Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3 results about "Tailstock" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A tailstock, also known as a foot stock, is a device often used as part of an engineering lathe, wood-turning lathe, or used in conjunction with a rotary table on a milling machine. It is usually used to apply support to the longitudinal rotary axis of a workpiece being machined. A lathe center is mounted in the tailstock, and inserted against the sides of a hole in the center of the workpiece. A tailstock has a Dead Center, while headstock has Live Center. A Tailstock is particularly useful when the workpiece is relatively long and slender. Failing to use a tailstock can cause "chatter," where the workpiece bends excessively while being cut.

Cylinder liner combined machining machine tool

ActiveCN104801977AMeet the needs of basic functionsSimple structureTailstocks/centresOther manufacturing equipments/toolsHigh volume manufacturingEngineering

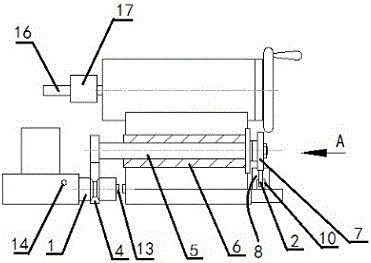

The invention relates to a cylinder liner combined machining machine tool. The machine tool comprises a machine tool body, wherein a motor device, an apron driving device, a tailstock driving device and three sets of guide rails are installed on the machine tool body, an upper apron is installed on the upper set of guide rails, an external turning tool is installed on the upper apron, a down-cutting device is installed on the lower set of guide rails, a facing tool set is installed on the down-cutting device, a headstock and a double-station complex programming tailstock are installed on the main guide rails in the middle, a headstock spindle is driven by the motor device to rotate, a boring tool and an expansion combination device are installed at the front end of the headstock spindle, a material pushing device is installed on the top of the headstock, and the double-station complex programming tailstock is a tailstock device which is provided with a telescopic hydraulic chuck mechanism and a hydraulic center mechanism at the same time. According to the cylinder liner combined machining machine tool, the machining efficiency and the accuracy of cylinder liners can be greatly improved; a production unit can formed when an automatic feeding and discharging device is further arranged so that automatic production can be achieved, the production cost can be greatly reduced, the productivity of enterprises can be improved, and the cylinder liner combined machining machine tool is particularly applicable to mass production of cylinder liners.

Owner:NING XIA XIN RUI CHANG CHENG JI CHUANG YOU XIAN GONG SI

Ball screw efficiency test equipment and test method

PendingCN112729640AGuaranteed accuracyFlexible operationMachine part testingWork measurementPush and pullPull force

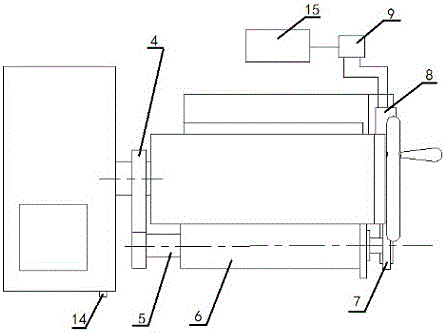

The invention discloses ball screw efficiency test equipment which comprises a bottom plate and further comprises a screw rod tension and compression device, a screw rod loading device, a screw rod fixing tailstock, a nut fixing structure, a nut rotation driving mechanism, a displacement test mechanism and a control device, the screw rod tension and compression device and the screw rod fixing tailstock are slidably arranged on the bottom plate; the lead screw loading device, the nut rotation driving mechanism and the displacement test mechanism are installed on the bottom plate, and the lead screw loading device carries out axial loading on a ball screw to be tested through the lead screw tension and compression device. The nut fixing structure is installed on the nut of a ball screw to be tested during testing, the nut rotation driving mechanism drives the nut to rotate through the nut fixing structure, and the displacement test mechanism tests the displacement of the screw rod in the ball screw to be tested through the screw rod tension and compression device. The invention further discloses a ball screw efficiency test method. The accuracy of the efficiency of the ball screw during forward and reverse rotation is effectively ensured through the load of push and pull force on the screw rod.

Owner:CIXING GROUP

Automatic control method of air cylinder driven numerical control lathe tailstock capable of achieving rigid tapping

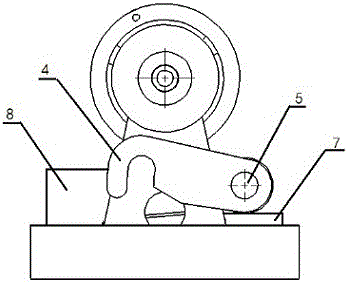

ActiveCN106041136AHigh degree of automationGapless junctionTailstocks/centresThread cutting auxillary apparatusAutomatic controlTailstock

Owner:东阳市金陵机械股份有限公司

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap