Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

84 results about "Drill hole" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

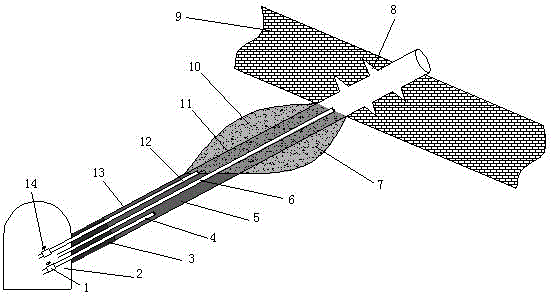

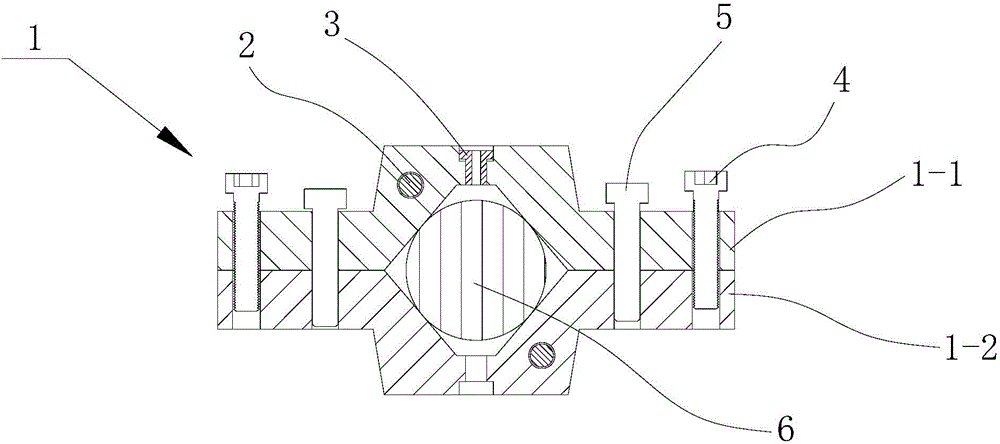

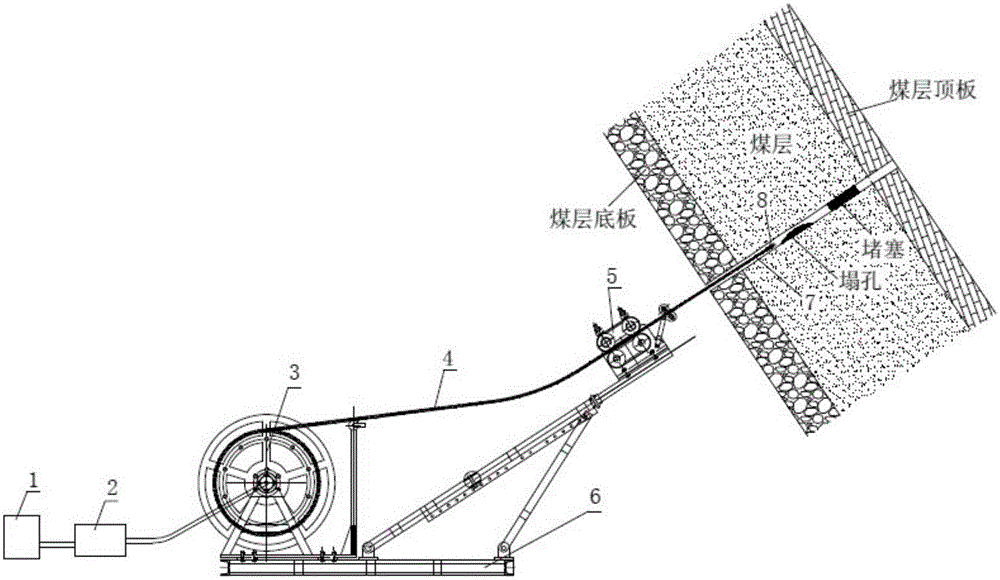

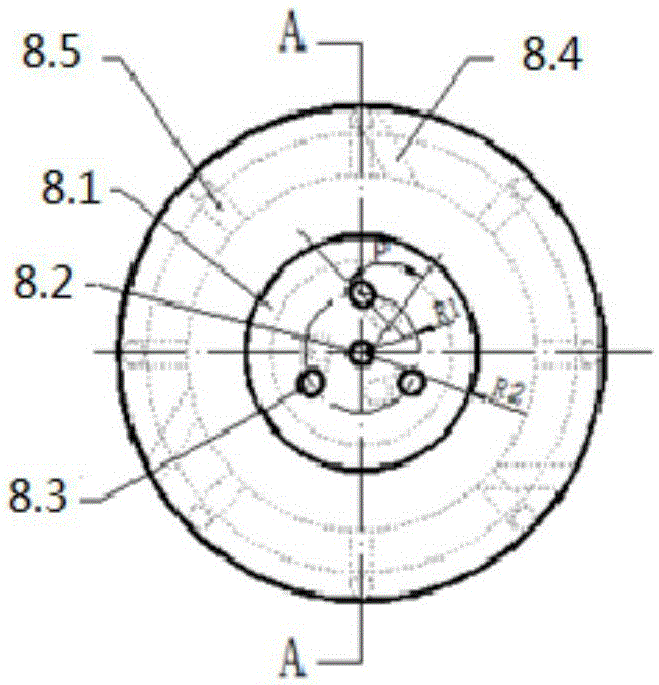

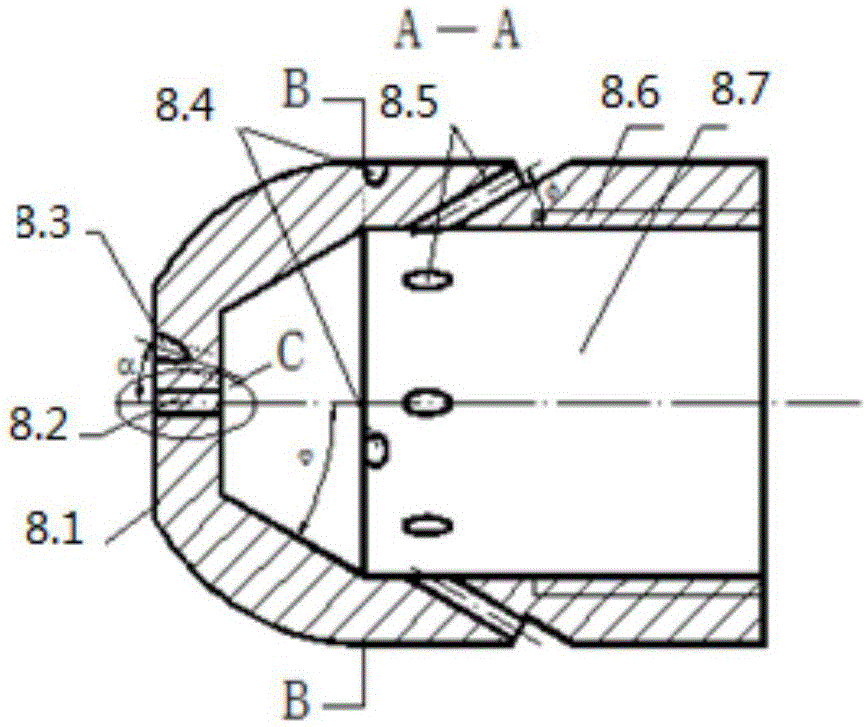

Method for fracturing coal seam by employing high-pressure gas

ActiveCN104405358ASolve the problem of air leakageGuaranteed gas pressureFluid removalSealing/packingParticulatesProduct gas

Owner:TAIYUAN UNIV OF TECH

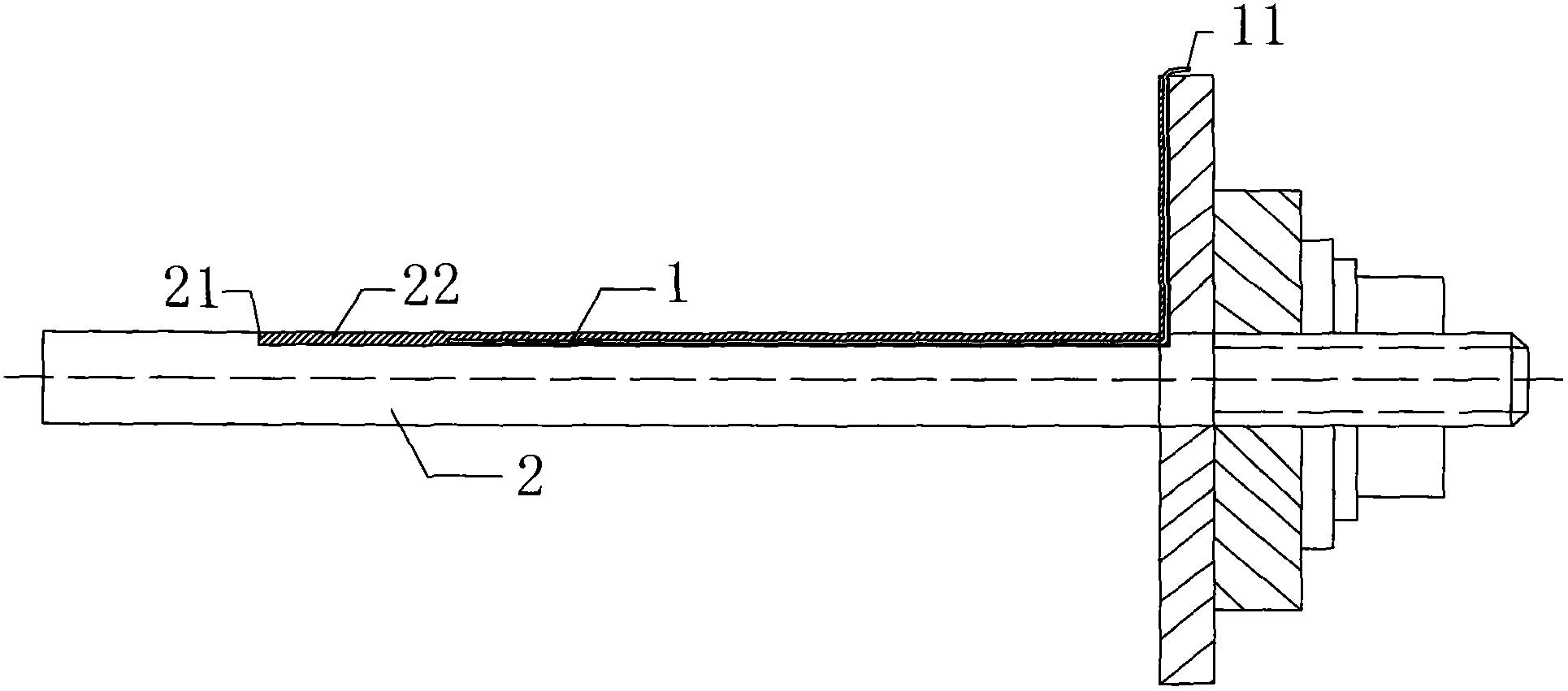

Coal seam anti-reflection method for circular damage by using cold shock of liquid nitrogen and phase change gas

ActiveCN111119829AGood cracking and anti-reflection effectFast injectionDrilling rodsFluid removalEngineeringNitrogen gas

Owner:CHINA UNIV OF MINING & TECH

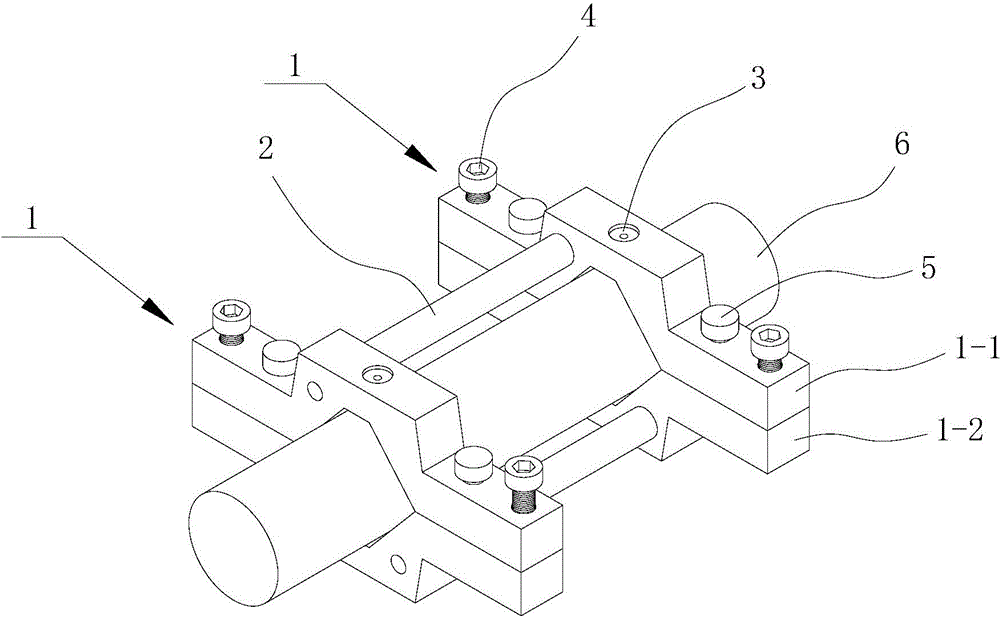

Rapid clamping and drilling mould for machining of side hole of round steel

Owner:TIANJIN ANSHUNCHENG METAL PROD

System and method for monitoring dynamic disaster of coal mine with fiber bragg gratings

InactiveCN102797491AAccurate predictionEasy to predictUsing optical meansTunnel/mines ventillationIntrinsic safetyFiber

Owner:HENAN POLYTECHNIC UNIV

Disposable cutting insert for boring cutter

A disposable cutting insert for a boring cutter can reduce the roughness of a cut surface and achieve a mirror-like surface effect. The disposable cutting insert has a long curved blade edge, and the radius vertex of the long blade edge is deviated slightly from an external side of a vertex of the radius of cutting edge. A short curved blade edge is formed between the radius arc vertex and the radius arc vertex of the cutting edge. The vertical distance of the short curved blade edge is greater than the feed rate. The cutting edge cuts the work piece and the short curved blade edge can scrape a small size of material precisely for scraping the peak cut by the cutting edge and lower the height of the peak, so as to lower the surface roughness, and produce a mirror-like surface for an internal periphery of a bored hole.

Owner:CHANG SC

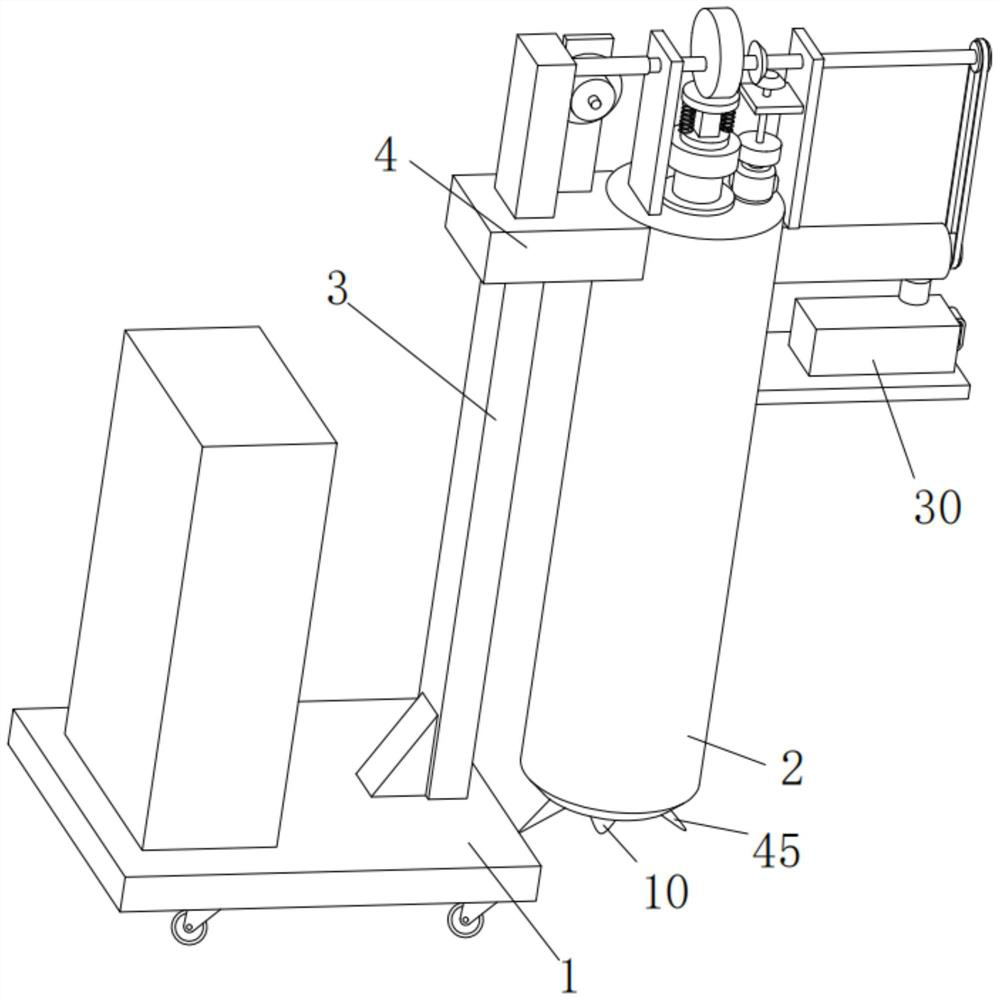

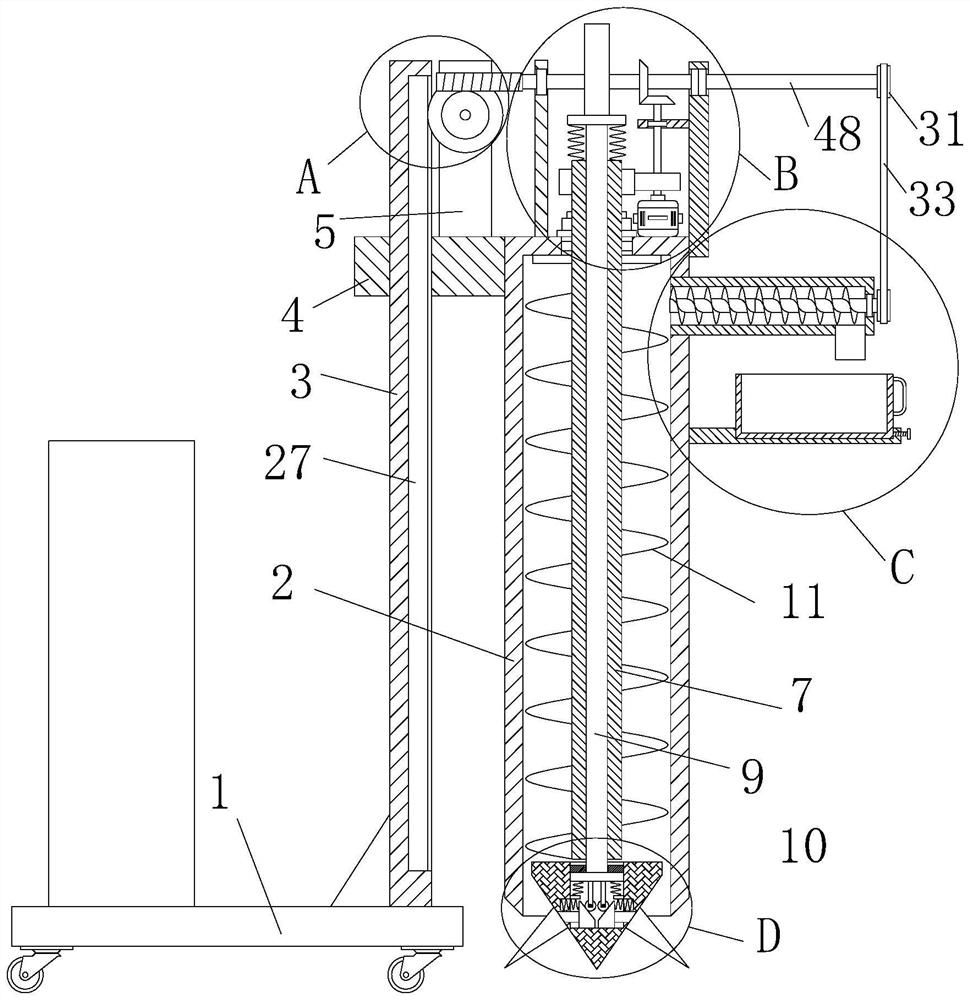

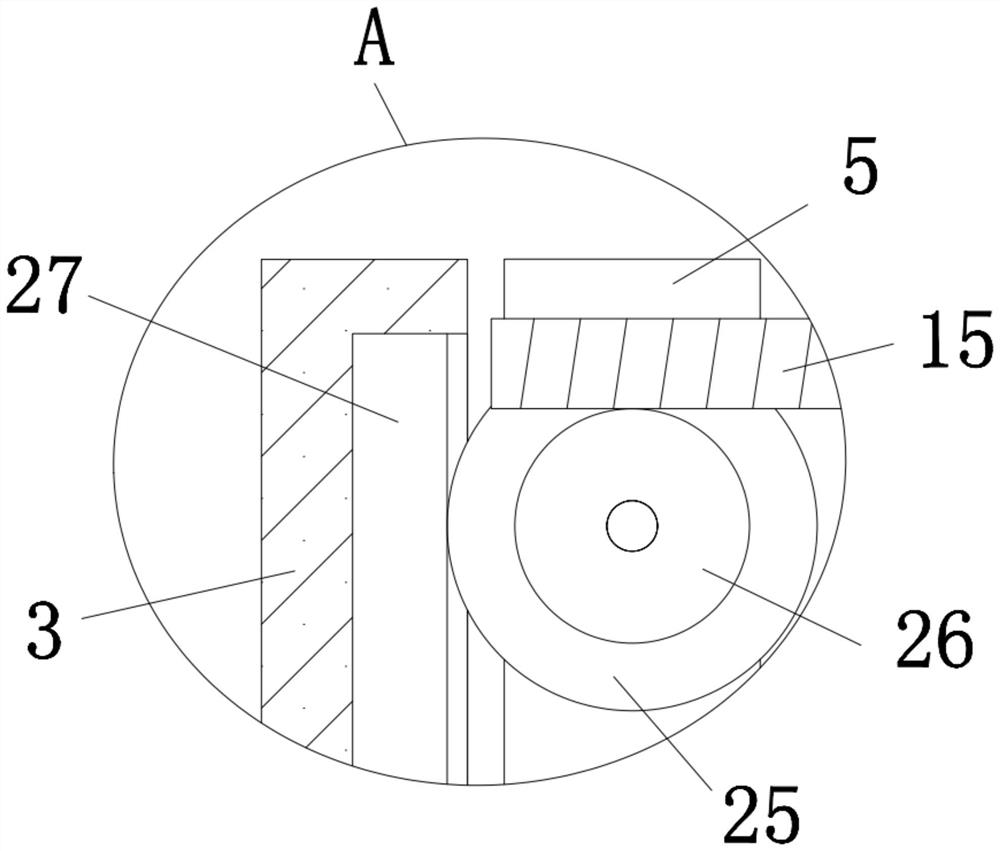

Soil sampling device for highway engineering road and use method thereof

PendingCN113404030AReduce manpower consumptionReduce difficultyIn situ soil foundationLow speedAgricultural engineering

Owner:谭小波

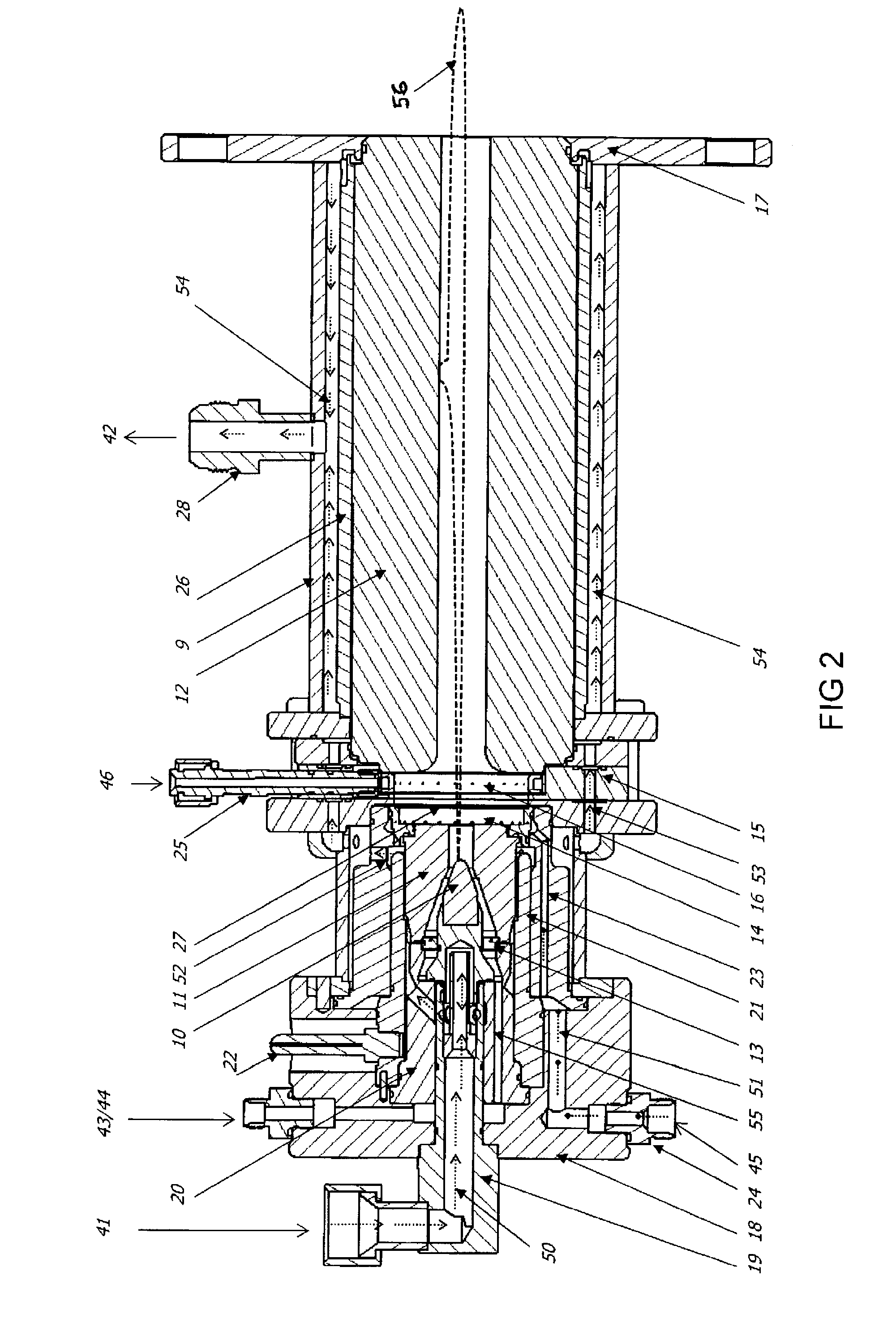

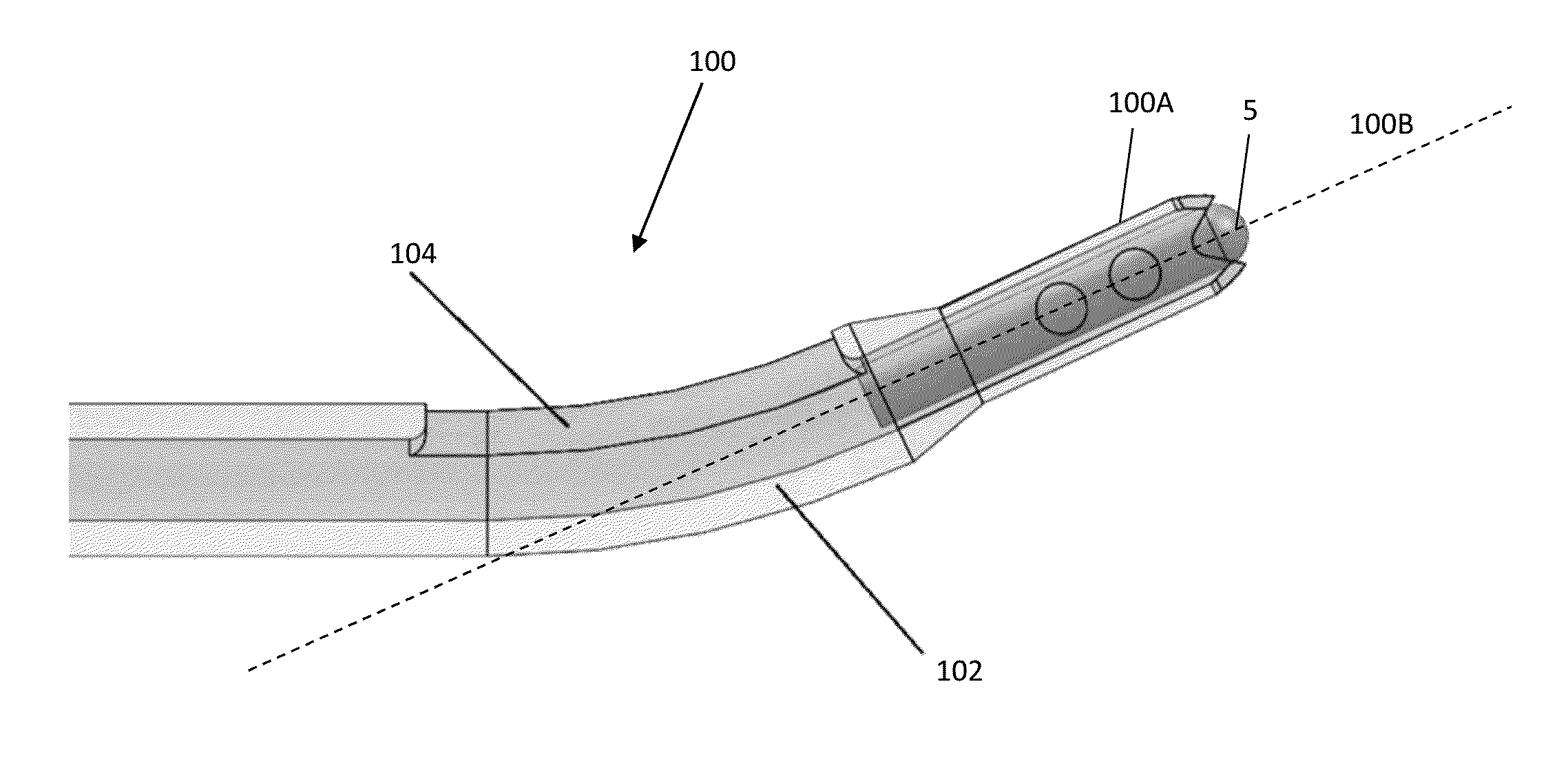

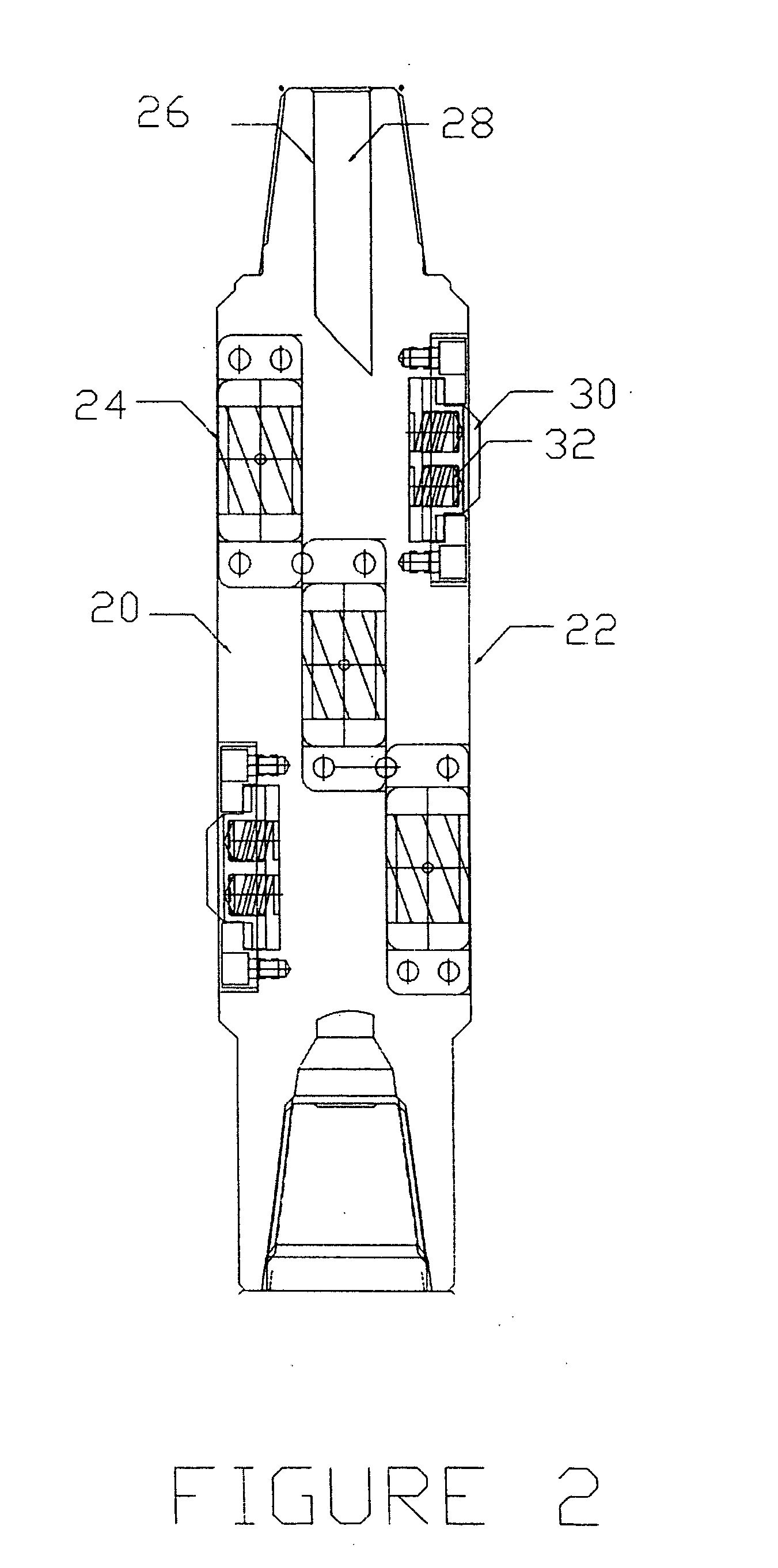

Adjustable Bent Drilling Tool Having in situ Drilling Direction Change Capability

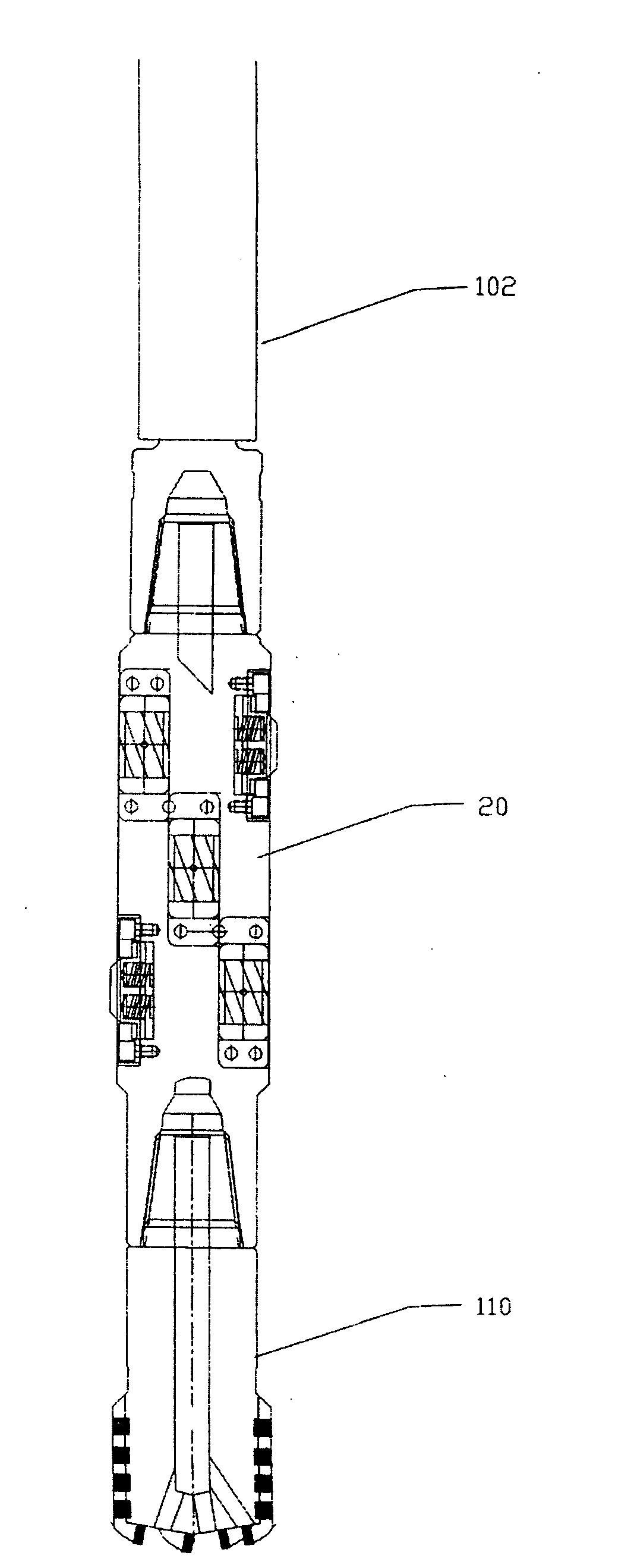

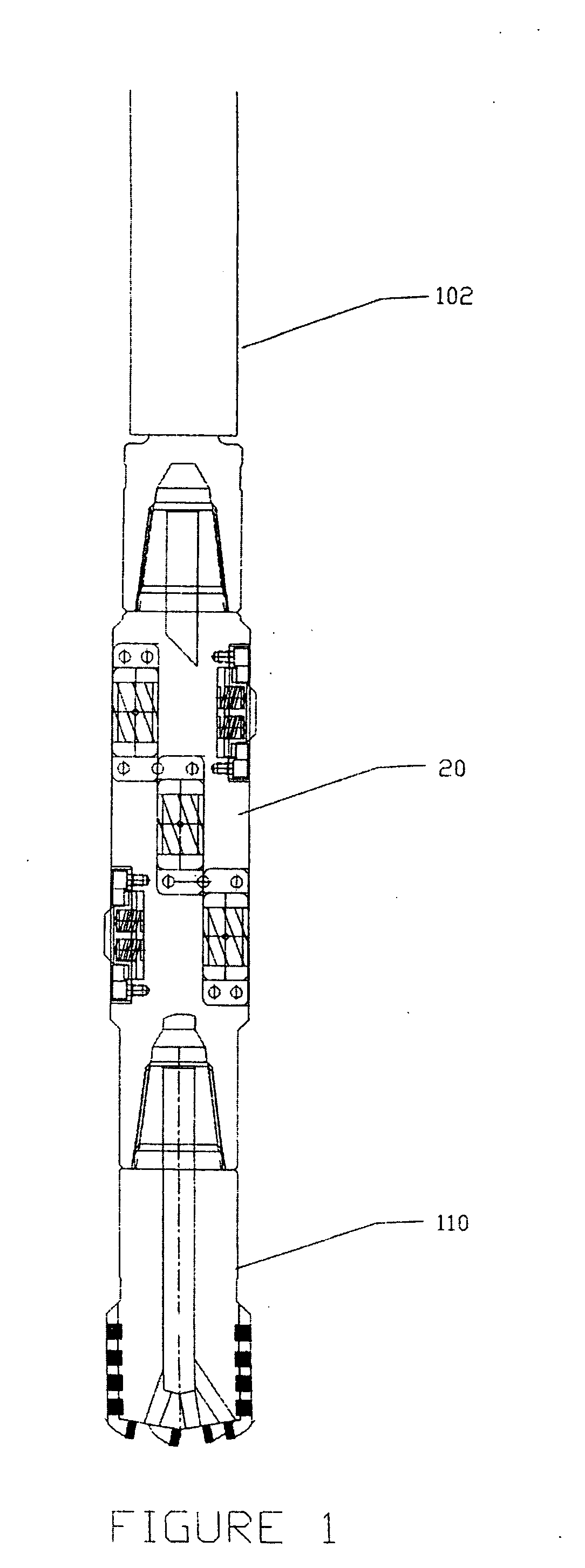

An adjustable bent drilling tool capable of changing in situ drilling direction to facilitate horizontal drilling. The drilling tool may be controlled from the surface and eliminates the need to bring the tool to the surface for reconfiguration. In one embodiment, the drilling tool utilizes a communications module to communicate with upstream sections of the tool. The communications module is connected to a programmable electronic control module which controls an electric motor. A hydraulic valve assembly follows the control module, which receives input signals and controls a pilot piston between two fixed points of a mid-assembly typically located adjacent to and downstream of the hydraulic valve assembly on the drill tool. A lower assembly is attached to the drill tool immediately following the mid-assembly, and provides both a safety release sub-assembly as well as a bendable sub-assembly which directs the adjustable drill tool to change drilling angle and direction.

Owner:DAVID L ABNEY

Method for construction of pipe sinking cast-in-place pile in pebble bed, gravel layer and sand layer

A method for the construction of a pipe sinking cast-in-place pile in a pebble bed, a gravel layer and a sand layer, wherein firstly, a hole is drilled in a pile position and mud or coal ash slurry is simultaneously injected into the hole; and then the construction of the pipe sinking cast-in-place pile is performed through a process of hammering double sleeves; therefore, the purposes of no sediment at the bottom end of the pile and high bearing capacity of single pile are achieved. The method has the characteristics of high construction speed, no pollution on the spot, ensured quality, low construction cost, and ensured designed pile diameter and pile length.

Owner:刘清洁

Mine grouting technology and device with hole opening closed and circulation performed in hole

Owner:HUBEI CENT SOUTH EXPLORATION & FOUND ENG

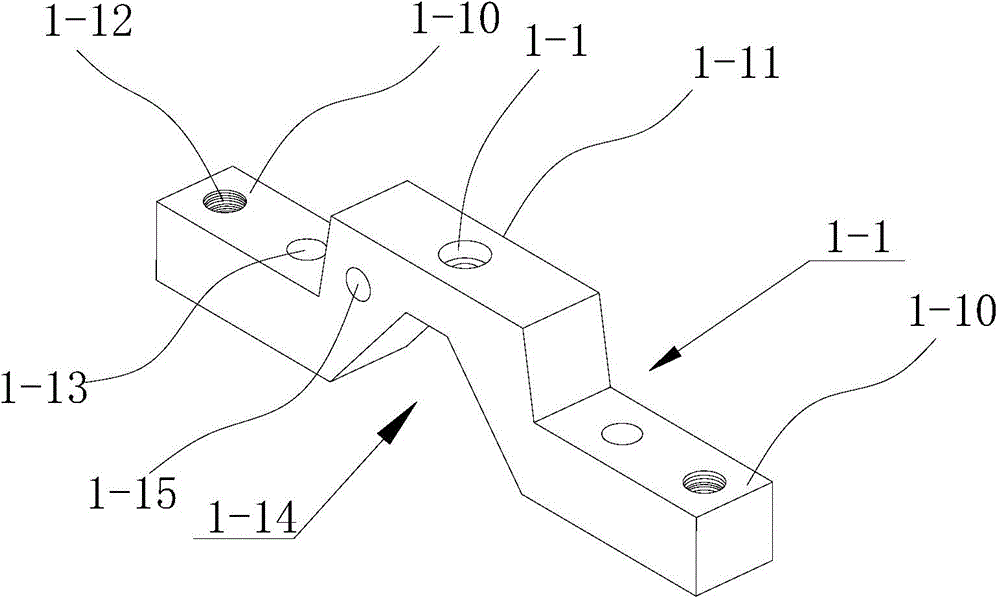

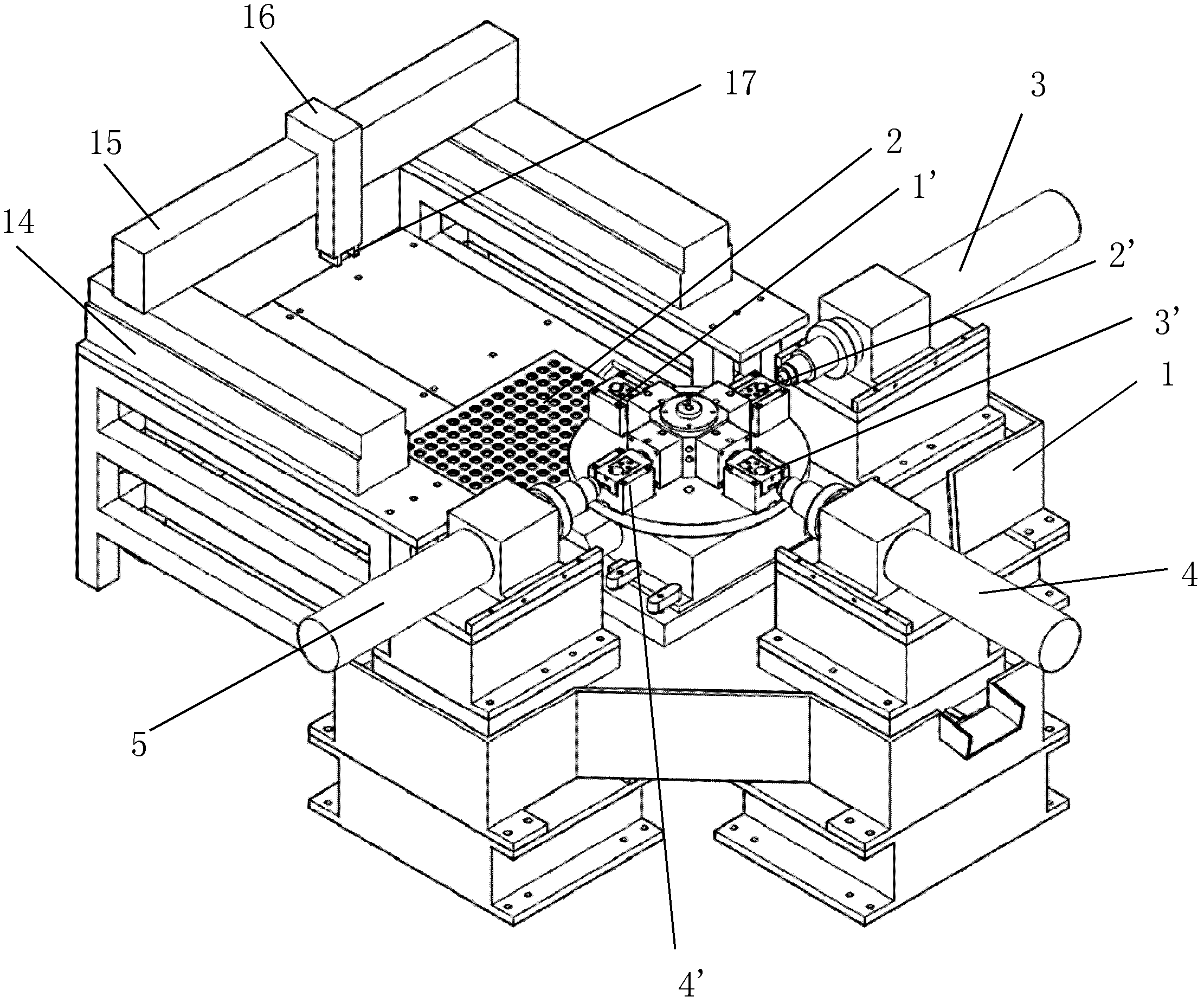

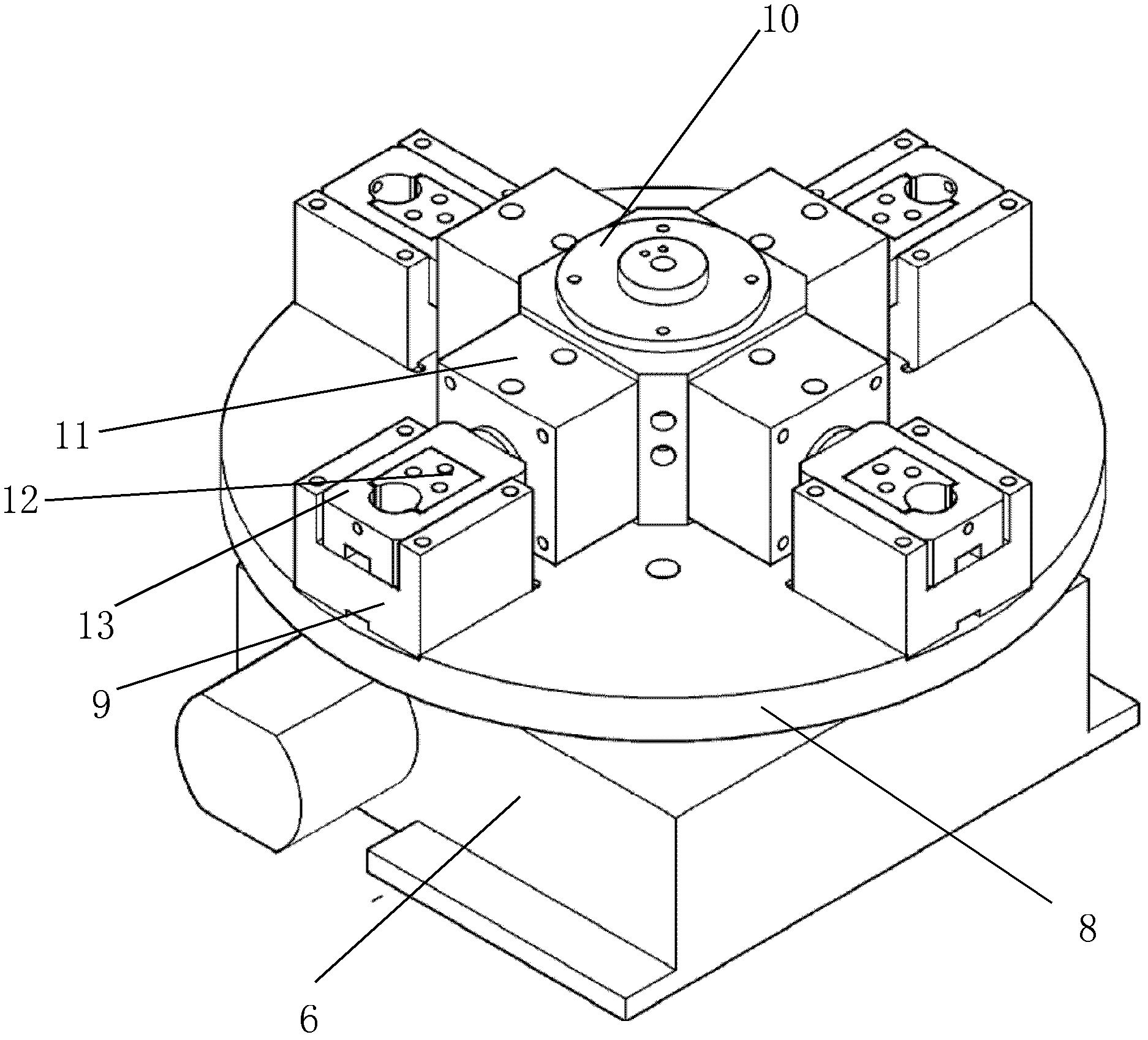

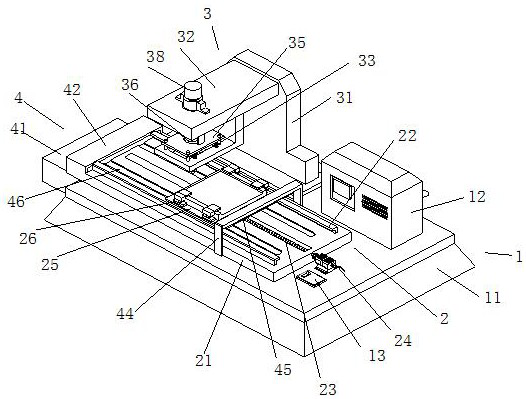

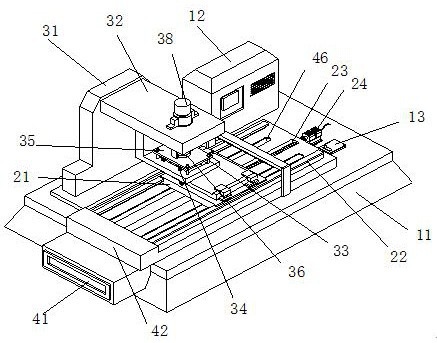

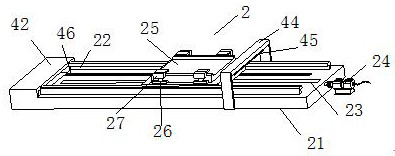

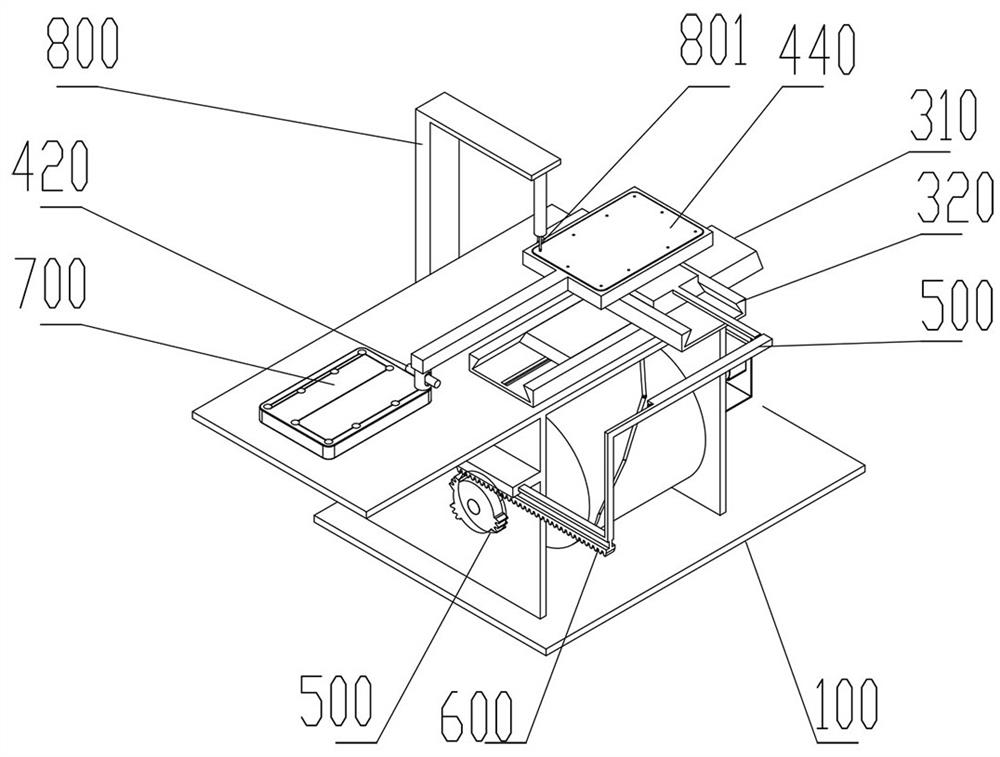

Special four-station machine tool for jackscrew holes of worms

InactiveCN102909554ANot affected by processing qualityFully automatedOther manufacturing equipments/toolsPositioning apparatusTransverse axisDrill hole

The invention relates to a special four-station machine tool for jackscrew holes of worms. The special four-station machine tool is characterized by comprising a tool body, a tray, a chamfering power head, a drilling power head, a tapping power head, a hydraulic turntable and fixtures; the hydraulic turntable is fixedly connected to the center of a working table of the tool body, the chamfering power head and the tapping power head are symmetrically fixedly connected onto the working table of the tool body along the transverse axis of the hydraulic turntable, the drilling power head is fixedly connected to the central position between the chamfering power head and the tapping power head along the radial direction of the hydraulic turntable, and the fixtures for mounting a workpiece are arranged on rotary work stations of the hydraulic turntable. The special four-station machine tool has the advantages that the special four-station machine tool are fully automatic, and labor cost is greatly reduced; various working procedures are centralized and can be carried out simultaneously, and accordingly the efficiency is improved; and influence of skills of operators to the machining quality is avoided, and the special four-station machine tool is stable and reliable.

Owner:天津市中马骏腾精密机械制造有限公司

Cyclic replacement grouting device and process of hole drilling fixing pipe

Owner:HUAINAN MINING IND GRP

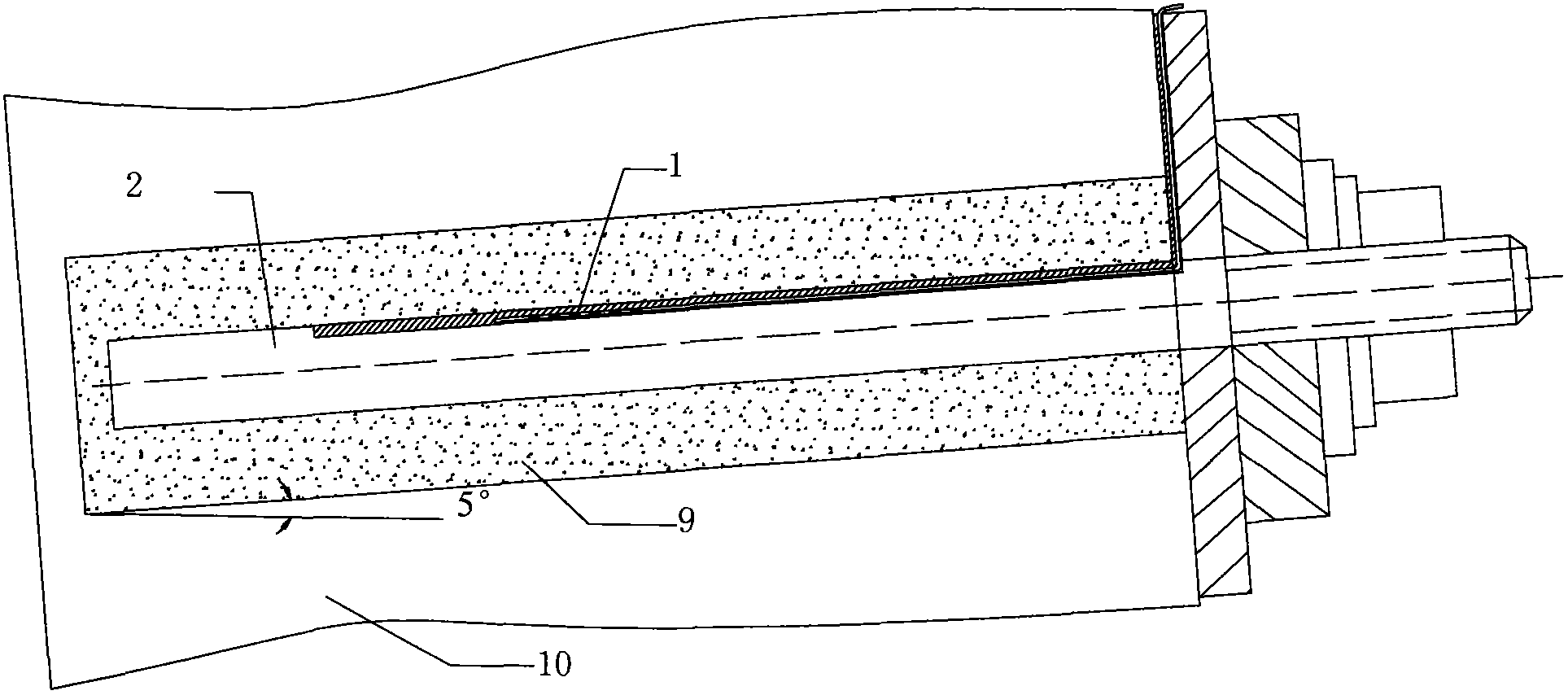

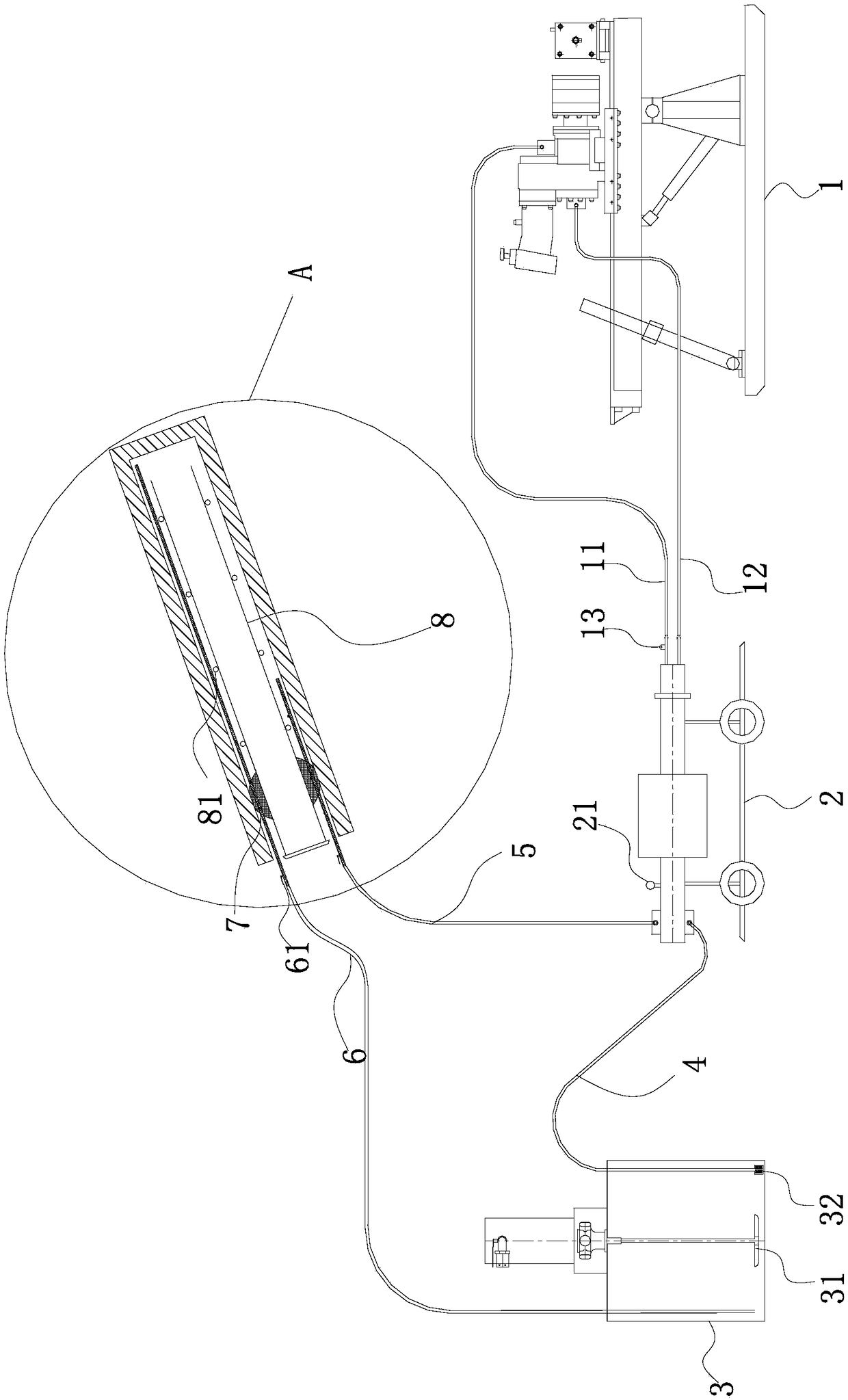

Construction method and system for hole cleaning and sediment thickness reducing of inclined steel pipe pile

ActiveCN107816324AEffectively and completely removesImprove flatnessDrilling rodsFlushingStructural conditionEngineering

The invention discloses a construction method and system for hole cleaning and sediment thickness reducing of an inclined steel pipe pile, and relate to the field of pile foundation construction. Themethod includes the following steps of S1, drilling holes through a reverse circulation drilling machine, and starting a gas lifting reverse circulation system to conduct sediment cleaning; S2, conducting sampling in a sediment discharge pipe after clean water flows out of the sediment discharge pipe, meanwhile the sand content of discharge, and stopping the gas lift reverse circulation system when the sand content is measured to be lower than 0.5%; S3, adding an alum or polyacrylamide solution into the inclined steel pipe pile, and starting the reverse circulation drilling machine to make theadded alum or polyacrylamide solution circulate and flow; S4, standing for 2-4 fours, and then starting the gas lift reverse circulation system for thoroughly removing sediments. By means of the method, the influences of hole drilling by means of turbid river water under silty-fine sand and intermediate-fine sand stratum structural conditions can be overcome, the good flatness of a soil insertingsurface is guaranteed, and the pile end bearing capacity is effectively improved.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD

Deep cover layer pipe drilling method

Owner:SINOHYDRO FOUND ENG

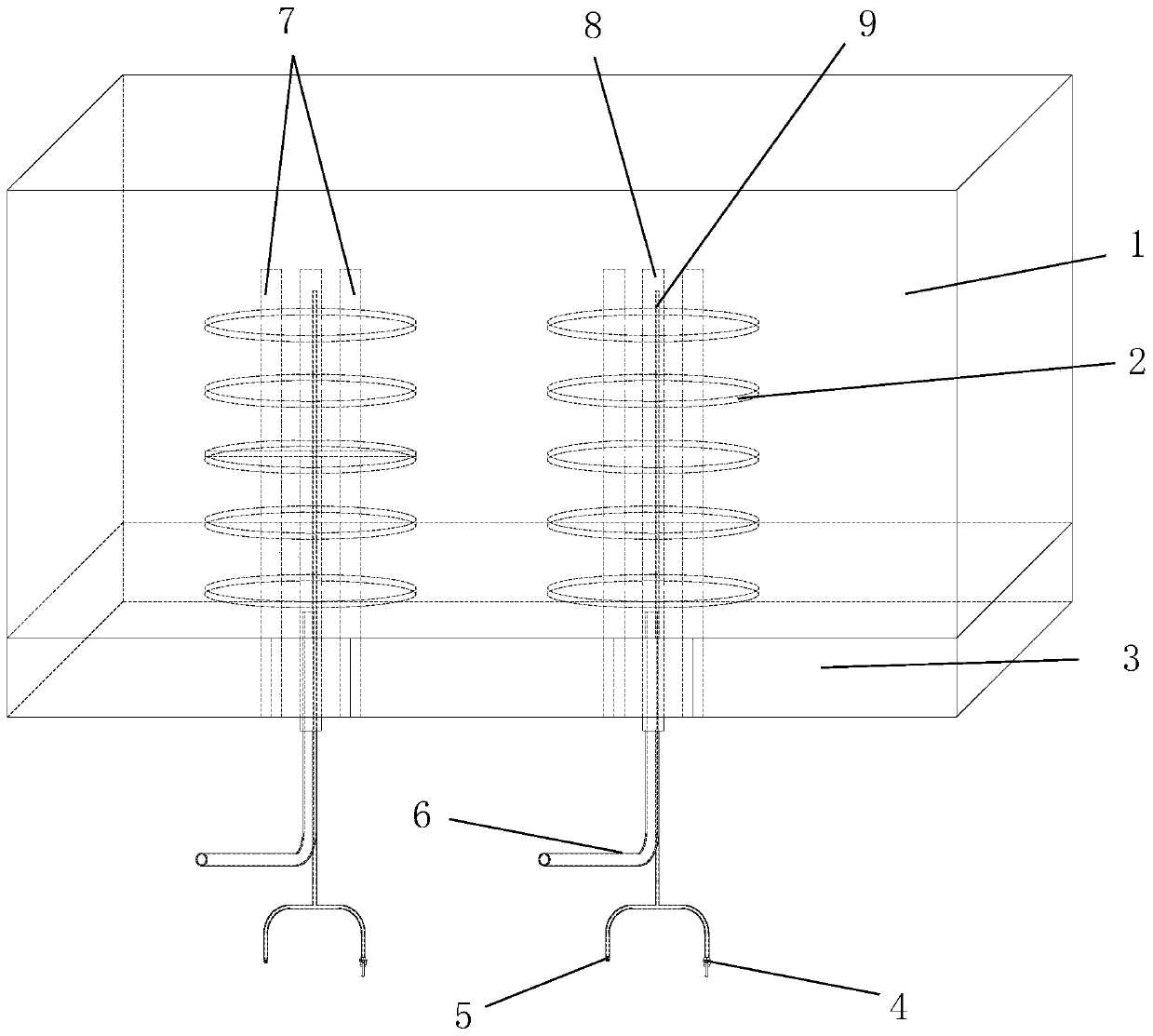

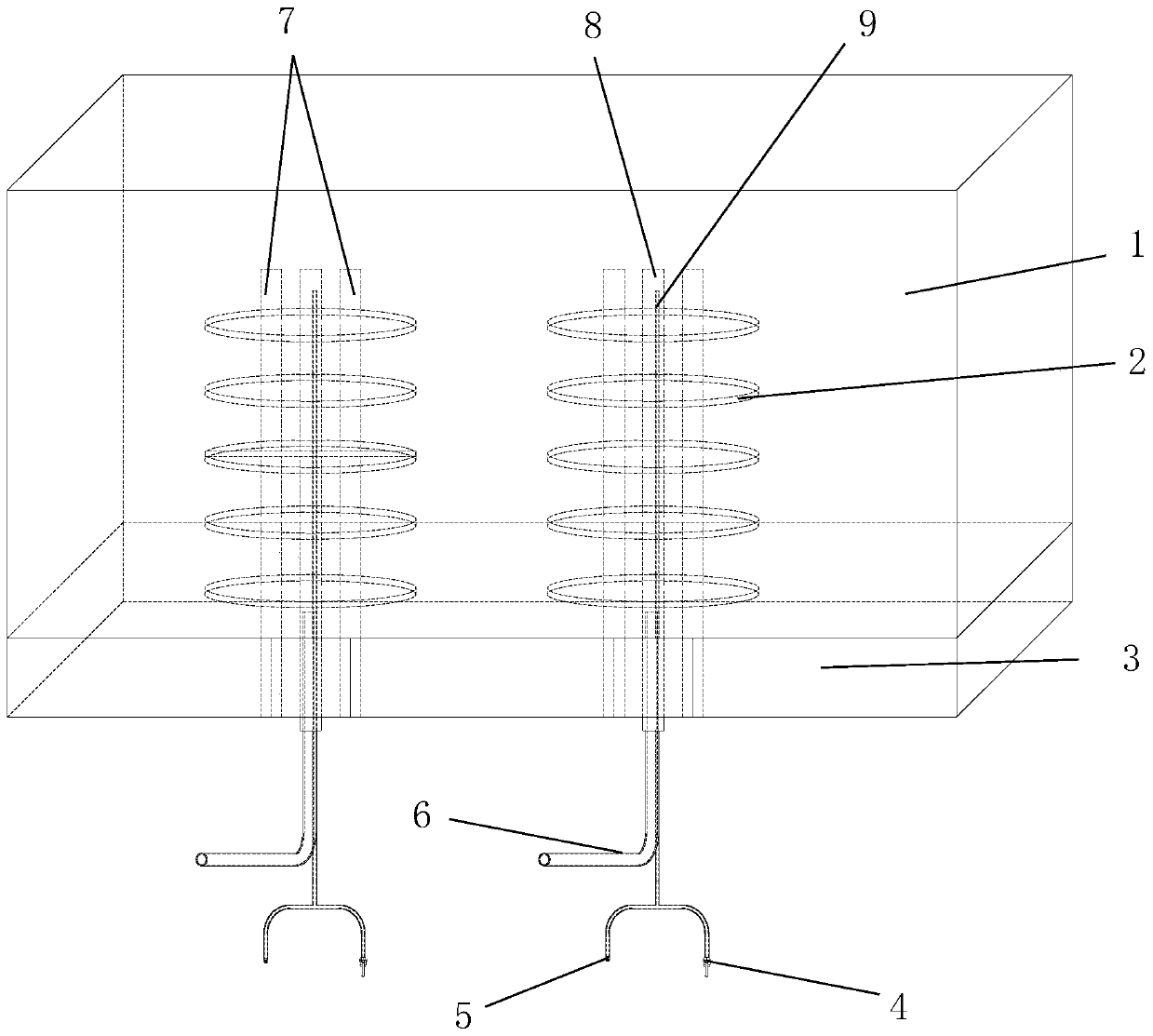

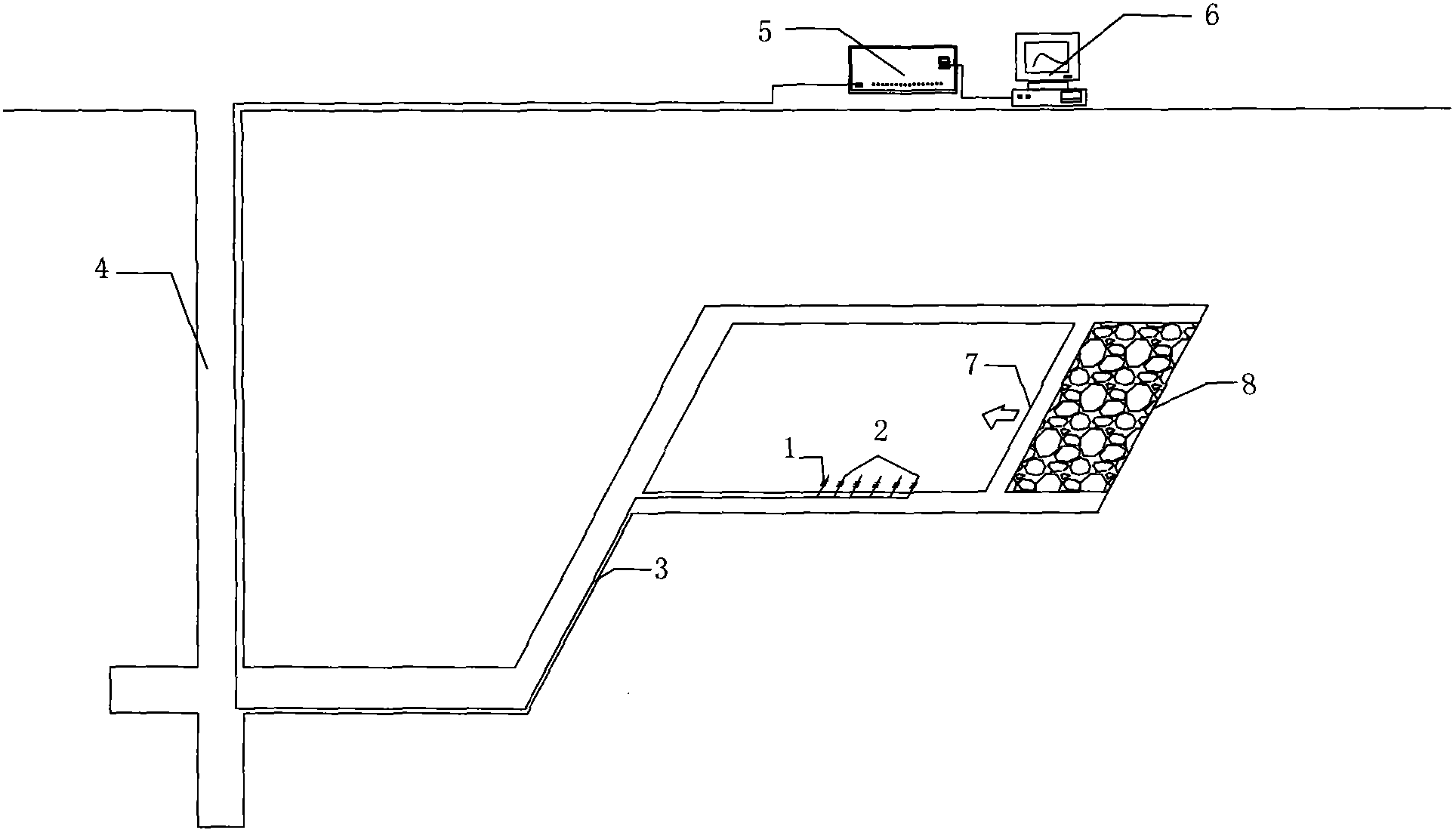

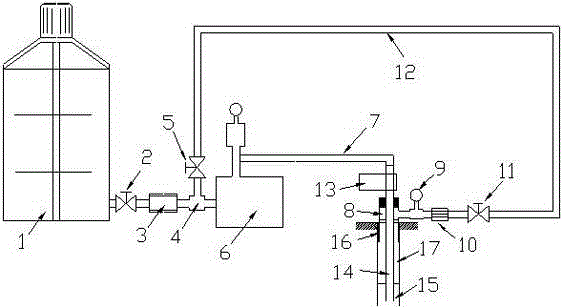

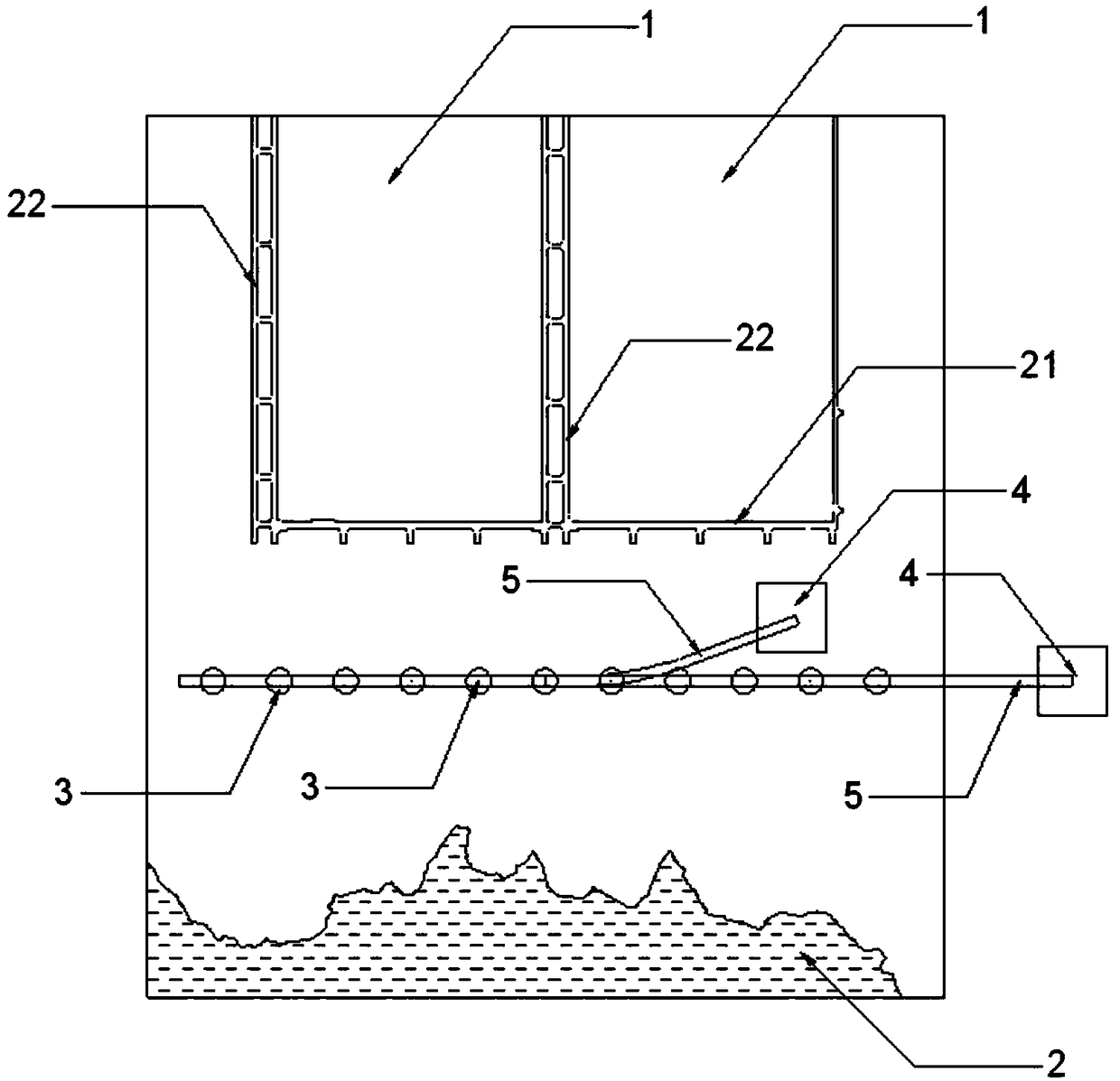

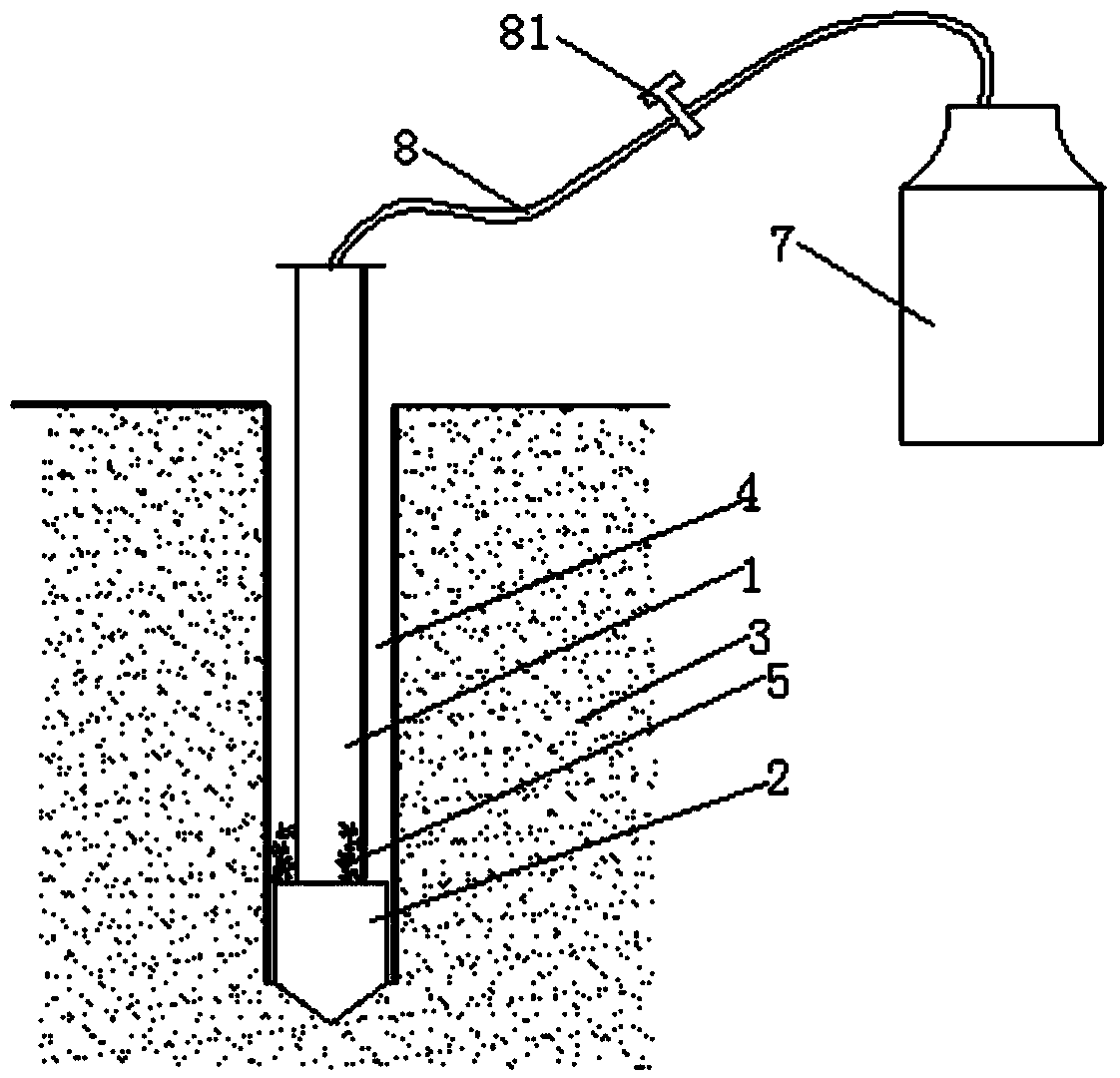

Monitoring system for settlement deformation of drill hole and monitoring method

ActiveCN107727065AWide adaptabilitySimple structureHydrostatic levellingElectricityDeformation monitoring

The invention discloses a monitoring system for settlement deformation of a drill hole and a monitoring method. The monitoring system comprises a liquid pipeline arranged in a horizontal drill hole ofa rock mass, and the outer end of the hole of the liquid pipeline is connected with a liquid reservoir; a reference point serving as a datum point is arranged at a relatively non-deformed point at the bottom of the drill hole or on the exterior of the drill hole, and a plurality of measuring points are distributed in the drill hole; both the datum point and the measuring points are provided withmicro-pressure sensors; the signal output ends of all micro-pressure sensors are electrically connected on corresponding ports of a hole external pressure sensor data acquisition instrument through lead wires. After the drill hole is deformed, the liquid level difference between the liquid pipeline and the liquid reservoir is changed, the pressure generated by the liquid level difference directlyacts on the micro-pressure sensors, and the settling volume of each measuring point is obtained by virtue of pressure values before and after degeneration of the drill hole. The monitoring system andthe monitoring method disclosed by the invention has the advantages of wide adaptability, simple structure, convenient implementation, low cost and stable and reliable measured data, and provides a way for deformation monitoring of geotechnical engineering.

Owner:SHANDONG UNIV OF SCI & TECH

Curtain grouting method for shallow buried nearly horizontal burnt rock water-bearing layer

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

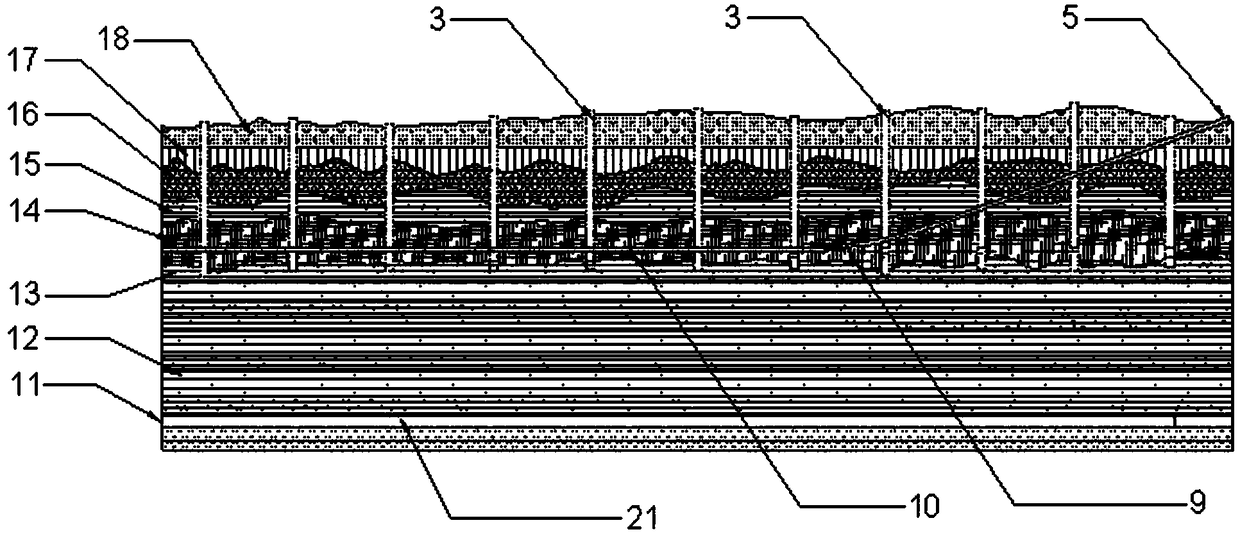

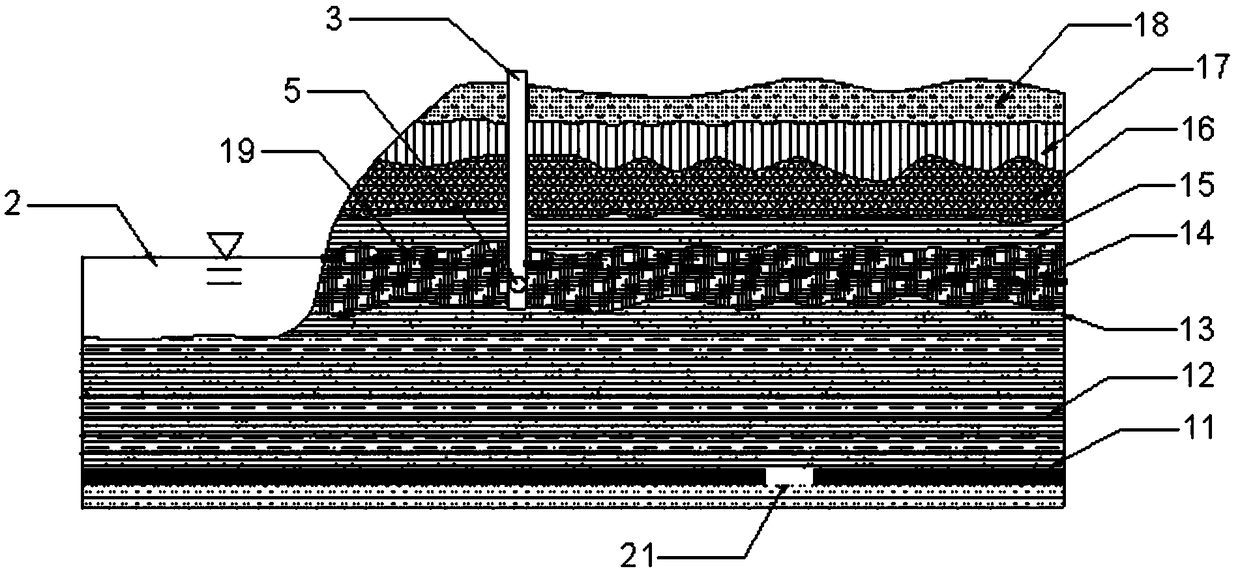

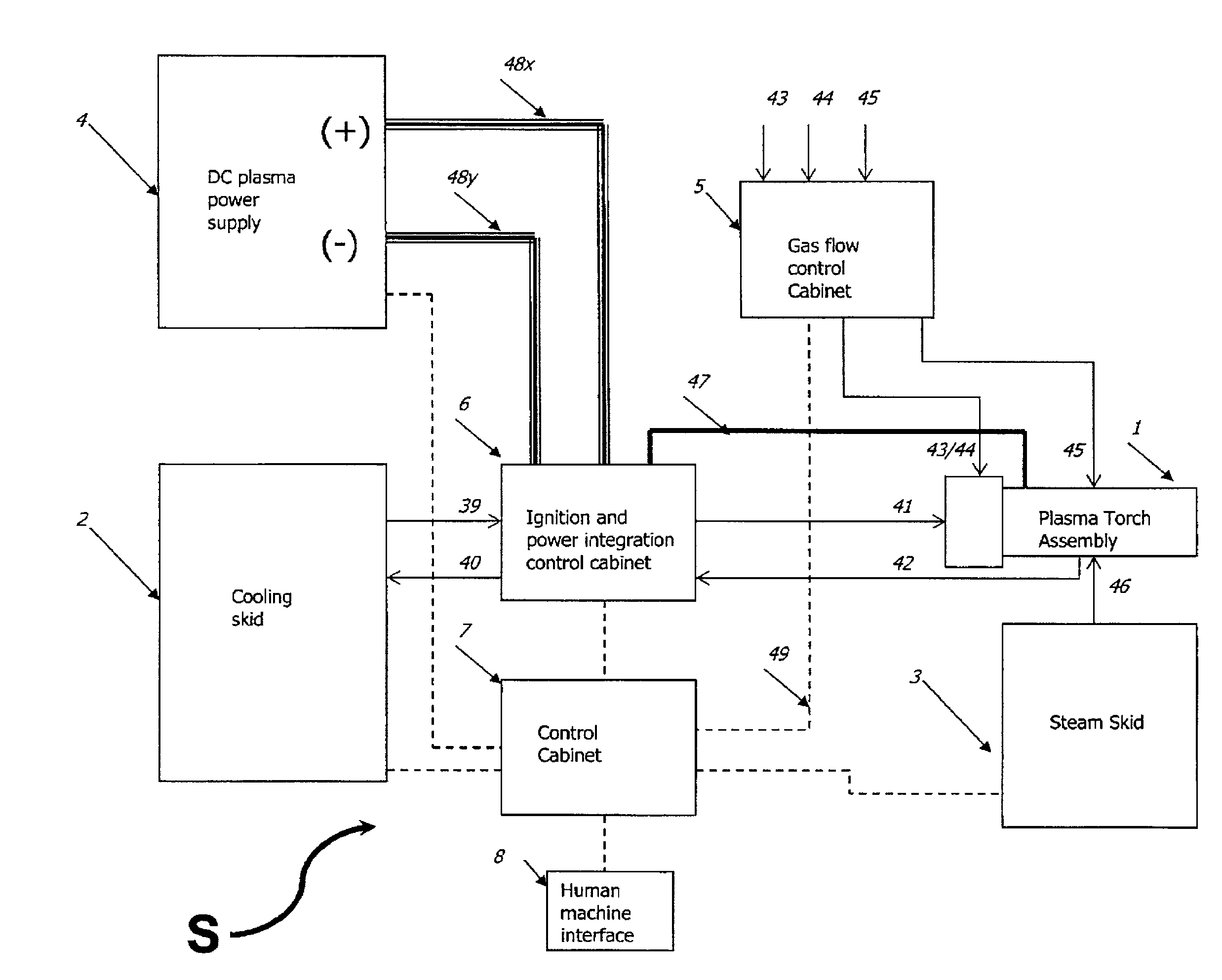

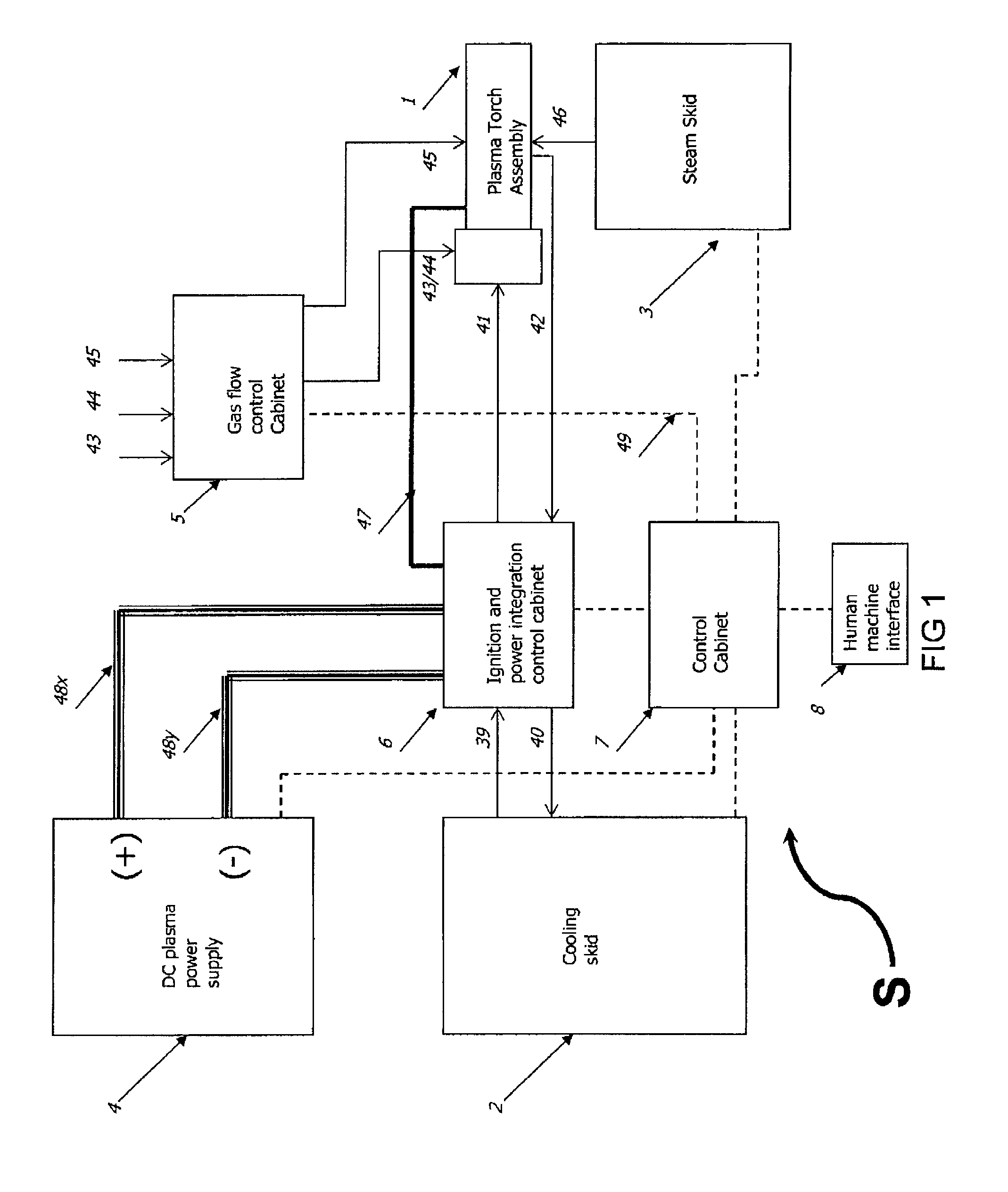

High power DC non transferred steam plasma torch system

Owner:PYROGENESIS CANADA INC

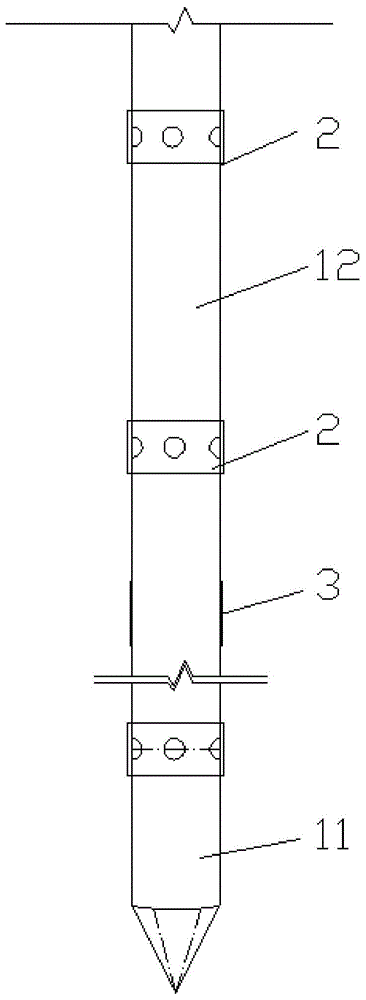

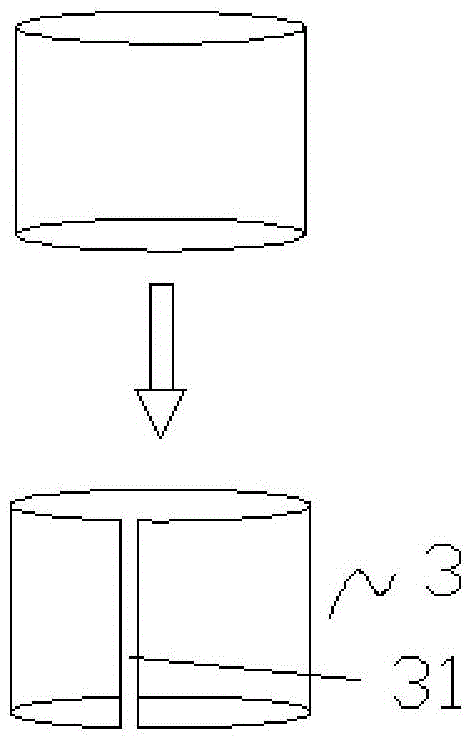

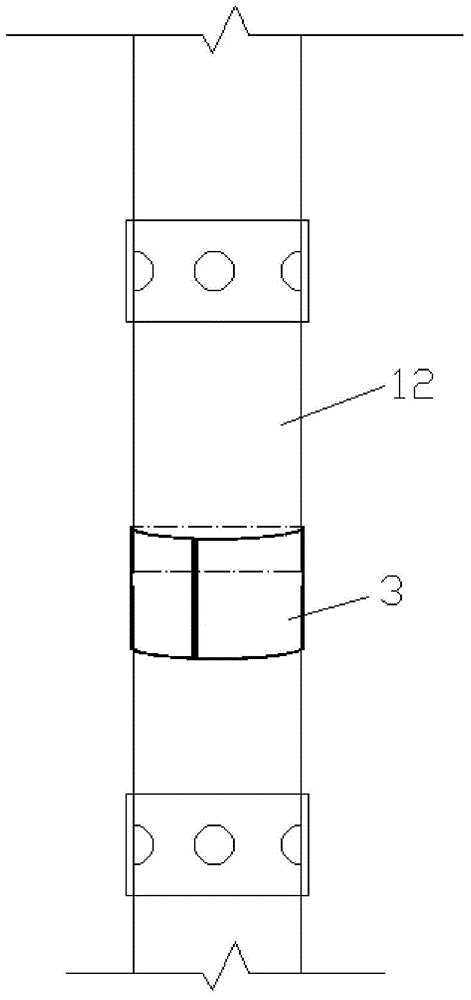

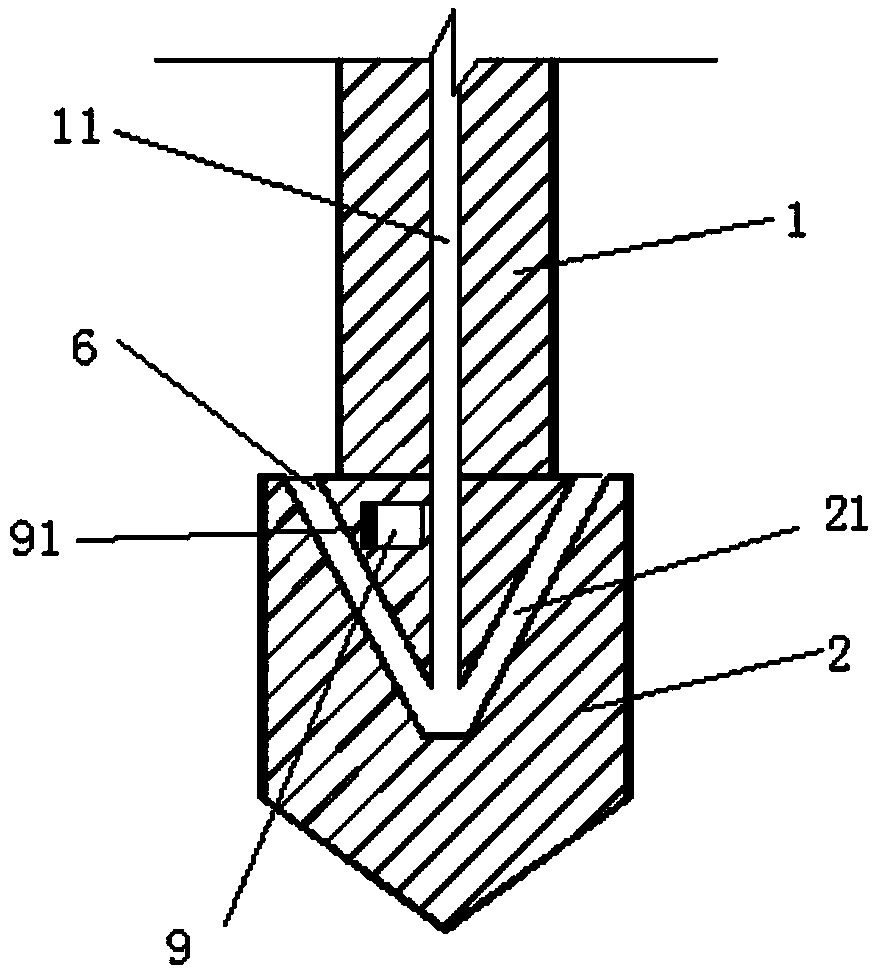

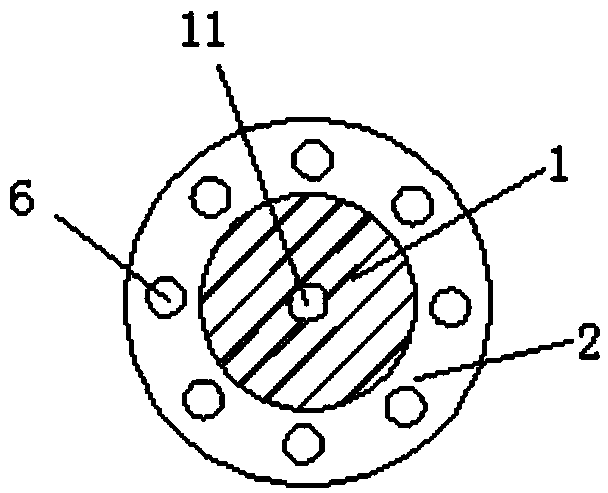

Device for quickly drilling in frozen earth and construction method thereof

ActiveCN104110221AHigh speedDecrease phenomenonEarth drilling toolsDrill bitsNitrogenLiquid nitrogen

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Integrated circuit board processing and drilling device

Owner:江苏微邦电子有限公司

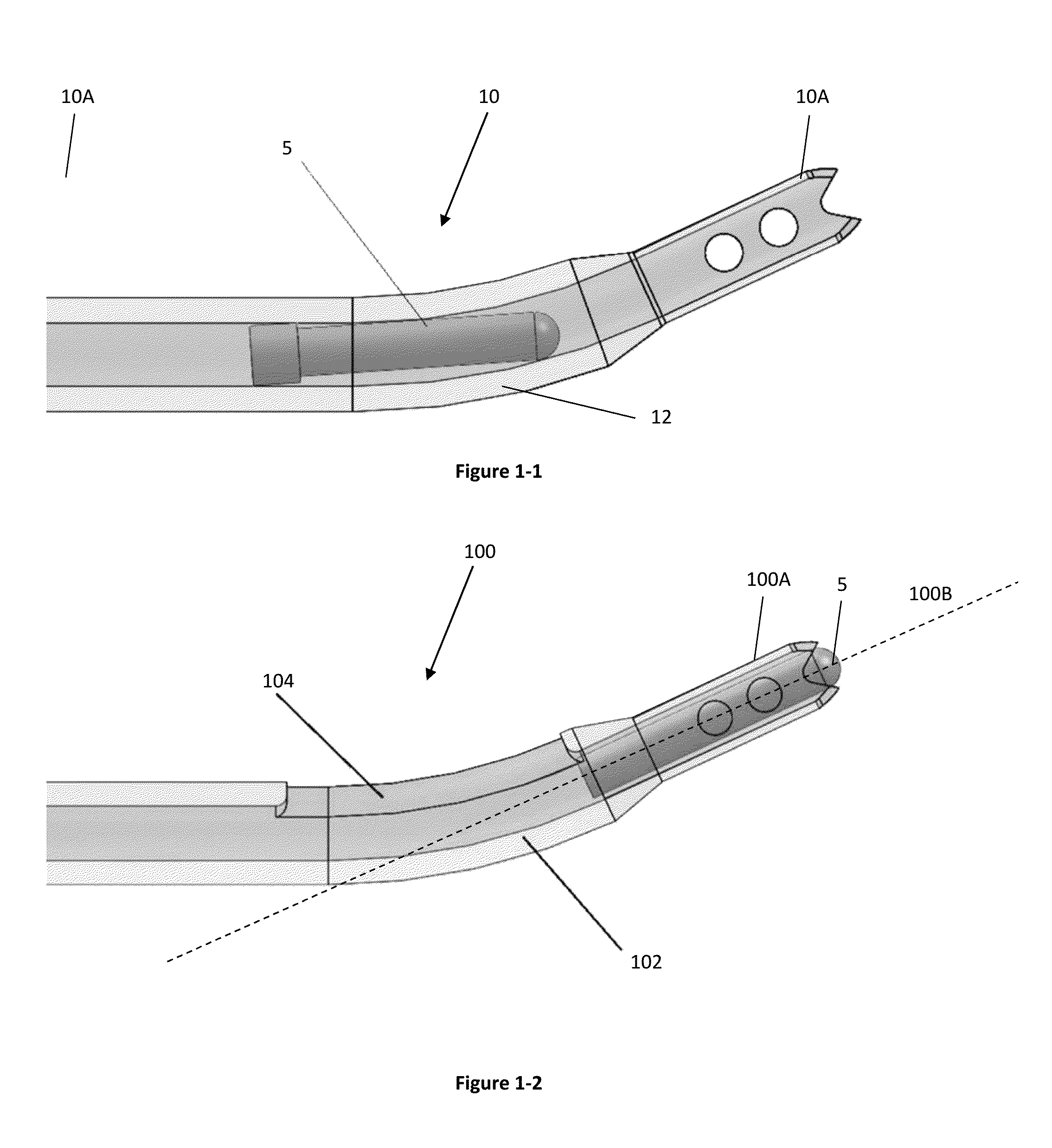

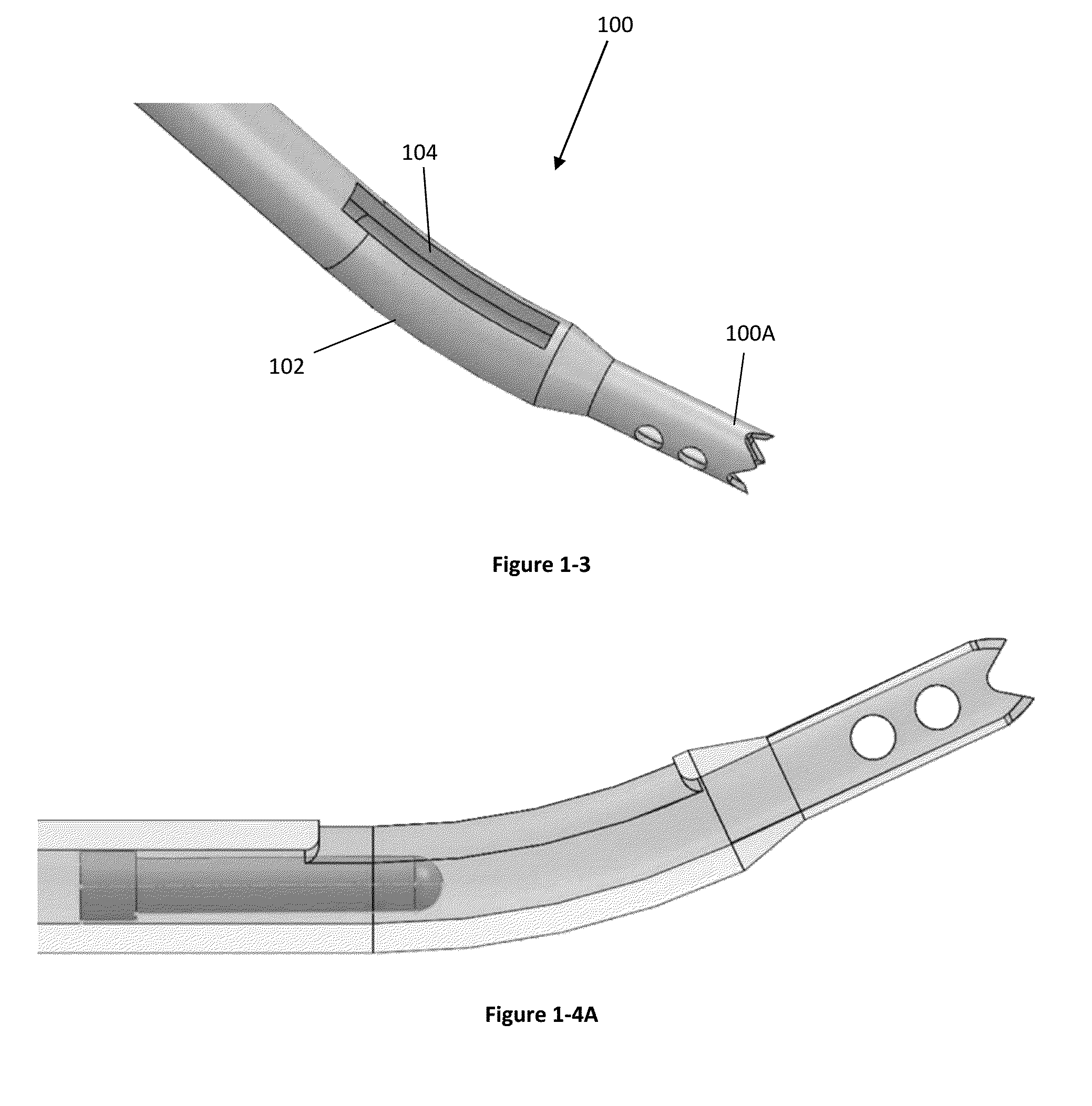

Windowed instrument drill guide and corresponding friction reducing instrument

Owner:SMITH & NEPHEW INC

Method of avoiding the need for a scraper run in drill out operations and a downhole drilling motor assembly

Owner:TARTAN ENERGY GRP INC +1

Hole-flushing method for gas extraction drilled hole under coal mine

Owner:CHONGQING UNIV

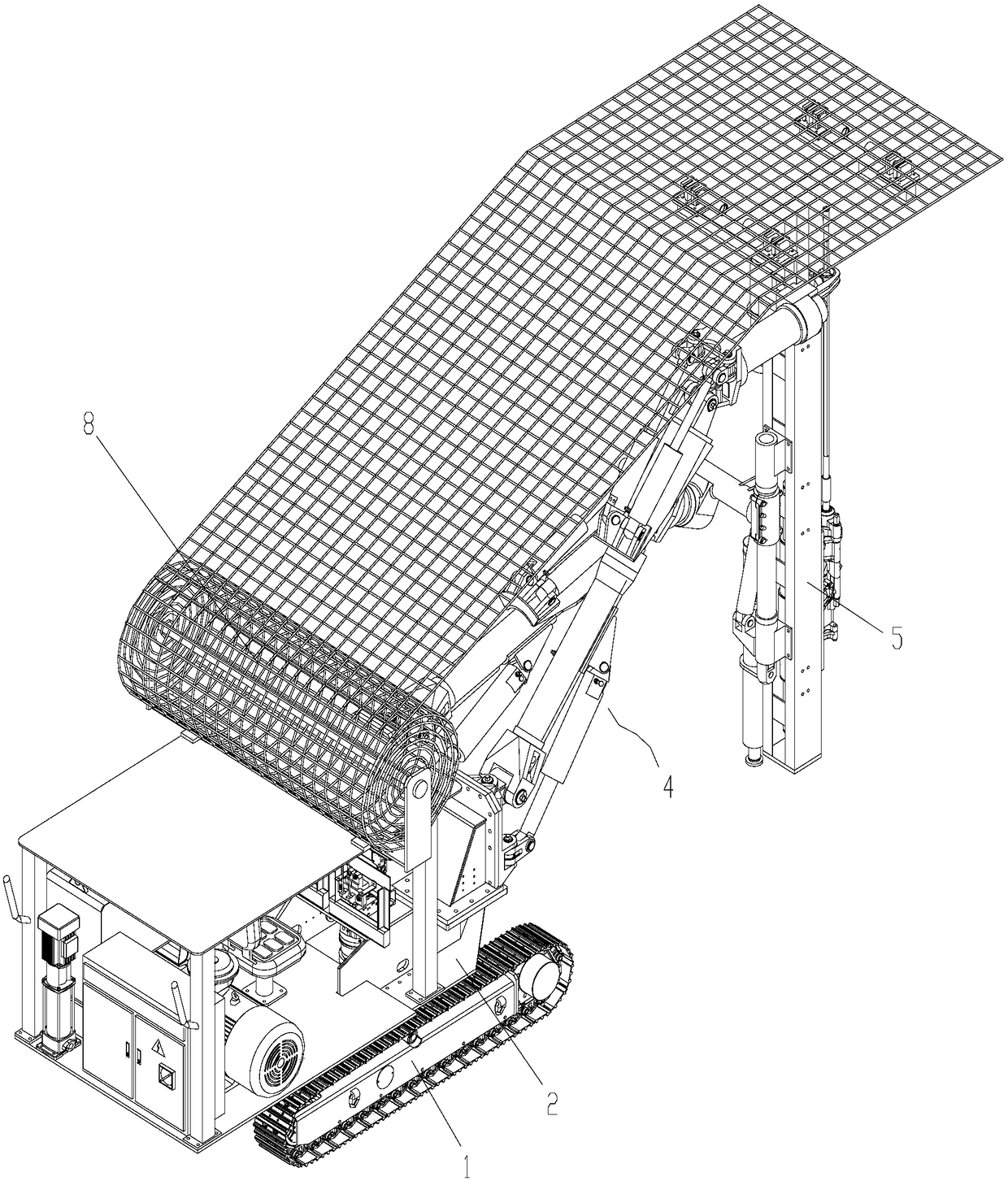

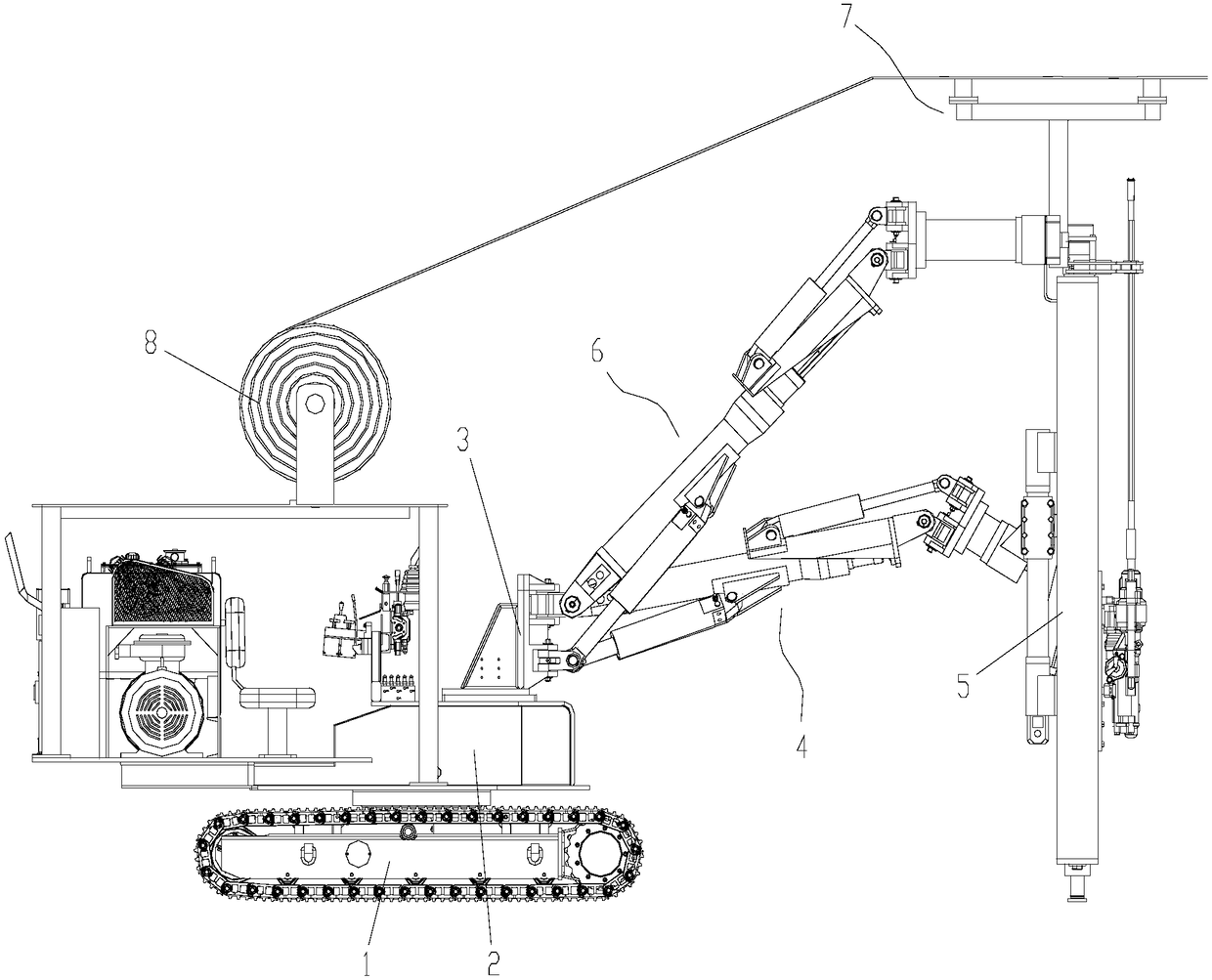

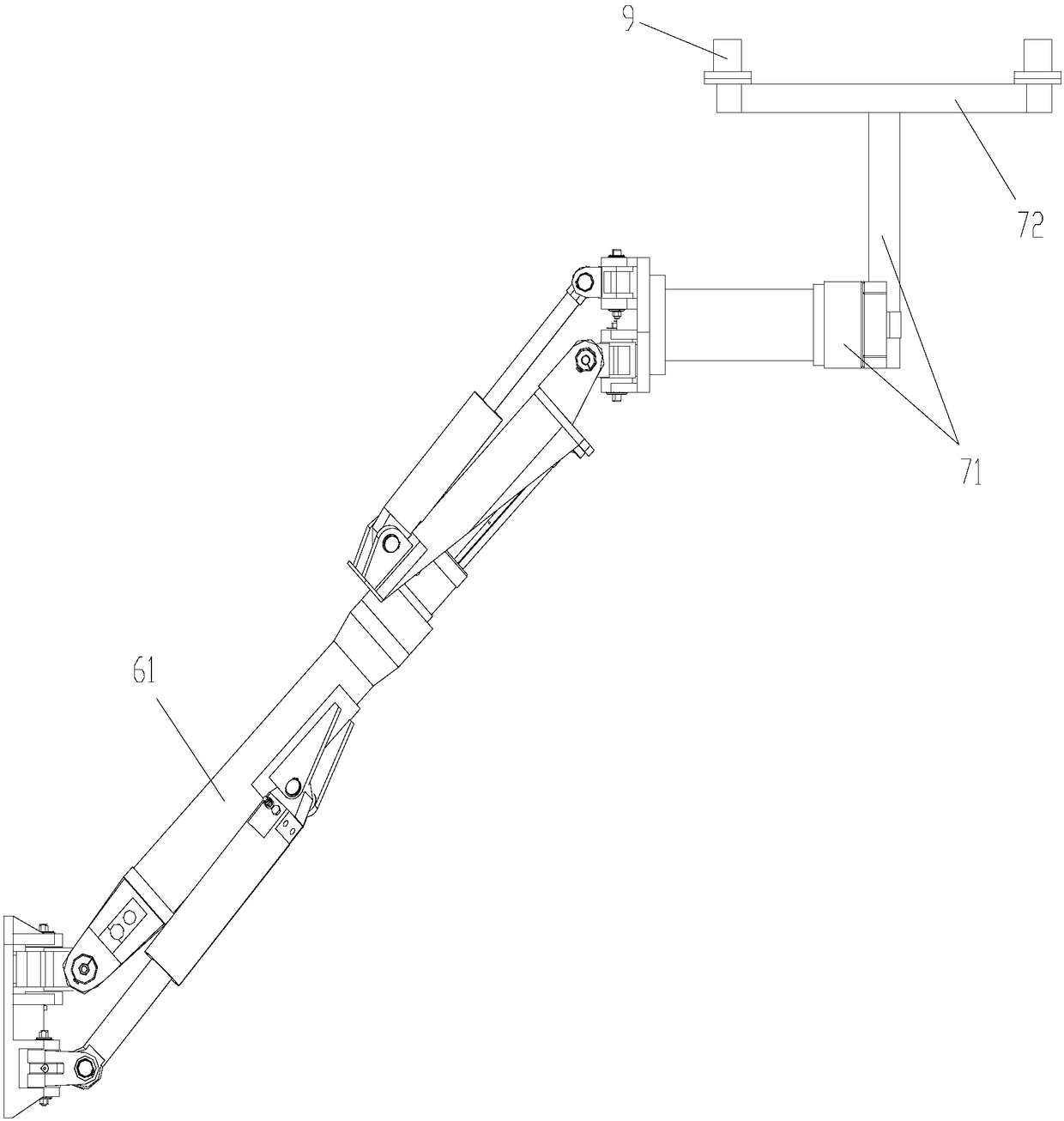

Net anchoring drill carriage

ActiveCN108104844AQuick SetupImprove work efficiencyUnderground chambersDerricks/mastsVehicle framePropeller

Owner:重庆格德瑞重工智能装备研究院 +1

Drilling equipment for hardware machining

ActiveCN111112670ASimple structureEasy to useDriving apparatusPositioning apparatusElectric machineGear wheel

The invention discloses drilling equipment for hardware machining. The drilling equipment comprises a box body, a bearing support is fixedly connected to the inner side of the box body, a horizontal rotating sleeve is rotationally connected to the inner side of the bearing support, a driving rotating rod is slidably connected to the right side of the horizontal rotating sleeve, the right end of the driving rotating rod is in threaded connection with the box body, a positioning rotating shaft is rotationally connected to the side wall of the box body, a transmission gear is fixedly connected tothe outer side of the positioning rotating shaft, driving threads are fixedly connected to the outer side of the horizontal rotating sleeve, the driving threads are meshed with the transmission gear,and guide rods are fixedly connected to the inner top of the box body in a left-and-right symmetry mode. The drilling equipment for hardware machining is simple in structure and convenient to use, during use, the driving rotating rod is manually rotated to drive a sliding vertical rod, clamping is achieved under the cooperation of a fixed vertical rod, meanwhile, the position of a motor is adjusted through an oscillating vertical rod, so that the motor is in a horizontal state, the equipment can be easy to store while hardware is machined, when not in use, the equipment is convenient to store, and then the use experience is good.

Owner:ZHONGSHAN SANTI TECH CO LTD

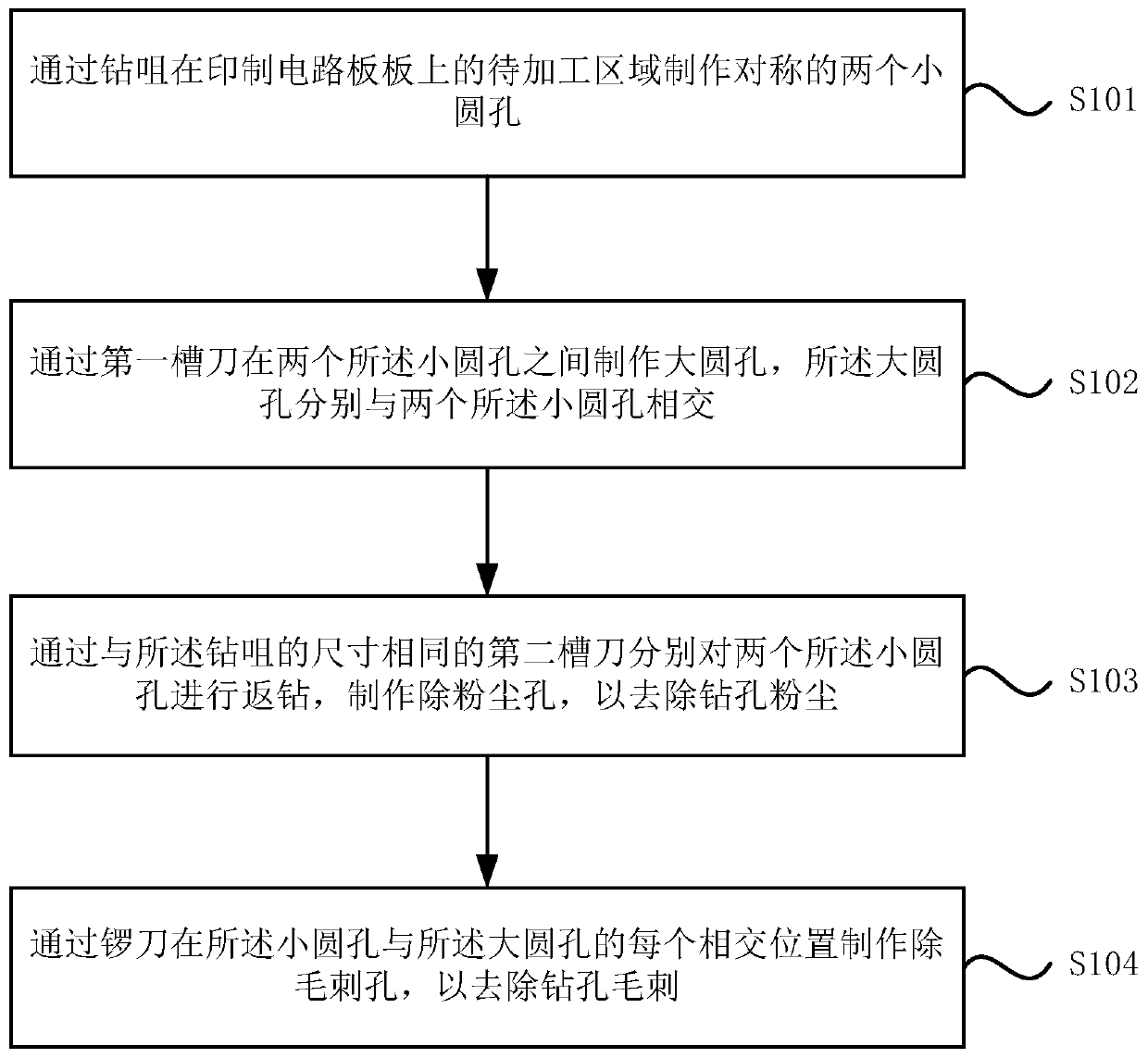

Tree core groove processing method and printed circuit board

ActiveCN111182731AMeet the installation requirementsAvoid the frontPrinted circuit manufactureMilling cutterStructural engineering

Owner:MEIZHOU ZHIHAO ELECTRONICS TECH

Planting method of square plastic strip disc glass brush

Owner:HUBEI C P NC MACHINERY

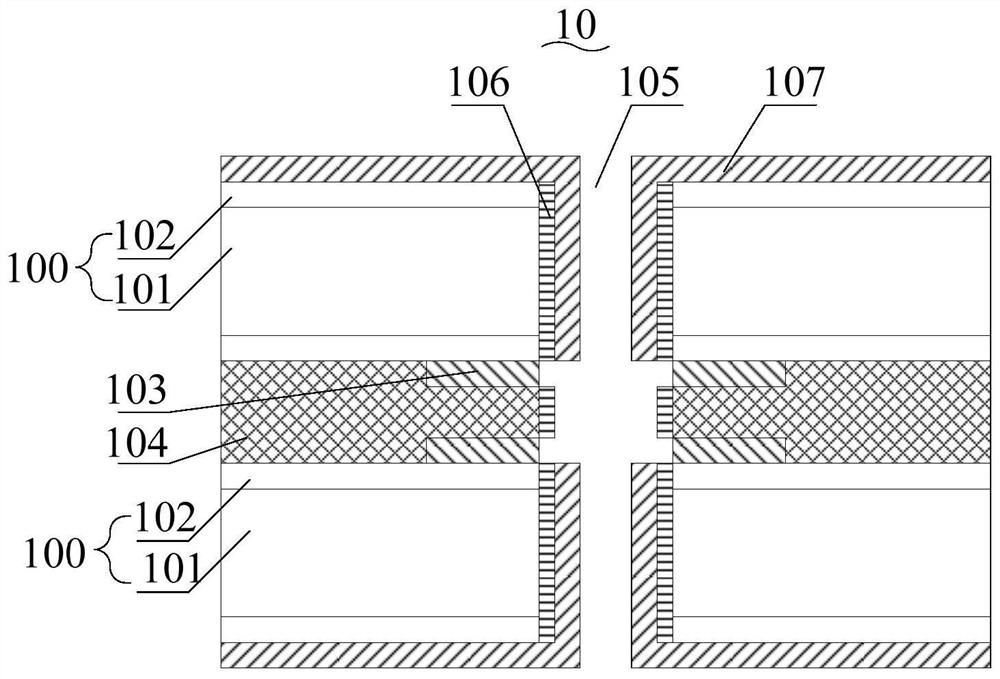

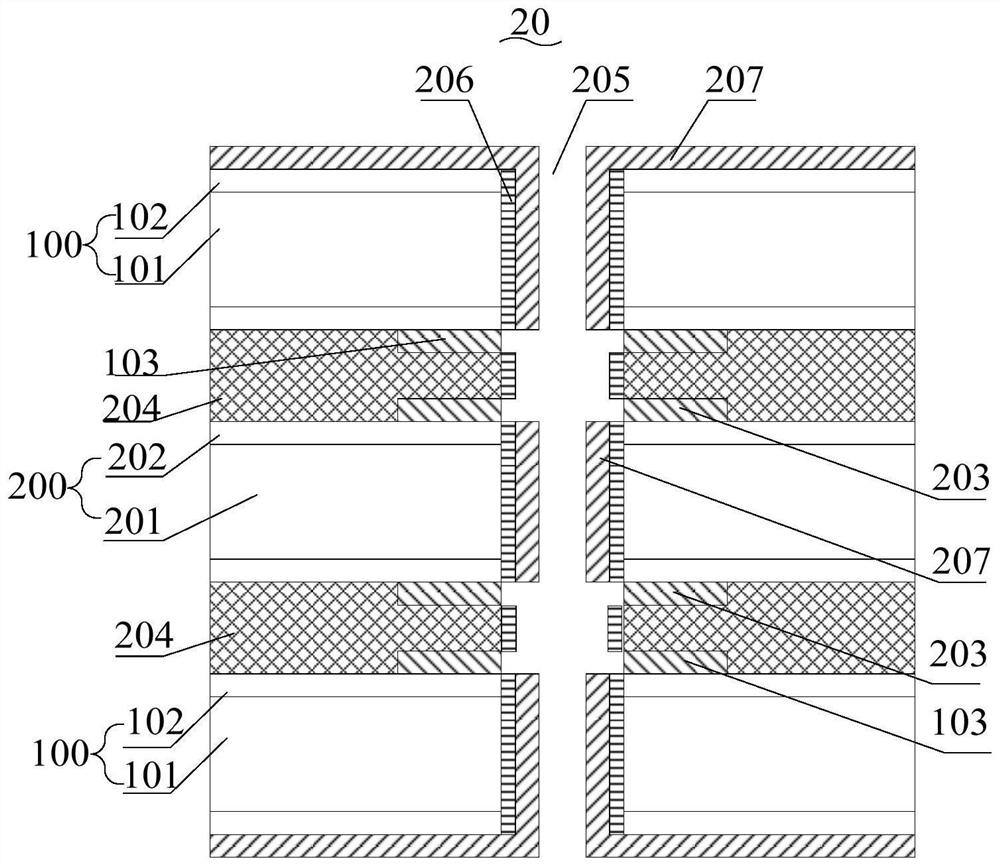

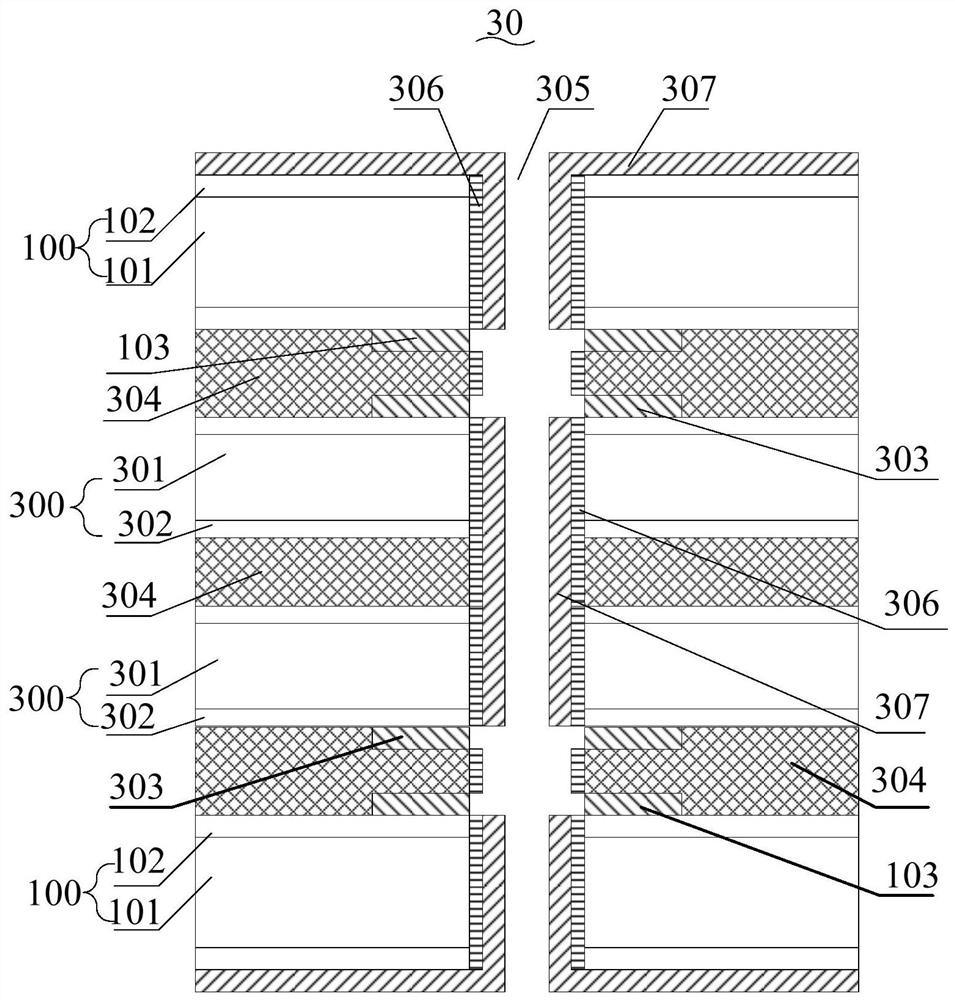

Circuit board and manufacturing method thereof

InactiveCN111800943APrinted circuit aspectsElectrical connection printed elementsElectrically conductiveDrill hole

Owner:SHENNAN CIRCUITS

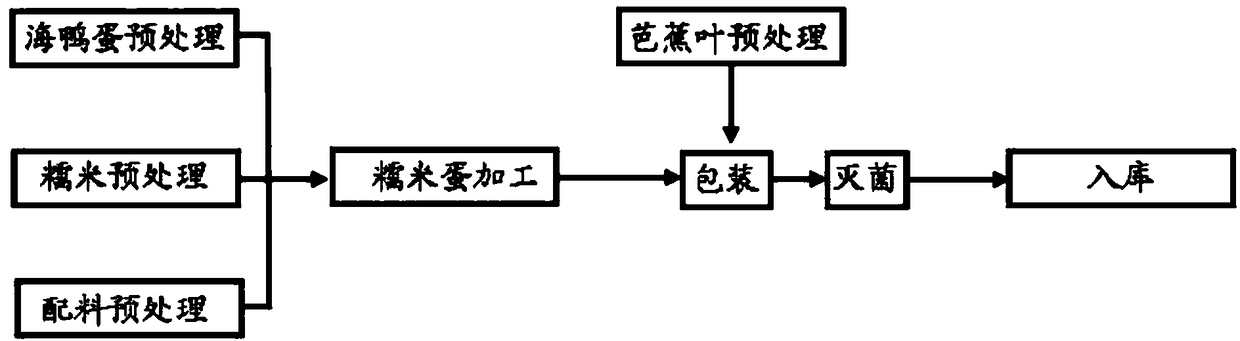

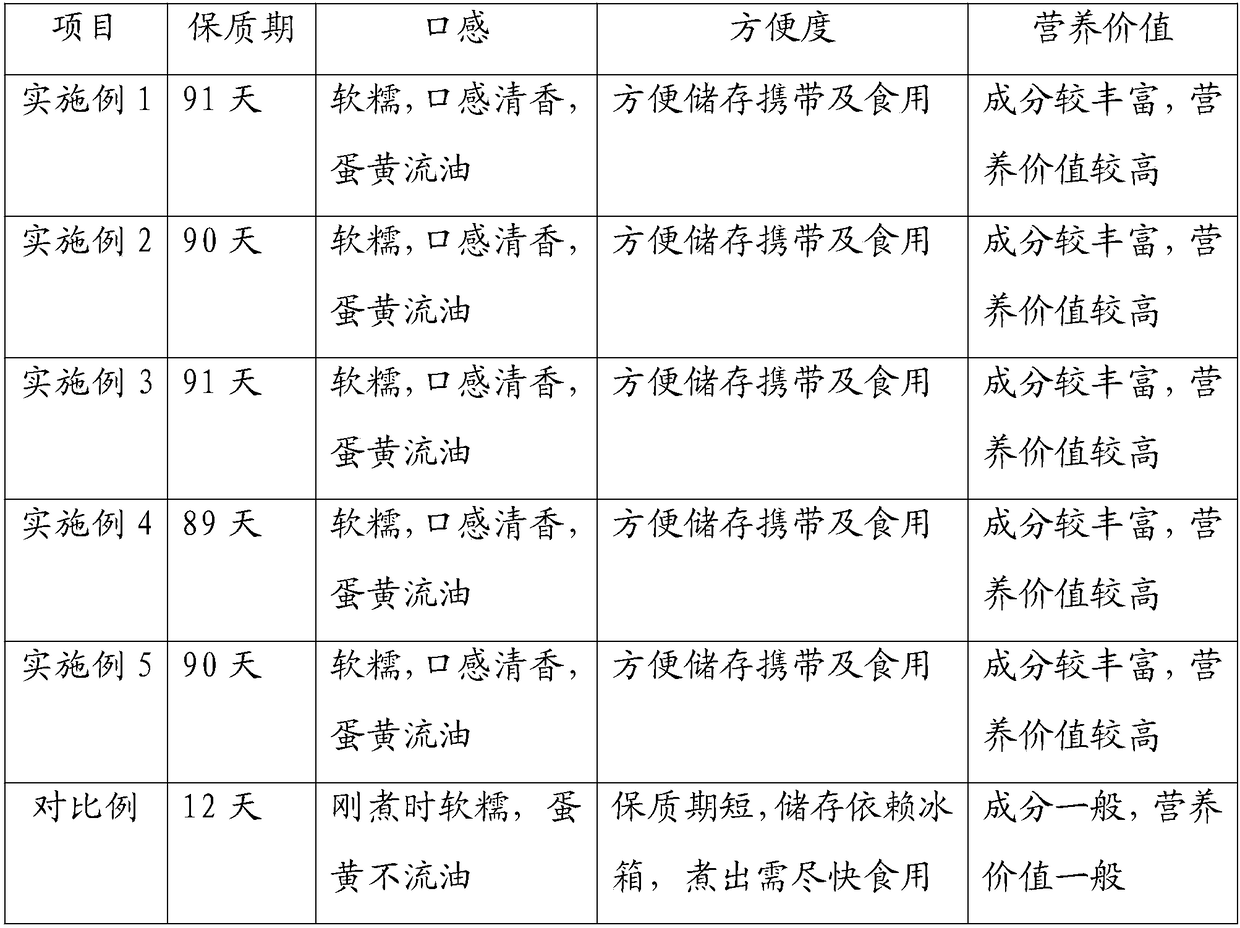

Glutinous rice sea duck eggs and making method thereof

Owner:合浦义家人食品有限公司

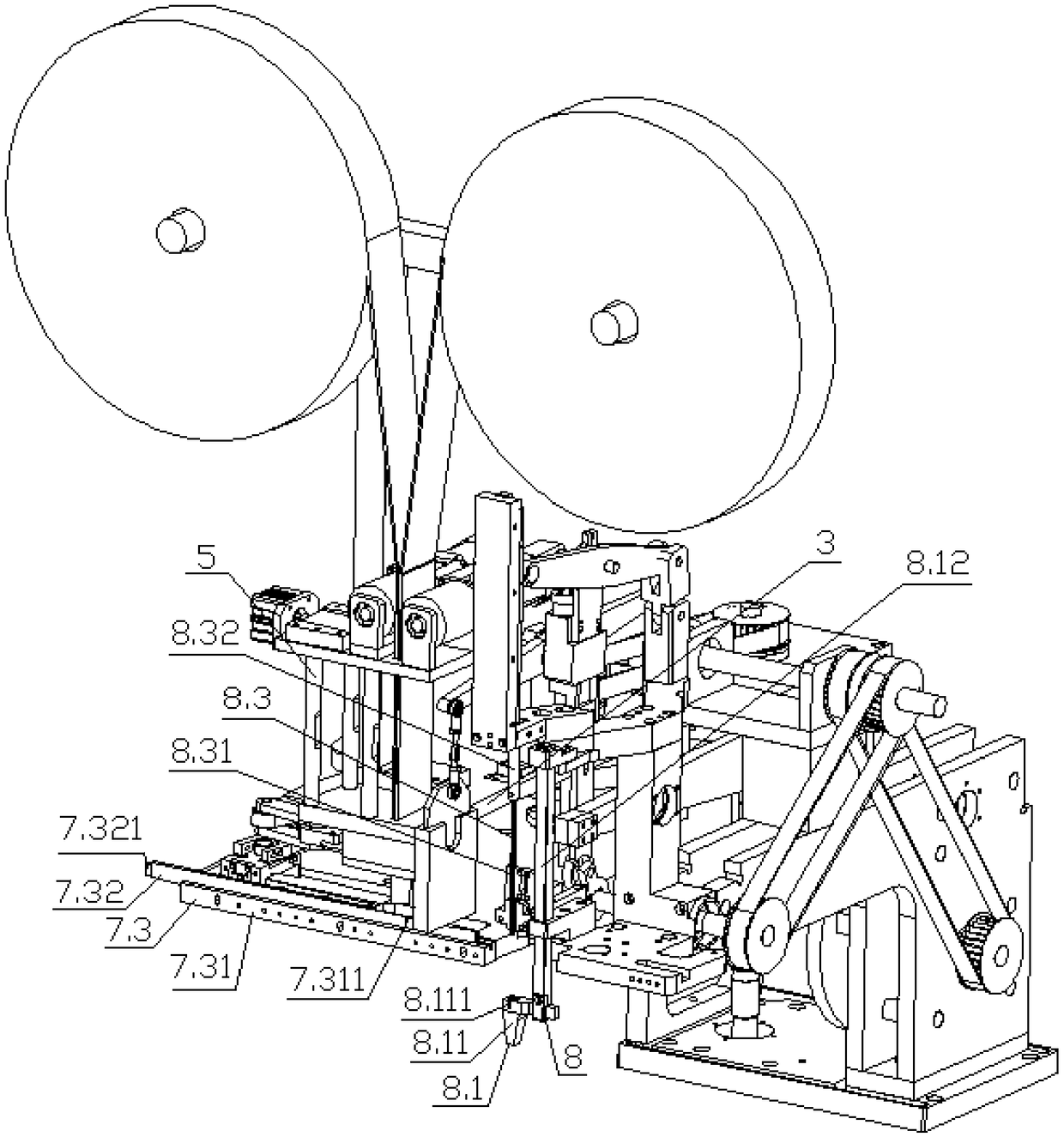

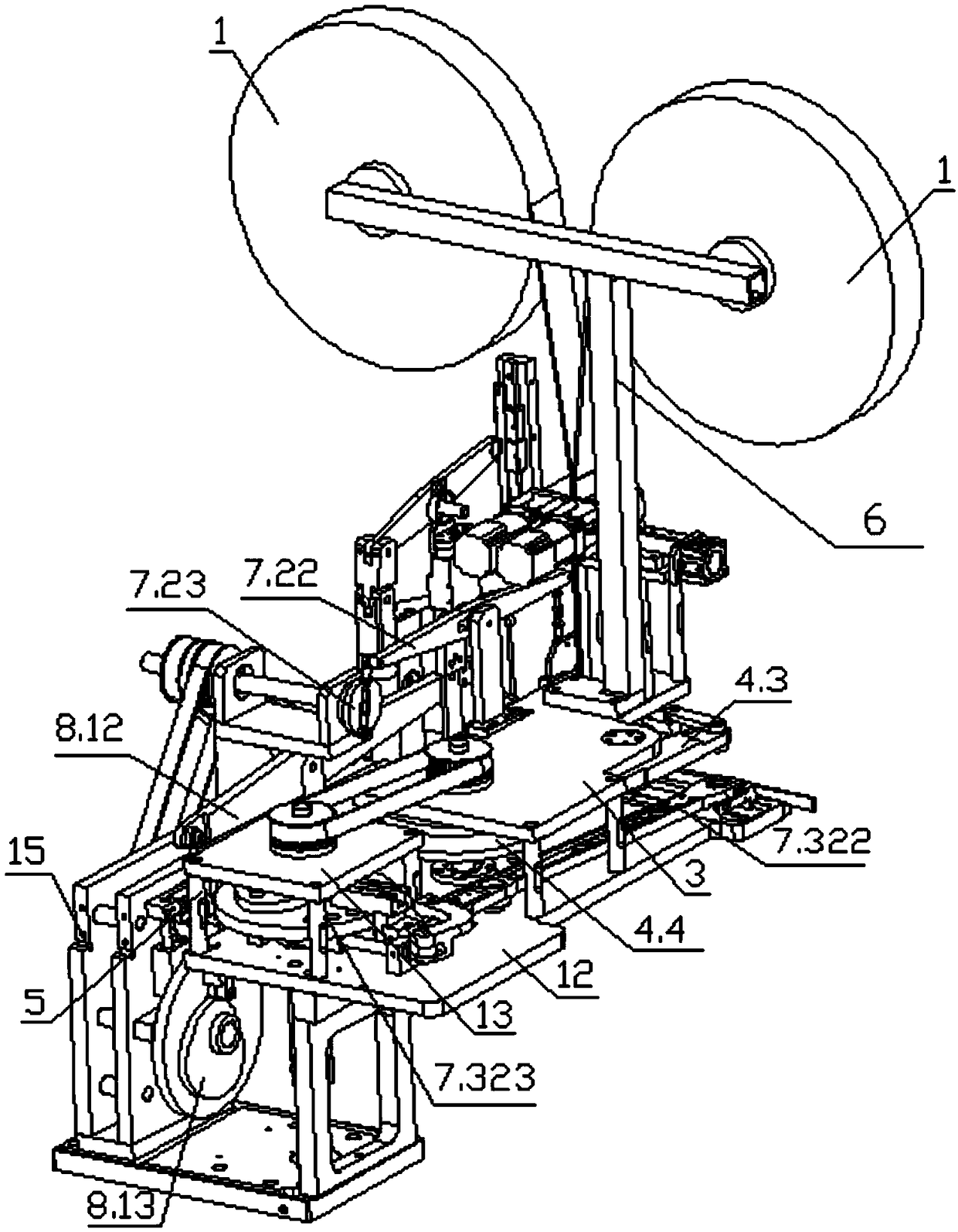

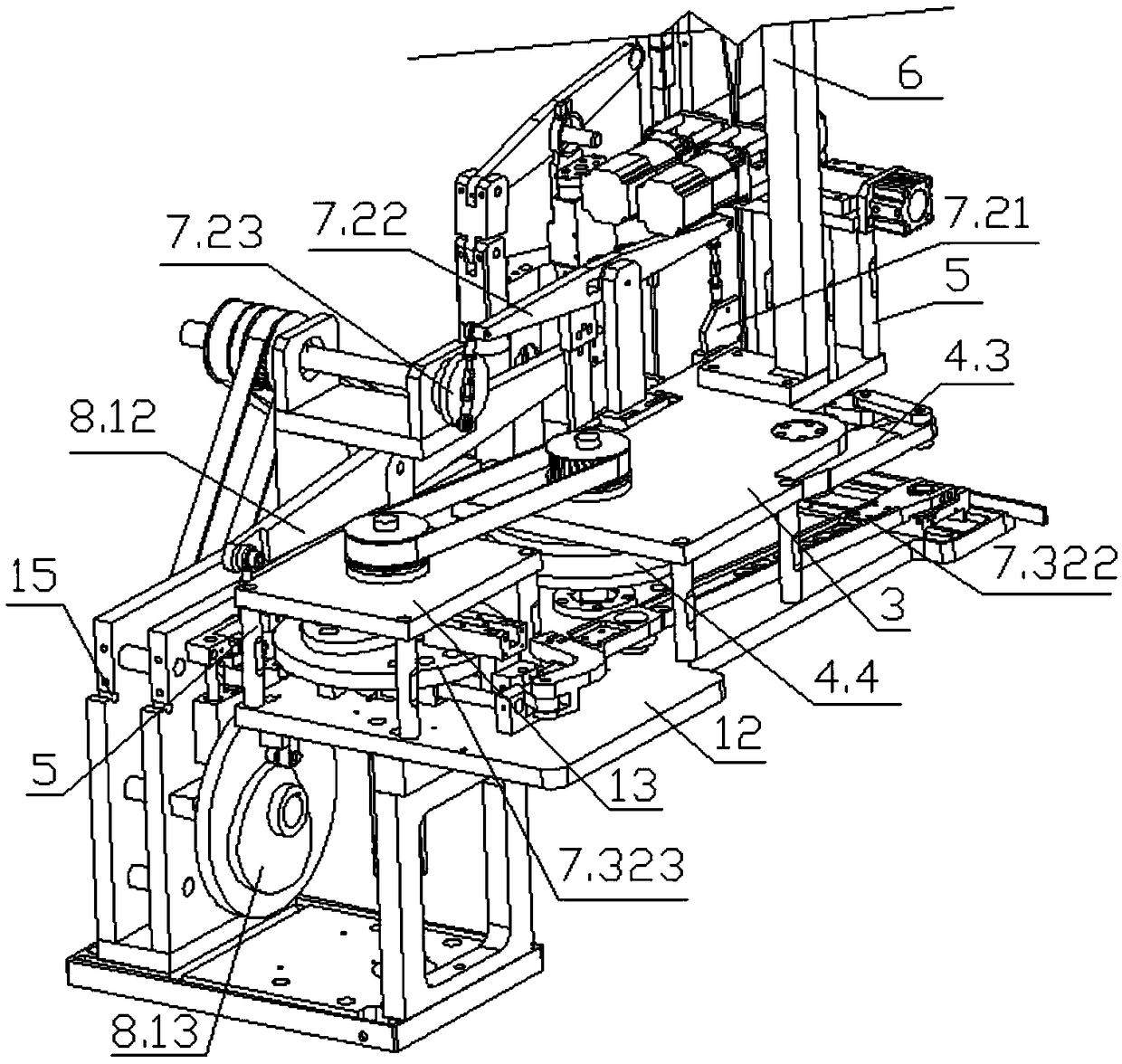

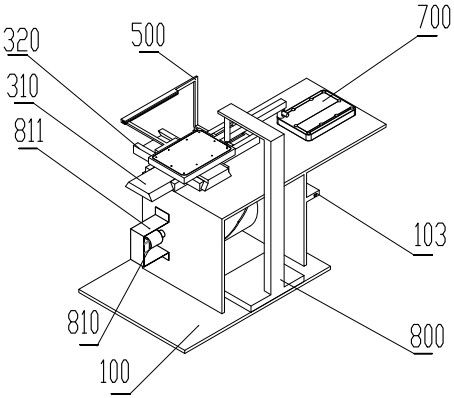

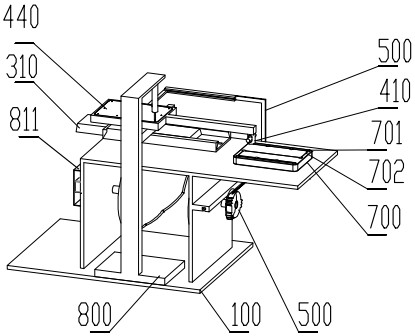

Drilling and rivet pressing equipment

PendingCN112828604ACompact structureHigh degree of automationOther manufacturing equipments/toolsEngineeringMachine

The invention belongs to the technical field of drilling equipment, and discloses drilling and rivet pressing equipment which comprises a cabinet. A platen is arranged on the cabinet, and a station rotating mechanism is arranged in the middle of the platen; a drilling mechanism is fixed to the left side of the station rotating mechanism, and a rivet feeding and pre-pressing mechanism is fixed to the rear side of the station rotating mechanism; a rivet pressing mechanism is fixed to the right side of the station rotating mechanism, and a control mechanism is arranged on the cabinet; and a workpiece is installed on the station rotating mechanism. According to the drilling and rivet pressing equipment, the station rotating mechanism, the drilling mechanism, the rivet feeding and pre-pressing mechanism, the rivet pressing mechanism and the control mechanism are arranged on one device, the structure is compact, and drilling, rivet insertion, pre-pressing and pressing of a plurality of rivet holes can be completed at a time, and all automatically completed by the equipment except for assembly and disassembly actions; the automation degree is high, and working procedures are reduced; manpower is reduced; and the machining efficiency and the machining precision are greatly improved.

Owner:JINHUA DEQI AUTOMATION TECH CO LTD

Foundation soil layer contour map drawing method

ActiveCN112529982ASimple stepsEasy to useDrawing from basic elementsDatabase management systemsData displaySoil science

The invention provides a foundation soil layer contour map drawing method, and belongs to the technical field of geotechnical engineering investigation, and the method comprises the following steps: S1, building a foundation soil contour map drawing drilling database; s2, processing abnormal data of a foundation soil layer; s3, surveying a drill hole data display point; s4, carrying out drilling and thinning; s5, analyzing the distance between the drill holes; and s6, drawing a foundation soil burial depth contour map. The method is concise in step, convenient to use, high in engineering applicability, rapid and convenient in mapping, high in precision and particularly suitable for foundation soil layer development distribution rule research of regional geology and geotechnical engineeringinvestigation projects.

Owner:TIANJIN TAIKAN ENG TECH CONSULTING CO LTD +1

Computer host drilling equipment and operation method

ActiveCN112935878APrecise positioningImprove stabilityFeeding apparatusPositioning apparatusGear wheelElectric machinery

Owner:HARBIN VOCATIONAL & TECHN COLLEGE

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap