Curtain grouting method for shallow buried nearly horizontal burnt rock water-bearing layer

A technology of curtain grouting and burial, which is applied in earthwork drilling, wellbore lining, tunnel lining, etc. It can solve the problems of high drilling cost, large drilling engineering volume, continuous drilling of drilling holes, etc., and achieve the effect of more options

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

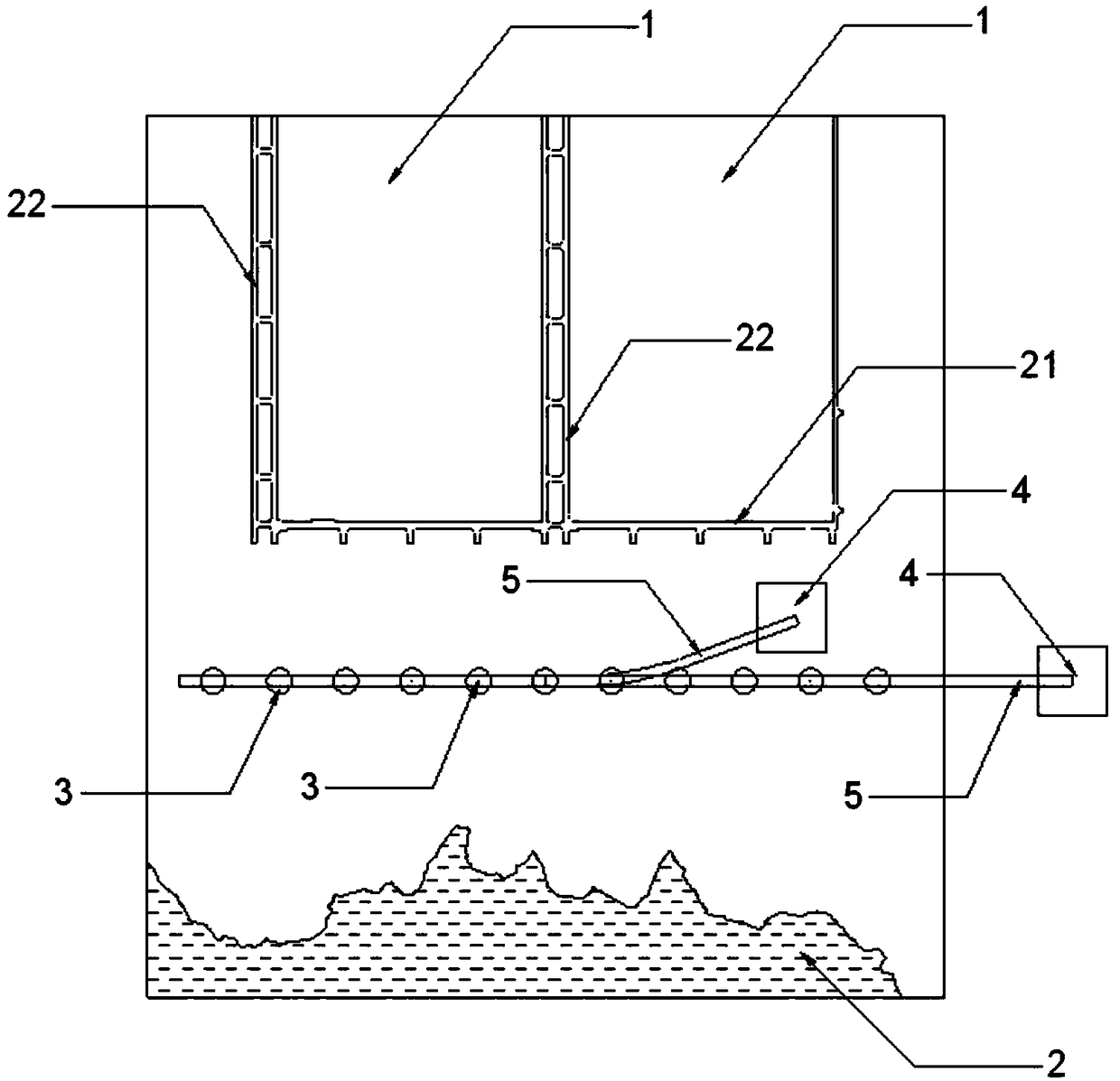

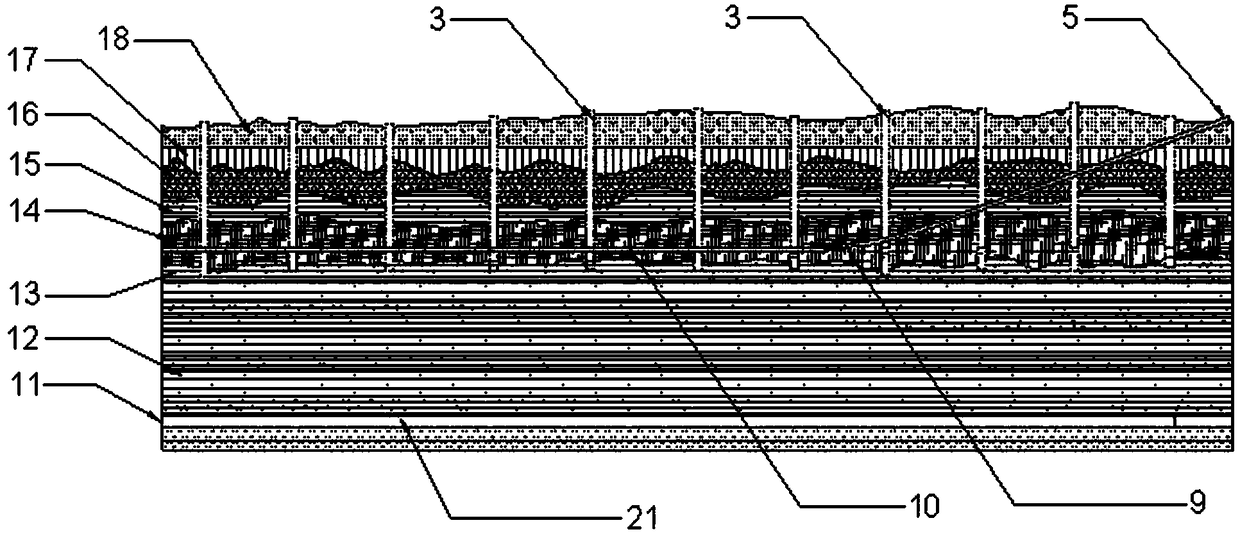

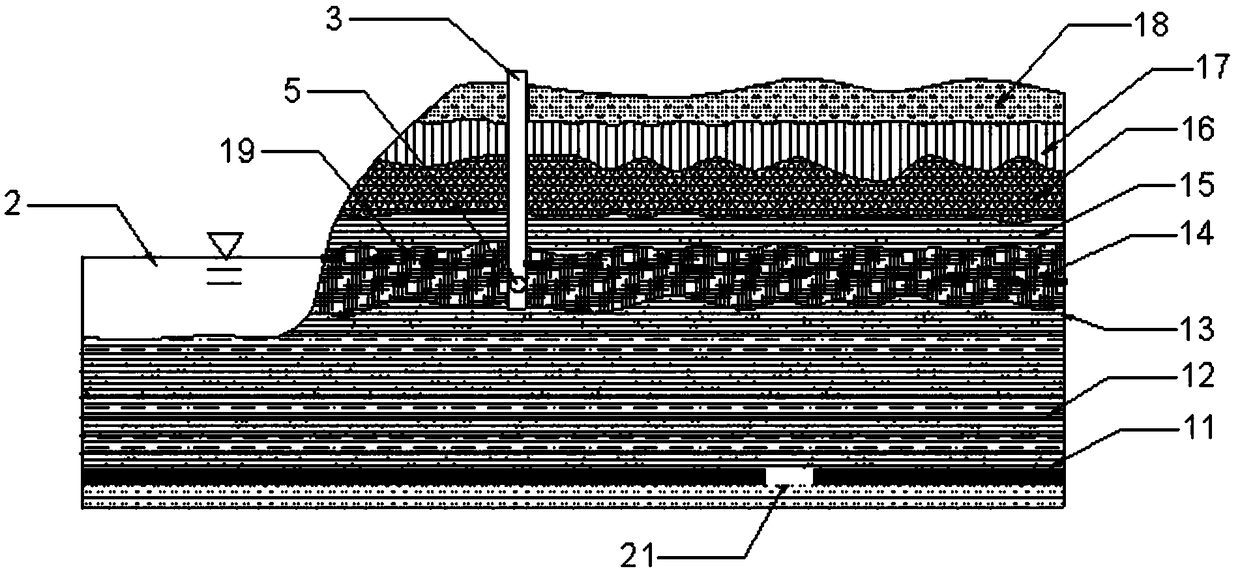

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

[0032] A coal seam in the northern Shaanxi mining area is a coal seam of the Jurassic Yan'an Formation. The geological structure is simple, and the coal seam dip is small. Main mining seam 4 -2 The average coal thickness is about 3.63m, and the middle part of the minefield is 4 -2 Burnt rocks are in direct contact with the reservoir after coal burning, 4 -2 coal below 5 -2 Coal is a complete coal seam that has not been burned. According to outcrop observations of burnt rocks, 4 -2 The average thickness of the coal-fired metamorphic rock is about 15-20m, and it is highly water-rich due to the water supply of the reservoir. 4 -2 Coal floor distance 5 -2 Coal about 75m, 5 -2 Coal thickness is about 6m, 5 -2 After the coal face is mined, the water-conducting fracture zone will develop to 4 -2 coal burnt rock, 4 -2 Water in burnt rocks in the coal-fired area contrib

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap