Method for recovering carbon dioxide from tail gas of industrial kiln and producing lithium carbonate

A carbon dioxide and lithium carbonate technology, applied in chemical instruments and methods, lithium carbonate;/acid carbonate, products, etc., can solve the problems of less components, more impurities, affecting separation and purification, etc., to reduce carbon Emission reduction, high gas purity, and large processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

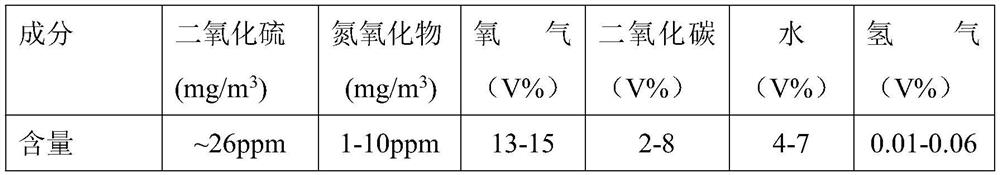

[0031] In this embodiment, the kiln tail gas used is the natural gas oxygen-enriched combustion kiln tail gas, and after analysis, its water vapor content is 4.70-6.78v%, O 2 Concentration is 13.90~15.10v%, CO 2 Concentration is 2.51~4.39v%, NOx concentration is 0.037~0.060v% (500~800ppm), SO 2 Concentration is 0.014v% (~400ppm), CO concentration is 0.02~0.6v%, H 2 The concentration is 0.01~0.06%, the rest is N 2 . The carbon dioxide in the exhaust gas of the industrial kiln is recovered, and the recovered carbon dioxide gas is used in the ore extraction enterprise to prepare high-purity battery-grade lithium carbonate, and the method is as follows:

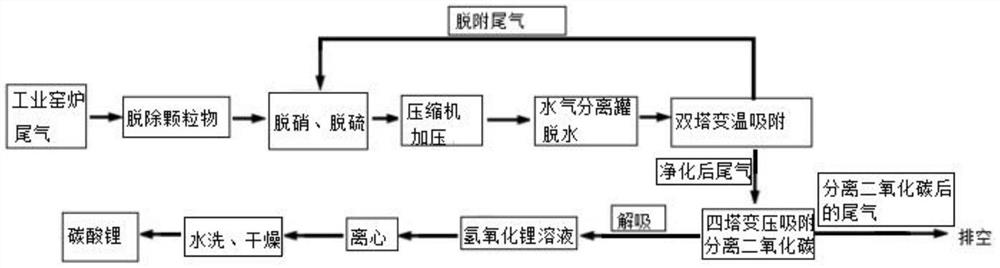

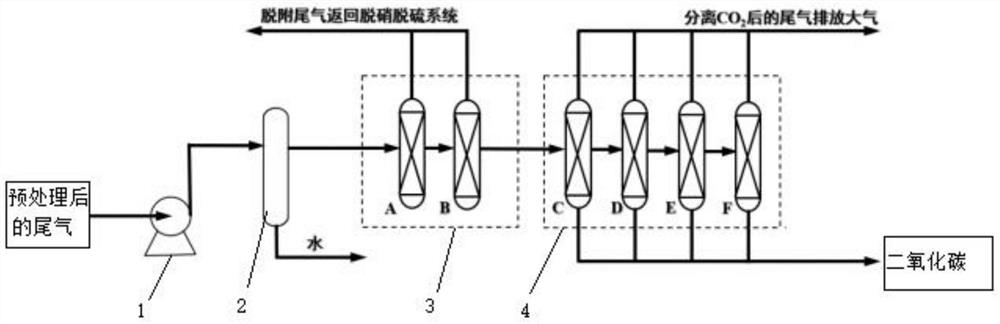

[0032] like Figure 1-2 As shown, a method for recovering carbon dioxide and producing lithium carbonate from industrial kiln tail gas comprises the following steps:

[0033] (1) Preprocessing:

[0034] After the industrial kiln exhaust gas is removed by the cyclone dust collector, the denitration and desulfurization system is

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap