Automatic circulation impact fatigue test device

An impact fatigue and testing device technology, applied in measuring devices, using repetitive force/pulsation force to test material strength, and testing of mechanical parts, etc. Improve circulation efficiency and not easy to loosen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

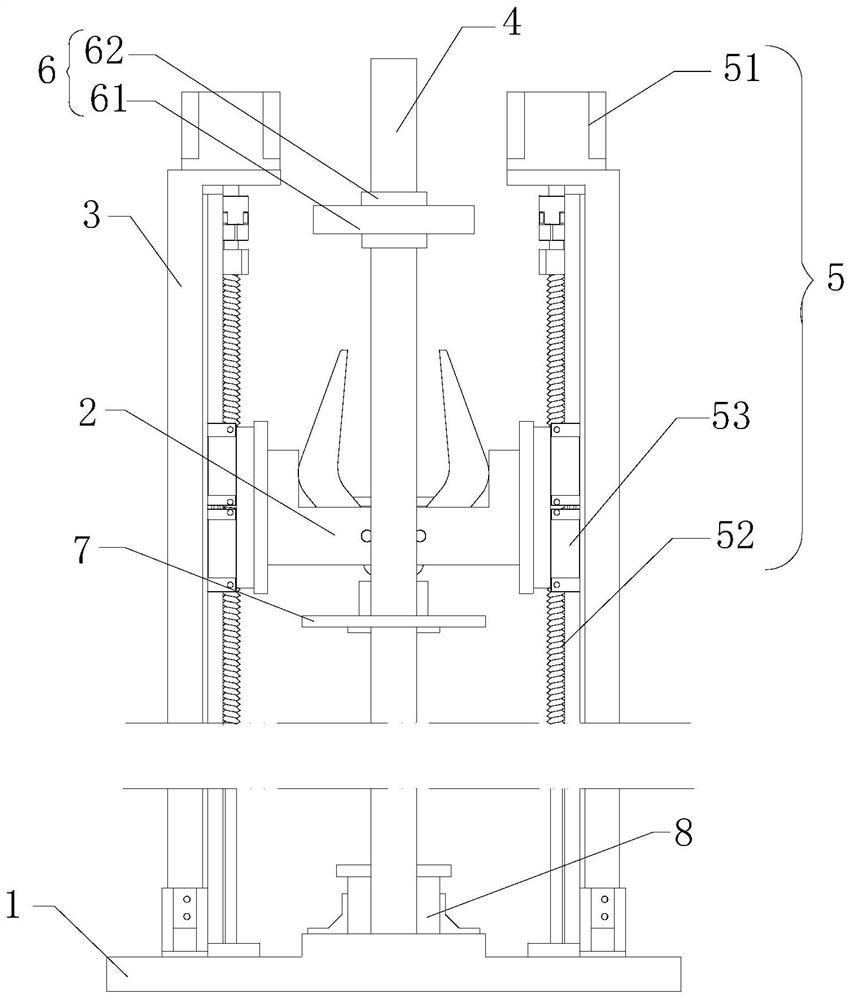

[0042] like figure 1 As shown, an automatic cyclic impact fatigue test device includes: a base 1, a clamping assembly 2, a support plate 3 vertically arranged on the base 1 and located on both sides of the clamping assembly 2, vertically arranged on the base 1 and connected to the support The guide rod 4 parallel to the plate 3, the lifting drive assembly 5 arranged on the top of the support plate 3 and used to drive the clamping assembly 2 to move up and down along the support plate 3, is sleeved on the guide rod 4 and used to control the opening and closing of the clamping assembly 2 The opening and closing assembly 6, and the impact assembly 7 sleeved on the guide rod 4 and clamped by the clamping assembly 2. The base 1 is used to support the entire test device, the clamping assembly 2 is used to clamp the impact assembly 7 on the guide rod 4, the opening and closing assembly 6 is used to drive the clamping assembly 2 to open and close, the guide rod 4 acts as a guide, and the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap