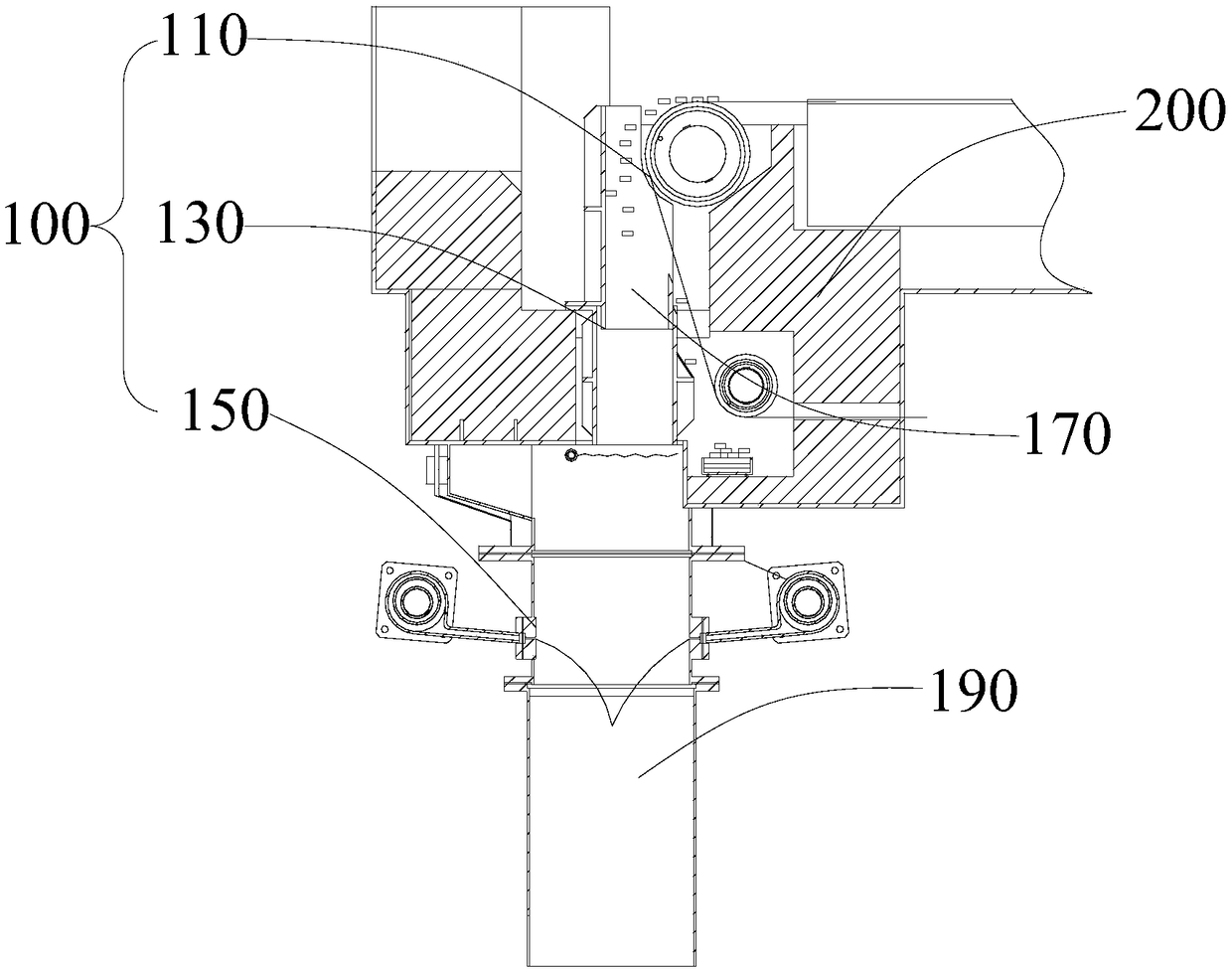

PendingCN108728612AFall into smoothQuality assuranceFurnace typesHeat treatment bathsBrickHeating furnace

Owner:江苏丰东热技术有限公司

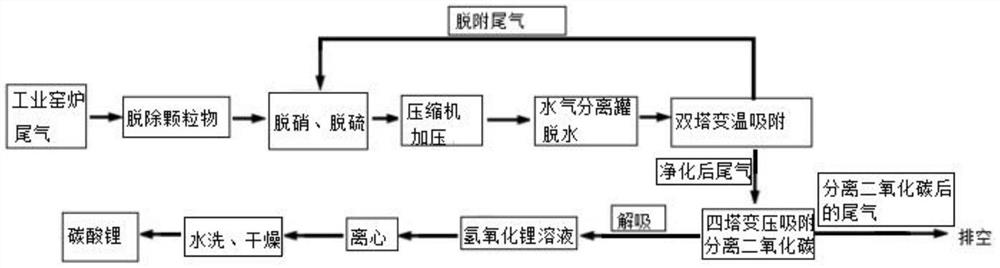

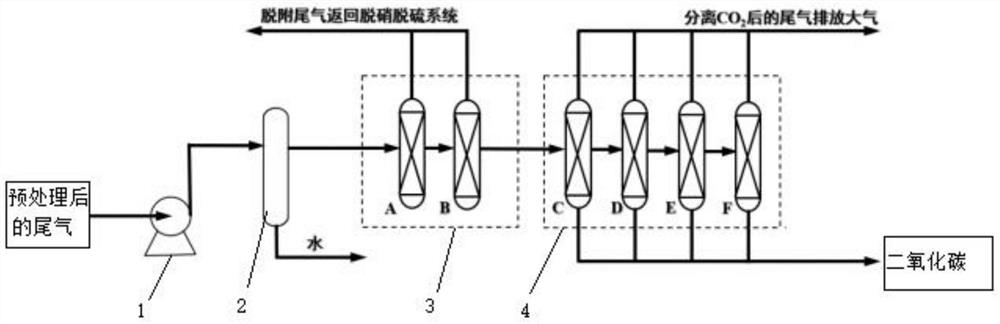

Method for recovering carbon dioxide from tail gas of industrial kiln and producing lithium carbonate

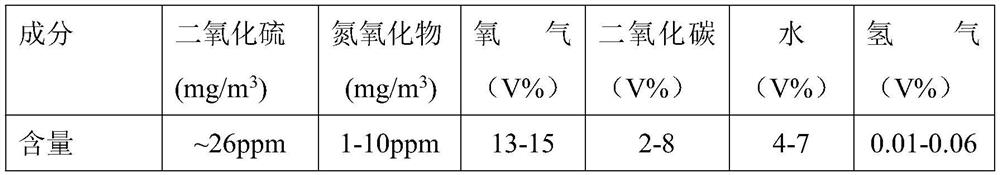

ActiveCN114835142AHigh gas purityHigh recovery rateProductsCarbon compoundsParticulatesLithium hydroxide

Owner:JIANGSU RONGHUI GENERAL LITHIUM IND CO LTD +1

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap