Salt bath furnace blanking device and salt bath heating furnace

A technology of blanking device and salt bath furnace, used in furnaces, heat treatment baths, heat treatment furnaces, etc., can solve problems such as affecting the quality of workpieces, poor quenching, and easily sticking materials, so as to ensure the quality of workpieces, avoid contact, and avoid poor quenching. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

no. 1 example

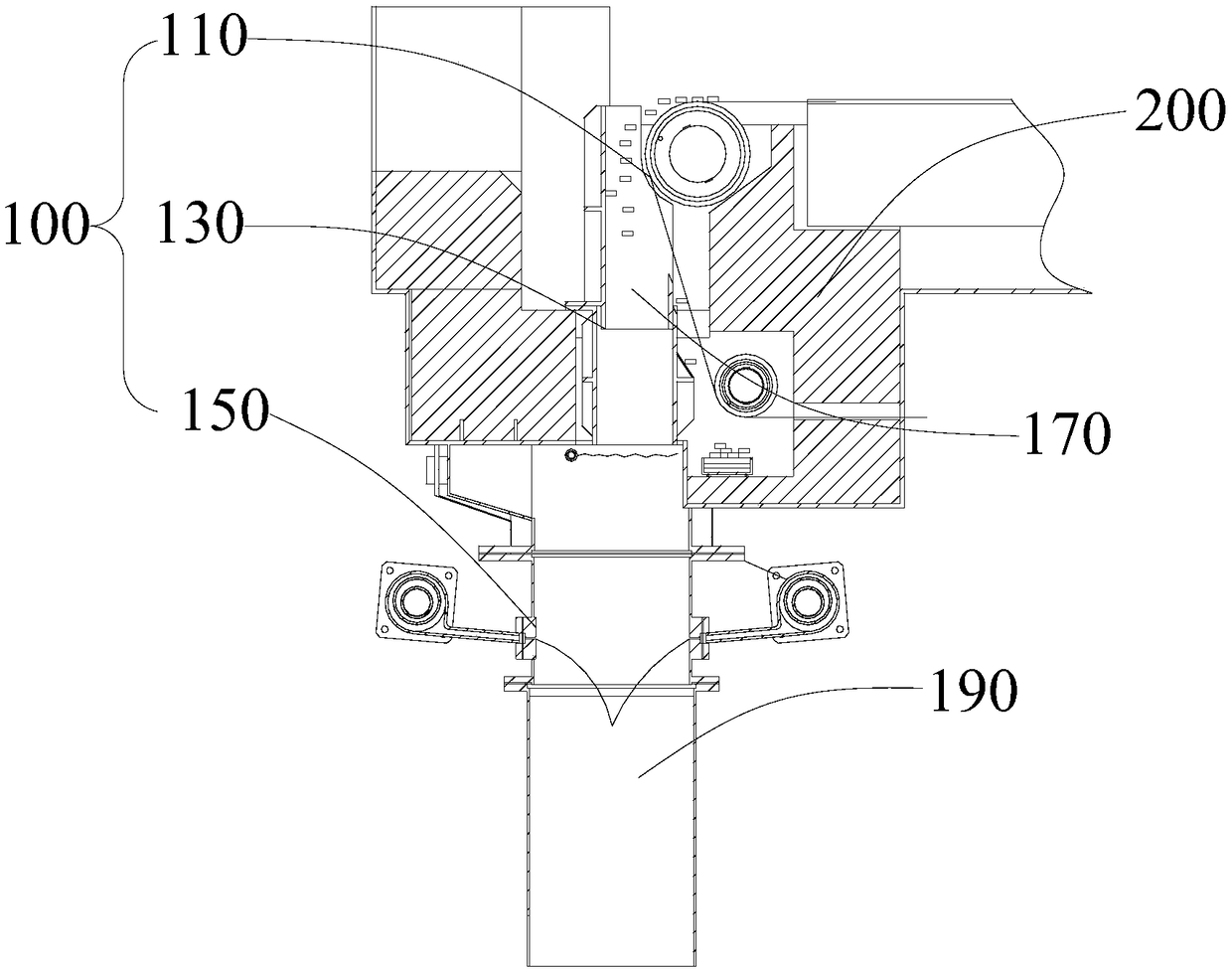

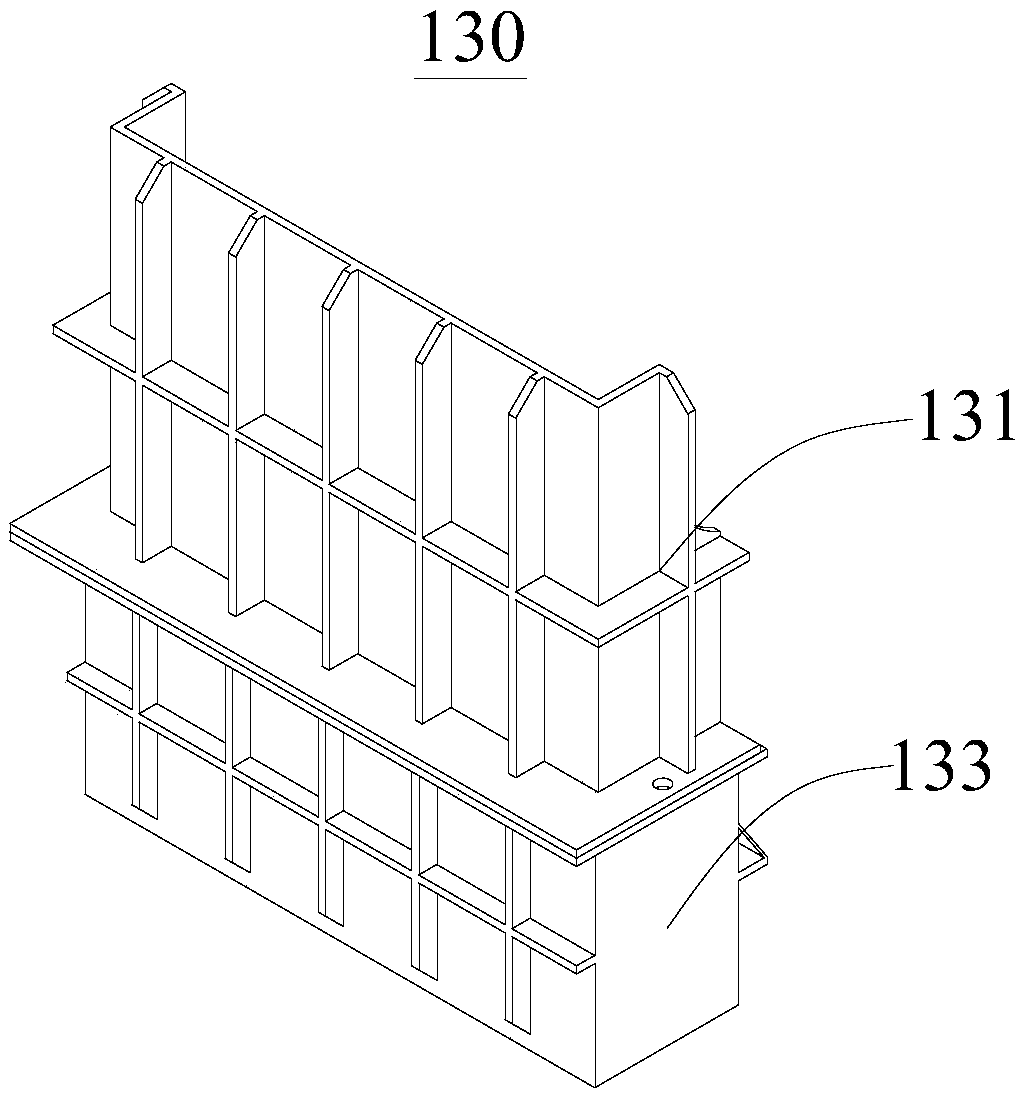

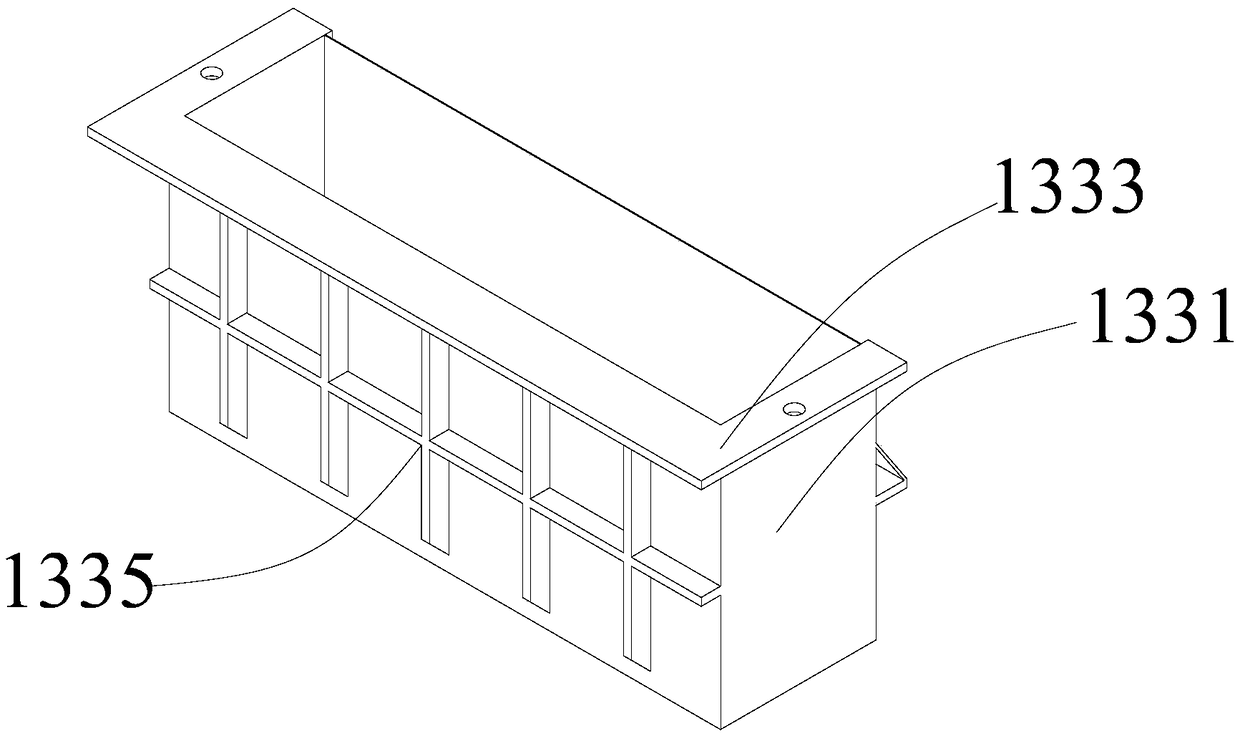

[0037] See figure 1 This embodiment provides a salt bath furnace blanking device 100, which is arranged in the heating furnace body 200. The heating furnace body 200 has a blanking port. The salt bath furnace blanking device 100 includes a workpiece conveying mechanism 110 and a workpiece blanking mechanism. 130 and the salt curtain blanking mechanism 150, the workpiece conveying mechanism 110 is used to be accommodated in the heating furnace body 200, and the workpiece conveying mechanism 110 has a discharge end corresponding to the blanking port, and the workpiece blanking mechanism 130 is used to be arranged in At the blanking port, and the workpiece blanking mechanism 130 has a first blanking channel 170 with a smooth inner wall. The top of the first blanking channel 170 is disposed opposite to the discharge end, and the salt curtain blanking mechanism 150 is used to be arranged at the blanking port The salt curtain blanking mechanism 150 has a second blanking channel 190, and

no. 2 example

[0052] See Figure 7 This embodiment provides a salt bath heating furnace 10, including a heating furnace body 200 and a salt bath furnace blanking device 100, wherein the basic structure and principle of the salt bath furnace blanking device 100 and the technical effects produced and the first implementation The examples are the same. For a brief description, for parts not mentioned in this embodiment, please refer to the corresponding content in the first embodiment.

[0053] The heating furnace body 200 has a blanking port. The salt bath furnace blanking device 100 includes a workpiece conveying mechanism 110, a workpiece blanking mechanism 130, and a salt curtain blanking mechanism 150. The workpiece conveying mechanism 110 has a discharge end corresponding to the blanking port. , The workpiece blanking mechanism 130 has a first blanking channel 170 with a smooth inner wall, and the top of the blanking channel is opposite to the discharge end. The salt curtain blanking mechanism

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap