Water-cooling cooling polishing machine

A water-cooled heat dissipation and polishing machine technology, applied in grinding/polishing equipment, grinding/polishing safety devices, grinding machines, etc., can solve problems such as surface damage, impact on the life of the grinding disc, and heating of the grinding disc, etc., to prolong the service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

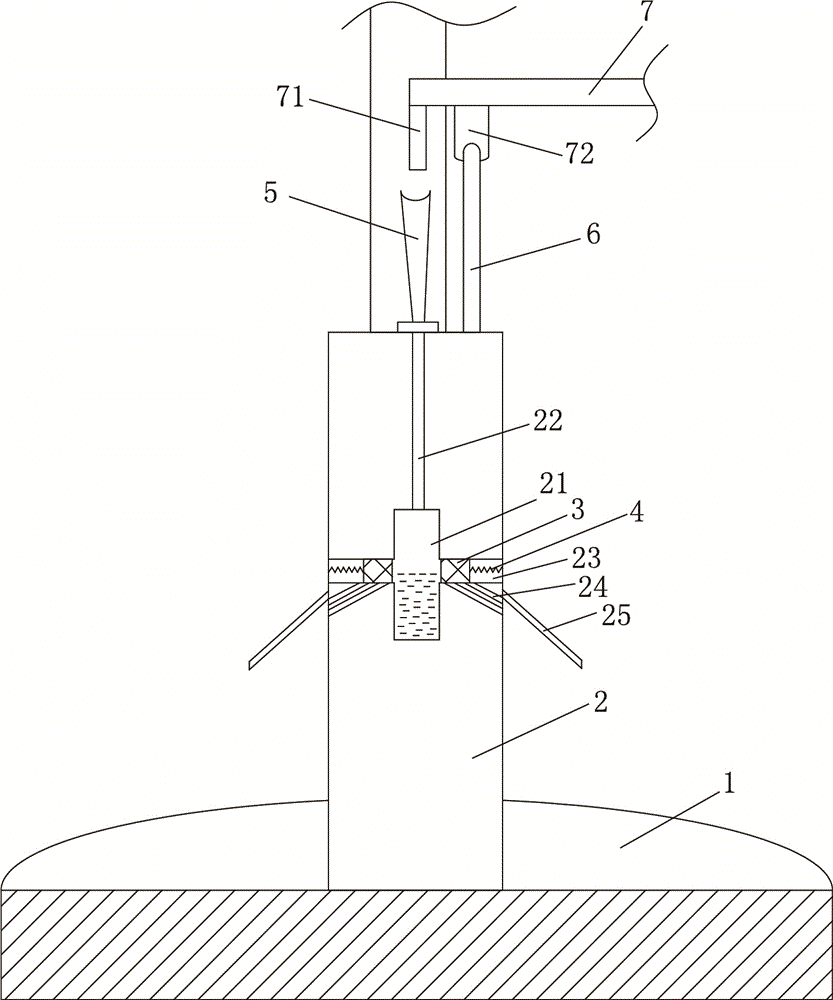

[0010] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: see figure 1 , a water-cooled and heat-dissipating grinder, comprising a grinding disc 1 and a rotating shaft 2 connected to the grinding disc 1, the rotating shaft 2 is provided with a cavity body 21 for accommodating cooling water, an axially arranged water inlet channel 22 and a surrounding To the several chutes 23 arranged around the hollow body 21, the water inlet channel 22, the hollow body 21 and the chute 23 are connected to each other in turn, and the chute 23 is slidably connected with a sliding Block 3, a spring 4 is arranged between the slider 3 and the inner wall of the chute 23, and several groups of water outlet grooves 24 are also provided in the shaft 2, and each group of the water outlet grooves 24 is connected with the corresponding slider. The grooves 23 communicate with each other, and when the rotating shaft 2 is stationary

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap