Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

62results about "Machine part testing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

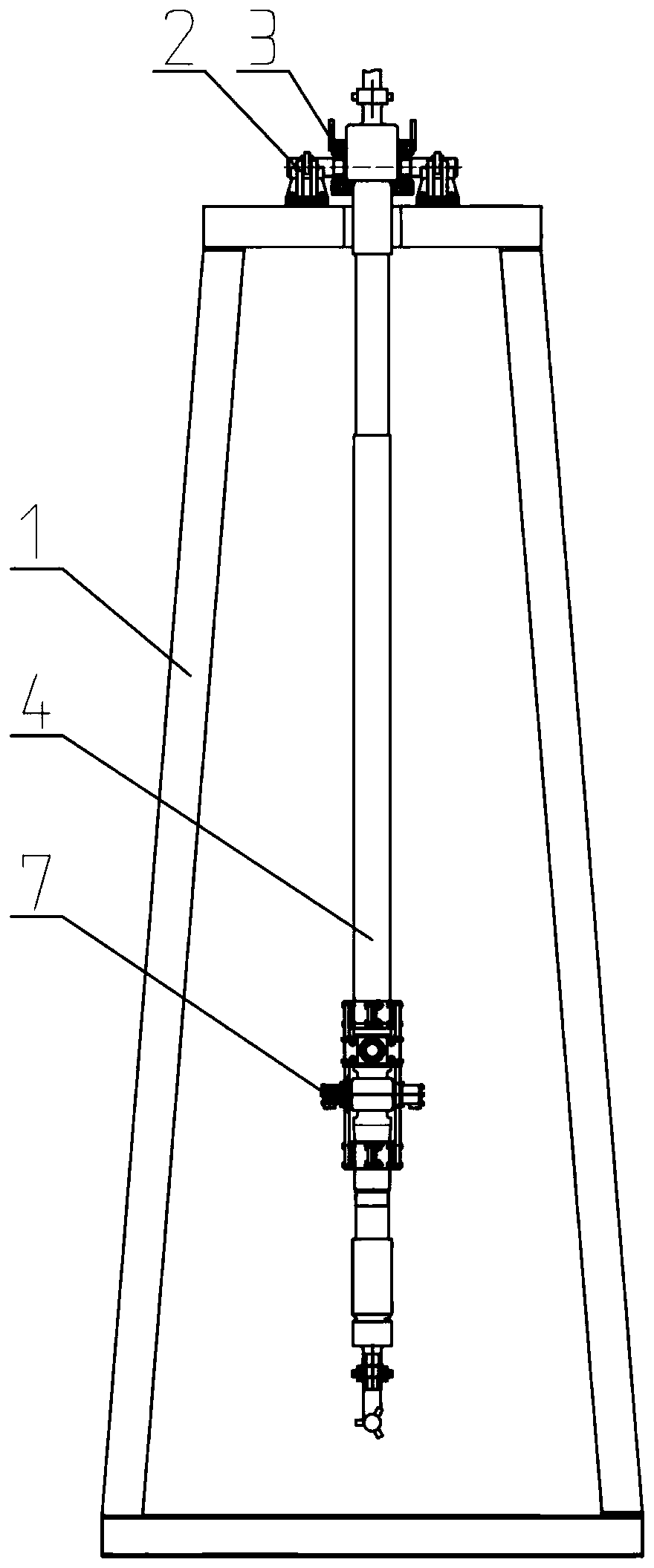

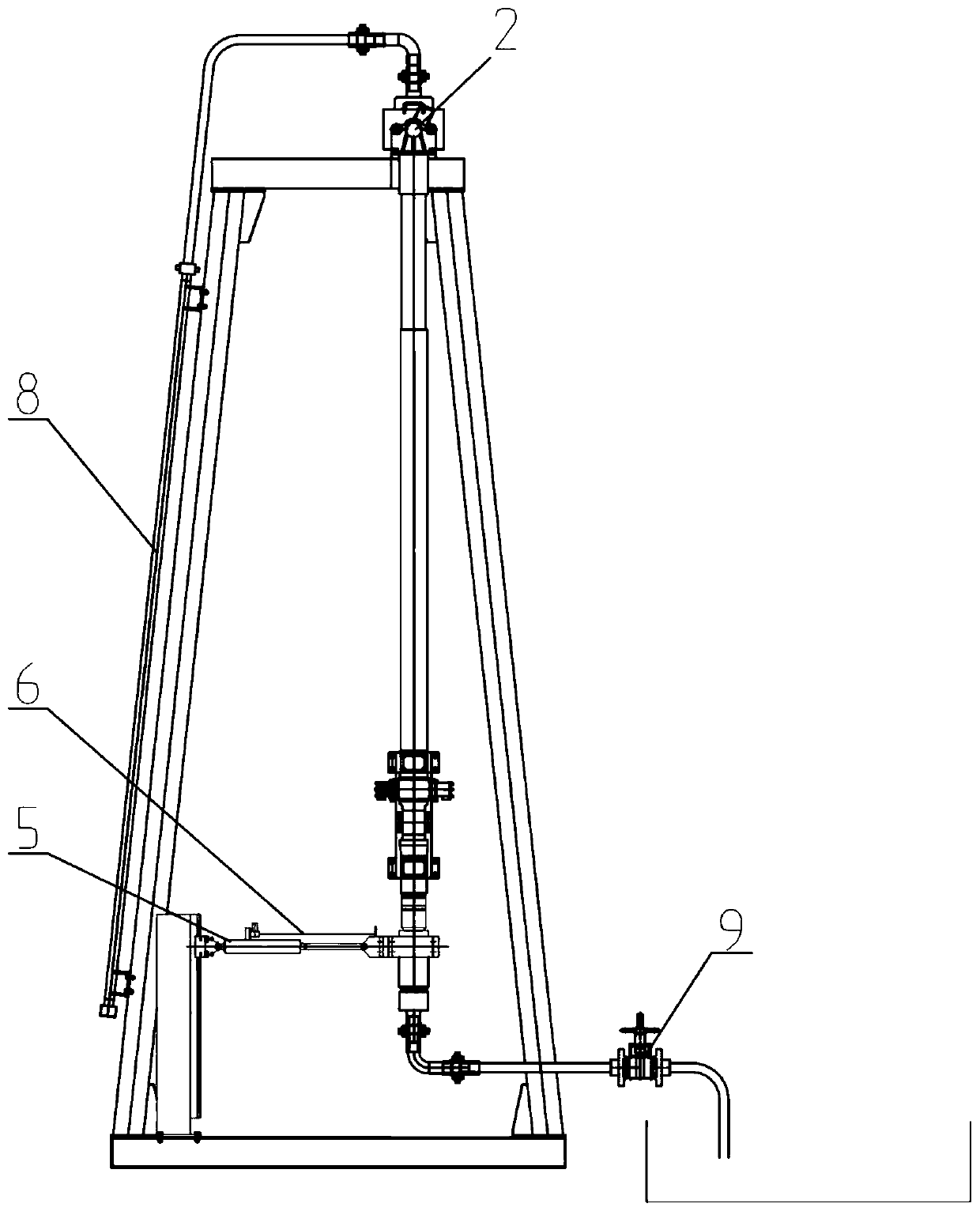

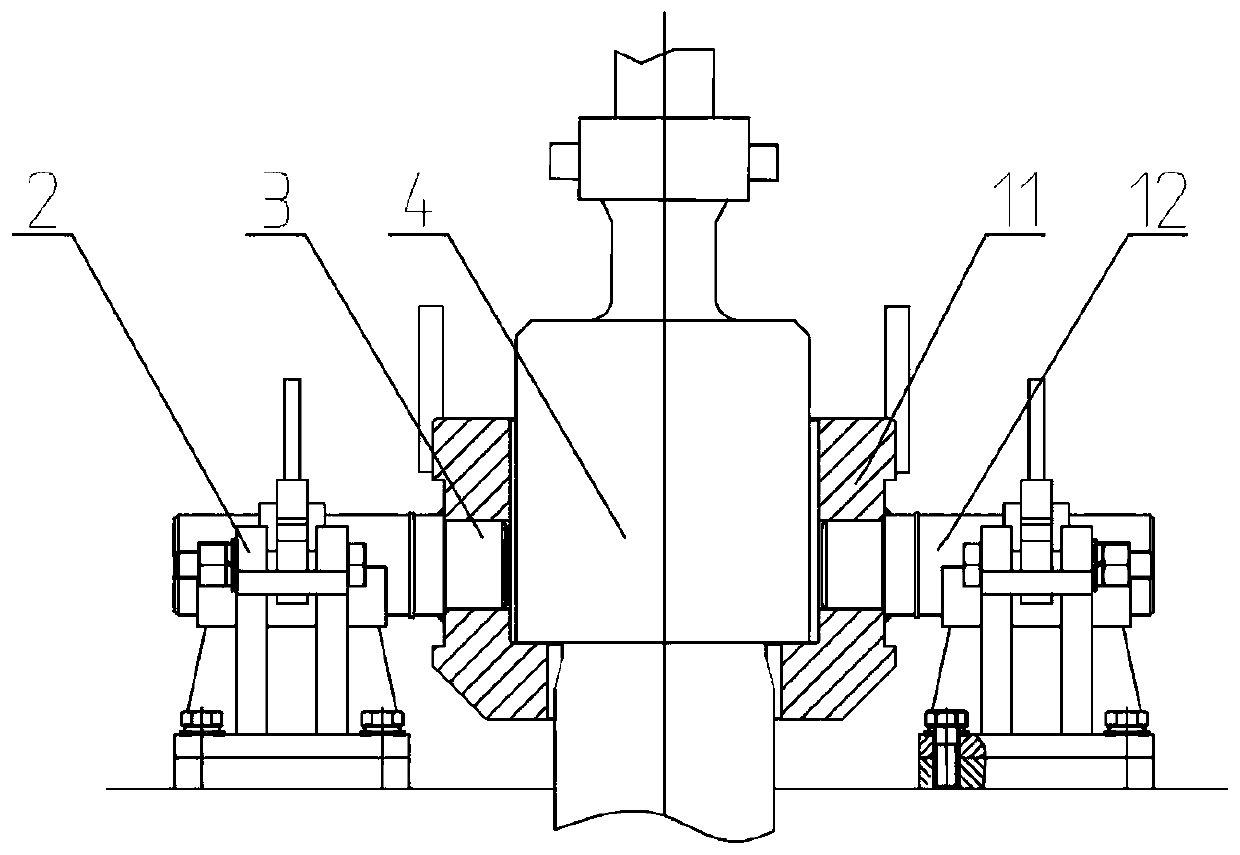

Screw drilling tool, vertical drilling tool testing method and well inclination simulation testing equipment

Owner:DEZHOU UNITED GASOLINEEUM MACHINERY

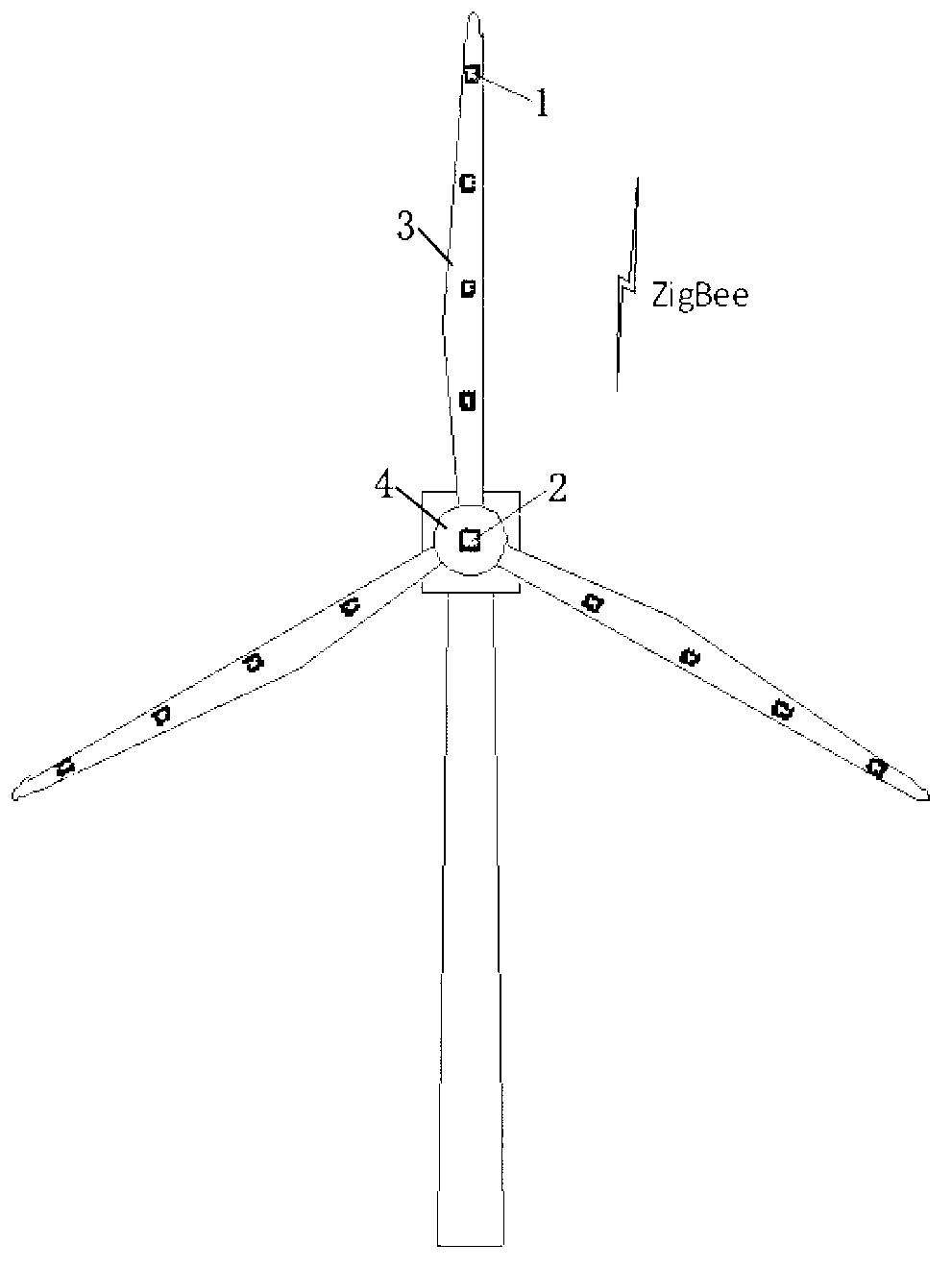

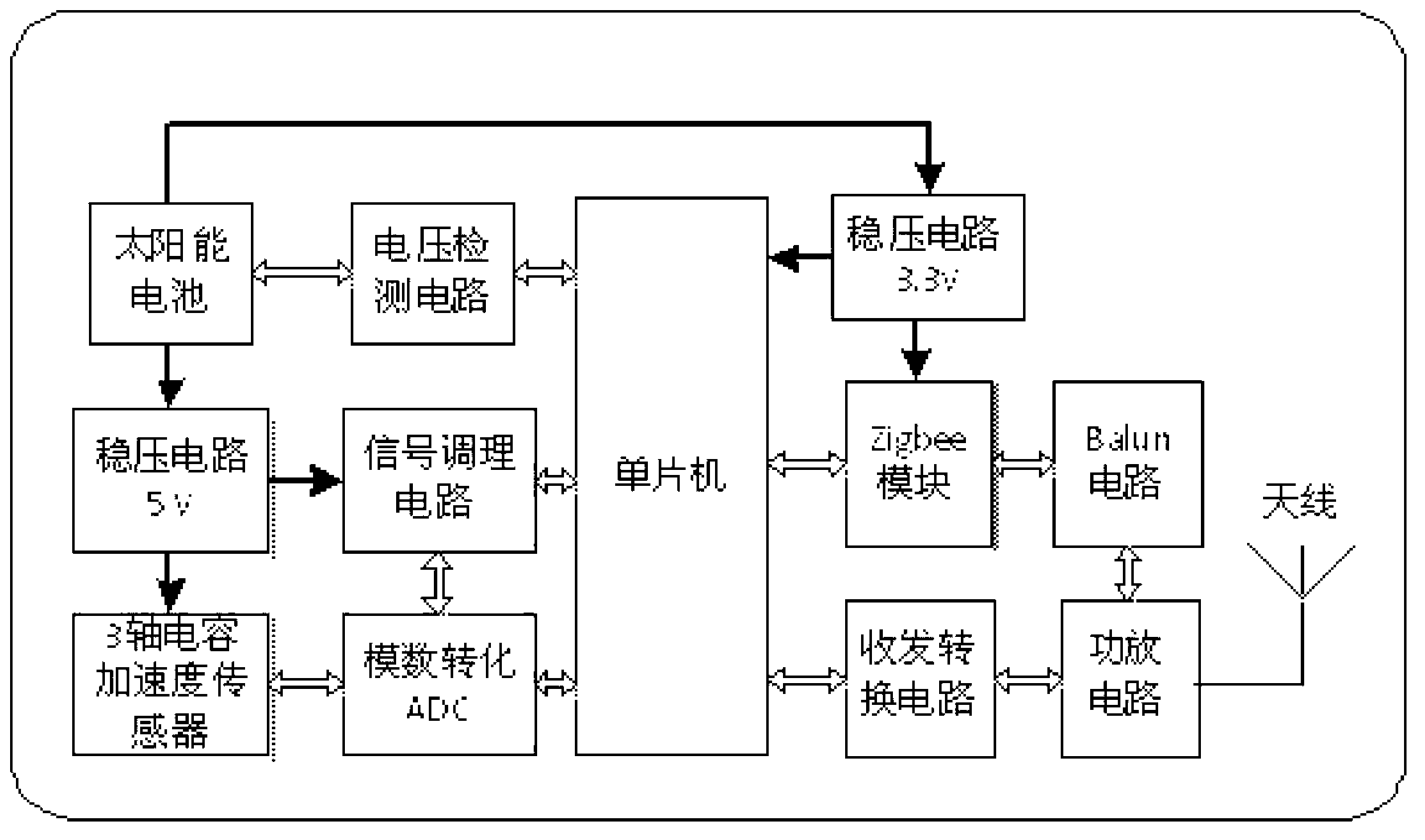

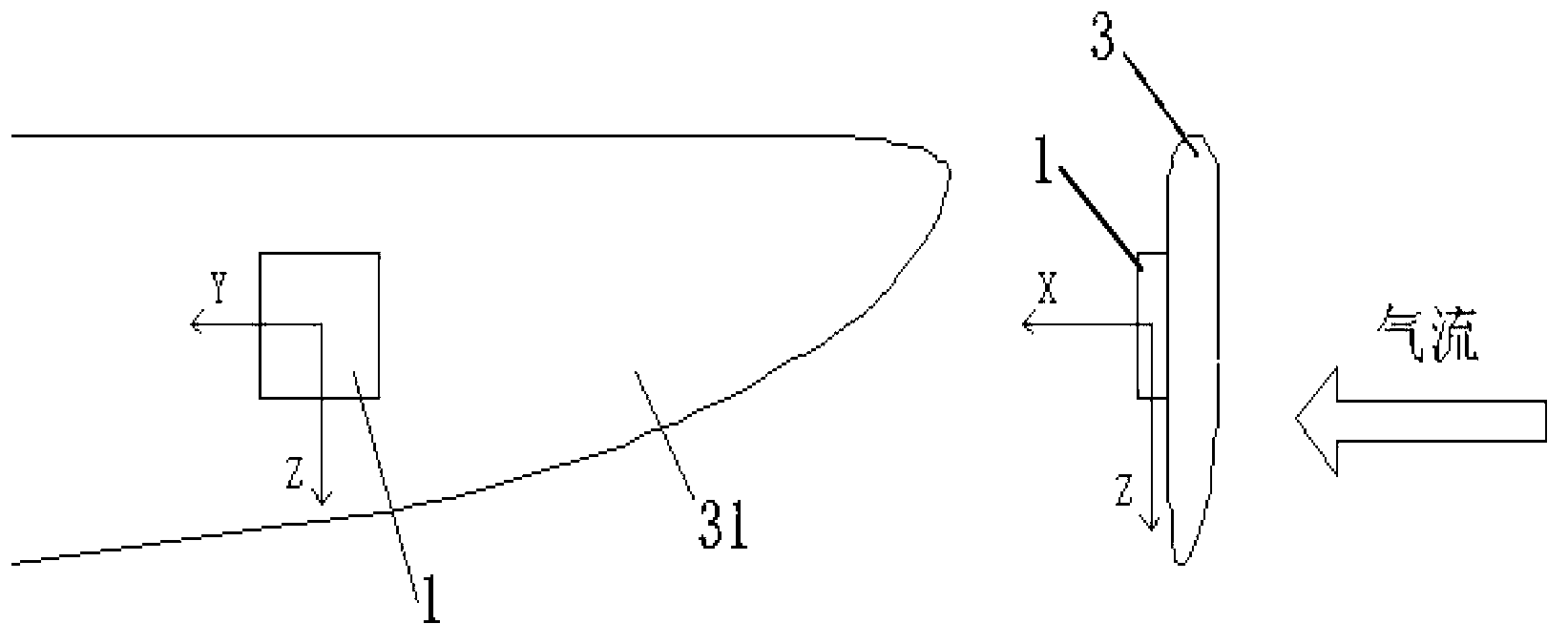

Wireless monitoring system and method for modal parameter of blade of fan

Owner:GUODIAN UNITED POWER TECH

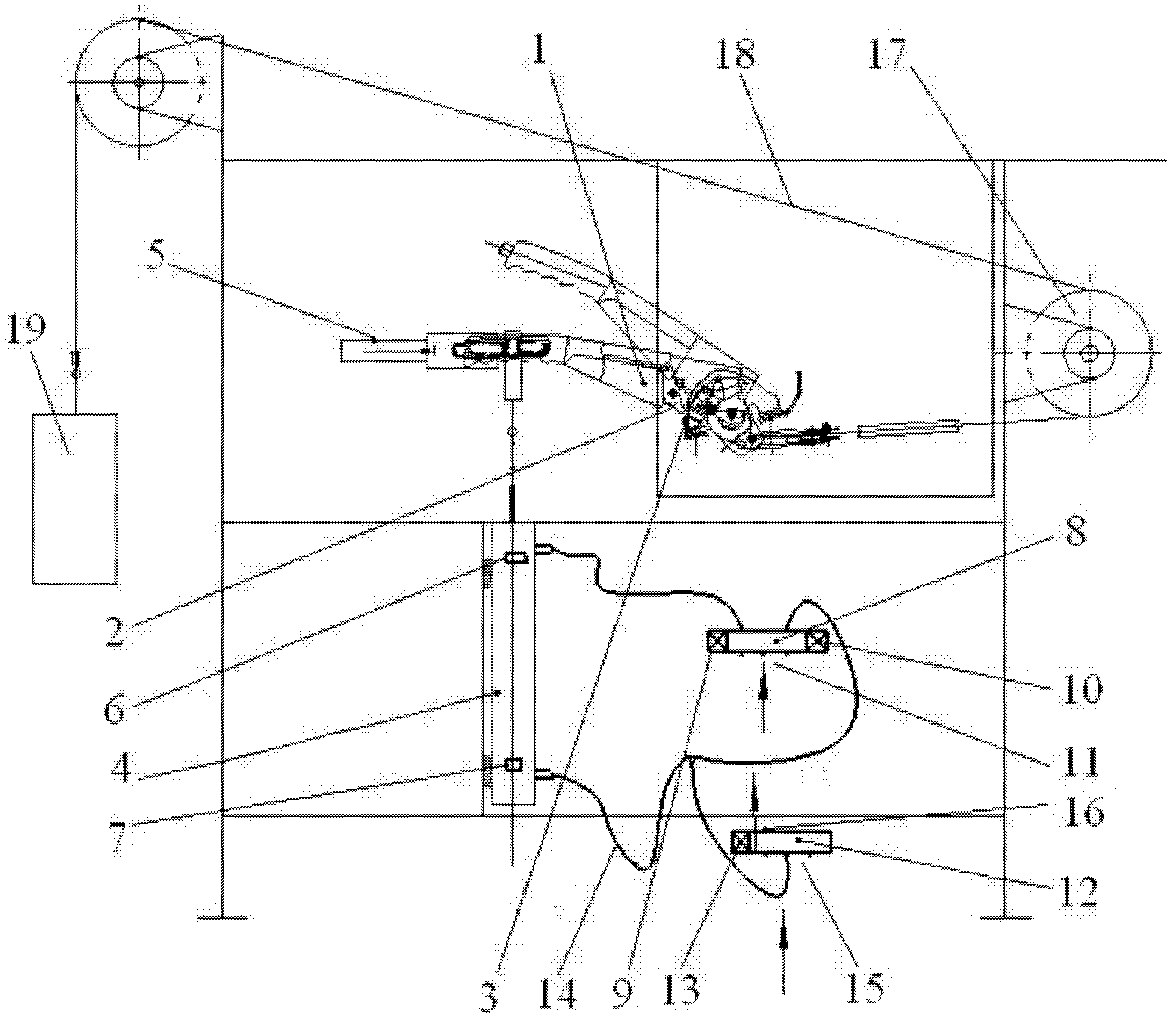

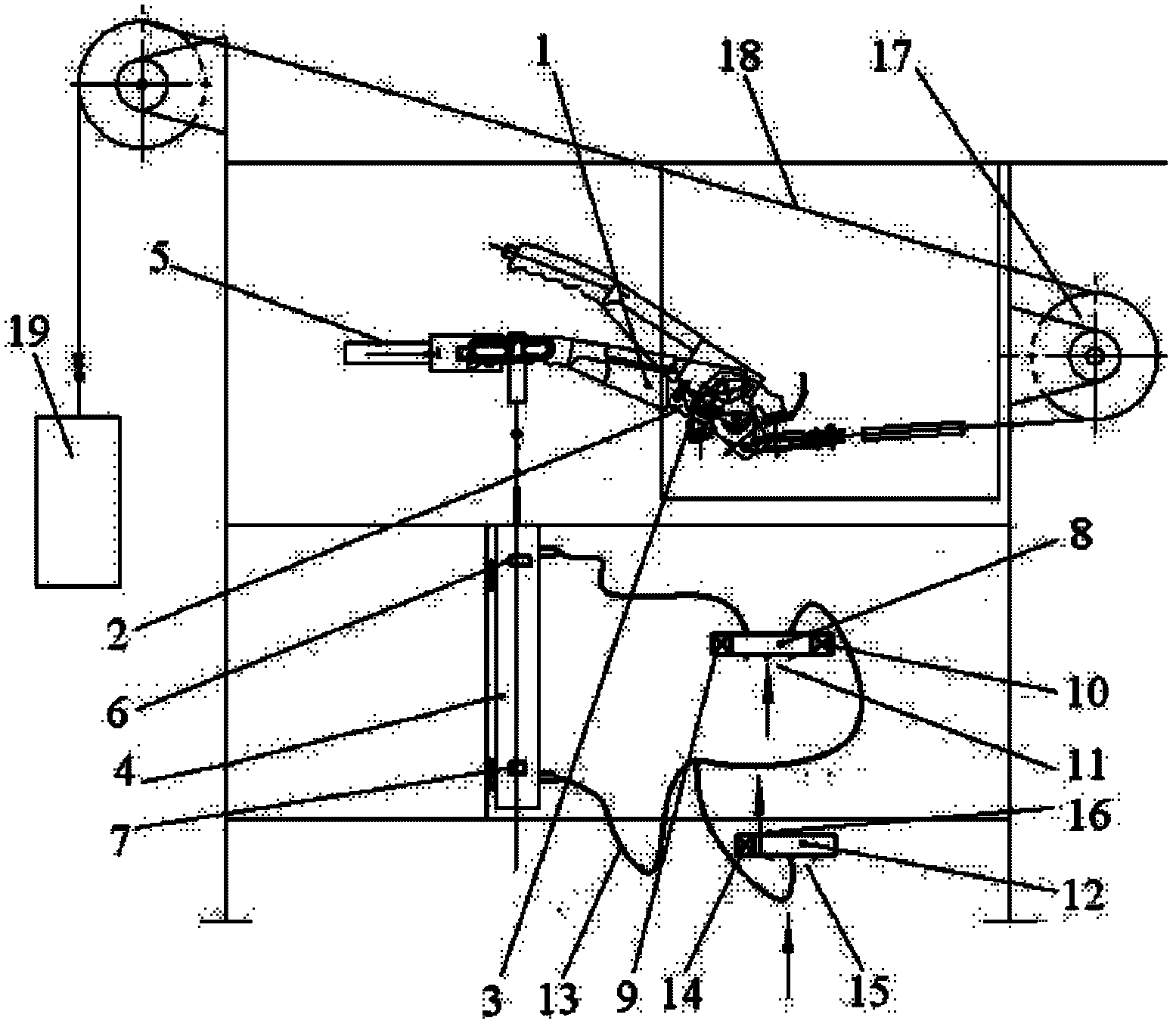

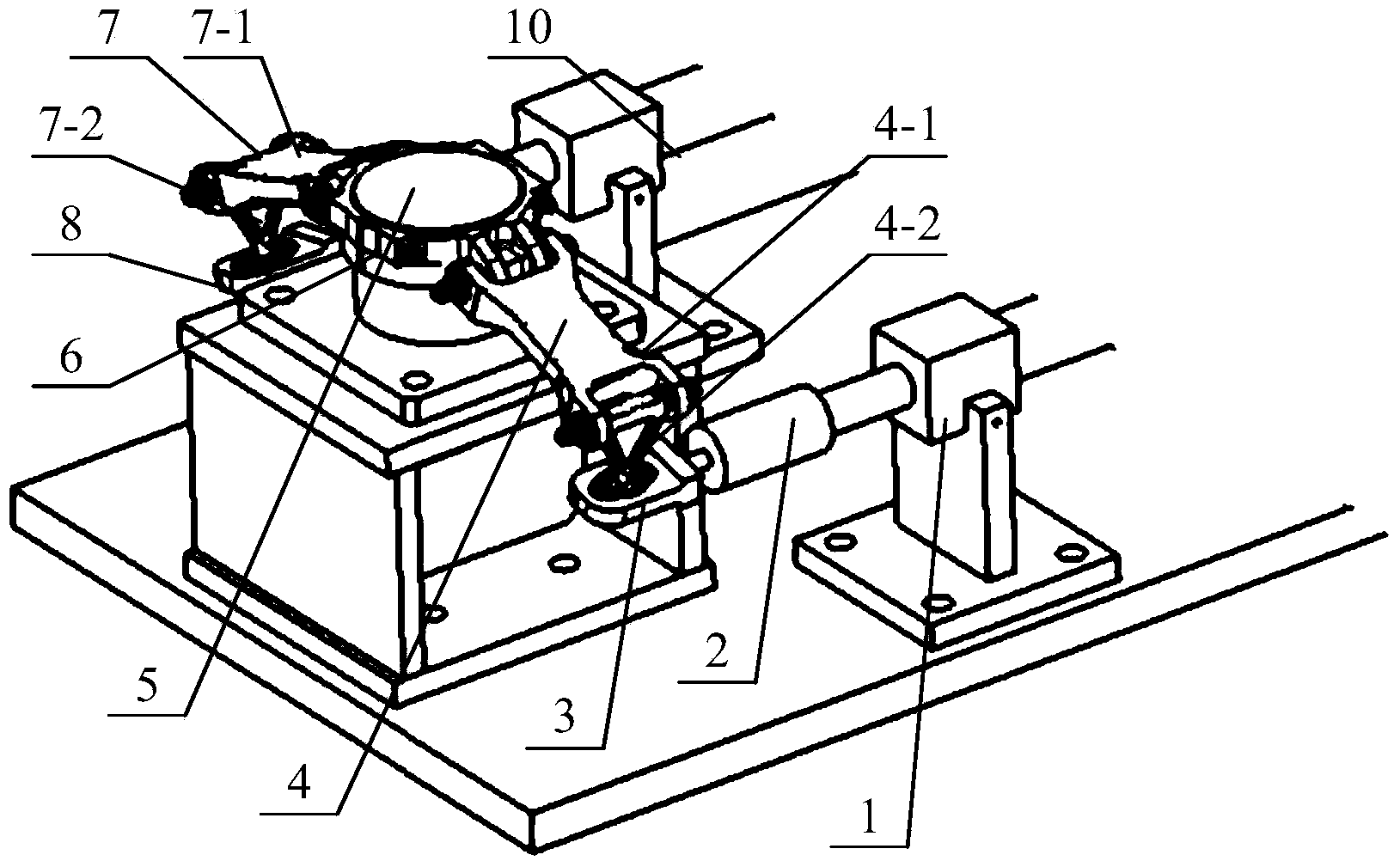

Automobile hand brake fatigue test rack

ActiveCN102426106AFlexible adjustment of loading timeImprove general performanceMachine part testingVehicle testingPoiseControl circuit

Owner:ANHUI DACHANG TECH

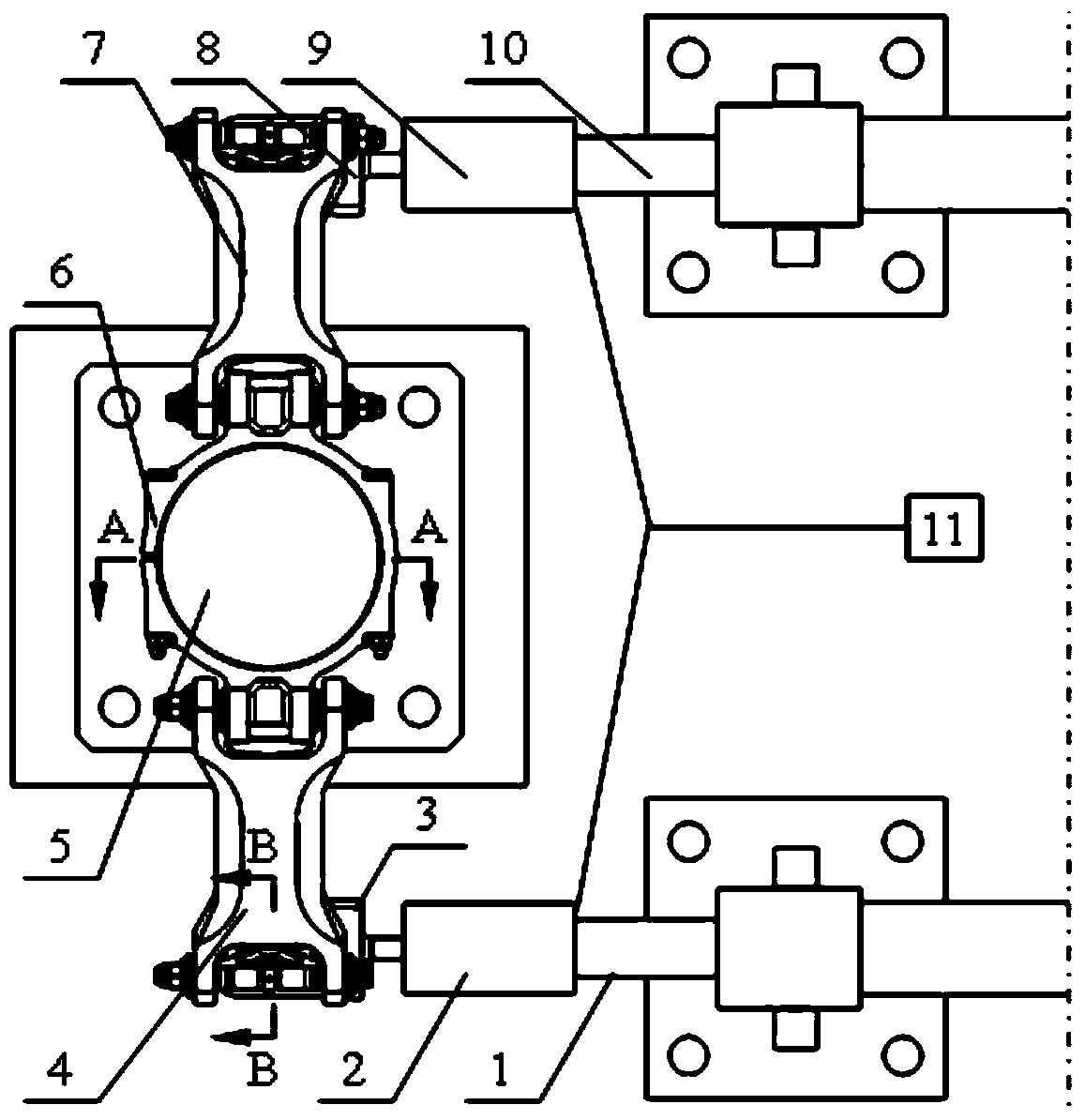

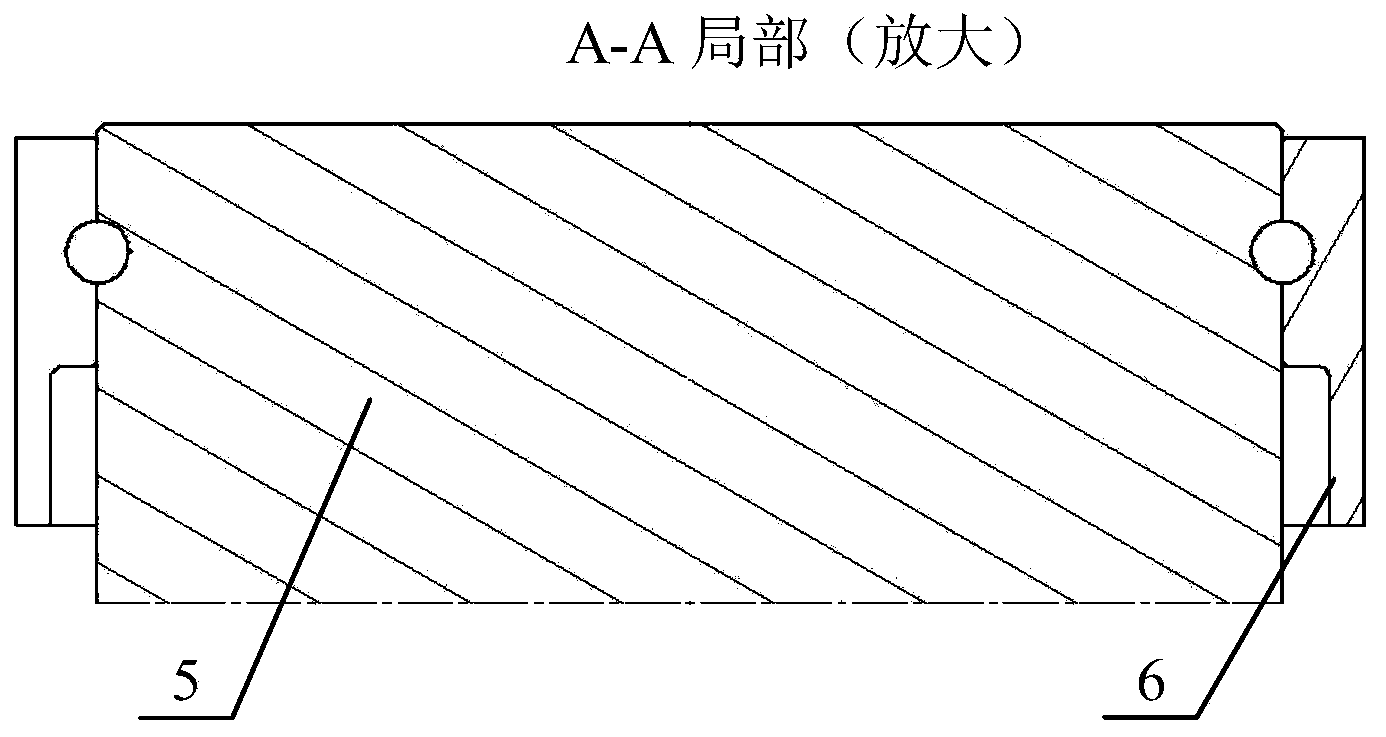

Fatigue test device for torque arm assembly

ActiveCN104236880ASimulate the realThe result is accurate and reliableMachine part testingStand/rackEngineering

Owner:CHINA HELICOPTER RES & DEV INST

Key-dialing switch testing device and testing method thereof

Owner:GUANGZHOU WEISI VEHICLE PART CO LTD

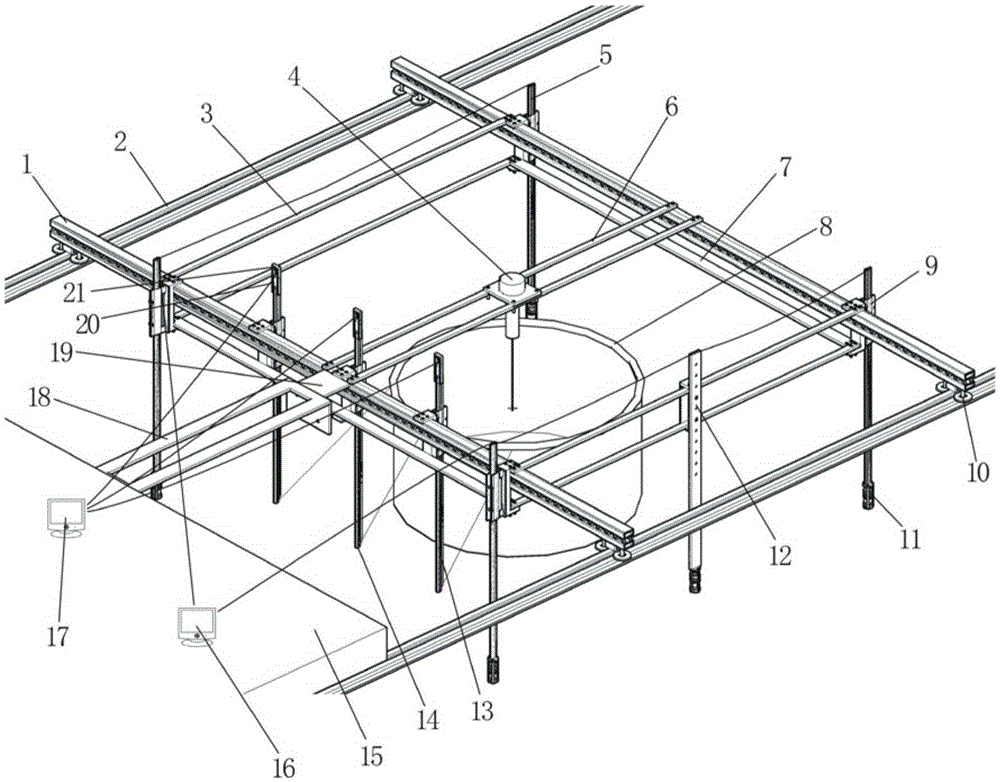

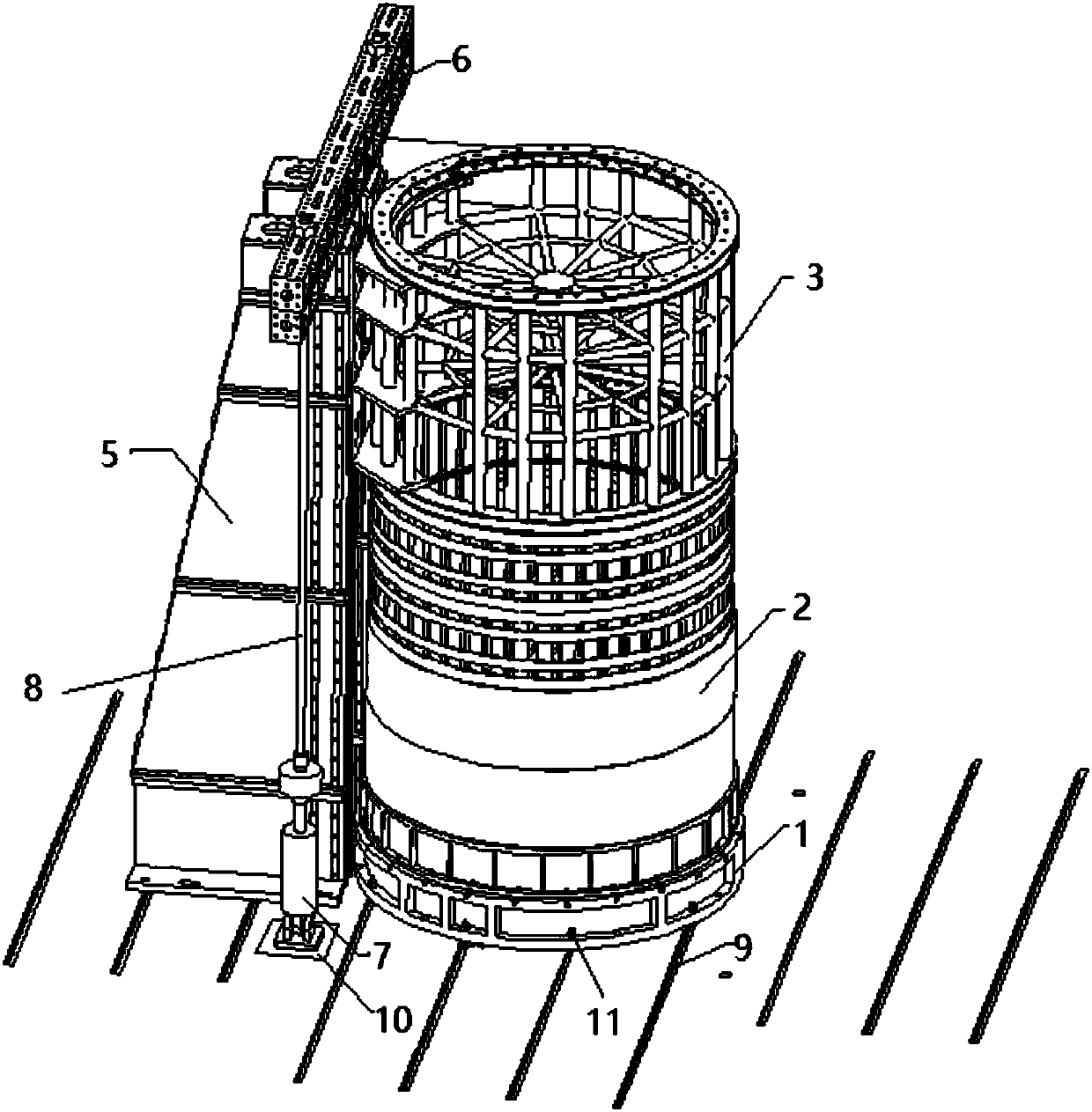

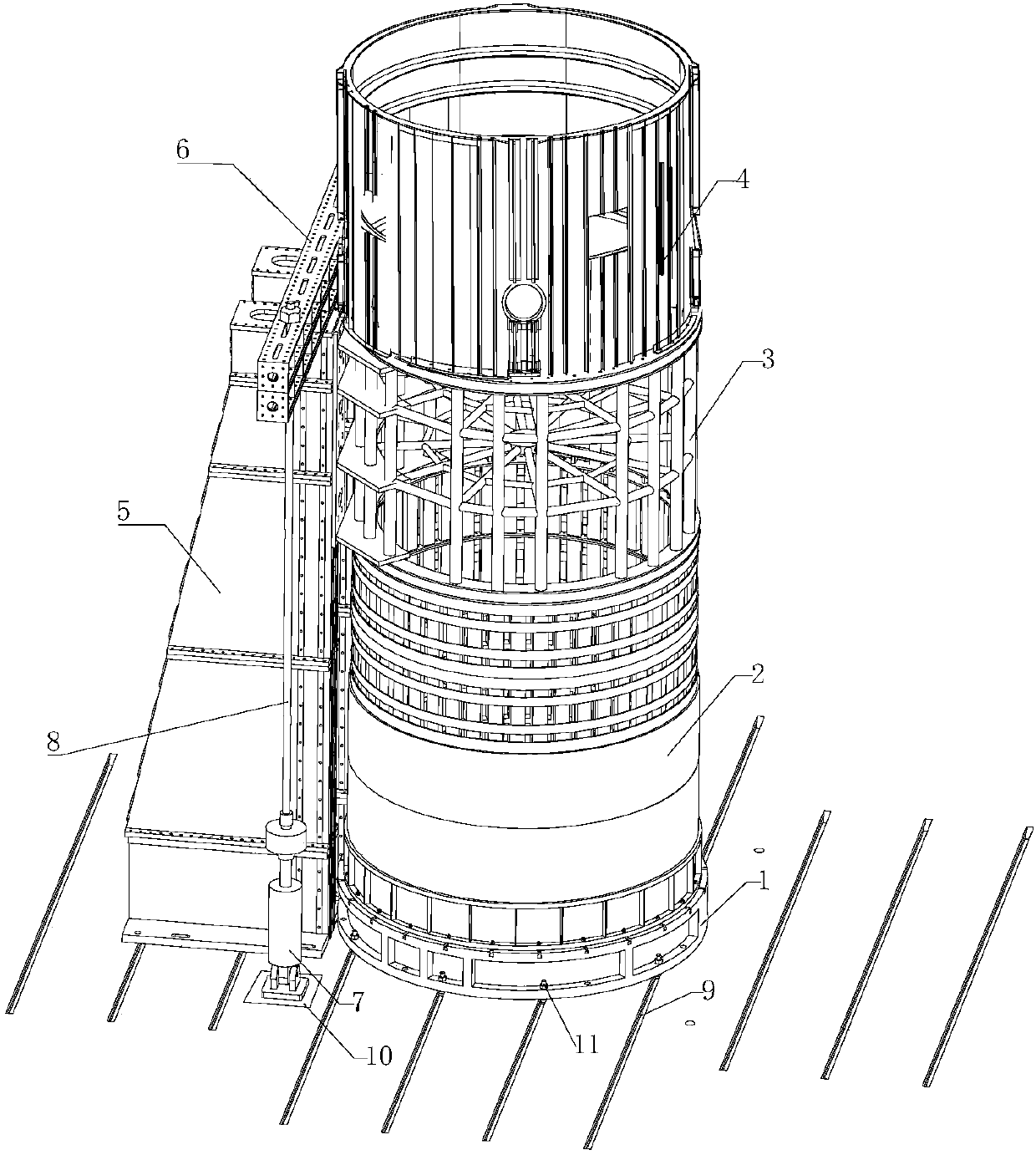

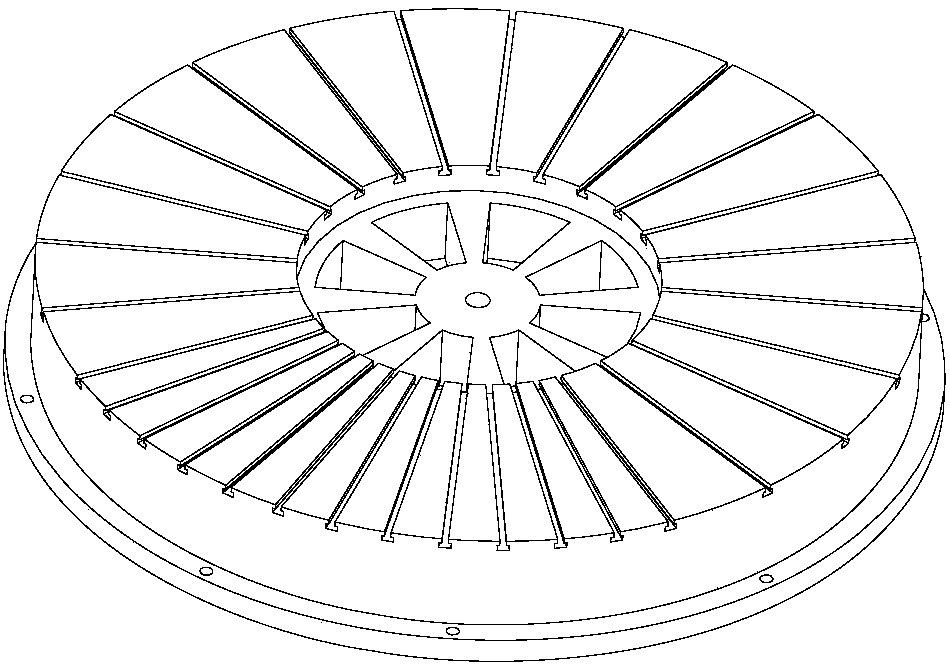

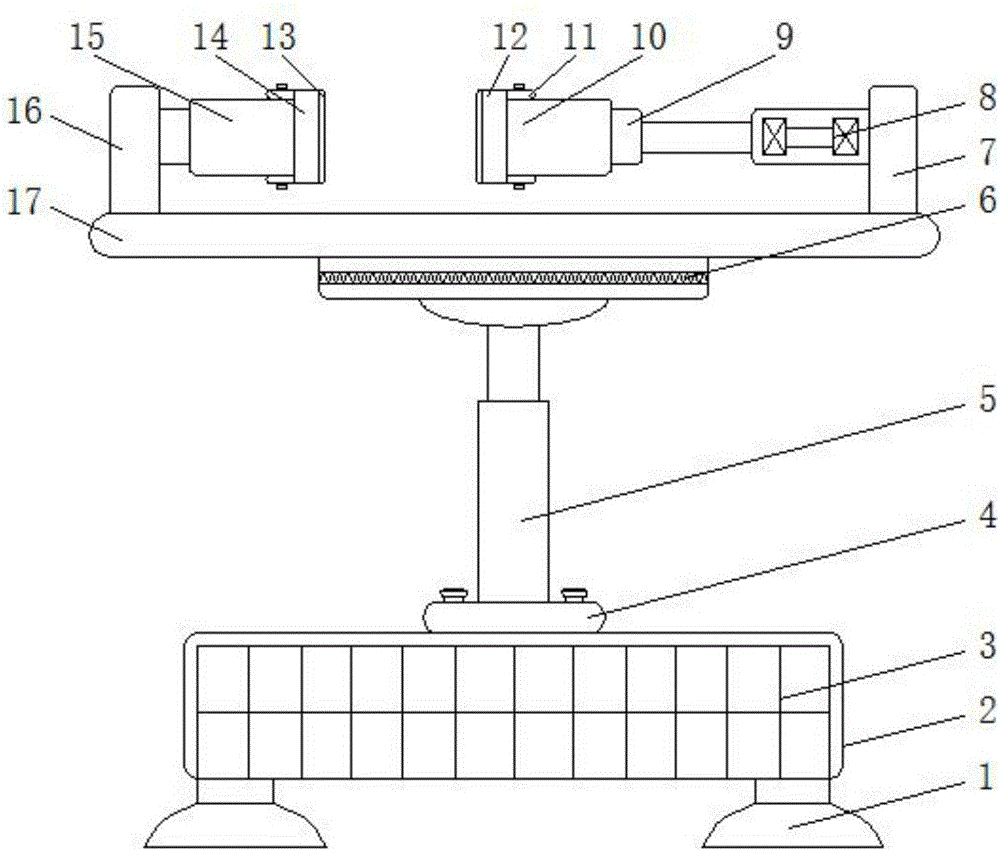

Net cage model test platform

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

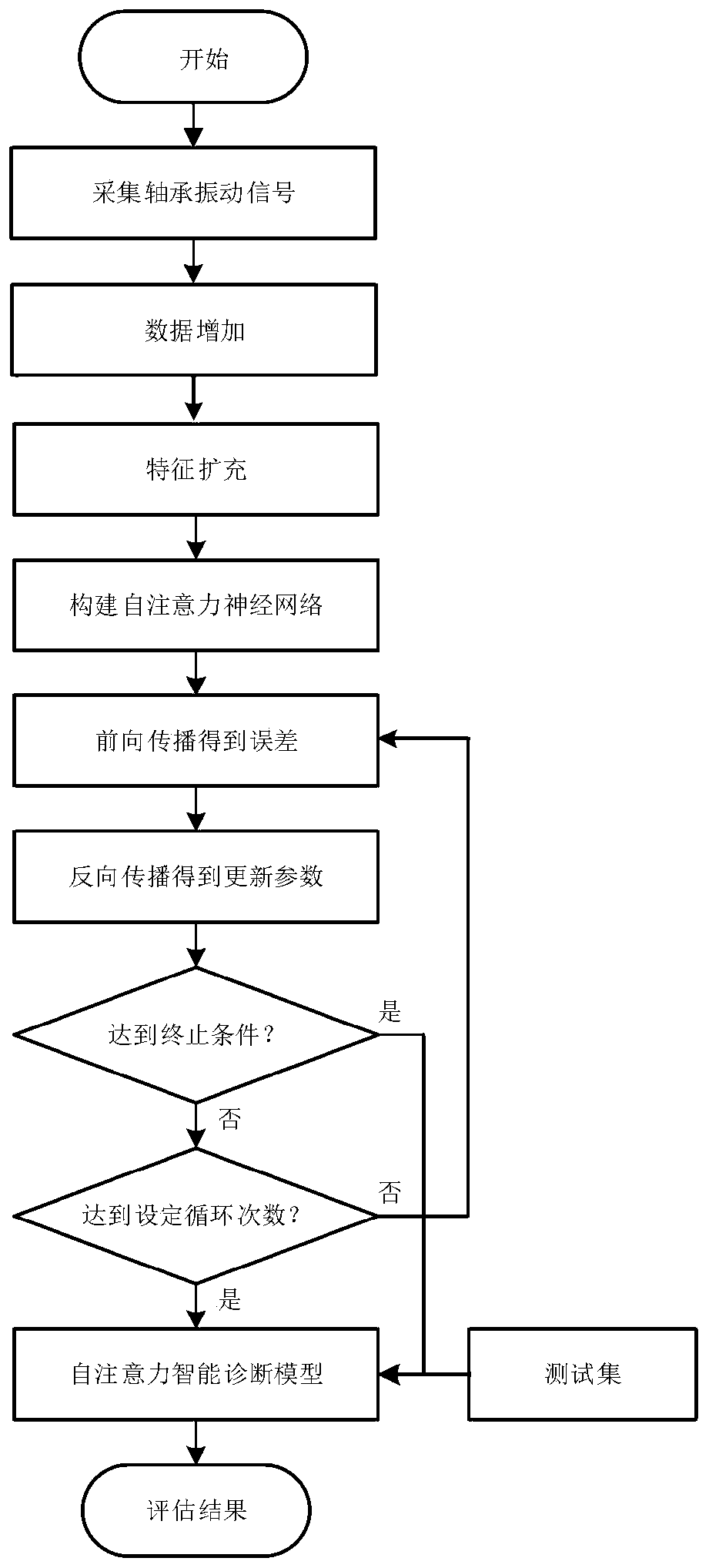

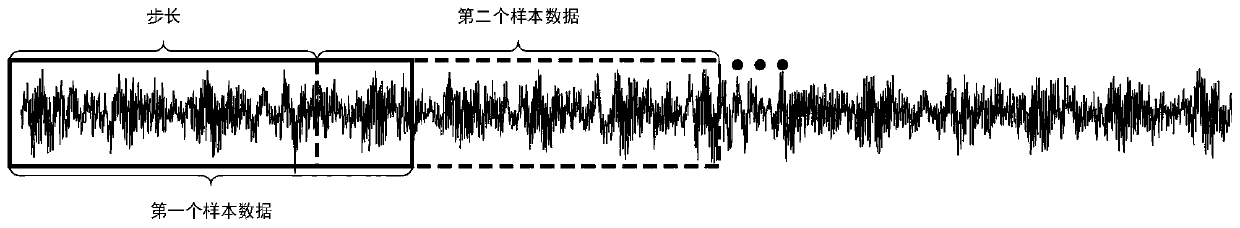

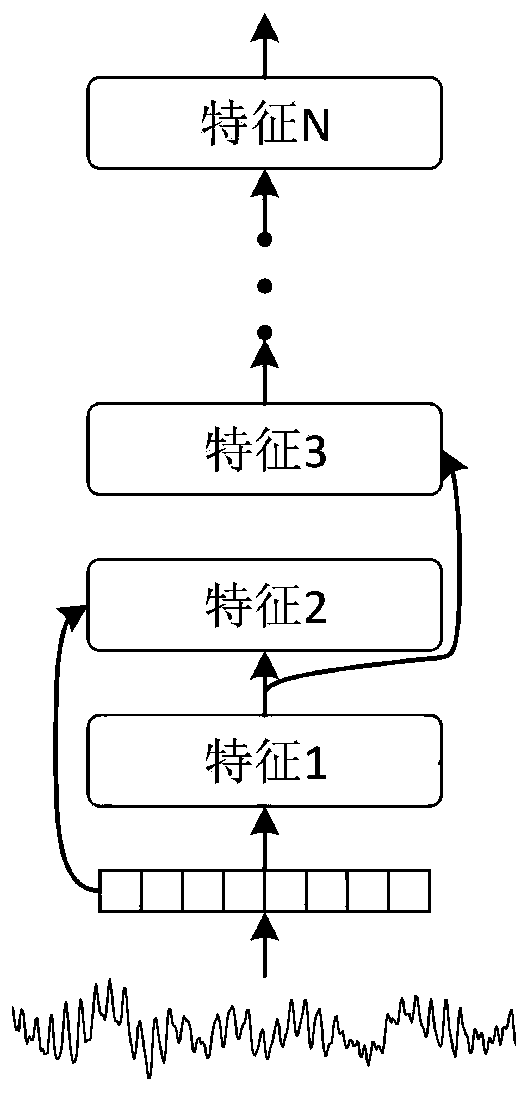

Method for diagnosing state of rolling bearing based on self-attention neural network

ActiveCN110608884AEasy to implementLow data volume requirementsMachine part testingNeural learning methodsSelf attentionVibration acceleration

Owner:GUILIN UNIV OF ELECTRONIC TECH

Constant rotation speed generating device for detecting elevator speed limiter tester

InactiveCN103935862AImprove work efficiencyIntuitive test resultsMachine part testingElevatorsMicrocontrollerLiquid-crystal display

The invention relates to a constant rotation speed generating device for detecting an elevator speed limiter tester. The constant rotation speed generating device mainly comprises a stepped motor control module, a microcontroller, a liquid crystal display module, a keyboard management module, a printer module and a communication module. The constant rotation speed generating device has an automatic testing work mode and a manual testing work mode, if the automatic testing work mode is selected, a plurality of rotation speed values can be set in one time of measurement, and when the set rotation speeds are generated, the set rotation speeds can be automatically and sequentially generated; if the manual testing work mode is selected, only rotation speed value can be set in one time. The constant rotation speed generating device further has the ability of communicating with a PC, the PC can be used for collecting and displaying the speed of the constant rotation speed generating device, and the constant rotation speed generating device has the advantages of being high in measuring precision, simple in structure, convenient to operate, and the like.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

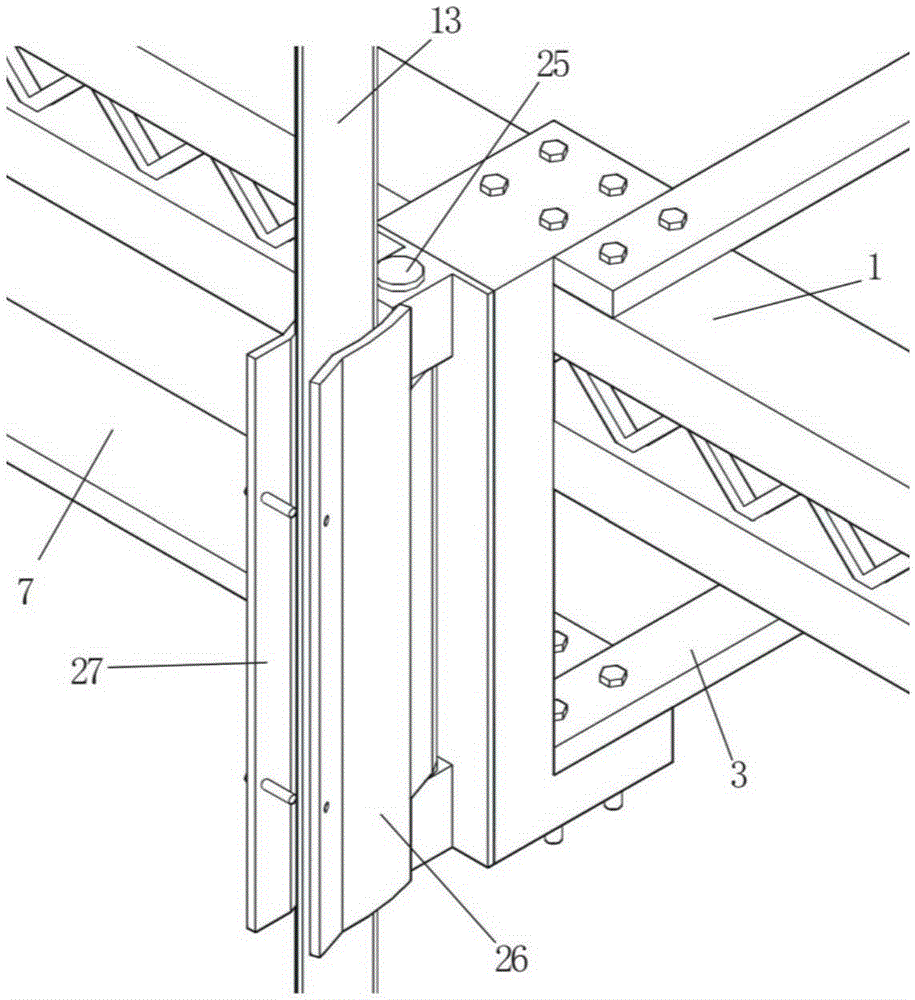

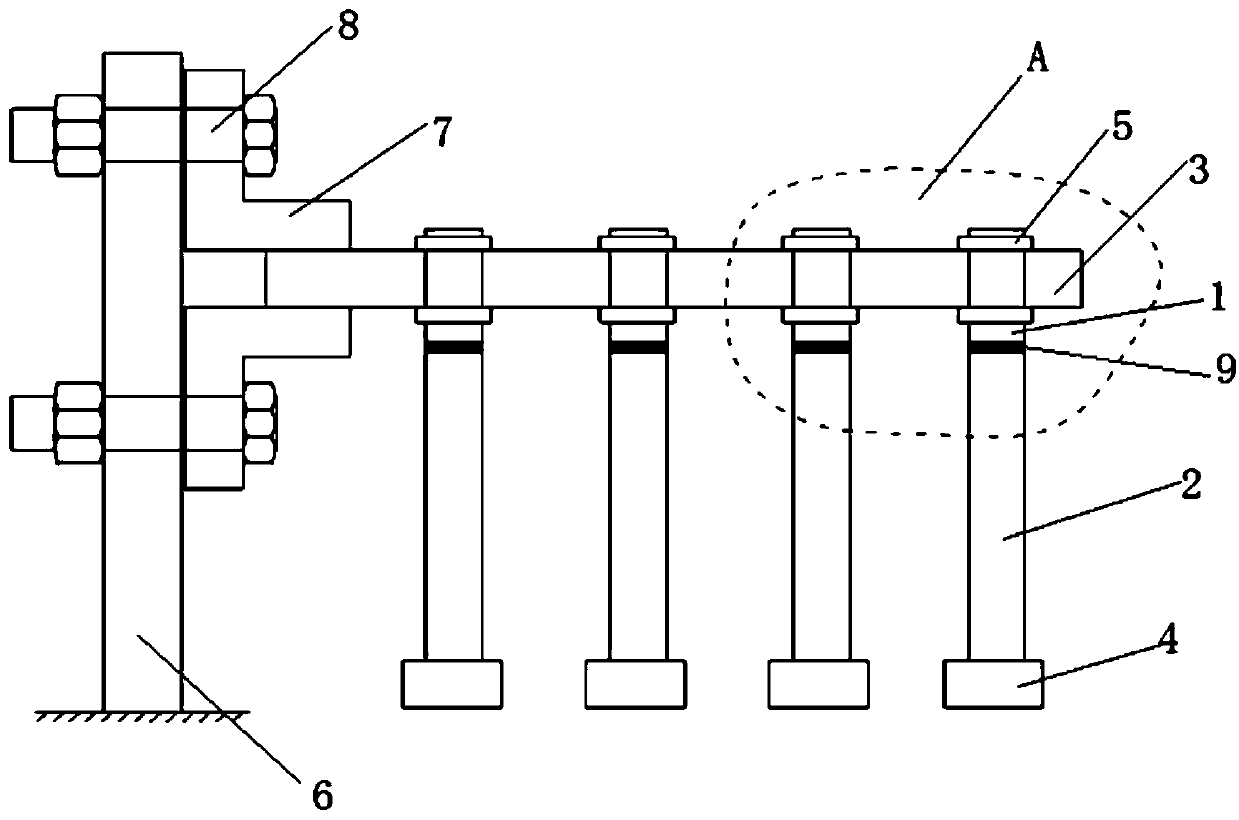

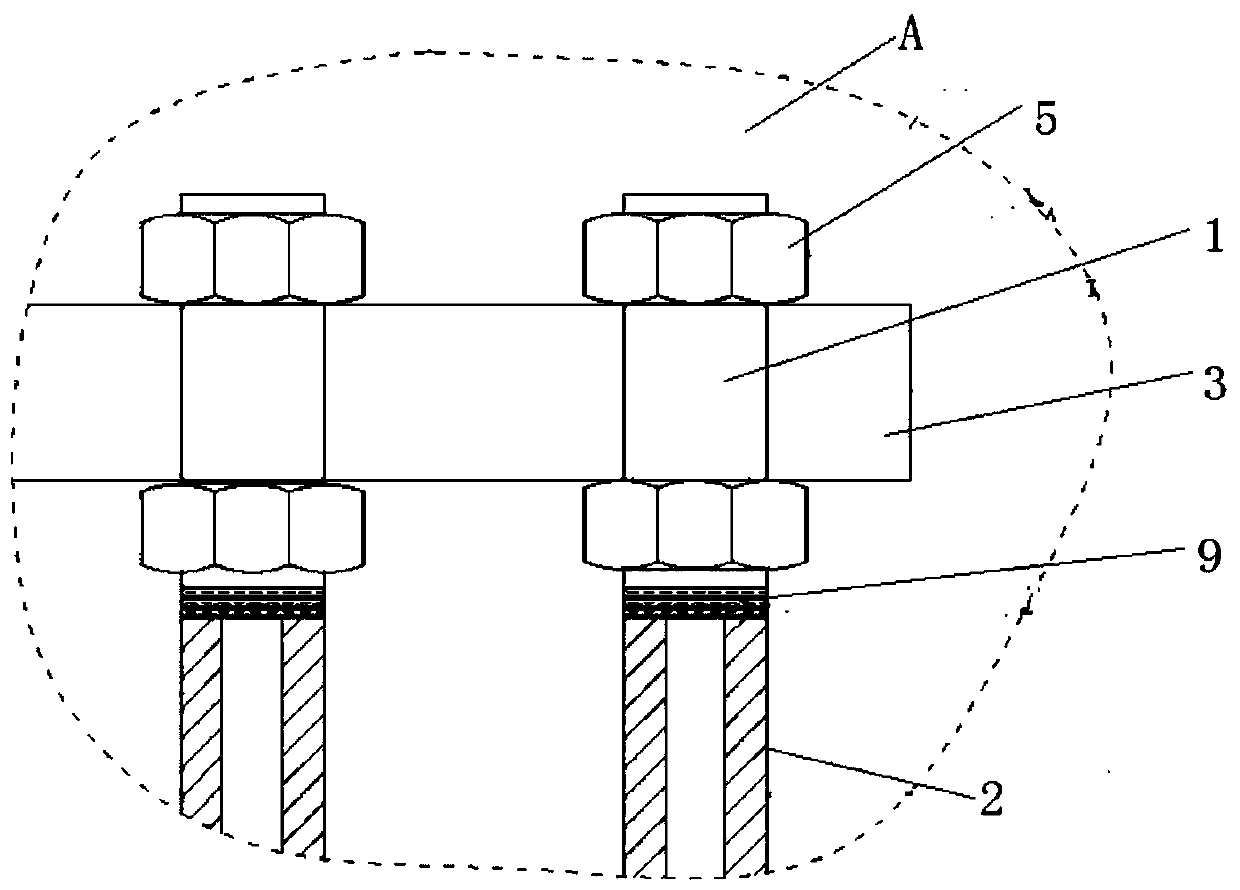

Energy dissipation property testing device of bolting connection part, testing method and molding method

ActiveCN106768943AReduce the numberGuaranteed Energy Dissipation CharacteristicsMachine part testingEngineeringTest fixture

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

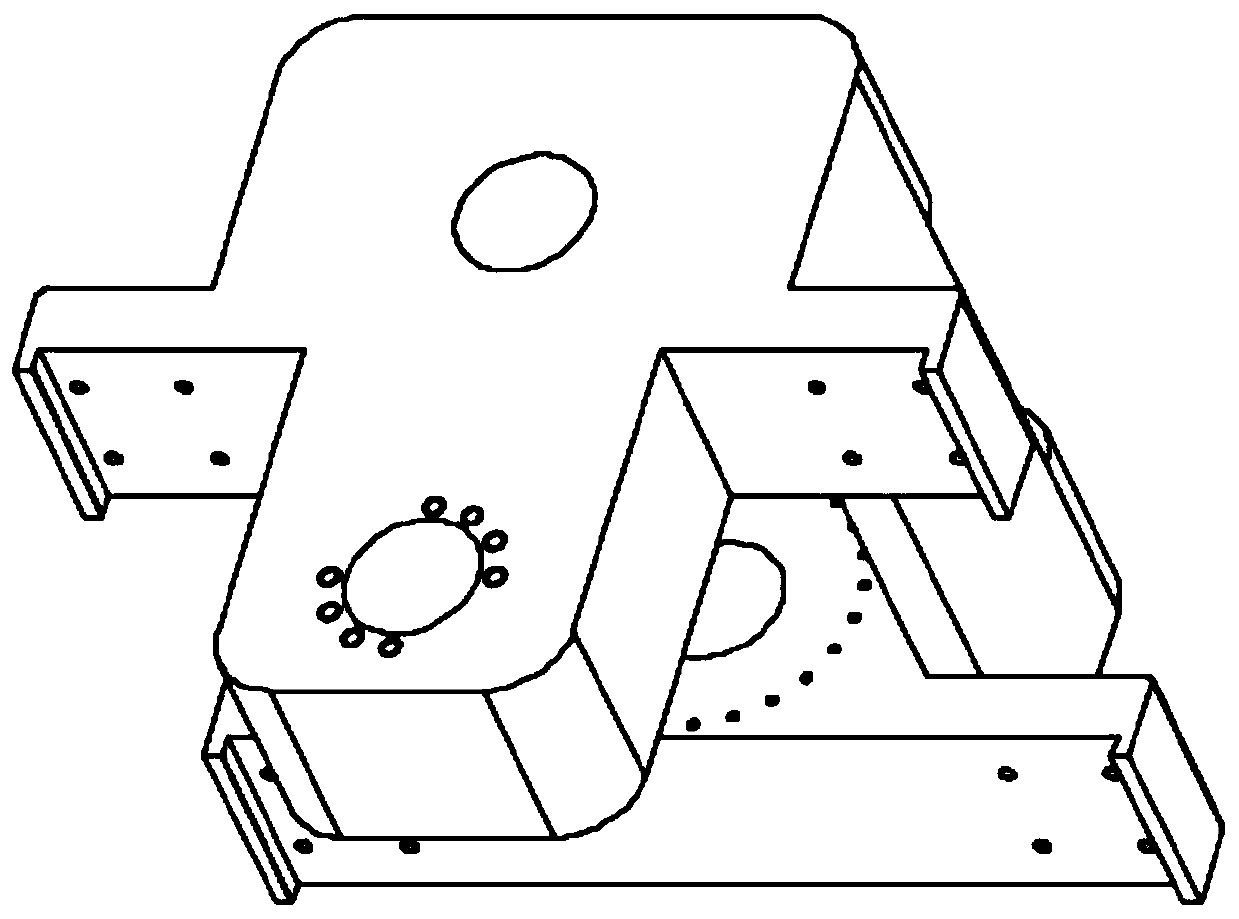

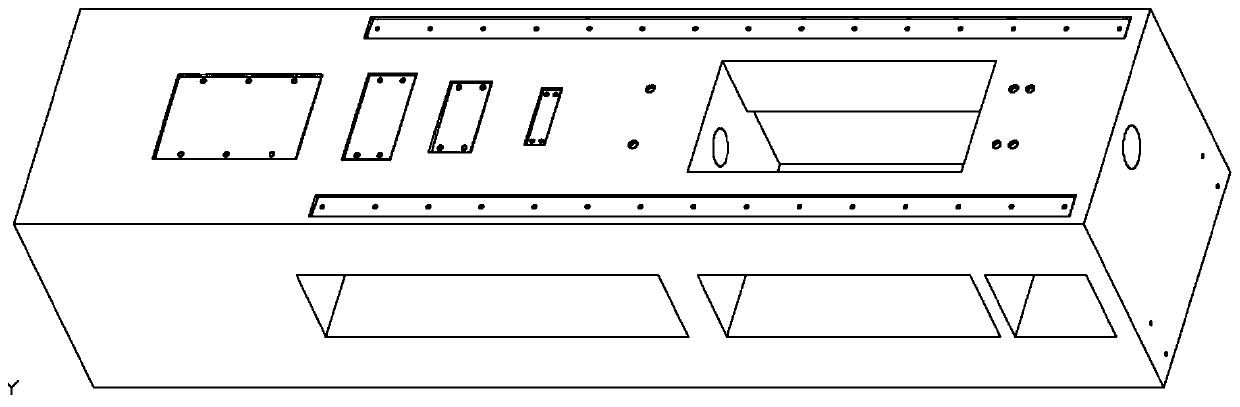

Universal fixture for highly accelerated centrifugal test of large dual-in-line devices

The invention discloses a universal fixture for highly accelerated centrifugal test of large dual-in-line devices, for the field of test equipment. The universal fixture comprises a base plate, sliders, a guide bar, a clamping slot and magnetic rubber pieces. The fixture has two degrees of freedom based on its sliding and expansion, can be regulated freely within a certain range according to outline dimensions of large dual-in-line devices of different length and width to meet clamping requirements of most dual-in-line devices, and thus, the universality of the fixture is improved greatly, full matching between the fixture and a tested device is guaranteed, problems such as low test efficiency, failure in sealing, cracking of device tubes and shells and high cost caused by poor universality of the fixture can be avoided, and the whole design is of skillful technical thought and simple structure and is economic and efficient.

Owner:NO 24 RES INST OF CETC

Intelligent manufacturing luggage pull rod detection device

InactiveCN112197946AEfficient screeningTo achieve the function of removing odorMachine part testingLiquid spraying apparatusEngineeringFixed position

The invention relates to the technical field of leather luggage, and discloses an intelligent manufacturing luggage pull rod detection device which comprises a steering valve, the steering valve is connected with a fixing device, the surface of a main body frame is fixedly connected with a pressed block, the top of the main body frame is fixedly connected with a bearing rod, and the bearing rod isconnected with a stretching device. The tension rod is connected with a deodorant spraying device; according to the luggage pull rod detection device, after a luggage reaches a fixed position, an airvalve is opened, compressed air enters the cylinder body through the steering valve, the compressed air pushes the piston rod to press the pull rod between the pressed block and a piezoelectric block, and at the moment, a piezoelectric contact is pressed to be in contact with the piezoelectric block, so that current is switched on, and a screw rod starts to rotate; the screw rod moves to drive astretching mechanism to move, so that the pull rod is driven to do stretching motion, if the phenomenon of jamming or jamming occurs in the process, an induction alarm connected with a screw rod moving block gives an alarm for prompting, and therefore, unqualified products are effectively screened out.

Owner:李帮建

Automatic circulation impact fatigue test device

PendingCN113820119AMachine part testingMaterial strength using repeated/pulsating forcesEngineeringImpact

Owner:NORTHWESTERN POLYTECHNICAL UNIV

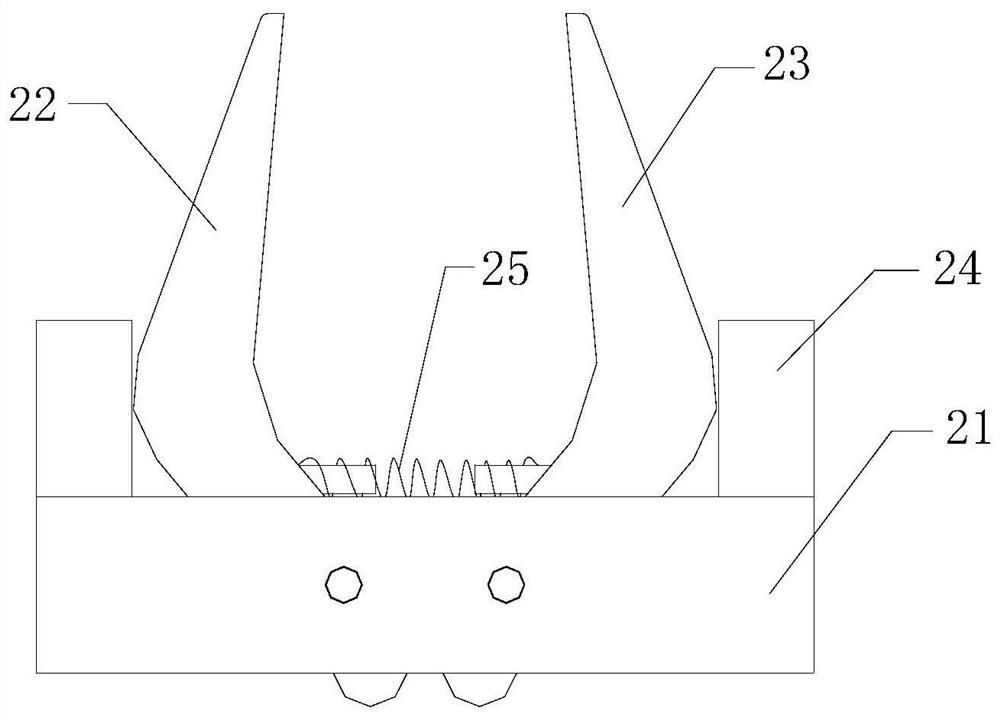

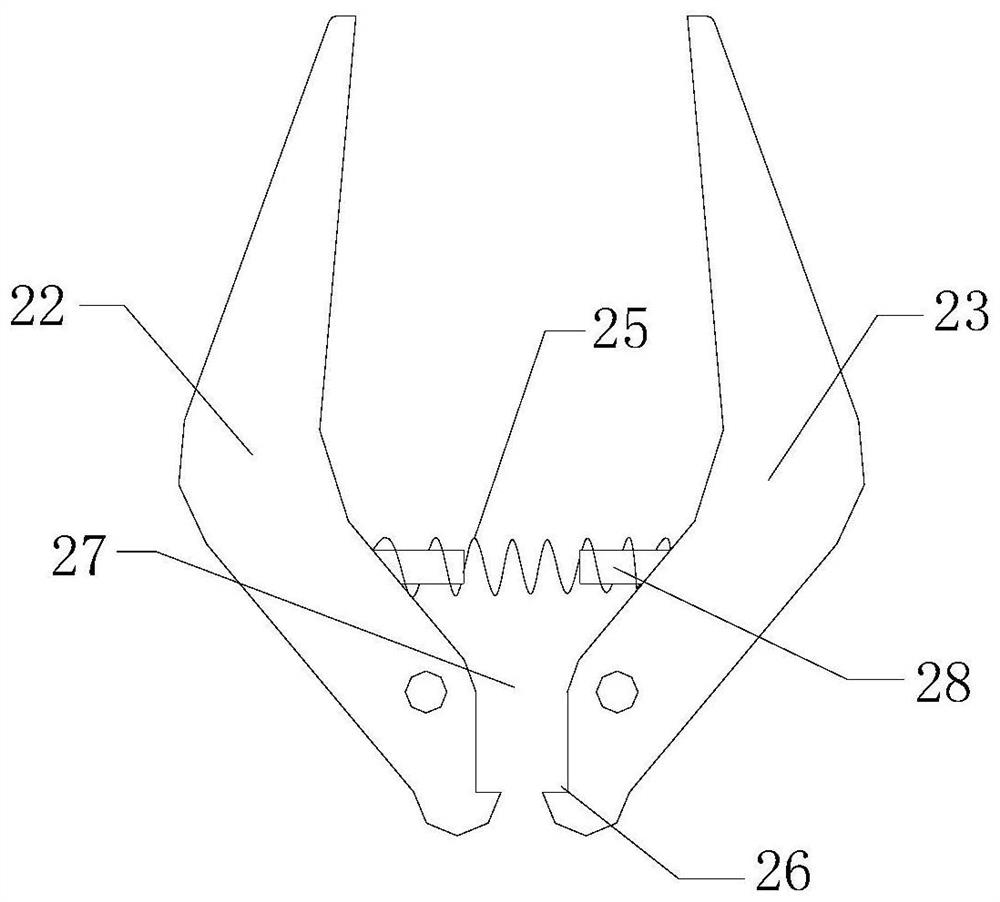

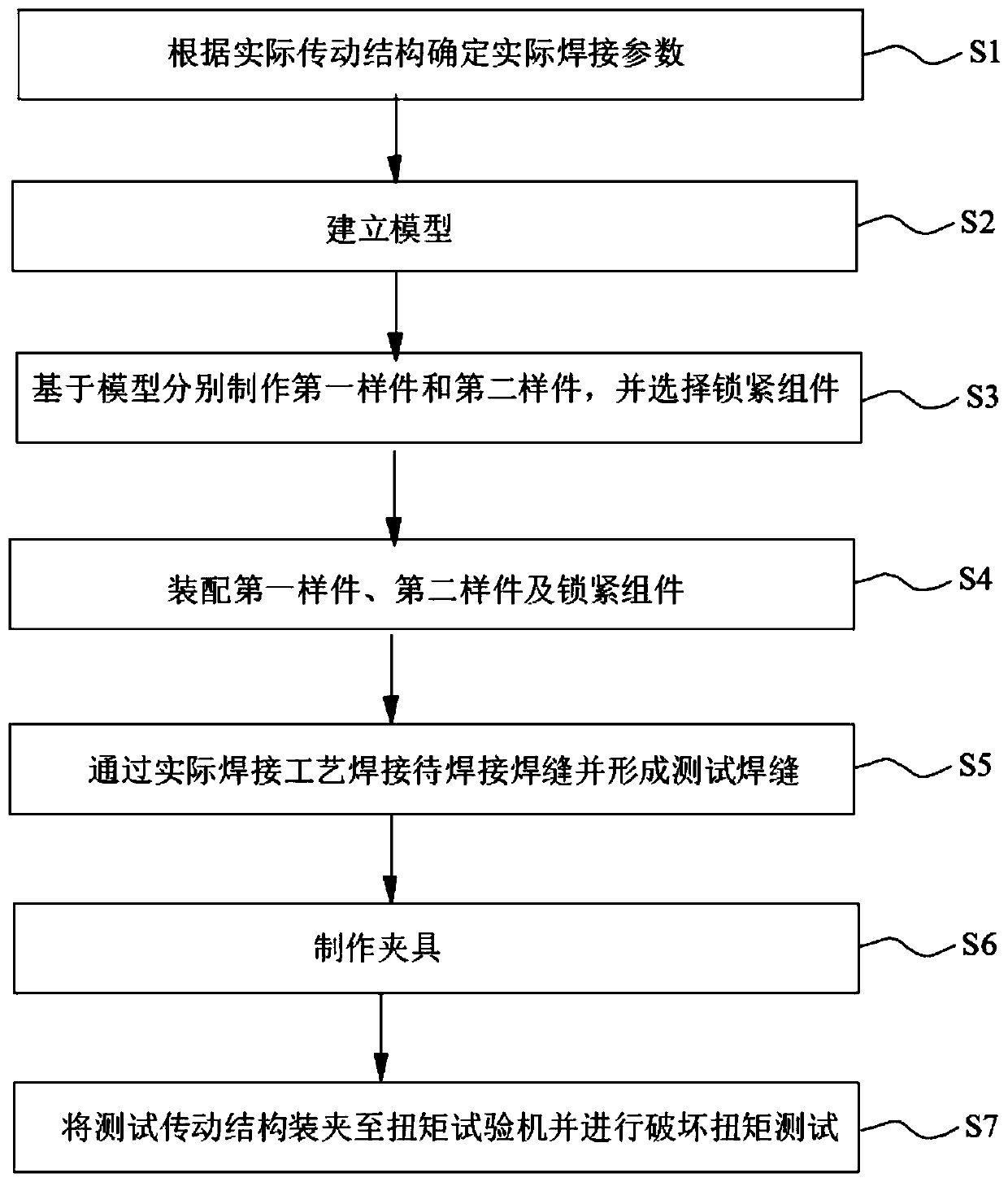

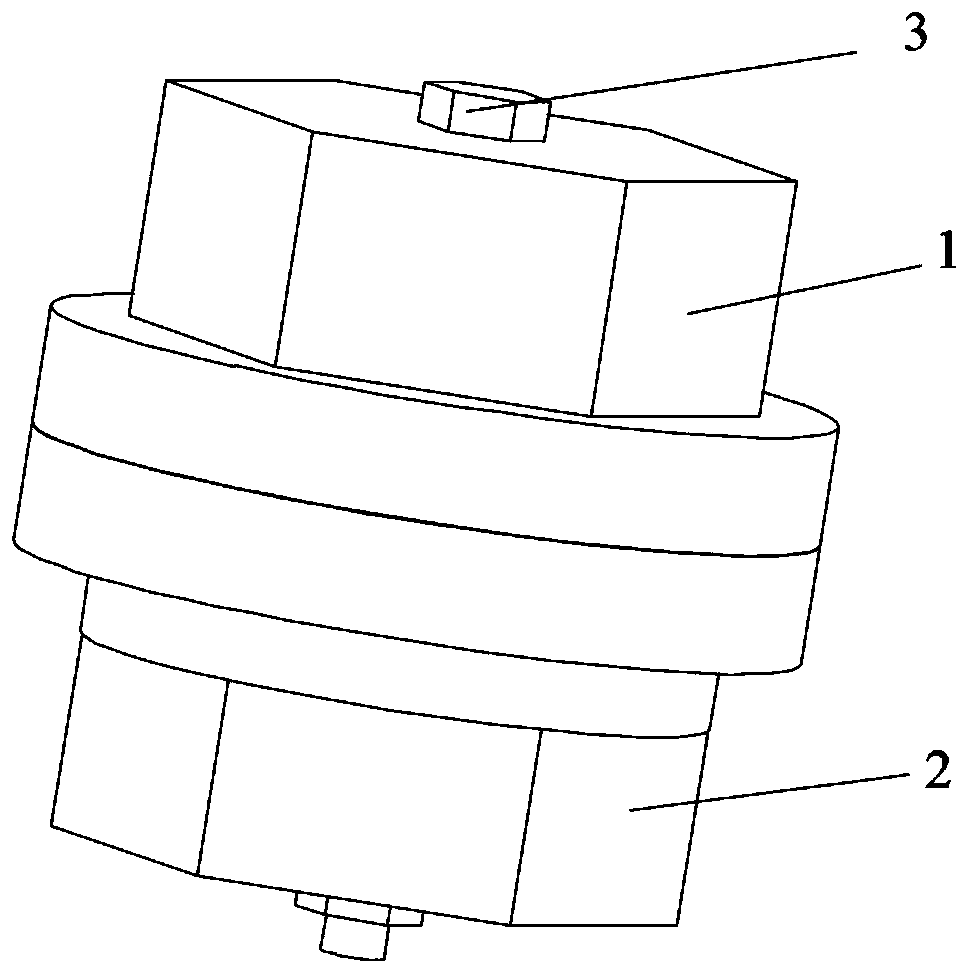

Circular radial butt weld damage torque testing method

ActiveCN111413213AAccurate assessment of maximum load torqueReduce manufacturing costMachine part testingPreparing sample for investigationButt weldingStructural engineering

Owner:CHINA FIRST AUTOMOBILE

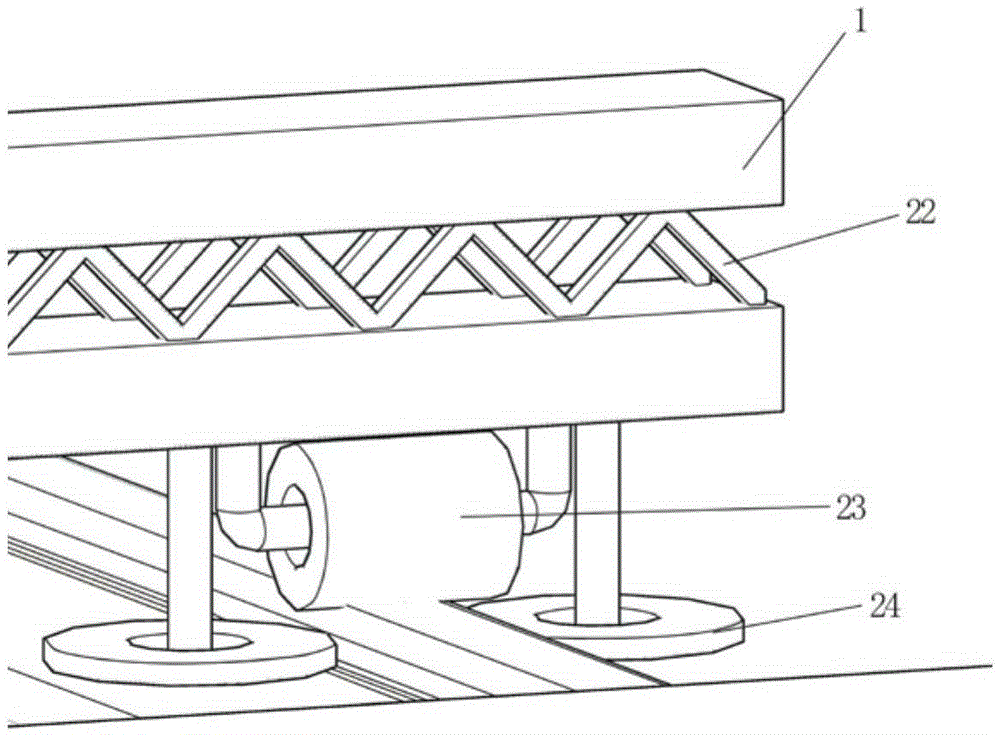

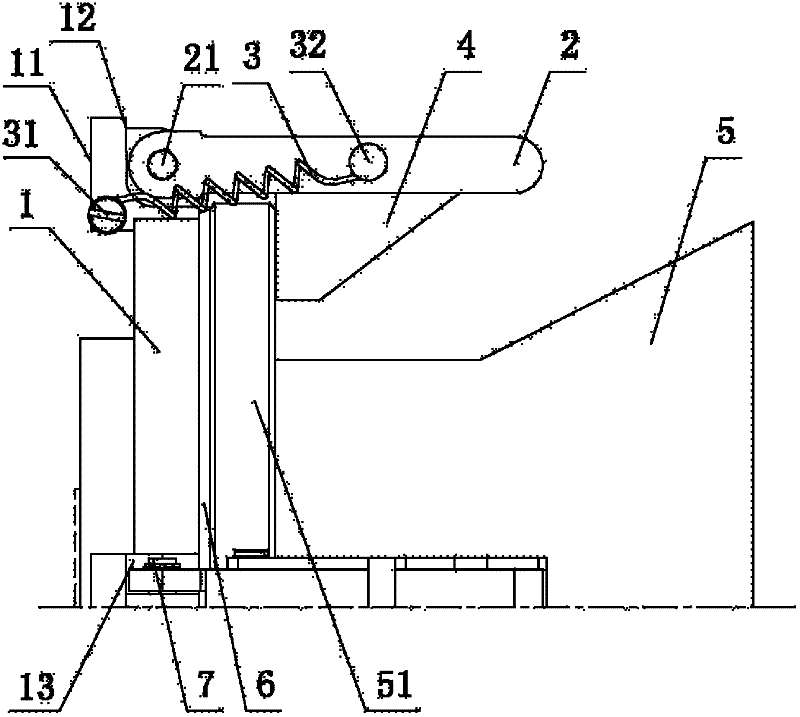

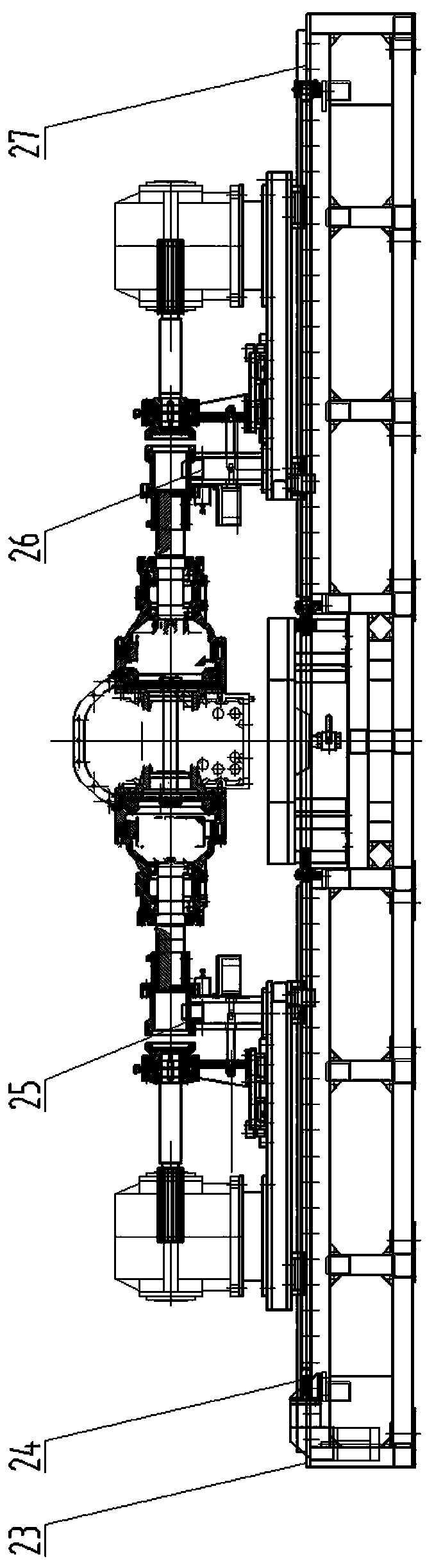

Bending resistant expandable type test platform system with auxiliary support

ActiveCN107702903AImprove the bending capacityReduce design difficultyMachine part testingHydraulic cylinderTest platform

Owner:SHANGHAI SPACE PRECISION MACHINERY RES INST

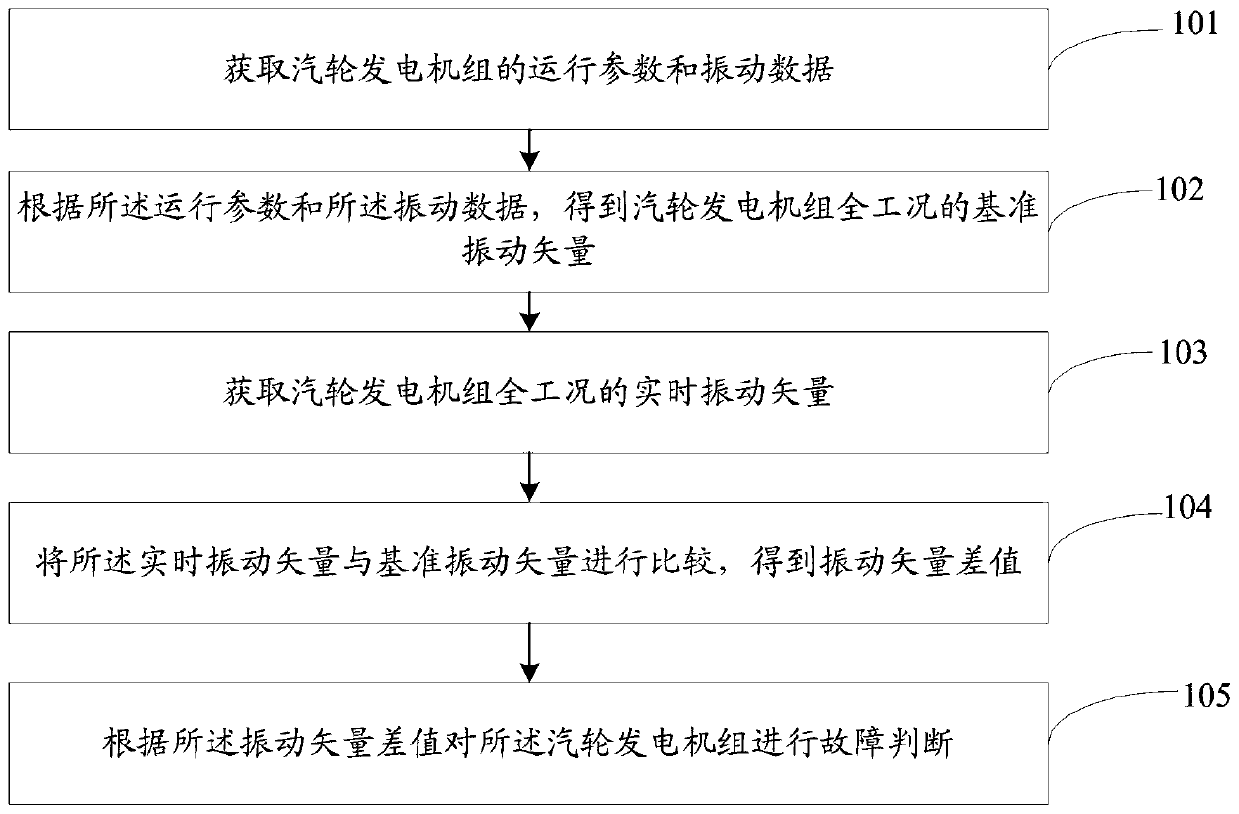

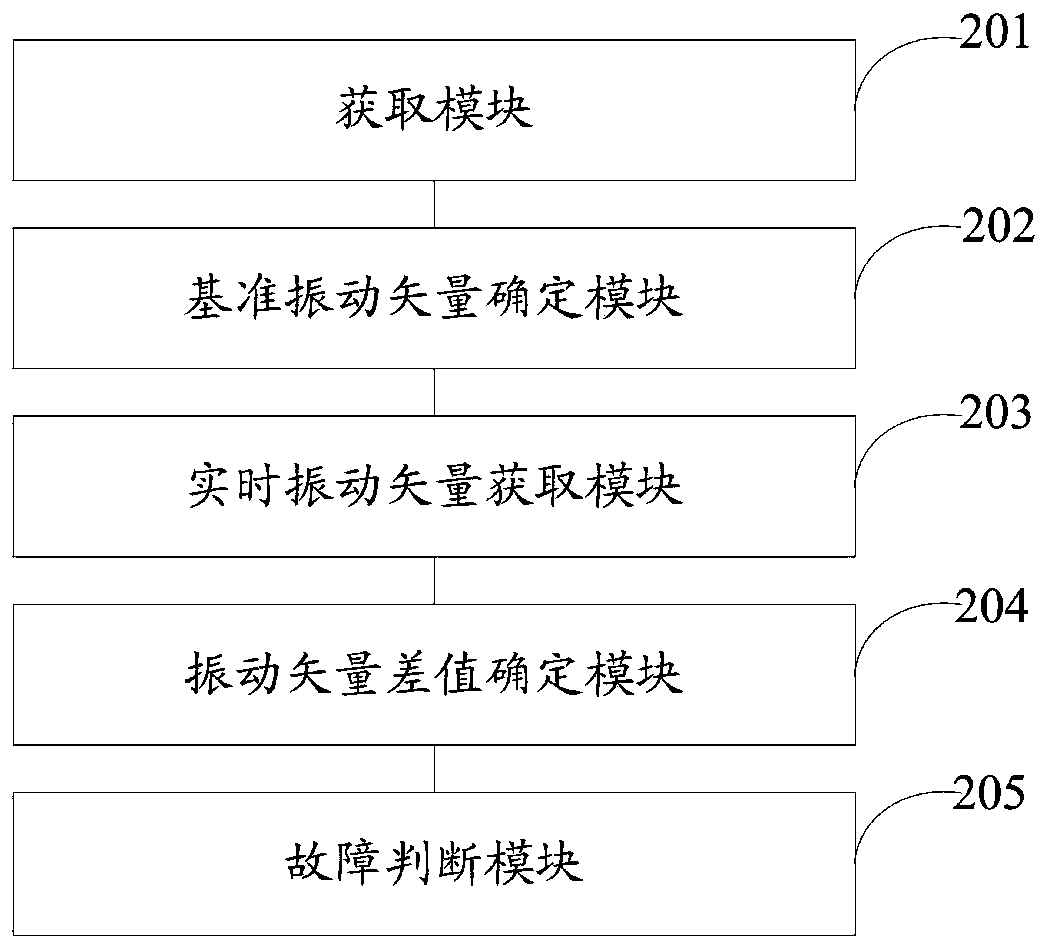

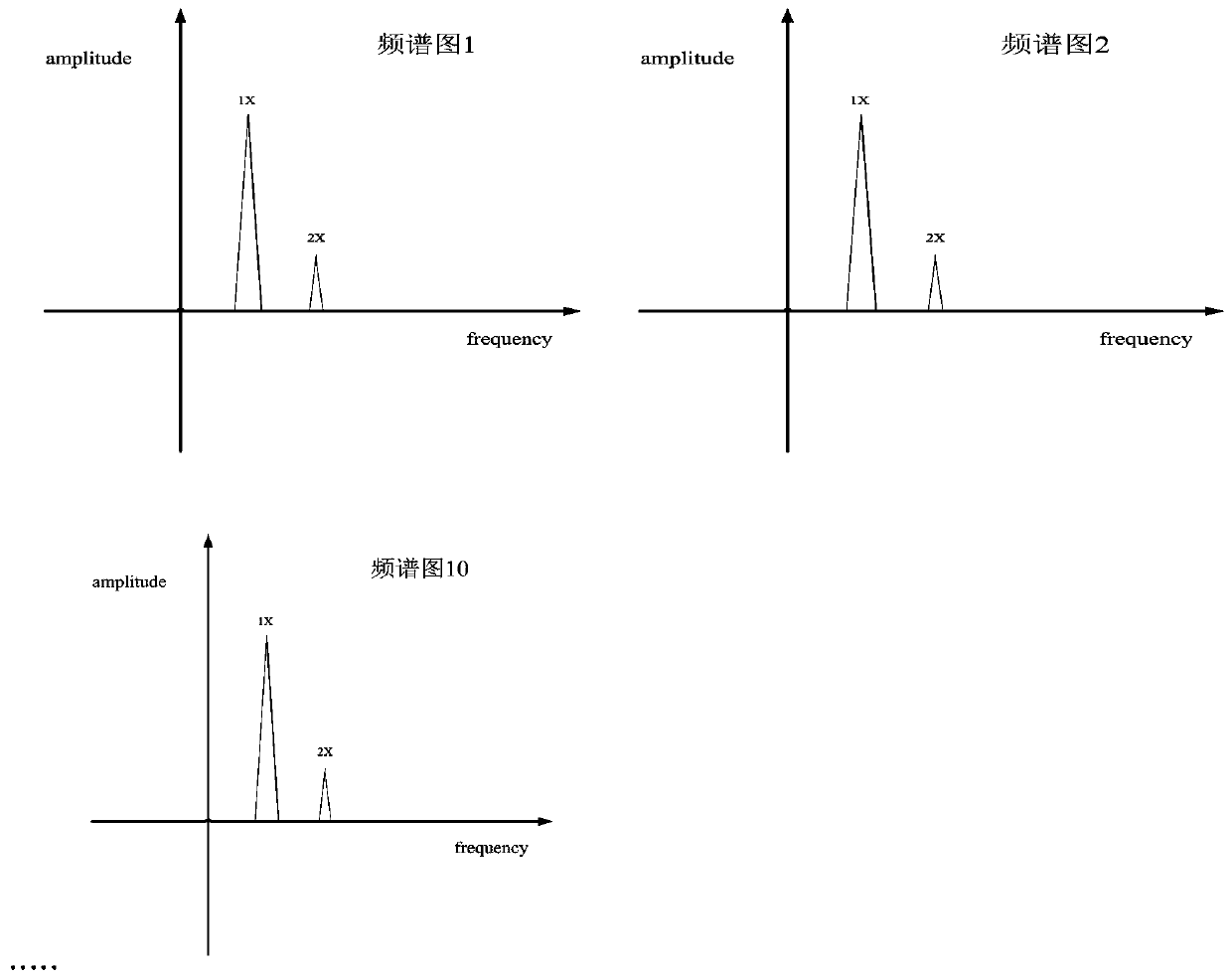

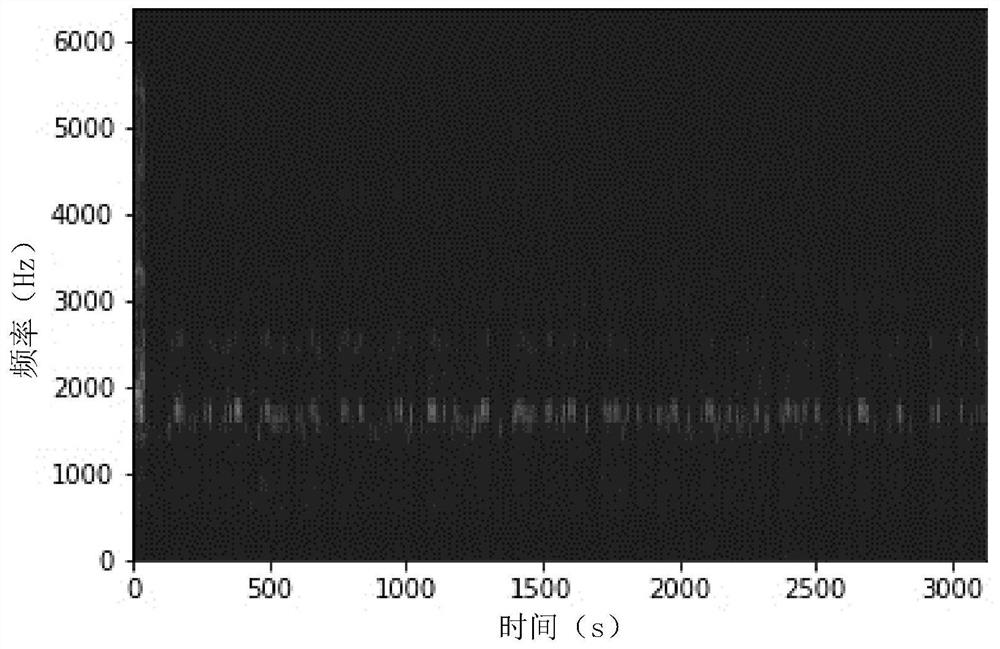

Steam turbine generator unit fault visual diagnosis method and system

InactiveCN110553821AMachine part testingSubsonic/sonic/ultrasonic wave measurementAutomotive engineeringGenerating unit

Owner:湖北华电襄阳发电有限公司 +1

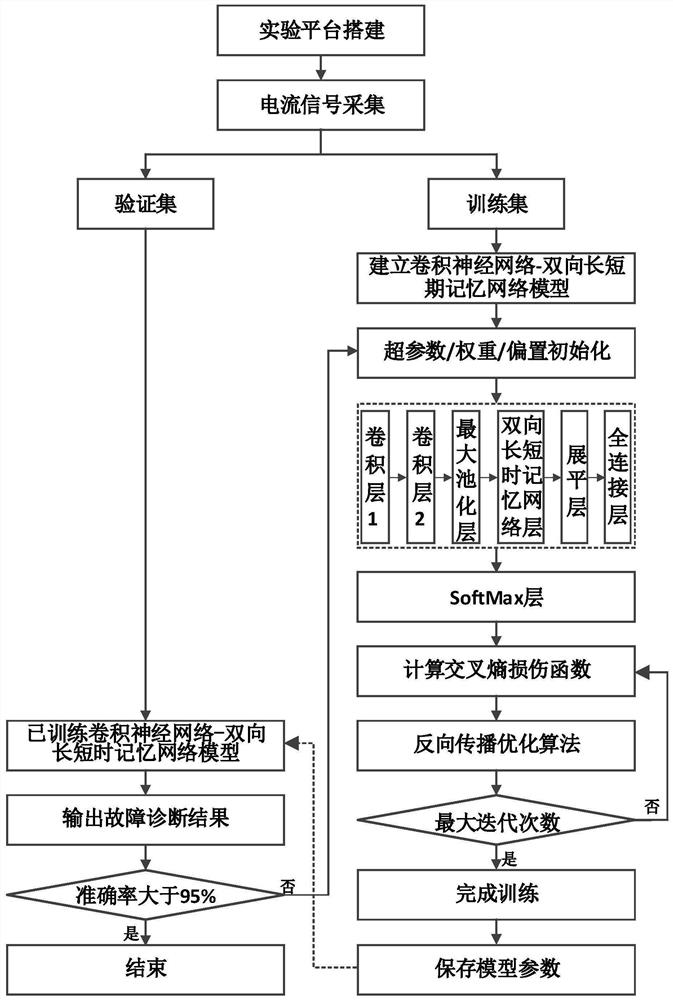

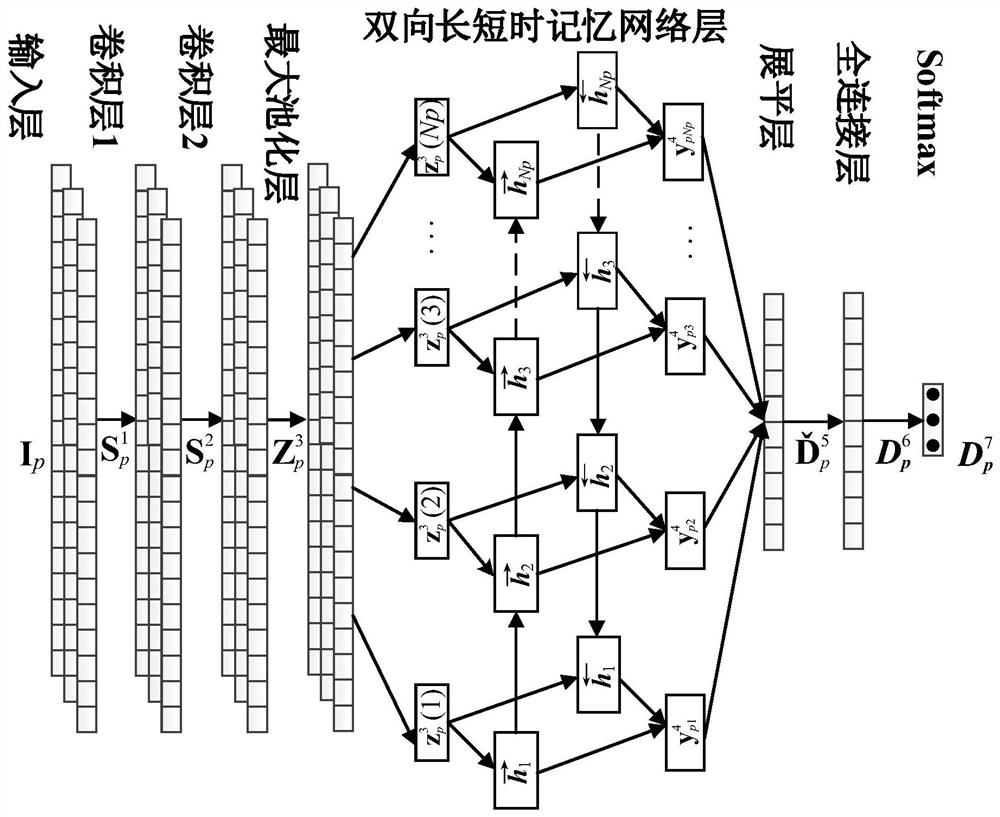

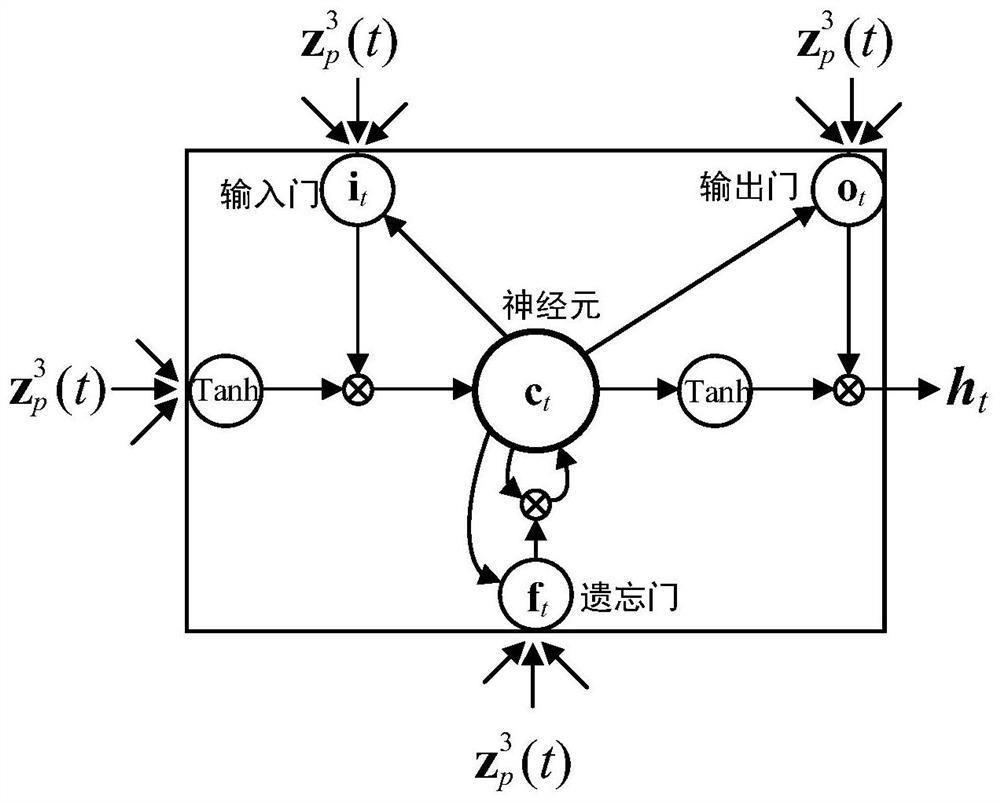

AC motor bearing fault diagnosis method adopting convolutional neural network and bidirectional long-short term memory network

Owner:JIANGSU UNIV

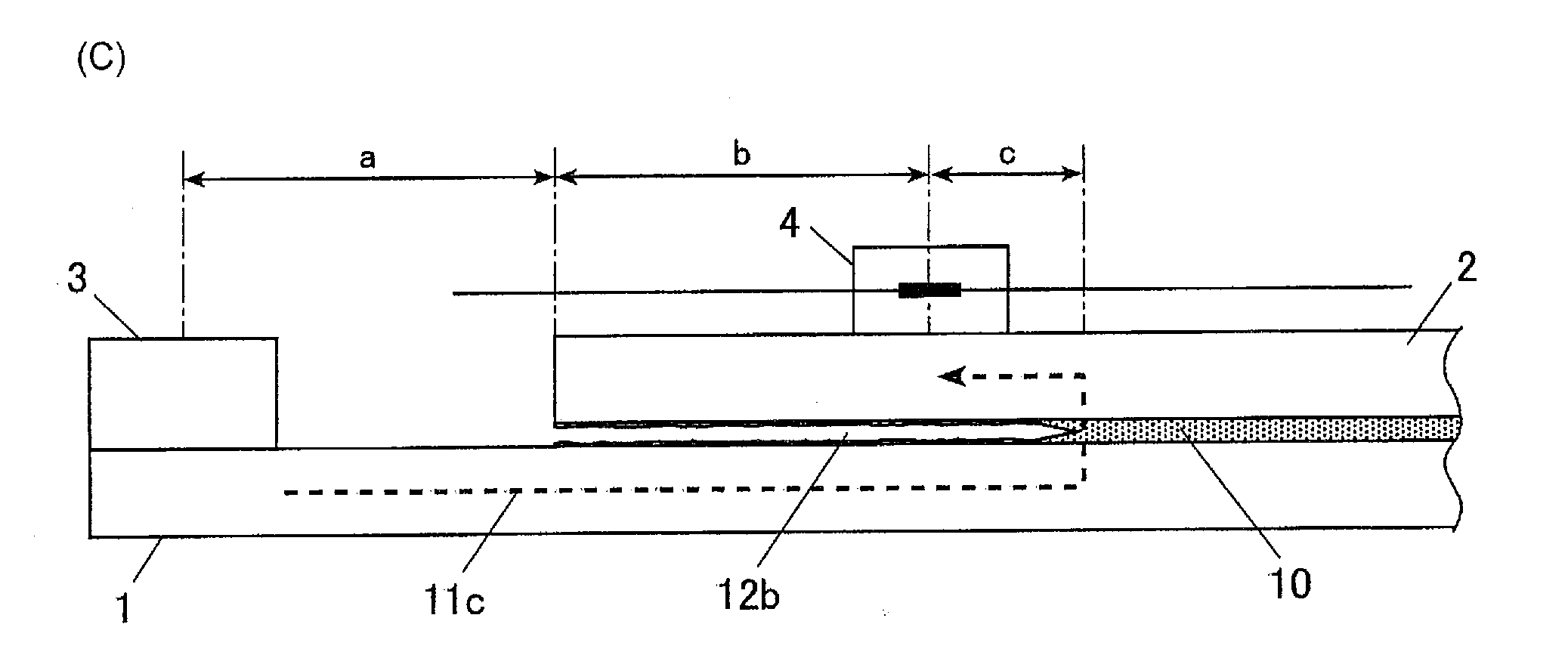

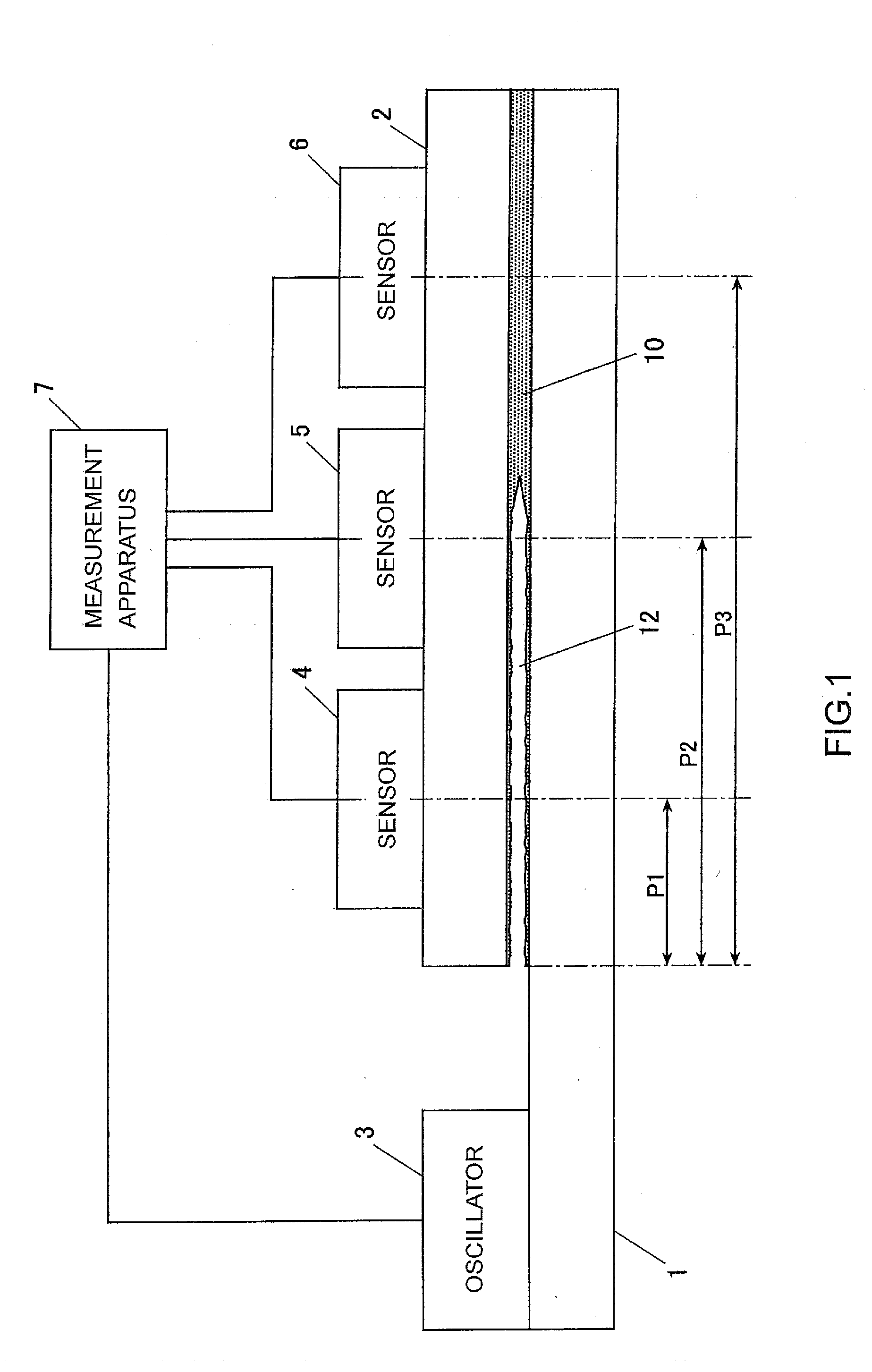

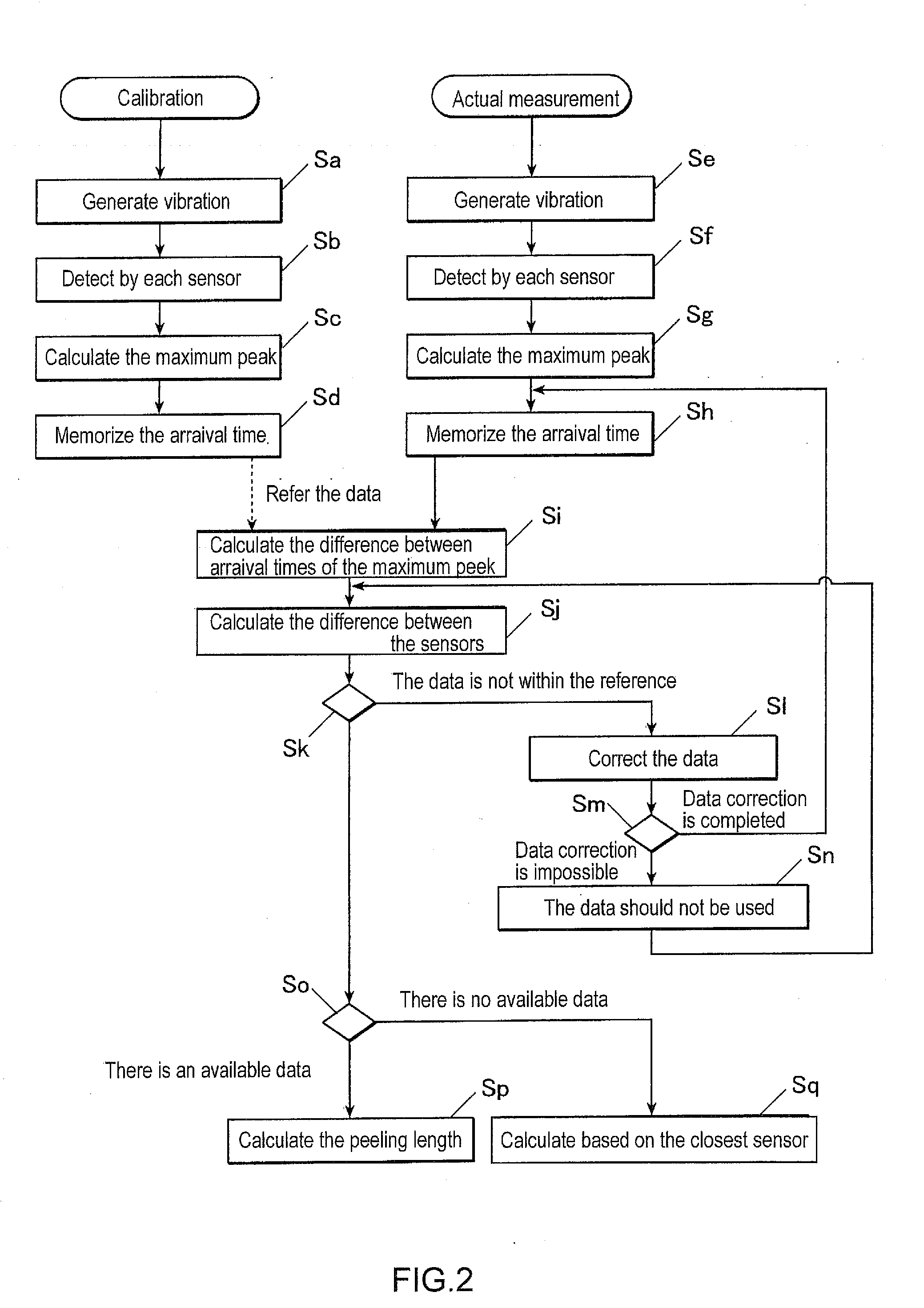

System and Method for Measuring Damage Length

ActiveUS20110196622A1Improve accuracyImprove reliabilityMachine part testingVibration measurement in solidsMeasurement devicePropagation time

Owner:SUBARU CORP

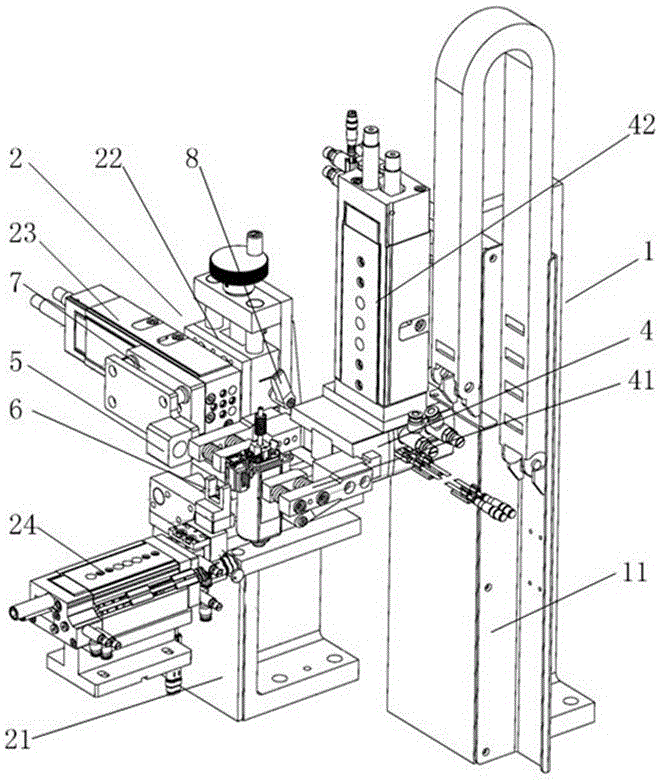

Vibration detection device

ActiveCN105136287AMachine part testingSubsonic/sonic/ultrasonic wave measurementLinear displacementEngineering

Owner:IXMATION SUZHOU CO LTD

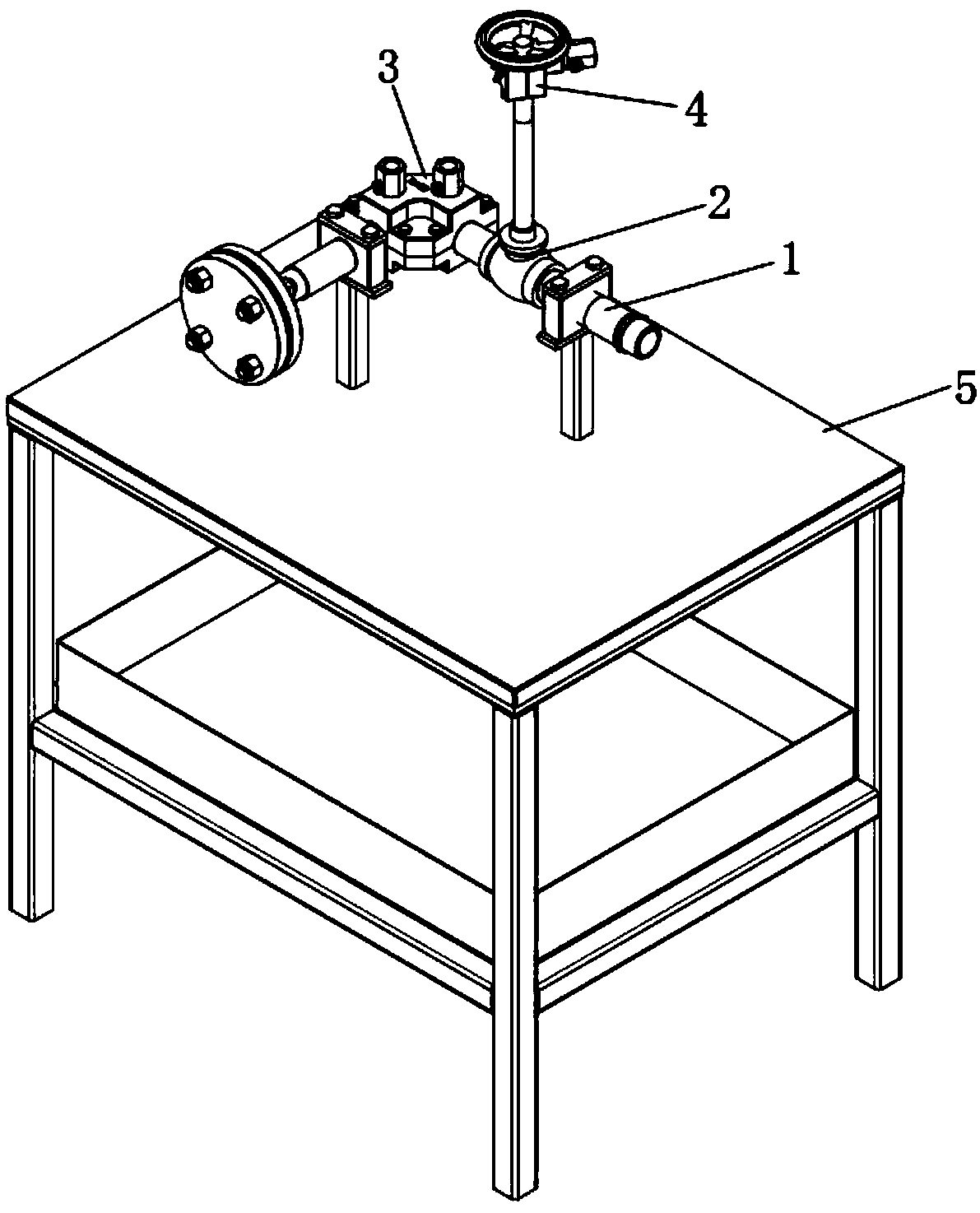

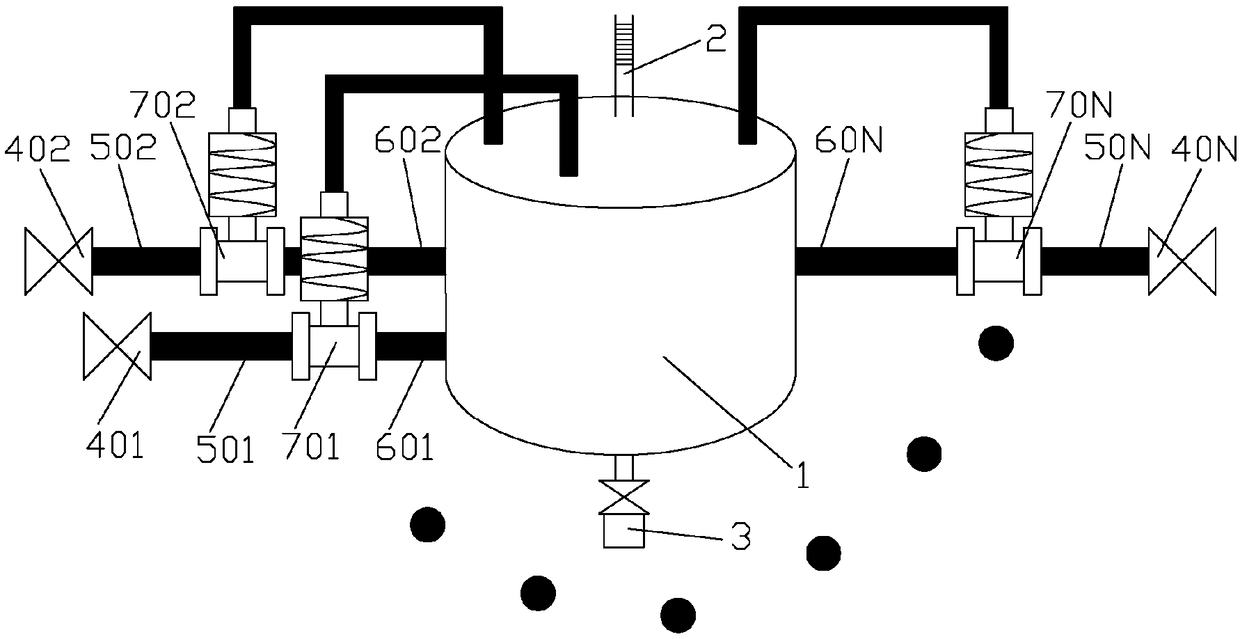

Low temperature liquefaction vehicle fuel tanker operation box pipeline equipment plugging simulation test bench

PendingCN109459225AMachine part testingFluid-tightness measurement using fluid/vacuumGas cylinderEngineering

Owner:SHANGHAI INST OF SPECIAL EQUIP INSPECTION & TECHN RES

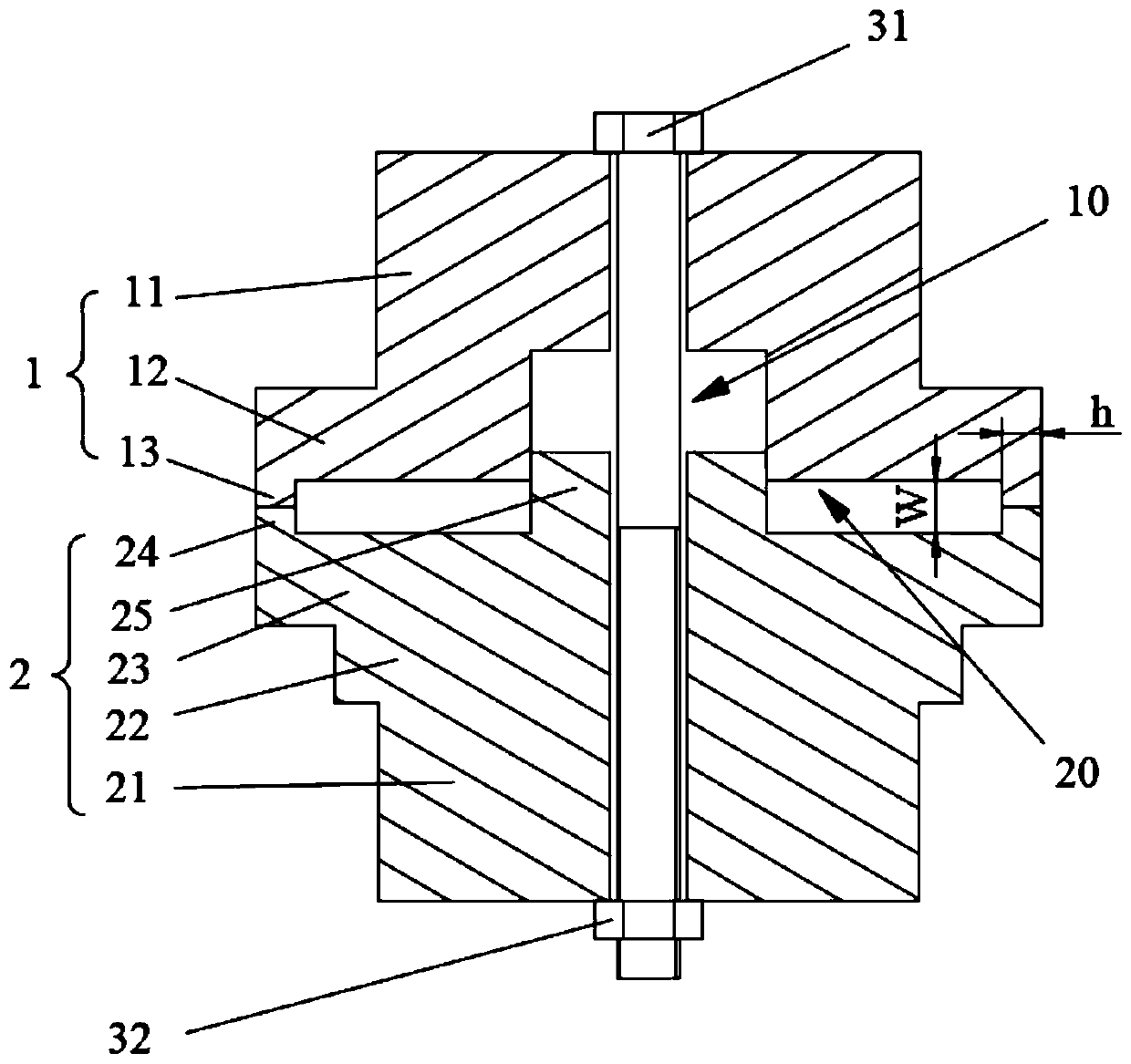

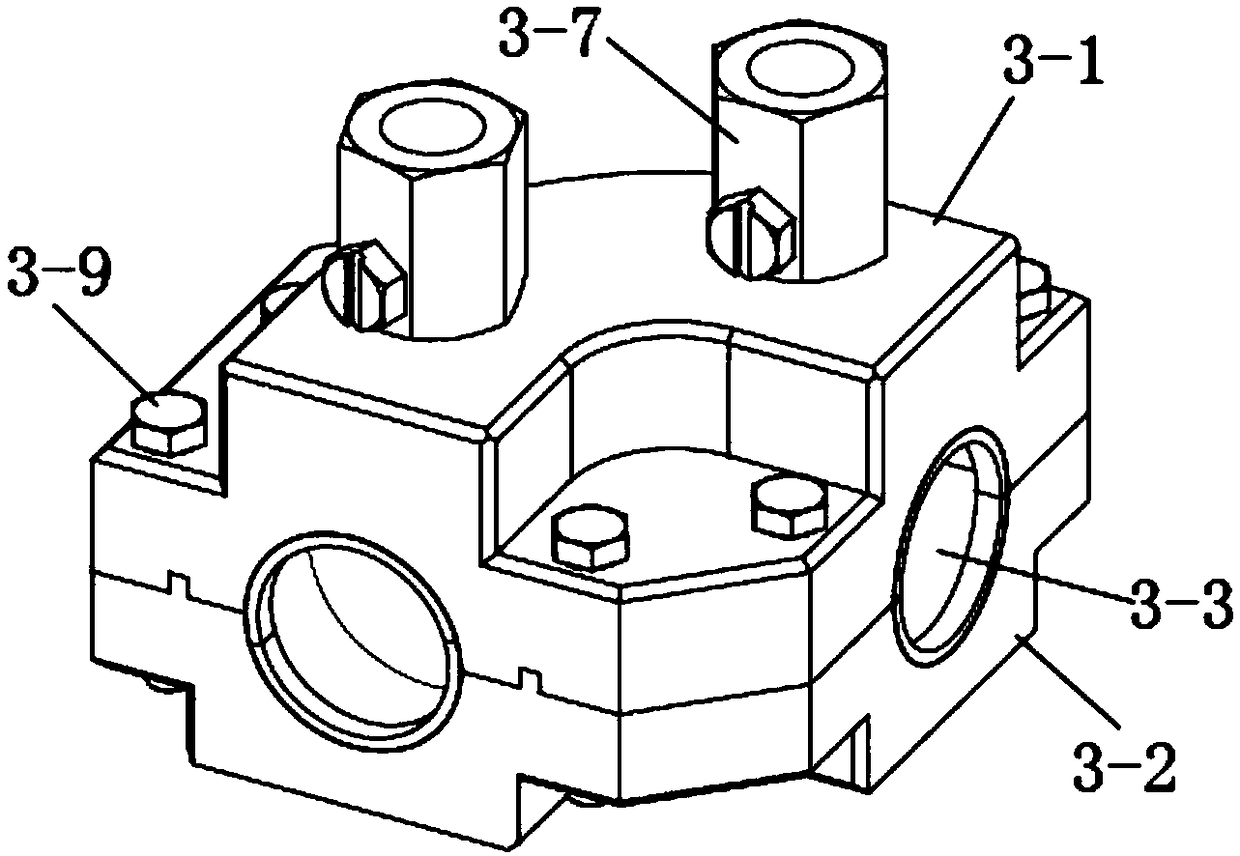

Swirler test fixture

Owner:CHINA AVIATION POWER MACHINE INST

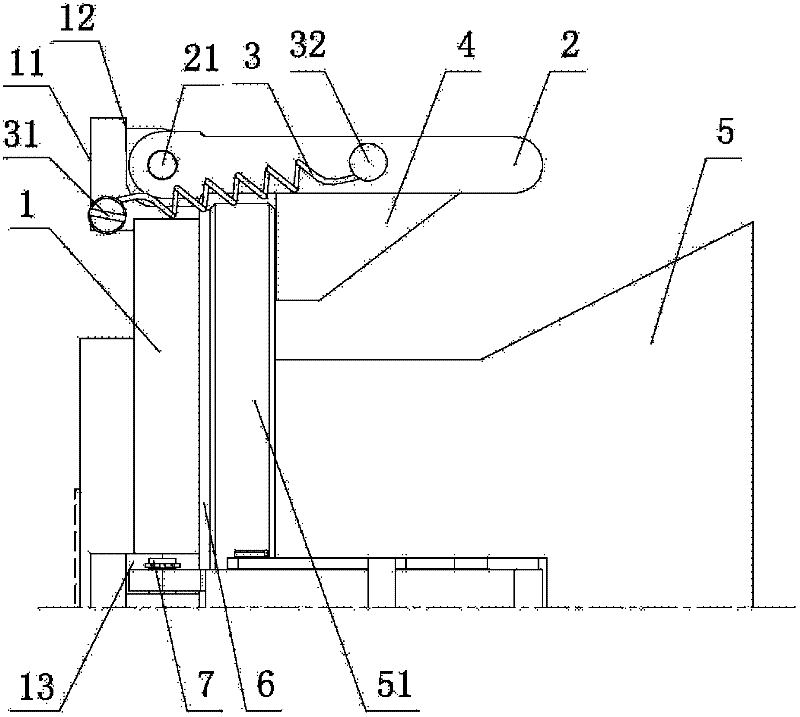

Limit load reliability test device for miniature ball screw pair

InactiveCN110207982ASimple structureEasy to operateMachine part testingReciprocating motionBall screw

Owner:NANJING UNIV OF SCI & TECH

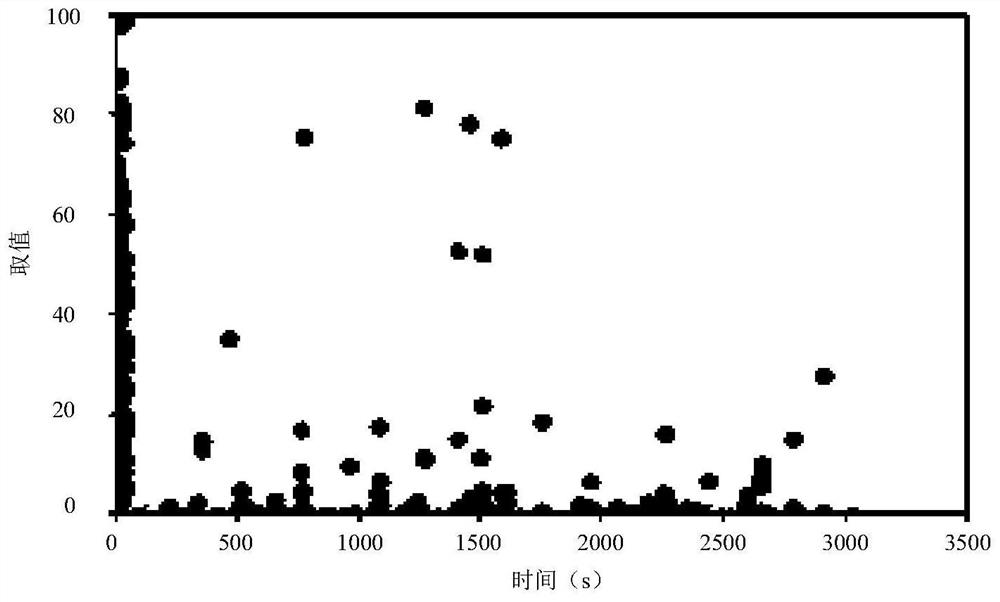

Abnormal data detection method and device and mechanical fault detection method and device

Owner:RICOH KK

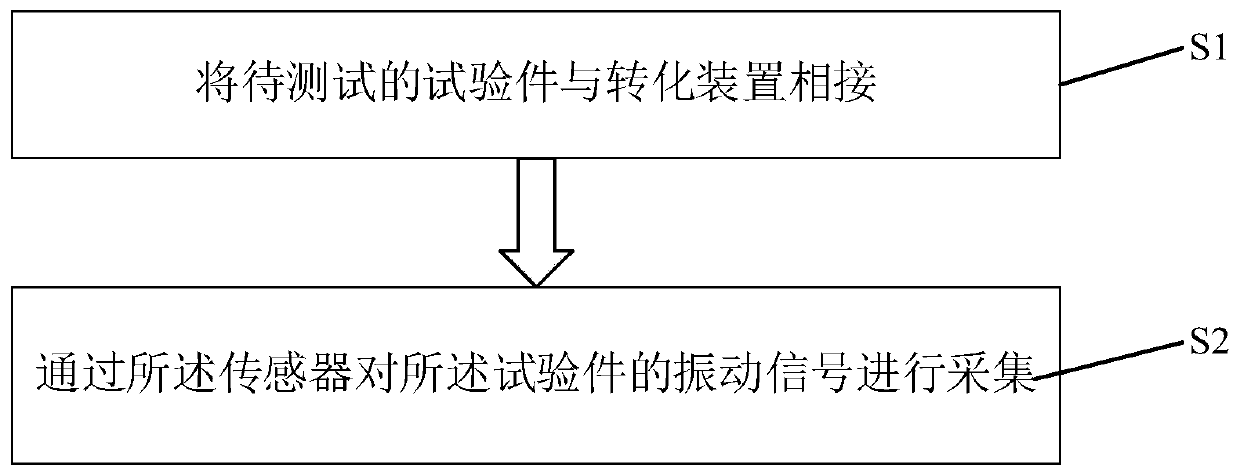

Conversion device for high temperature modal test and vibration test method

Owner:CASIC DEFENSE TECH RES & TEST CENT

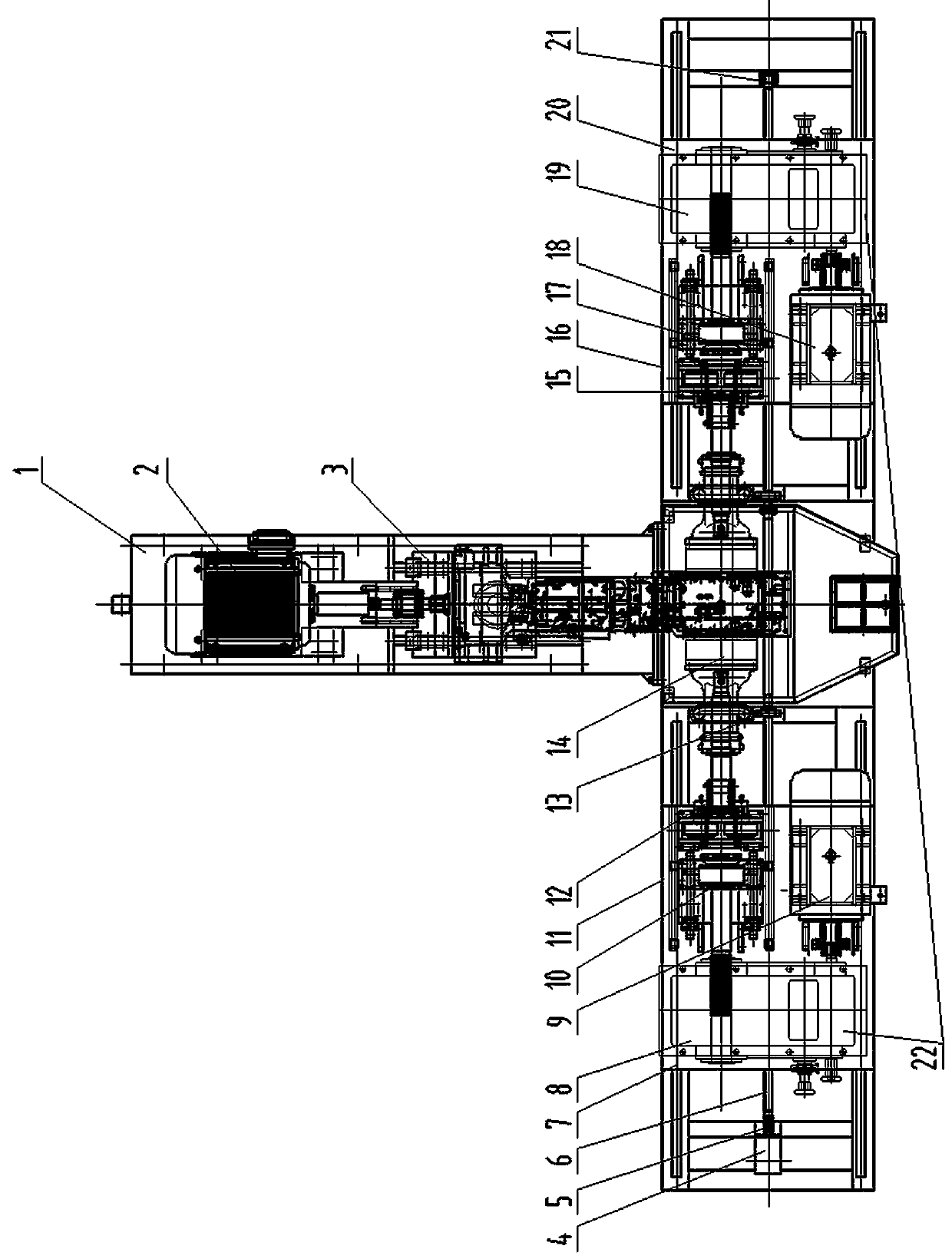

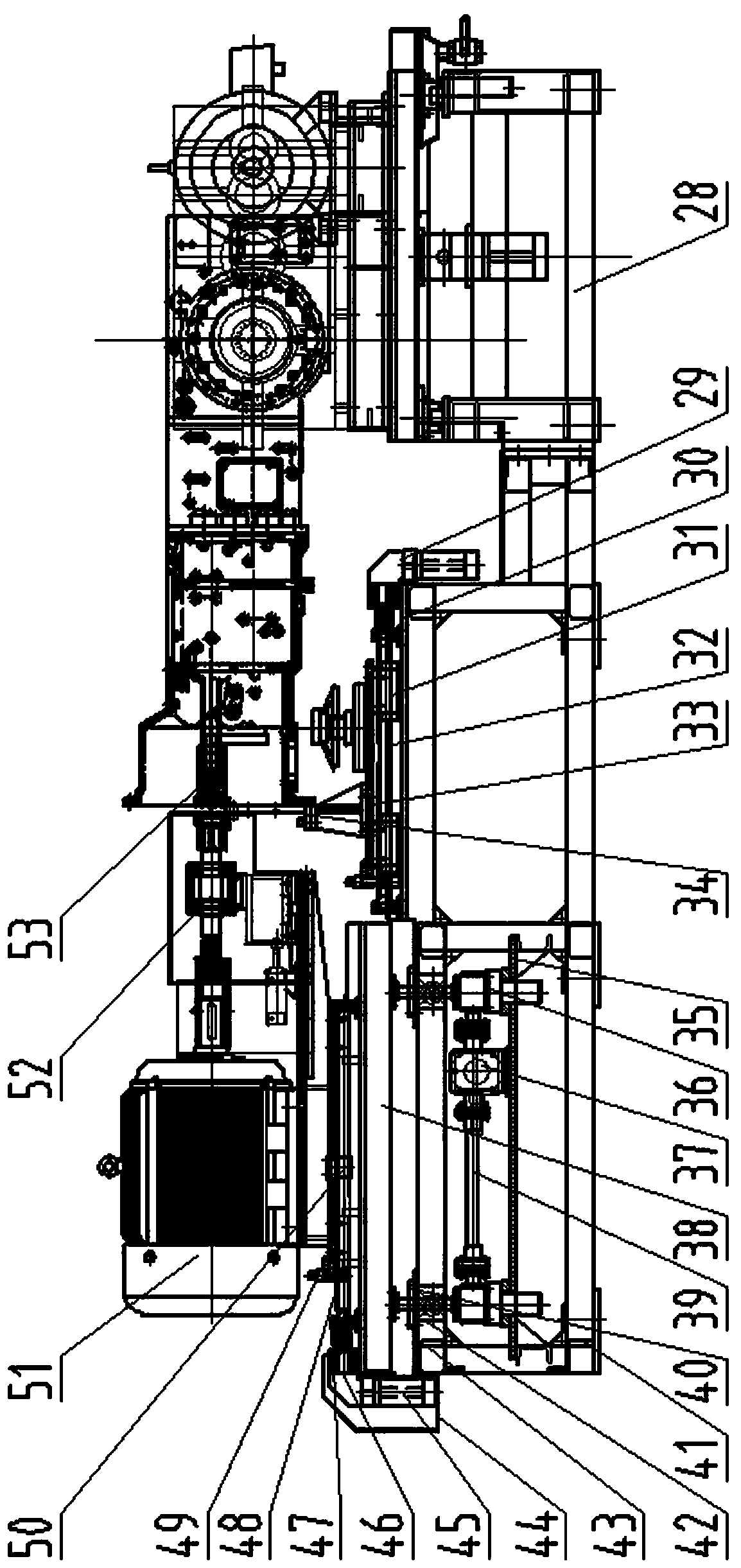

Tractor chassis two-machine loading running-in test stand

PendingCN109520751ARunning in is effectiveRun in thoroughlyMachine part testingVehicle testingAutomatic controlReal-time data

Owner:湘潭科达电工专用成套设备有限责任公司

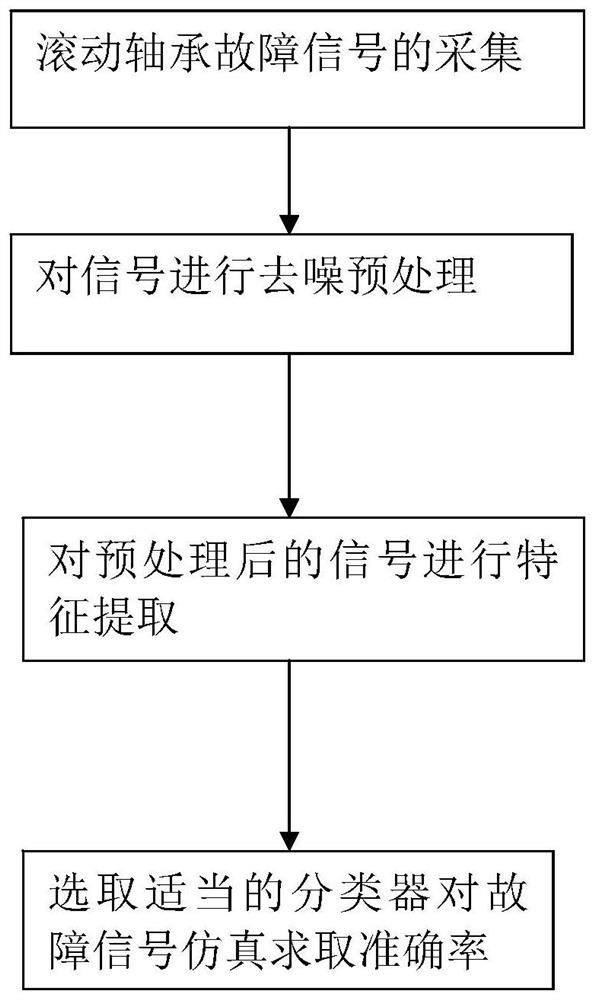

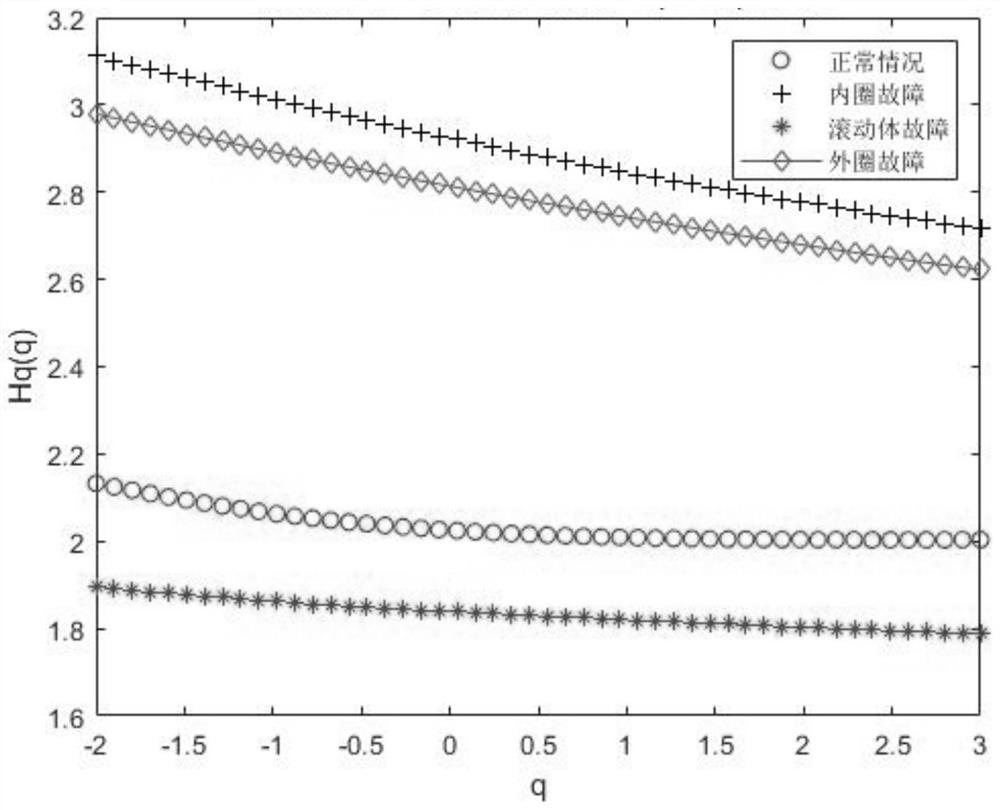

Bearing fault identification method based on combination of VMD and multi-fractal

PendingCN113390640AGet the characteristic frequency of the fault signalImprove diagnostic accuracyMachine part testingWaveform analysisFeature extraction

Owner:SHANGHAI DIANJI UNIV

Method for confirming air spring parameter and device thereof

The invention provides a method for confirming air spring parameter and a device thereof; the method includes steps of setting a target position of an air spring on the first zone through confirming a first zone, a second zone and a rotary axis between the first zone and the second zone; receiving quality parameter of the first zone input externally, and confirming the first distance between the gravity of the first zone and the rotary axis; according to the target position and the first distance, calculating parameter of the air spring. The scheme provided by the invention can effectively improve the accuracy of the air spring parameter.

Owner:INSPUR FINANCIAL INFORMATION TECH CO LTD

Fixing device for automobile rubber and plastic part production detection

InactiveCN107436233AEasy to fixEasy to useMachine part testingVehicle testingMechanical engineeringBattery pack

Owner:枞阳县金源汽车零部件有限公司

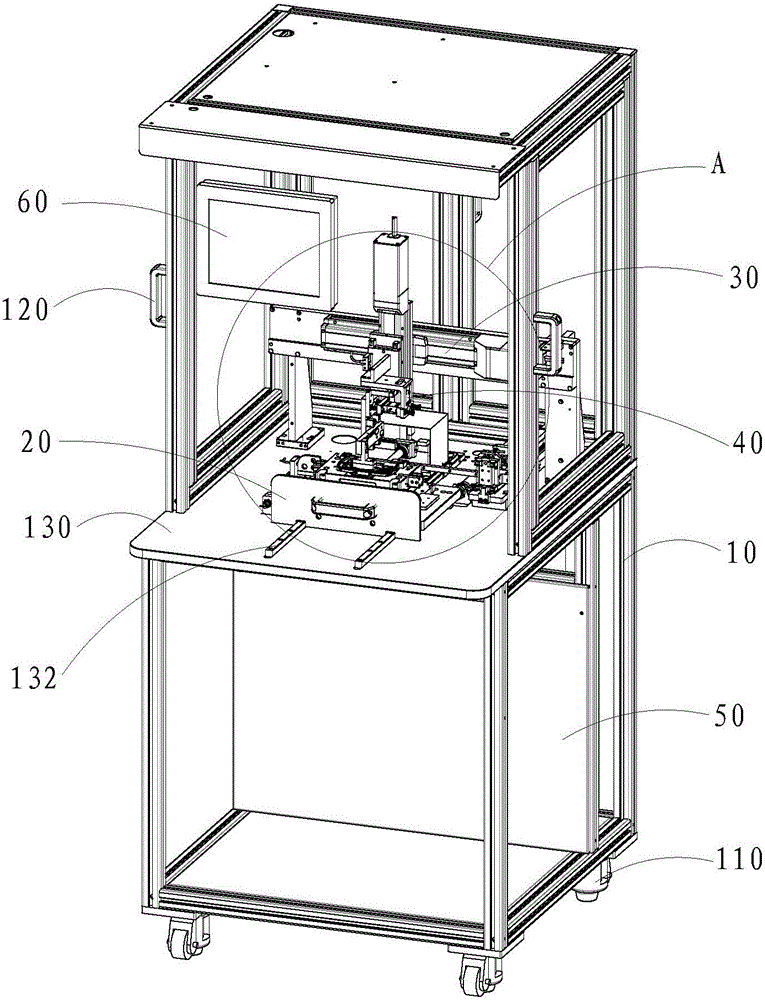

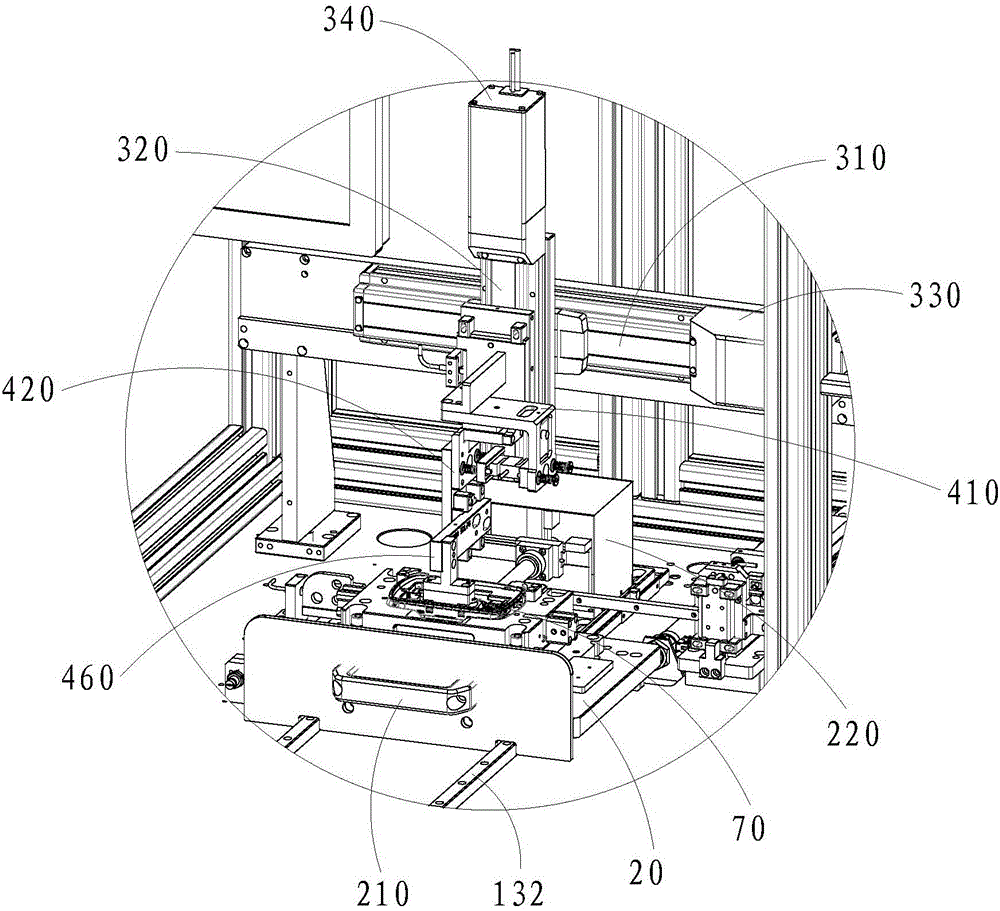

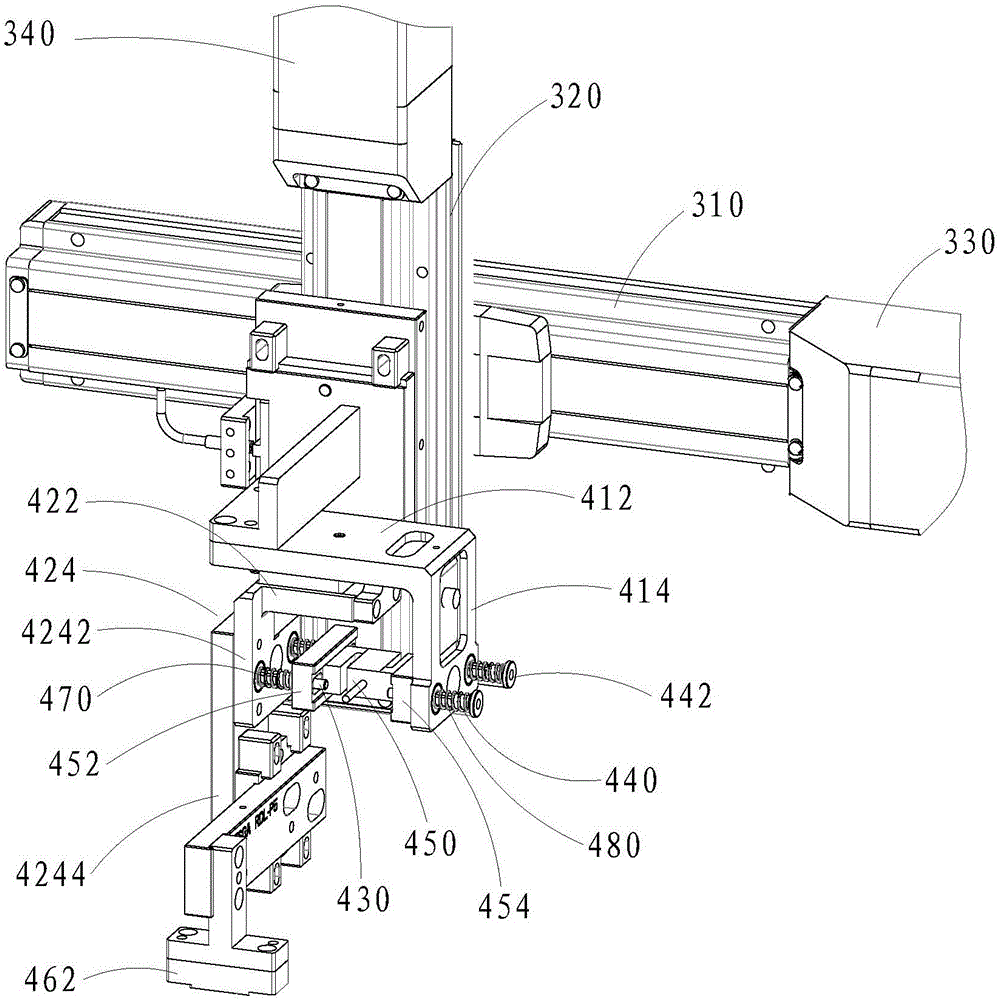

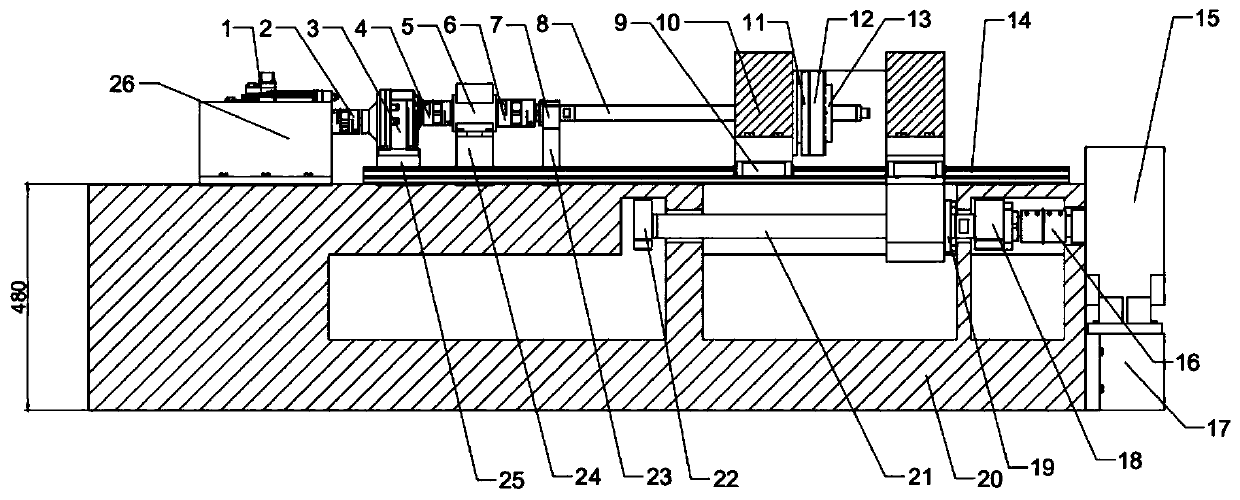

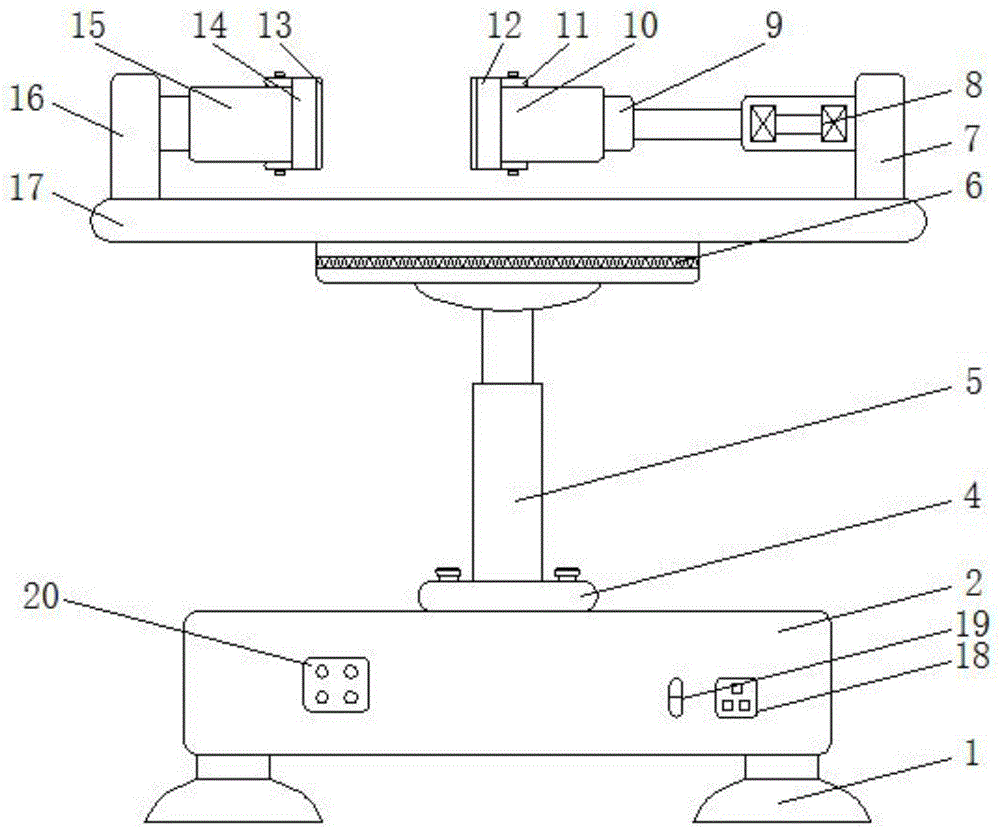

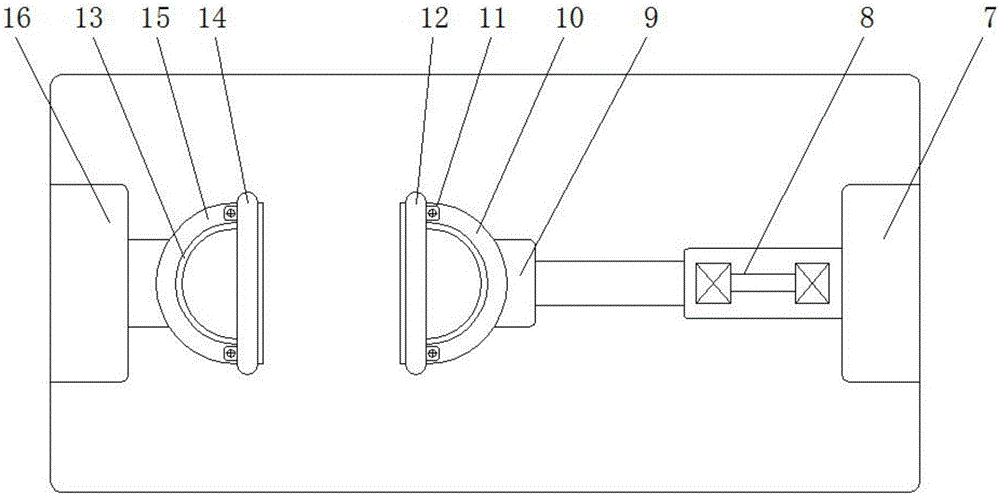

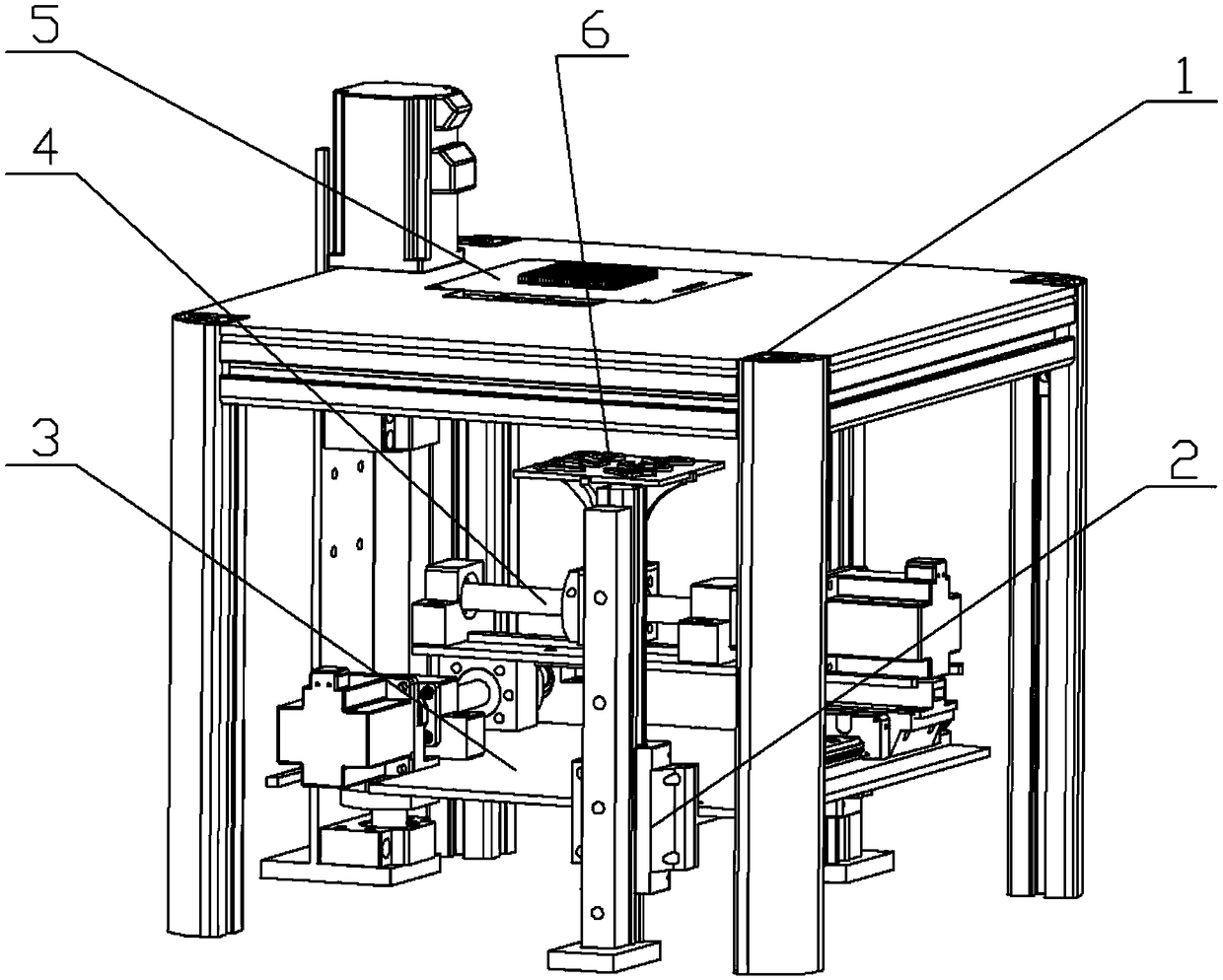

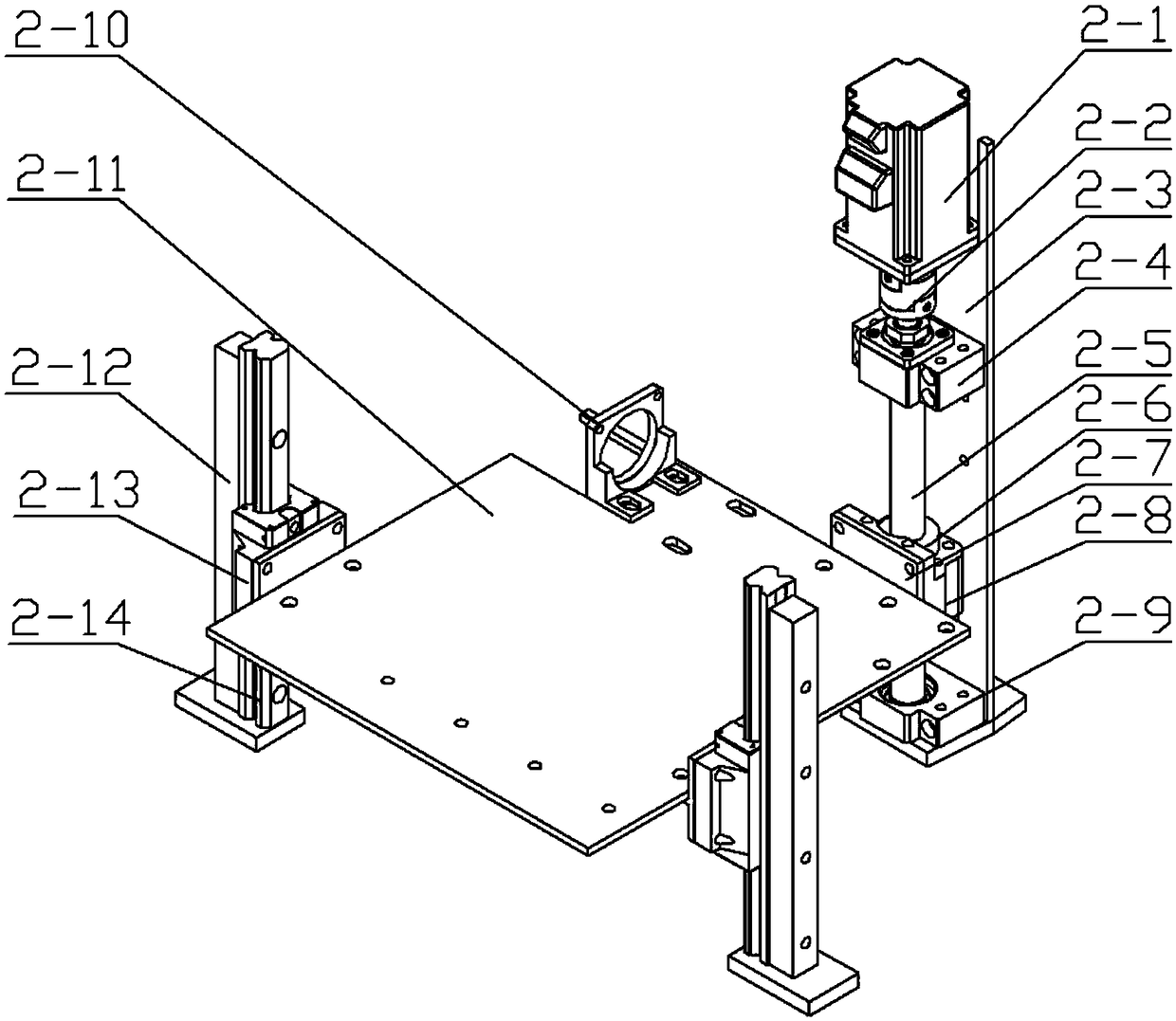

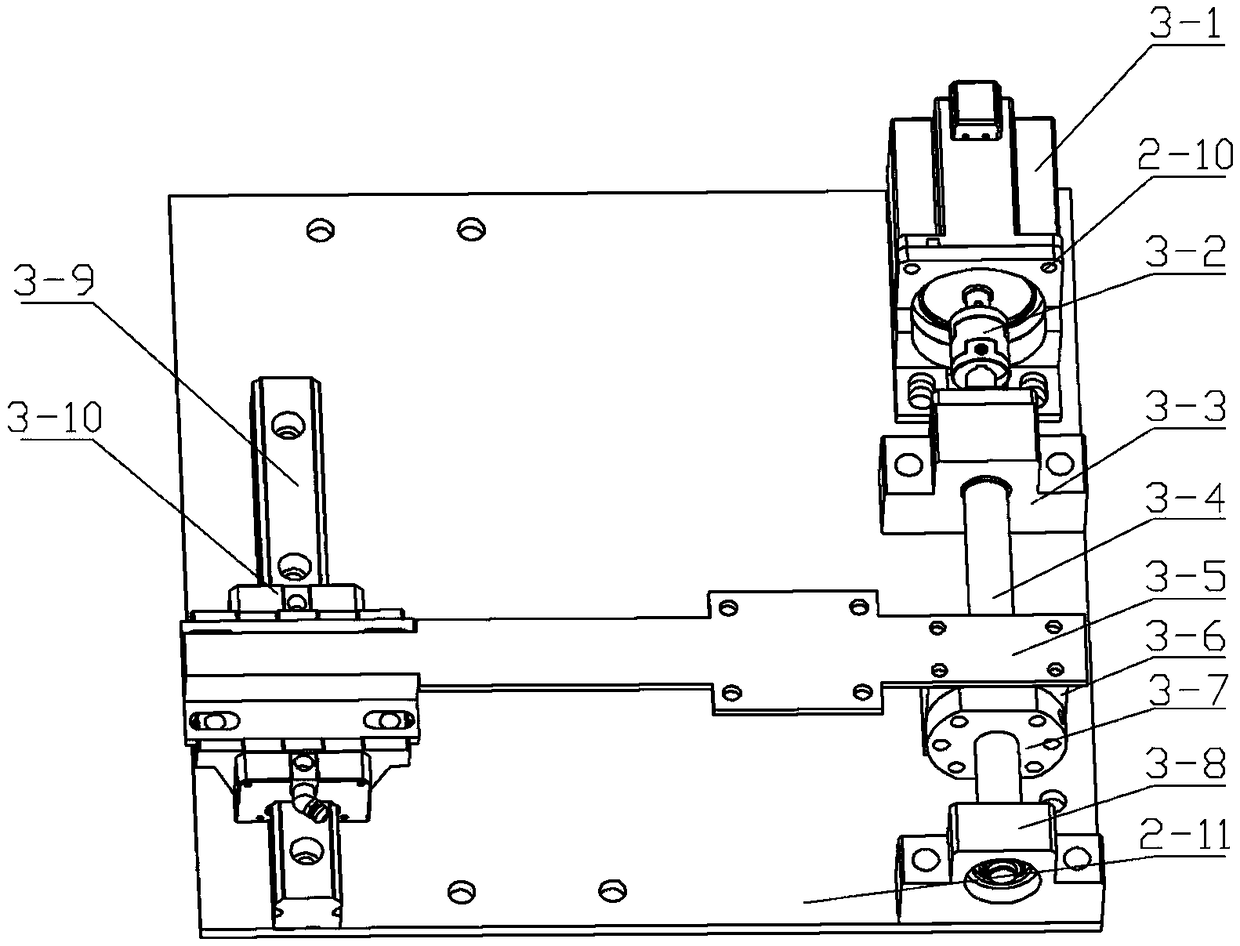

Ball screw efficiency test equipment and test method

PendingCN112729640AGuaranteed accuracyFlexible operationMachine part testingWork measurementPush and pullPull force

The invention discloses ball screw efficiency test equipment which comprises a bottom plate and further comprises a screw rod tension and compression device, a screw rod loading device, a screw rod fixing tailstock, a nut fixing structure, a nut rotation driving mechanism, a displacement test mechanism and a control device, the screw rod tension and compression device and the screw rod fixing tailstock are slidably arranged on the bottom plate; the lead screw loading device, the nut rotation driving mechanism and the displacement test mechanism are installed on the bottom plate, and the lead screw loading device carries out axial loading on a ball screw to be tested through the lead screw tension and compression device. The nut fixing structure is installed on the nut of a ball screw to be tested during testing, the nut rotation driving mechanism drives the nut to rotate through the nut fixing structure, and the displacement test mechanism tests the displacement of the screw rod in the ball screw to be tested through the screw rod tension and compression device. The invention further discloses a ball screw efficiency test method. The accuracy of the efficiency of the ball screw during forward and reverse rotation is effectively ensured through the load of push and pull force on the screw rod.

Owner:CIXING GROUP

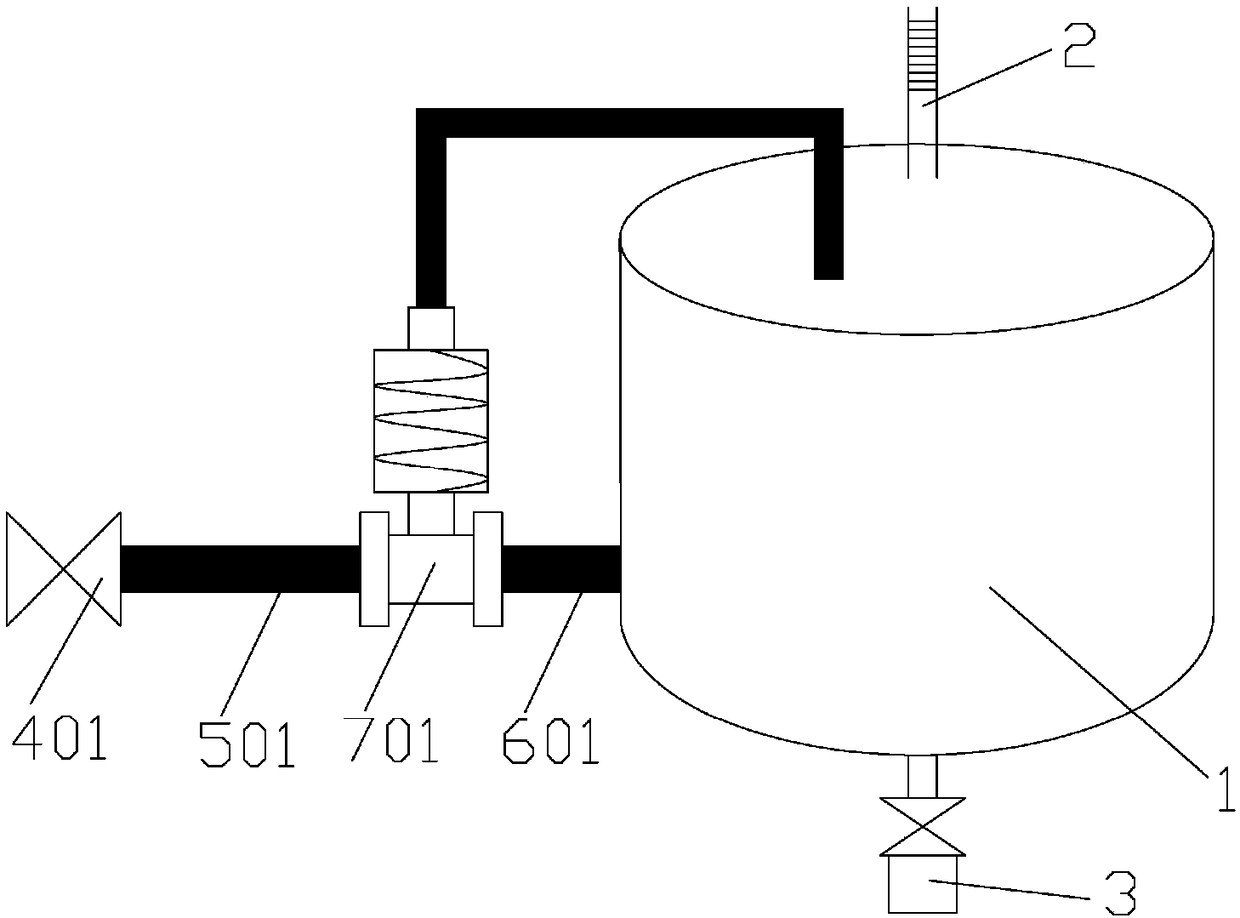

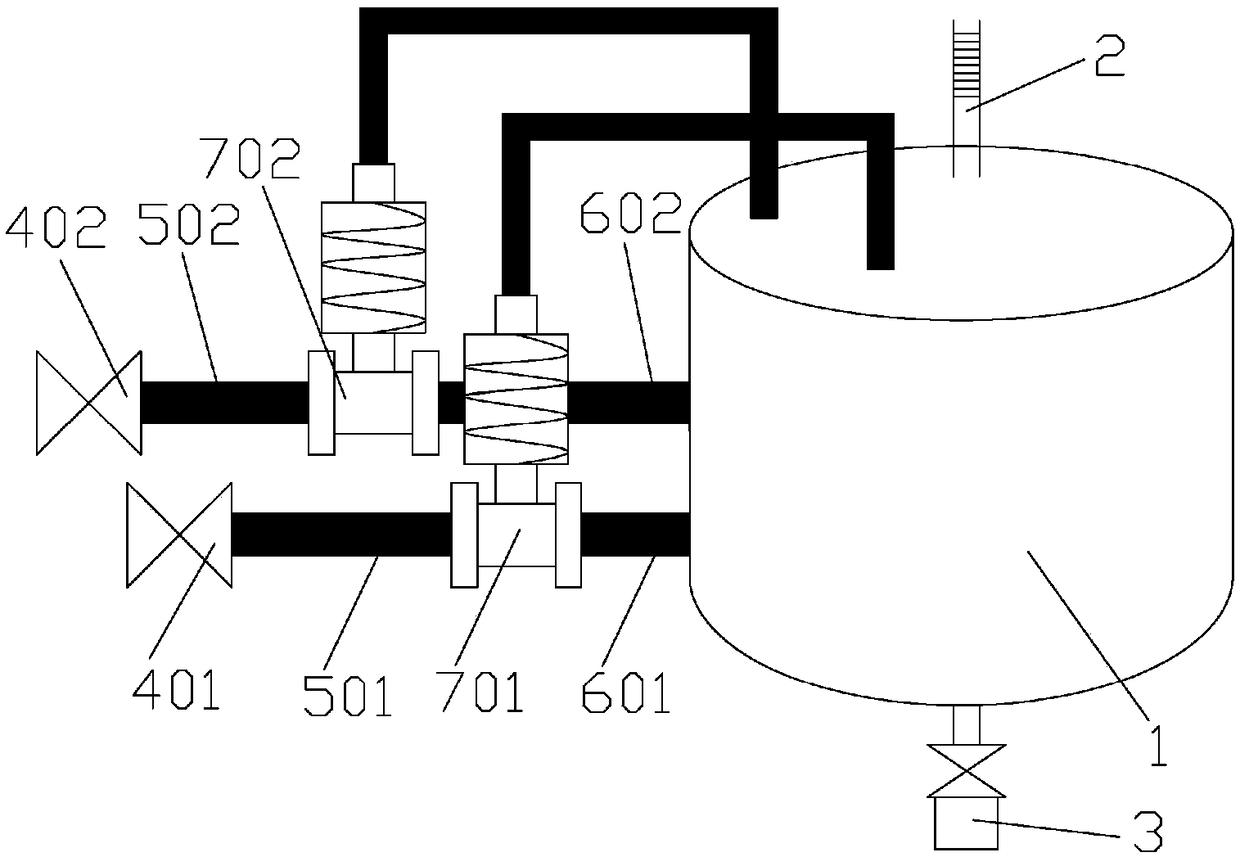

Self-operated temperature control valve detection device and detection method

Owner:SHANDONG IRON & STEEL CO LTD

Fingertip tactile performance test experimental device

PendingCN108956113AMachine part testingMechanical counters/curvatures measurementsActive touchTactile sense

Owner:ZHEJIANG SCI-TECH UNIV +1

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap