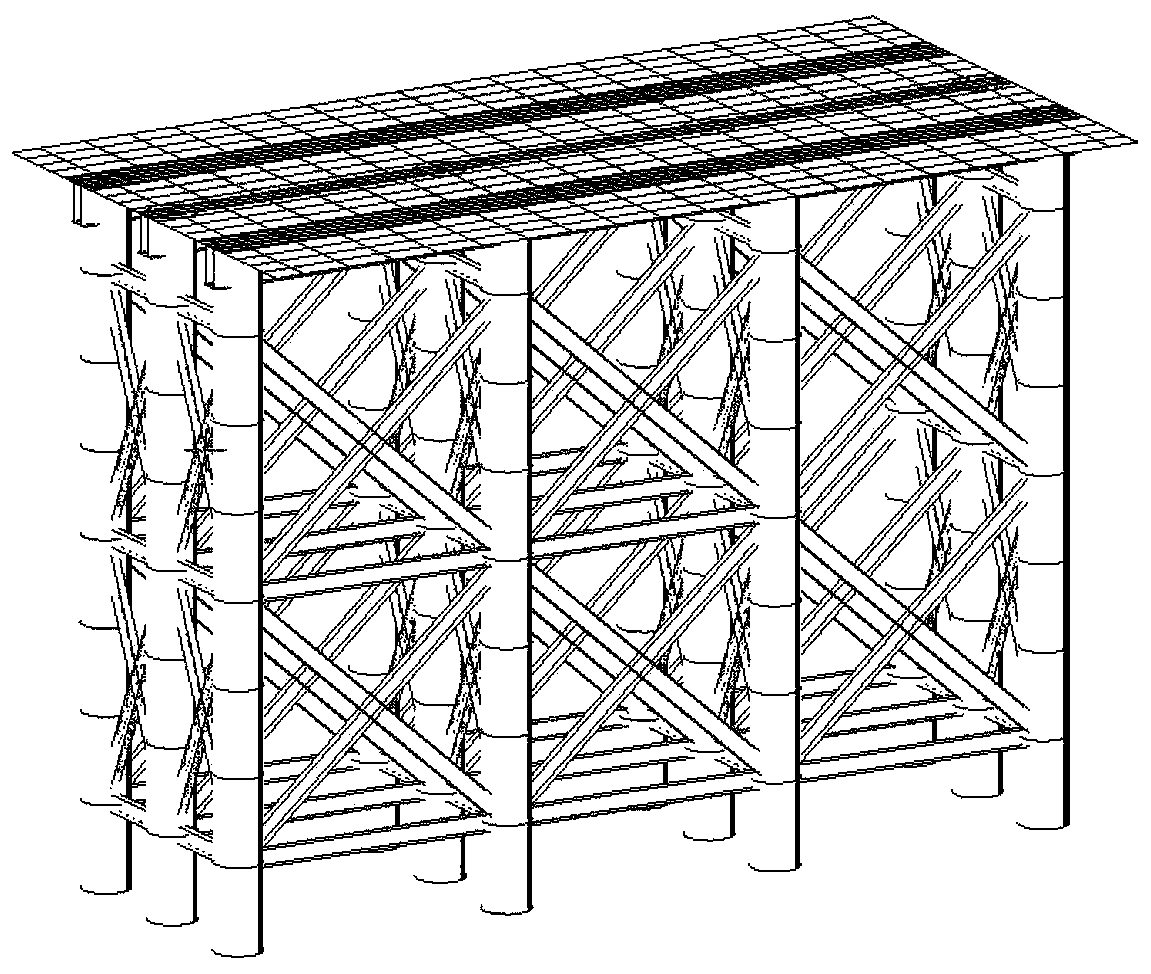

Shield machine receiving steel platform

A technology of shield machine and steel platform, which is applied in the field of receiving steel platform, can solve the problems of inability to provide negative two-story shield receiving conditions on time, inability to complete the construction of mid-slab concrete structure, and large engineering volume, etc., to achieve simple and stable structure High resistance, anti-slip effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

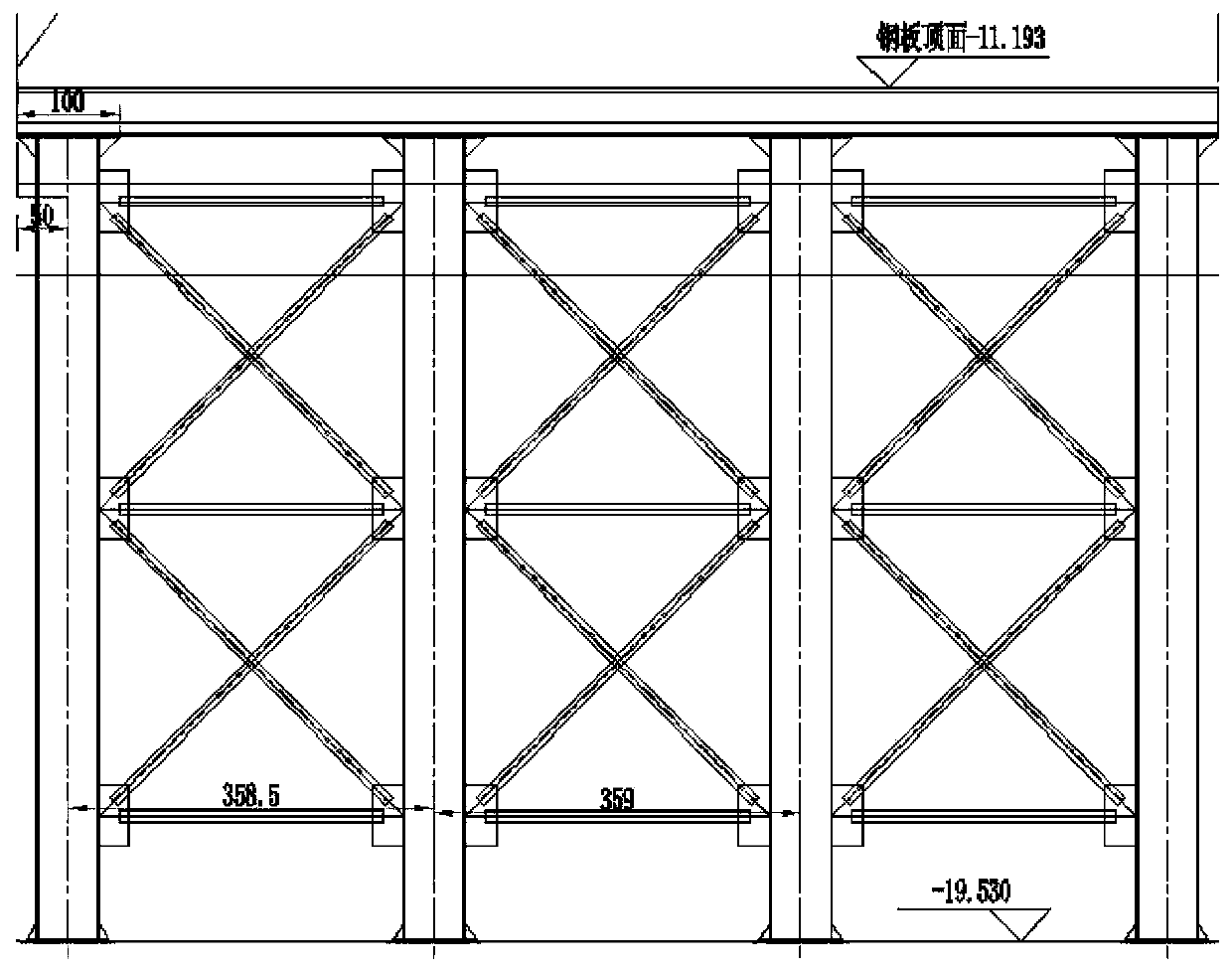

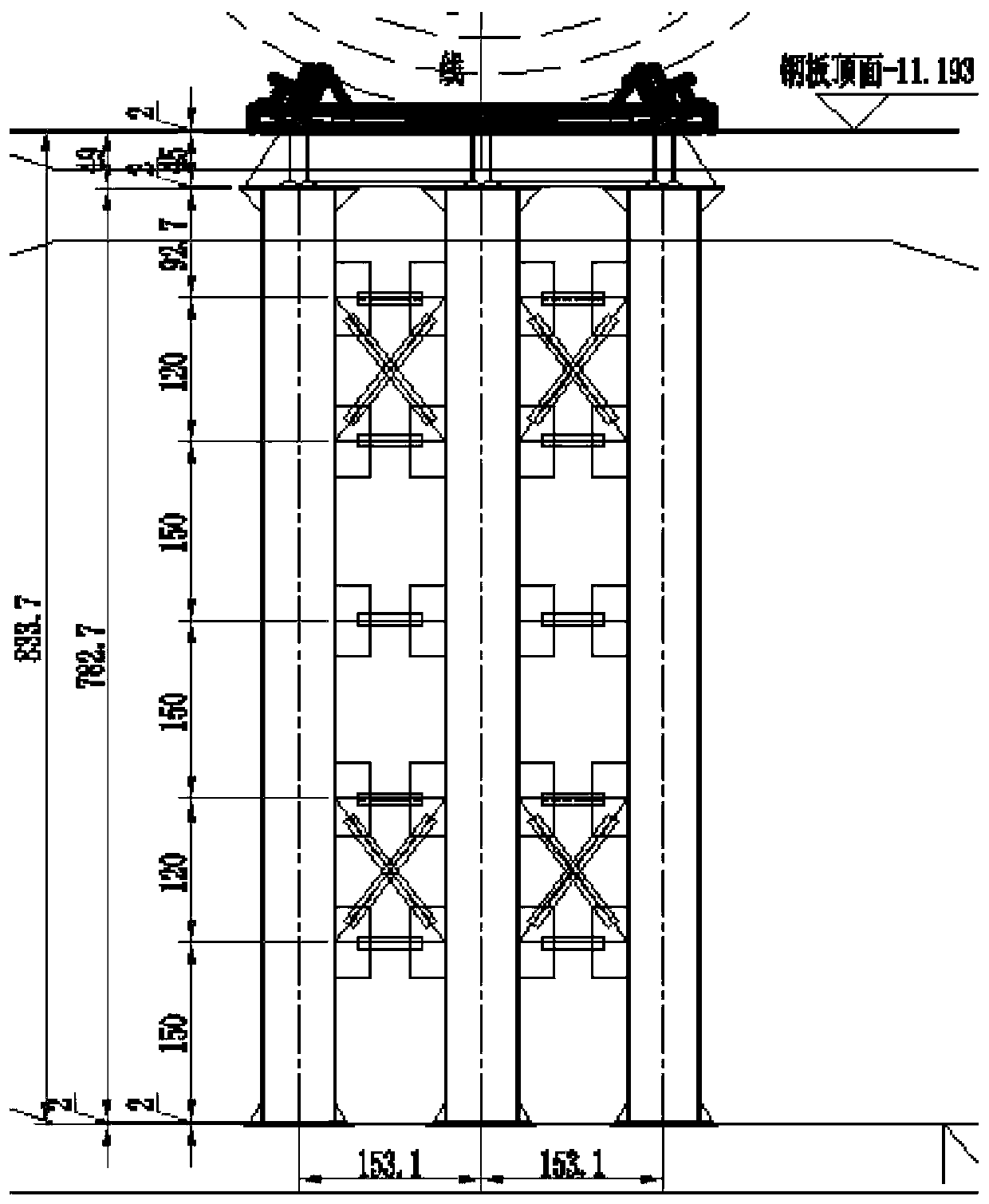

[0049] Example 1: In the section from Xiangxicun Station to Wenjin Station of Shenzhen Metro Line 9, the mileage from the left line of the section is 498.56m, and the exit of the left line is Xiangxicun Station, which is a transfer station. There is a height difference in the floor of the riding section. In order to receive the construction when the shield arrives, the shield receiving steel platform needs to be set up. The size of the reserved hole at the shield receiving end well is 11.5×7.5m. The enclosure of the main structure adopts an underground diaphragm wall with a thickness of 1000mm.

[0050] The diameter of the shield machine that is used to enter the hole this time is φ6340; the length of the main body of the shield machine is 8650mm, and the length of the cutter head is 1650mm. The weight of the machine head is 320T.

[0051] Combined with the site conditions, Xiangxicun Station is a transfer station, and the height difference between the bottom of the shield tun

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap