Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

58results about "Underground chambers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

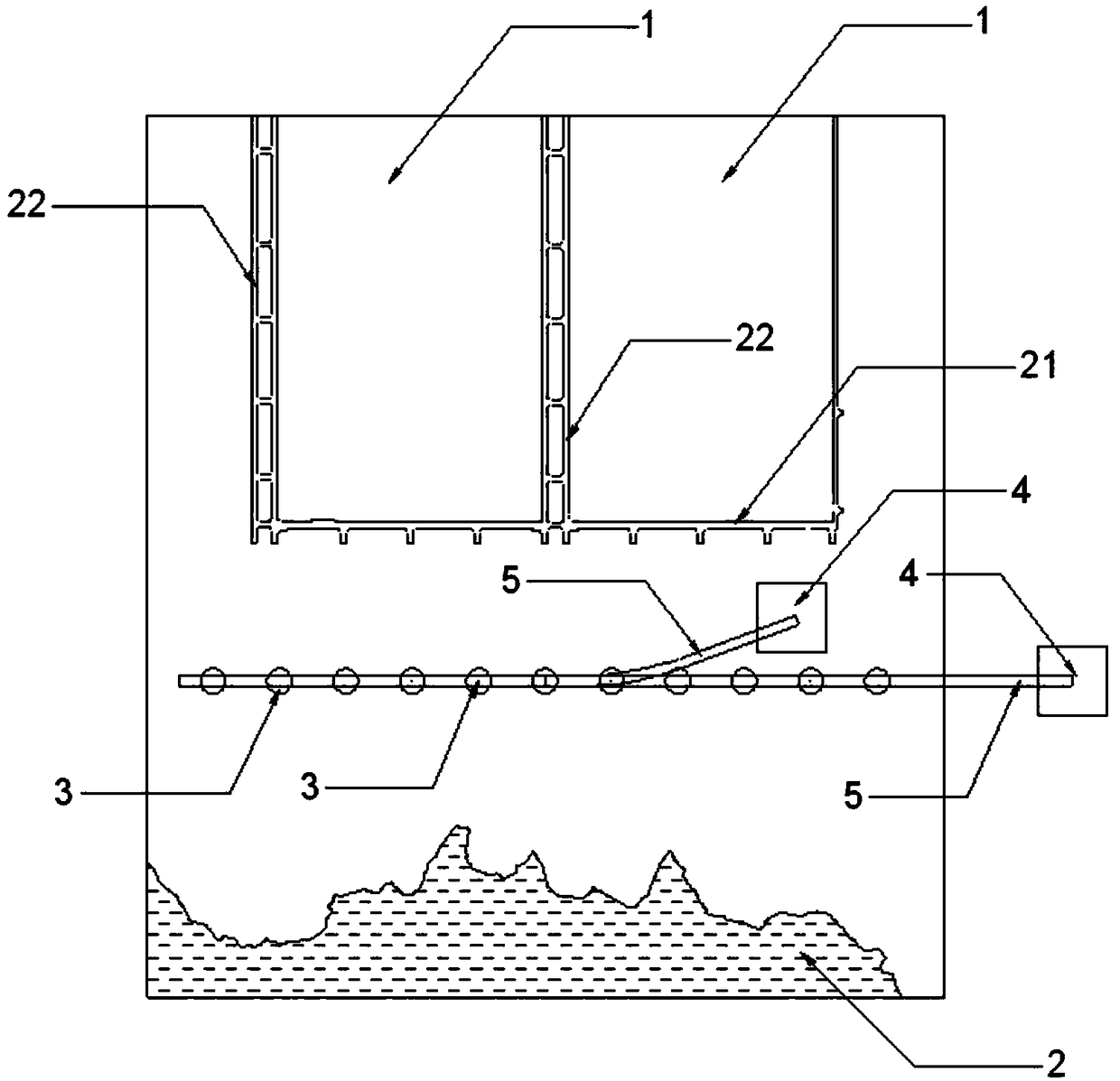

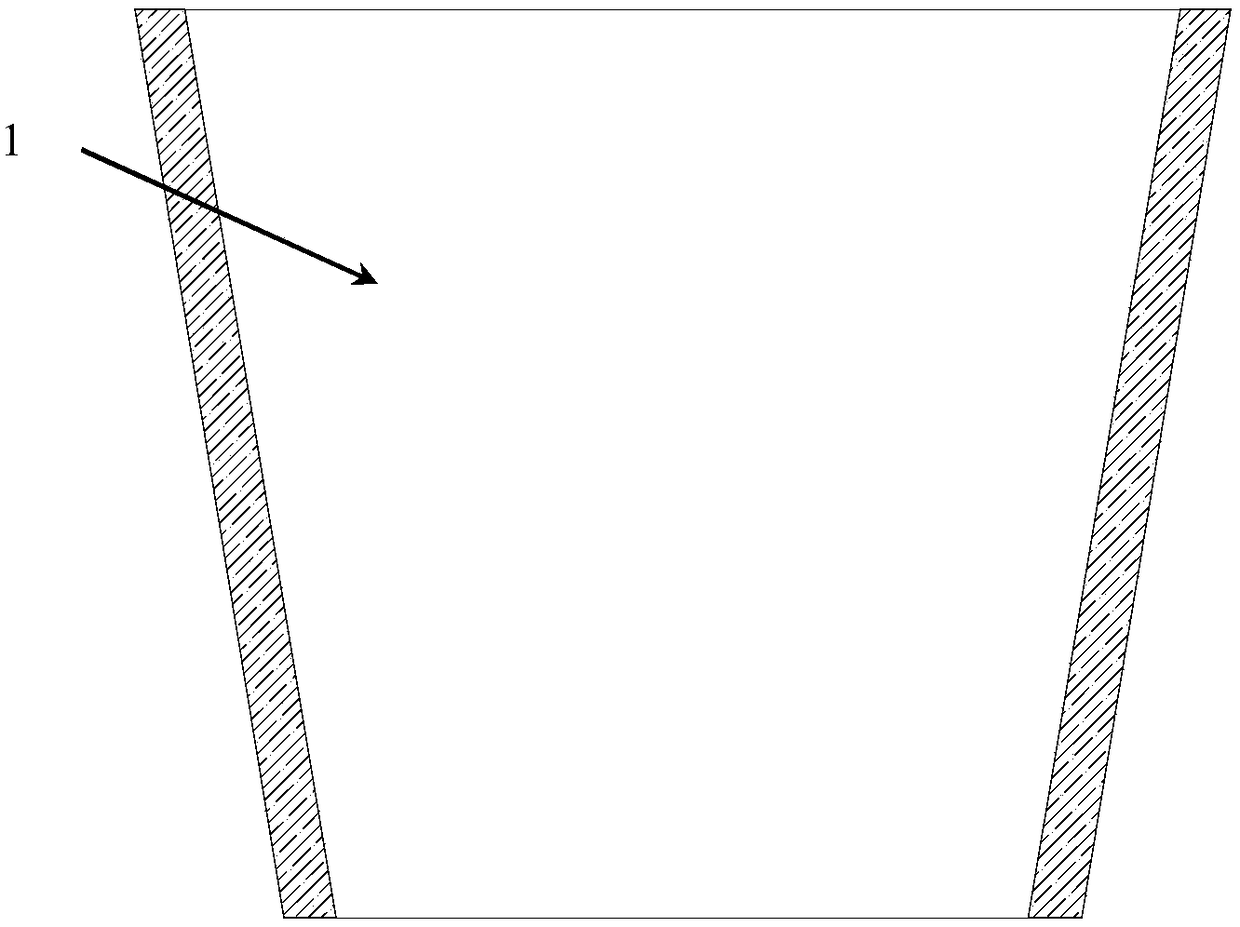

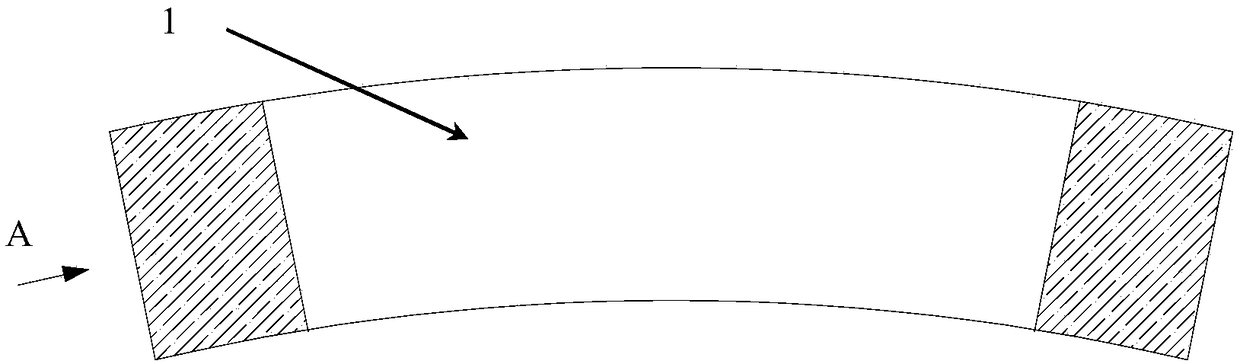

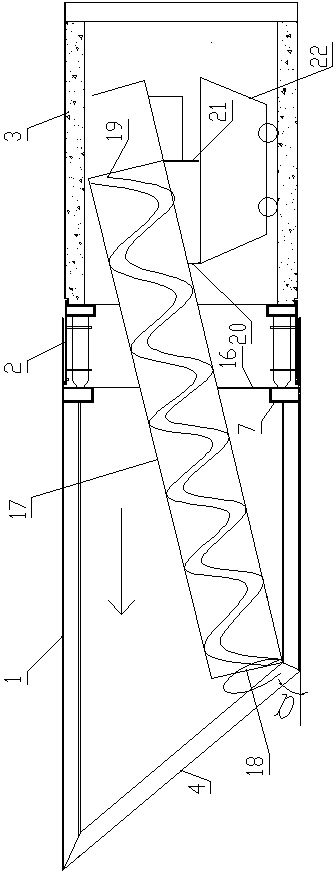

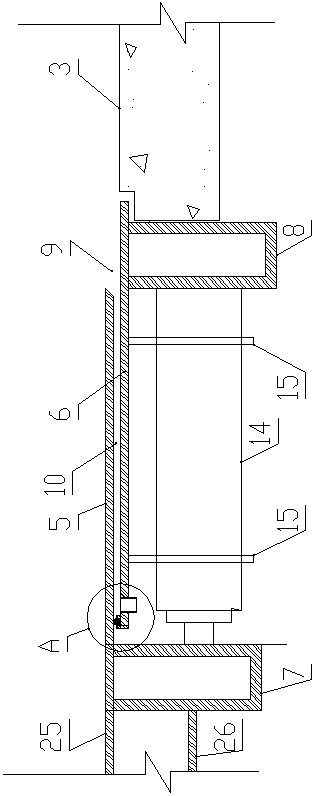

Standing type mechanical loading device for three-ring prototype irregular shield segment

InactiveCN104533470AEasy to operateRealize self-respecting issuesUnderground chambersTunnel liningControl systemEngineering

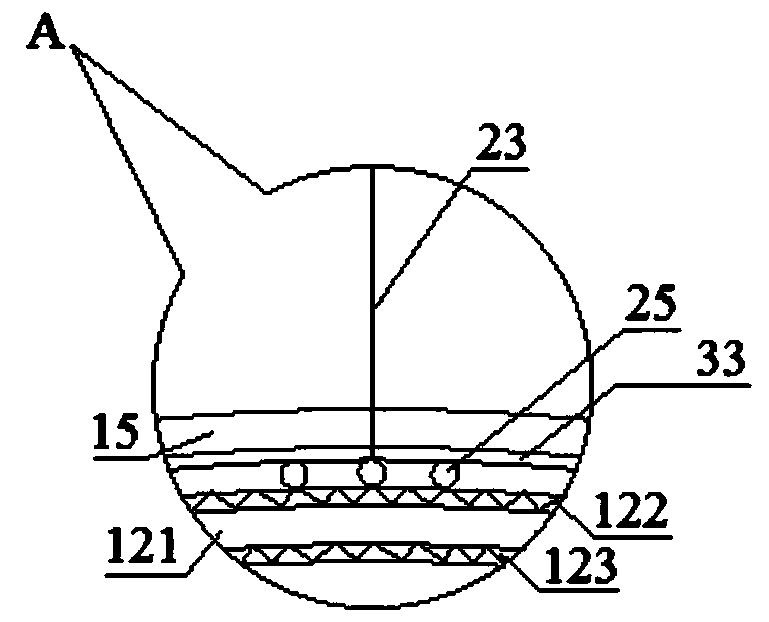

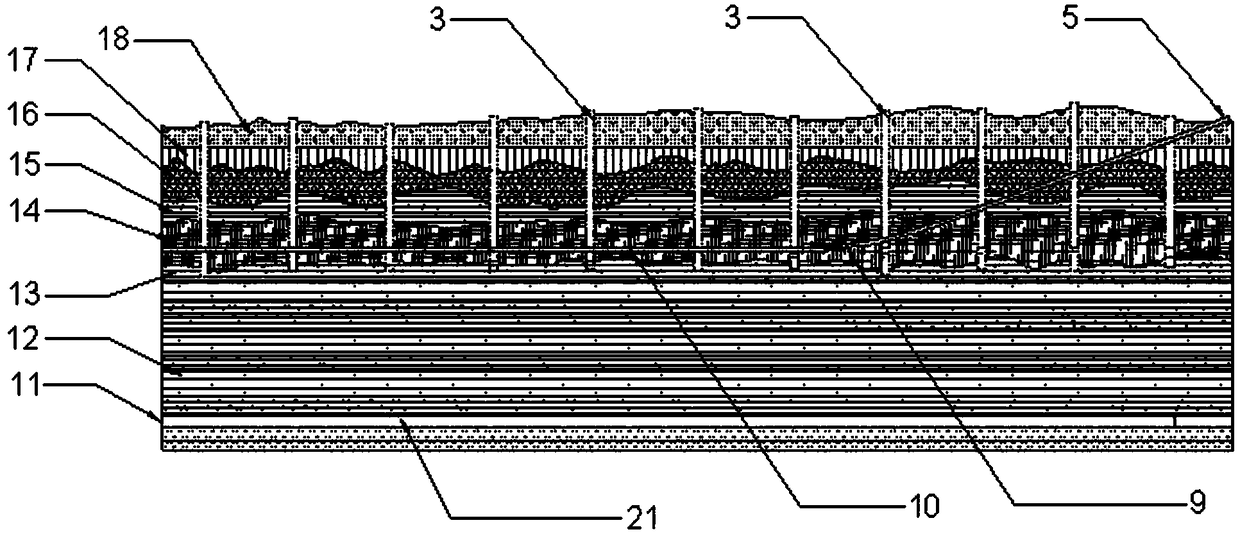

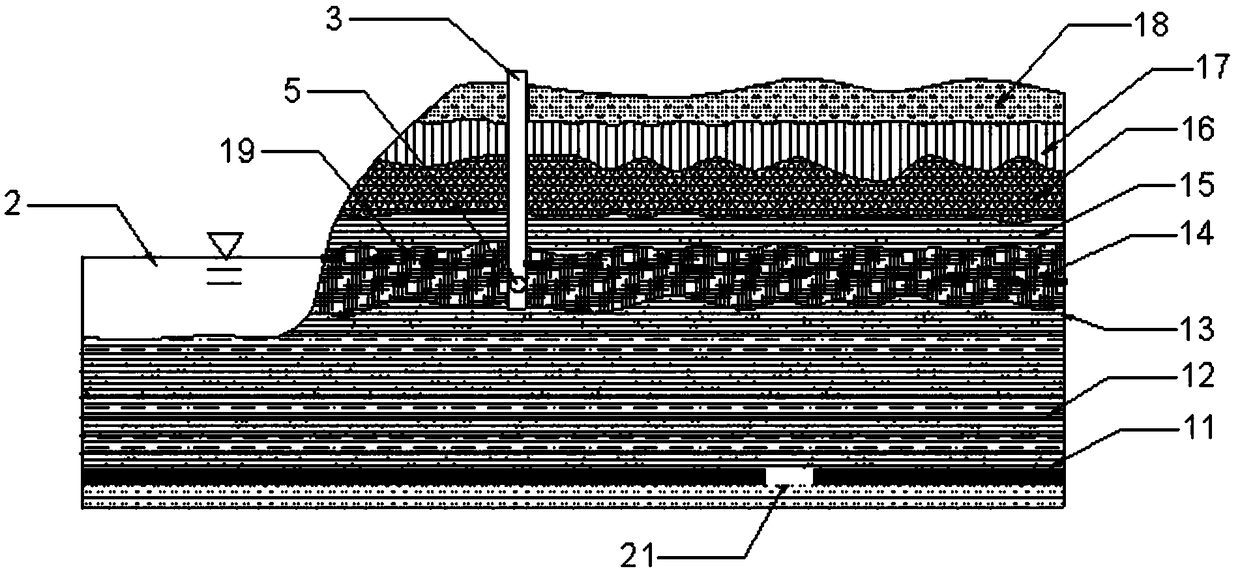

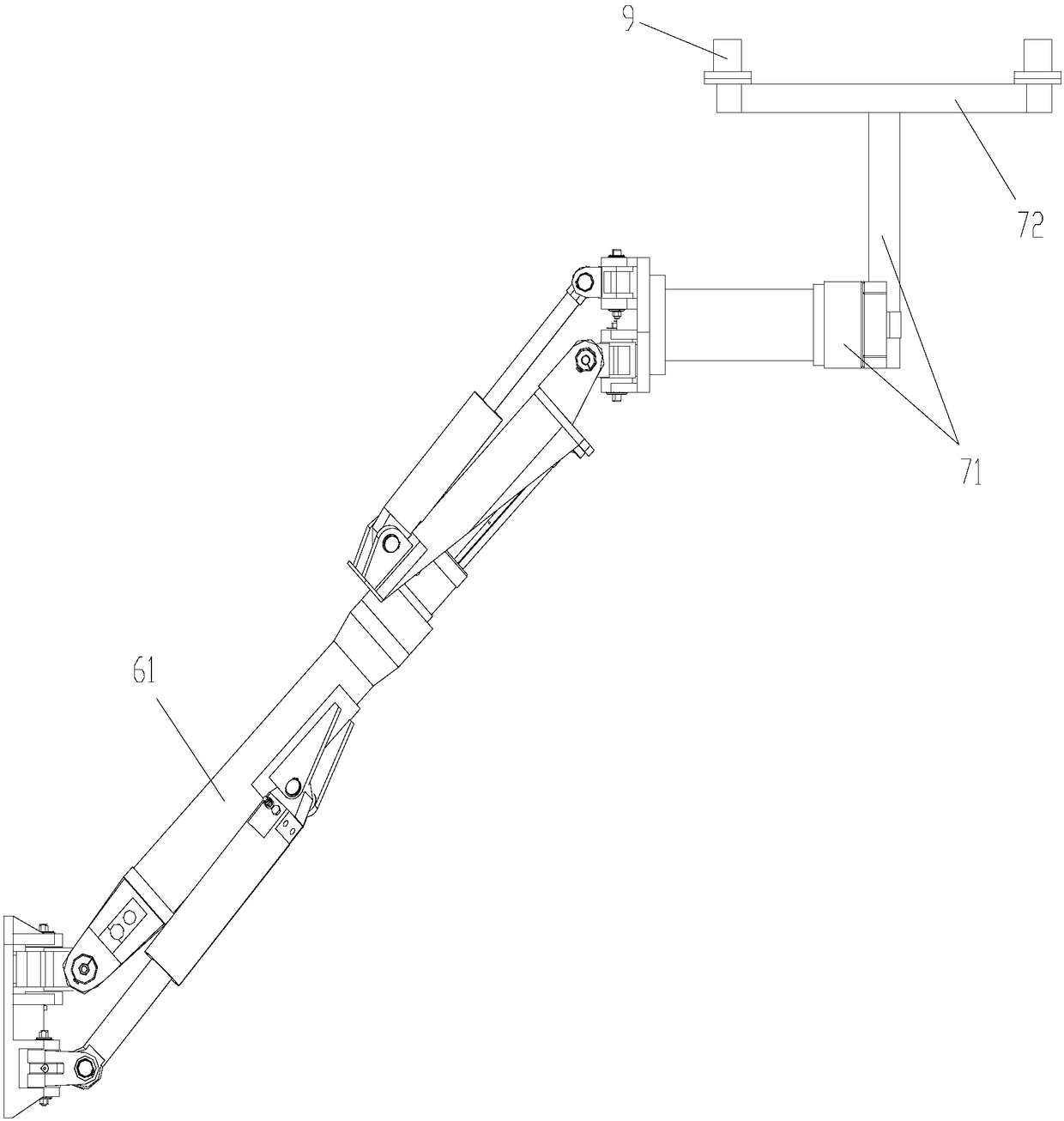

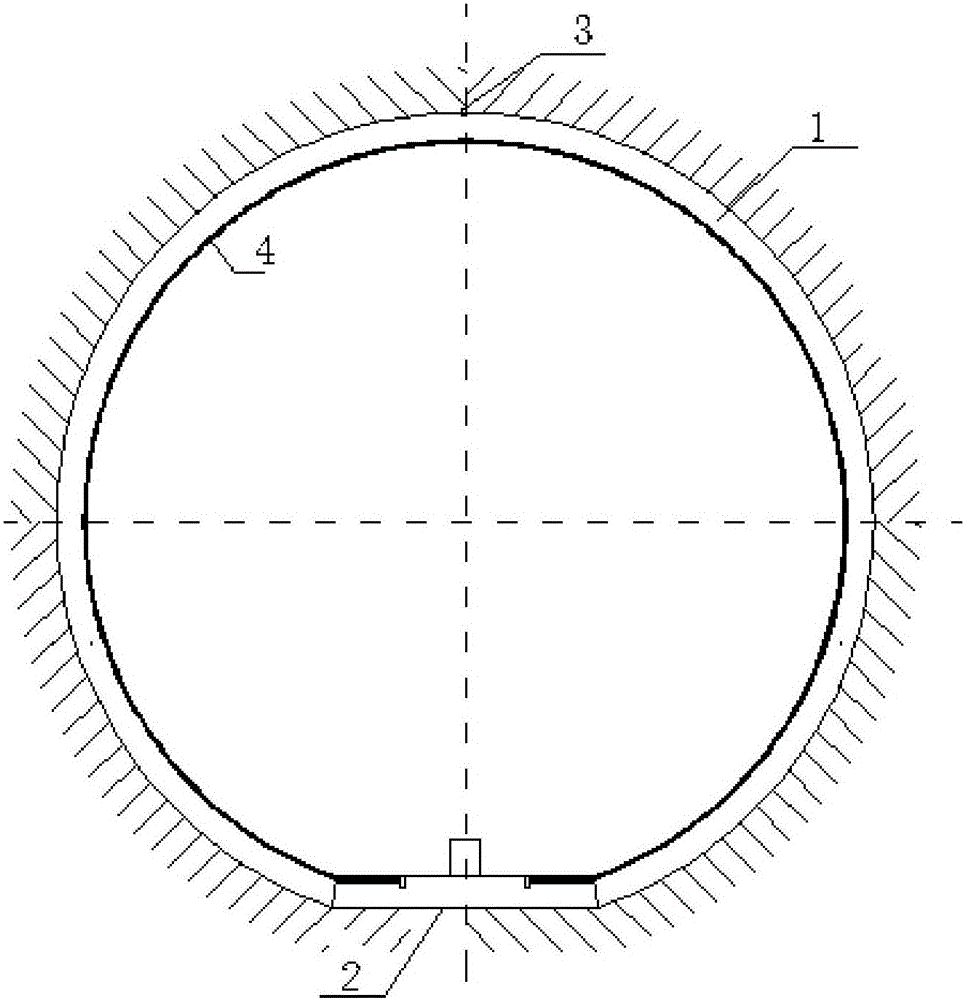

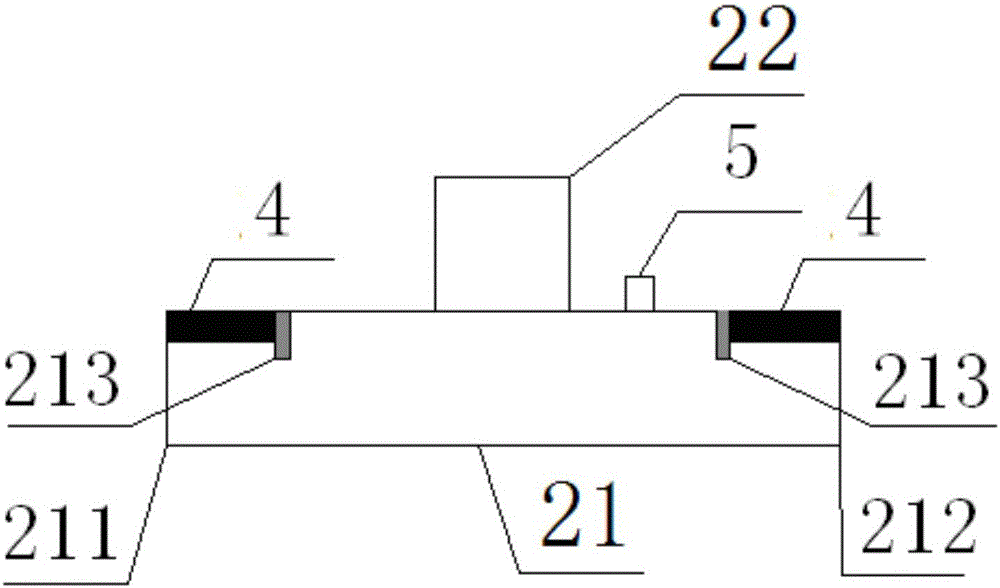

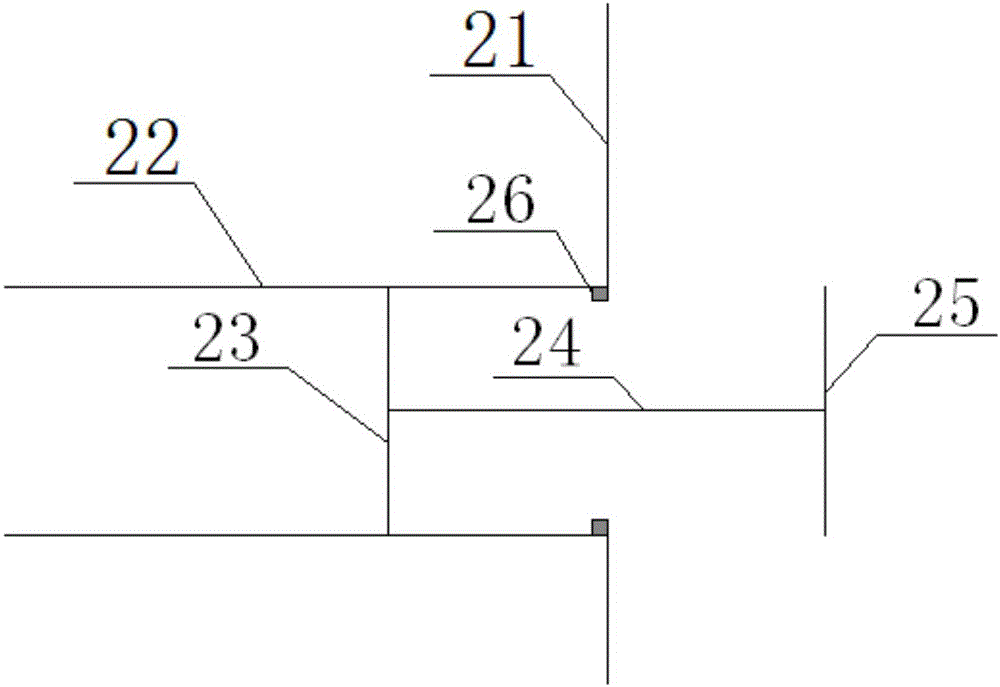

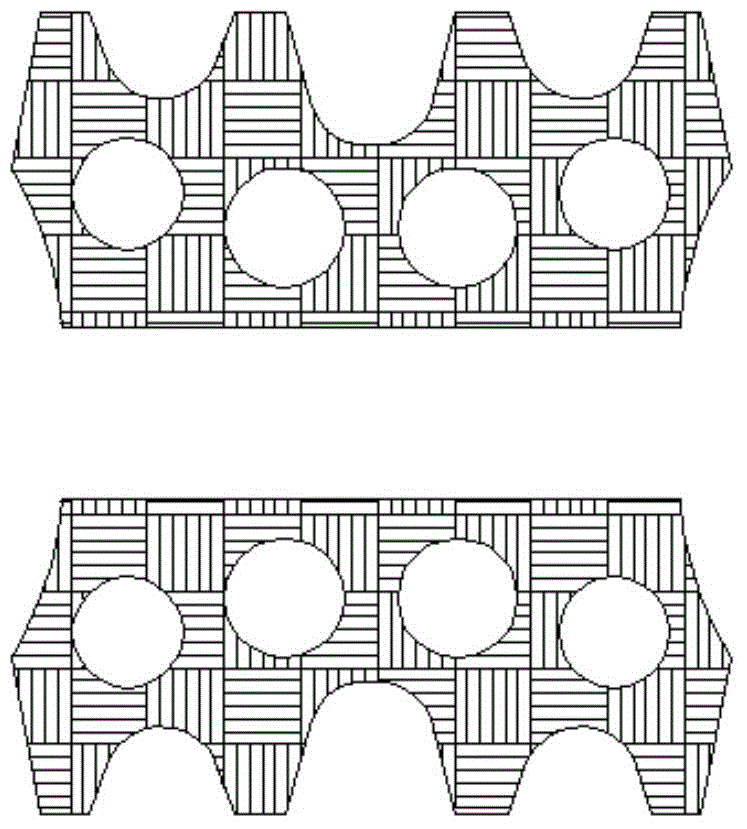

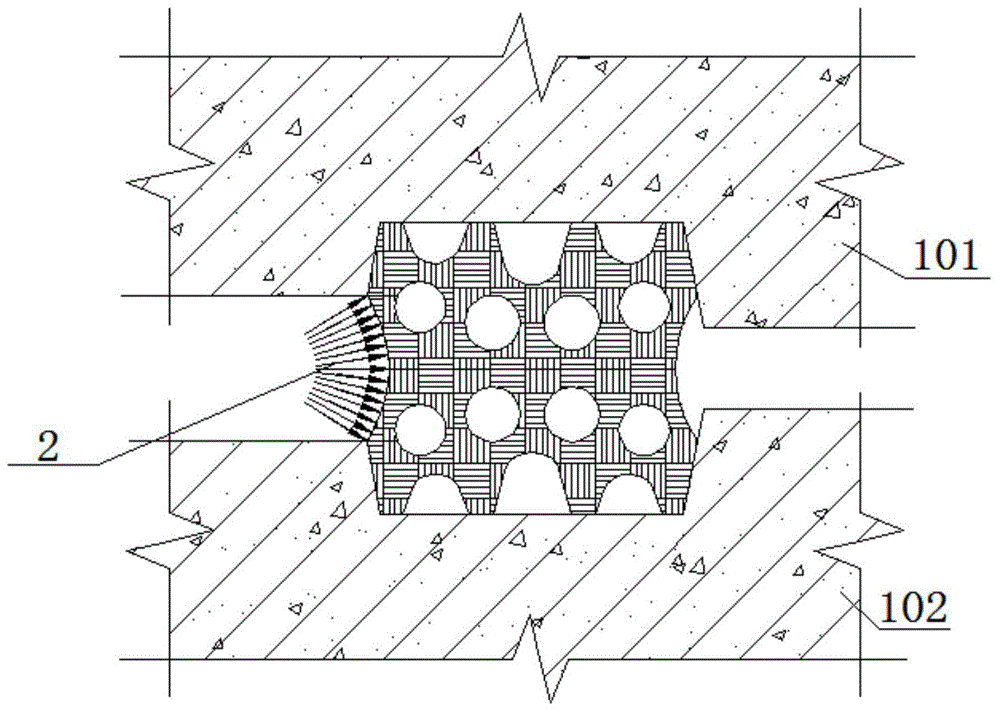

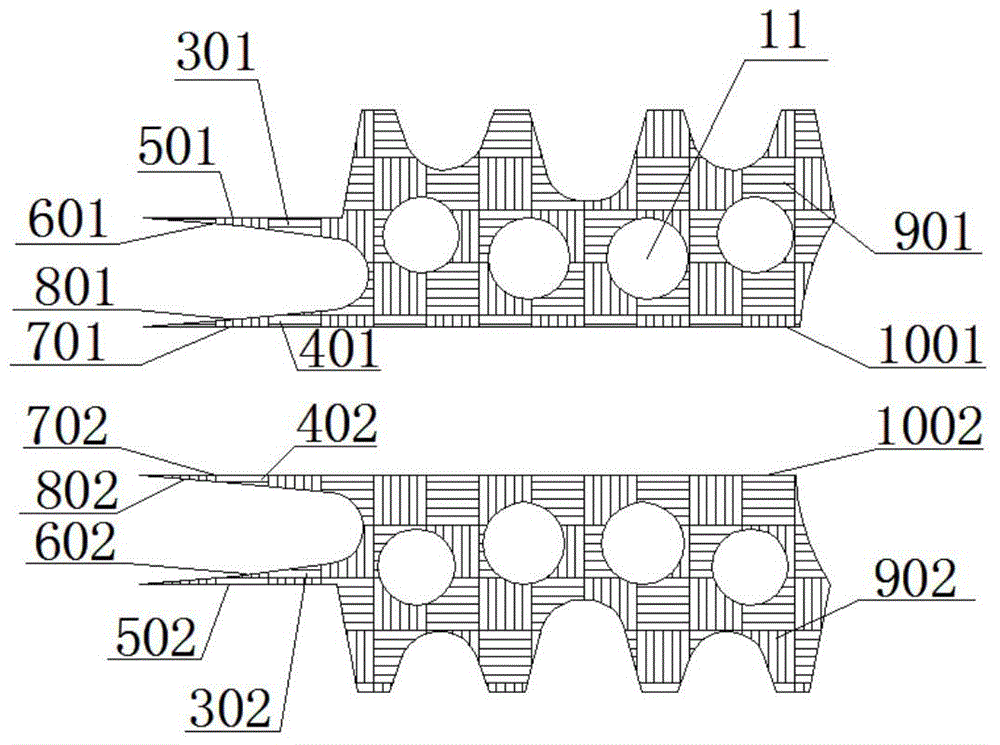

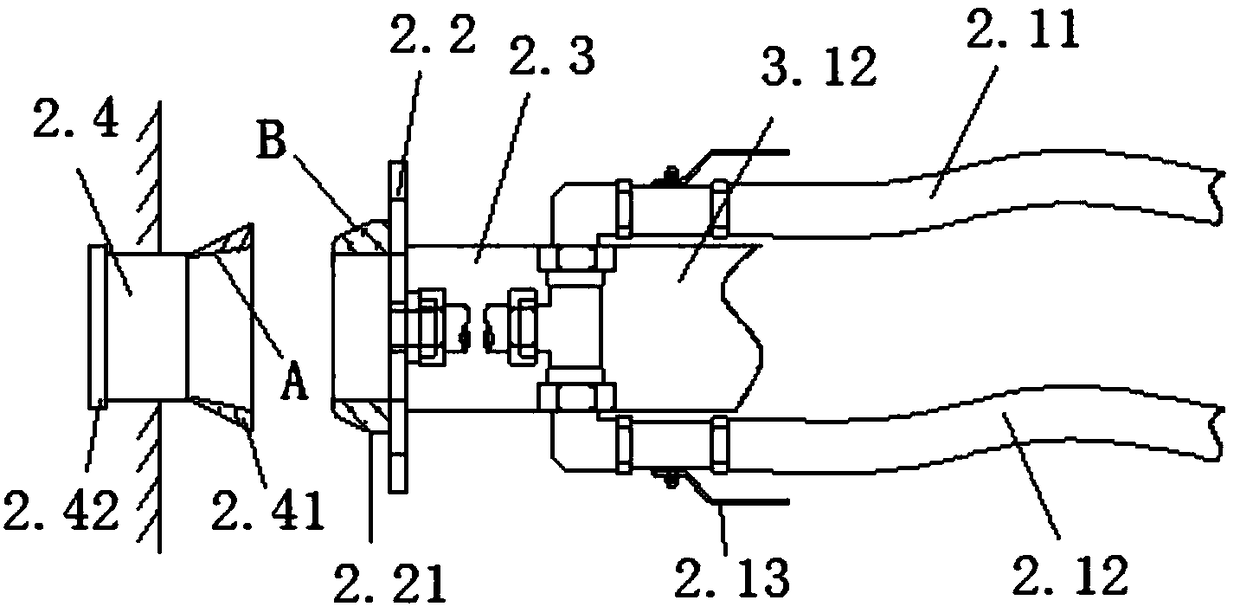

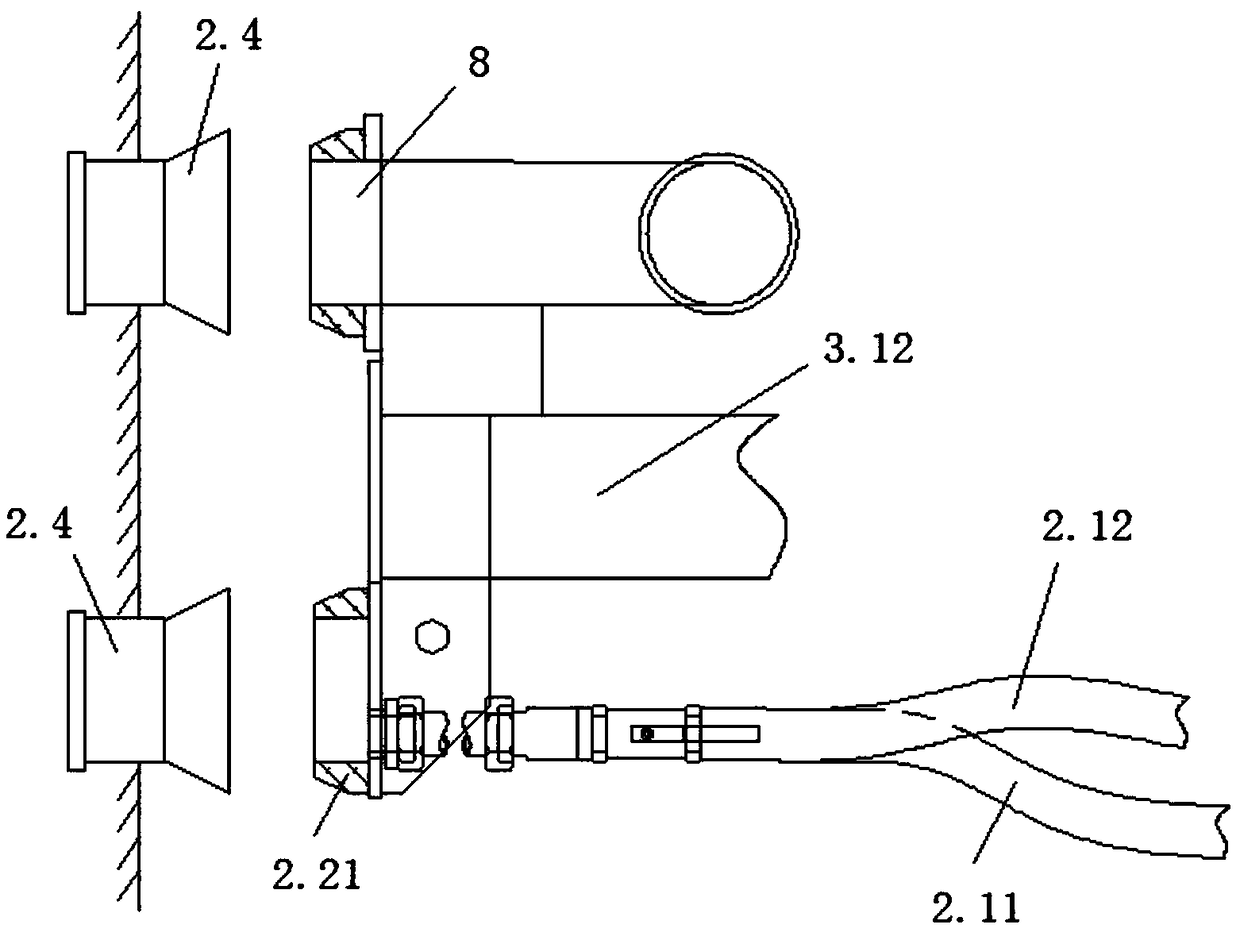

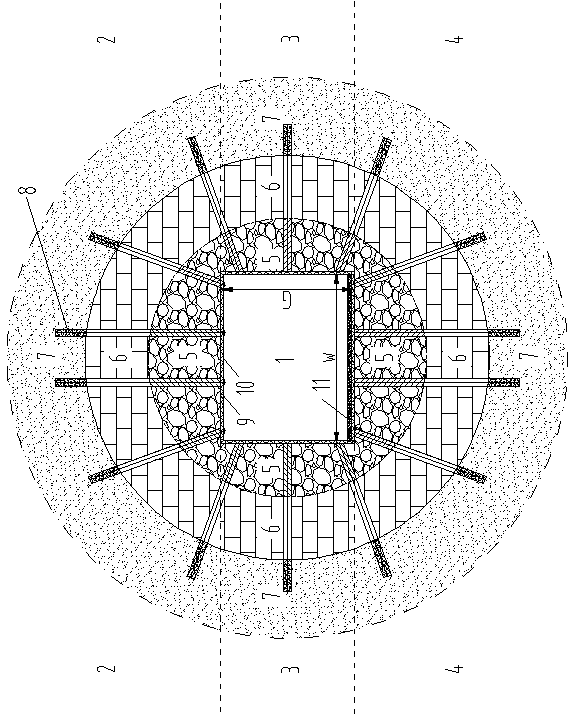

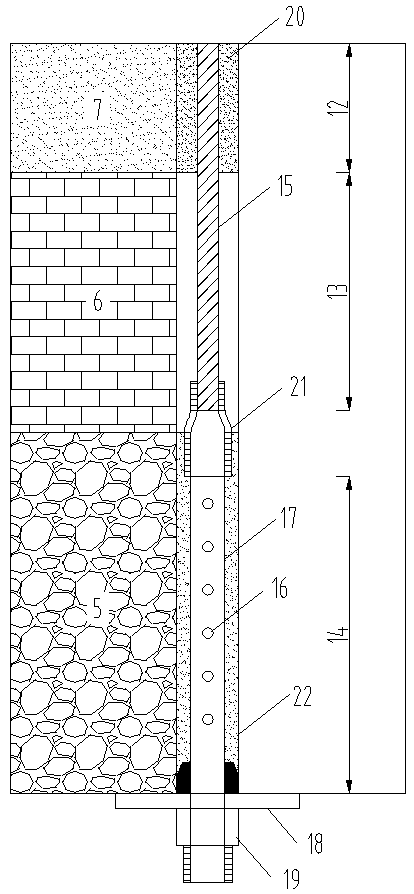

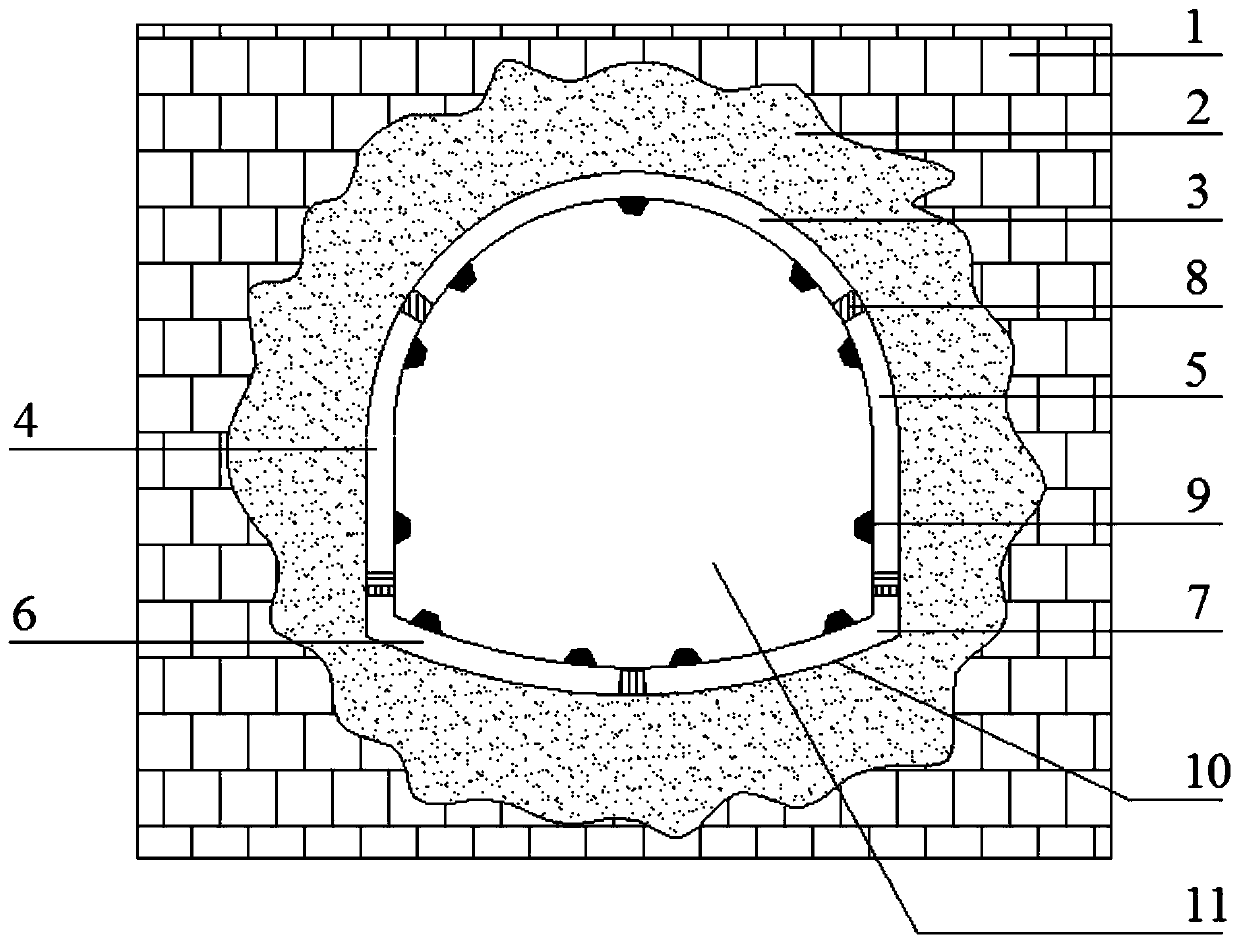

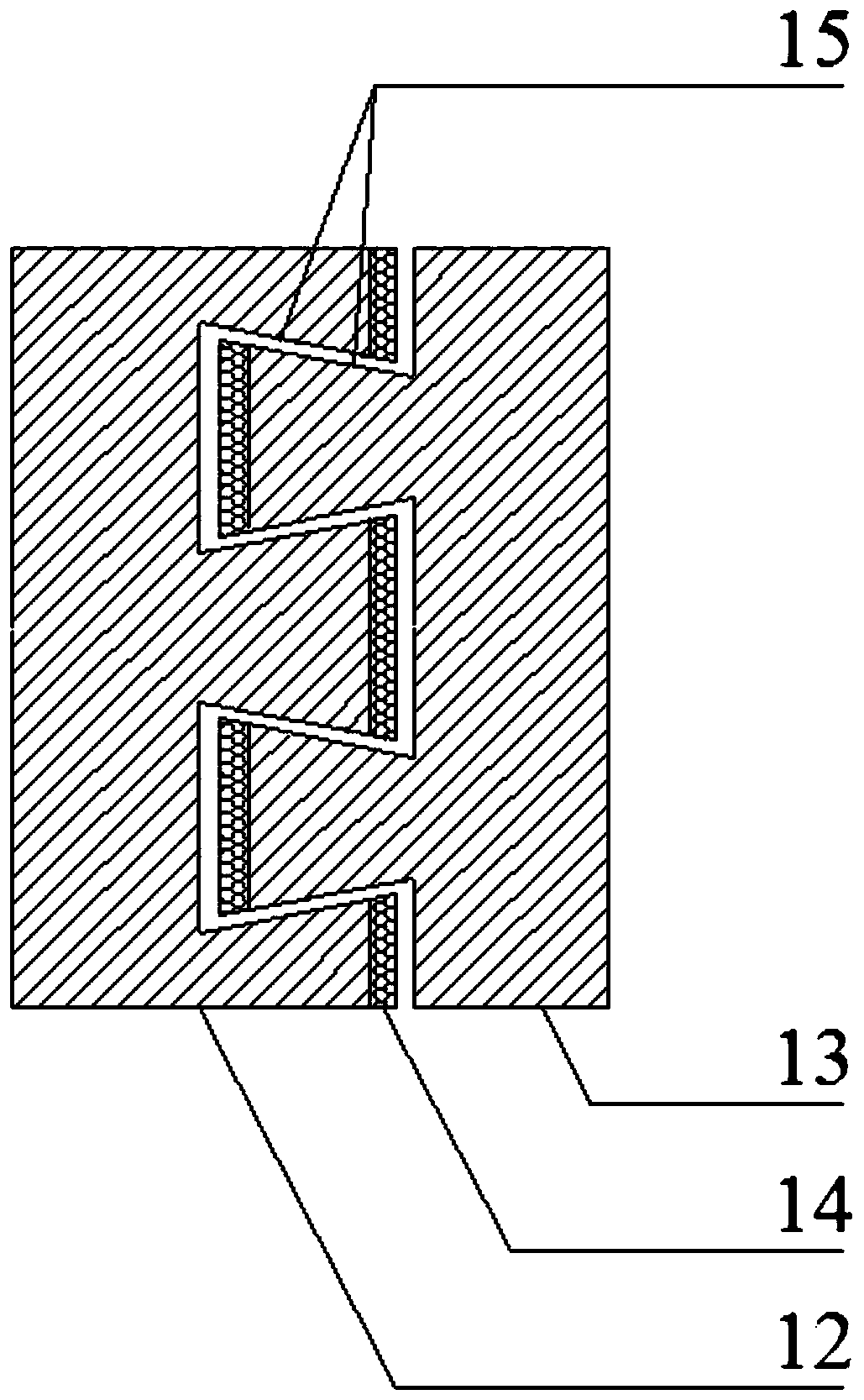

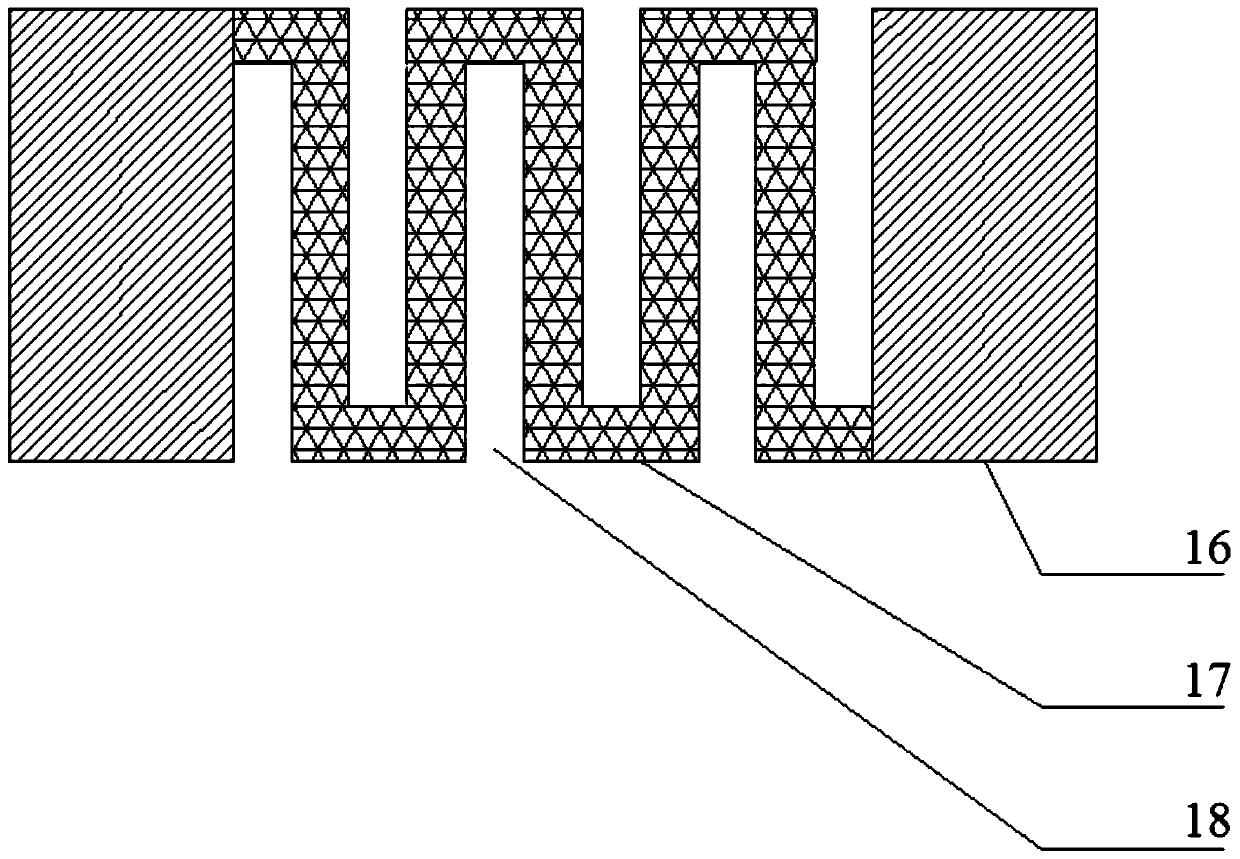

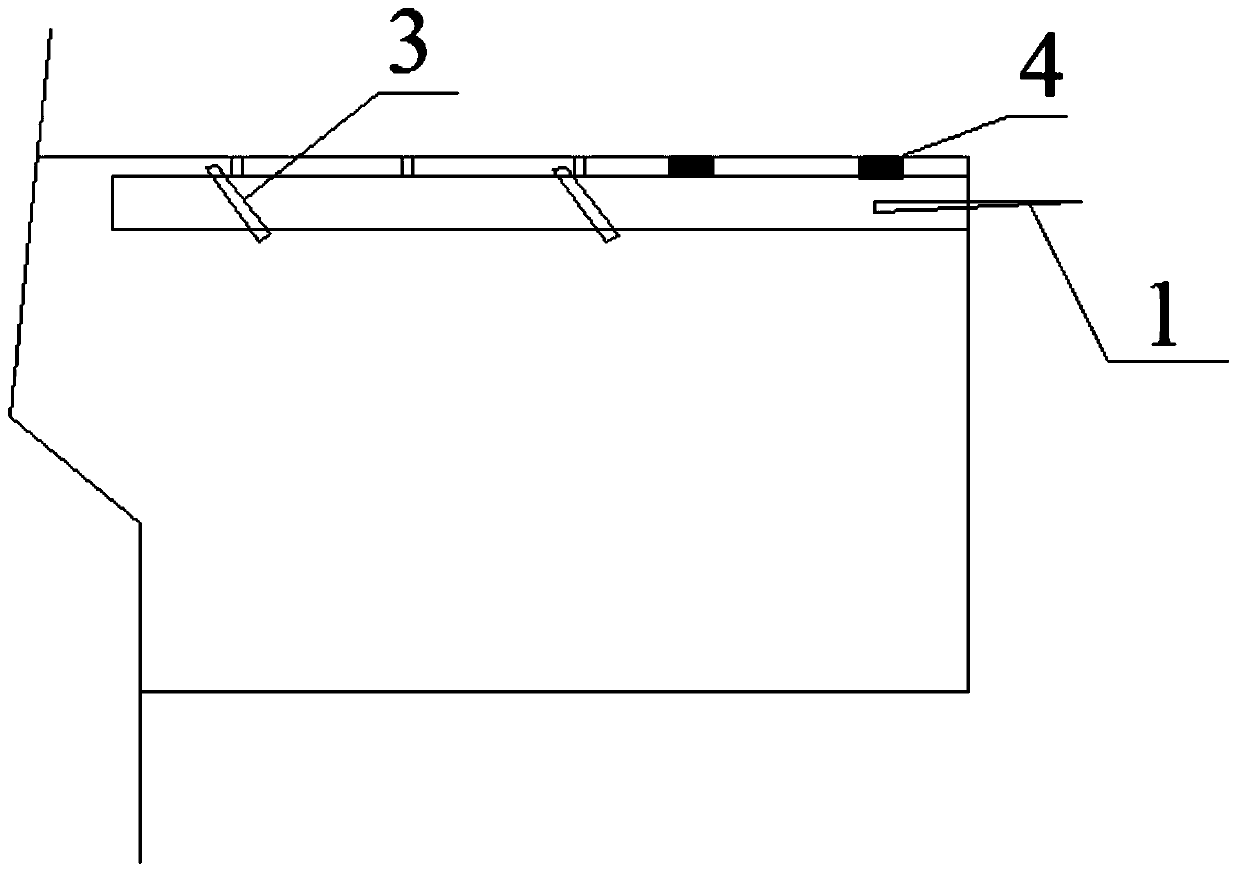

The invention provides a standing type mechanical loading device for a three-ring prototype irregular shield segment. The device comprises a full-steel loading reaction frame, a loading system, a control system and a testing shield segment; the full-steel loading reaction frame is positioned by a vertical standing manner; three-ring segments which are spliced into rings are vertically positioned in the full-steel loading reaction frame by a standing manner; a top plate and two sides of each segment are loaded through annular jacks which are fixed into reserved holes in the full-steel loading reaction frame; the actual pressure value of water and soil on each sectional segment is respectively calculated under the condition that the ground reaction pressure is considered; the load is applied to a center point of the arc length of an outer arc-shaped surface of the sectional segment long the outer arc-shaped surface of each segment in the radial direction through the annular jacks; a bottom plate of each segment that the segment independently balances the force borne through a liquid bag; a propping and pushing force applied to each segment during excavating a shield is simulated through a longitudinal pulling rod system; the control system comprises a jack oil pressure control system and a liquid bag water pressure control system. With the adoption of the device, the mechanical behavior characteristics of the segments under different stratum conditions can be really simulated, so that the basis is provided for the design of the irregular shield segment and the construction of an irregular shield tunnel, and the test result meets the objective fact.

Owner:TONGJI UNIV

Comprehensive control method for rockburst in multiple-coalbed mining mine

ActiveCN103397883AImprove the level of prevention and controlImprove targetingUnderground chambersUnderground miningHigh pressure waterHigh pressure

Owner:DATONG COAL MINE GRP

Construction method of close-range down-traversing operation lines at initial stages or receiving stages of shield

ActiveCN104594911AImprove construction qualityControl deformationMining devicesUnderground chambersWater flowLine segment

Owner:CHINA CONSTR COMM ENG GRP UNITED

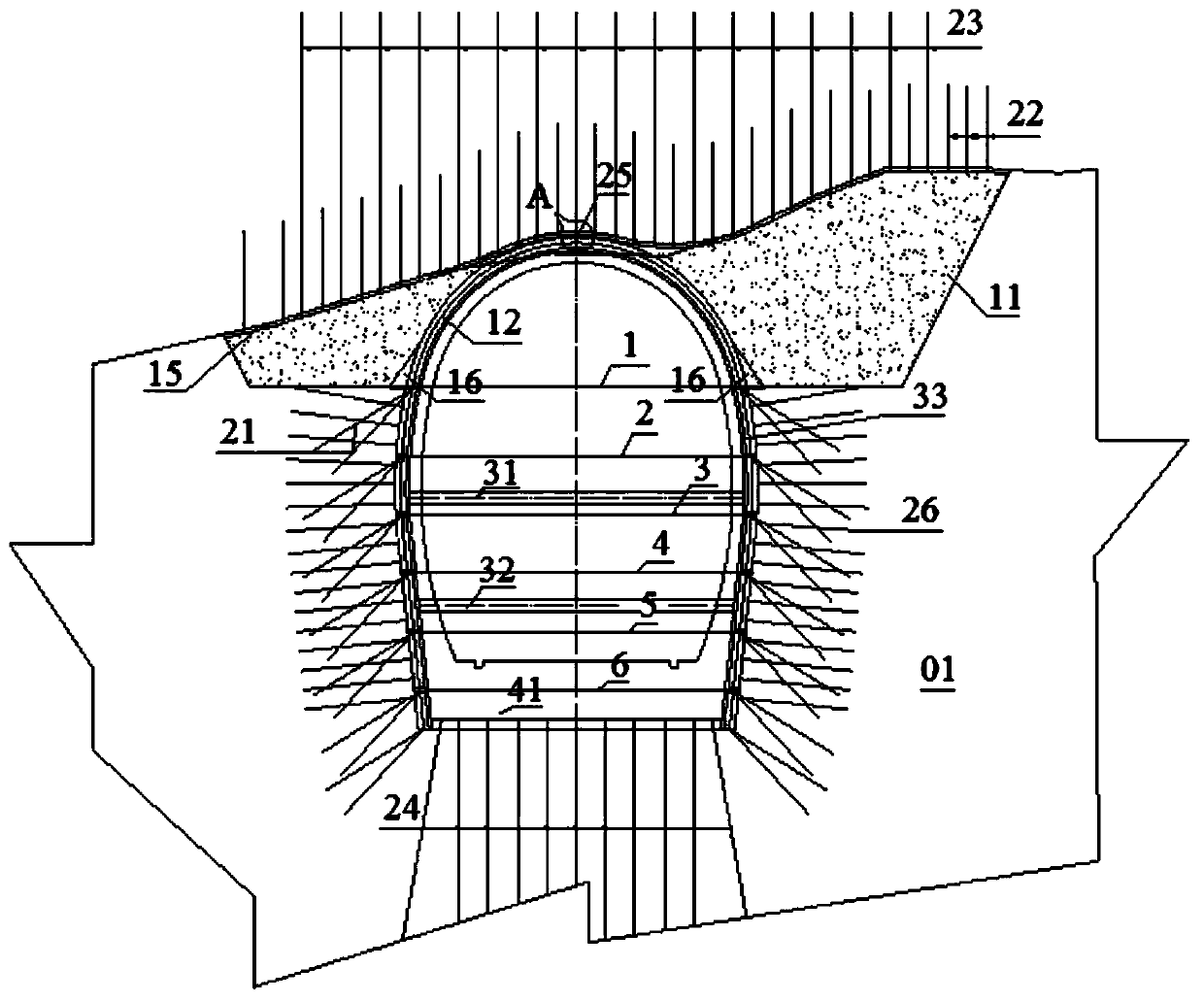

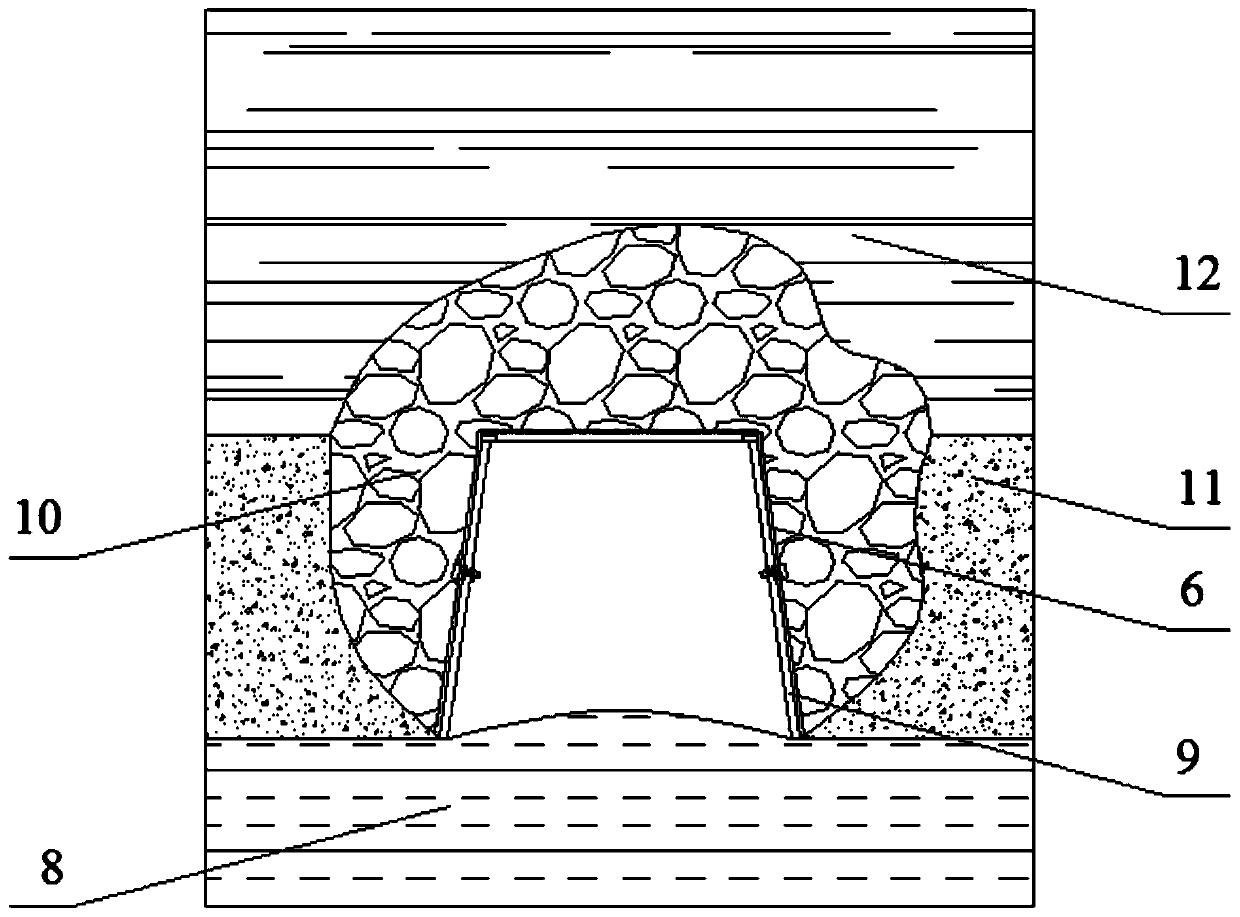

Large-section tunnel supporting system penetrating through giant karst cave hall and construction method thereof

PendingCN111411993AAvoid delayAvoid economic lossUnderground chambersMaterial fill-upSupporting systemArchitectural engineering

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

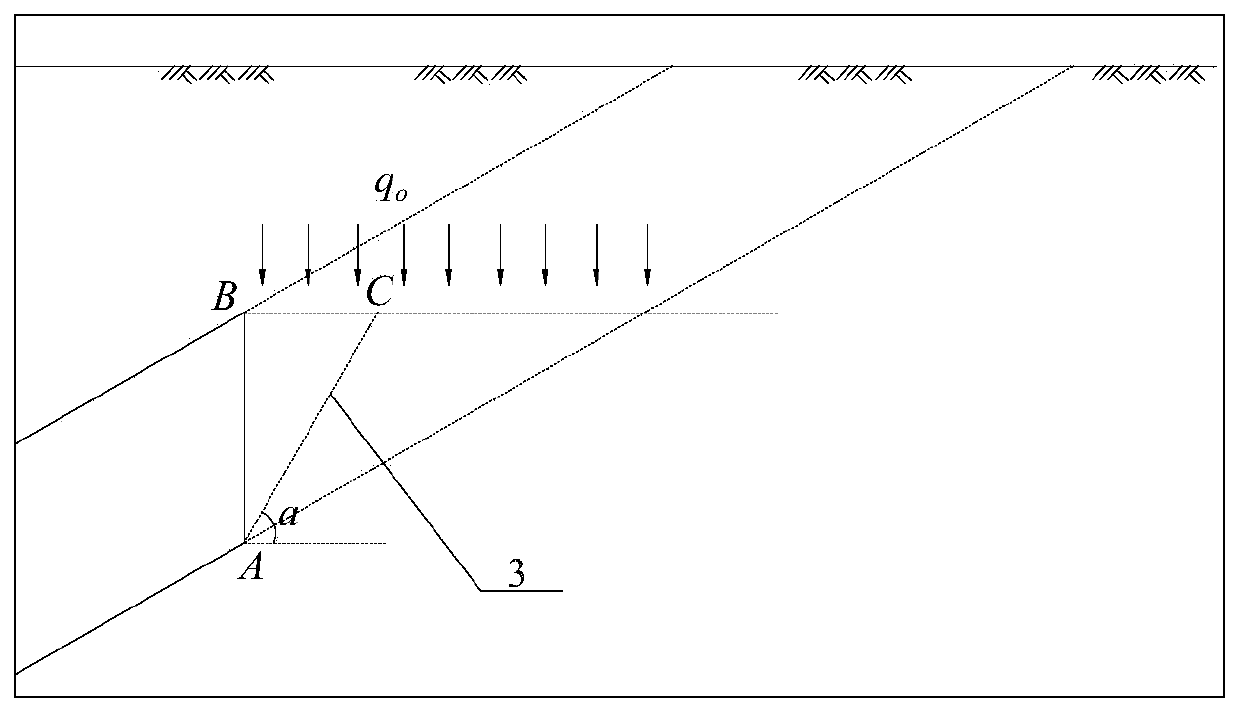

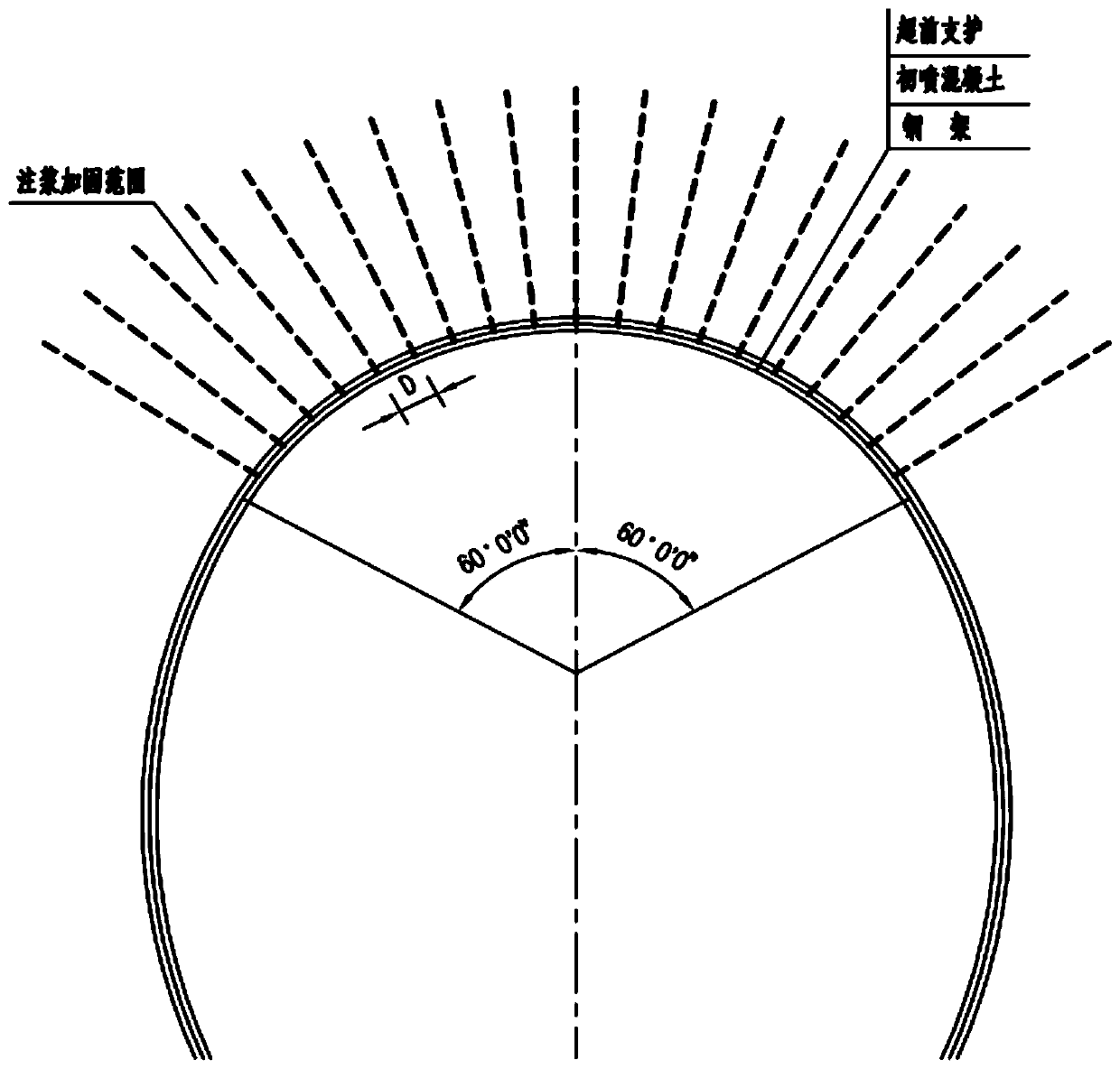

Fore support and excavating method of inclined tunnel

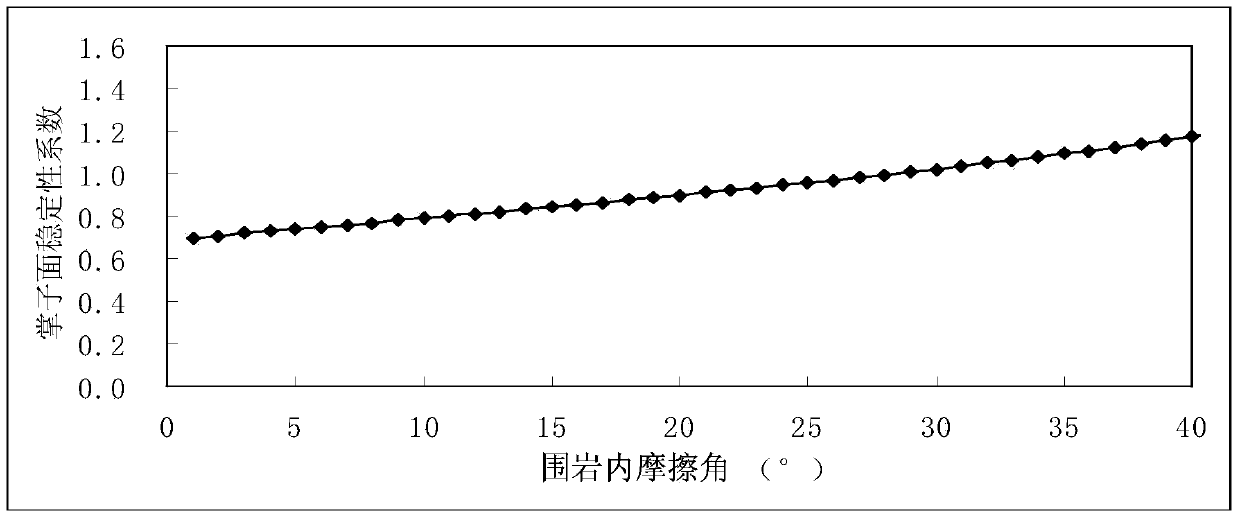

ActiveCN103742158AImprove securityGuaranteed stabilityUnderground chambersTunnel liningStability coefficientGrout

Owner:CHINA RAILWAY ENG CONSULTING GRP CO LTD +1

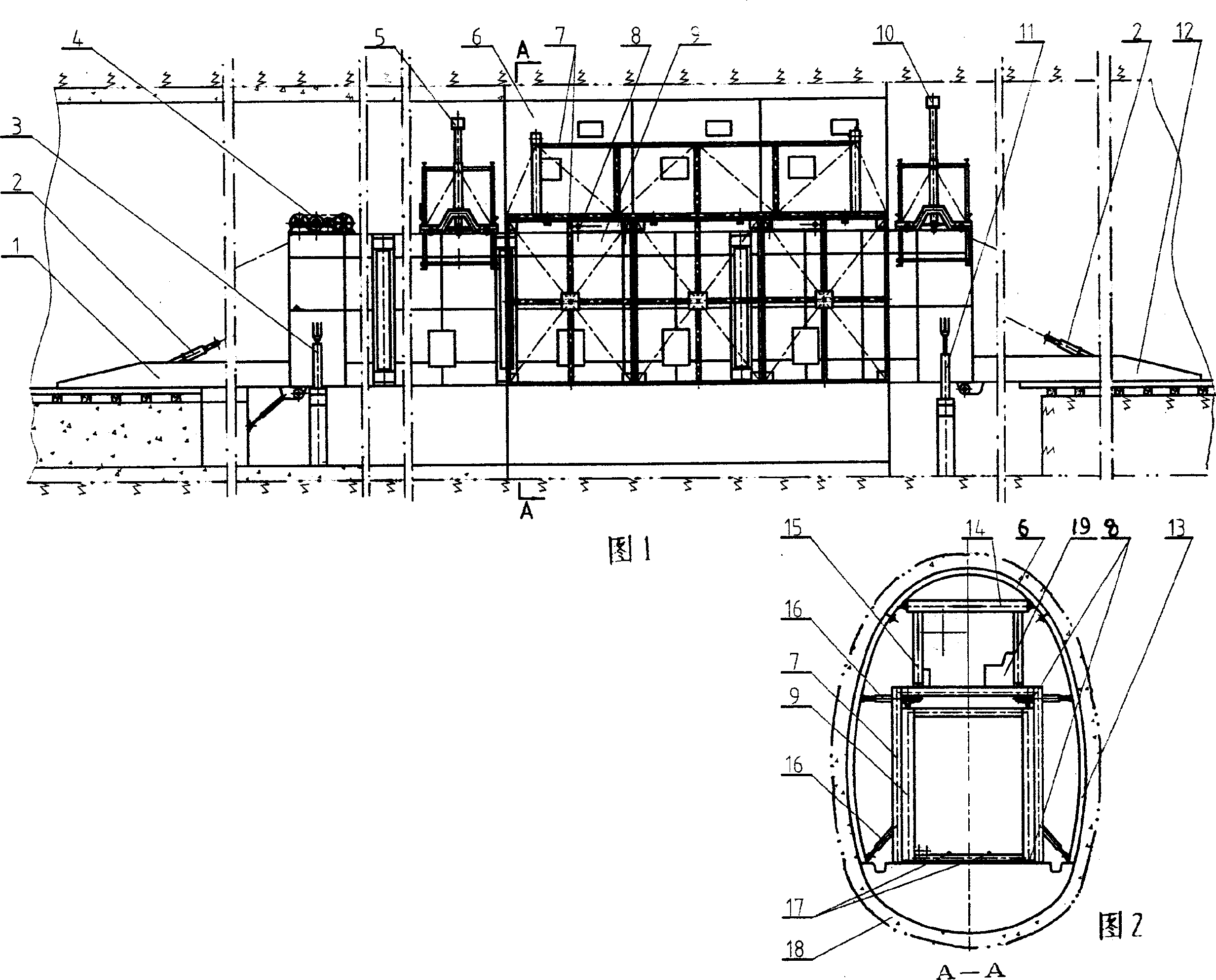

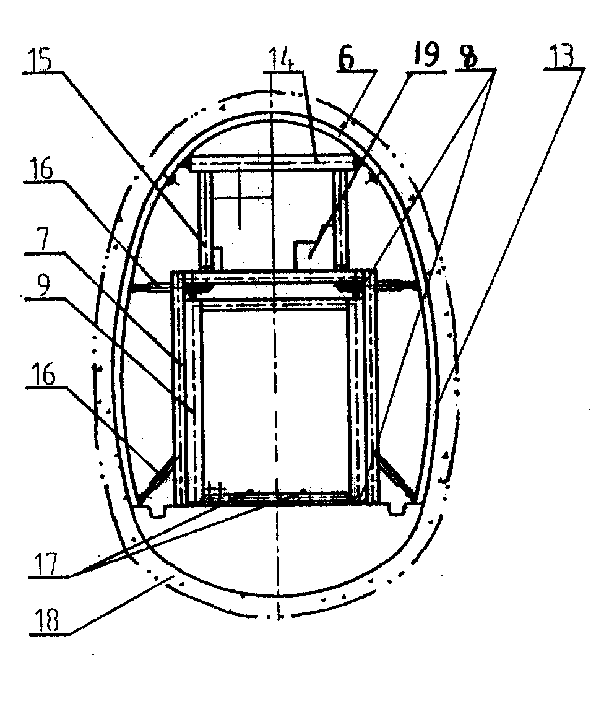

Trolley for construcing integral mould and building lining moulding board in loopful tunnel

Owner:中铁西南科学研究院有限公司

Steep cliff tunnel hole excavation construction method

Owner:DALIAN MUNICIPAL DESIGN & RES INST

Tunnel transverse cave-to-master cave top brushing construction method and top brushing structure

InactiveCN104929649ASmall excavation areaReduce construction riskUnderground chambersTunnel liningEngineeringStep method

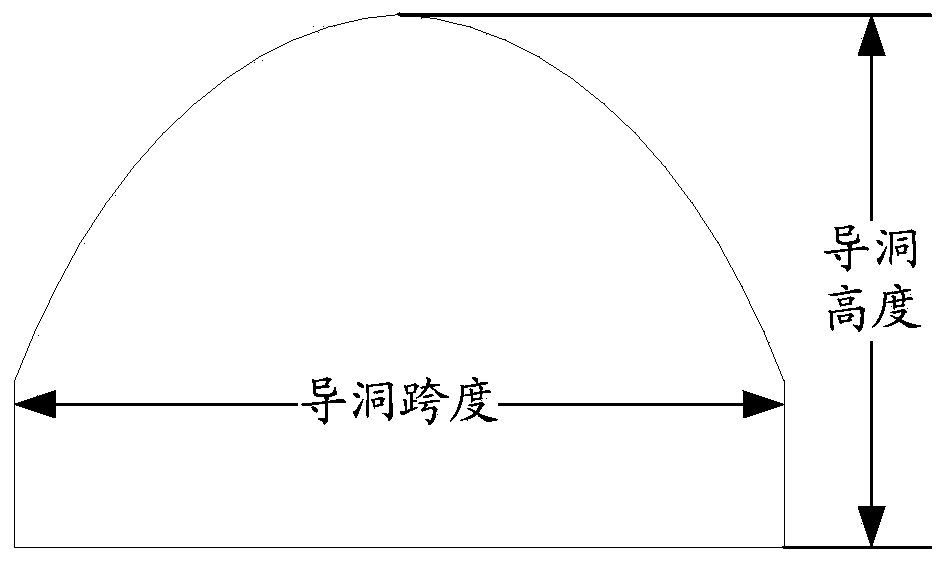

The invention discloses a tunnel transverse cave-to-master cave top brushing construction method. The tunnel transverse cave-to-master cave top brushing construction method comprises the steps that firstly, a transverse cave is constructed to an upper step of a regulated master cave, climbing and direct top brushing are carried out from the top arc outline of the master cave to the width direction of the master cave through a small guiding cave, and a beam is erected at the joint of the transverse cave top and the master cave; secondly, a primary support is carried out on the master cave of the small guiding cave part; thirdly, a vertical support temporarily supported by the small guiding cave in the master cave large mileage direction is dismounted, and the upper step of the master cave is excavated through expanding in the master cave large mileage direction; fourthly, a vertical support temporarily supported by the small guiding cave in the master cave small mileage direction is dismounted, and the upper step of the master cave is excavated through expanding in the master cave small mileage direction through a step method. The invention further discloses a tunnel transverse cave-to-master cave top brushing structure. The small guiding cave top and the master cave top of the top brushing structure are consistent in structure, the beam is erected at the joint of the transverse cave top and the master cave, and a small guiding cave temporary support is located above a master cave primary support. The top brushing excavation area is small, and the construction risk is low.

Owner:DALIAN MUNICIPAL DESIGN & RES INST

Rapid construction method of long tunnel under complex geologic conditions

ActiveCN106089217AImprove working environmentReduce economic lossUnderground chambersTunnel liningGeomorphologyShortest distance

Owner:CHINA RAILWAY CONSTR BRIDGE ENG BUREAU GRP OF THE FIFTH ENG +1

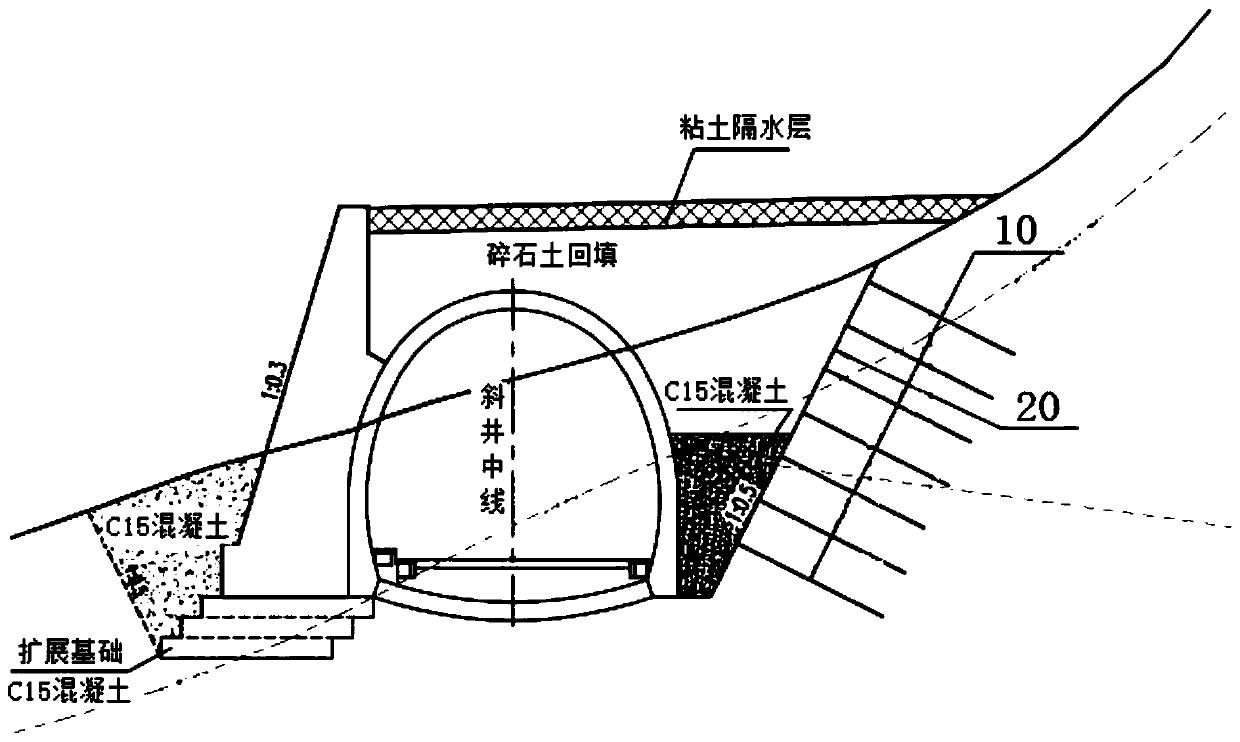

Construction method for tunnel inclined shaft opening

InactiveCN110107310AGuaranteed construction periodSimple processUnderground chambersArtificial water canalsEngineeringTruck

Owner:CCCC THIRD HARBOR ENG +1

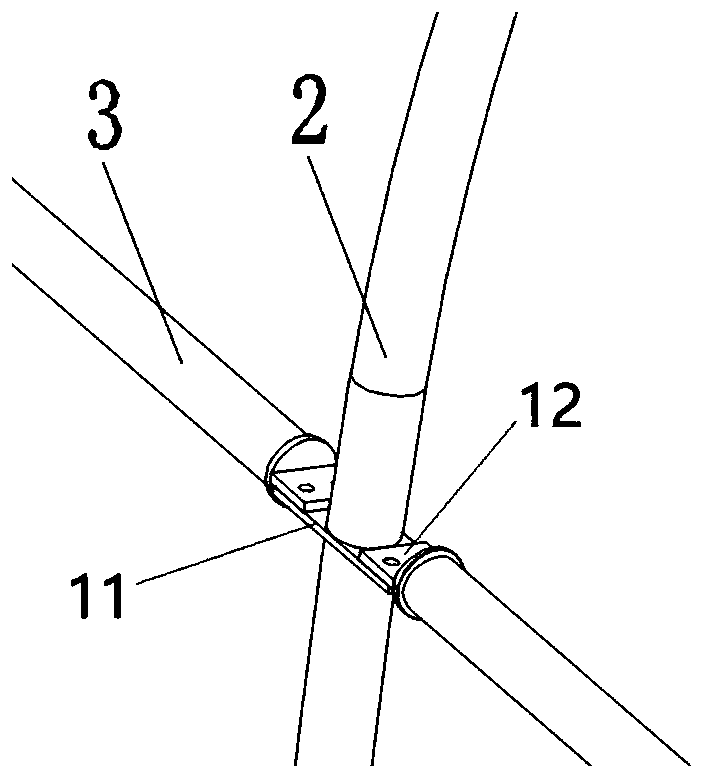

Concrete curing device carried by secondary lining trolley and using method of concrete curing device

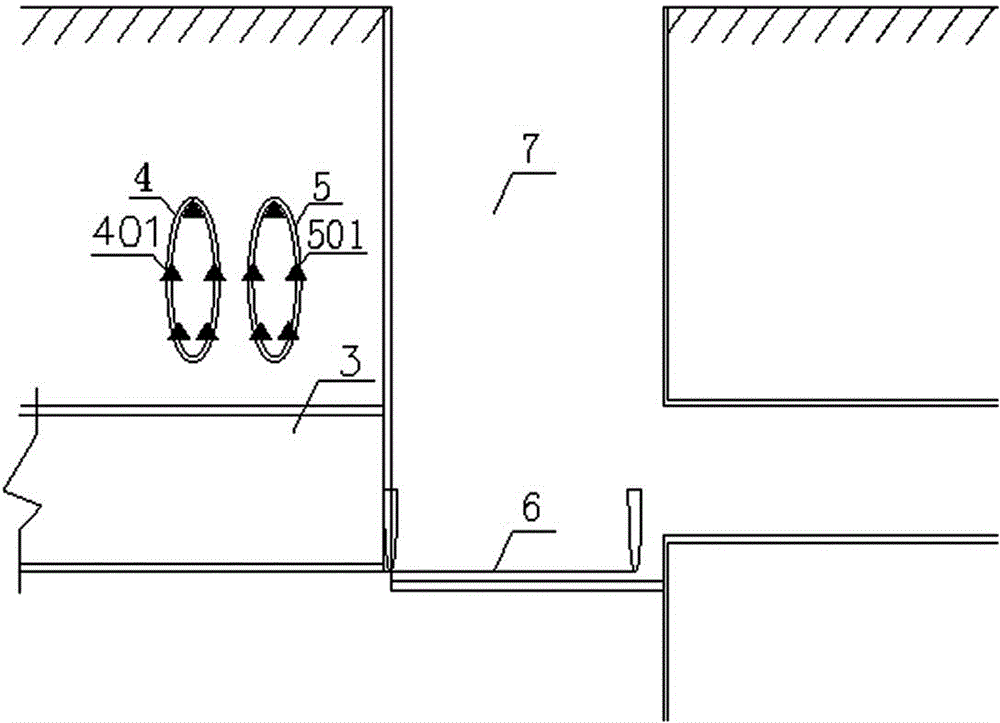

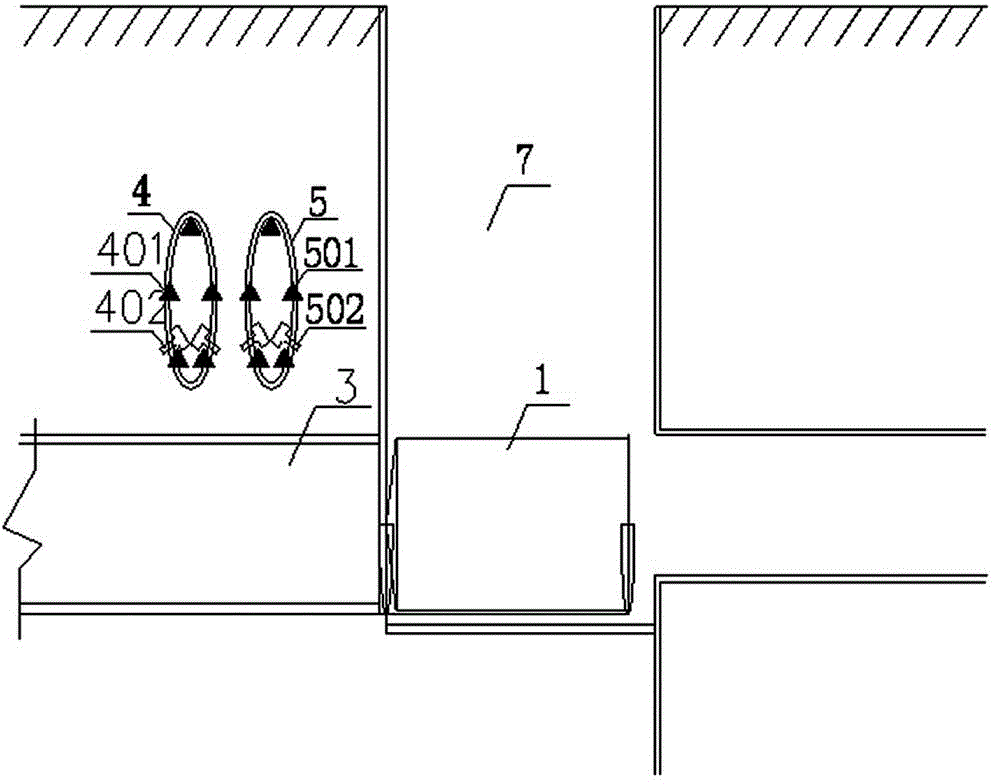

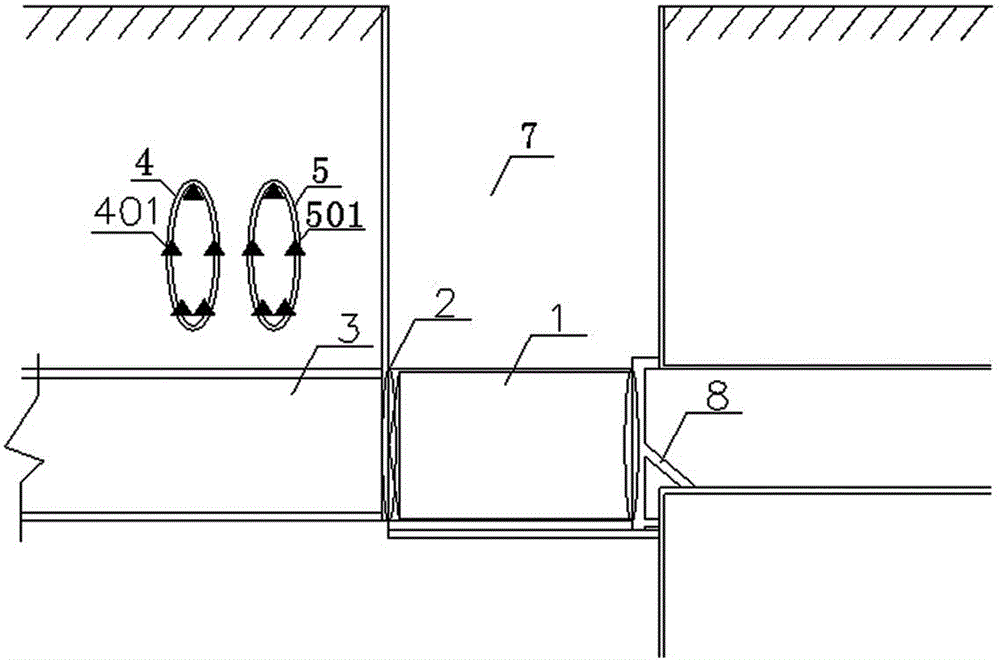

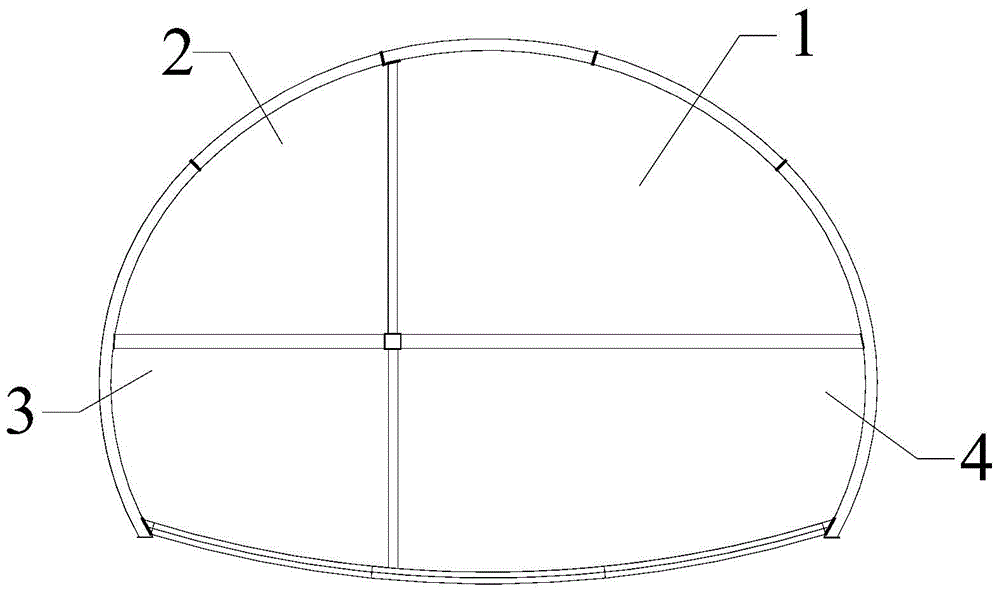

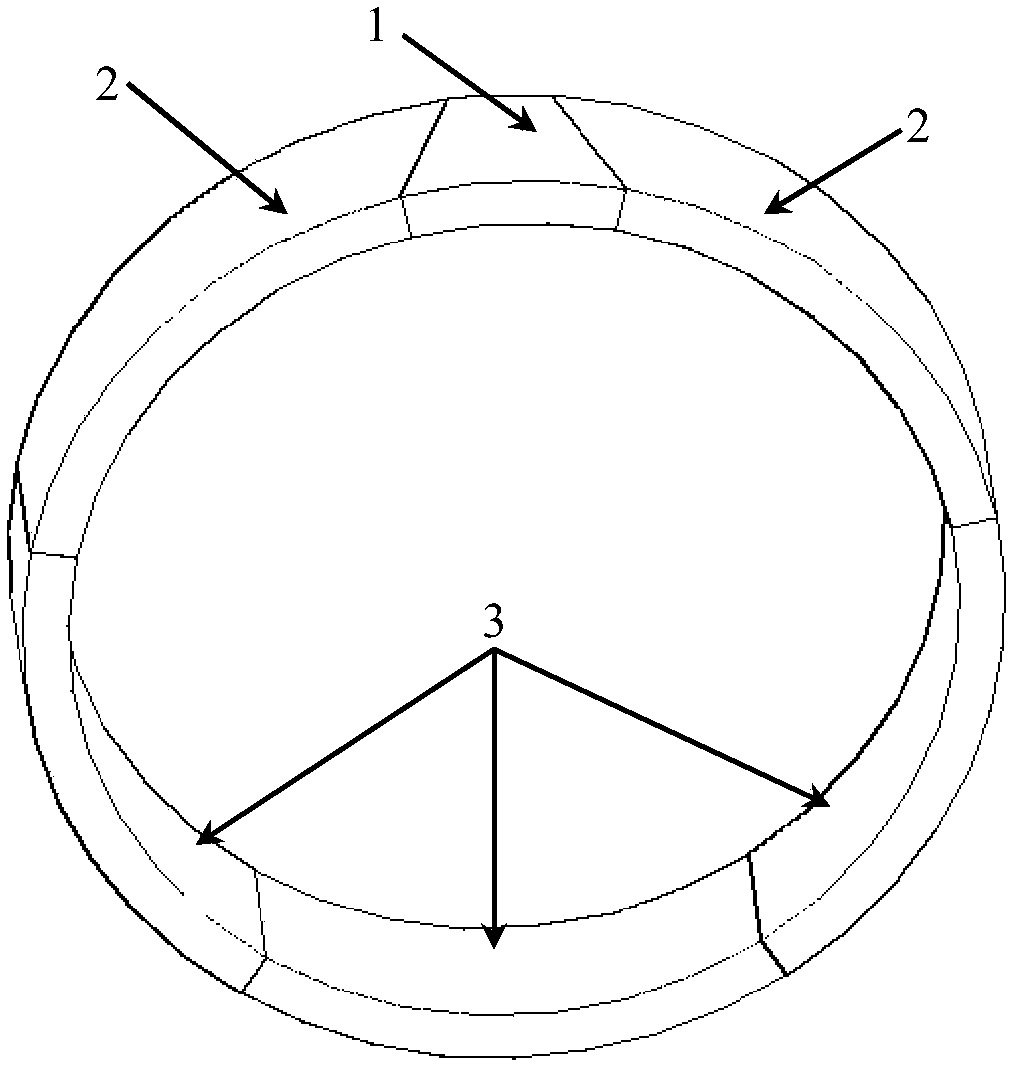

PendingCN107269296ANovel ideaSimple structureUnderground chambersTunnel liningWater storage tankStructural engineering

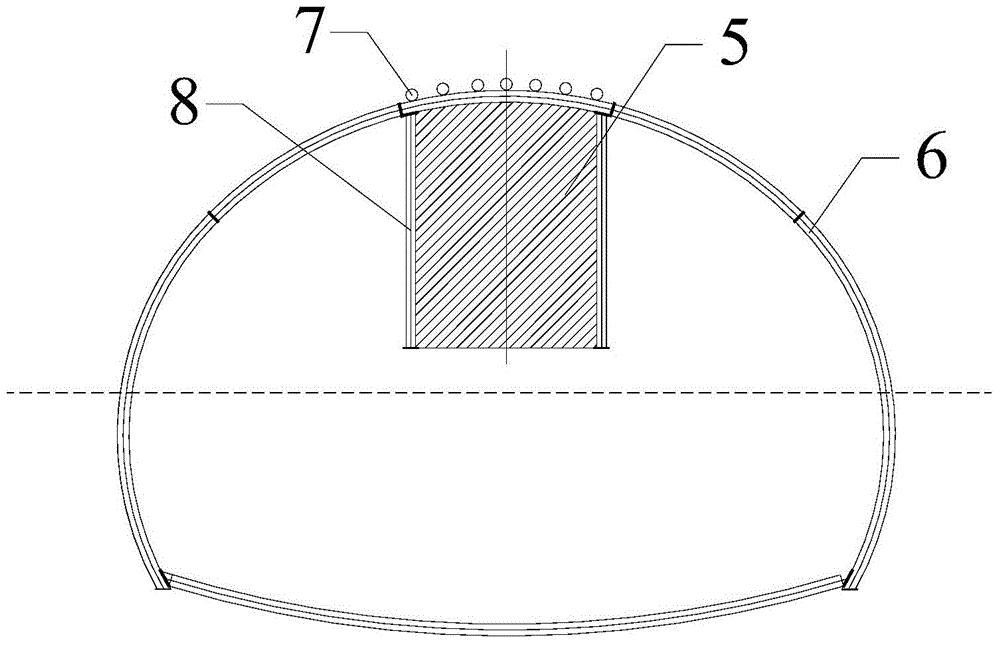

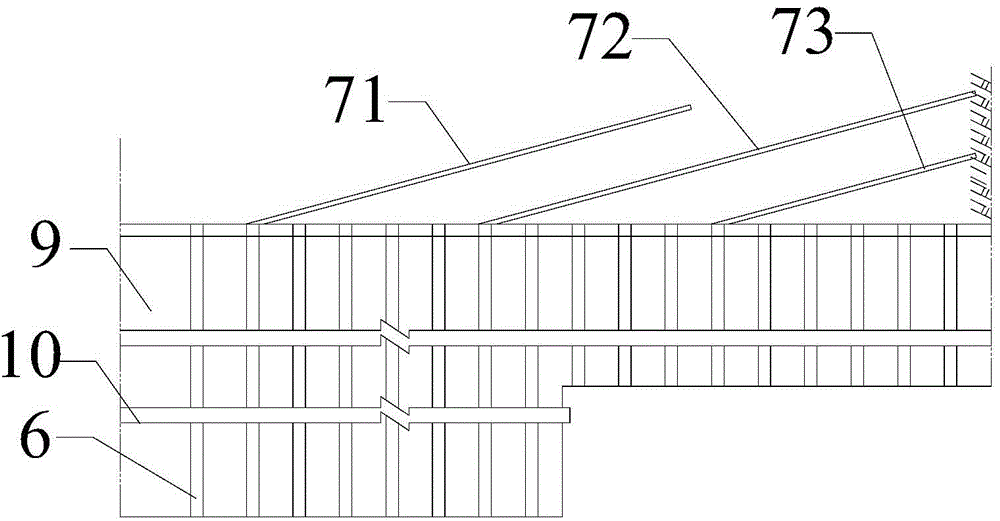

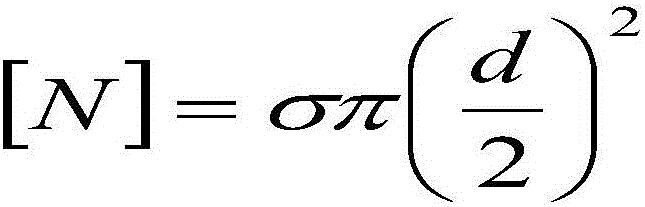

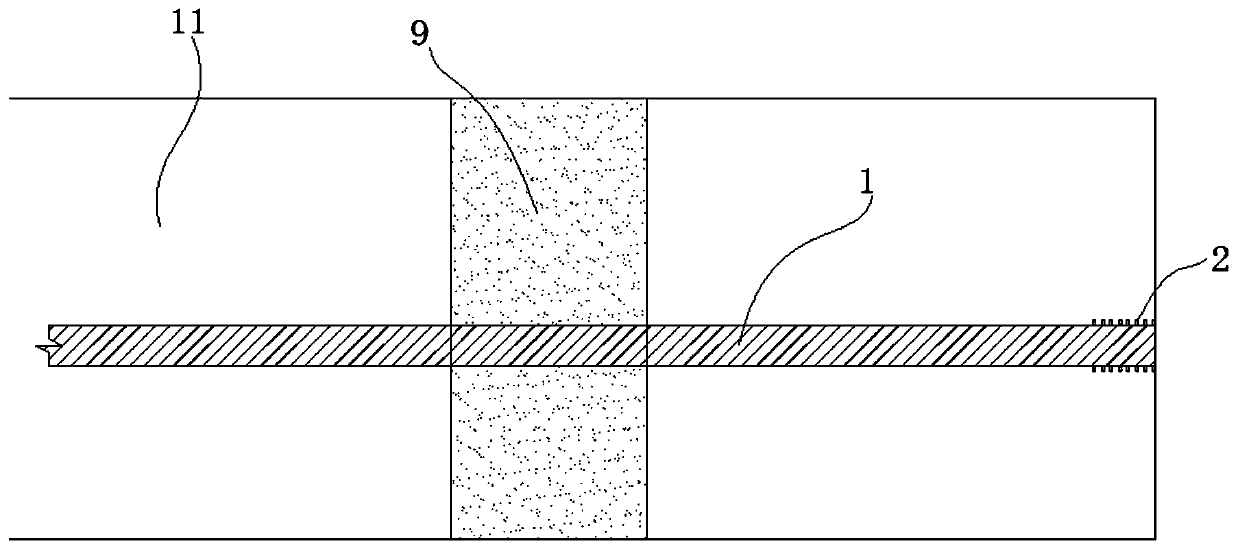

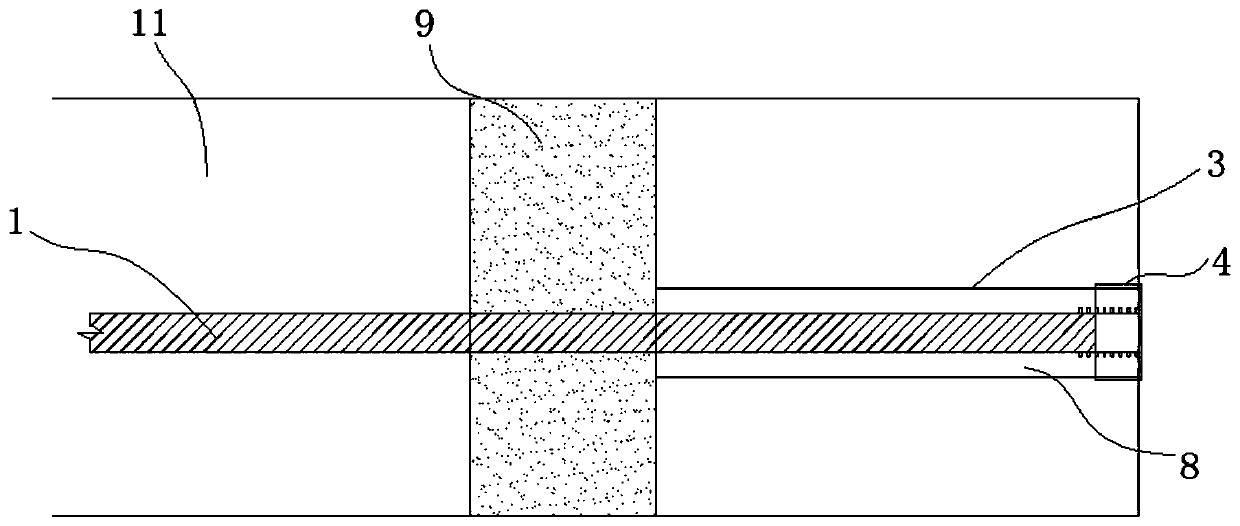

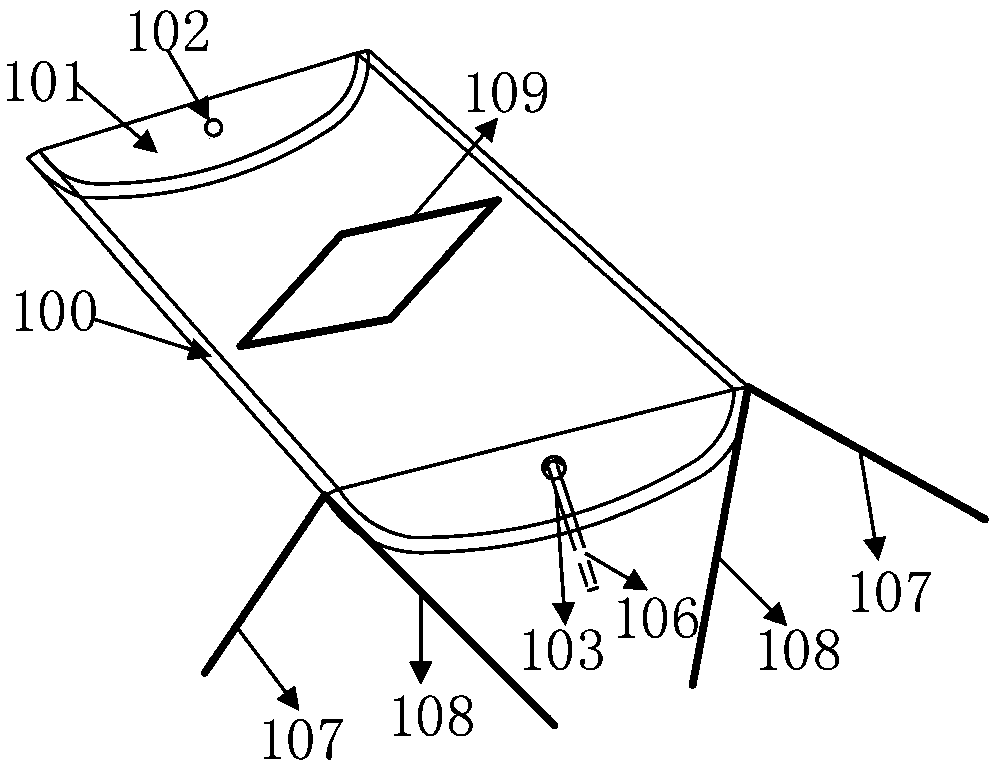

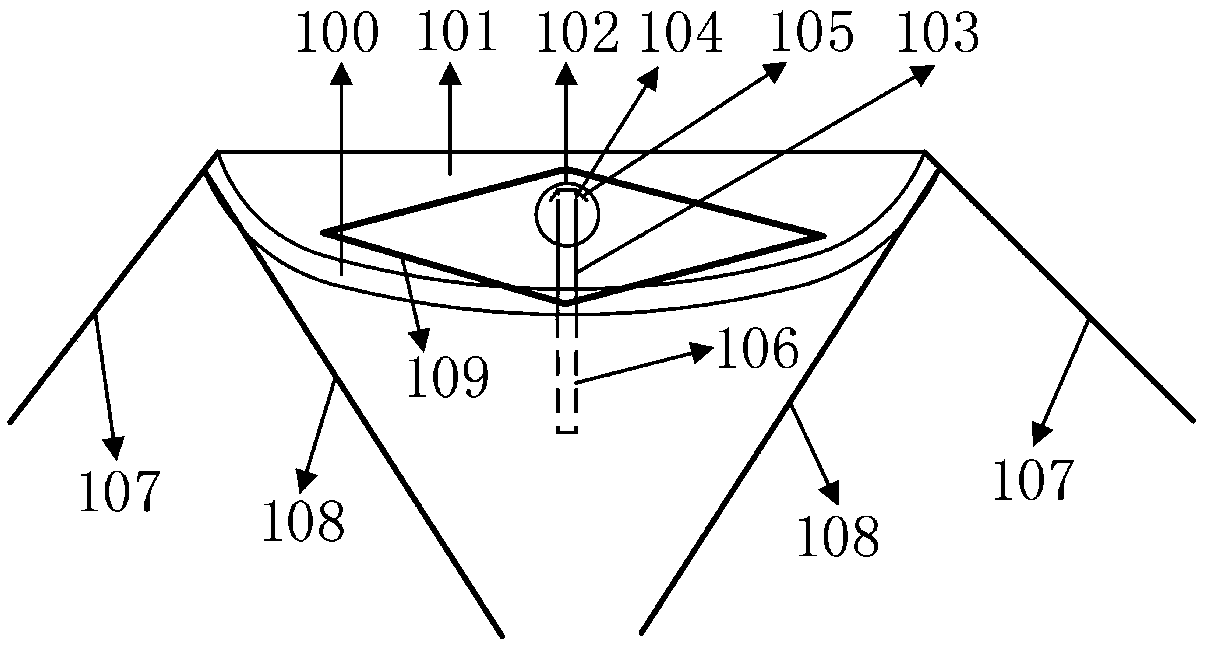

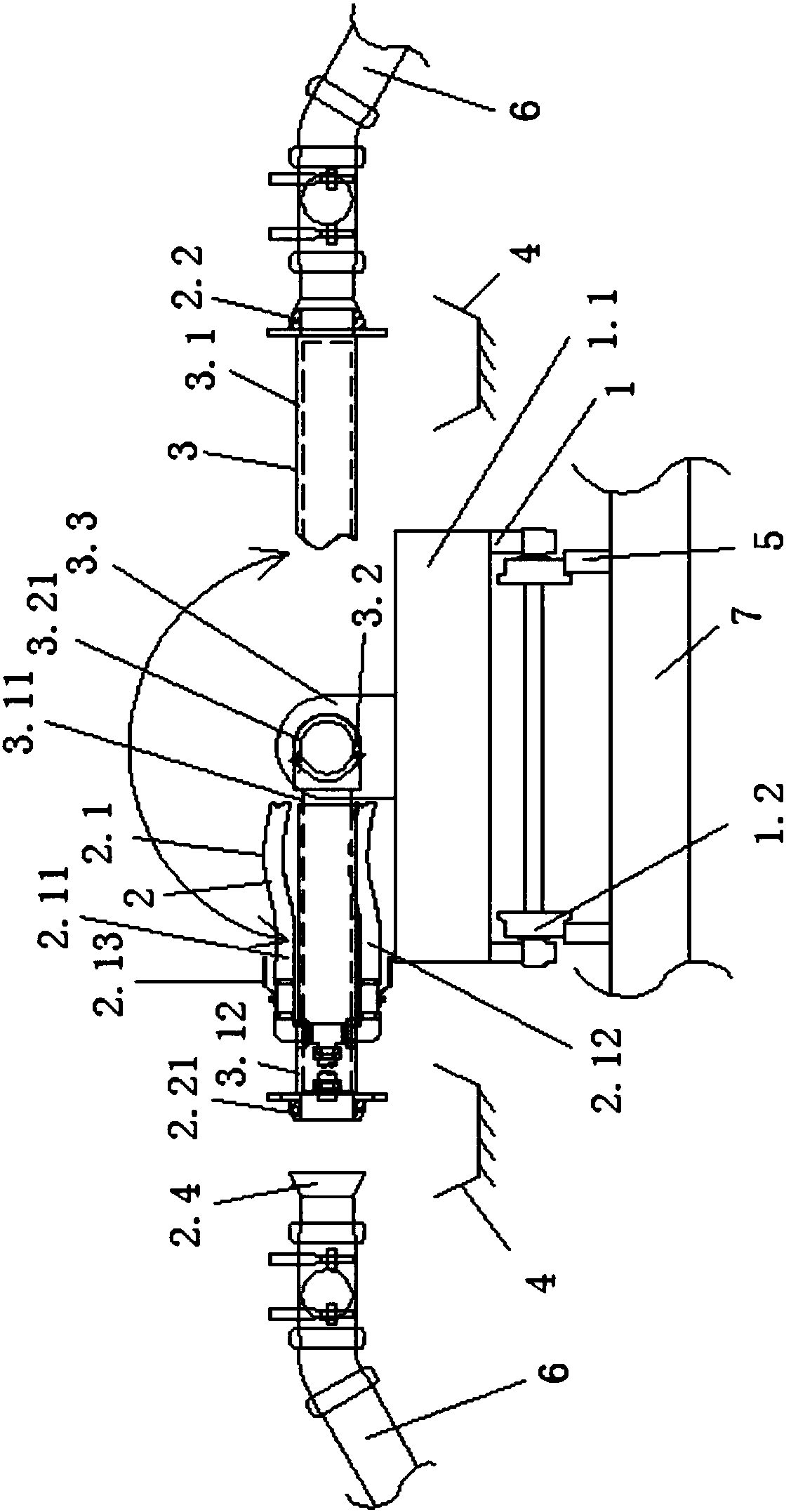

A concrete curing device carried by a secondary lining trolley and a using method of the concrete curing device are disclosed. The device comprises a water spraying system, the water spraying system comprises a water storage tank (1), a water spring pipeline and a water pump, the water spraying pipeline comprises a left arc-shaped water spraying pipeline (2) and a right arc-shaped water spraying pipeline (3), a plurality of spray heads (9) are arranged on the left arc-shaped water spraying pipeline (2) and the right arc-shaped water spraying pipeline (3) correspondingly, the left arc-shaped water spraying pipeline (2) is connected with the water storage tank (1), and the right arc-shaped water spraying pipeline (3) is connected with the water storage tank (1). The method comprises the steps of enabling a left arch ring (6) and a right arch ring (10) to rise above a top formwork of the secondary lining trolley, enabling the left arch ring (6) and the right arch ring (10) to cross edge formworks of the secondary lining trolley, adjusting the distance between each spray head (9) and secondary lining concrete, enabling the left arc-shaped water spraying pipeline (2) and the right arc-shaped water spraying pipeline (3) to spray water, and conducting water spraying curing on the concrete. According to the concrete curing device carried by the secondary lining trolley and the using method of the concrete curing device, the purpose that the concrete is cured timely after lining is subjected to formwork removing is achieved, and the problem that at present, concrete cannot be cured timely some time is solved.

Owner:CHINA RAILWAY 11TH BUREAU GRP +1

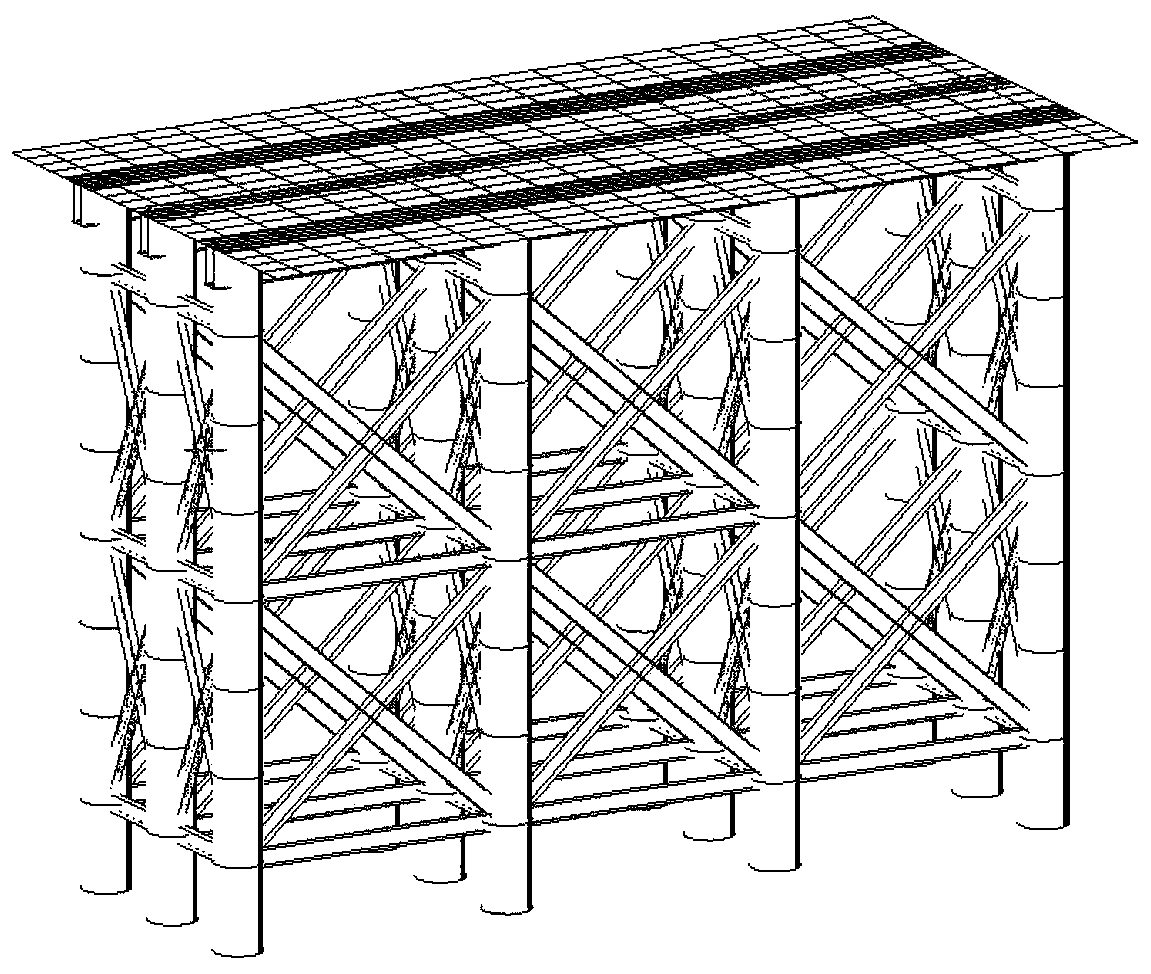

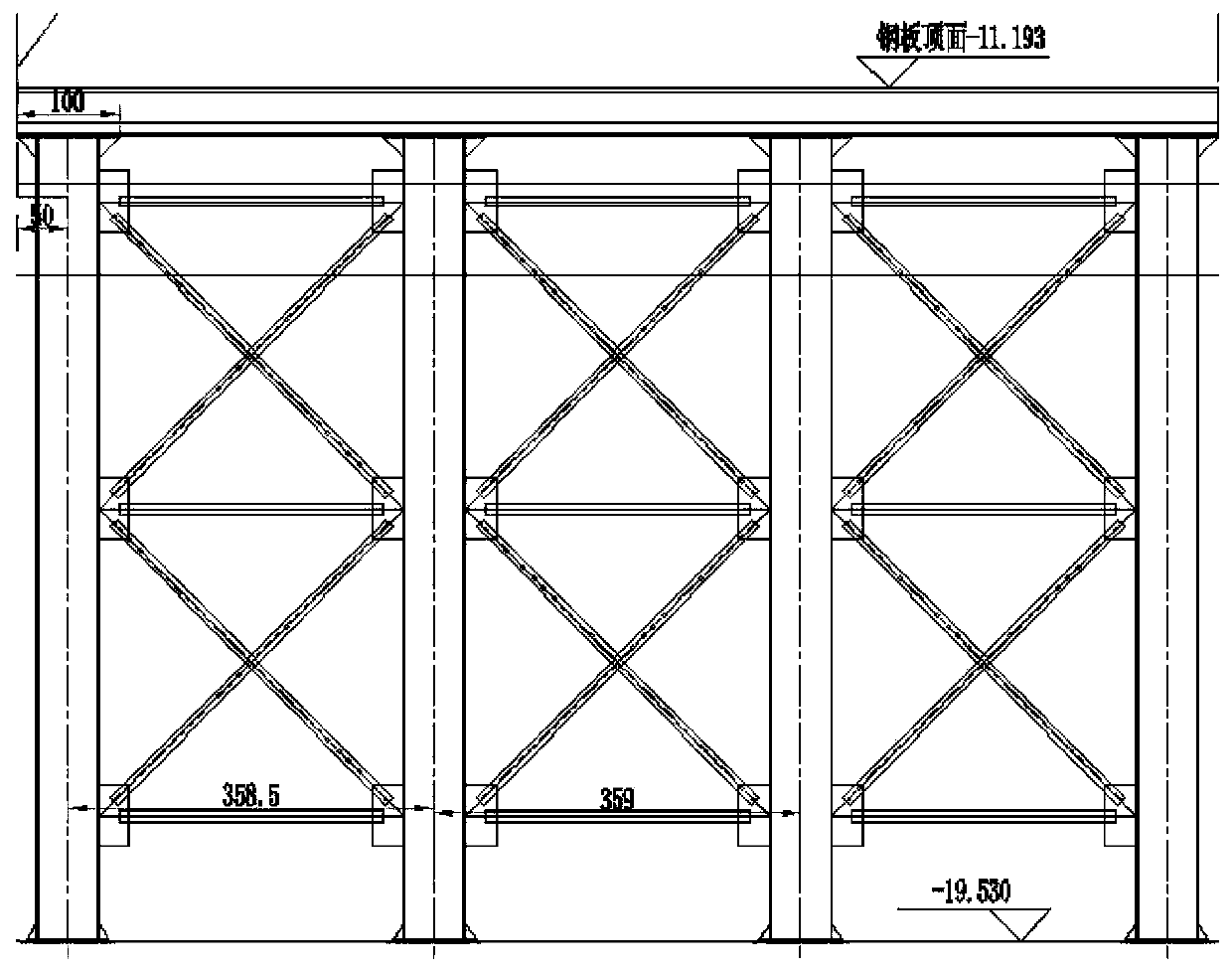

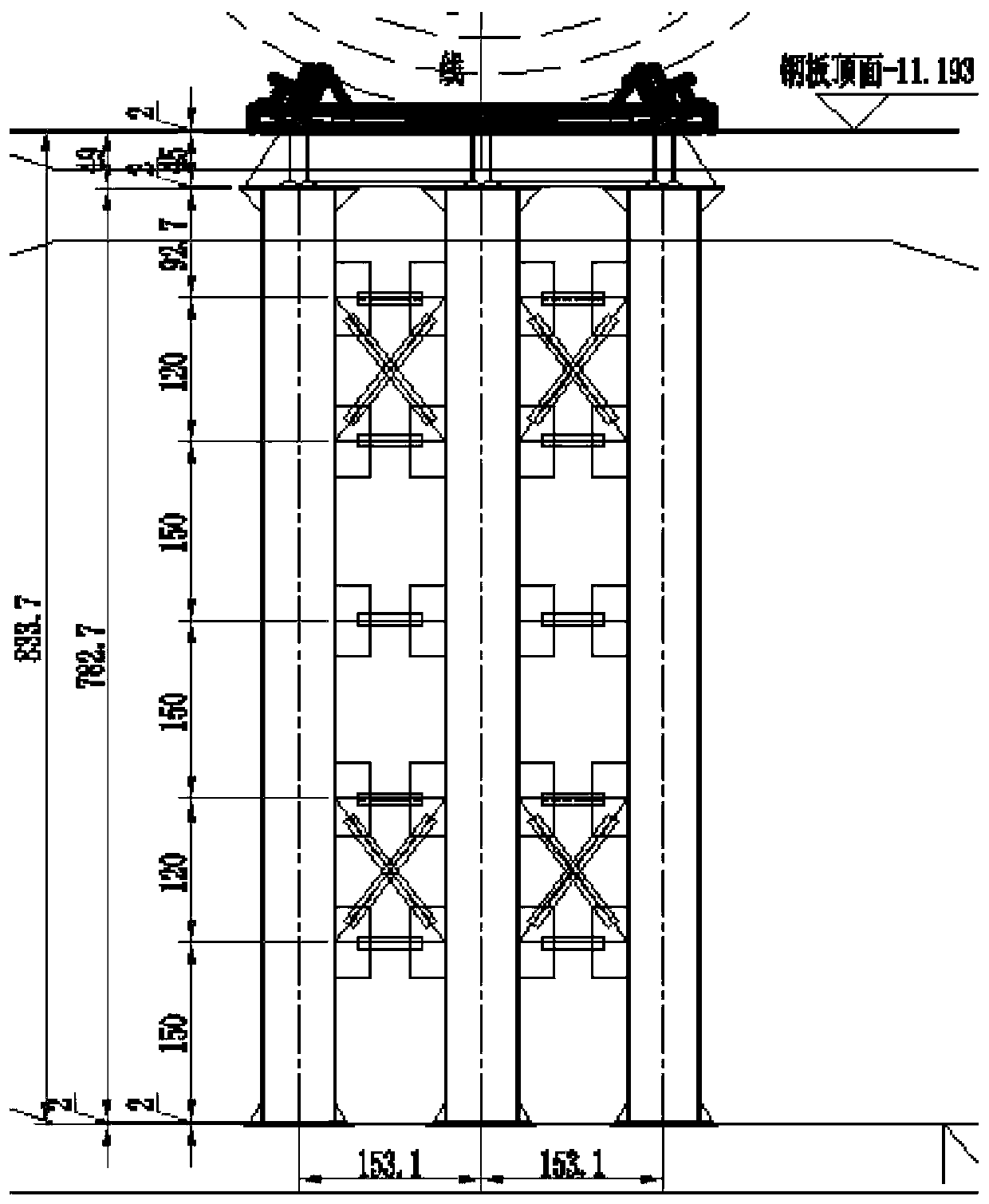

Shield machine receiving steel platform

InactiveCN109763835AGuaranteed normal formationImprove stabilityUnderground chambersTunnel liningSheet steelShield machine

Owner:中建铁投轨道交通建设有限公司

Liquid accelerator

ActiveUS20070044686A1Underground chambersMixing operation control apparatusHydrofluoric acidAluminium sulfate

To provide a liquid accelerator which excels in accelerating effect and which also excels in storage stability at low temperature and inhibitory effect of alkali-aggregation reaction. A liquid accelerator composed of a fluoride-containing aqueous aluminum salt which is obtained through the reaction of aluminum sulfate and hydrofluoric acid, aluminum hydroxide, and one or more kinds of lithium salts selected from the group consisting of lithium hydroxides, lithium carbonates, and lithium sulfates.

Owner:CONSTR RES & TECH GMBH

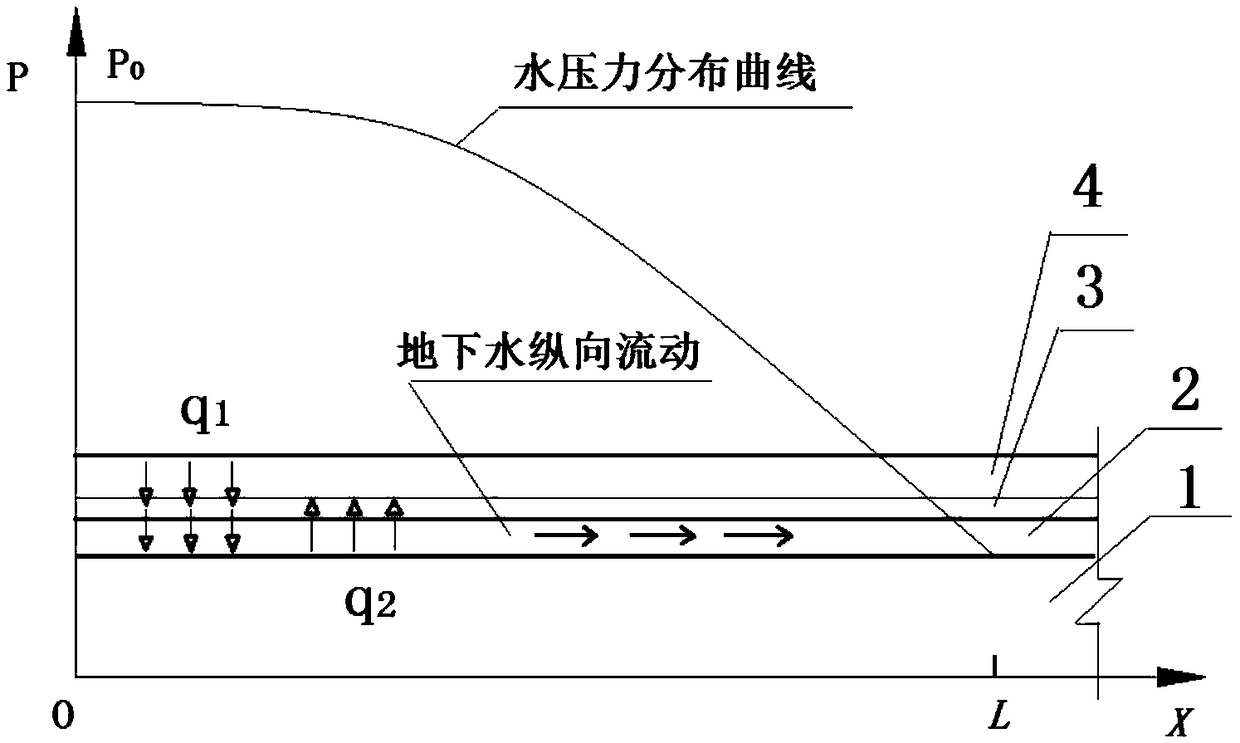

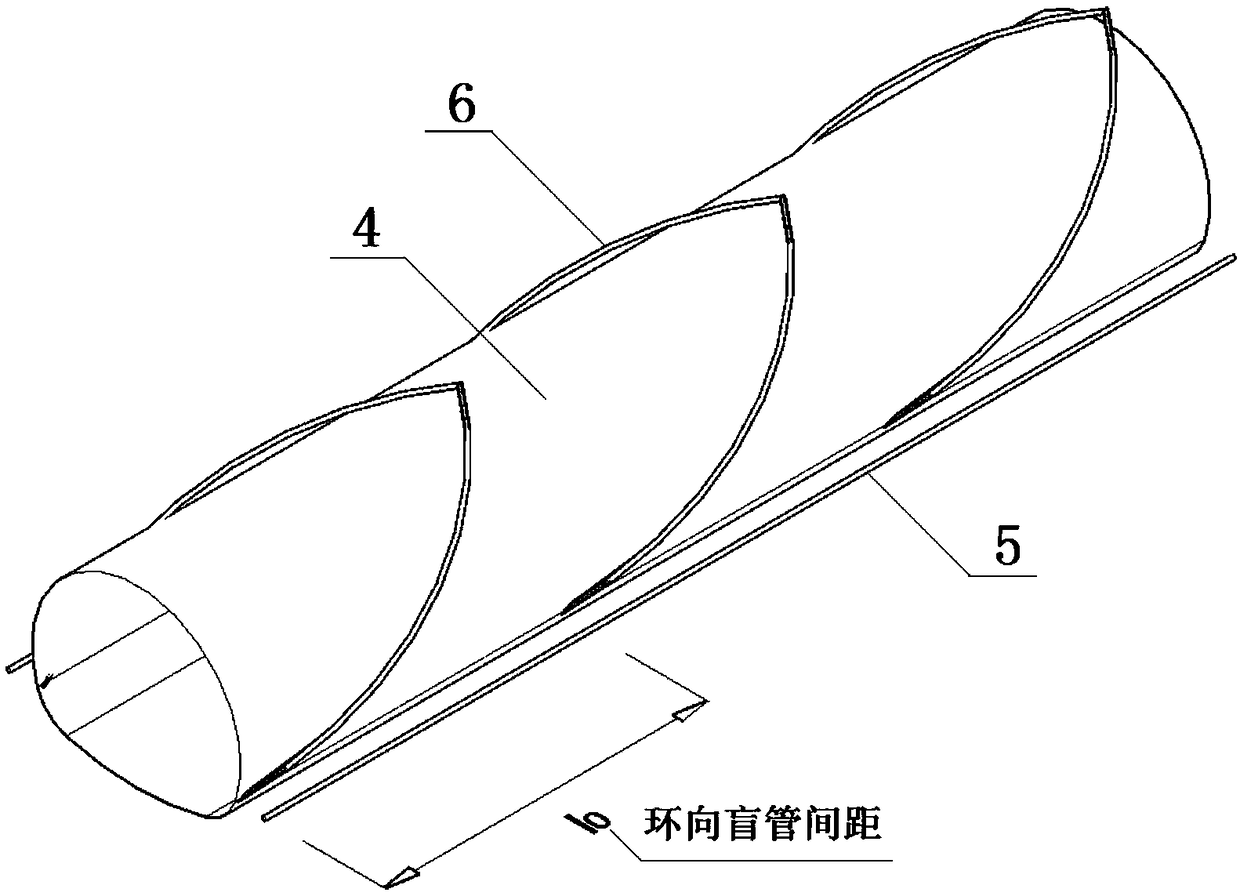

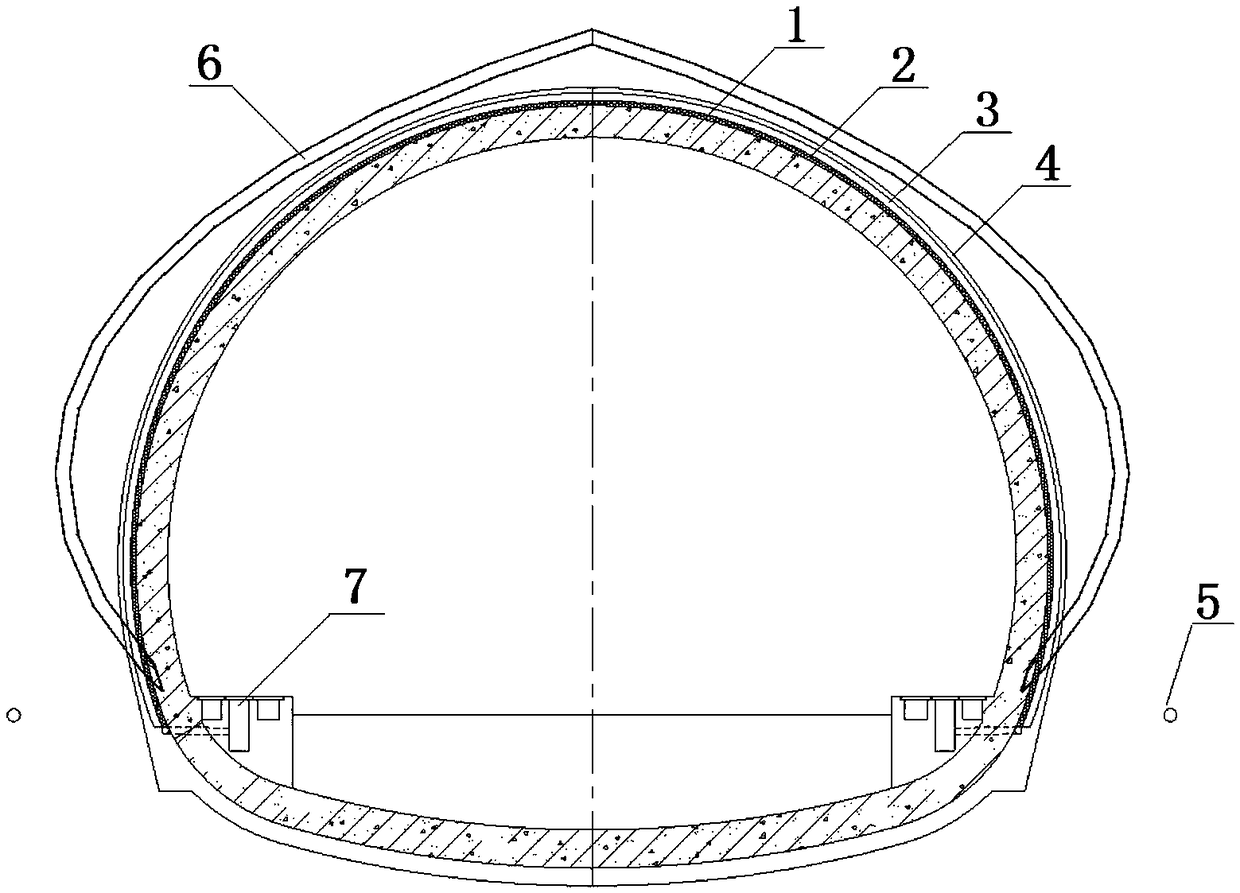

Tunnel drainage disease prevention processing method and system

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Curtain grouting method for shallow buried nearly horizontal burnt rock water-bearing layer

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

Pre-laying waterproof coiled material construction process for welding and adhesive bonding combined construction

Owner:KESHUN WATERPROOF TECH CO LTD

Gas tunnel system anchor rod and anchor rod detection safety construction method

Owner:ROAD & BRIDGE INT +1

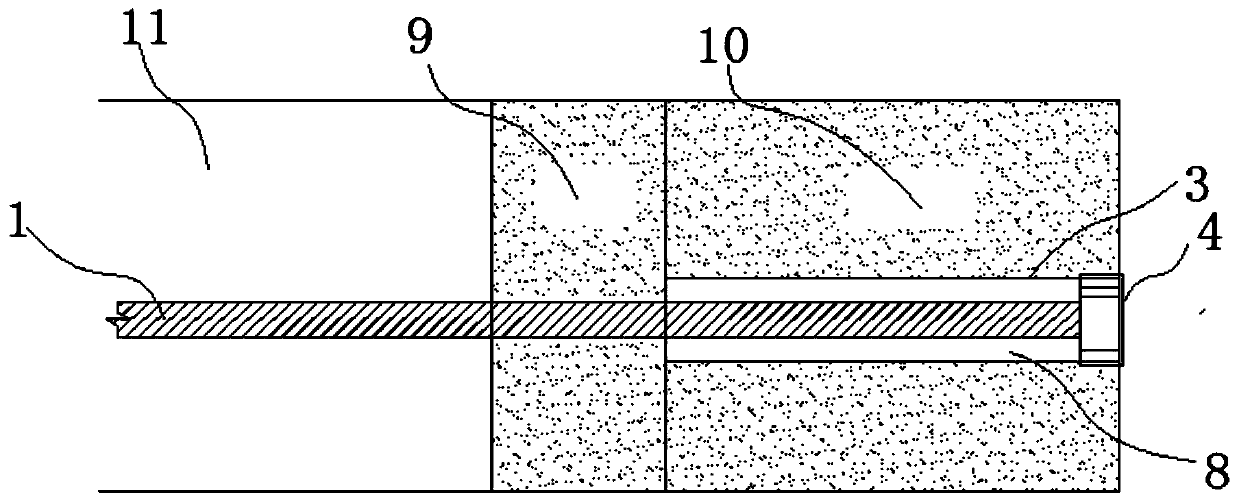

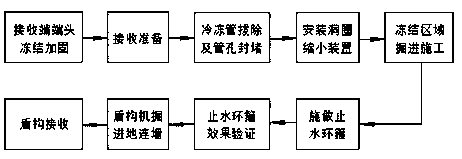

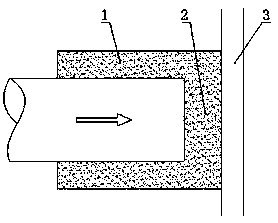

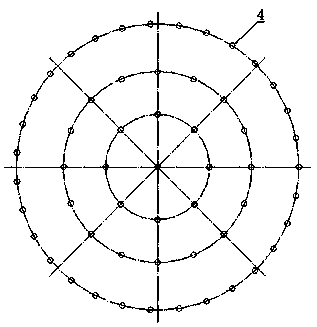

Shield horizontal freezing receiving construction method

ActiveCN110030007AGuaranteed water stop effectDone successfullyUnderground chambersTunnel liningArchitectural engineeringShield machine

Owner:JINAN URBAN CONSTR GRP +6

Tunnel inverted arch structure capable of resisting floor heave

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

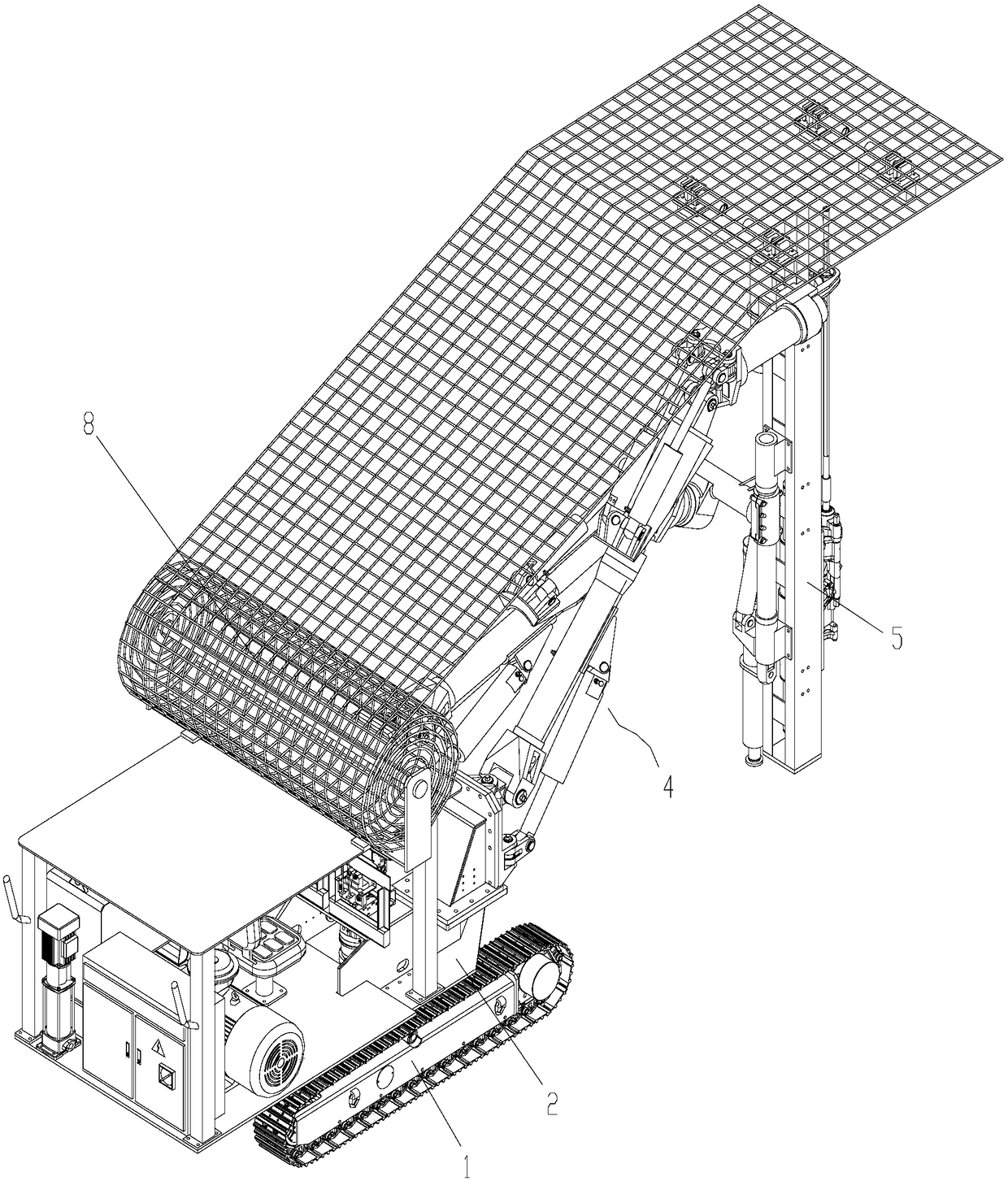

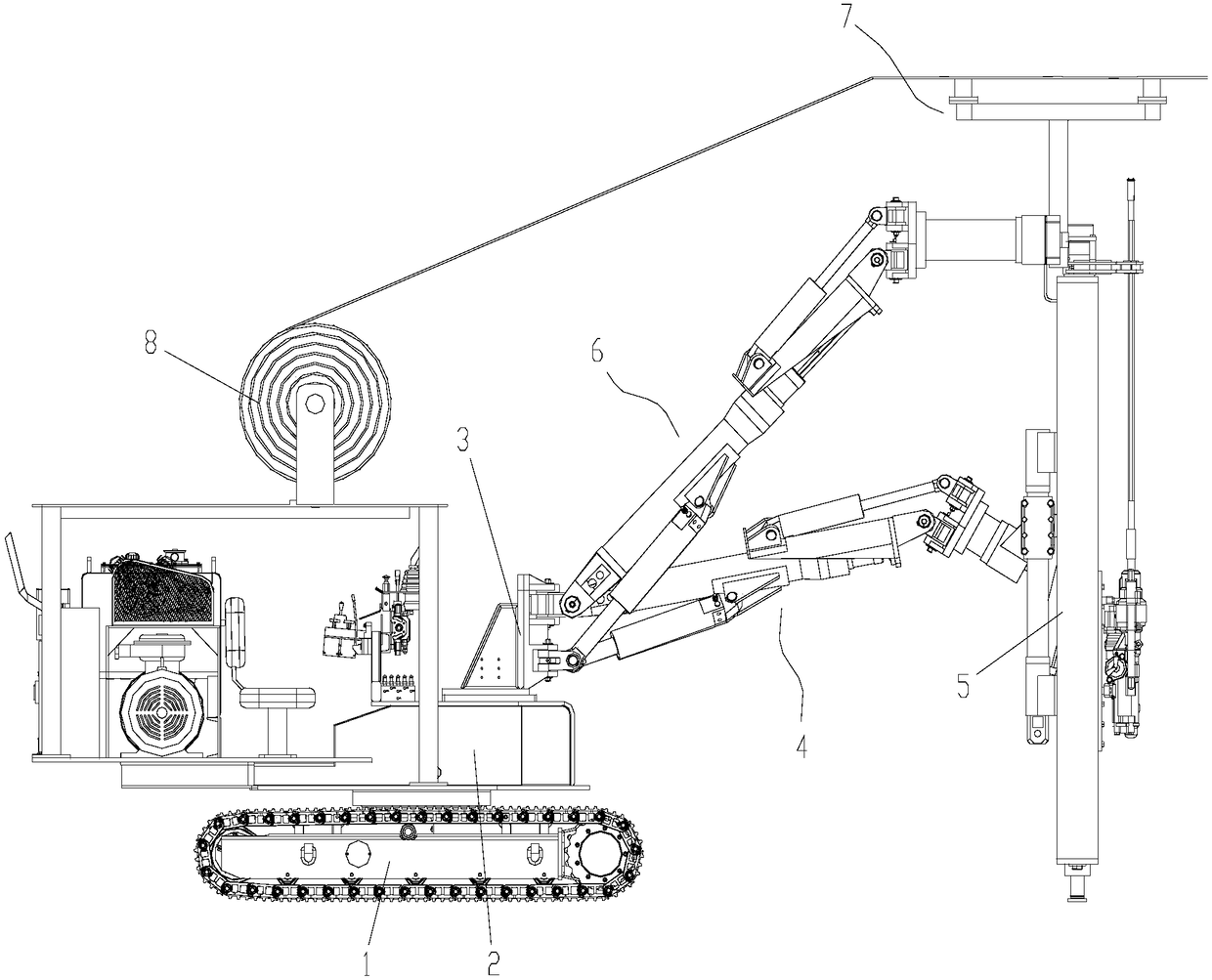

Net anchoring drill carriage

ActiveCN108104844AQuick SetupImprove work efficiencyUnderground chambersDerricks/mastsVehicle framePropeller

Owner:重庆格德瑞重工智能装备研究院 +1

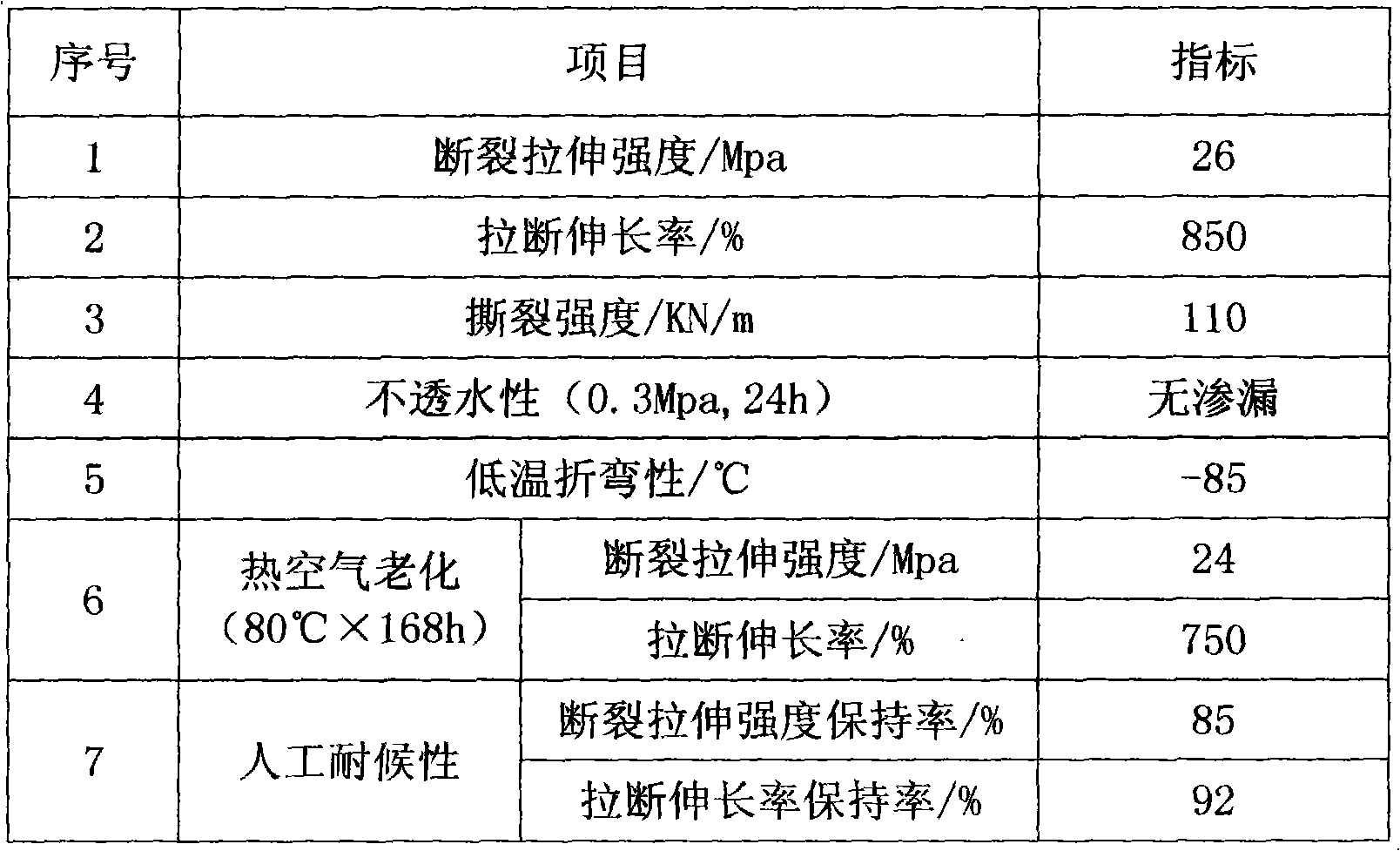

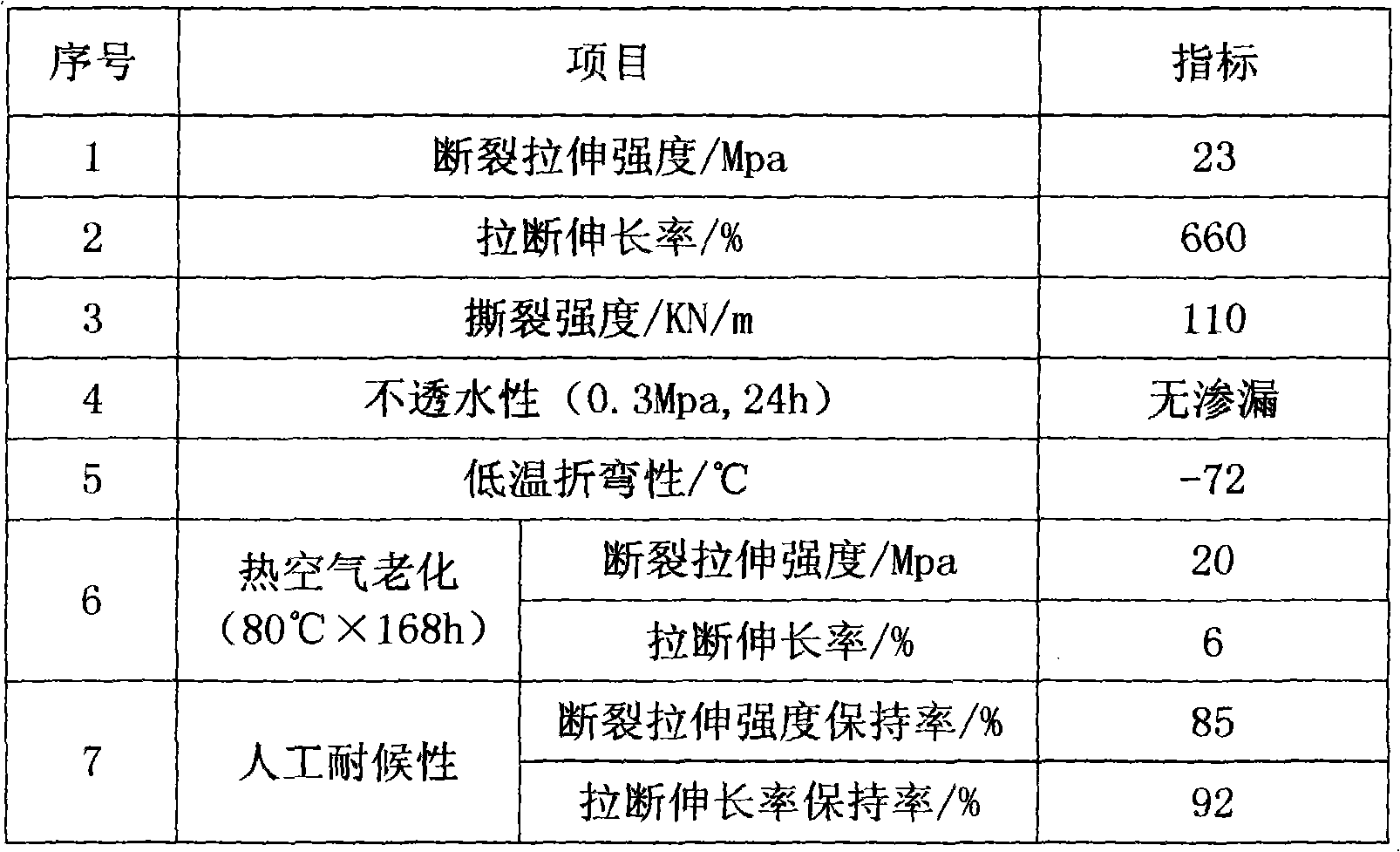

High-temperature-resistant and corrosion-resistant waterproof board for tunnels and production process thereof

ActiveCN103541745AEasy to useImprove toughnessUnderground chambersSynthetic resin layered productsGround temperatureAntioxidant

Owner:HONGXIANG NEW GEO MATERIAL

Segment capable of being dismantled in subway tunnel and construction method thereof

ActiveCN108397211AShorten the timeImprove efficiencyUnderground chambersTunnel liningEngineeringStructural engineering

Owner:JINAN RAILWAY TRANSPORT GRP CO LTD

Sand pebble pipe jacking machine and pipe jacking construction method

ActiveCN109026051AAvoid manual excavationIncrease the correcting torqueUnderground chambersHydro energy generationTruckScrew conveyor

Owner:河南省水利第一工程局集团有限公司

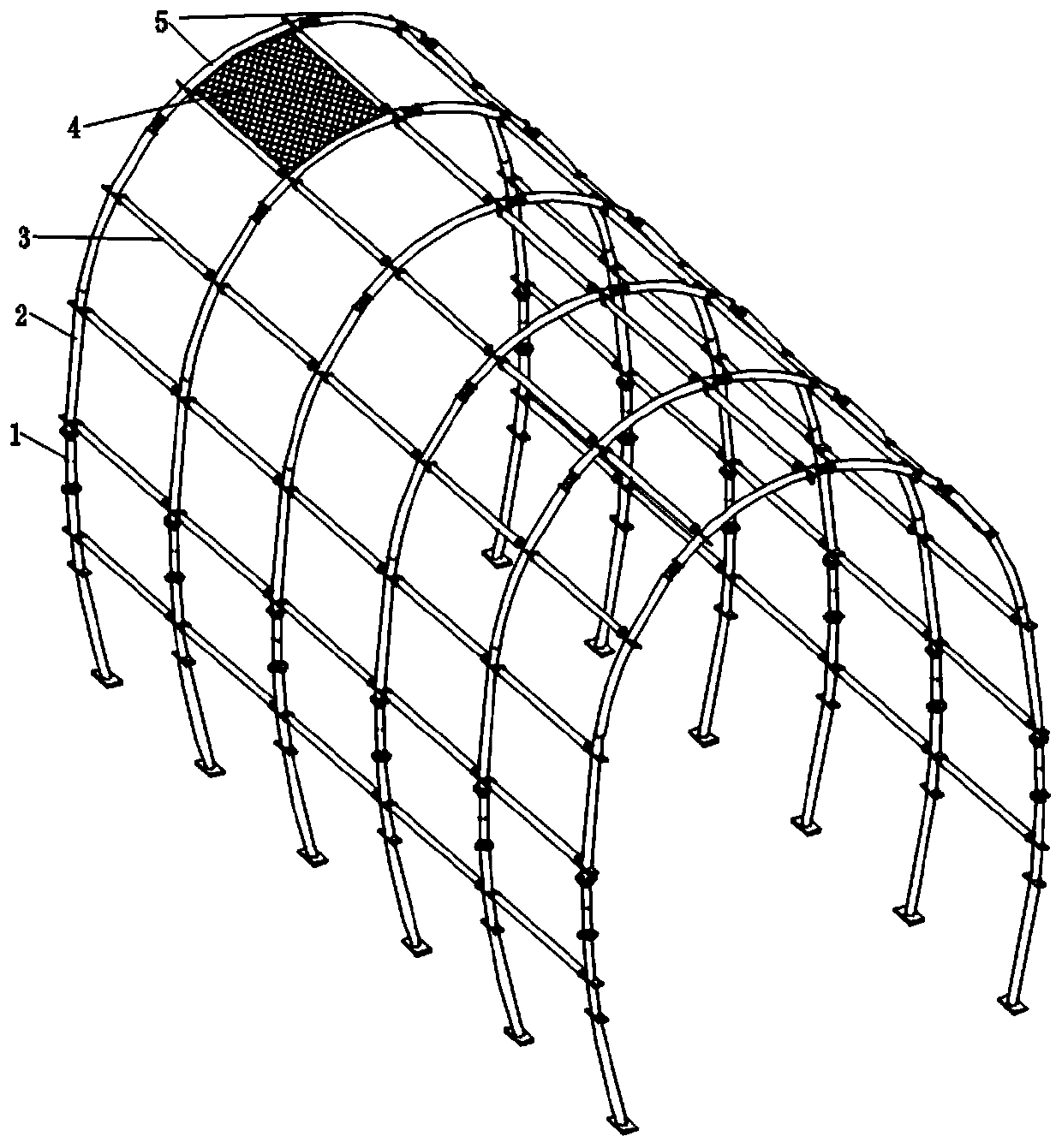

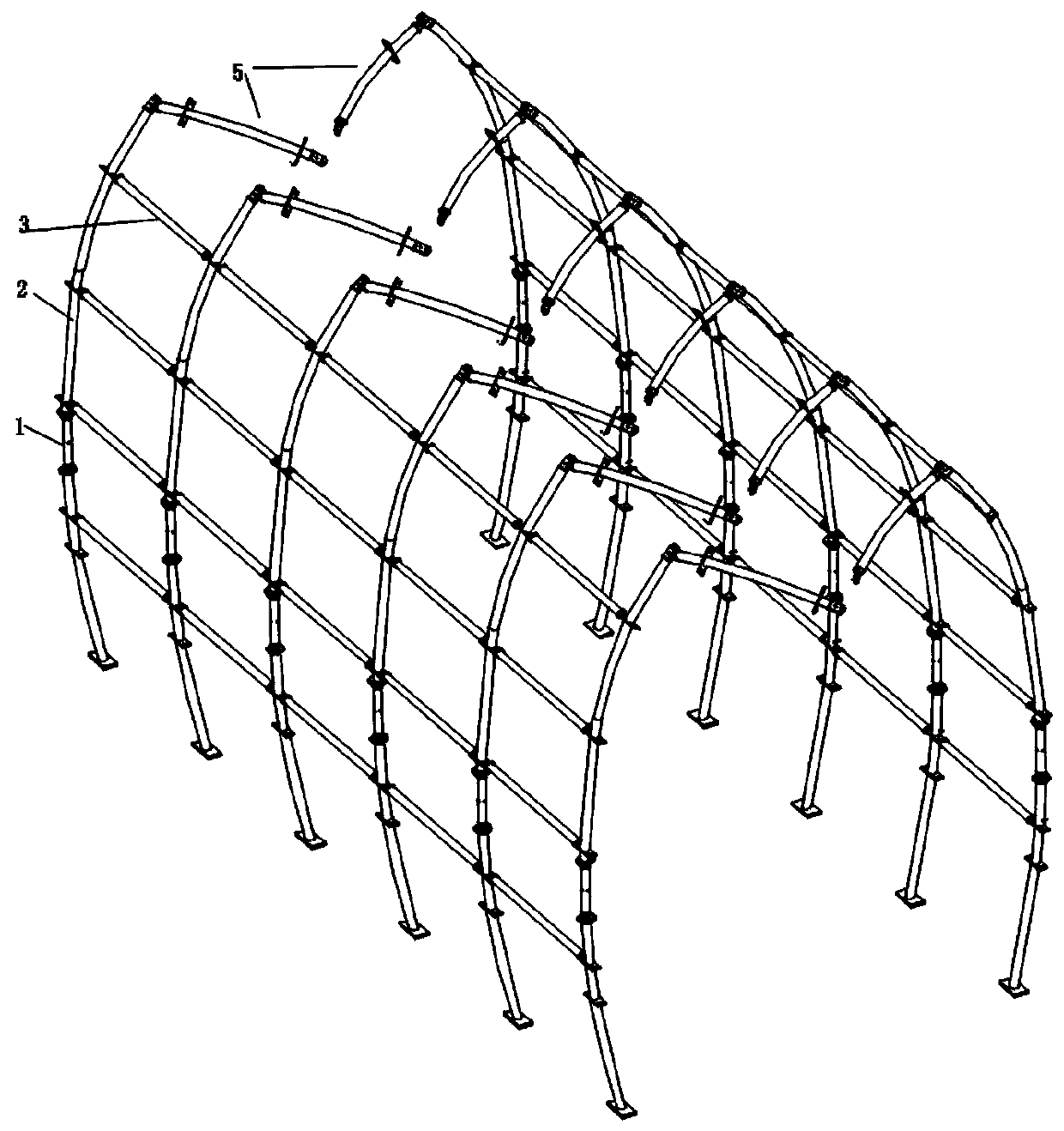

Rapid splicing supporting shed frame

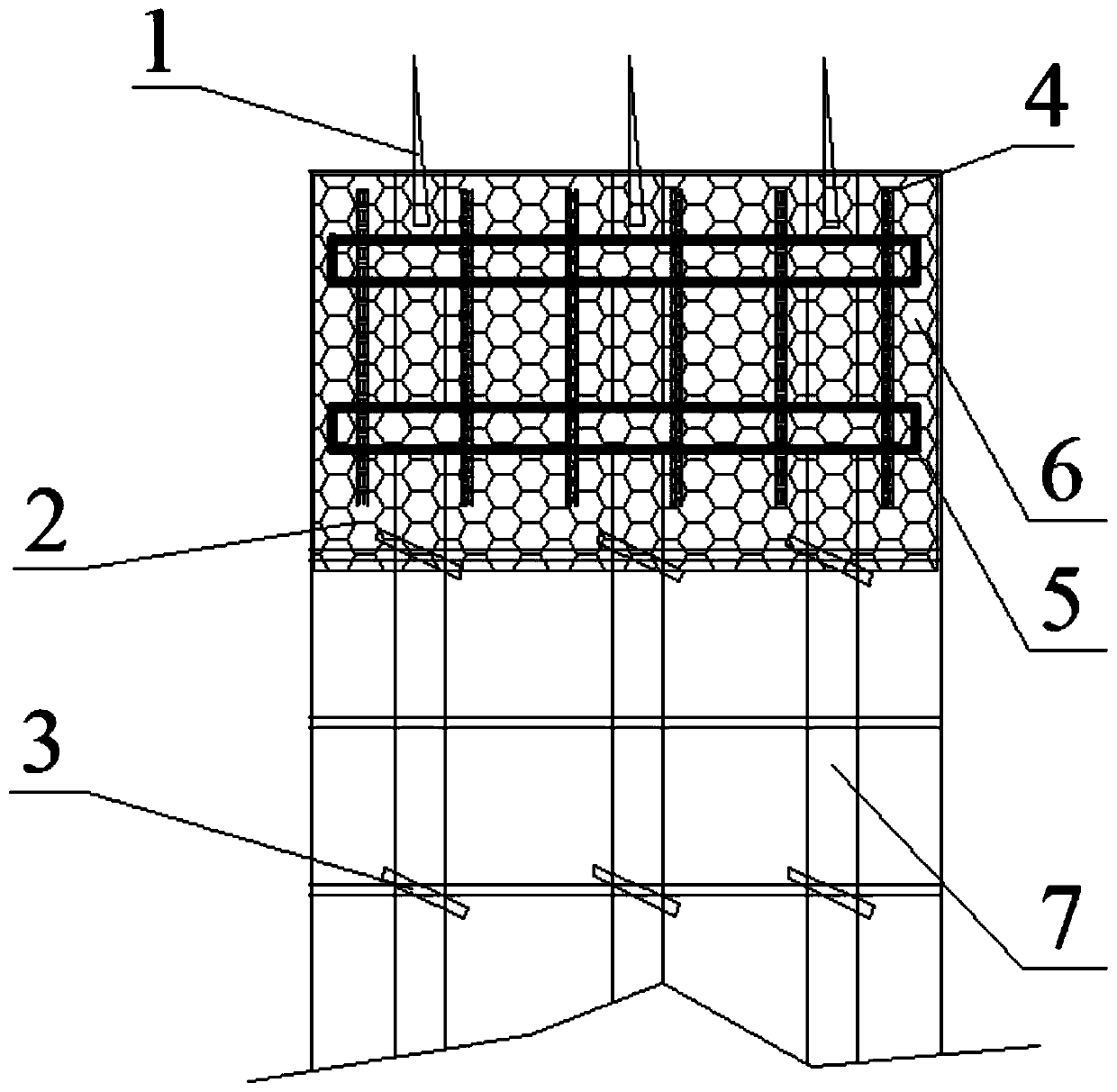

PendingCN110566241ADoes not affect traffic operationsShort construction timeUnderground chambersTunnel liningEngineeringWire mesh

Owner:SICHUAN RUITIE TECH +1

Cleaning device, lining trolley comprising same, and construction method

PendingCN108798699AFirmly connectedQuick dockingUnderground chambersTunnel liningEngineeringMultiple modes

Owner:HUNAN WUXIN TUNNEL INTELLIGENT EQUIP CO LTD

Fractured surrounding rock roadway three-region coordinated and coupled supporting system and construction method thereof

Owner:HENAN POLYTECHNIC UNIV

Fabricated semi-active connection tunnel suitable for passing through fault fracture zone and method

Owner:SHANDONG UNIV

Multi-support cooperation method for controlling broken surrounding rock of coal mine

Owner:HUNAN UNIV OF SCI & TECH

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap