Wastewater solid-liquid separator and separation method thereof

A technology of solid-liquid separation and separation method, which is applied in chemical instruments and methods, animal husbandry wastewater treatment, biological water/sewage treatment, etc., to achieve the effect of reducing the difficulty of sewage treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

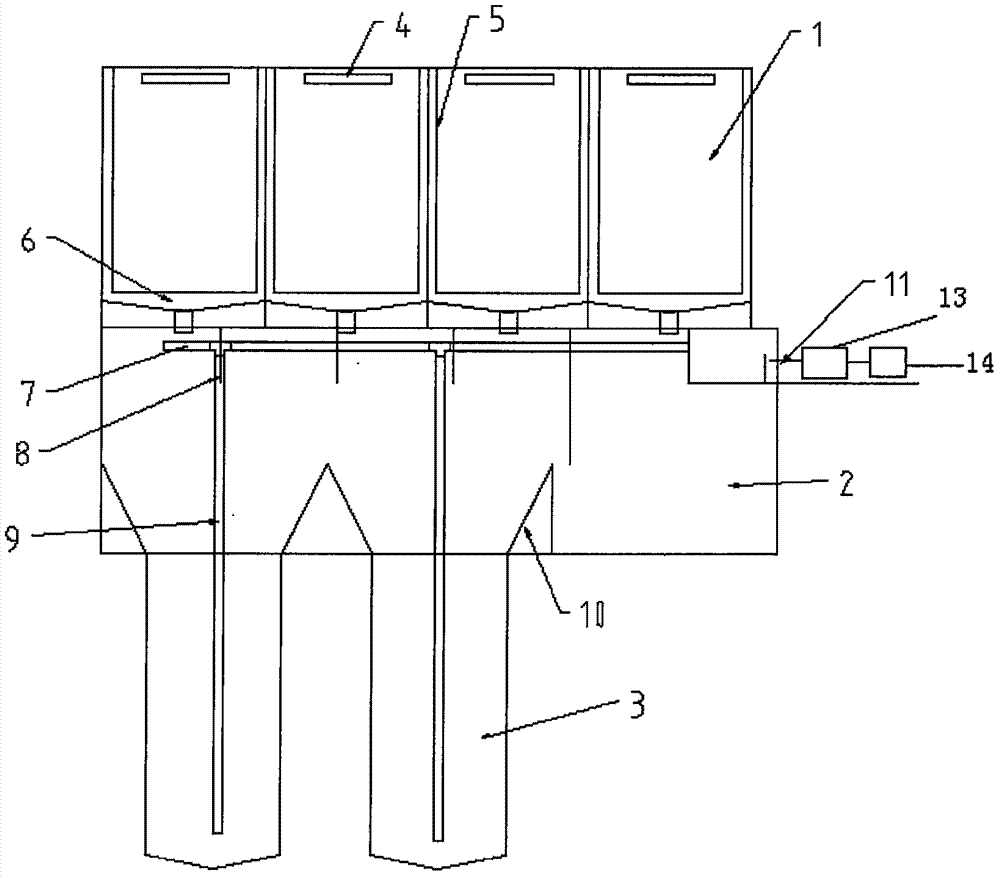

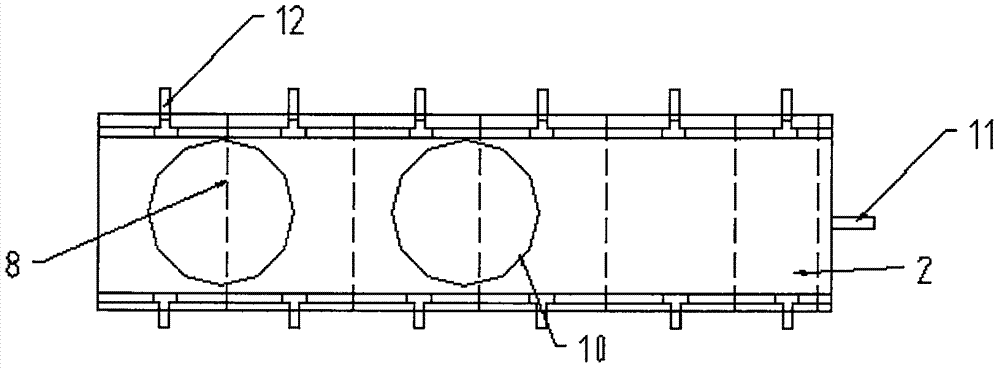

[0028] The specific implementation manner of the present invention is described with reference to the drawings and examples.

[0029] like figure 1 As shown, the solid-liquid separation equipment includes a solid-liquid separation cabinet 1, a mud-water separation tank 2 and an upflow anaerobic reaction tank 3;

[0030] The inside of the solid-liquid separation cabinet 1 is provided with a plurality of multi-layer filter components 5, and the multi-layer filter components 5 include a bottom plate and four side walls, and the four side walls are respectively three screens and a The discharge door, the bottom plate is a bottom plate screen; the top of the multi-layer filter component 5 is provided with a water inlet distribution pipe 4;

[0031] Below the multi-layer filter part 5 is the water collection area 6; the water collection area 6 is connected to the anaerobic water distribution pipe 9 through the water collection pipe 7, and the anaerobic water distribution pipe 9 is ins

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap