Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

108 results about "Water flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

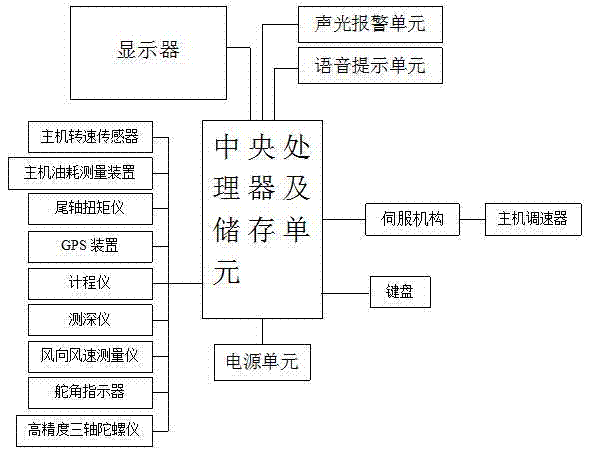

System optimization method and device of ship operation energy efficiency

ActiveCN102768524AStrong targetingVersatileElectrical controlWatercraft hull designMathematical modelData acquisition

Owner:CHANGSHA LVHANG ENERGY SAVING SCI & TECH

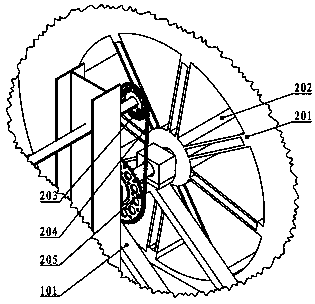

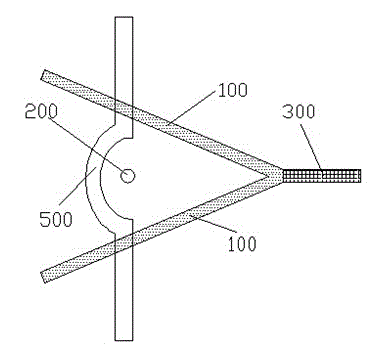

Multifunctional sprinkler structure

ActiveUS7255291B1Accurate operationEqually distributedMovable spraying apparatusSpray nozzlesImpellerWater discharge

A multifunctional sprinkler structure comprises a water motor having an outlet seat and a top cover mounted to a top-end side, and two adjusting seats and a water supply seat assembled onto a bottom-end side. The bottom-end side of the water motor has a guide groove with a restrictive hole for the extension of a switch shaft there-through. The outlet seat has a water-discharge chamber with multiple barriers extending thereon corresponding to an impeller of the water motor, and an oblique-extending central guide port matching to a spray nozzle having multiple water-guiding ribs obliquely extending towards the same direction therein. Therefore, the barriers of the outlet seat and the water-guiding ribs of the spray nozzle are utilized to correspond to the direction of the water flow so that the water discharge can be easily switched to eject either in more direct and forceful column-like spray or in more expanding spray.

Owner:YUAN MEI CORP

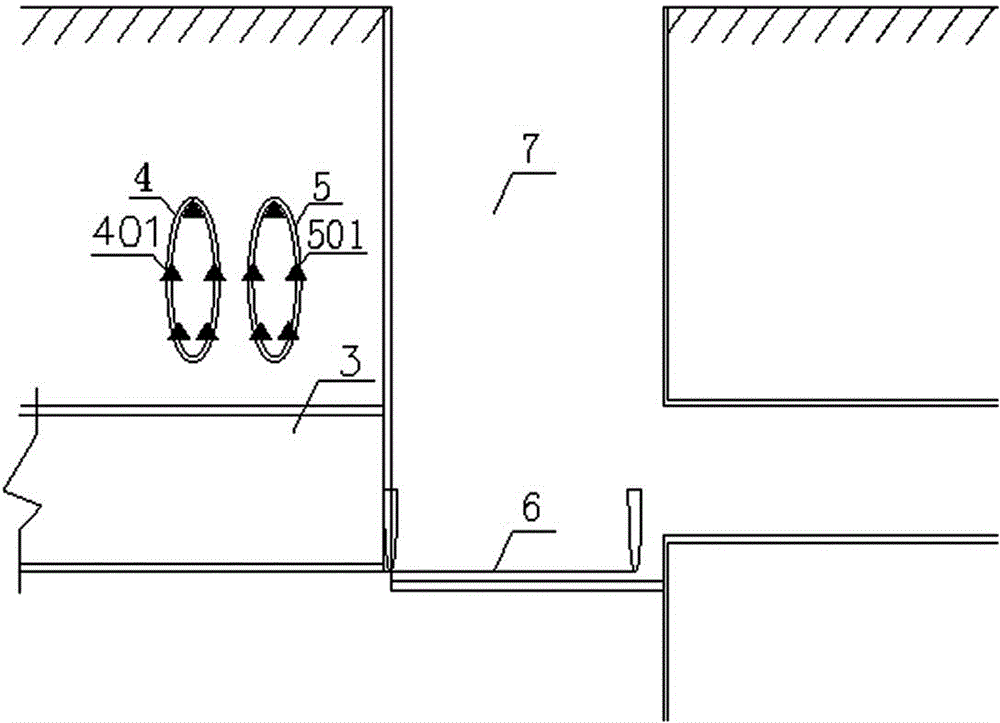

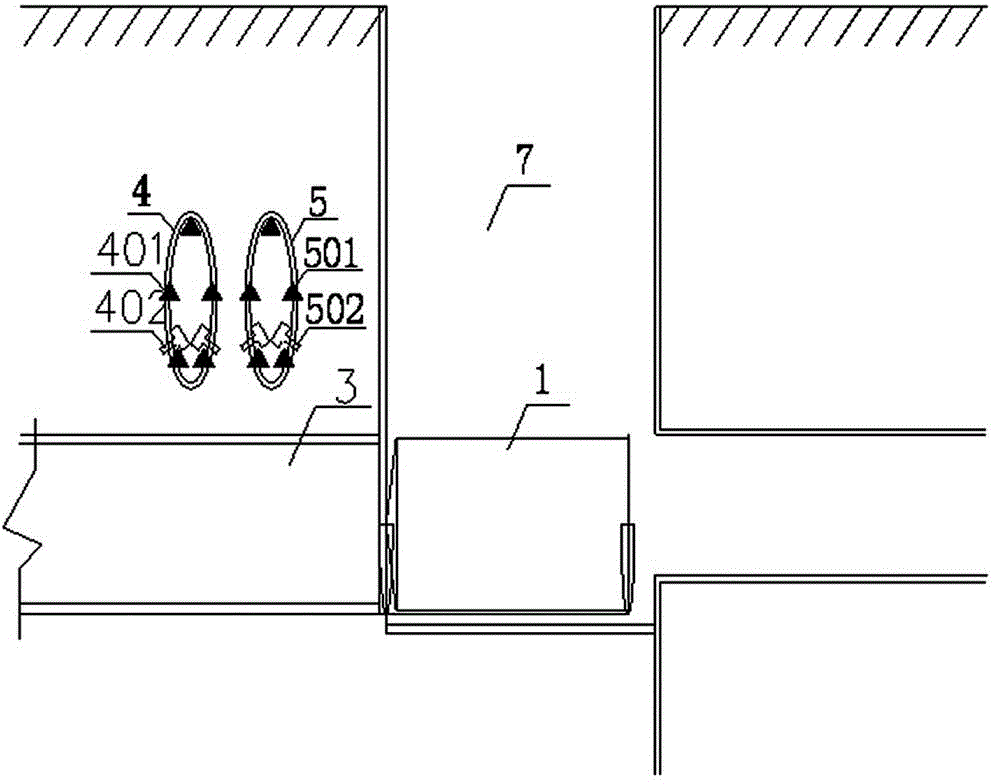

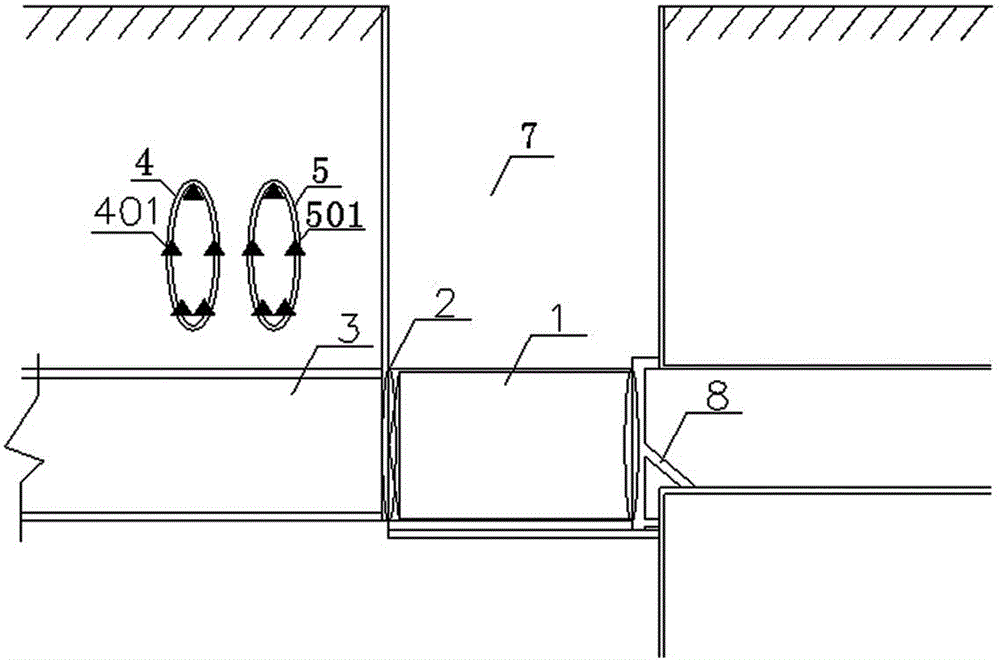

Construction method of close-range down-traversing operation lines at initial stages or receiving stages of shield

ActiveCN104594911AImprove construction qualityControl deformationMining devicesUnderground chambersWater flowLine segment

Owner:CHINA CONSTR COMM ENG GRP UNITED

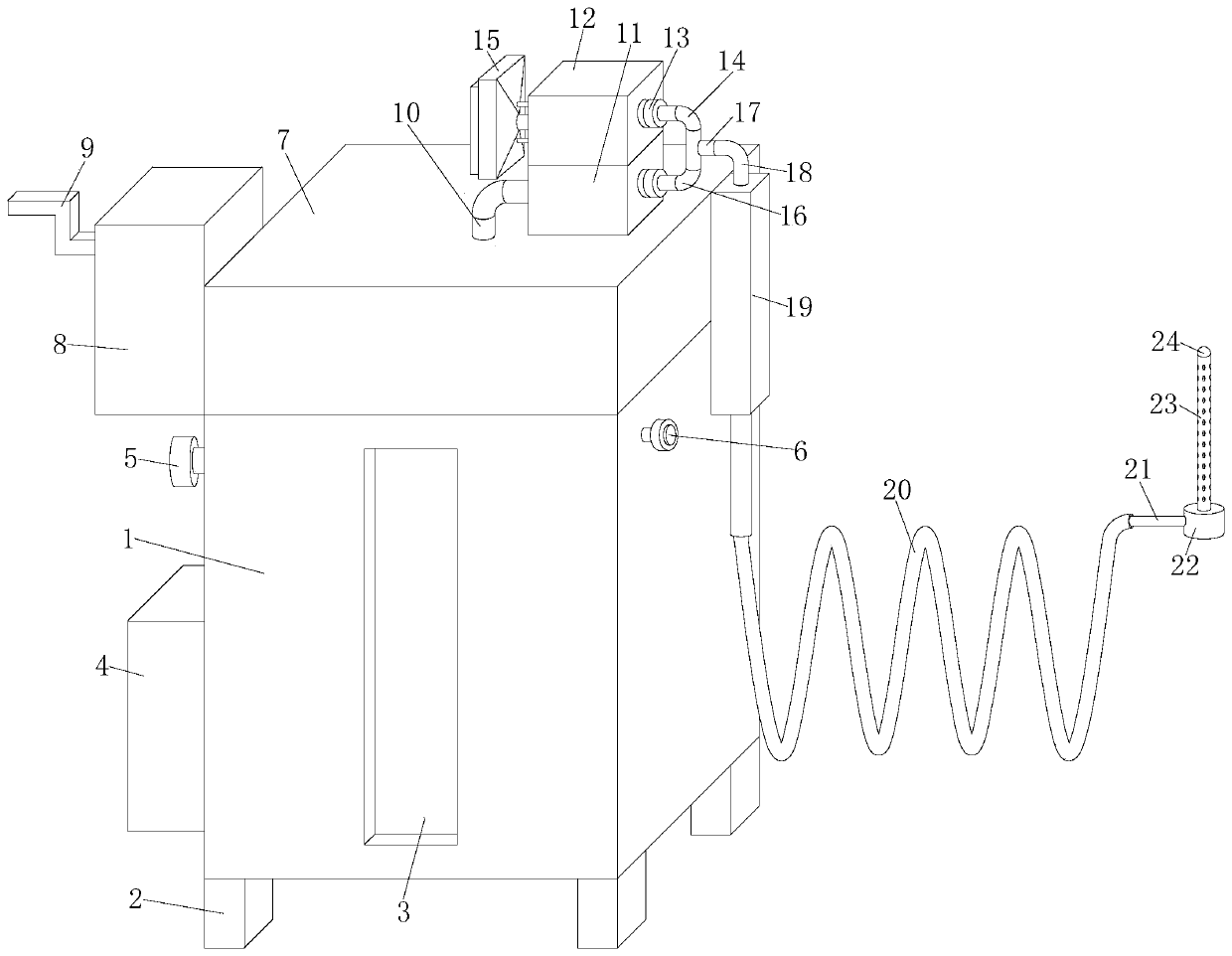

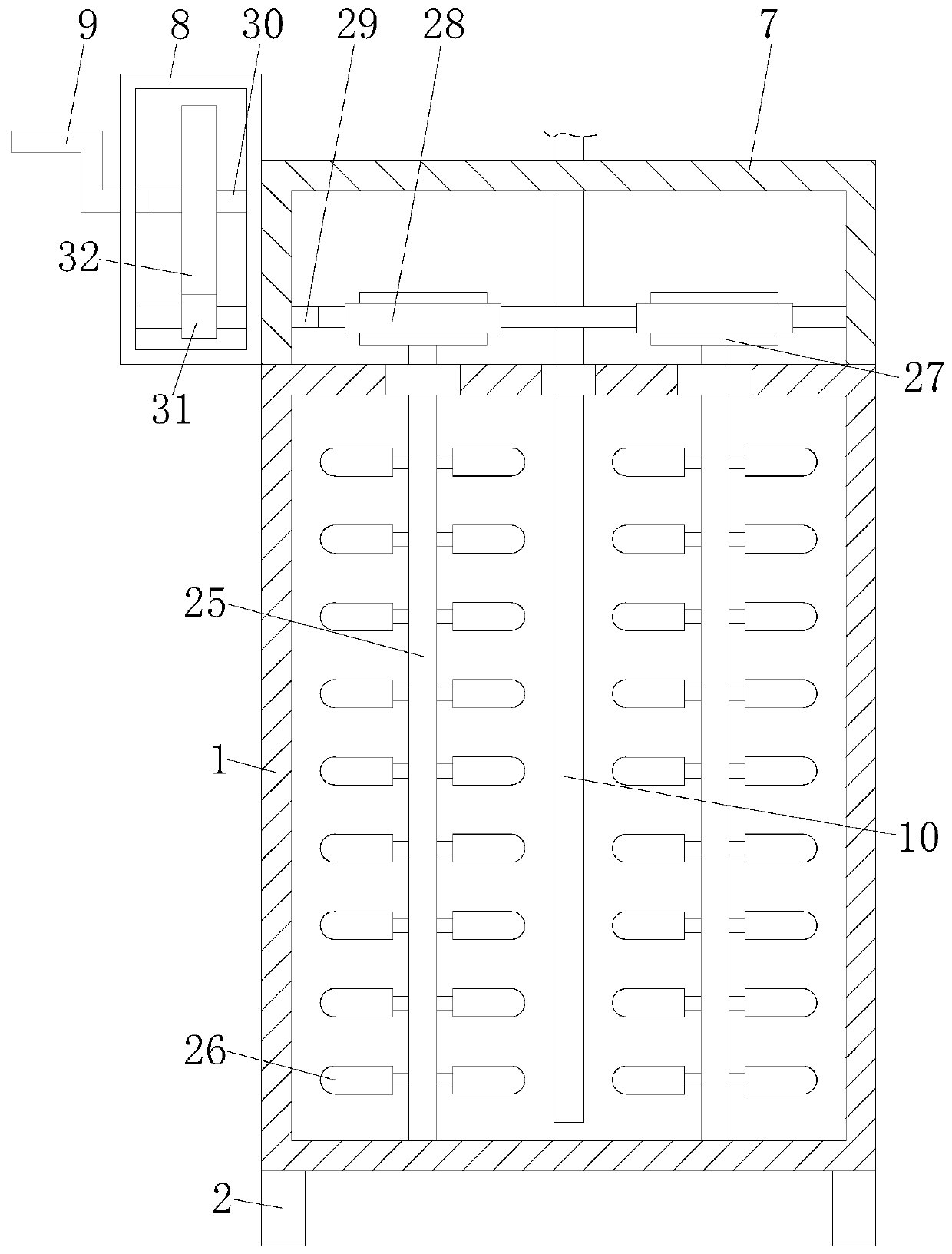

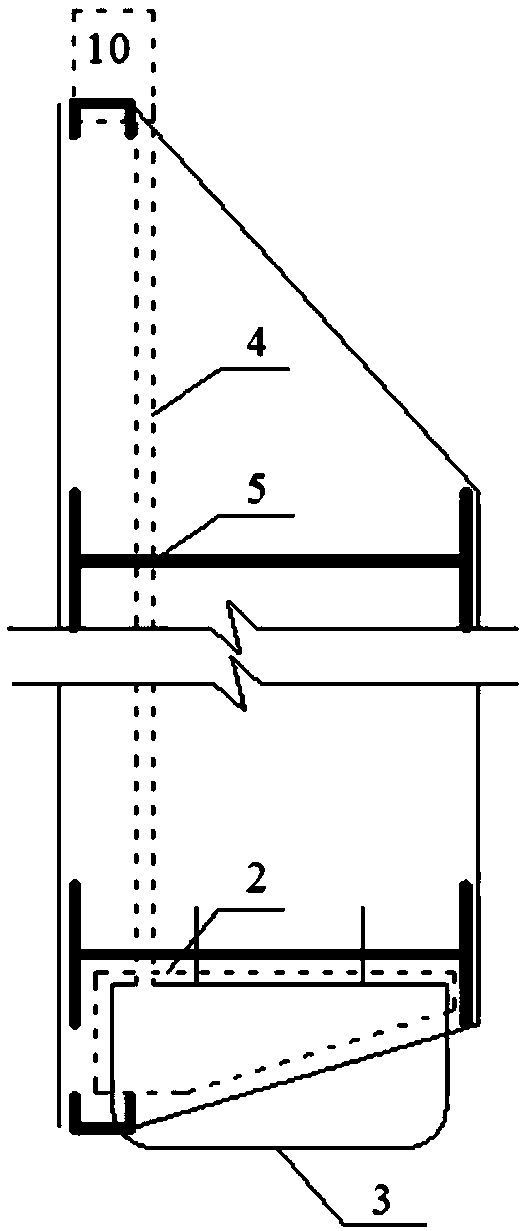

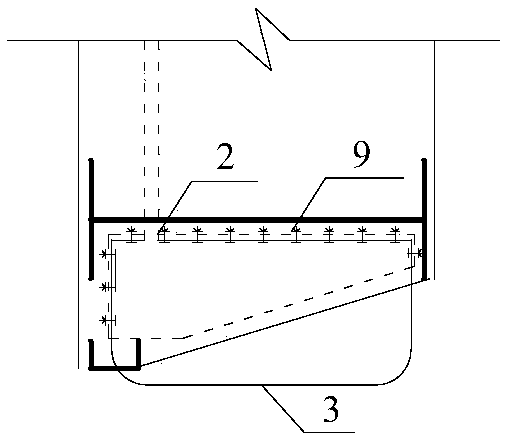

Ground water seepage coefficient testing device

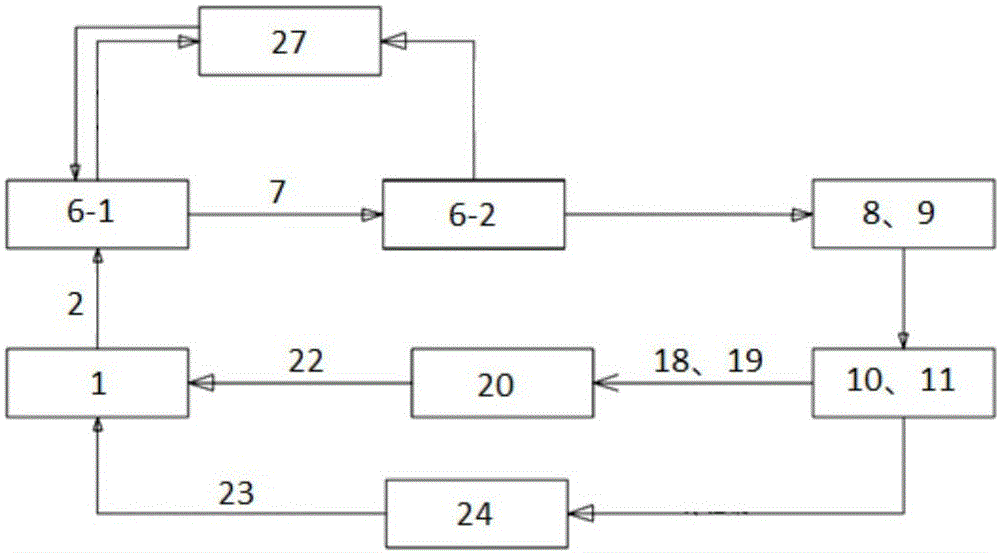

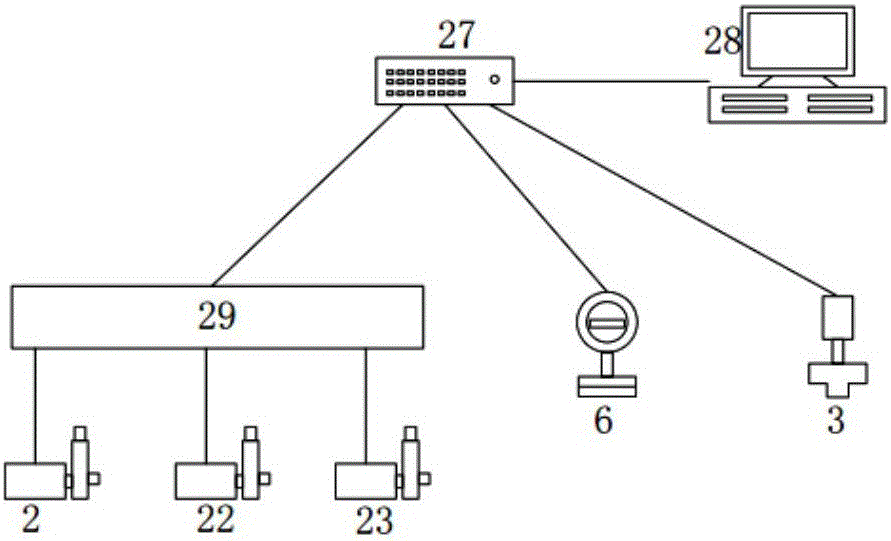

ActiveCN102410977ASimple structureLow costPermeability/surface area analysisOsmotic coefficientData acquisition

The invention relates to a ground water seepage coefficient testing device, belongs to the field of hydraulic engineering, and the IPC(international patent classification) number is E02B 1 / 00. The testing device provided by the invention comprises a operation control system, a water level sensor, a flow sensor, an on-line monitoring control device, a data acquisition system and a water pump for pumping water, wherein the water pump for pumping water is positioned under the water level sensor, and the flow sensor is connected with the water pump for pumping water through a system connection valve. In the testing process, the water pump for pumping water is started, and the groundwater on-line water level sensor and a water pump effluent water flow sensor 7 are started at the same time, then the data acquisition system automatically records water level and water flow in real time so as to obtain pumped water amount of the water pump and corresponding data on groundwater level drawdown, thereby calculating seepage coefficient and other hydrogeological parameters of a corresponding aquifer. The device disclosed by the invention is suitable for various ground water seepage coefficient tests, can accurately reflect the geohydrological conditions of the aquifer, thus improving the equipment level in the field of groundwater environment in China.

Owner:BEIJING WATER SCI & TECH INST

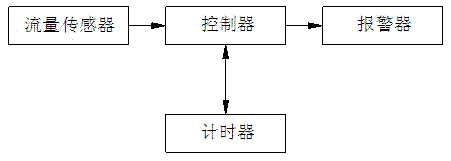

Alarm device used for filter core replacing

InactiveCN102728137AReplace scienceGuaranteed water purification effectFiltration separationWater channelWater flow

Owner:WUXI LAIJITE INFORMATION TECH

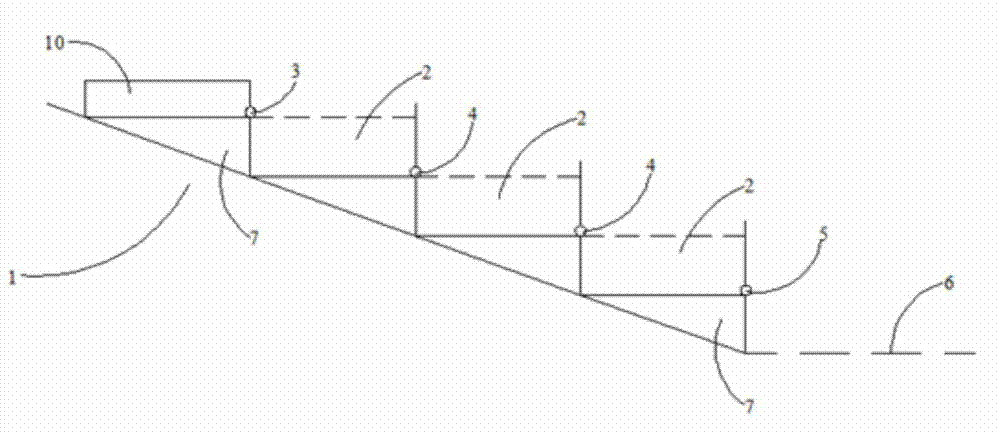

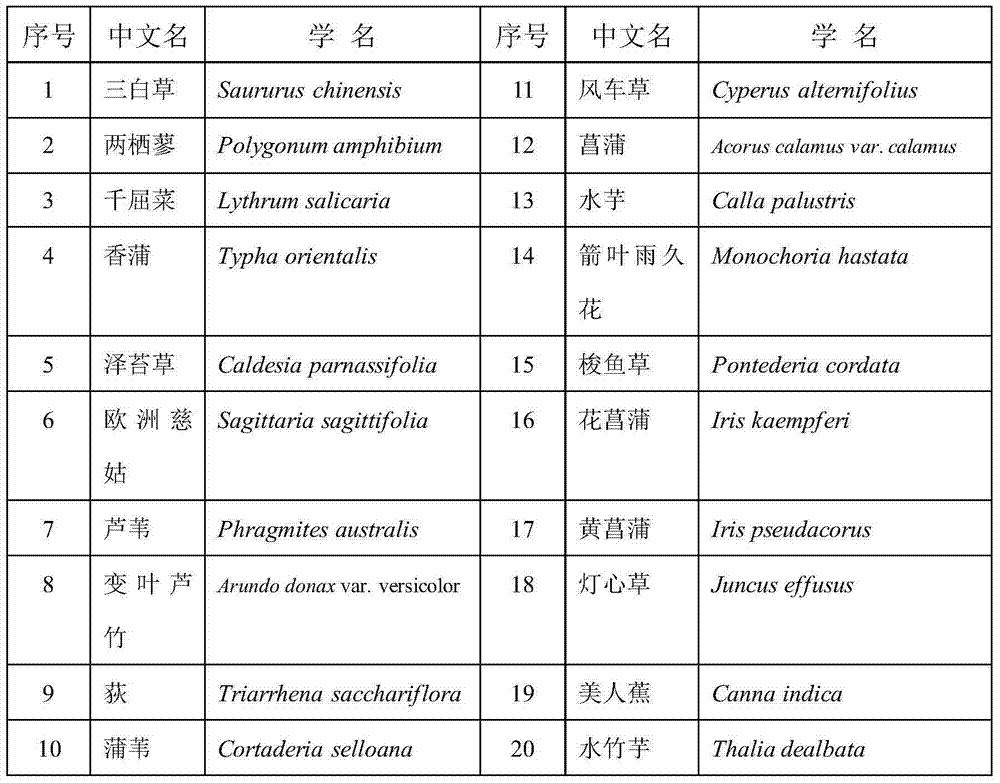

Method for constructing multi-stage subsurface flow constructed wetland system

ActiveCN103663859AStructure does not affectStructural influenceMultistage water/sewage treatmentSustainable biological treatmentConstructed wetlandChemical oxygen demand

Owner:广东四季景山园林建设有限公司

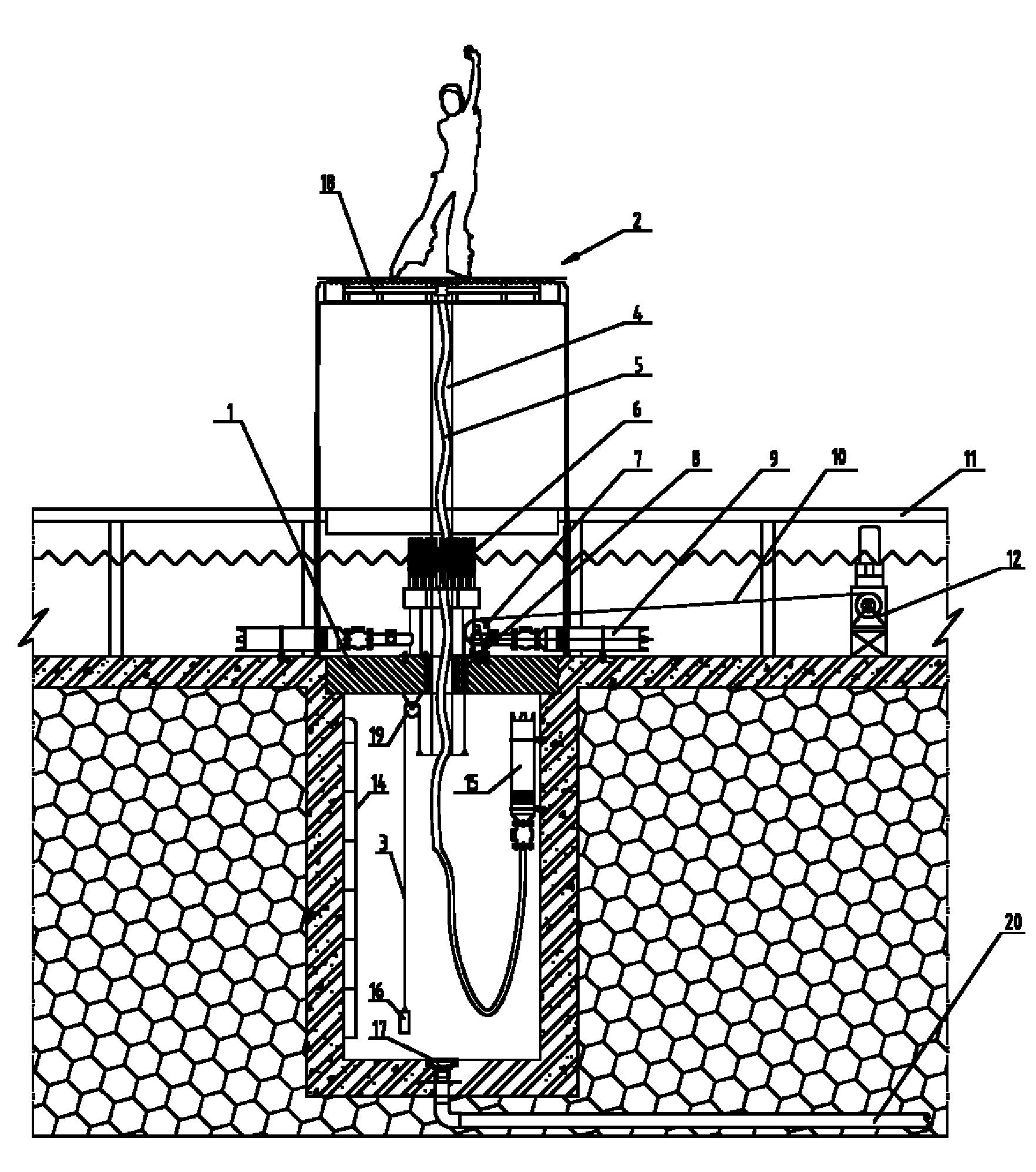

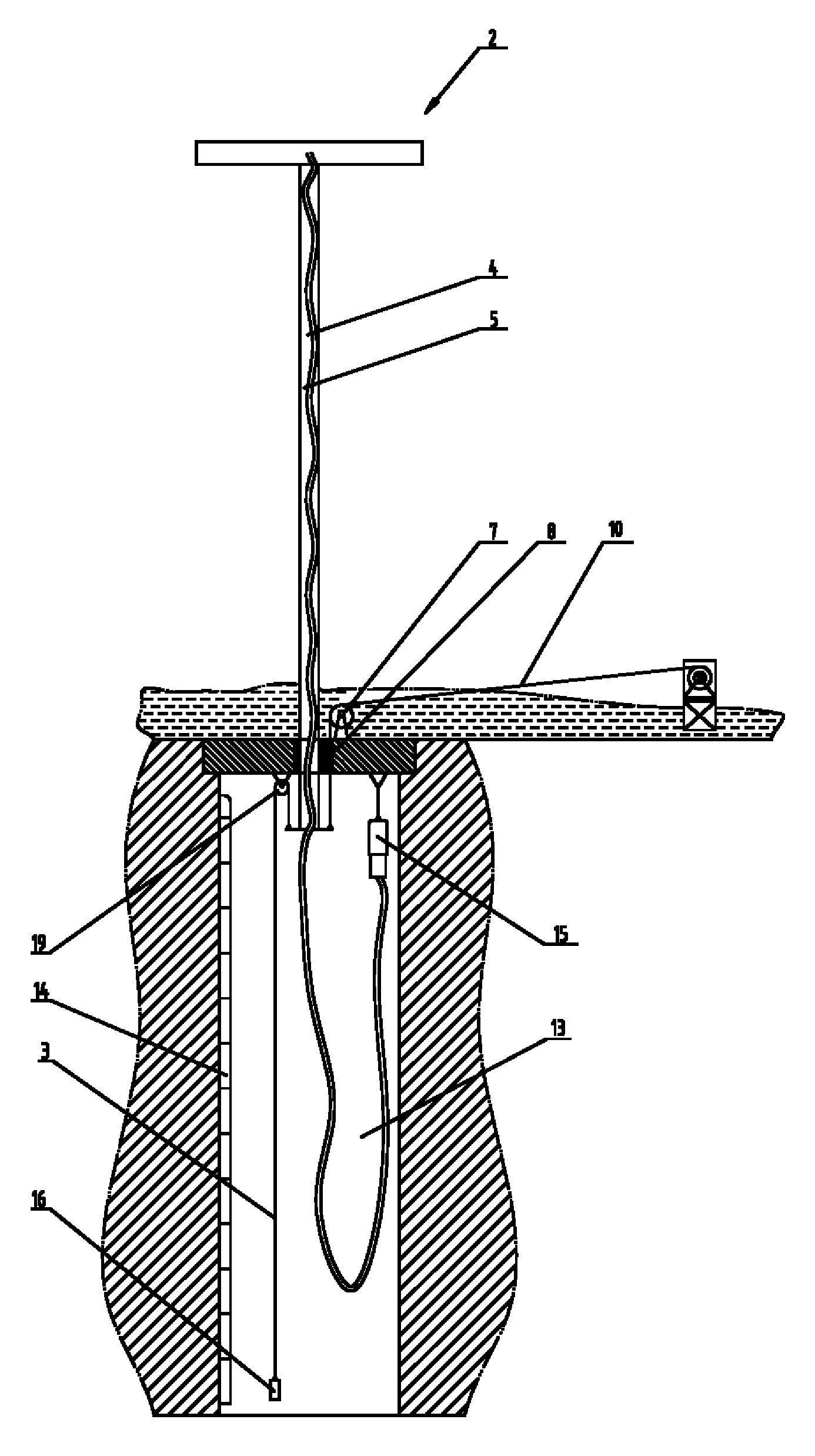

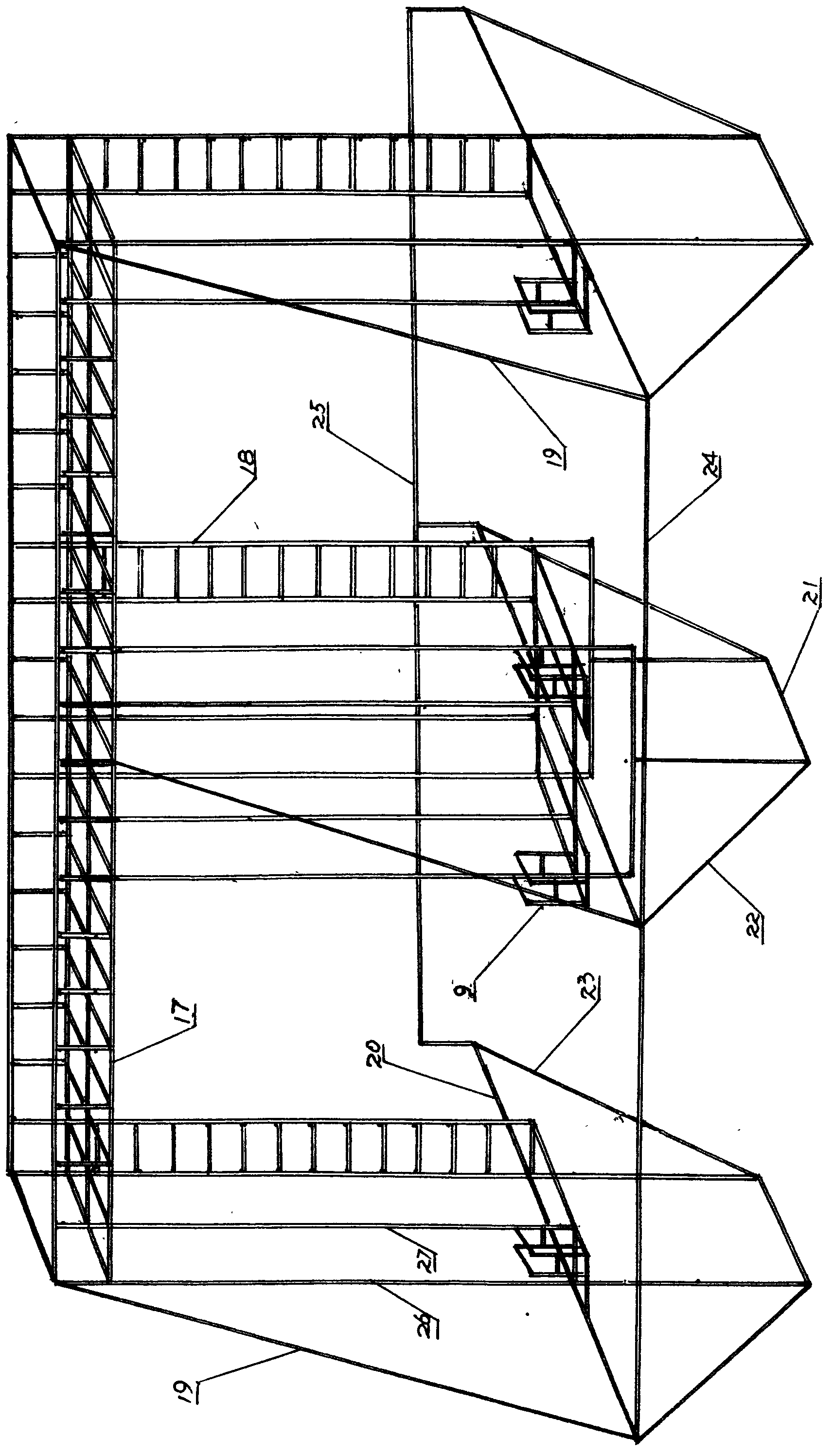

Elevating fountain stage

ActiveCN102031881AEnhance dynamic look and feelPracticalLiquid spraying apparatusTheatresWater flowSpray nozzle

Owner:东莞市环宇文化科技有限公司

Method for dynamically determining breathing oxygen consumption and hypoxia device for same

InactiveCN103340629AAutomatic dynamic monitoring of respiratory rateAutomatic dynamic monitoring rangeRespiratory organ evaluationWater flowDistilled water

Owner:ZHEJIANG UNIV

Method for producing continuous casting round billet of wind power tower cylinder flange steel

The invention discloses a method for producing a continuous casting round billet of wind power tower cylinder flange steel. The method comprises the steps that the degree of superheat of continuous casting liquid steel is controlled within the range from 21 DEG C to 25 DEG C in the continuous casting process; air water atomizing cooling serves as the cooling mode in a secondary cooling area, the specific water flow is controlled within the range from 0.15 L / kg to 0.18 L / kg, the casting speed is controlled within the range from 0.30 m / min to 0.34 m / min, the current of electromagnetic stirring of a crystallizer is controlled within the range from 200 A to 300 A, the frequency of electromagnetic stirring of the crystallizer is controlled within the range from 2.0 Hz to 3.0 Hz, the current of electromagnetic stirring of the tail end of solidification is controlled within the range from 350 A to 400 A, and the frequency electromagnetic stirring of the tail end of solidification is controlled within the range from 8 Hz to 12 Hz. According to the method, the surface quality and interior quality of the continuous casting round billet of wind power tower cylinder flange steel can be effectively improved by setting and optimizing technological parameters. In addition, a finished wind power tower cylinder flange machined through the round billet obtained according to the method can completely meet the quality requirement of the wind power tower cylinder flange steel after ultrasonic flaw detection.

Owner:LAIWU IRON & STEEL GRP

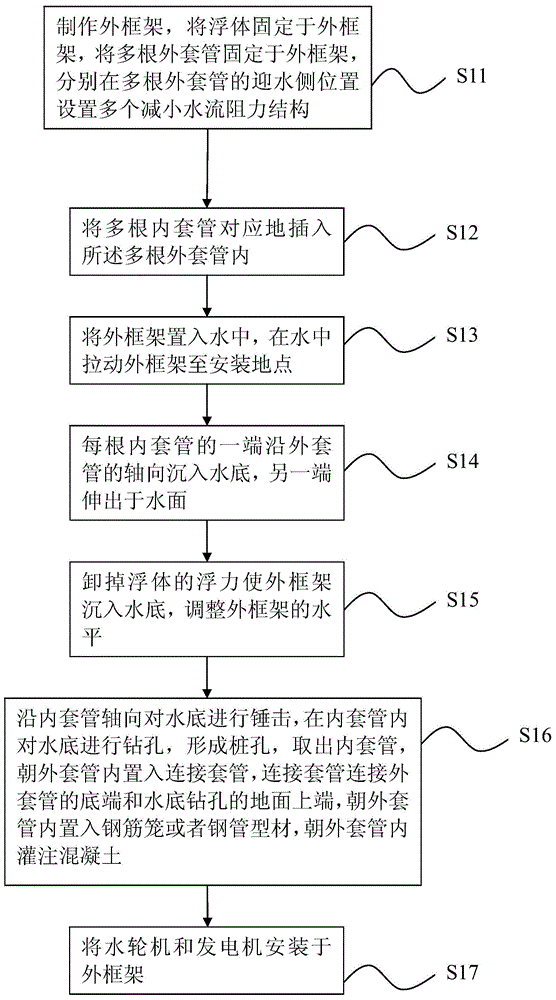

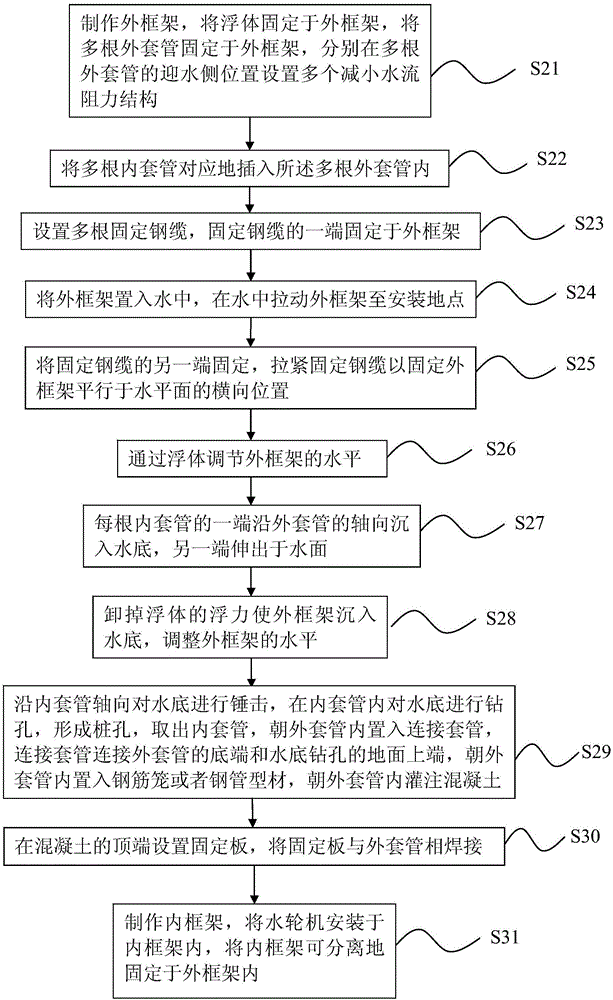

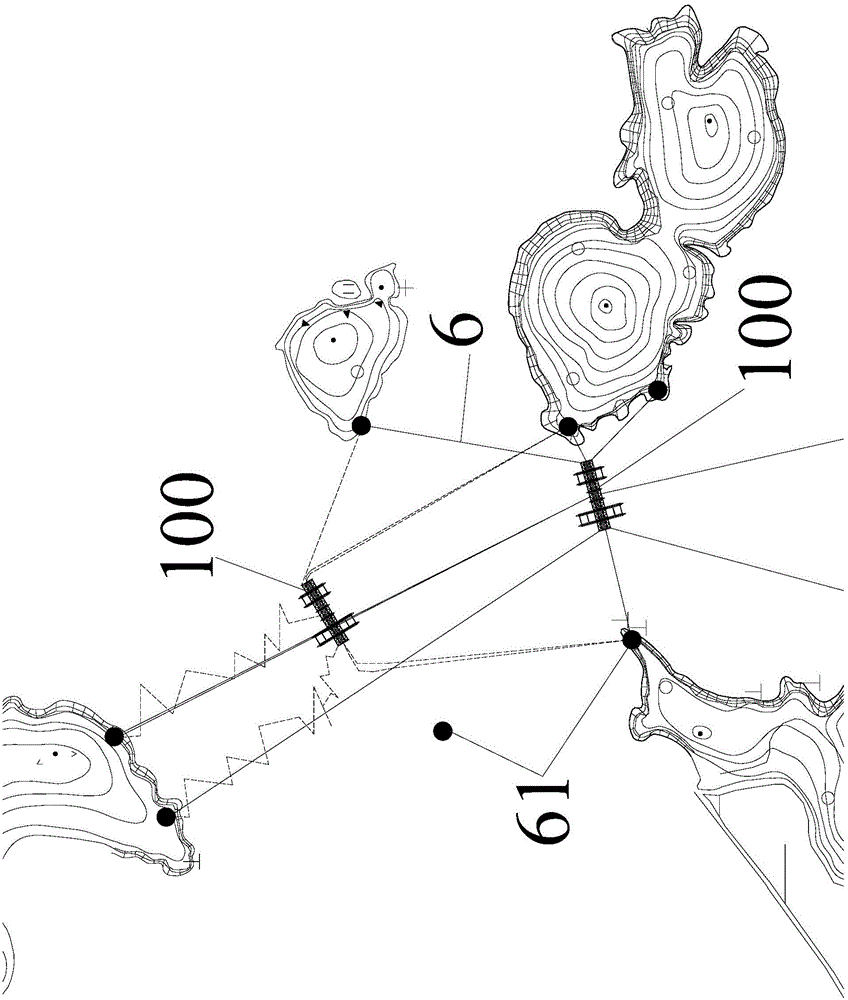

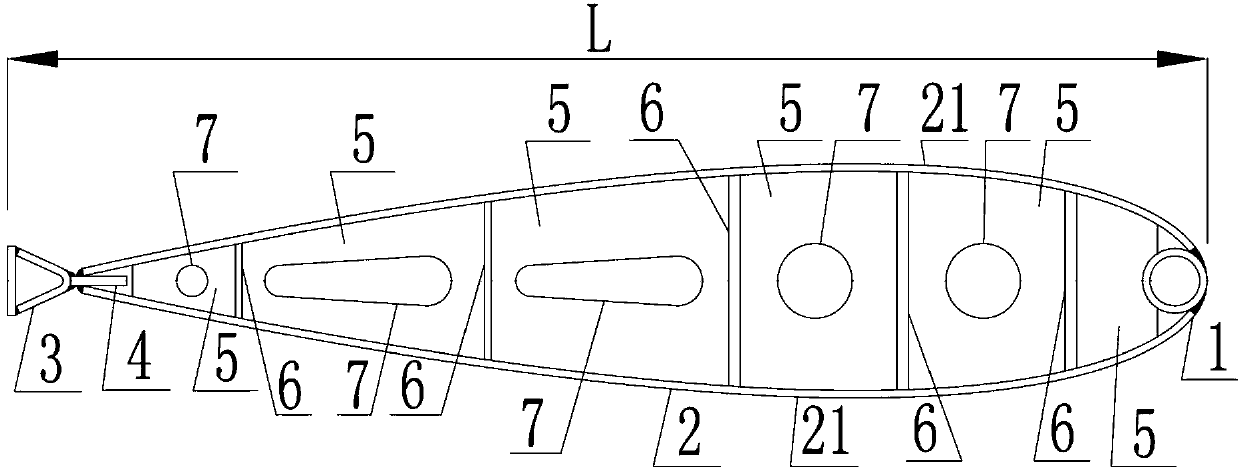

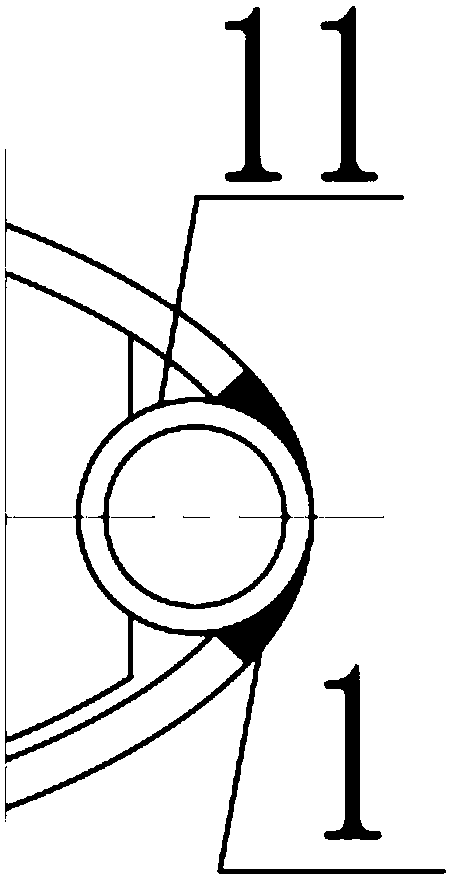

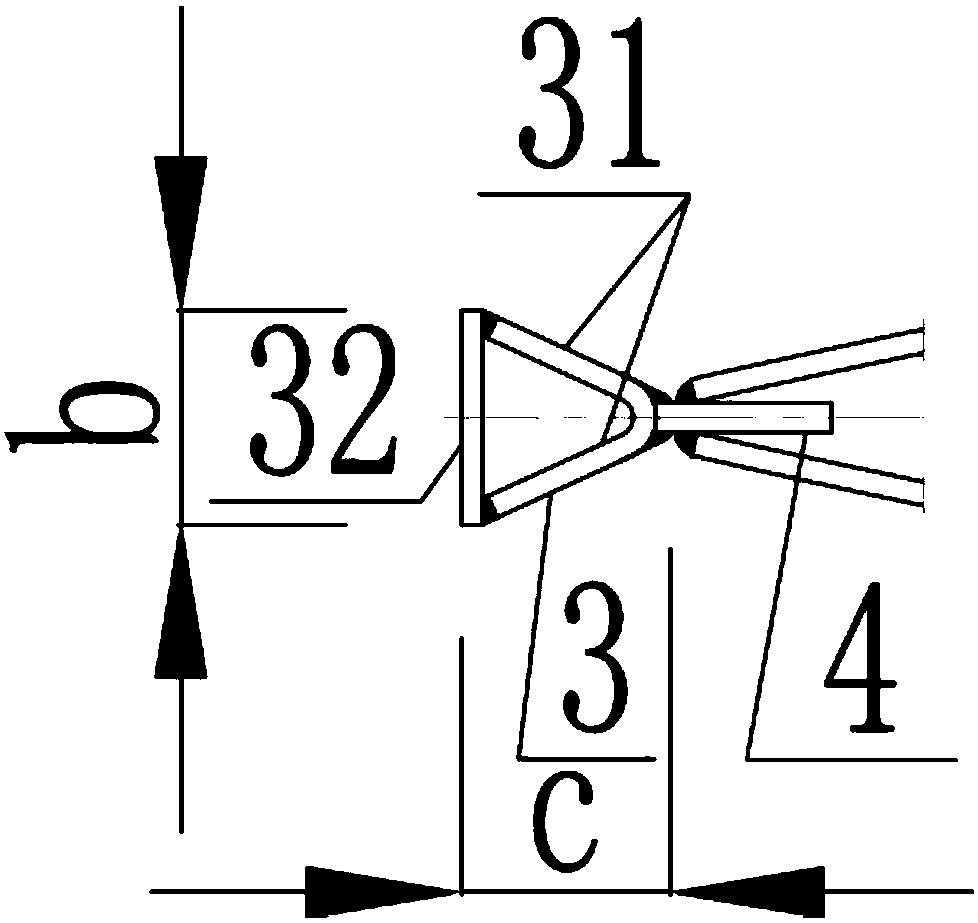

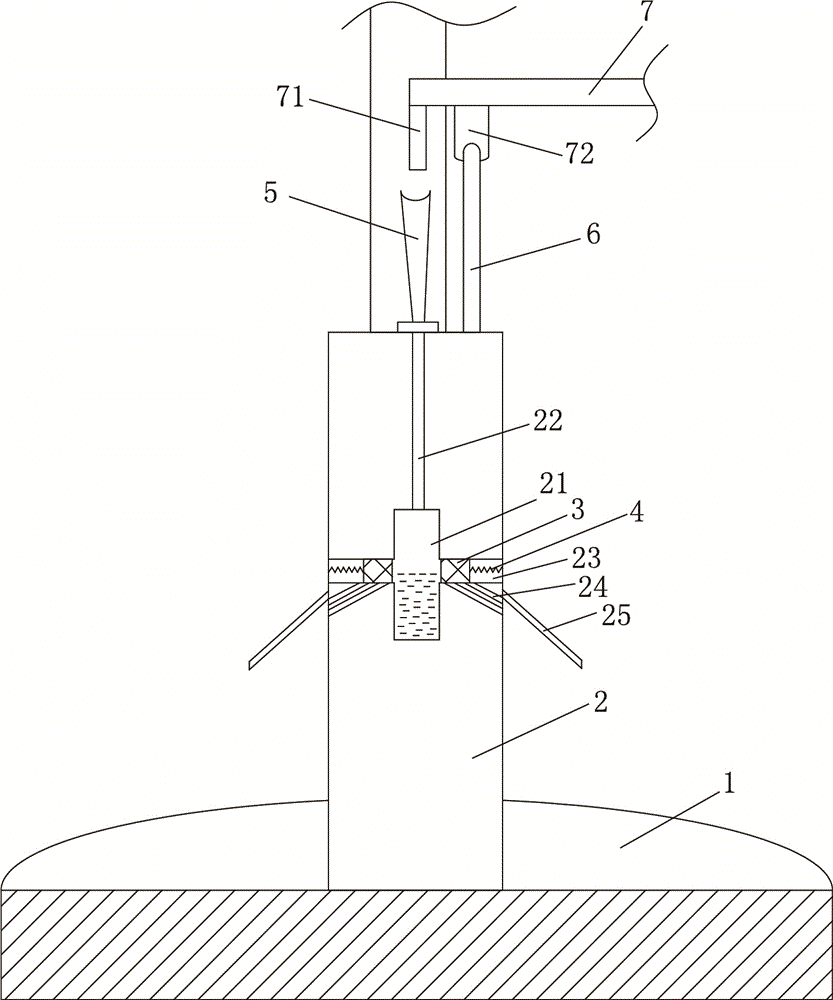

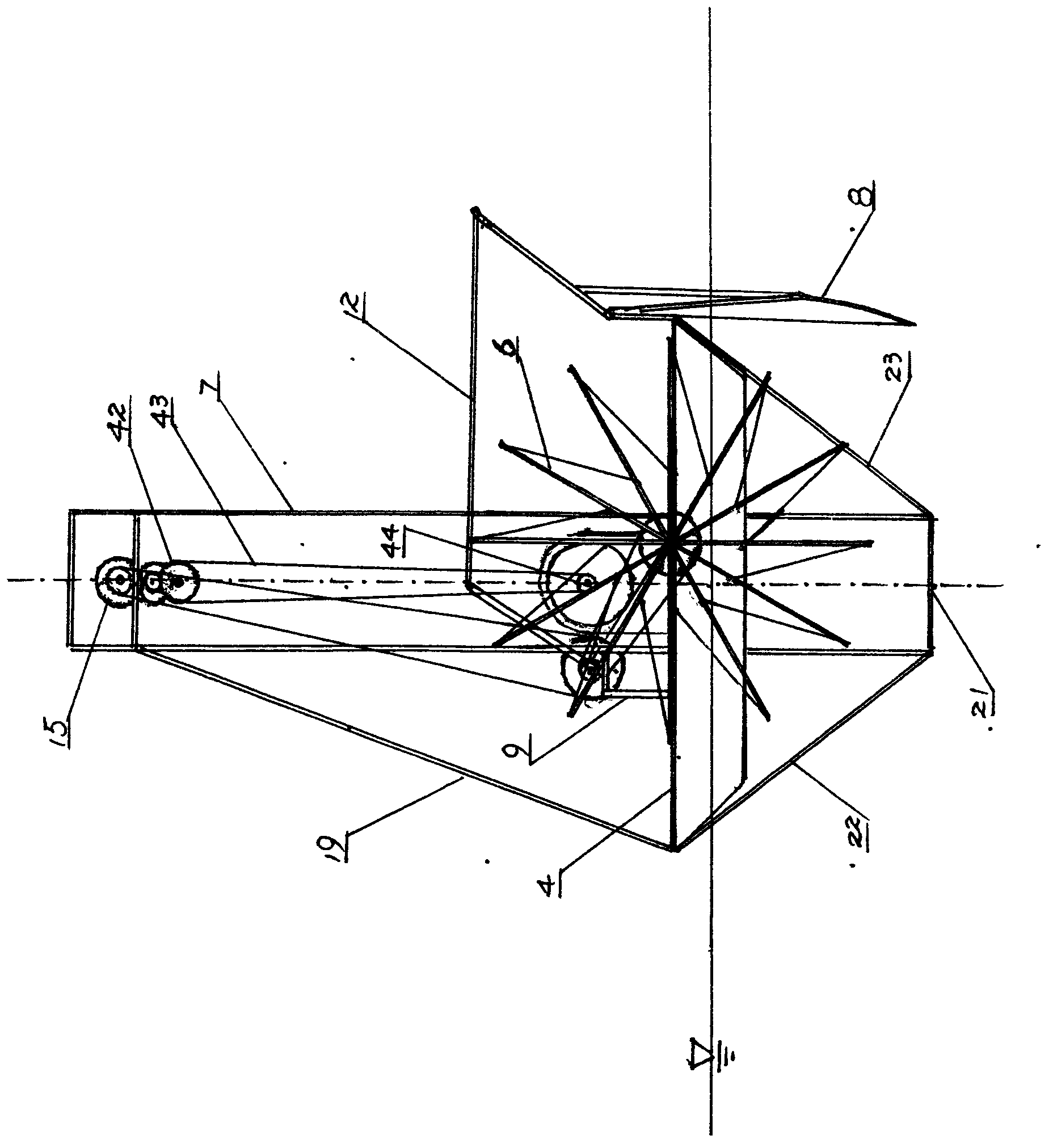

Construction method for fixing tidal current energy power generation device to water bottom and tidal current energy power generation device

ActiveCN105401564APromote commercial applicationsOvercome the disadvantages of not being able to scale upFinal product manufactureWater-power plantsWater turbineWater flow

Owner:ZHEJIANG ZHOUSHAN LHD ENERGY DEV

Fishtail rudder

Owner:CHINA SHIP SCI RES CENT SHANGHAI DIV +1

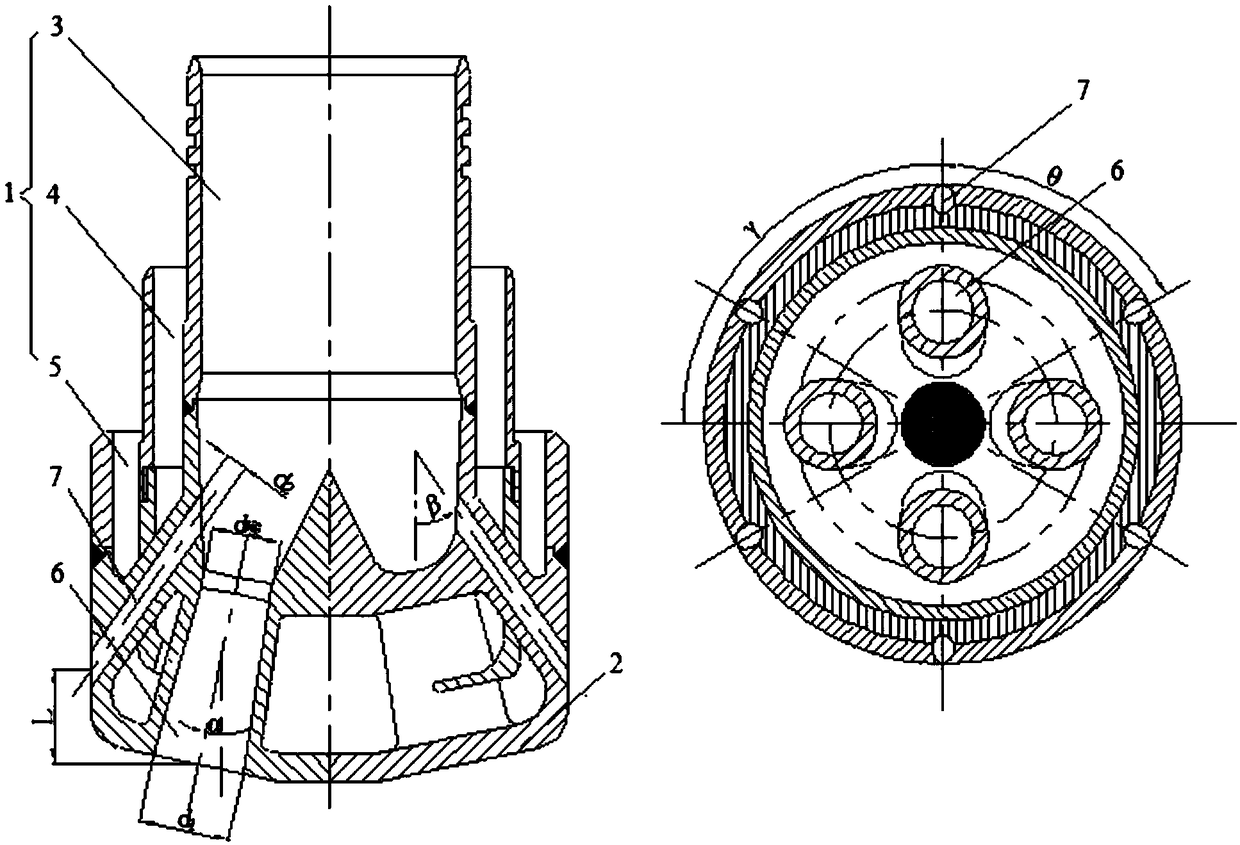

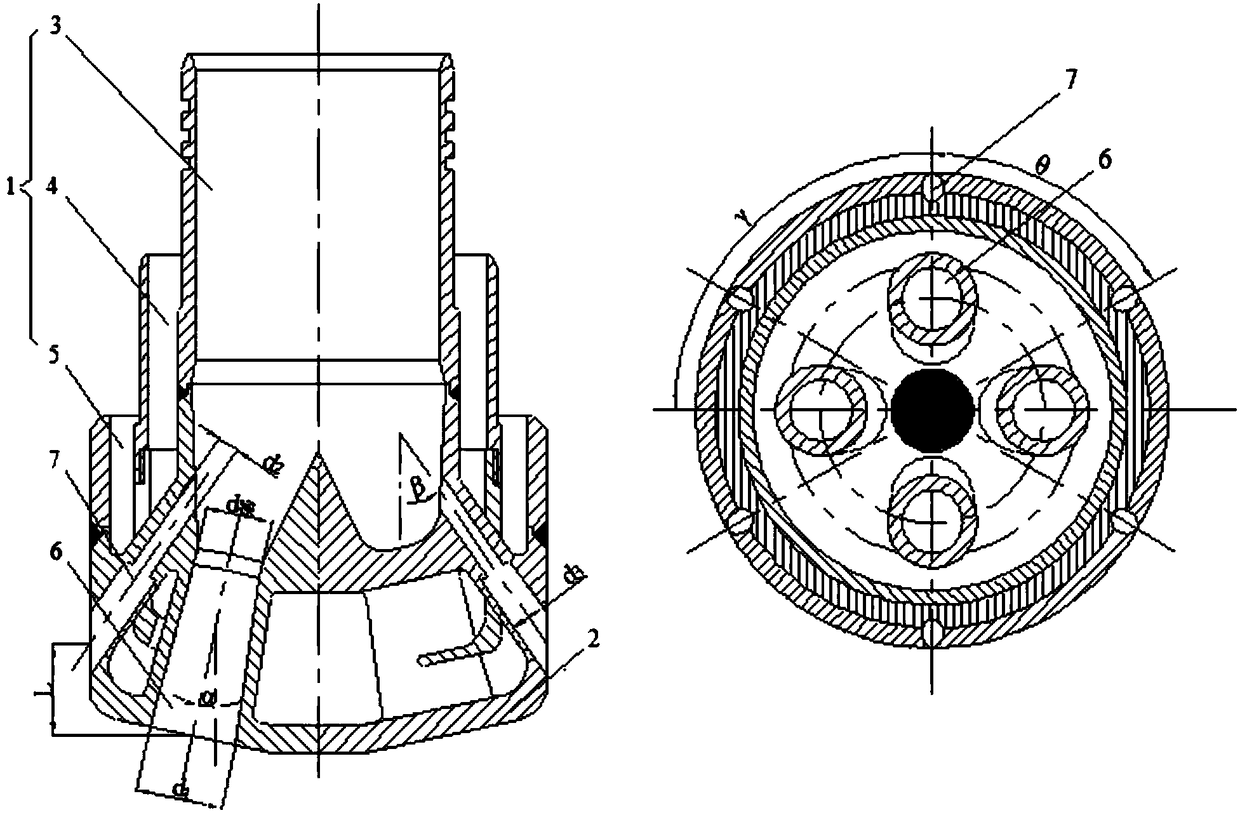

Ceramic valve element with drinking water control function

The invention discloses a ceramic valve element with a drinking water control function. The ceramic valve element is formed in the manner that a rotating base is arranged in a valve shell in an assembled manner, a linking block, a movable valve block and a fixed valve block which are sequentially overlapped are arranged below the rotating base, a valve rod upwards extending out of the valve shell is arranged in the rotating base in pivoted manner, a stirring part at the bottom end of the valve rod and the linking block are embedded, the movable valve block is embedded through the linking block, and the movable valve block is driven by the linking block to move horizontally or rotate through the operation of the valve rod; by means of the change of the position corresponding relation between the movable valve block and the fixed valve block, a tap is controlled to allow water to flow or stop water flowing, or the mixing proportion of cold water and hot water and the output water flow are changed, and internal members such as the fixed valve block, the movable valve block, the linking block and the rotating base are stopped from dropping out through combination of a valve seat below the valve shell. The ceramic valve element can control use of tap water and drinking water, and the complexity of the whole structure is effectively simplified.

Owner:SHANGHAI GEAR PLASTIC

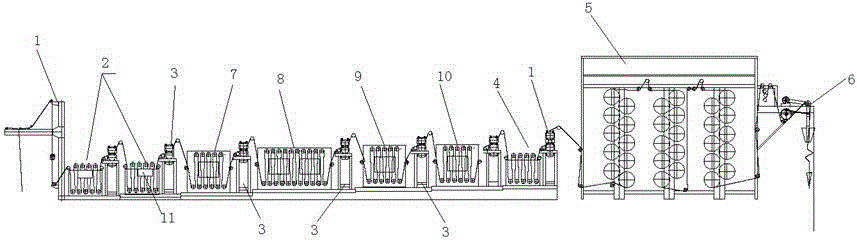

Woven fabric and jean desizing and boiling-off combined machine

InactiveCN104947339ASoft and comfortableSucessive textile treatmentsTextile treatment containersFiberDenim

Owner:扬州市江都区东盛印染机械厂

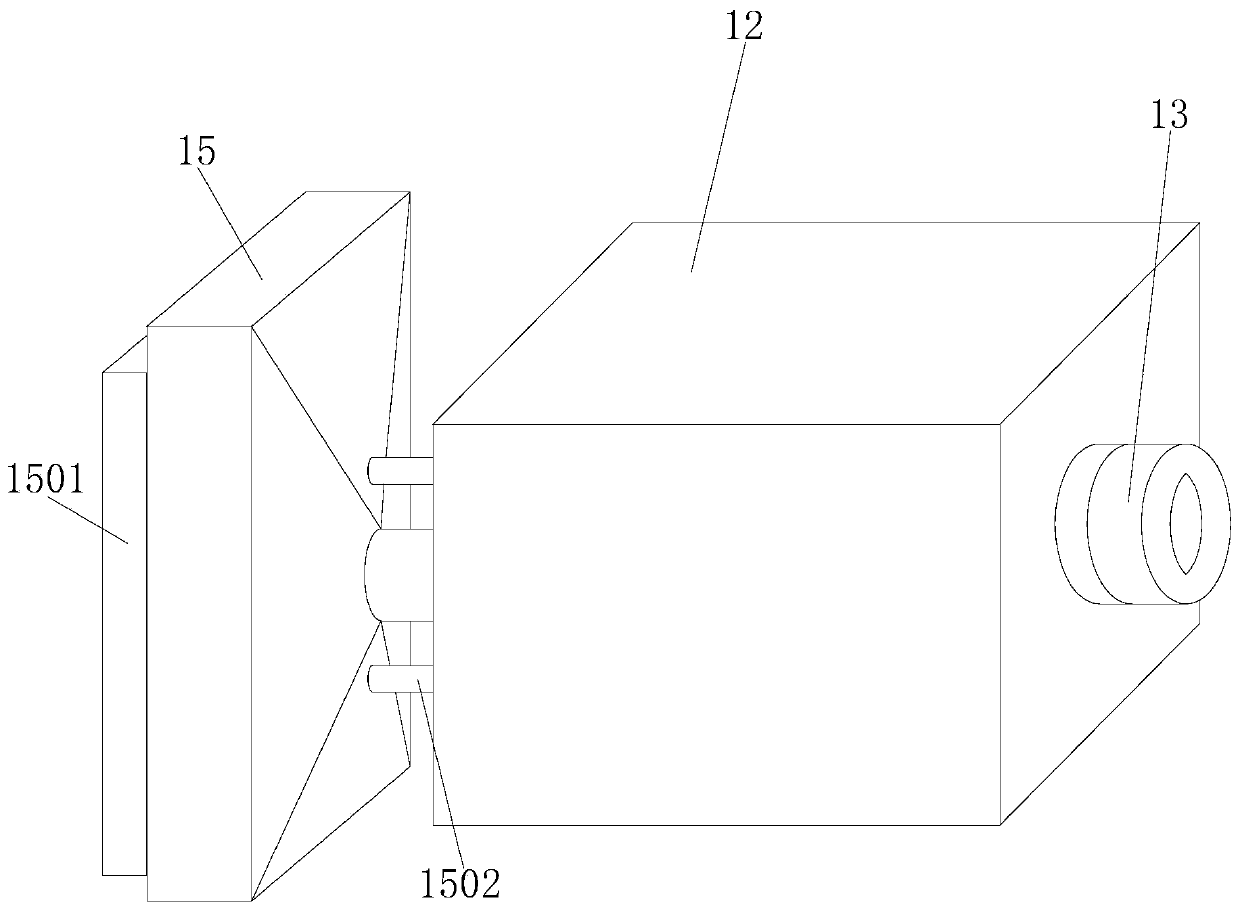

Faucet assembly with aerator cartridge and method for mounting said assembly

InactiveUS20170101768A1Torque required for unscrewing may be minimalMinimal torqueDomestic plumbingScrew threaded jointsWater flowAeration

Faucet assembly with aerator cartridge (1′), which is screwed by means of an attachment thread (12) into the mouth (100), which has no sealing gasket, wherein water (W) seeping through the attachment thread (12) is at least partially reintroduced into a casing (10) of cartridge (1′) through suitably positioned aeration windows (13), being dragged by the air flow (A), which is sucked into said aeration windows (13) by the water flow within an internal flow path (2) of said cartridge (1).

Owner:AMFAG

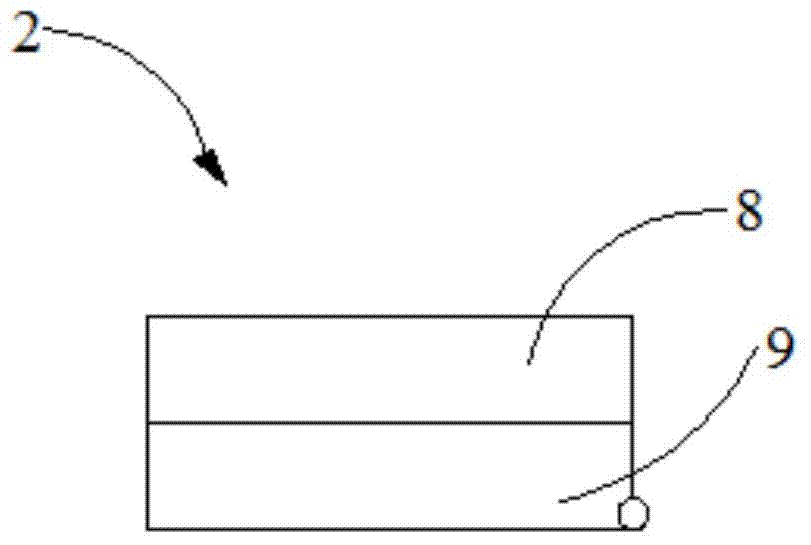

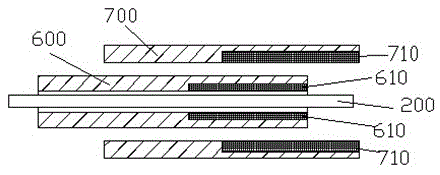

LED lamp with water-circulating heat dissipation function

ActiveCN105221970AEven heat absorptionImprove heat absorption efficiencyPoint-like light sourceLighting heating/cooling arrangementsWater flowEngineering

The invention discloses an LED lamp with a water-circulating heat dissipation function. The LED lamp comprises an LED wafer (1), a connecting wire (2), a lens (3), an LED wafer substrate (5), a system circuit board (6) and a heat dissipation fin (7), wherein a heat dissipation device (8) used for heat dissipation is arranged below the heat dissipation fin (7); the water inlet (9) of the heat dissipation device (8) is positioned under the heat dissipation device (8); and two or more water outlets (10) are arranged the heat dissipation device (8) and uniformly distributed on the side surface of the heat dissipation device (8). The LED lamp has the beneficial effects that the water inlet is arranged under the heat dissipation device and the water outlets are arranged on the side surface of the heat dissipation device, and water flows in from below and flows out from the surroundings, so that water flow of relative low temperature is formed from the middle to both sides of the heat dissipation fin, heat on the heat dissipation fin is brought away, uniform heat absorption of the water flow is achieved, heat absorption efficiency of the water flow is improved, and all regions of the heat dissipation fin can keep the same and stable temperature.

Owner:JIANGSU TIWIN OPTO ELECTRONICS TECH

Laboratory drainpipe network simulation system and simulation method

ActiveCN105841922AReal-time observation of confluence nodesHydrodynamic testingWater storageWater flow

Owner:BEIJING RES CENT OF URBAN SYST ENG

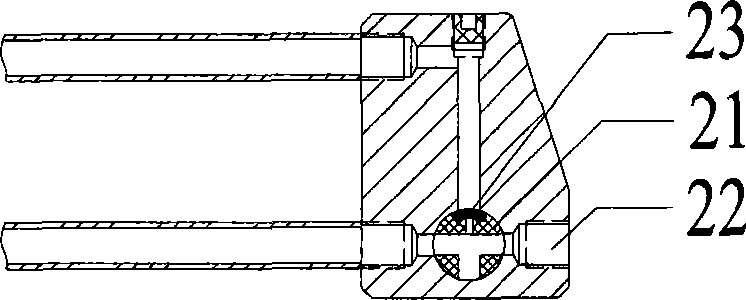

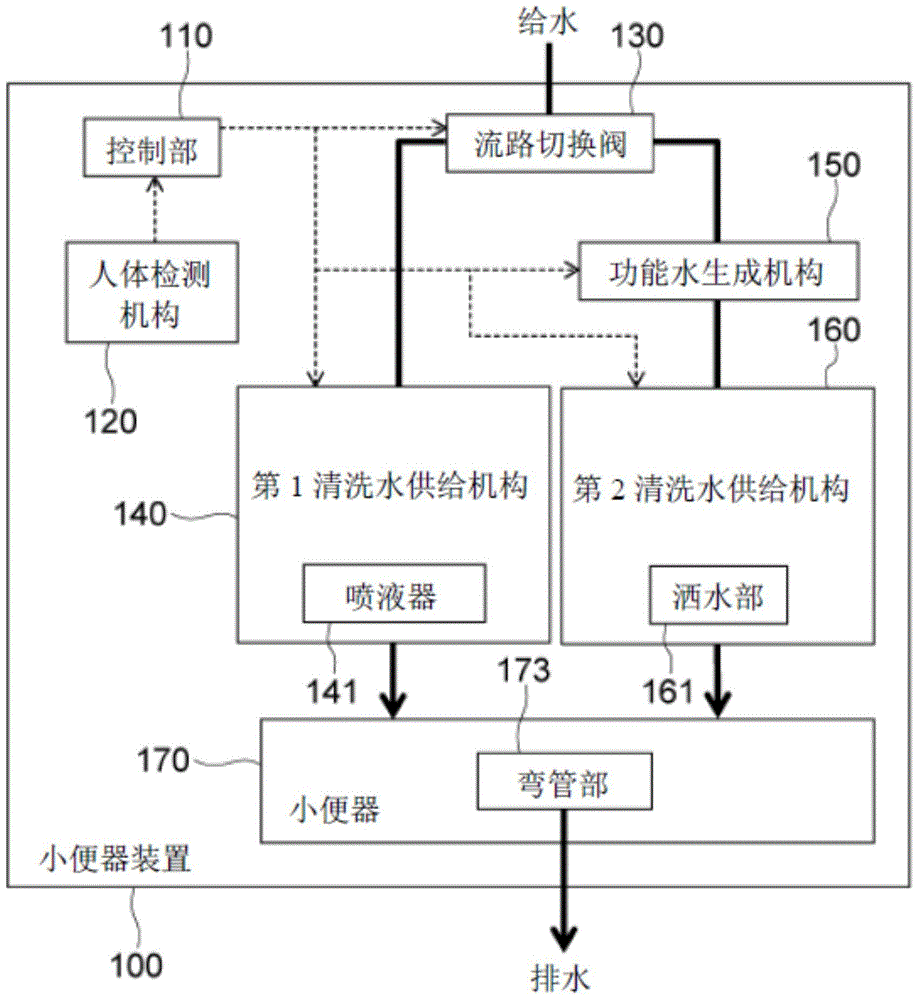

Nozzle device and sanitary washing device using the same

ActiveCN102518196AThere is no need to increase the cross-sectional areaSmall pulsationSpray nozzlesLavatory sanitoryWash waterBuffer tank

A nozzle and a sanitary washing device using the same are provided. The nozzle device has a nozzle port arranged on a nozzle body, a flow passage supplies washing water to the nozzle port from a rear end of the nozzle body and a buffer tank which is connected through a communication path from the halfway of the flow channel.

Owner:PANASONIC CORP

Device for cleaning away riverway floating objects

Owner:湖北万英机械股份有限公司

Fuel cell system

ActiveUS20160129808A1Easy to operateAvoid flowFuel cell heat exchangeBattery/fuel cell control arrangementFuel cellsWater flow

A flow control valve 26 can adjust the percentage of the flow rate of cooling water to a radiator 23 to a predetermined value (50%) or smaller. When the temperature of the cooling water in a fuel cell 11 is determined to be a predetermined temperature (0° C.) or higher after the cooling water is supplied to the fuel cell 11 with the percentage of the flow rate of the cooling water to the radiator 23 set to the predetermined value (50%) or larger, a controller 41 performs a predetermined percentage supply operation for controlling the flow control valve 26 and a pump 22 to supply the cooling water to the fuel cell 11 with the percentage of the flow rate of the cooling water to the radiator 23 set to the predetermined value (50%) or larger.

Owner:TOYOTA JIDOSHA KK

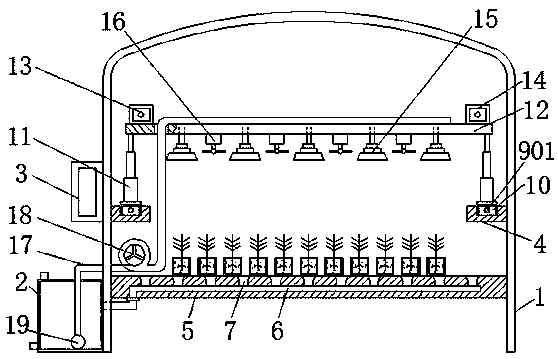

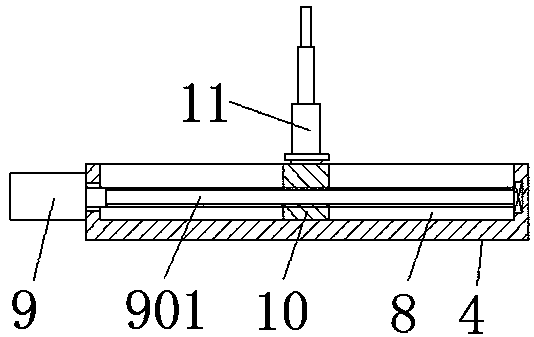

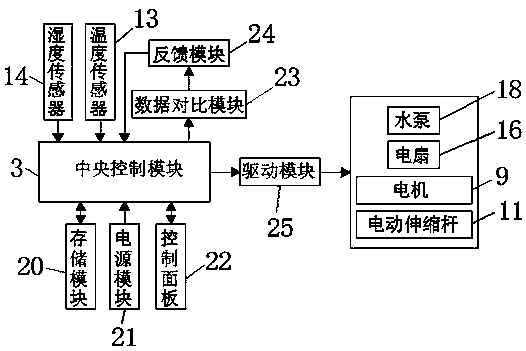

Novel intelligent irrigation system

PendingCN109452054AImprove irrigation effectSolve the problem of artificial irrigationClimate change adaptationGreenhouse cultivationGreenhouseAgricultural engineering

Owner:魏秋欣

Water-cooling cooling polishing machine

InactiveCN105619252AExtended service lifeFree from damagePortable grinding machinesGrinding/polishing safety devicesInlet channelWater flow

Owner:NINGBO XINSHENG TOOLS

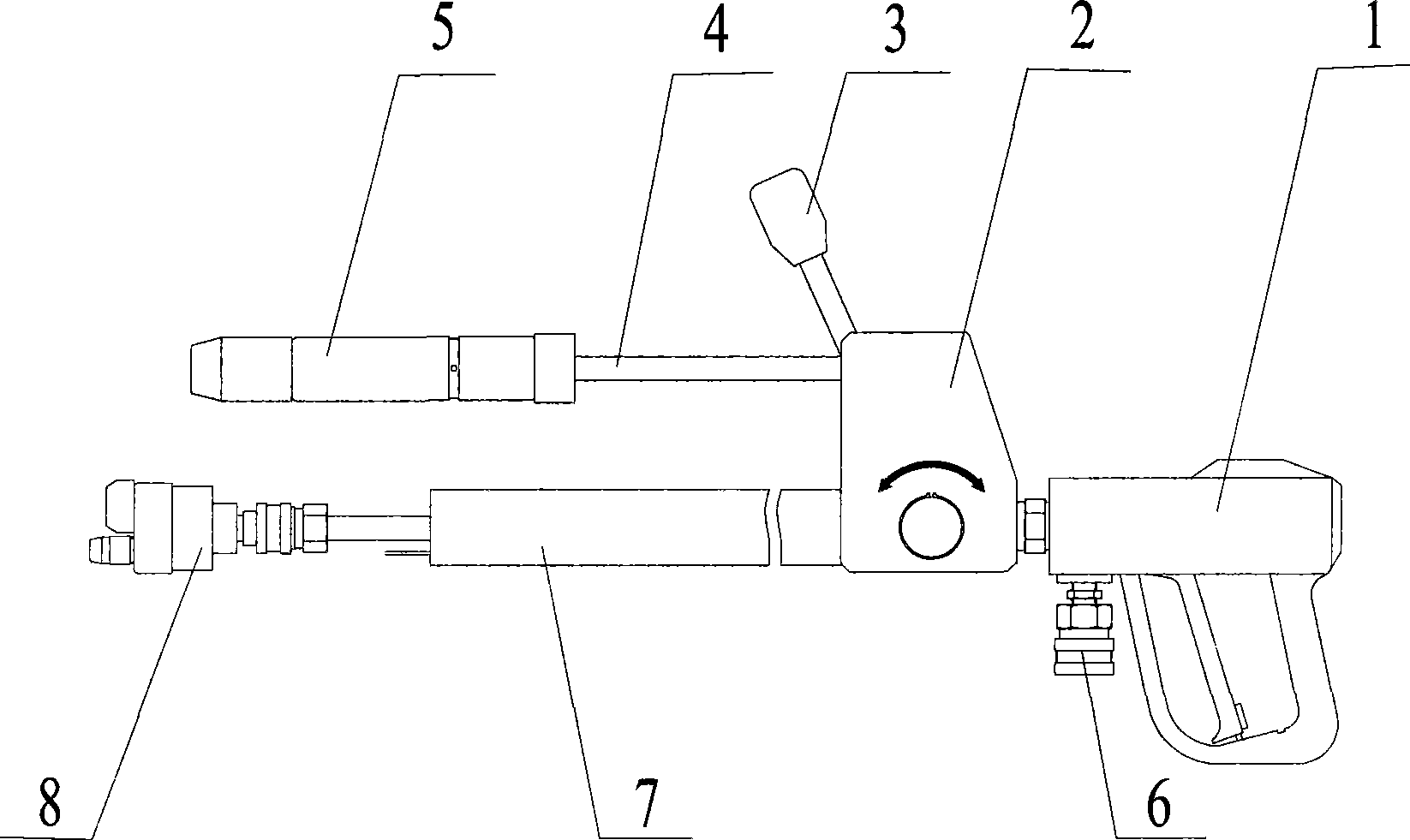

Injection gun for fire fighting

Owner:SINCERE PIONEER MACHINERY

Shipborne type hydroelectric generation device

InactiveCN102979659APromote development and utilizationSmall terrain constraintsHydro energy generationReaction enginesElectricityWater wheel

Owner:林文初

Single-flow-channel secondary combustion oxygen lance capable of improving scrap ratio of converter and application method of single-flow-channel secondary combustion oxygen lance

PendingCN108977620AHigh desulfurization rateIncrease the amount of steel scrap into the furnaceManufacturing convertersProcess efficiency improvementCombustionSpray nozzle

Owner:NORTHEASTERN UNIV

Self-cleaning system and self-cleaning method suitable for honey beverage vending machine

InactiveCN110974024AWell mixedAvoid enteringBeverage vesselsActivated carbon filtrationStraight tube

Owner:杭州为我健康新零售科技有限公司

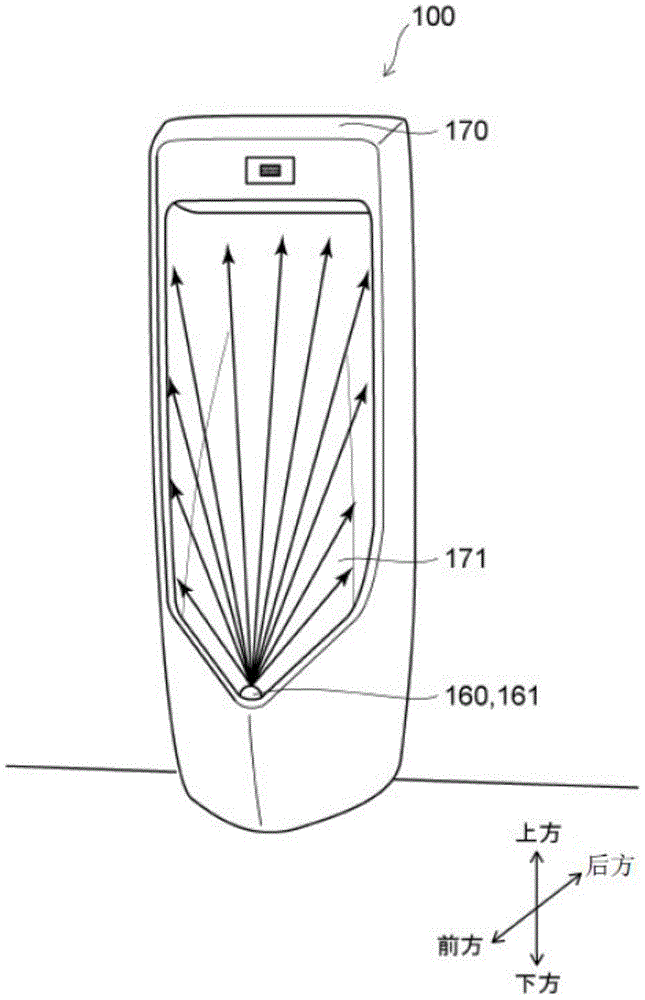

Urinal apparatus

Owner:TOTO LTD

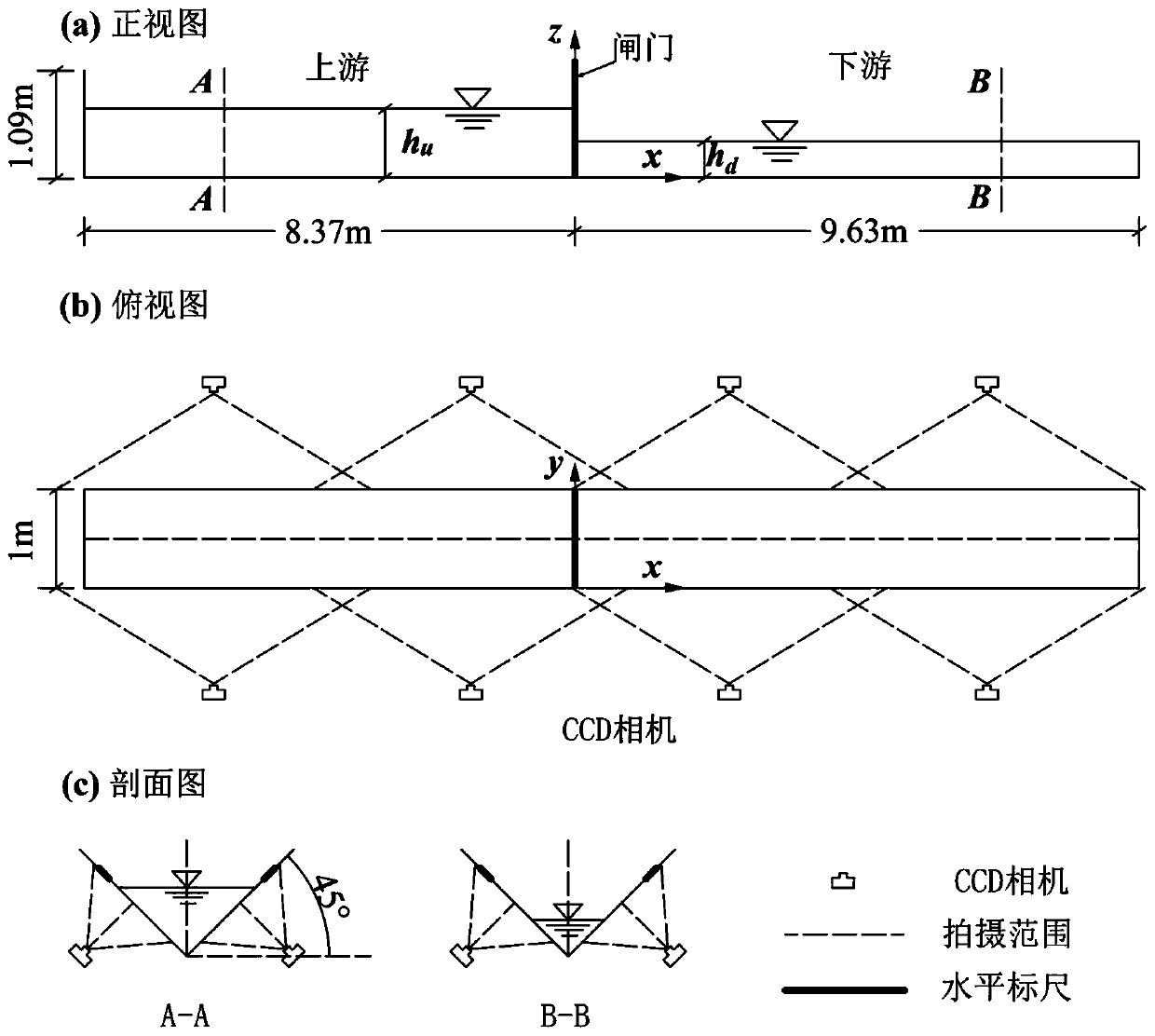

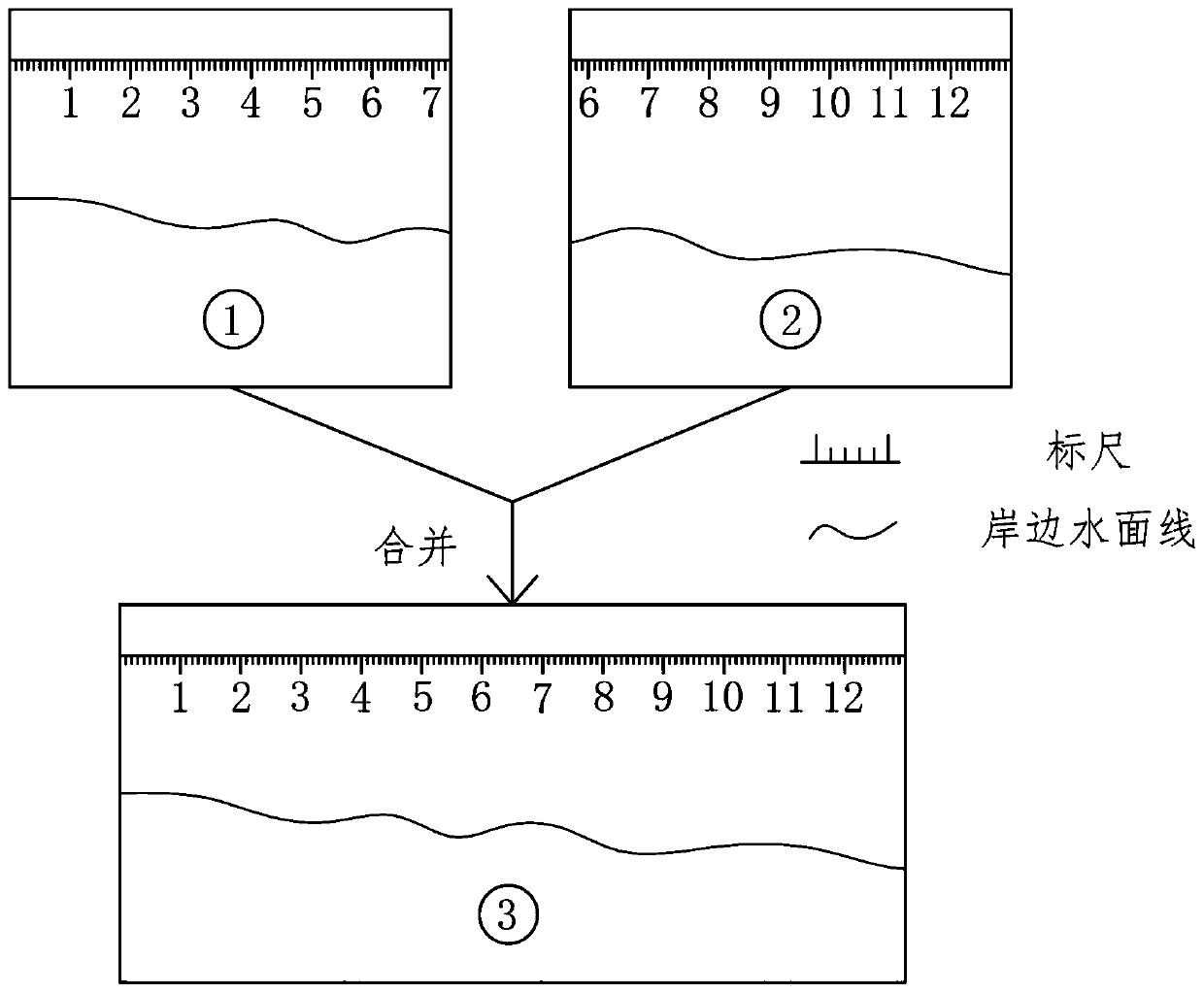

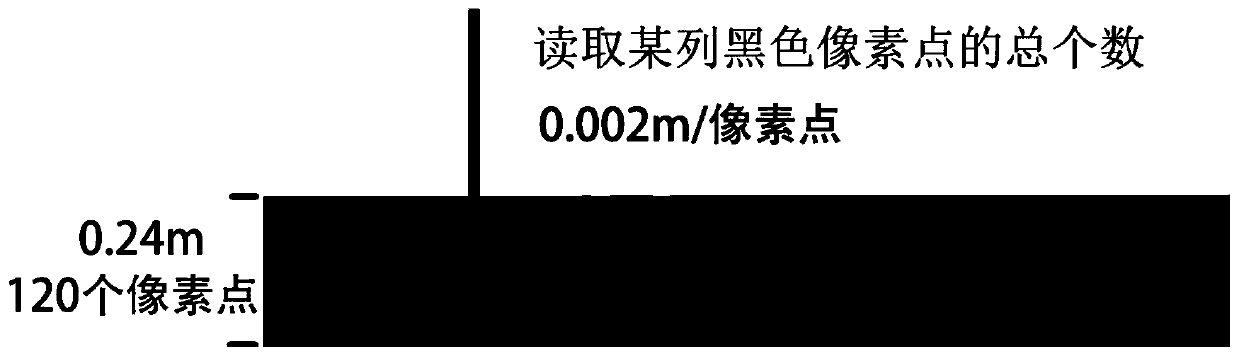

Laboratory acquisition method and device for water level change of two sides of V-shaped river course

InactiveCN110672076ABeneficial technical effectGet change resultGeometric image transformationMeasuring open water depthImaging processingRiver routing

Owner:SICHUAN UNIV

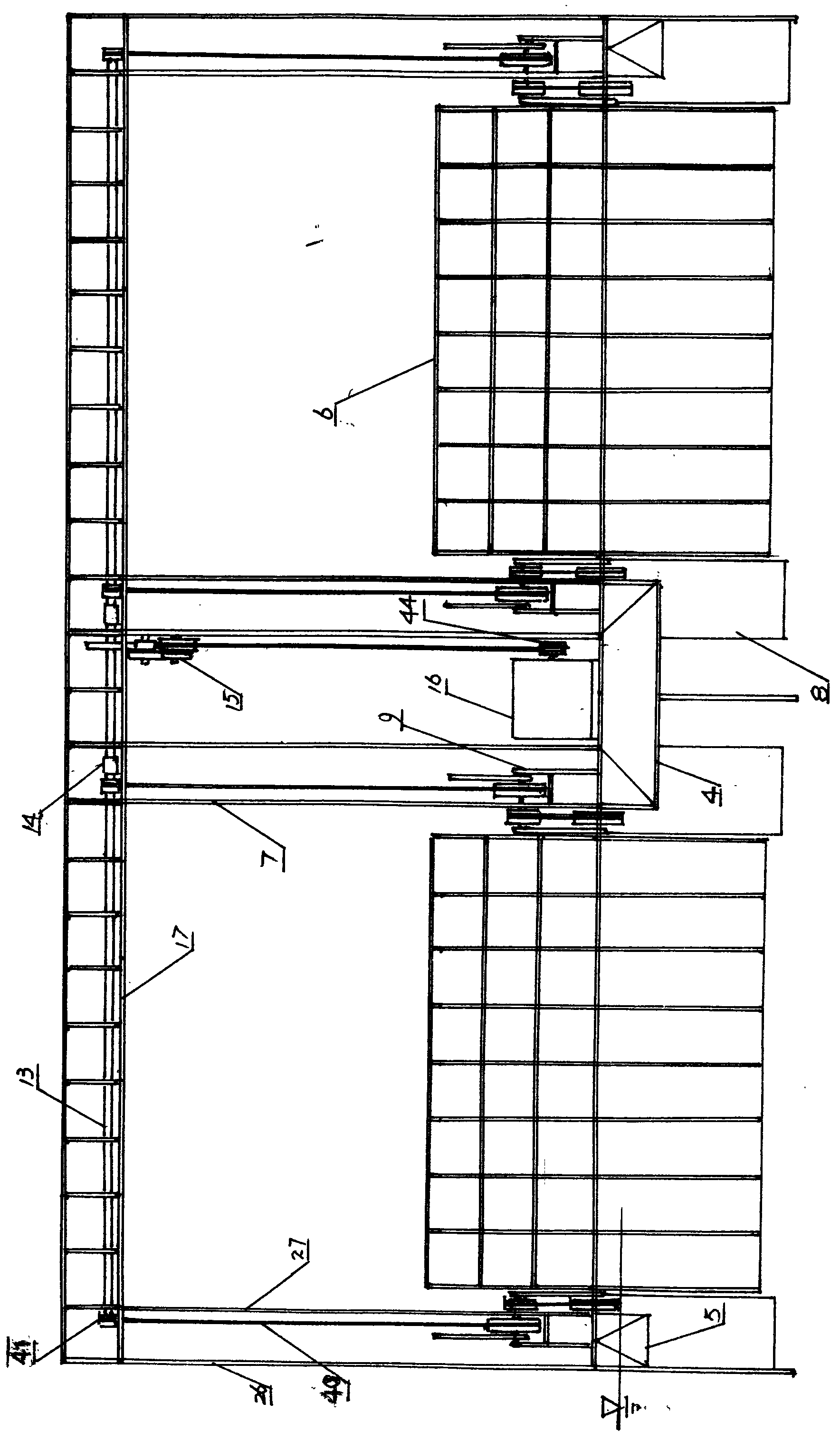

Broad water jet loom

ActiveCN103147214APrevent proliferationIncrease weft insertion distanceLoomsWater flowAbnormal shaped

Owner:HAITAI TEXTILE SUZHOU

Gate vertical vibration reduction and bottom edge adjustable system

Owner:TIANJIN UNIV

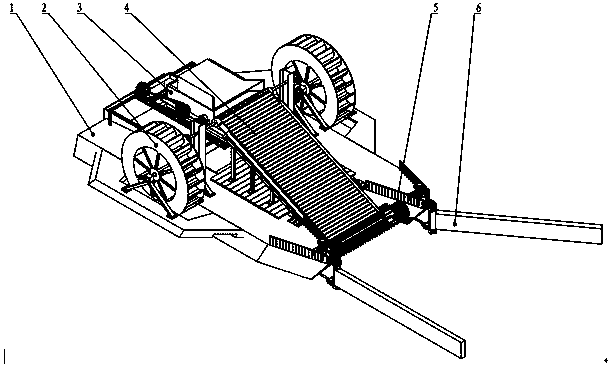

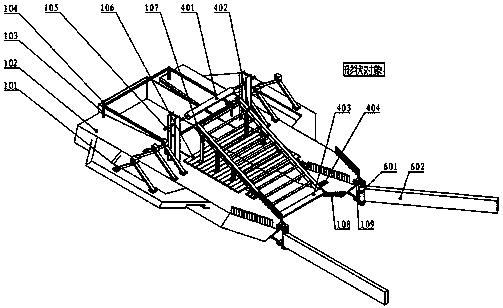

Water garbage cleaning equipment

InactiveCN112323748AEasy to collectAvoid cloggingWater cleaningStationary filtering element filtersMotor driveElectric machine

The invention relates to the technical field of environmental protection, and discloses water garbage cleaning equipment. An abutting rod is arranged on the outer circle wall surface of an abutting disc, a protruding block is fixedly mounted on the wall surface of the side, away from the abutting disc, of the abutting rod, a collecting box is placed on the horizontal ground, a suction box is placed on the water surface, a water pump pumps garbage in water into the suction box in the water pumping process, the pumped water flows out from a water outlet hole in the suction box, garbage is intercepted on the surface of a filter screen by the filter screen in the suction box, and protrusions are arranged on the surface of the filter screen to prevent the garbage from blocking meshes in the surface of the filter screen. A motor in a mounting box is connected with external power supply equipment, the motor drives the abutting disc on a fixing column to rotate, when the abutting disc rotates,the protruding block arranged on the abutting rod can be driven to impact the lower side of the filter screen, when the filter screen is impacted, a tension spring is stretched, a rotating shaft rotates in a rotating hole, the filter screen inclines towards the collecting box in the suction box, and when the filter screen inclines, the garbage on the surface of the filter screen slides into the collecting box to be collected.

Owner:李玉苓

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap