Automobile hand brake fatigue test rack

A fatigue test, hand braking technology, applied in vehicle testing, mechanical component testing, machine/structural component testing, etc. Equipment can not meet the requirements of the new standard and other problems, to achieve the effect of strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

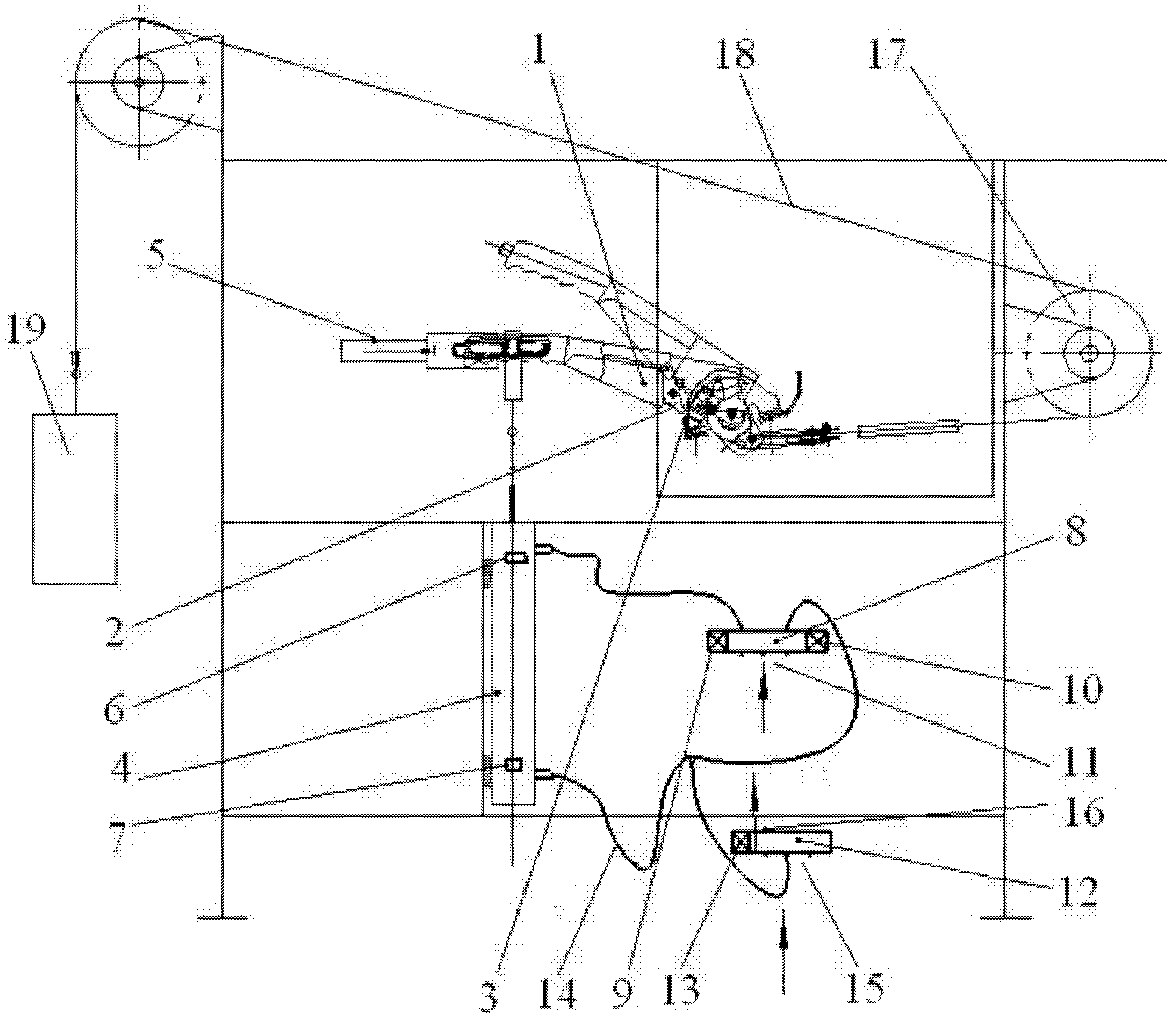

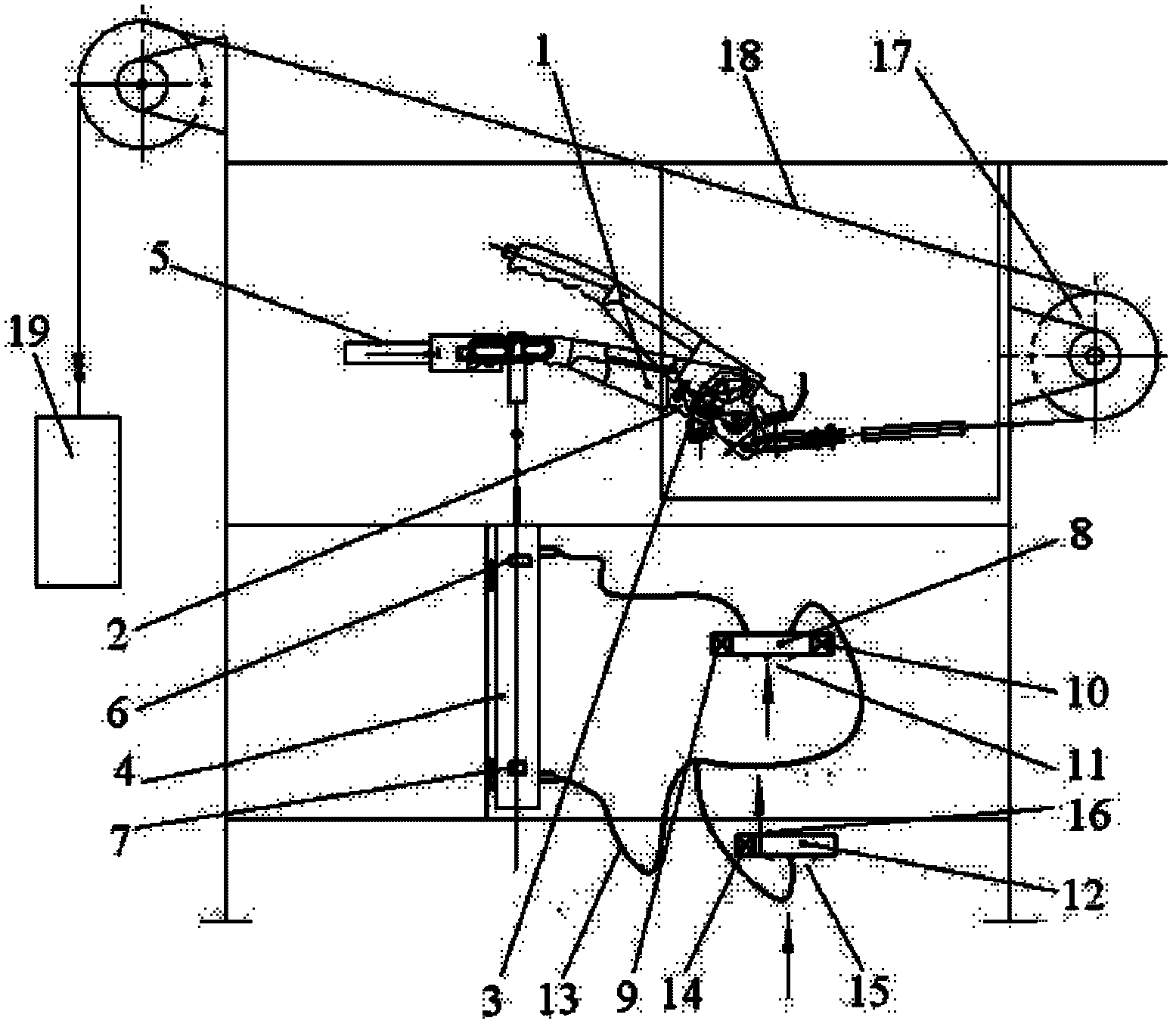

[0030] With reference to the accompanying drawings, the specific implementation of the present invention will be further described in detail through the description of the embodiments to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concept and technical solution of the present invention.

[0031] Such as figure 1 , figure 2 The structure of the present invention expressed is an automobile hand brake fatigue test bench, which is used for the fatigue test of the test sample 1 of the hand brake. The test sample 1 includes a ratchet wheel 2, a tooth plate 3, and The test bench described is provided with a traction cable 18, a traction pulley 17 and a traction weight 19, and the test bench is also provided with a hand brake control cylinder 4 and a hand brake button cylinder 5. The invention is proposed for improving the automobile hand brake fatigue test bench.

[0032] The traction cable 18, the traction pulley 17 and the trac

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap