Tunnel inverted arch structure capable of resisting floor heave

An arch structure and tunnel technology, applied in tunnels, tunnel linings, shaft equipment and other directions, can solve the problems of small curvature of the inverted arch, can not effectively use the arch effect to resist buoyancy, etc. The effect of increasing the ability to resist buoyancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

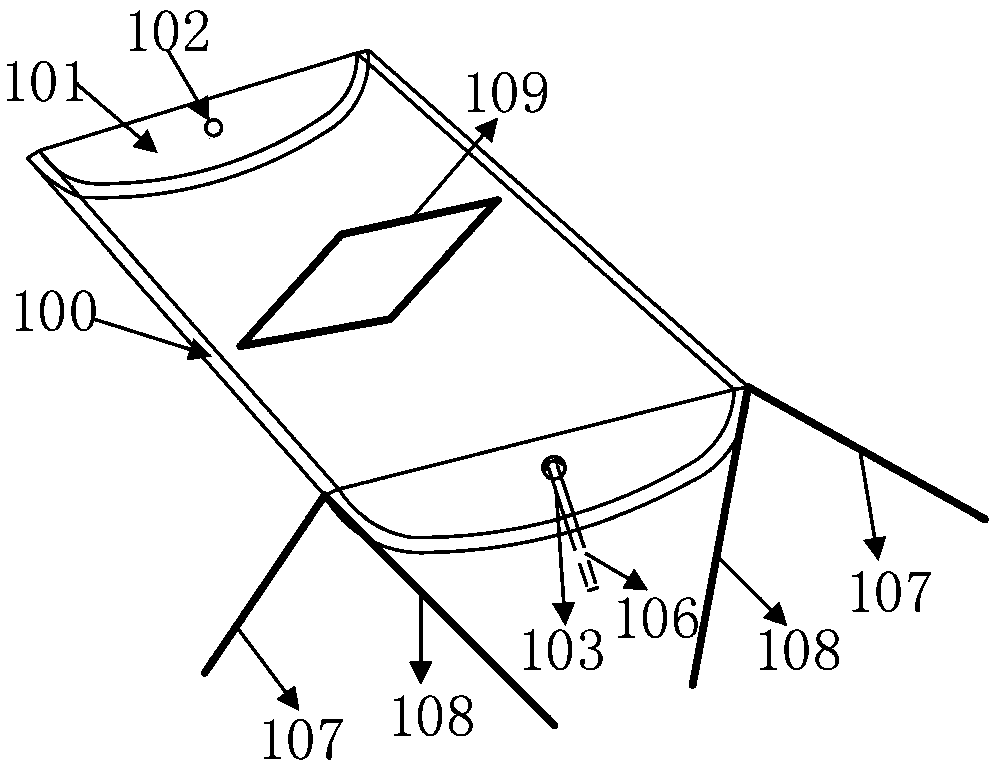

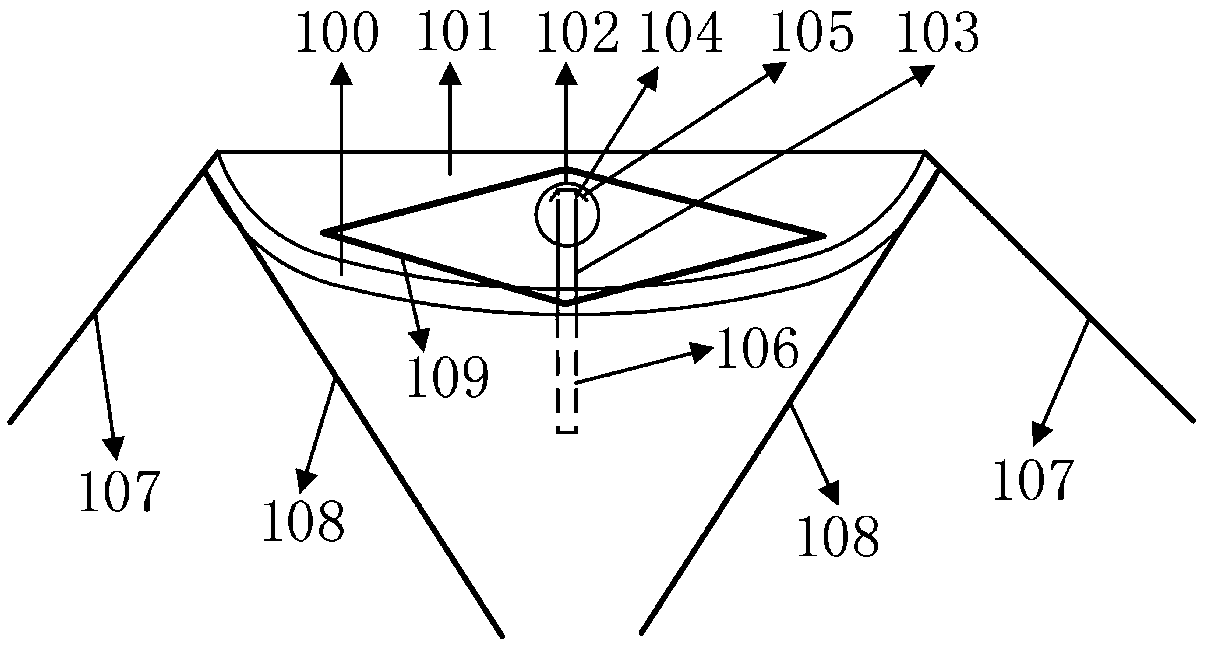

[0018] The bottom drum-resistant tunnel inverted arch structure involved in this embodiment mainly includes an inverted arch 100, an inverted arch filling 101, a drainage channel 102, a drain pipe 103, a water discharge port 104, an anti-water reverse adhesive strip 105, a water seepage hole 106, an arch Foot locking anchor rod 107, anti-floating anchor rod 108, diamond-shaped steel grid 109; drainage channel 102 is arranged longitudinally through the tunnel in the inverted arch filling 101, and the drainage channel 102 has a downward slope from the middle to both ends, so that the drainage channel The water in 102 is discharged to the outside of the tunnel; the drainage channel 102 is uniformly provided with a plurality of pressure relief pipes 103 along the longitudinal direction of the tunnel, one end of the pressure relief pipe 103 extends into the drainage channel 102, and the other end goes deep into the surrounding rock, so that the The high-pressure water is squeezed into

Embodiment 2

[0020] Such as figure 1 and figure 2 As shown, the anti-bass drum invert structure includes an invert 100 and an invert filling 101. The invert filling 101 is provided with a drainage channel 102, and the drainage channel 102 is arranged along the longitudinal length of the tunnel and has a certain slope, so as to To facilitate the water in the channel to drain out of the tunnel.

[0021] Specifically, the anti-floor invert structure also includes a drain pipe 103, which connects the surrounding rock and the drainage channel 102, and squeezes the high-pressure water in the surrounding rock into the drainage channel 102 to play the role of releasing water pressure. .

[0022] Specifically, the drain pipe 103 is provided with a drain port 104, and the drain hole 104 is located at the top of the drain pipe 103, close to the top of the drain channel 102, and discharges the high-pressure water infiltrated into the drain tube in the surrounding rock to the drain channel 102 in time.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap