Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

67results about "Printed circuit aspects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

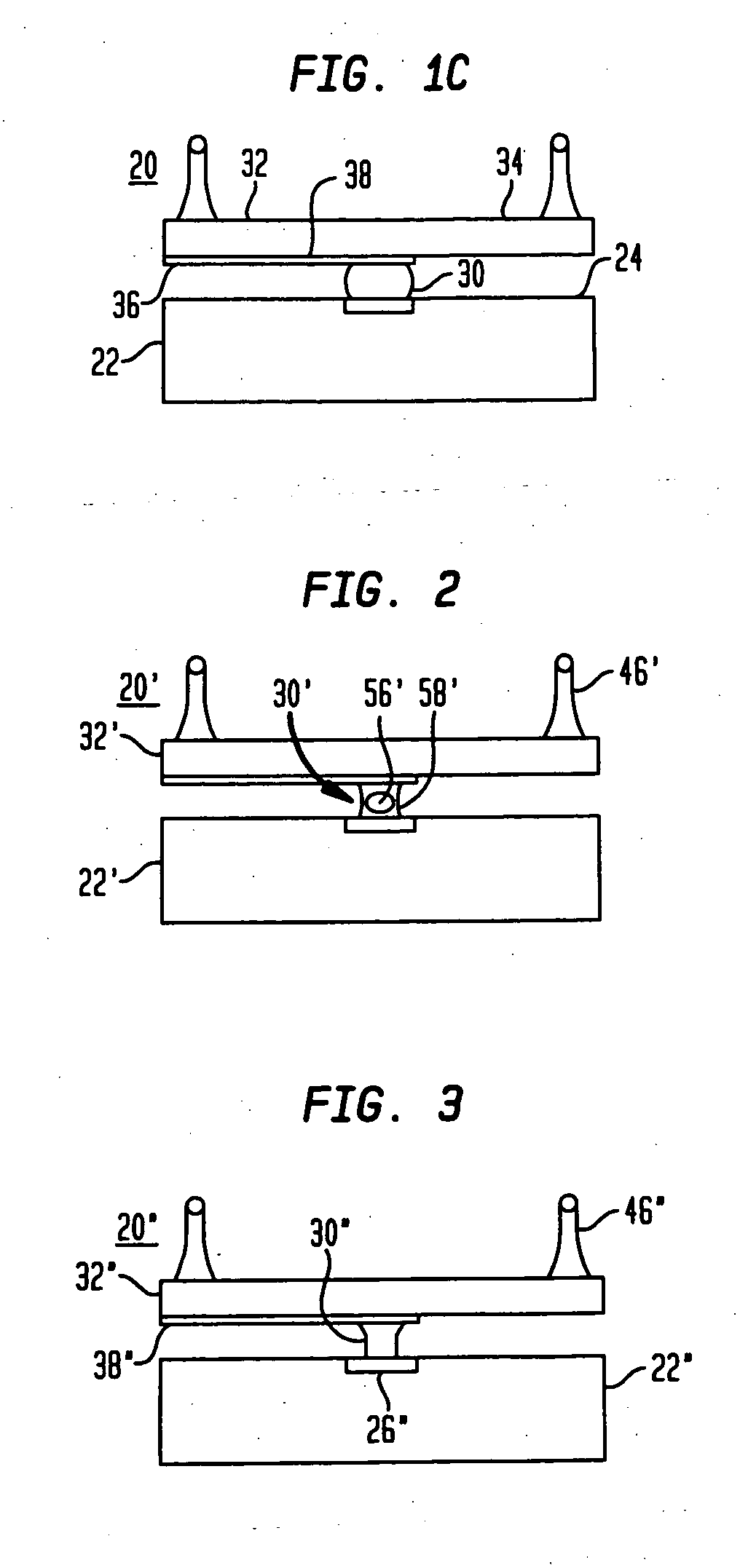

Electronics module having high density interconnect structures incorporating an improved dielectric lamination adhesive

InactiveUS6294741B1Improve electrical performanceAdequate processing propertyInsulating substrate metal adhesion improvementPrinted electric component incorporationComposite filmHigh density

A multi-chip electronics module is provided which utilizes benzocyclobutene as a laminate adhesive for bonding the upper dielectric films in a high density interconnect structure. The benzocyclobutene thermosetting polymer is spin coated on a polyimide film, and baked at low temperature to remove any solvent to leave a B-staged coating on the polyimide film. The composite film can be laminated to an underlying electrical structure using a vacuum laminator and heat. As the heat is applied, the BCB layer softens, flows and then cures to bond the polyimide film to the underlying electrical structure.

Owner:LOCKHEED MARTIN CORP

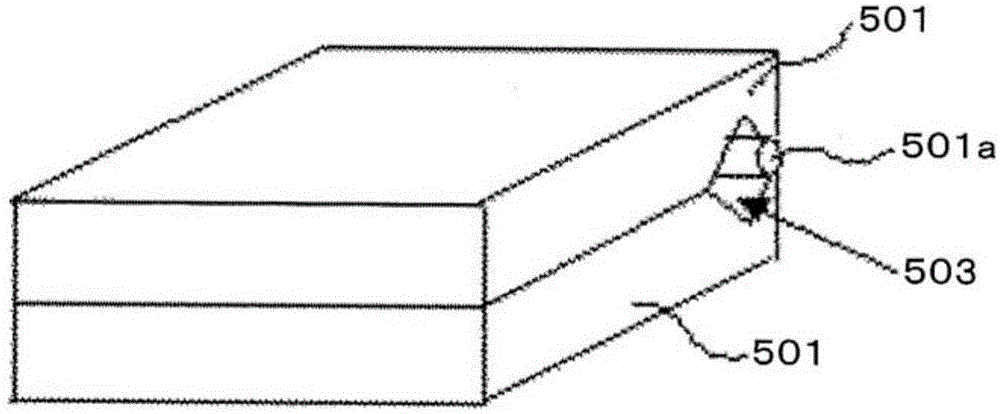

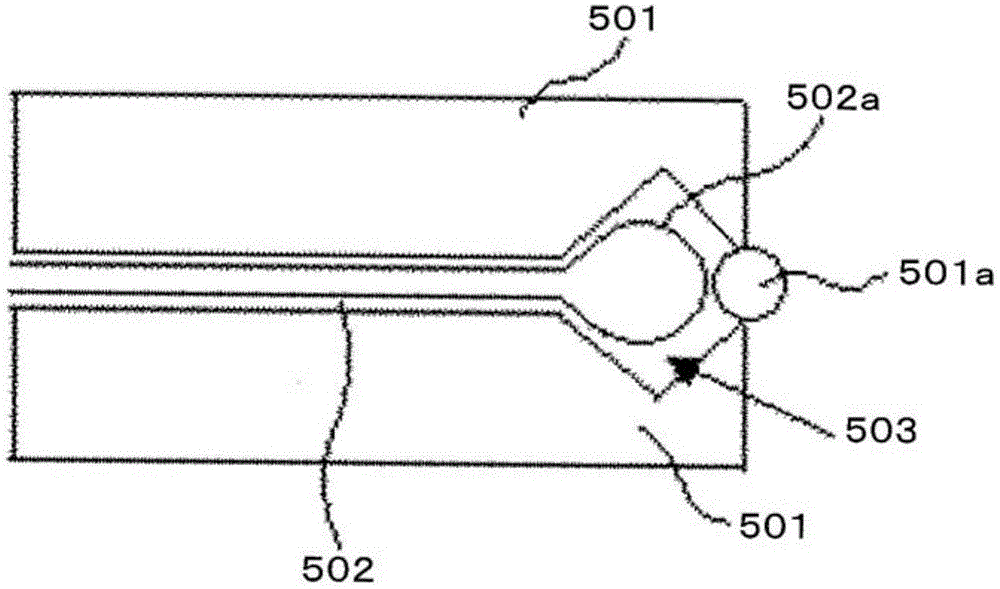

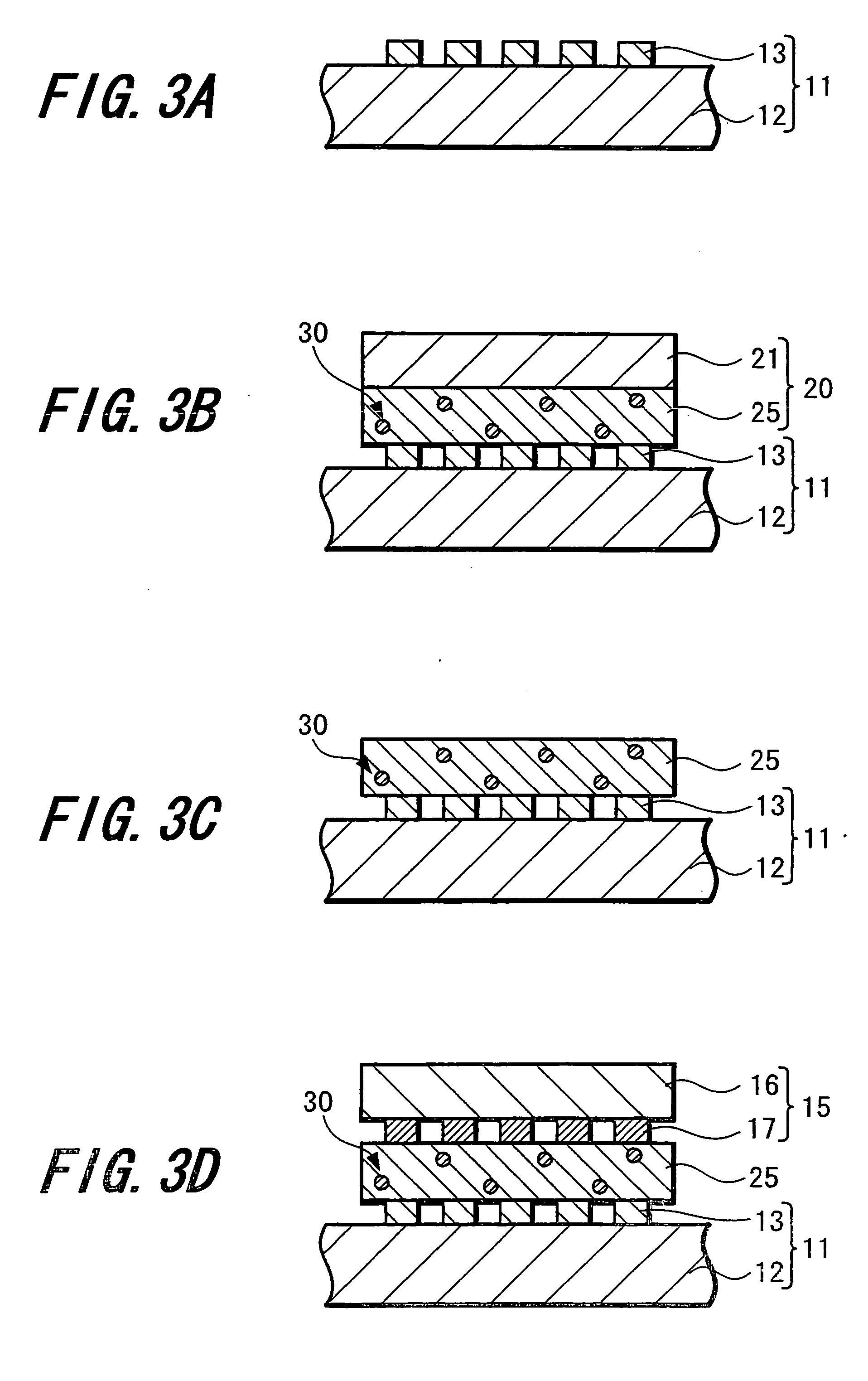

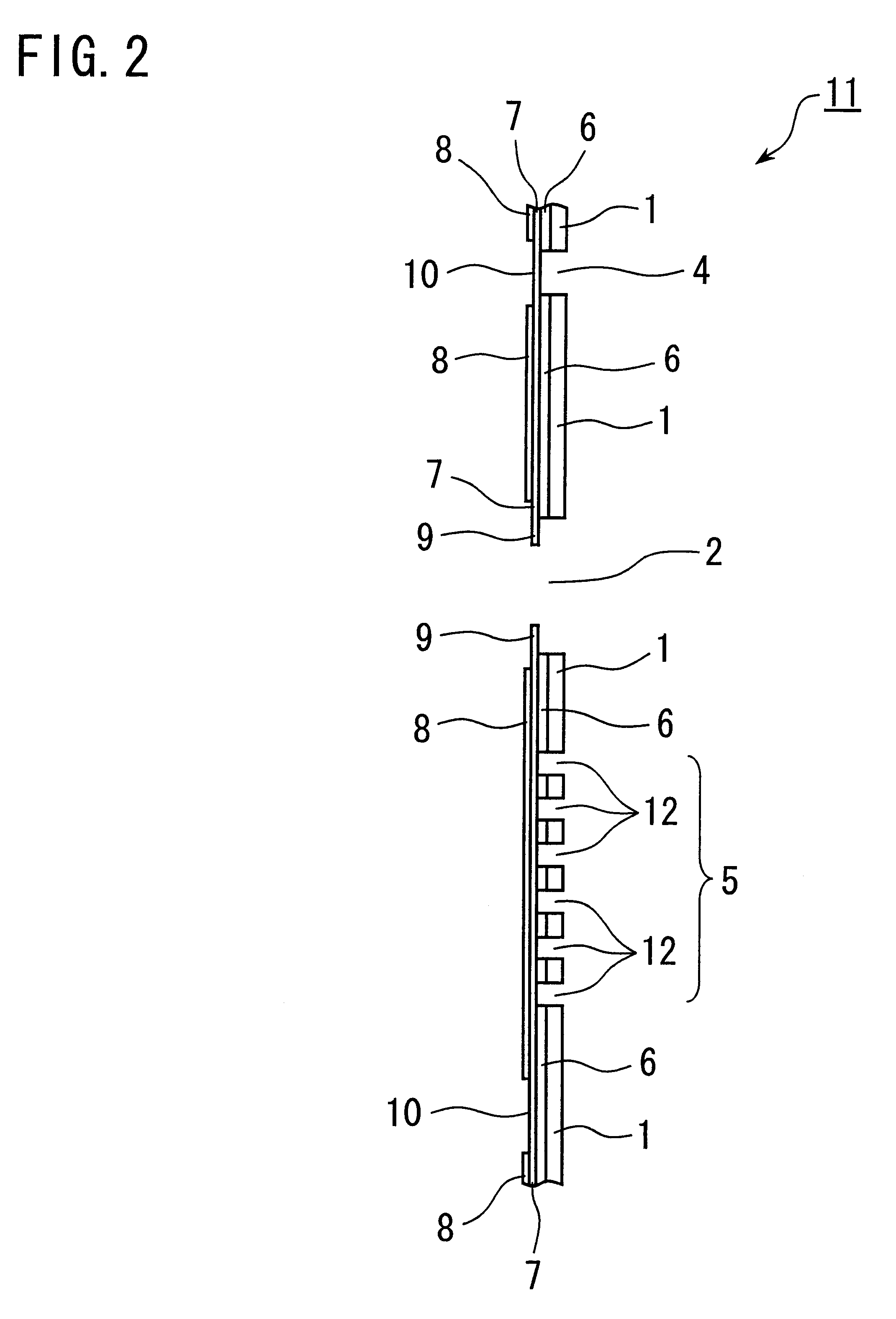

Wireless transmission system and wireless transmission method

ActiveUS20110038282A1Limited rangeFixed station waveguides transmission systemsSemiconductor/solid-state device detailsWireless transmissionEngineering

Disclosed herein is a wireless transmission system, including: a plurality of systems of millimeter wave signal transmission lines capable of individually transmitting information in a millimeter waveband independently of each other; a sending section disposed on one end side of each of the plural systems of millimeter wave signal transmission lines; and a reception section disposed on the other end side of each of the plural systems of millimeter wave signal transmission lines. The sending section is adapted to convert a signal of an object of transmission into a millimeter wave signal and supply the millimeter wave signal to the millimeter signal transmission line. The reception section is adapted to receive the millimeter wave signal transmitted thereto through the millimeter wave signal transmission line and convert the received millimeter wave signal into the signal of the object of transmission.

Owner:SONY CORP

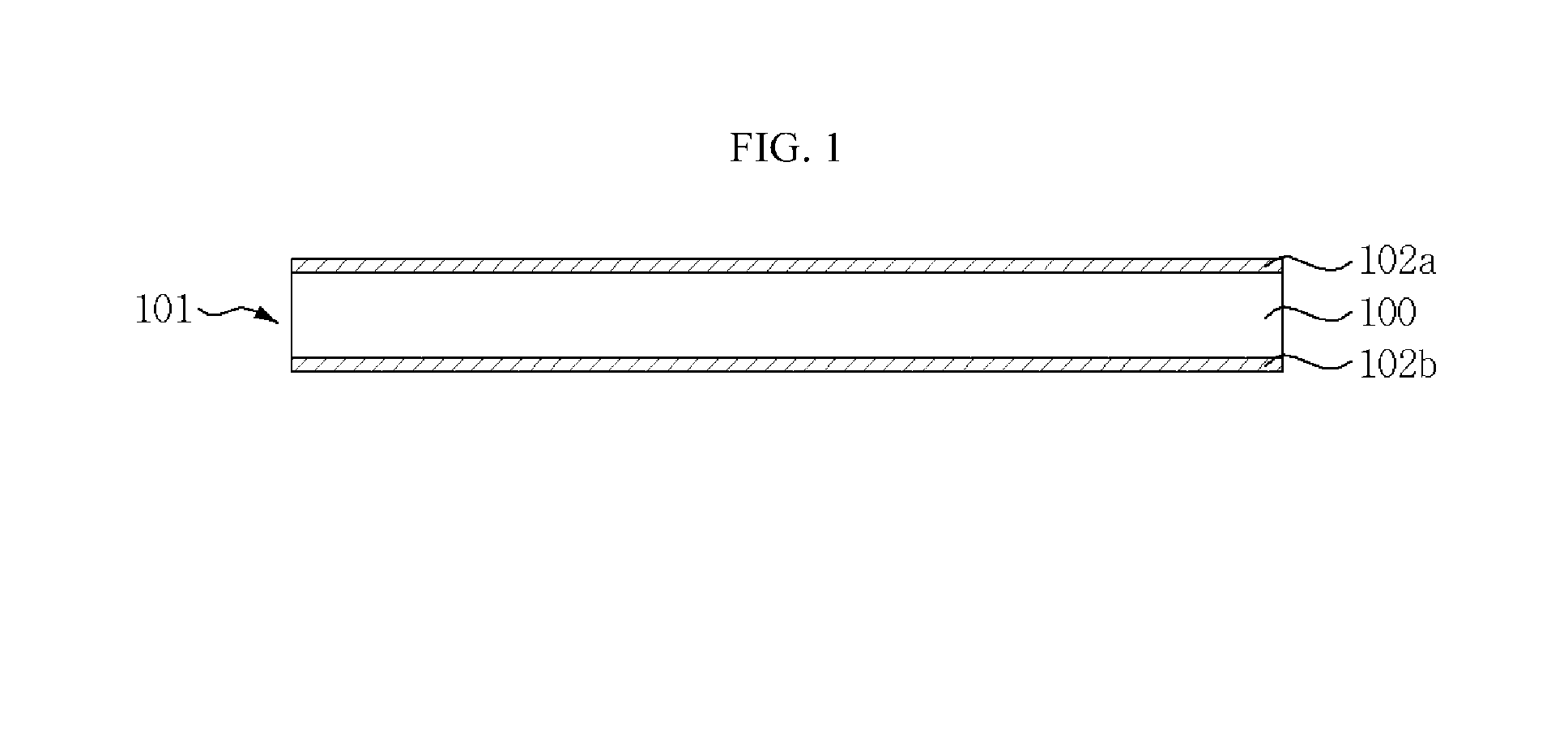

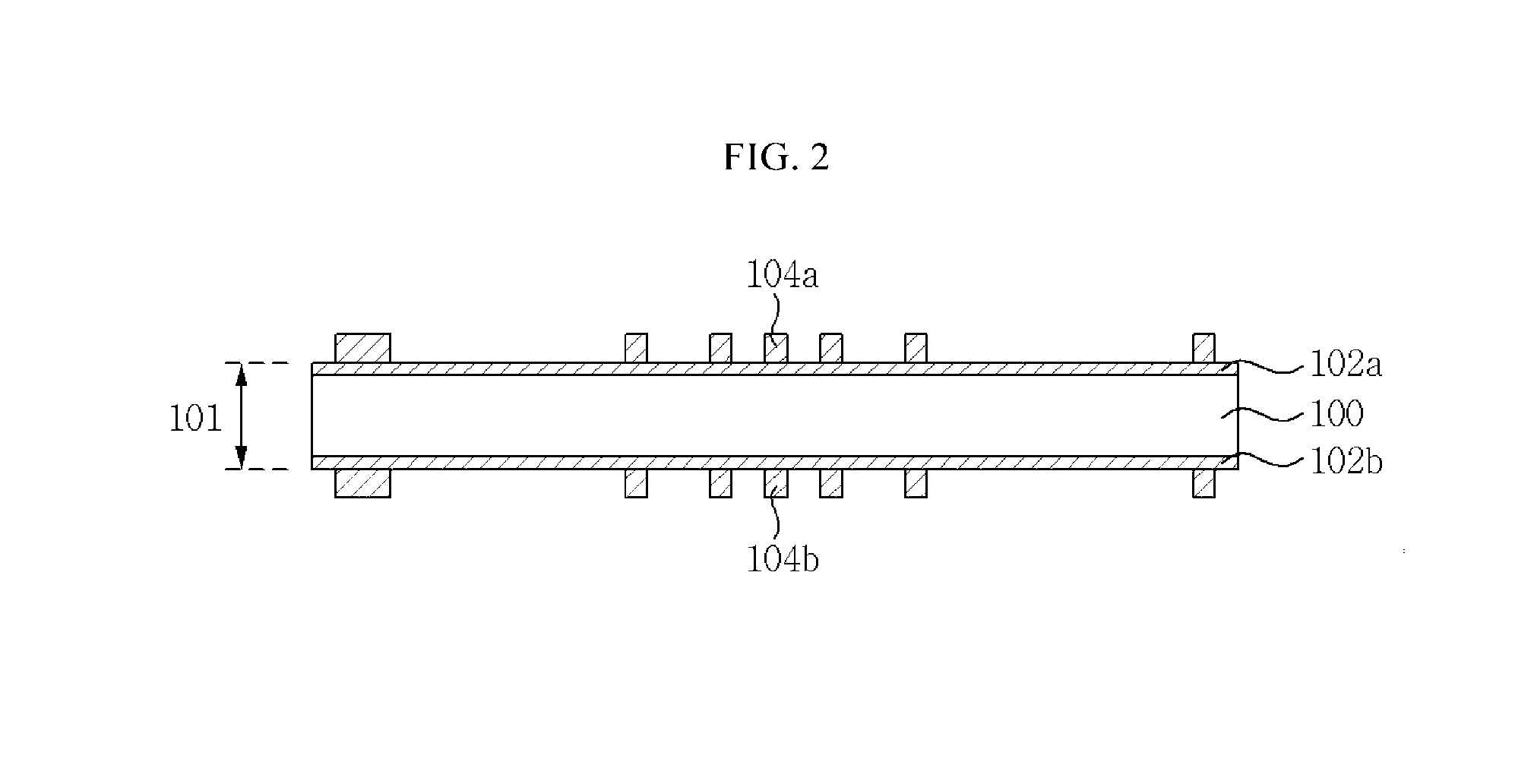

Multilayer wiring board and power supply structure to be embedded in multilayer wiring board

InactiveUS20080149384A1Lower resistanceHigh currentPrinted electric component incorporationSemiconductor/solid-state device detailsEngineeringCopper

Owner:NGK SPARK PLUG CO LTD

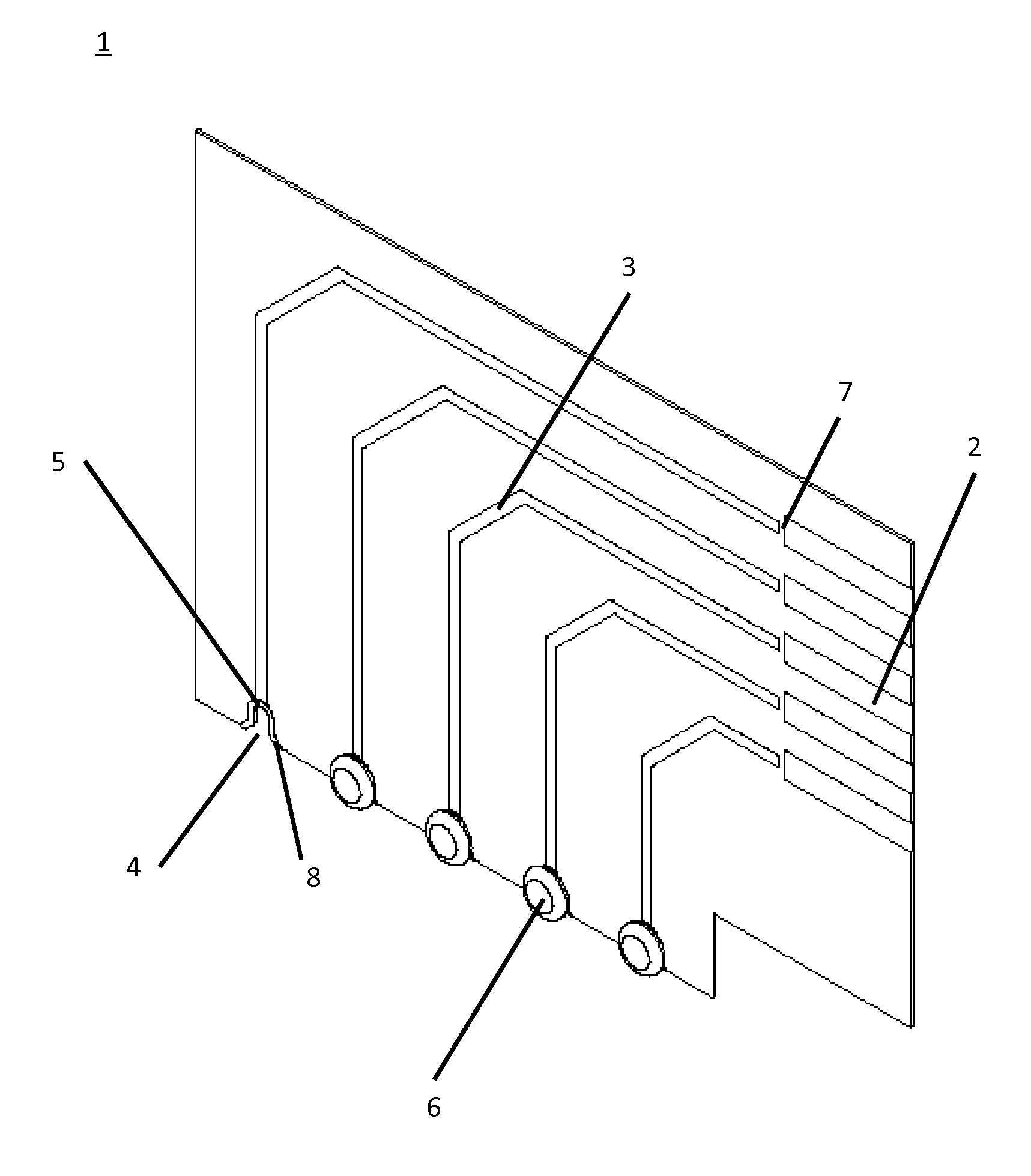

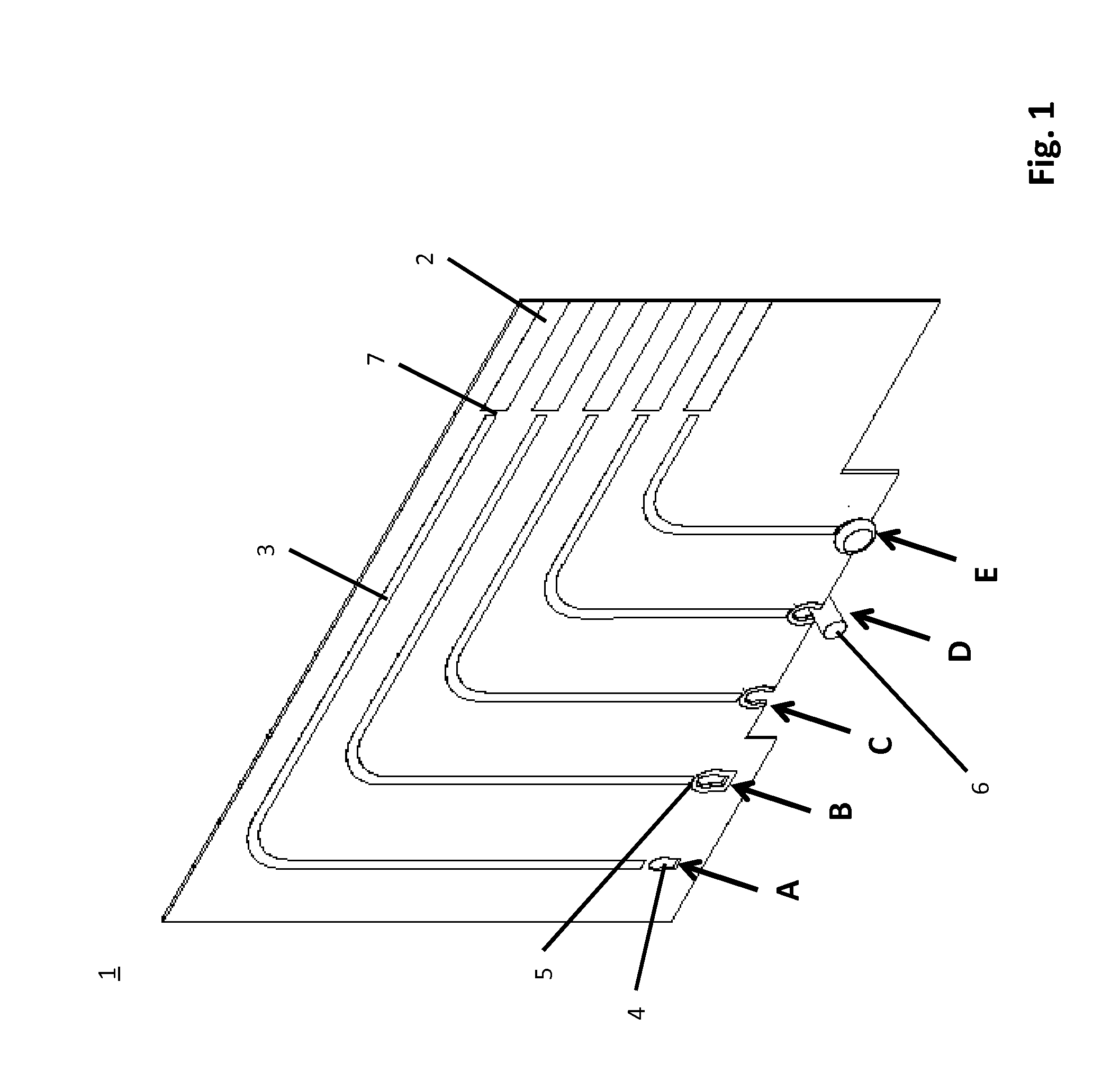

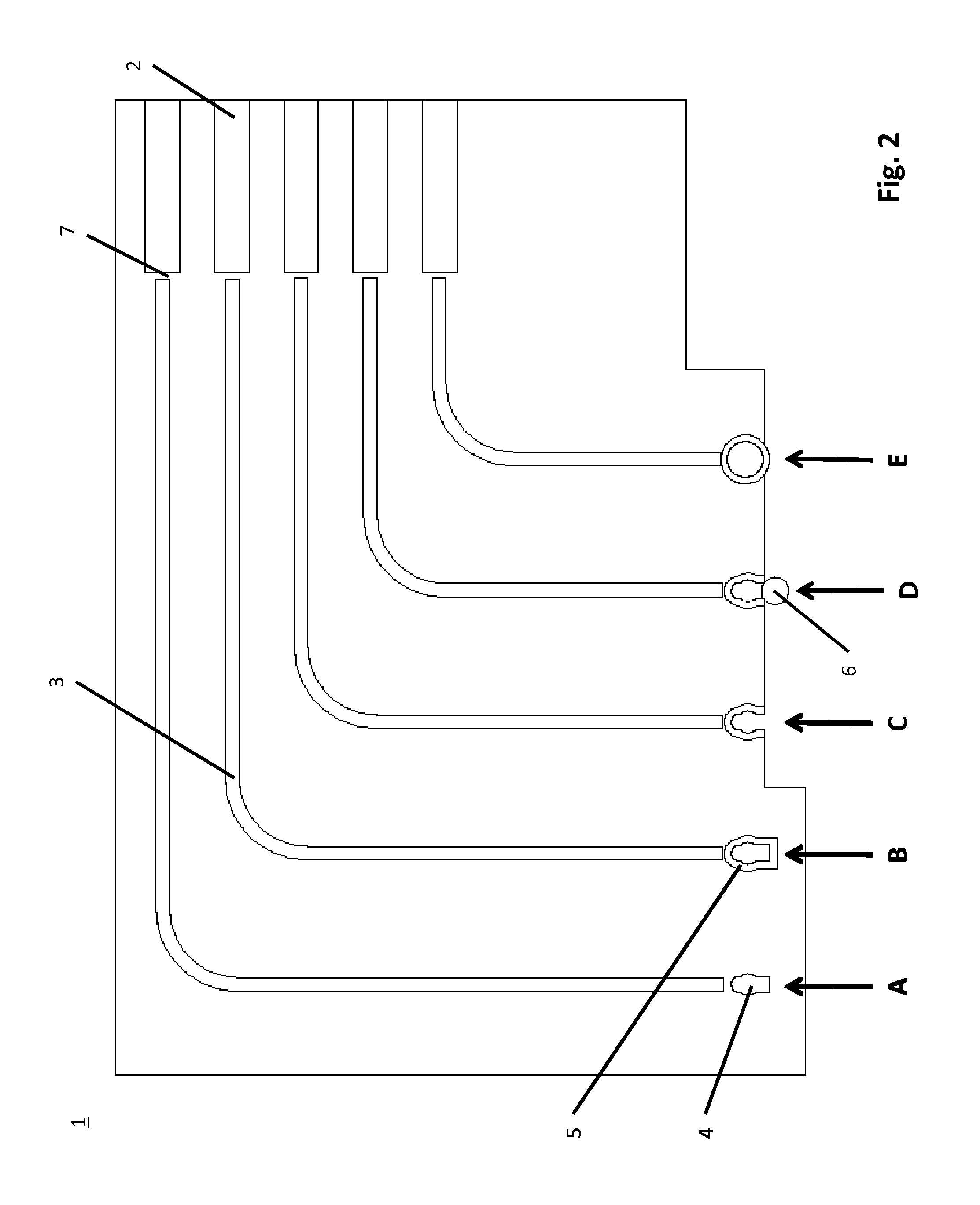

Textile arrangement and method for manufacturing

InactiveUS20130160183A1The process is simple and fastCost-effective manufacturingGlovesLaminating printed circuit boardsFlexible circuitsEngineering

Owner:CLOTHING PLUS MBU

Folding type display apparatus and electric equipment

InactiveCN105280099AEnsure curvatureKeep touch operableStatic indicating devicesSolid-state devicesElectric devicesFlexible display

Owner:TIANMA MICRO ELECTRONICS CO LTD

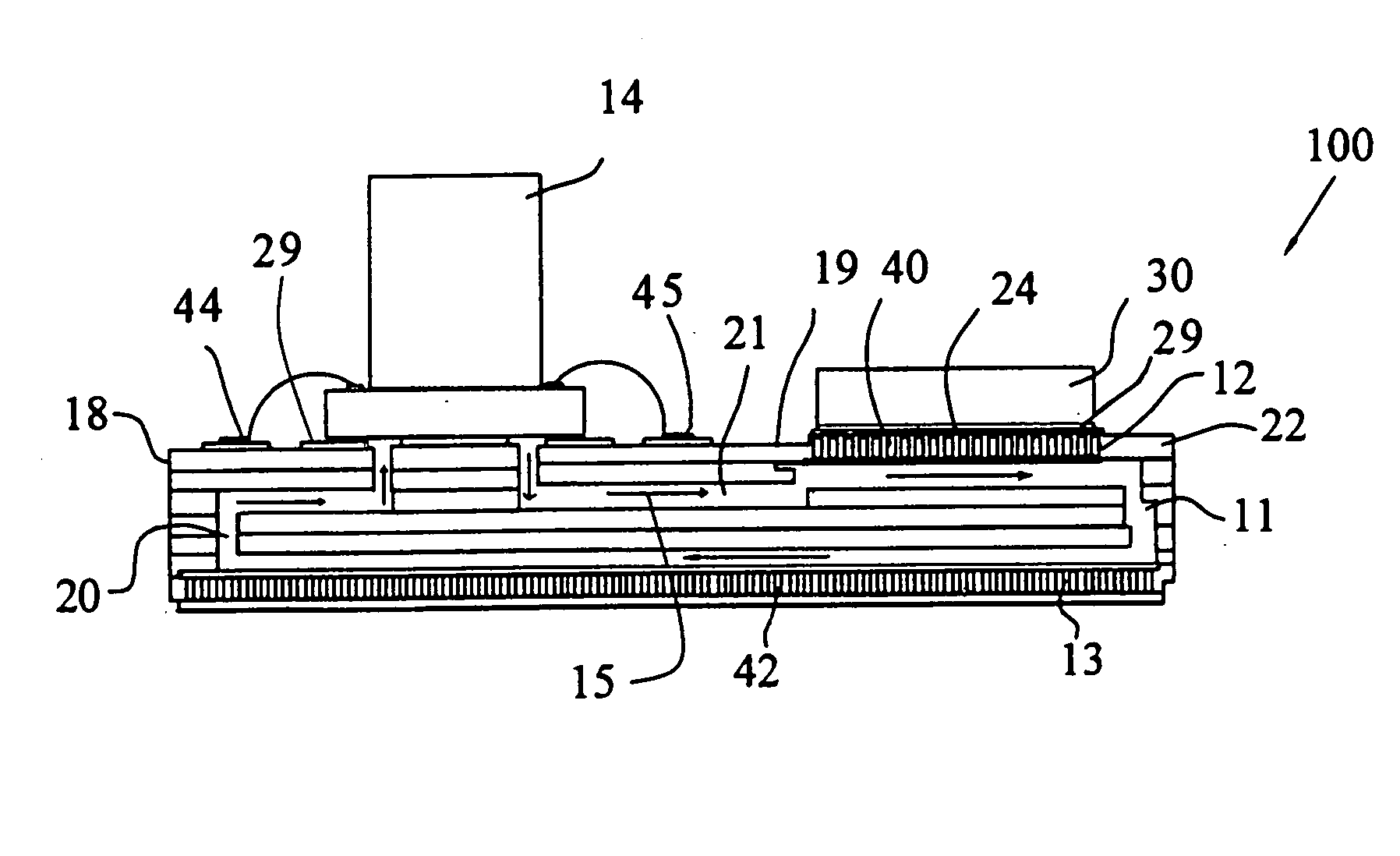

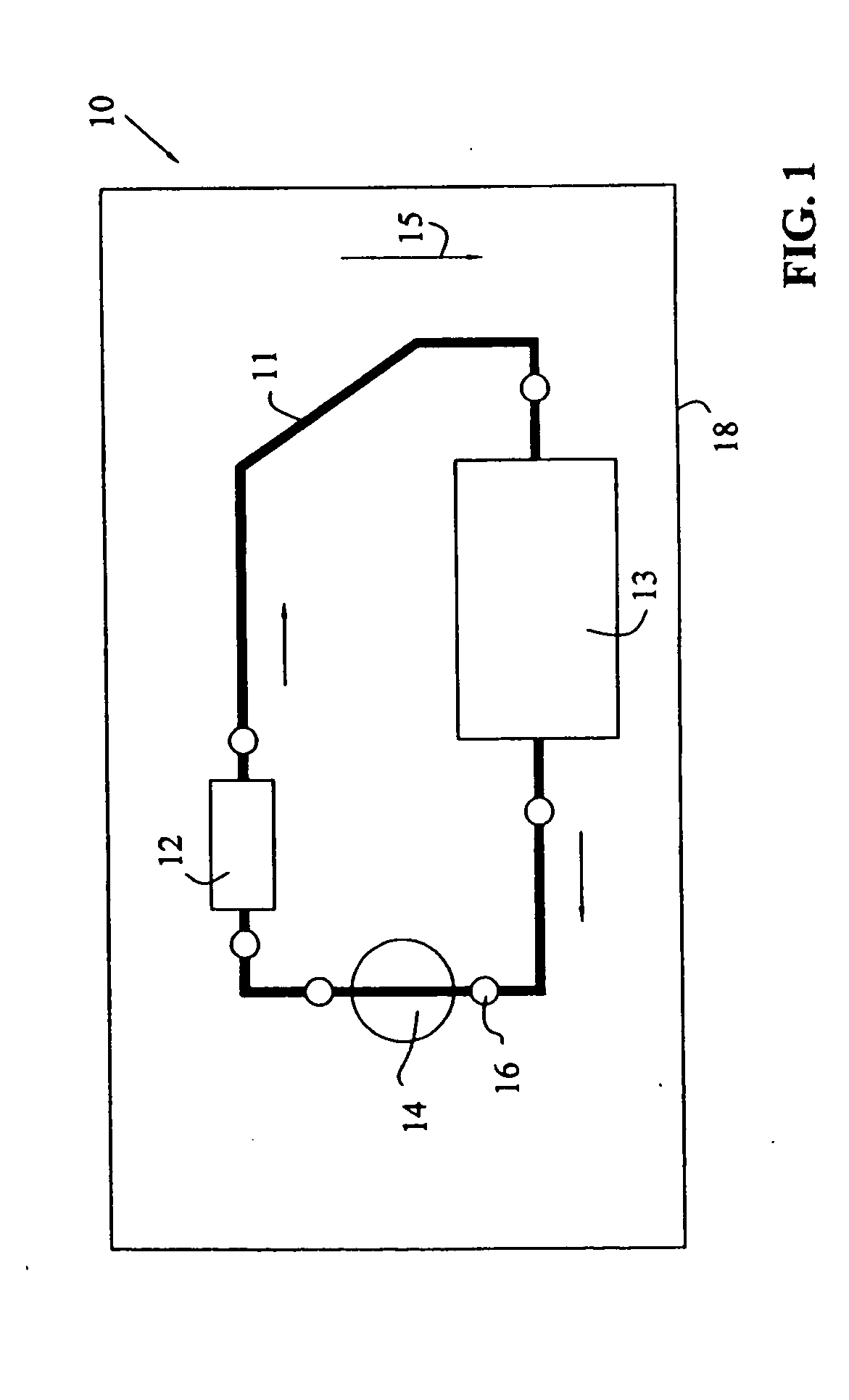

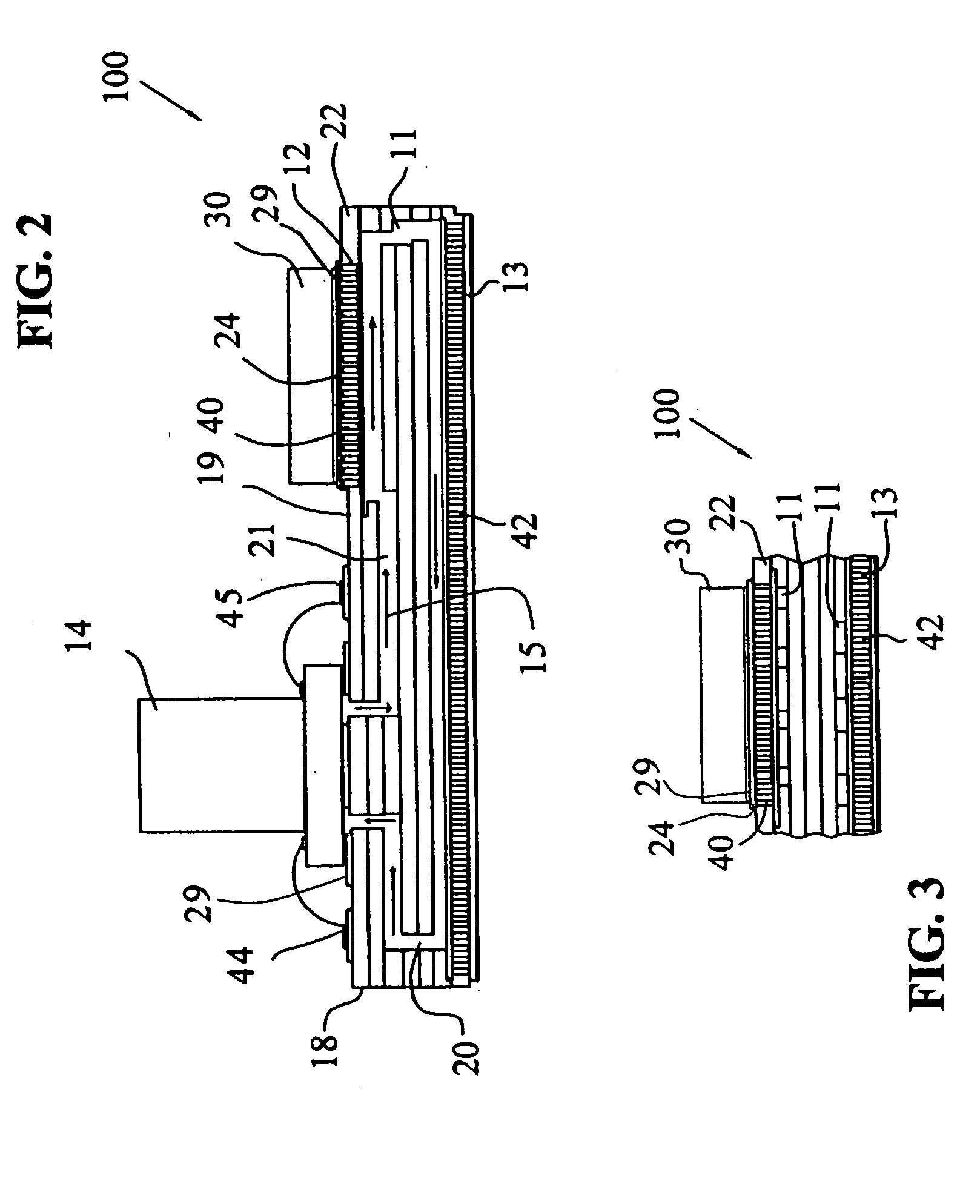

Integrated cooling system for electronic devices

ActiveUS20060034052A1Printed circuit aspectsCircuit fluid transportElectronic assembliesHeat exchanger

Owner:DELPHI TECH IP LTD

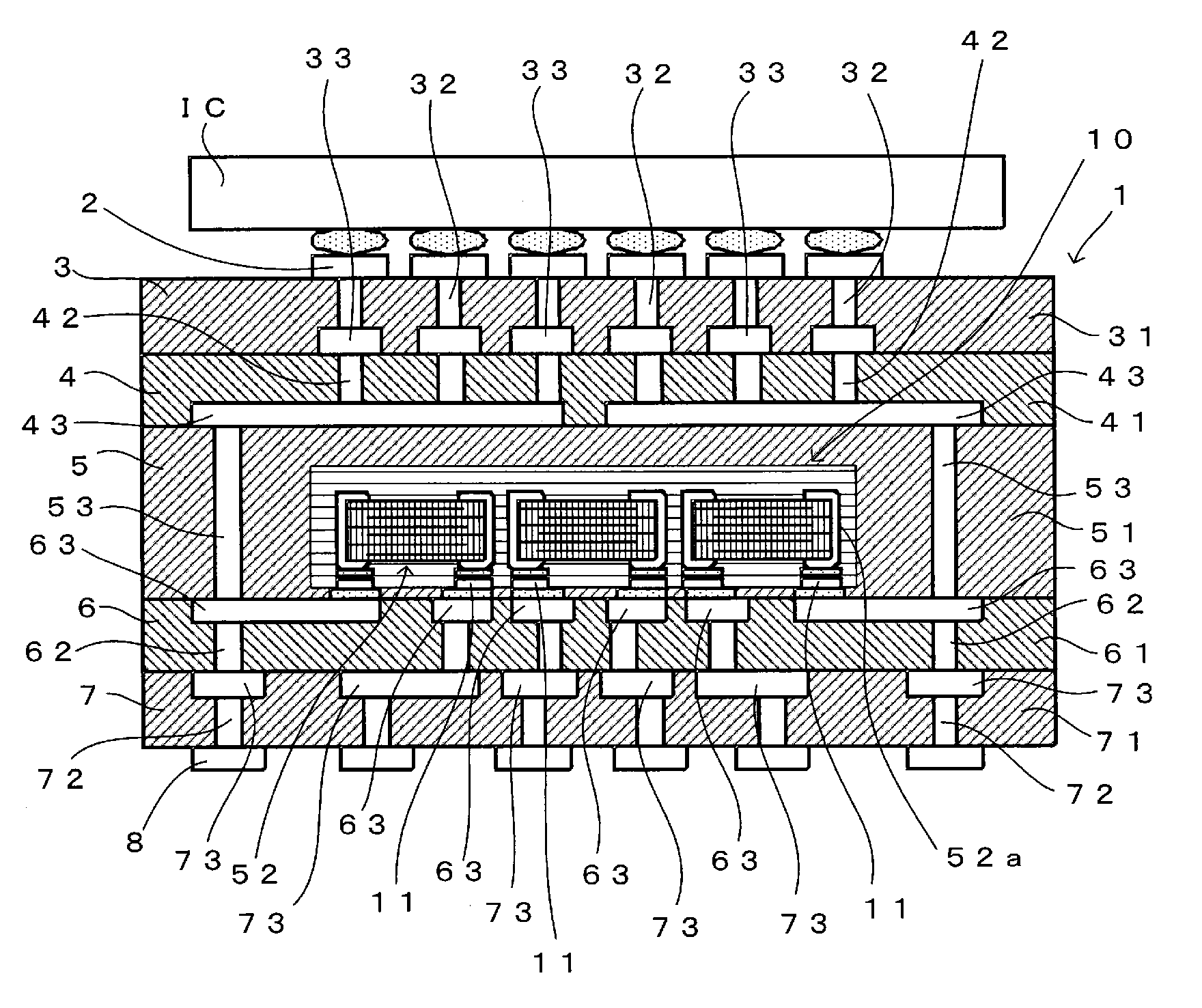

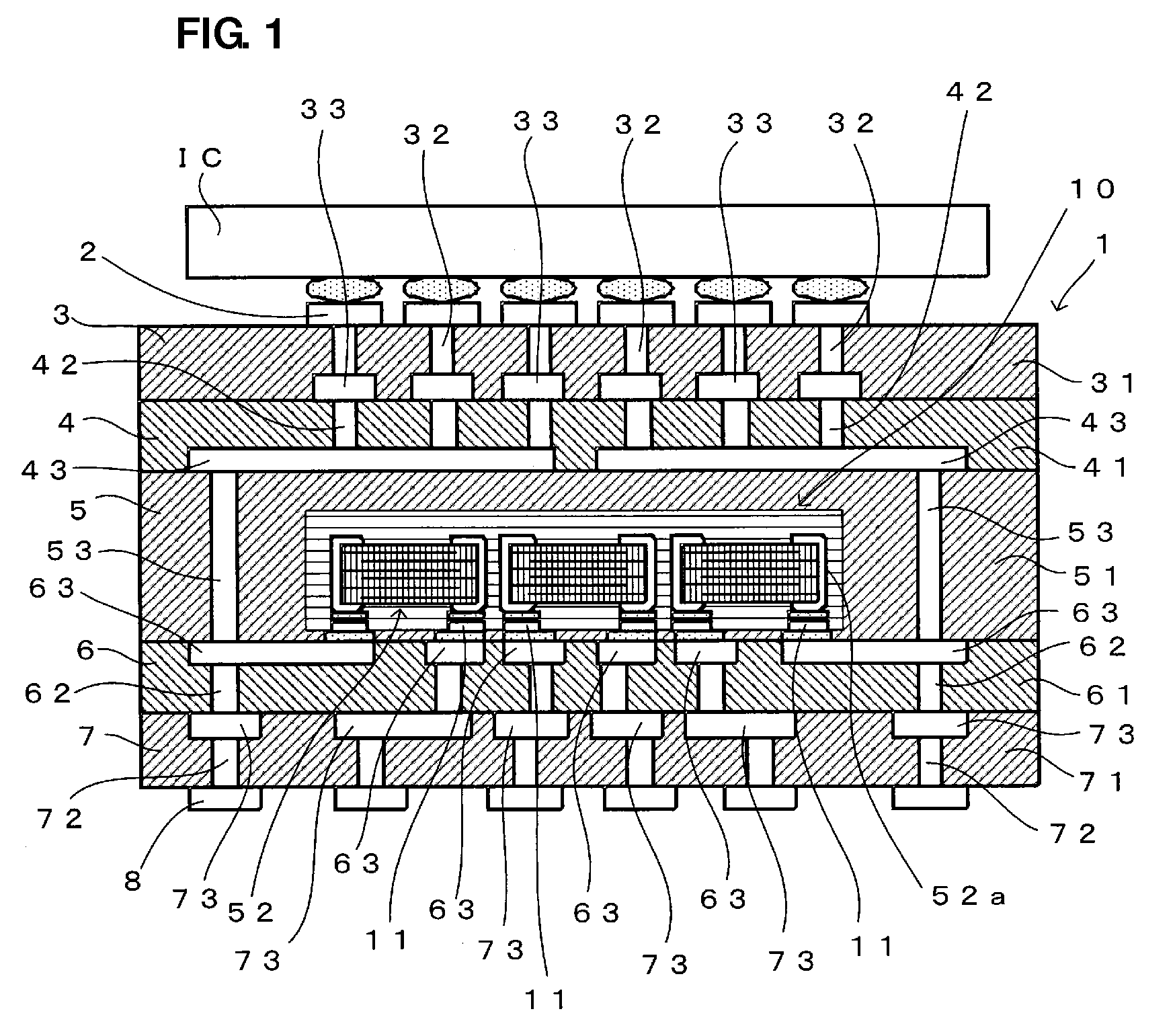

Multilayer Printed Wiring Board And Manufacturing Method For Same

InactiveUS20080121416A1Prevented from short circuitingLine/current collector detailsPrinted circuit detailsConductive pasteAdhesive

In a case of multilayer circuit boards where a plurality of conventional films are used as insulating layers, the films are connected with each other using an adhesive, and therefore, the adhesive sometimes negatively affects reduction in thickness. Therefore, a plurality of two-sided boards with films used therein are pasted together with a paste connection layer interposed therebetween, the paste connection layer being configured such that through holes formed in a prepreg are filled in with a conductive paste which is then cured, and second wires are electrically connected with each other through the conductive paste with which the through holes formed in the paste connection layer in advance are filled in, and thus, a multilayer board can be provided without using an adhesive, and the entirety of the multilayer circuit board can be reduced in thickness.

Owner:PANASONIC CORP

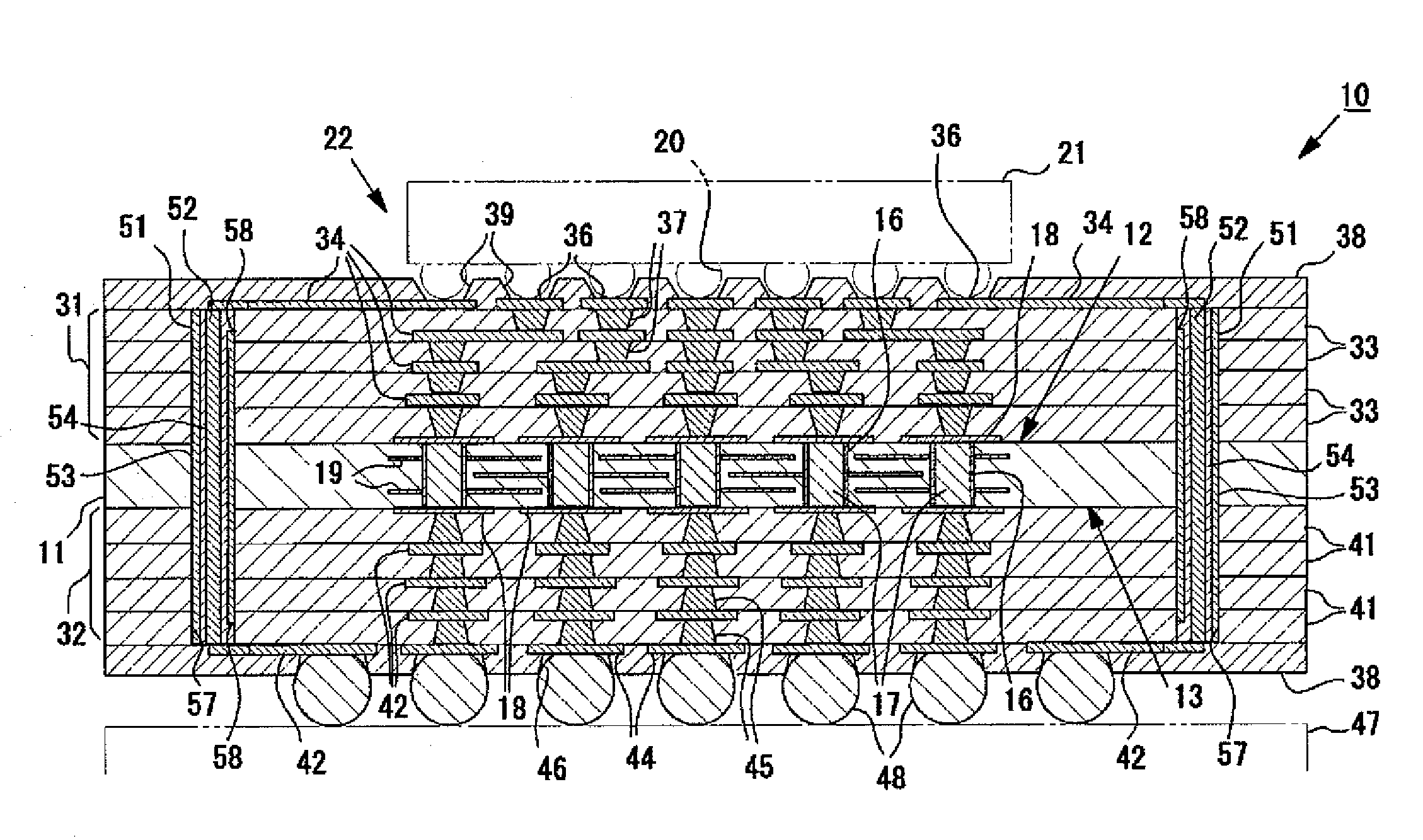

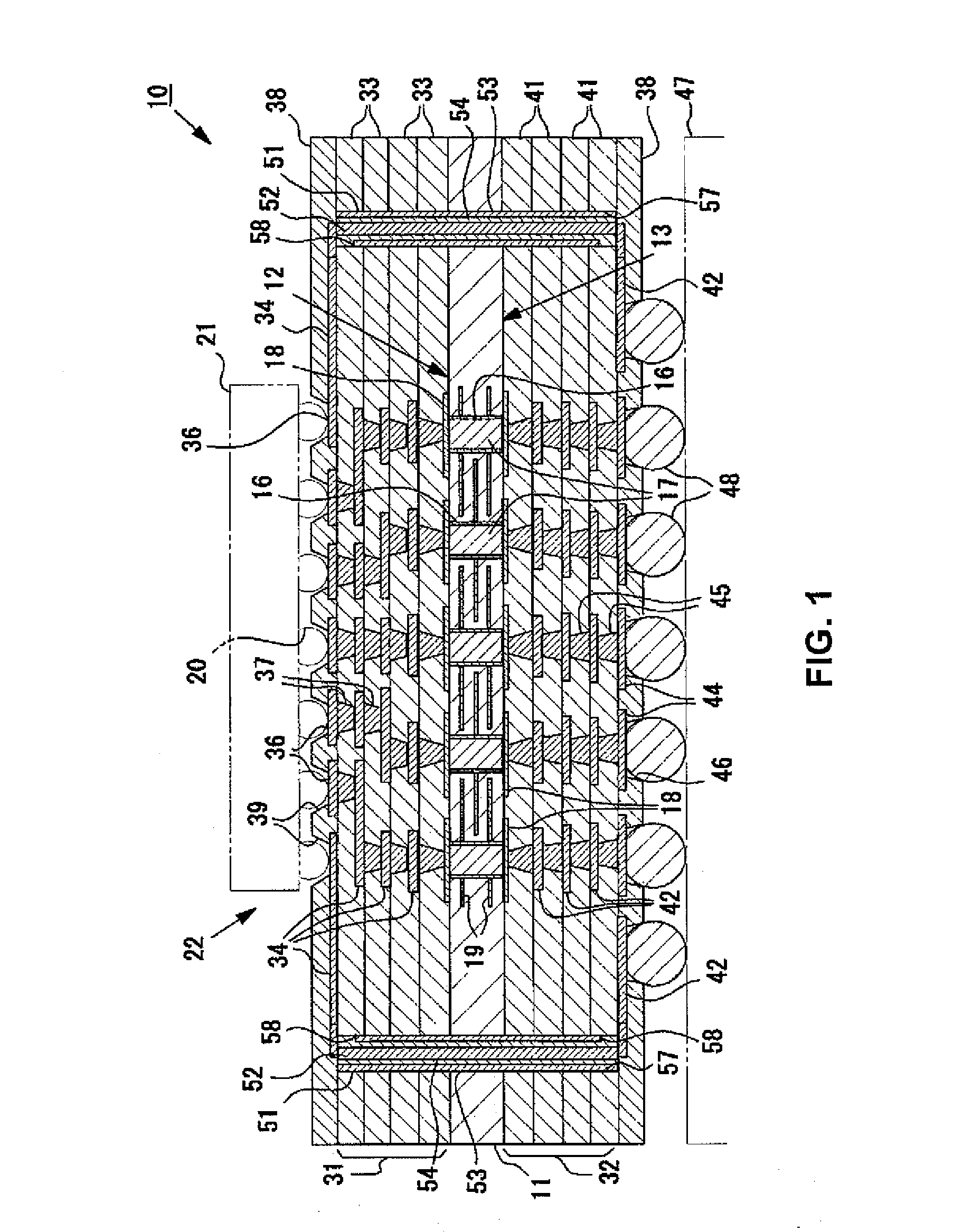

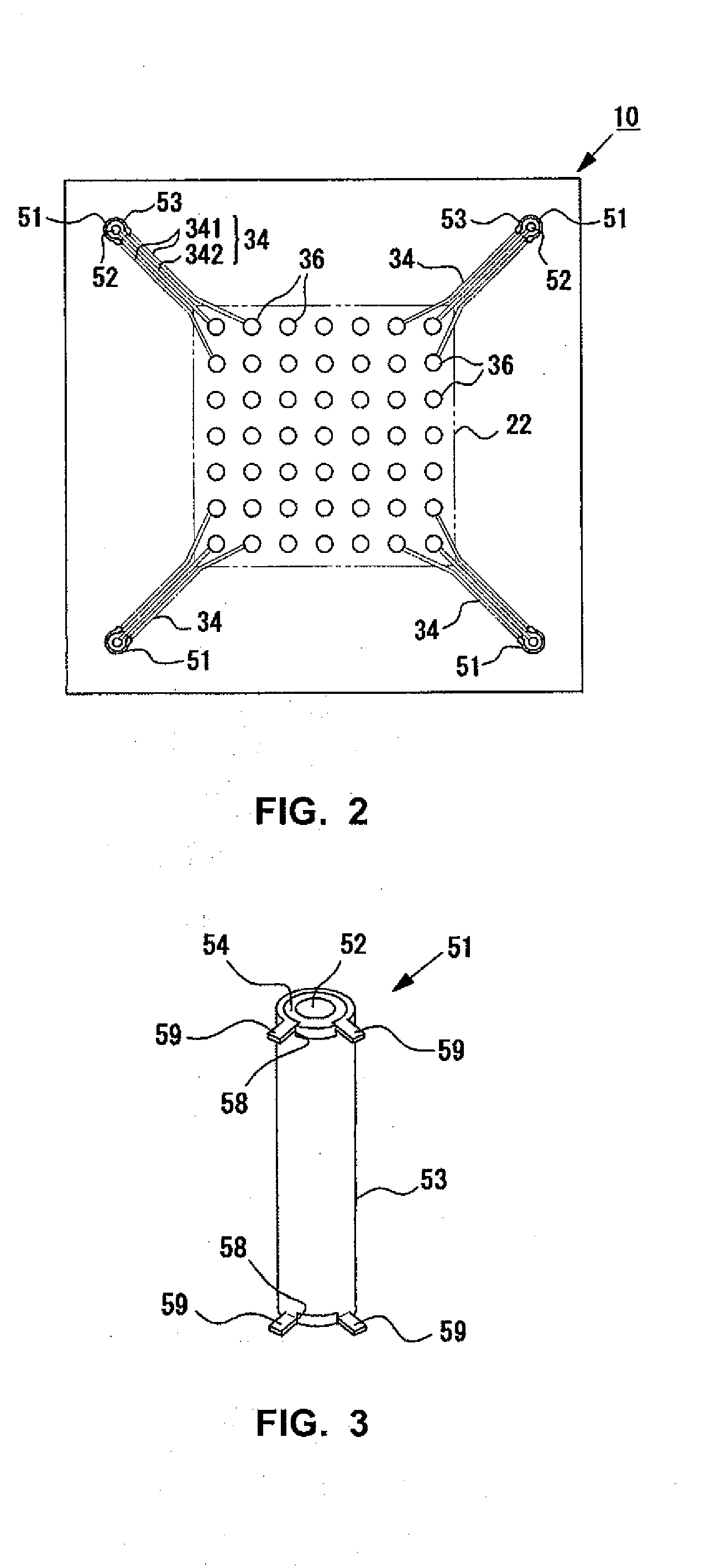

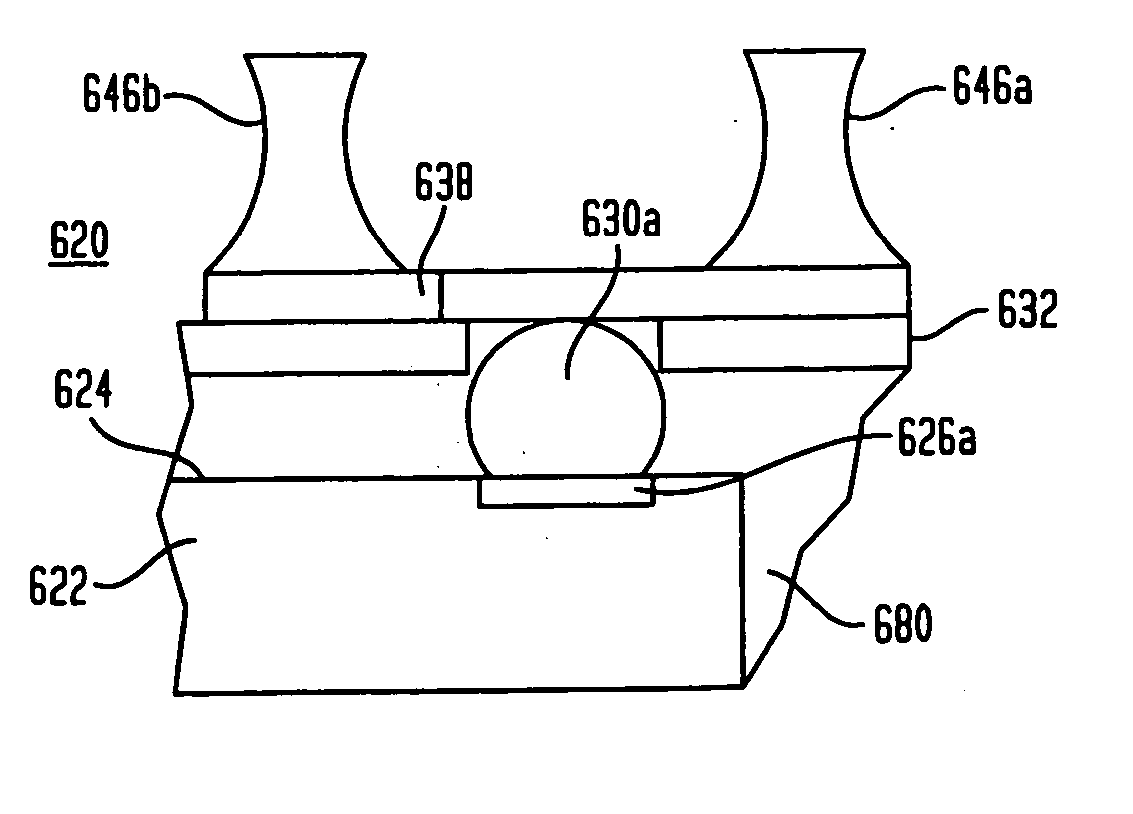

Microelectronic packages and methods therefor

InactiveUS20060249857A1Easy to testAvoid the needElectrical measurement instrument detailsSemiconductor/solid-state device detailsElectronic componentElectronic packaging

Owner:TESSERA INC

Embedded printed circuit board and method of manufacturing the same

InactiveUS20160174381A1Well formedSolid-state devicesElectrical connection printed elementsInsulation layerElectronic component

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

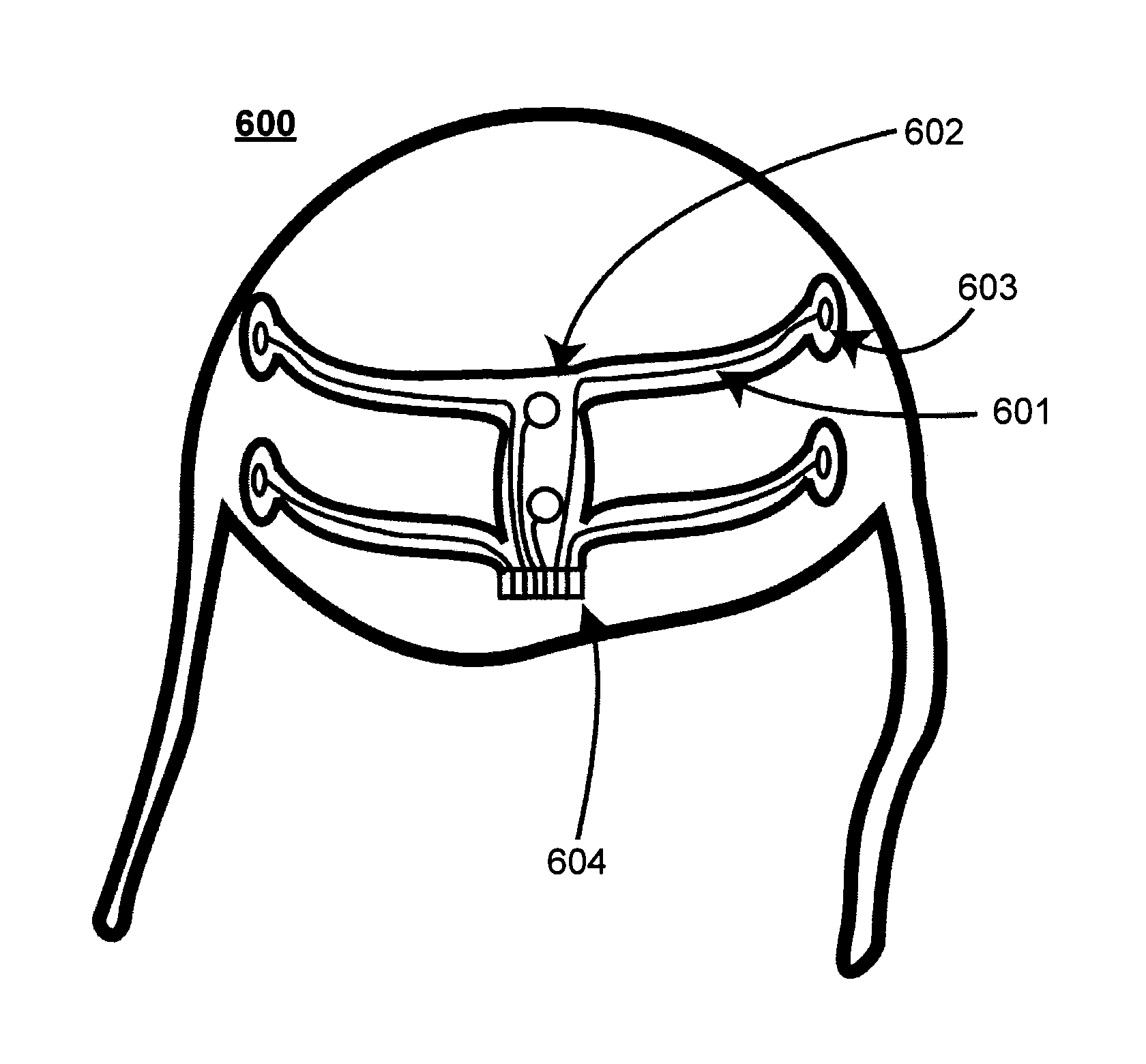

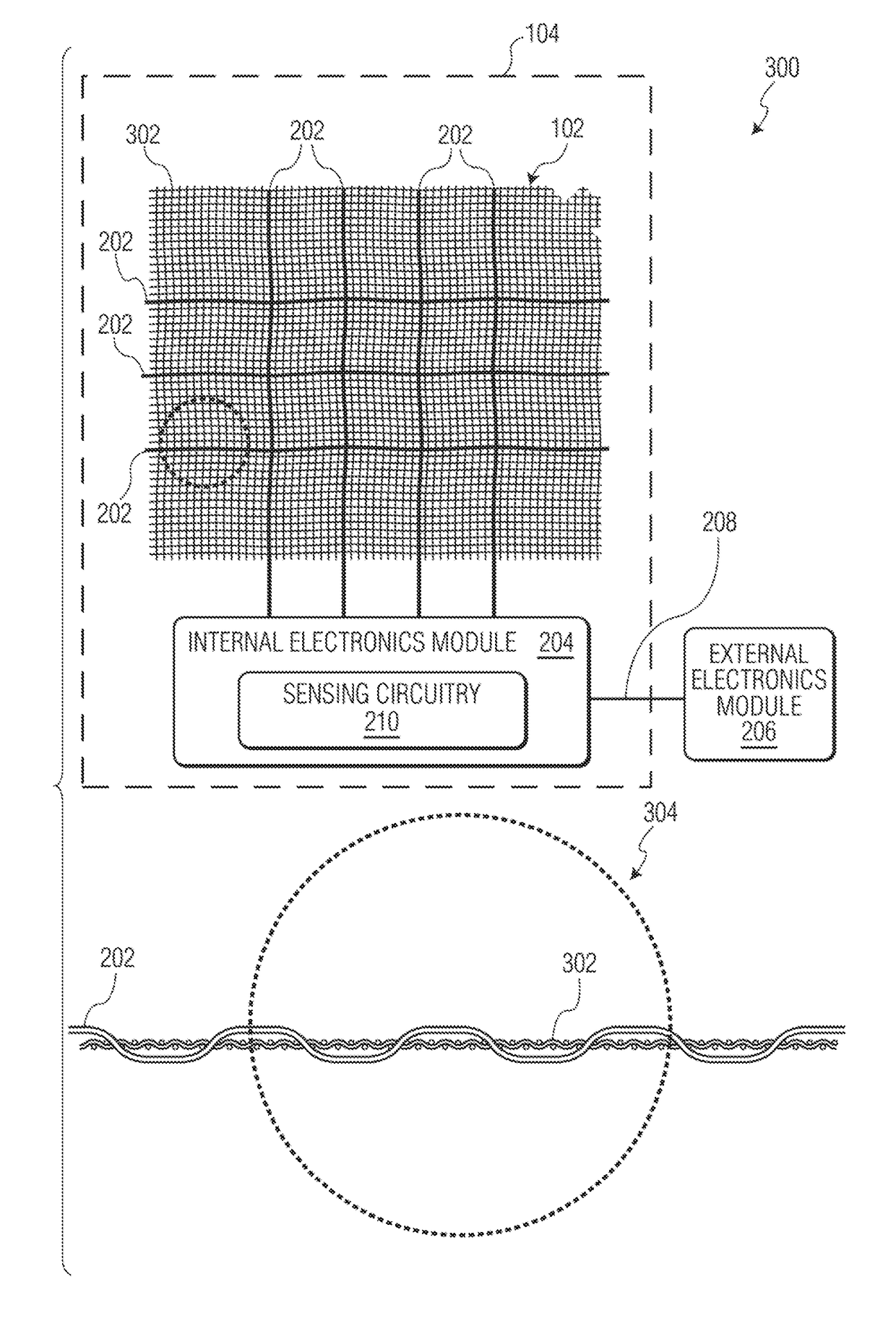

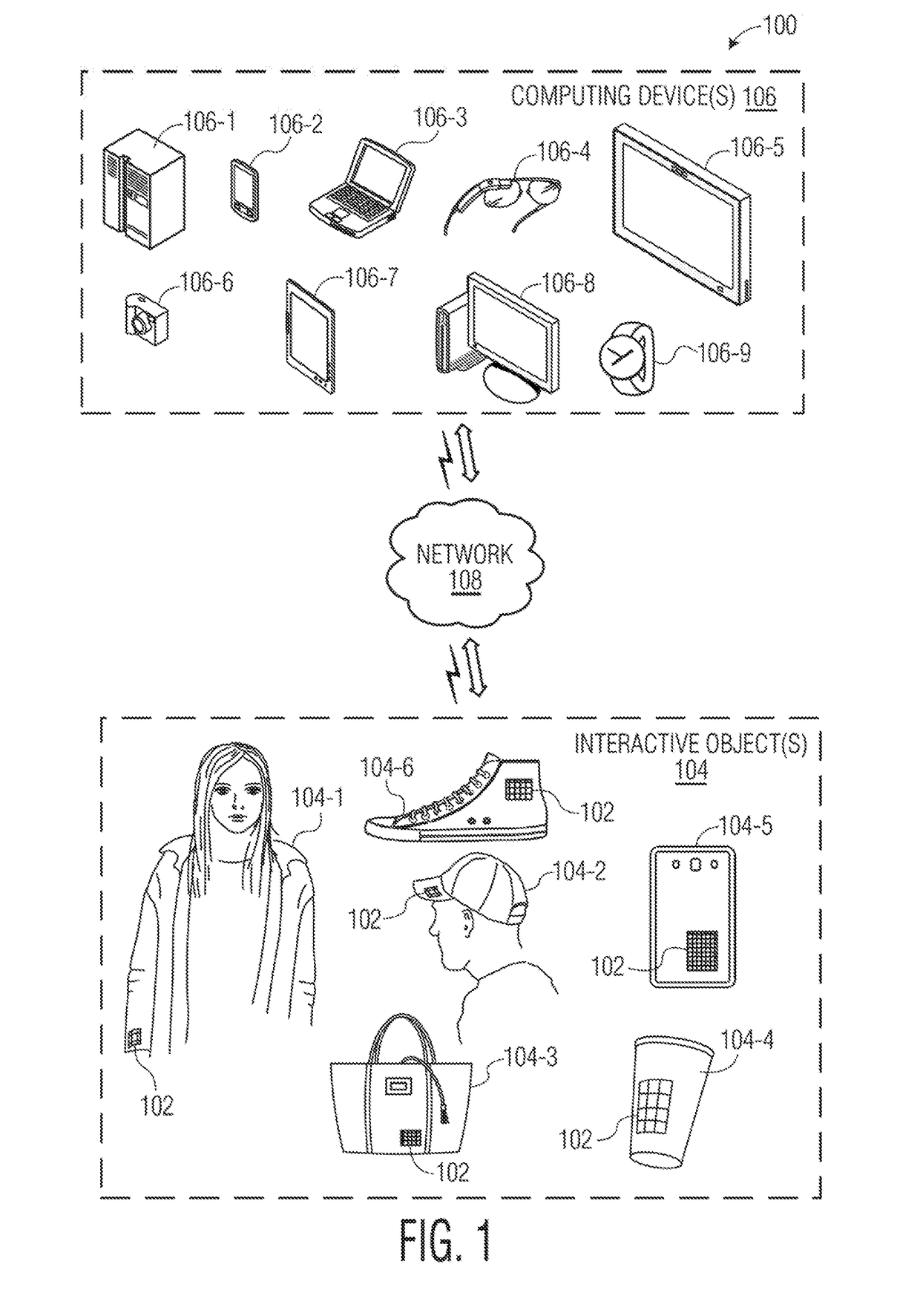

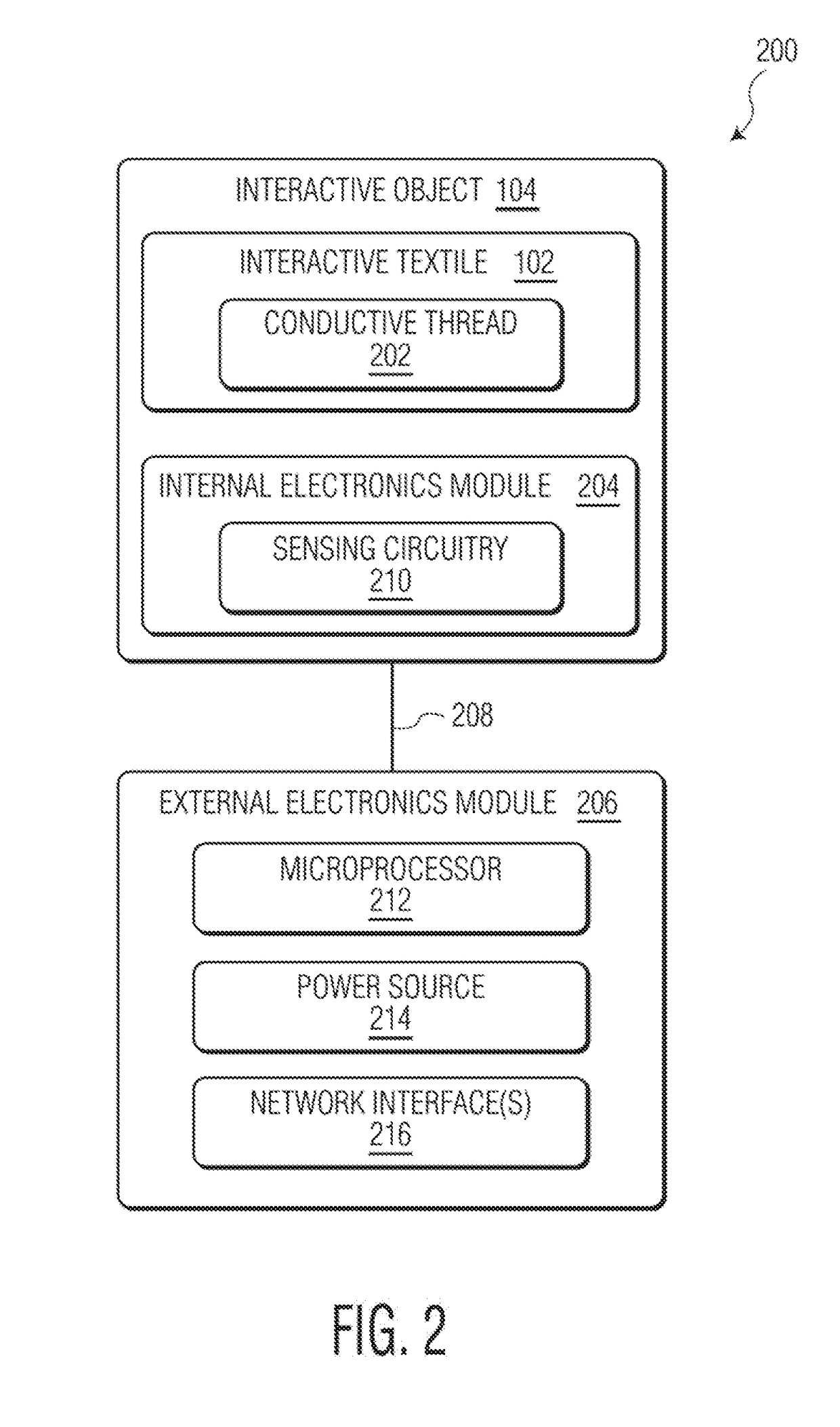

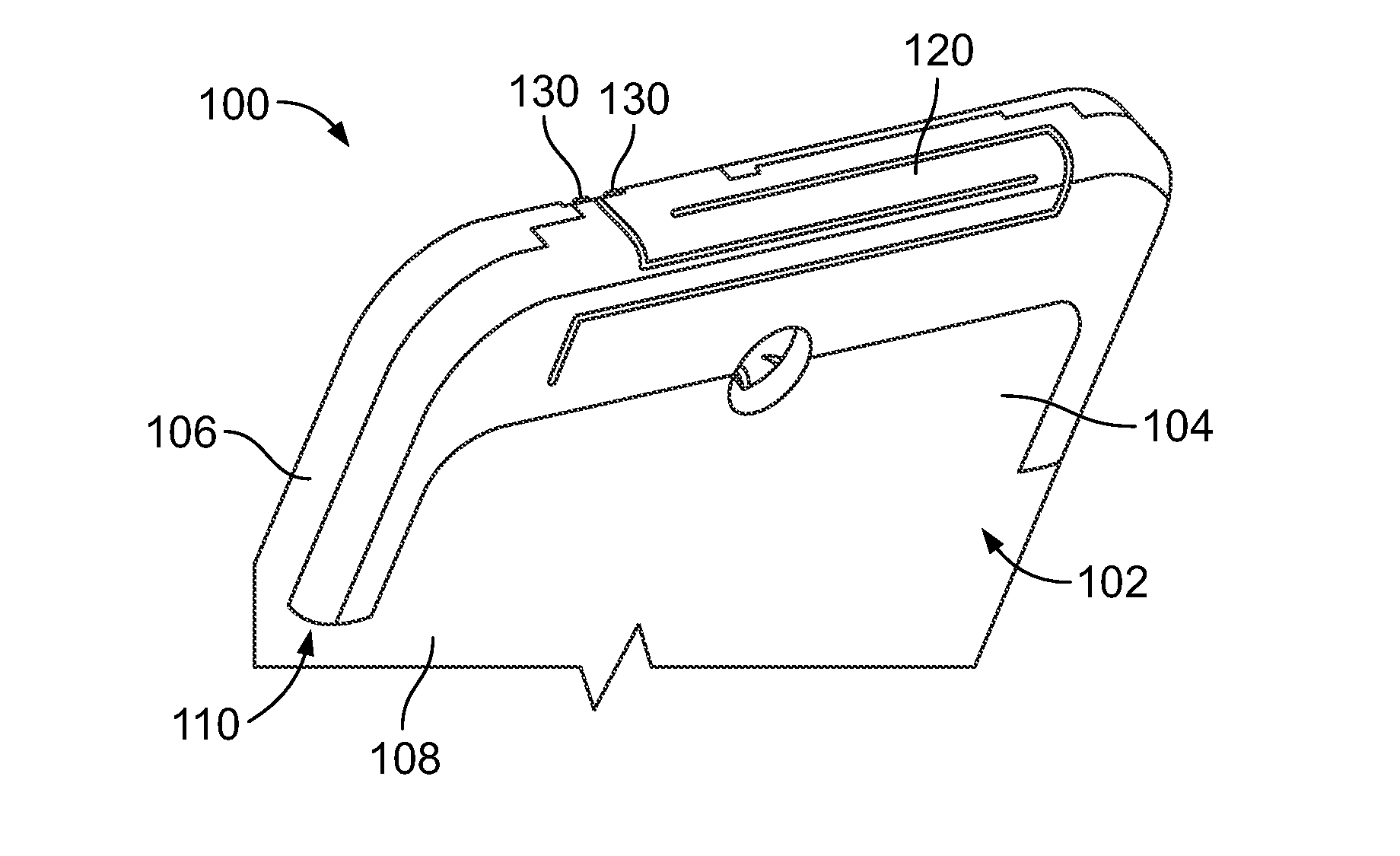

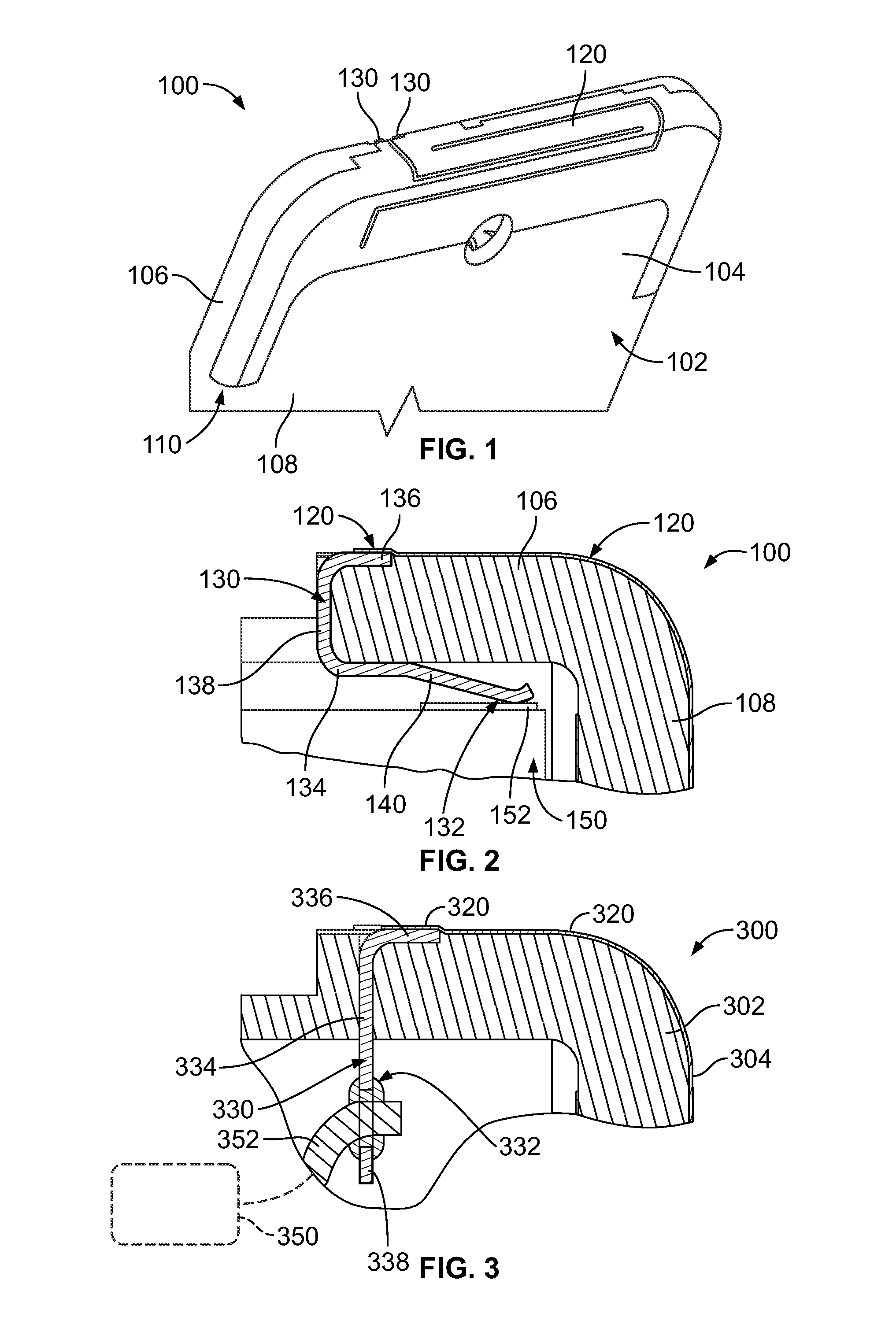

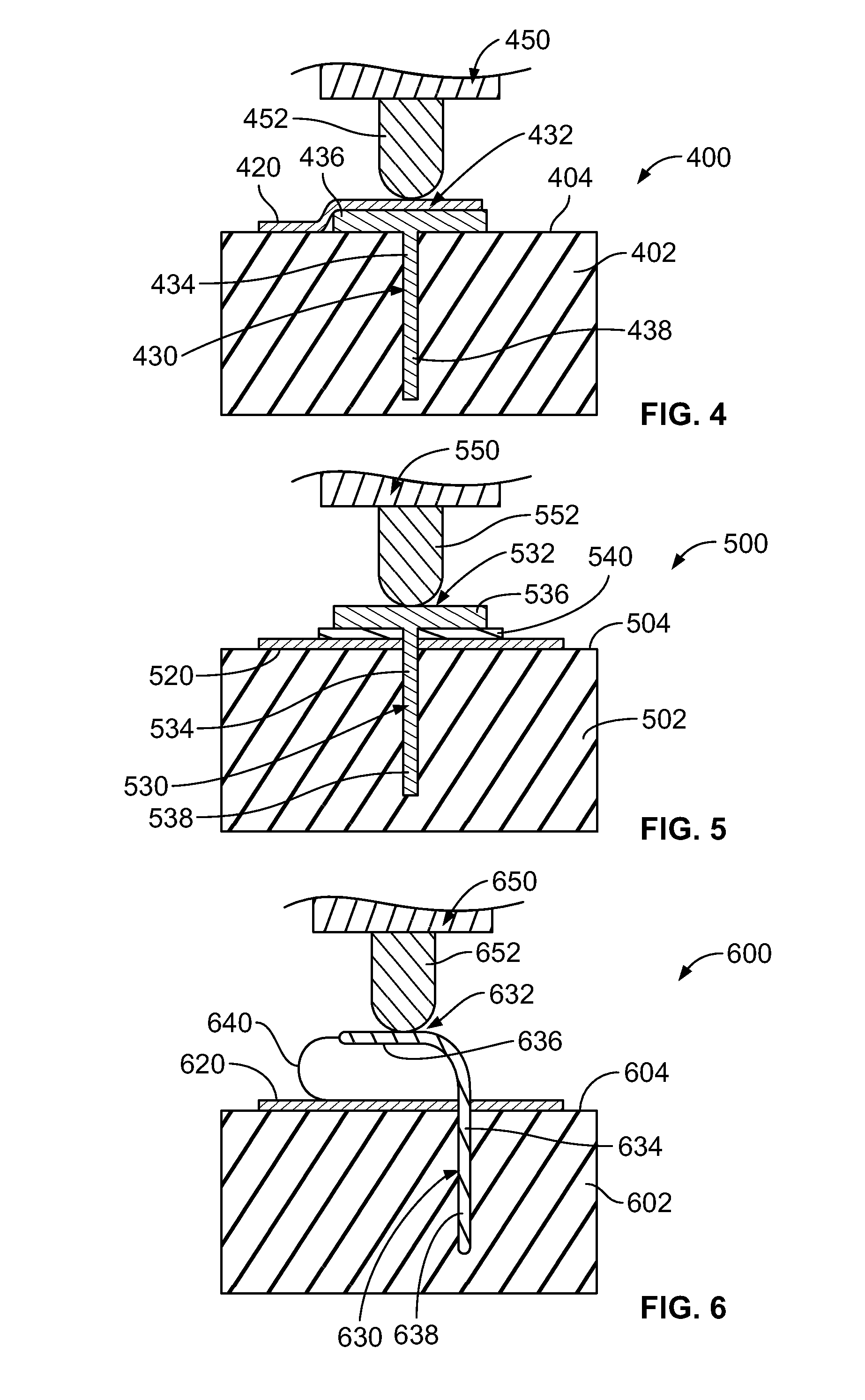

Connector Integration for Smart Clothing

ActiveUS20180260052A1Provide strain reliefPrinted circuit aspectsOvergarmentsCommunication interfaceComputer module

Owner:GOOGLE LLC

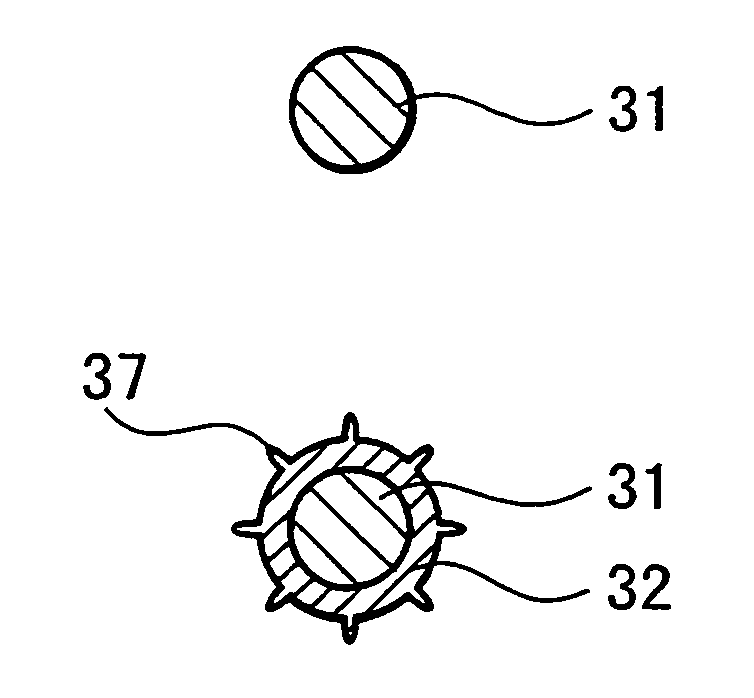

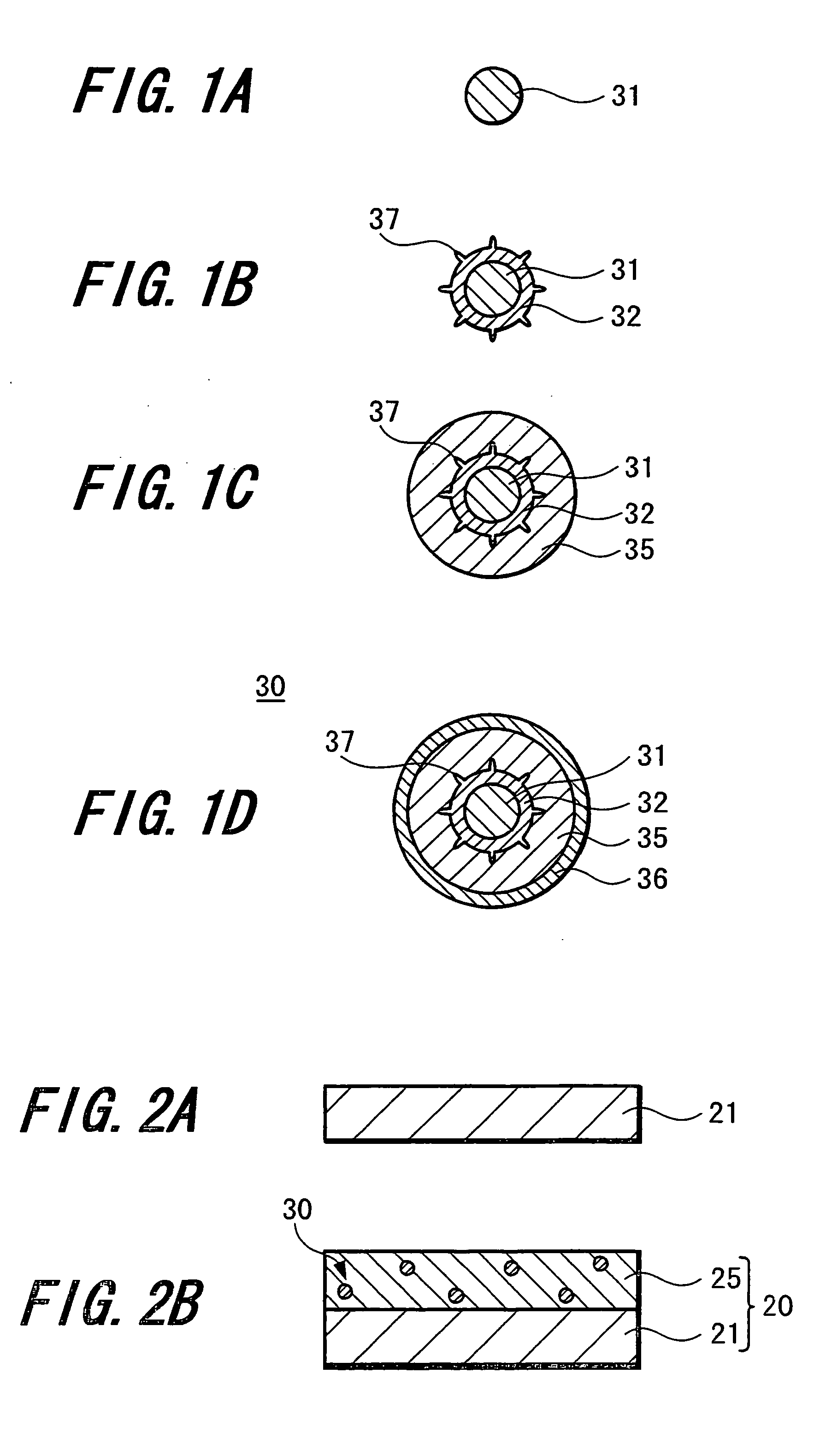

Conductive particle and adhesive agent

ActiveUS20060054867A1Avoid deformationReliable electrical connectionNon-insulated conductorsSolid-state devicesResin coatingMaterials science

Owner:SONY CORP +1

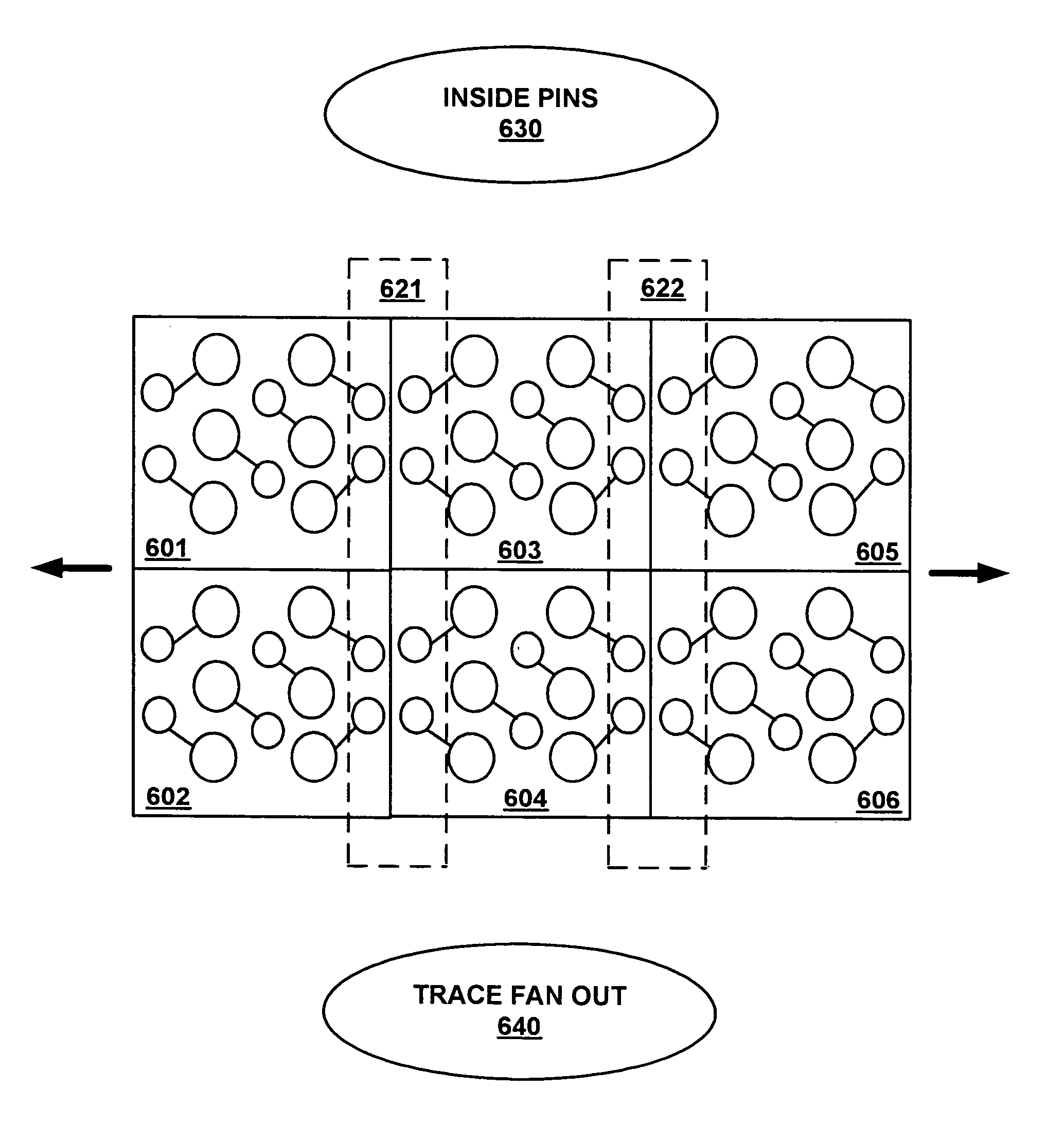

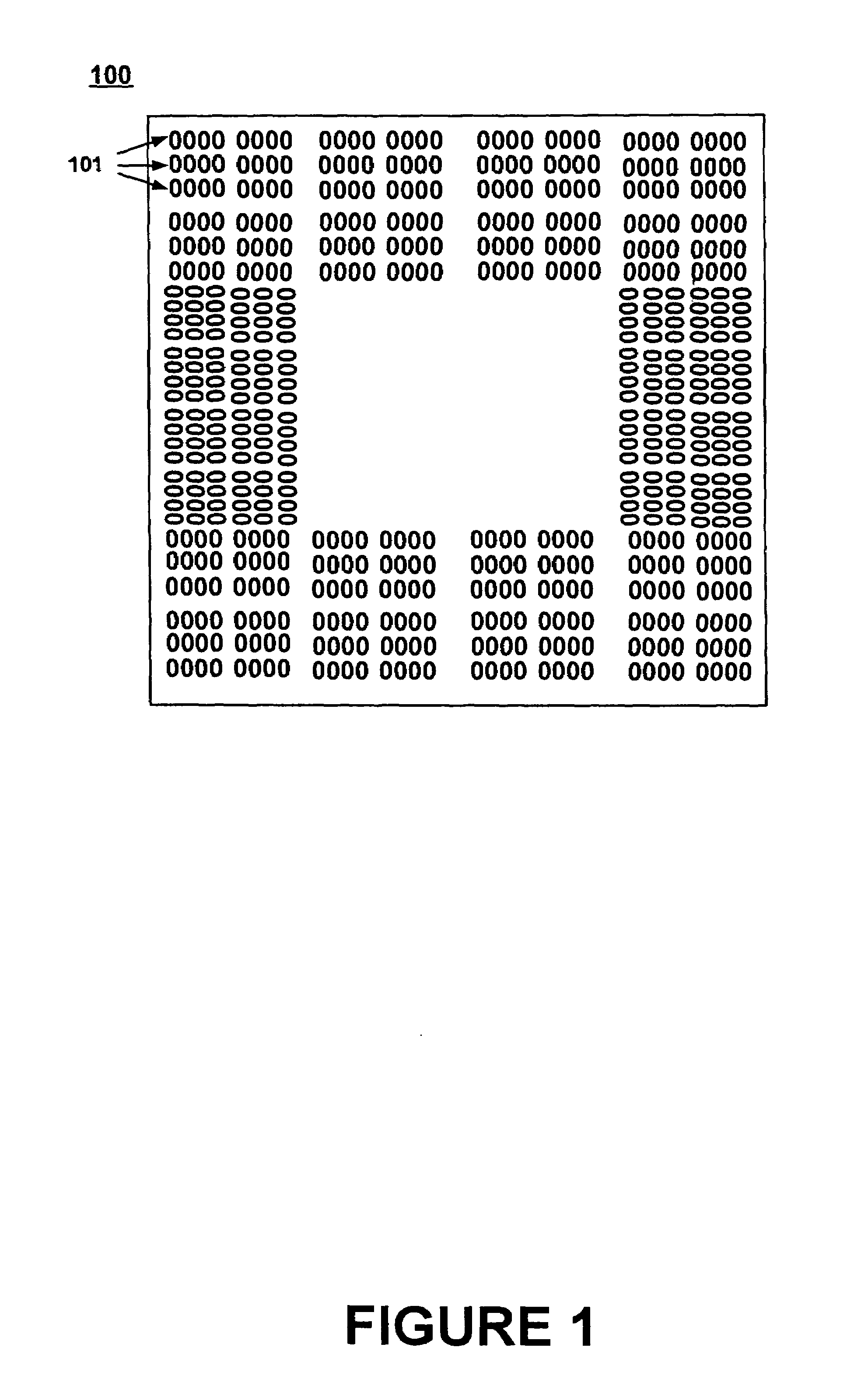

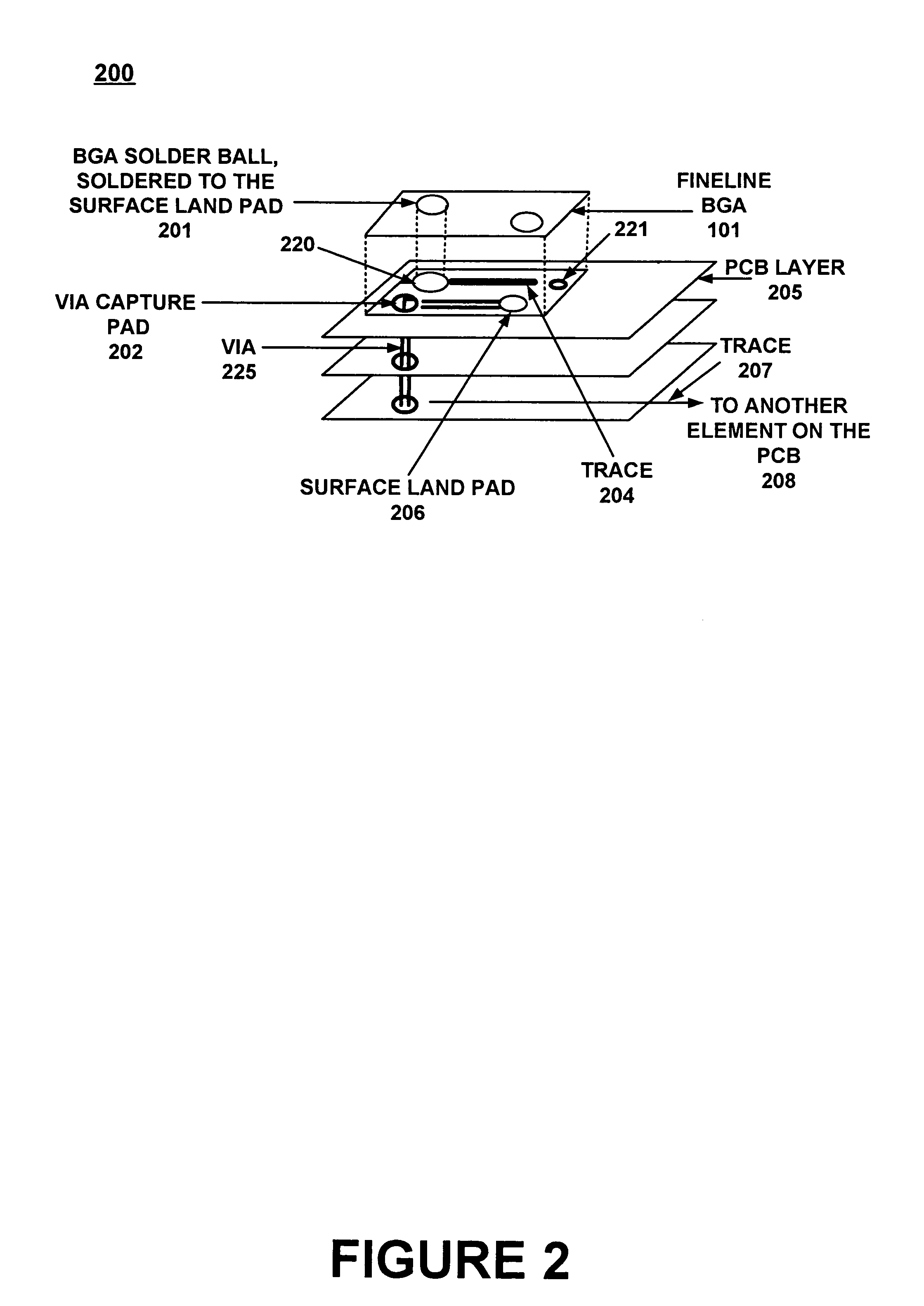

System for arraying surface mount grid array contact pads to optimize trace escape routing for a printed circuit board

ActiveUS7161812B1Circuit arrangements on support structuresPrinted circuit aspectsContact padIntegrated circuit

Owner:NVIDIA CORP

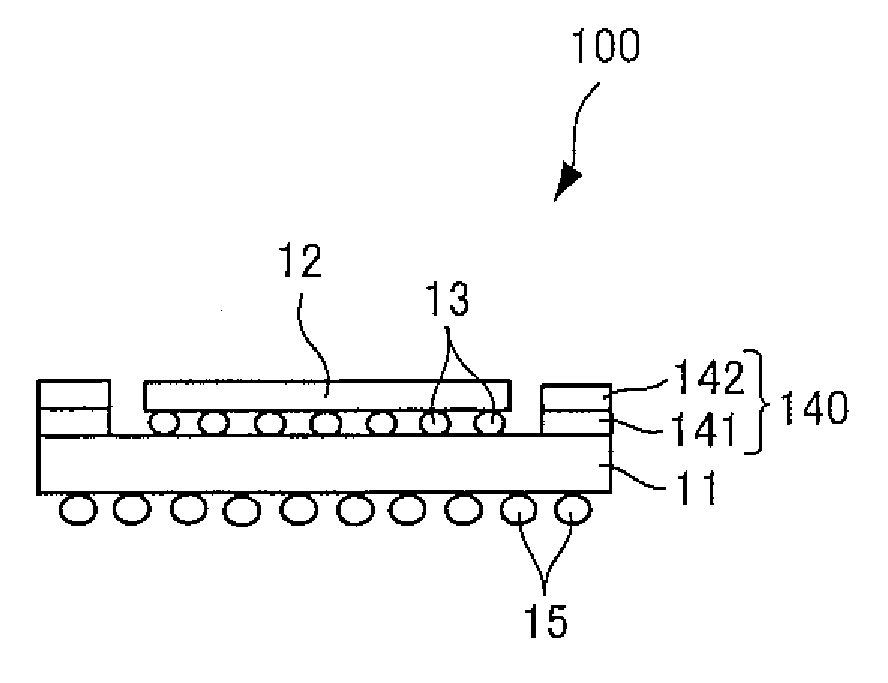

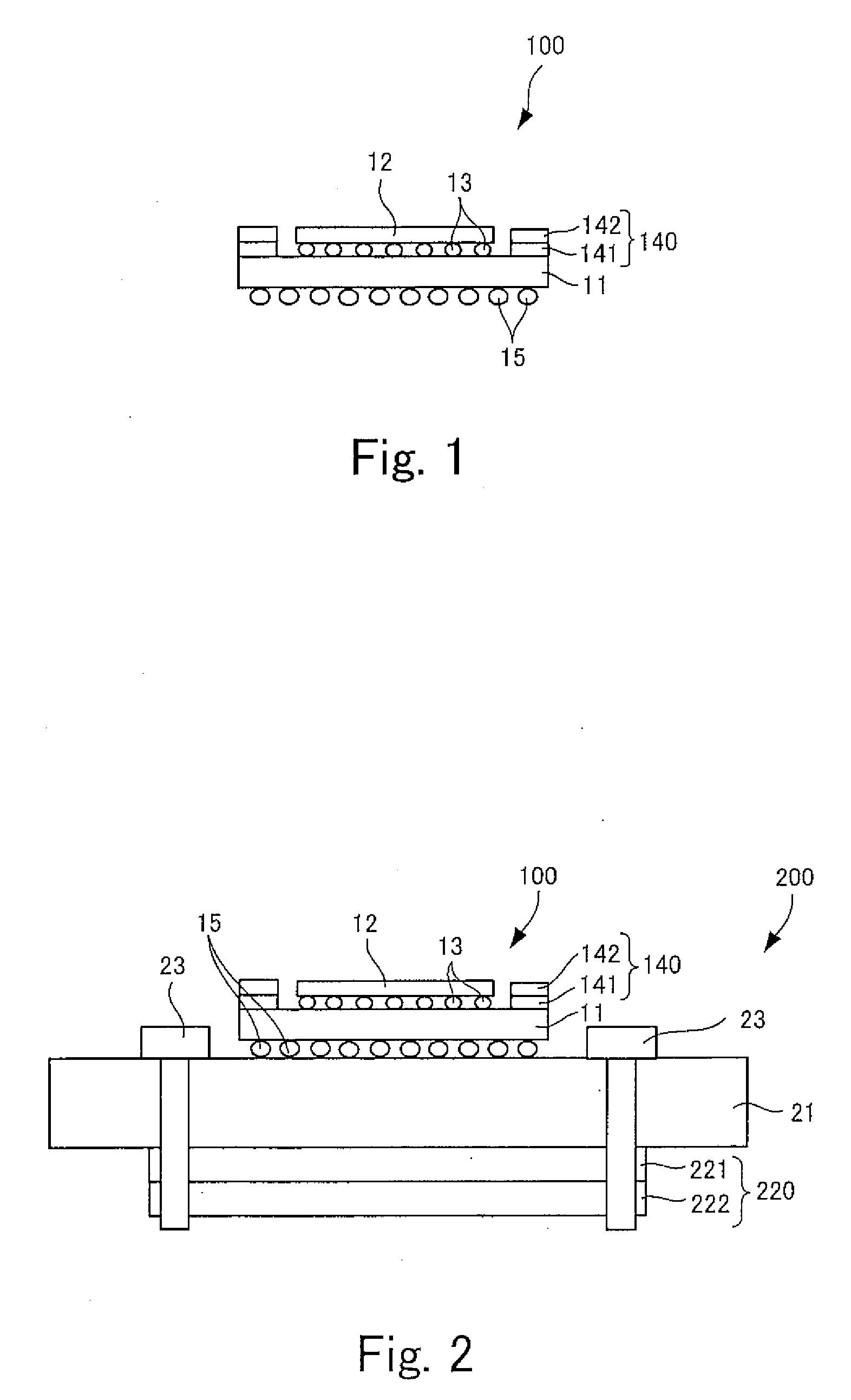

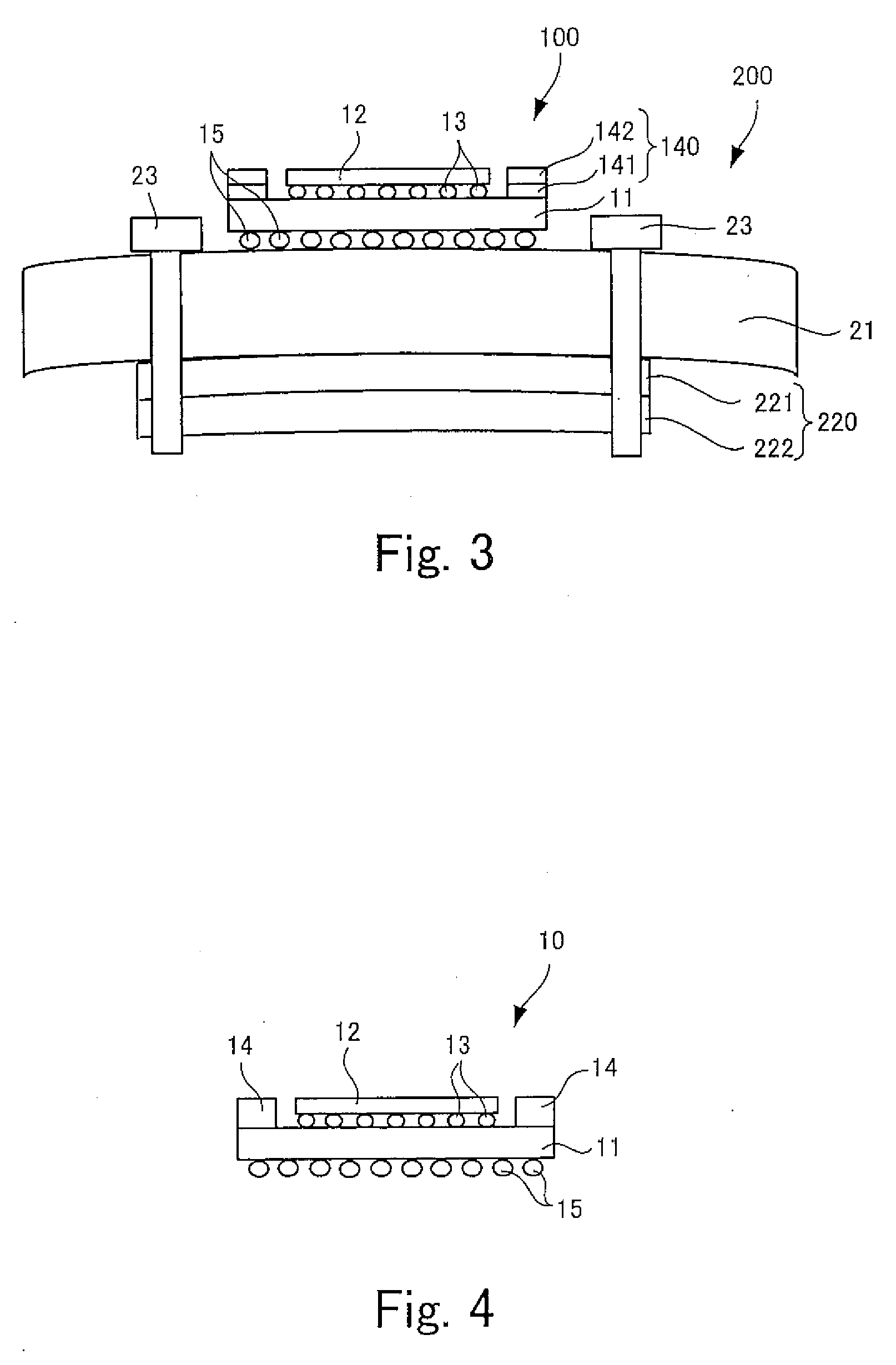

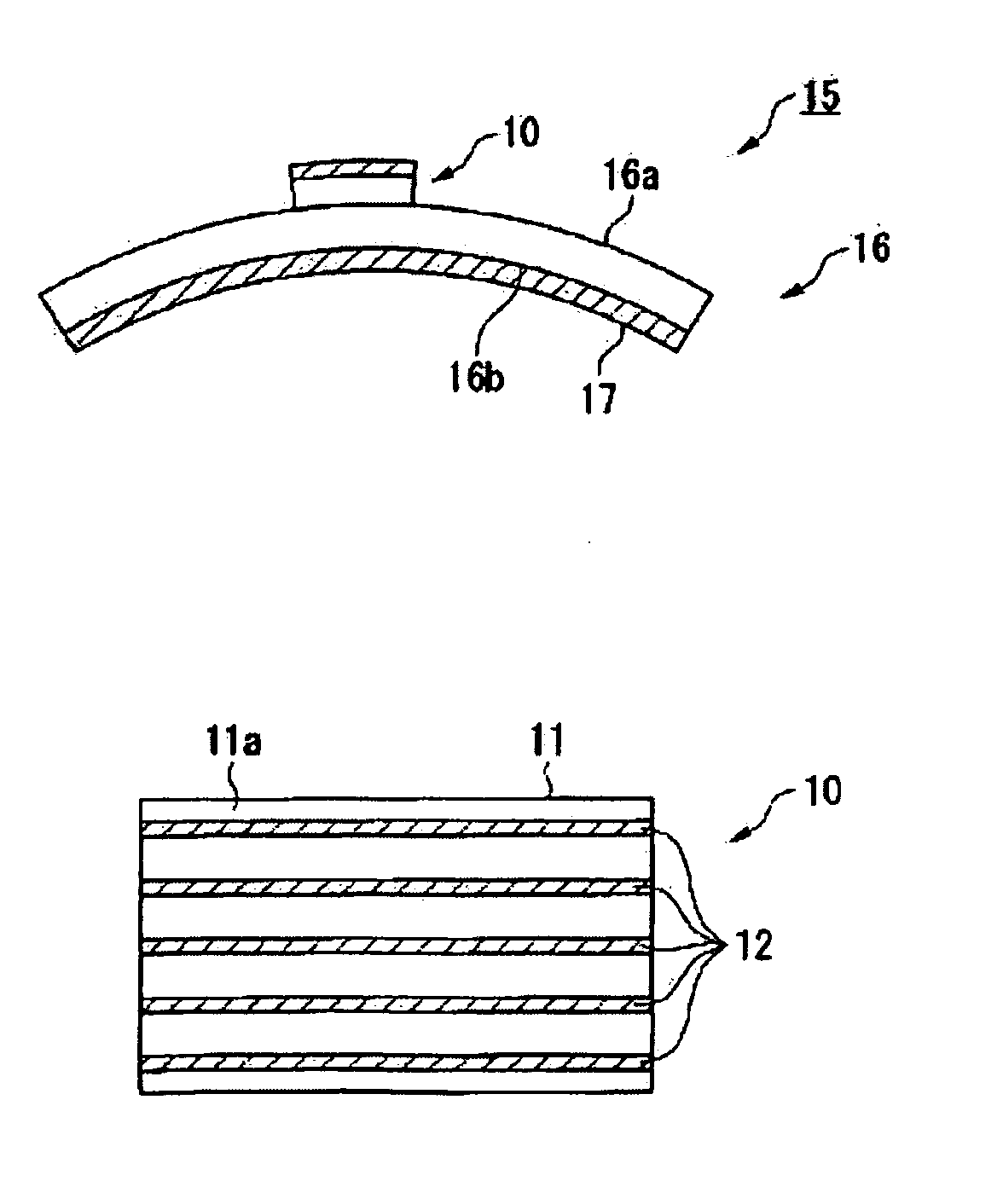

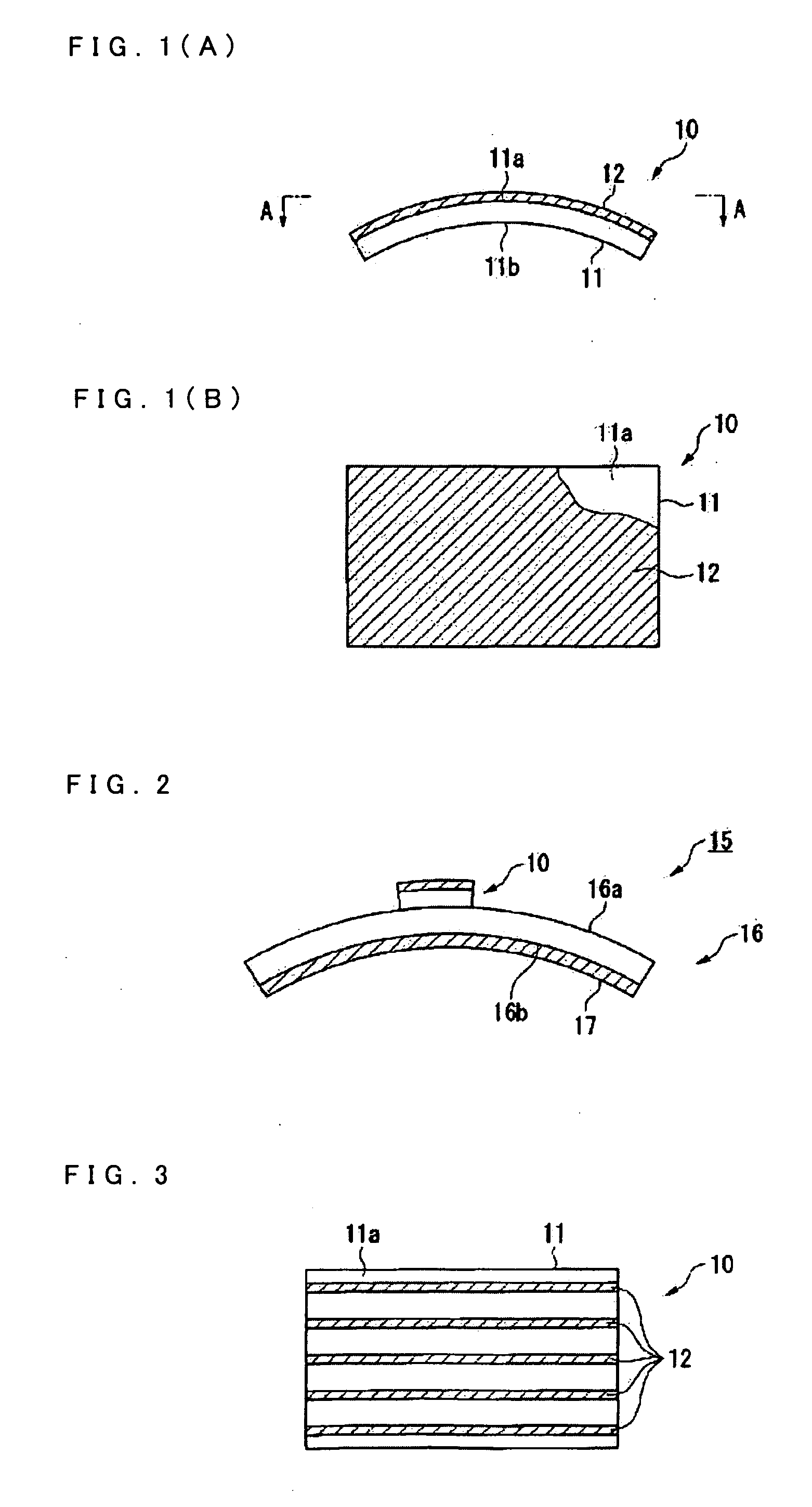

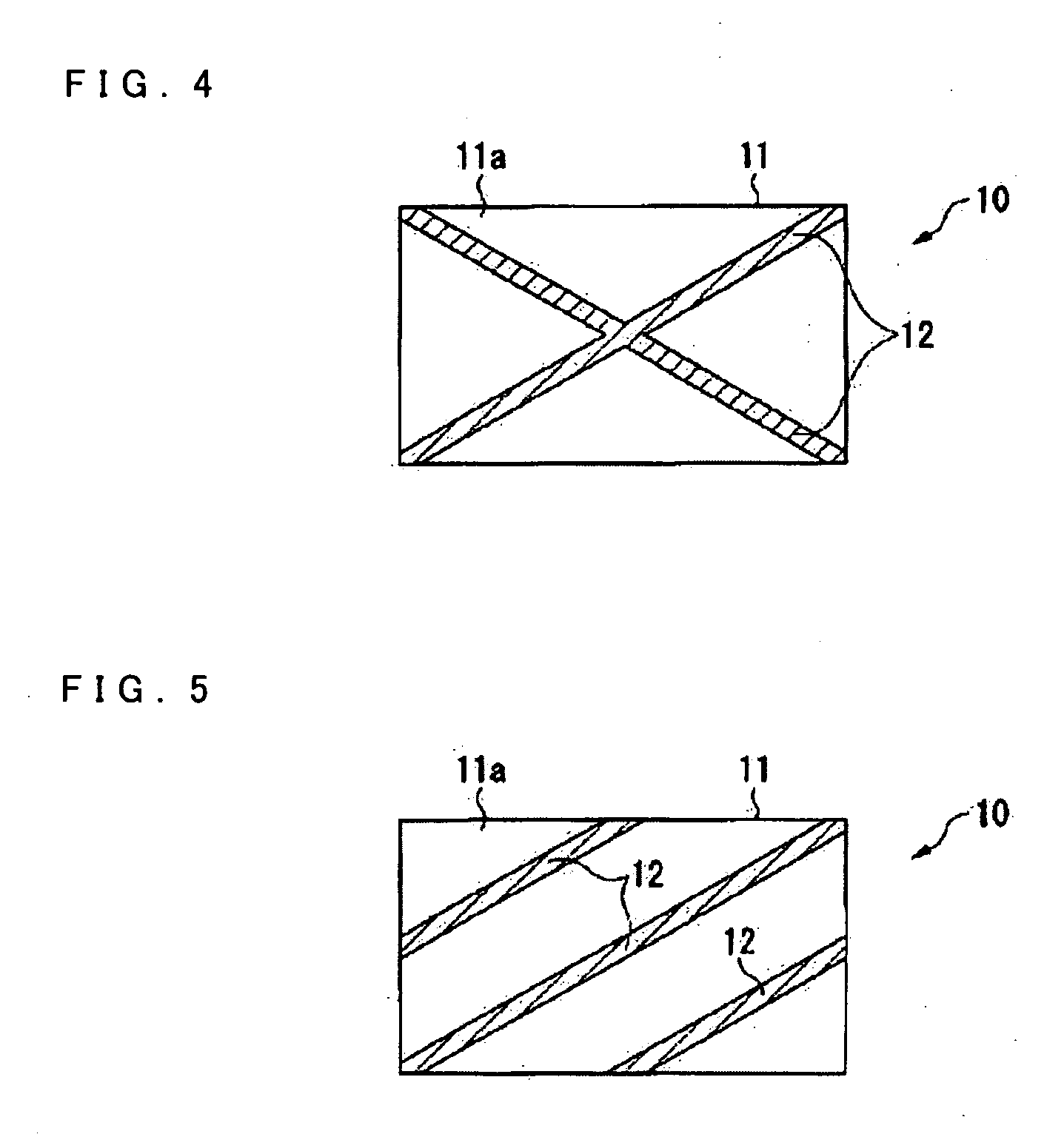

Package mounted module and package board module

InactiveUS20070278647A1Relieve stressMaintain reliabilitySemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipEngineering

Owner:FUJITSU LTD

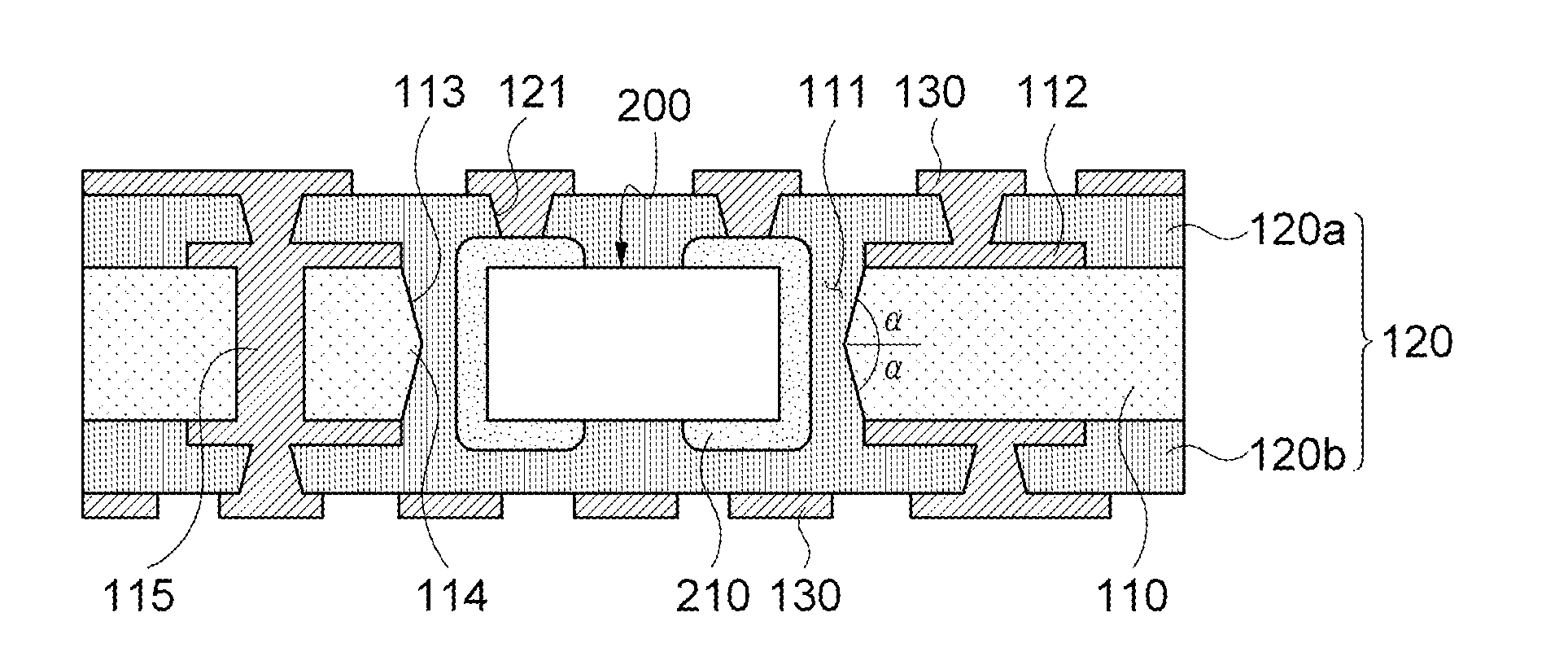

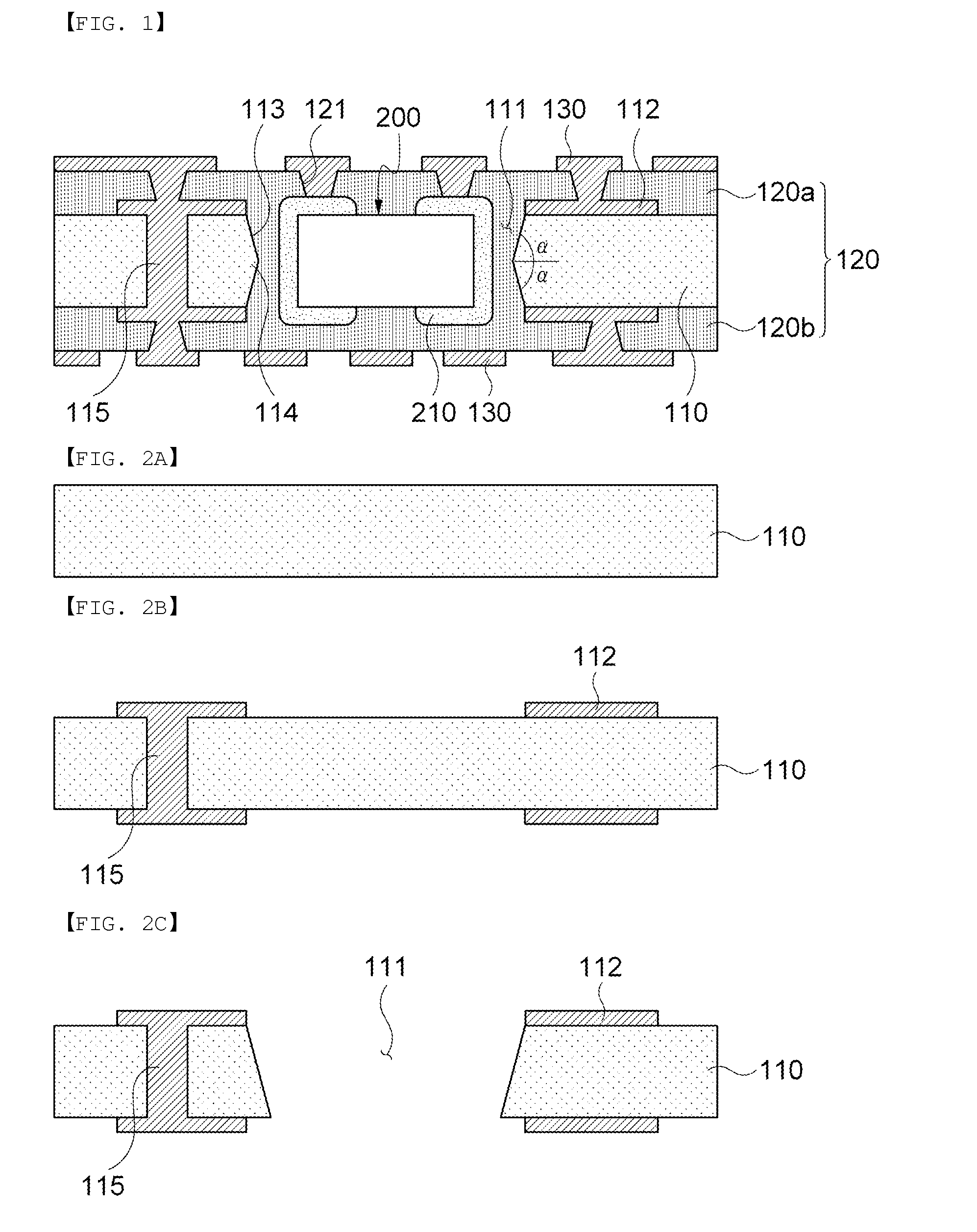

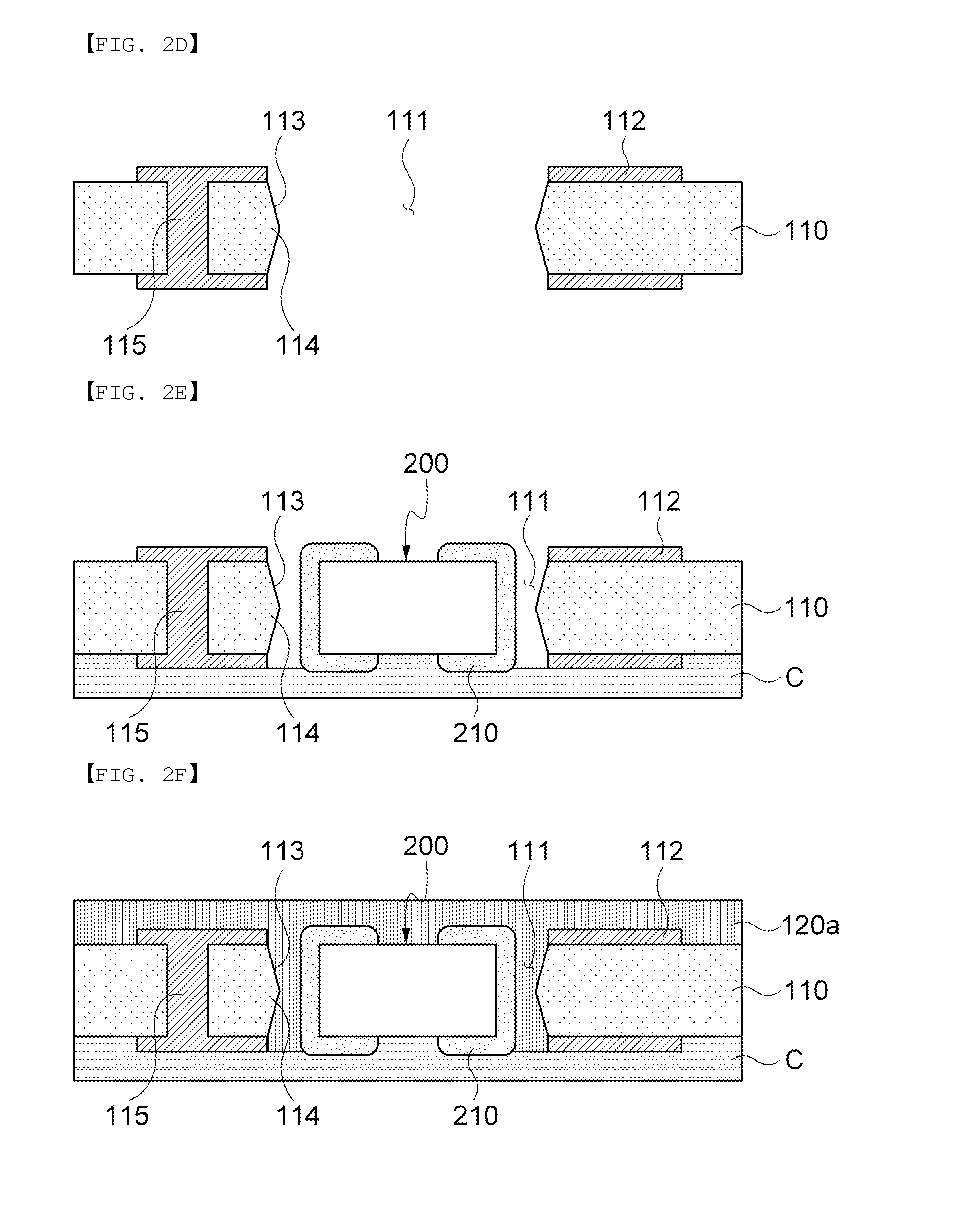

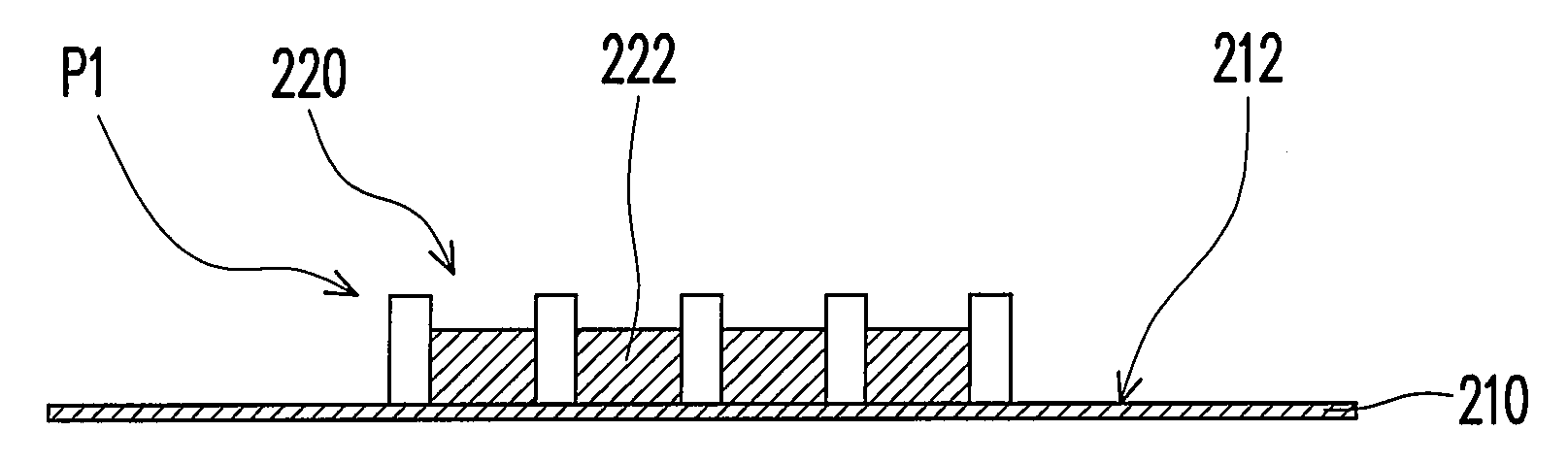

Semiconductor chip and circuit board, manufacturing method of same, and electronic equipment

InactiveUS20050253235A1Enhancing coupling reliabilityImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipEngineering

Owner:SEIKO EPSON CORP

Low viscosity precursor compositions and methods for the deposition of conductive electronic features

A precursor composition for the deposition and formation of an electrical feature such as a conductive feature. The precursor composition advantageously has a low viscosity enabling deposition using direct-write tools. The precursor composition also has a low conversion temperature, enabling the deposition and conversion to an electrical feature on low temperature substrates. A particularly preferred precursor composition includes silver metal for the formation of highly conductive silver features.

Owner:CABOT CORP

Display device and a televsion receiver having the same

InactiveUS20090231506A1Electric discharge tubesPrinted circuit aspectsDisplay deviceElectrical element

A display device is capable of efficiently cooling electronic or electrical components disposed therein without installing a cooling element or member on the electronic or electrical components. In the display device, a ceramic or ceramic-containing layer is formed on any one of a surface of a member placed in proximity to the electronic or electrical component, the surface facing at least the electronic or electrical component, a surface of the member placed in proximity to the electronic or electrical component, the surface opposite to the surface facing the electronic or electrical component, a surface of the electronic or electrical component, and a surface of a circuit board, the surface opposite to a surface of the circuit board on which the electronic or electrical component is mounted.

Owner:SHARP KK

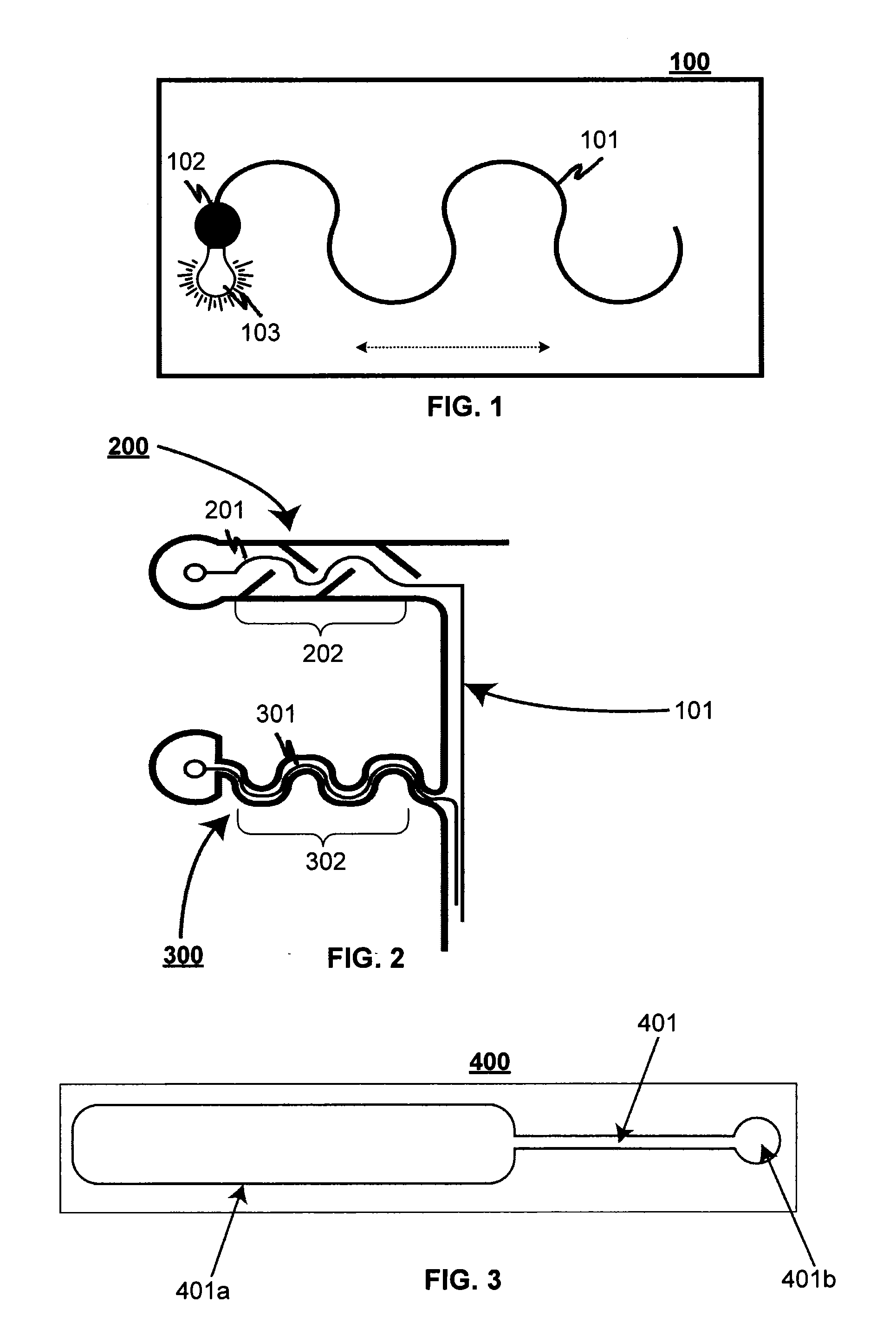

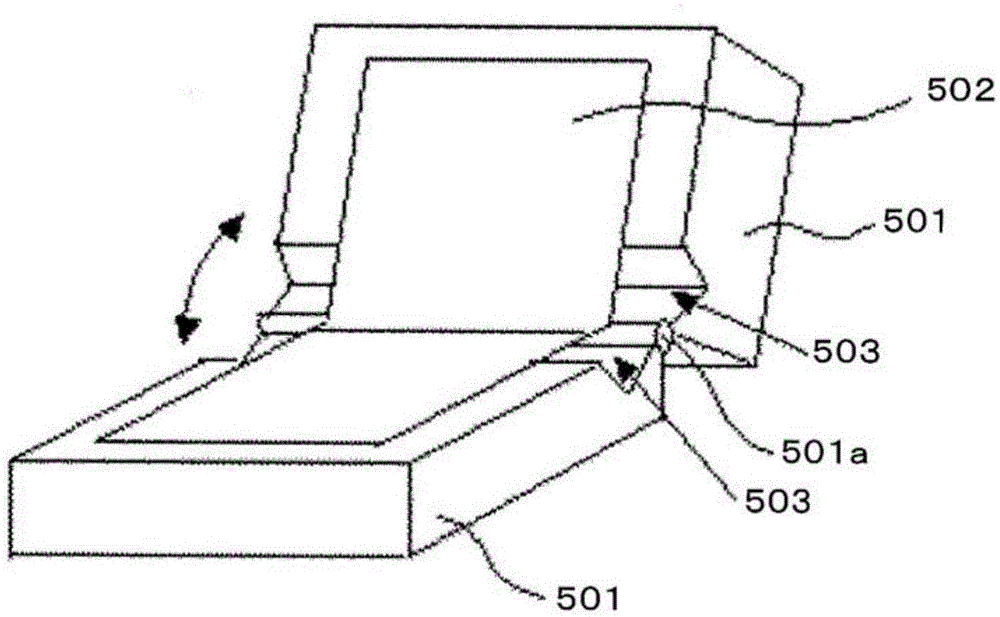

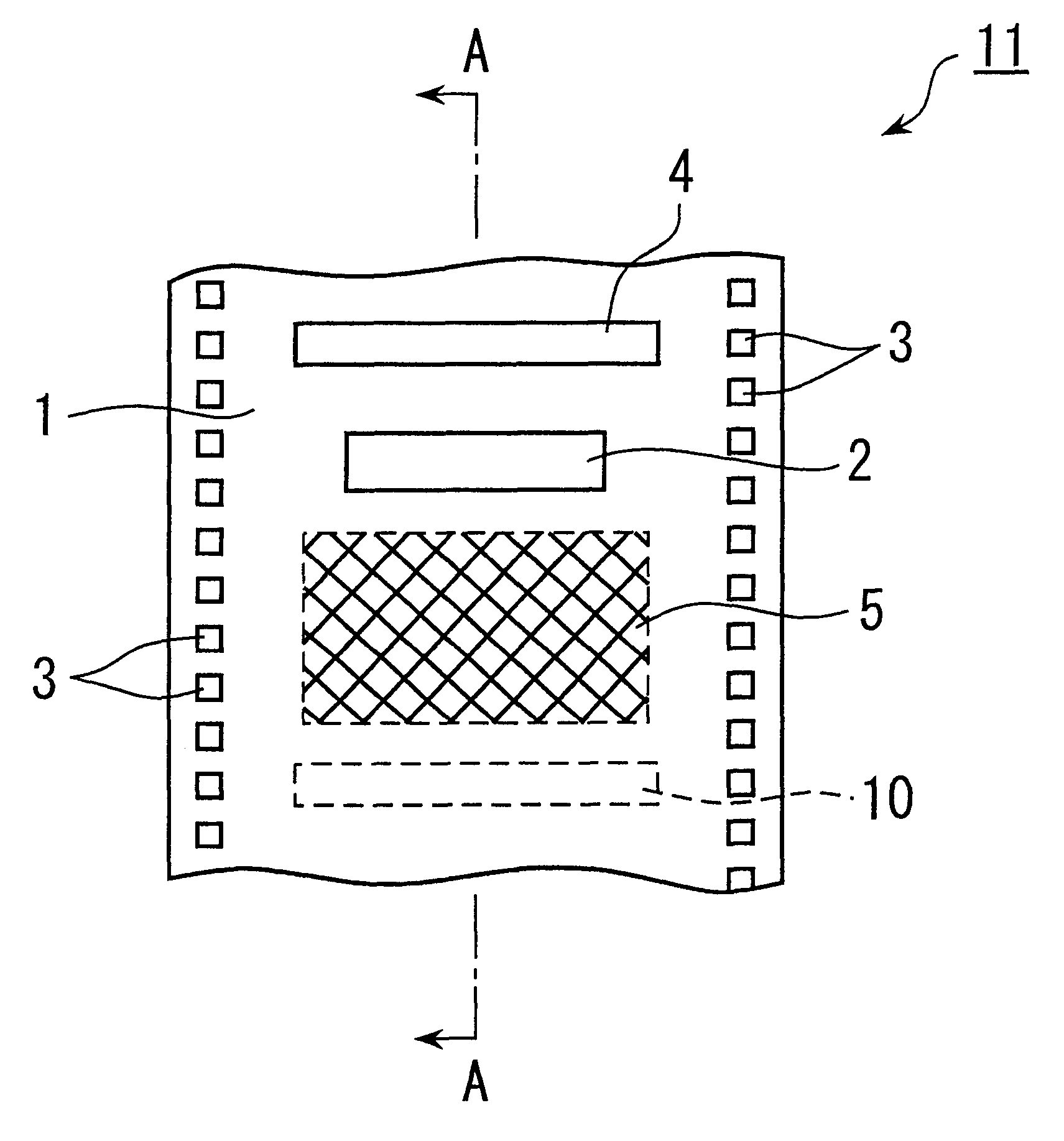

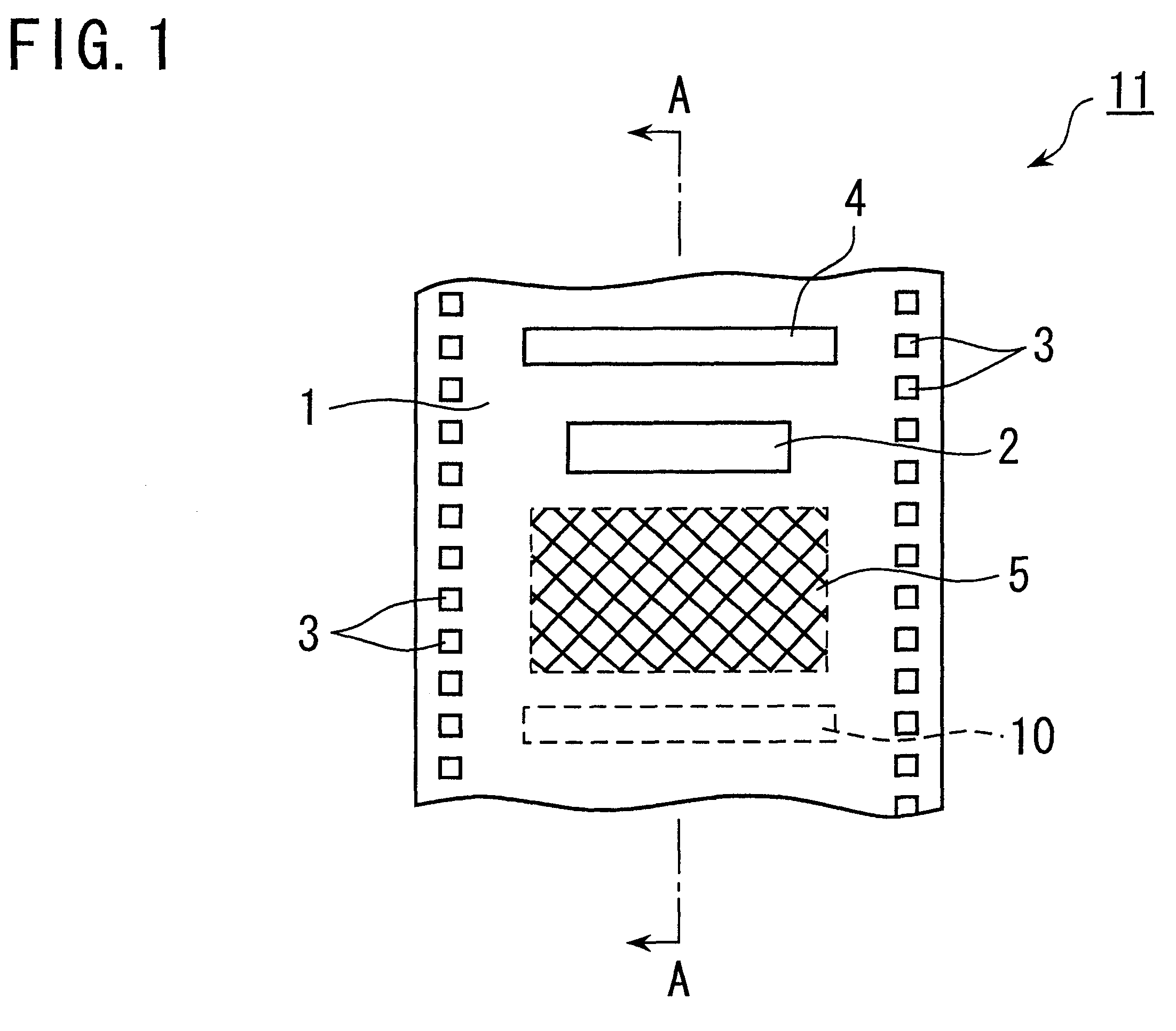

Tape carrier having high flexibility with high density wiring patterns

Owner:VISTA PEAK VENTURES LLC

Printed circuit board including electronic component embedded therein and method for manufacturing the same

ActiveUS20140321084A1Improve reliabilityHigh yieldPrinted circuit assemblingPrinted electric component incorporationEngineeringElectronic component

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

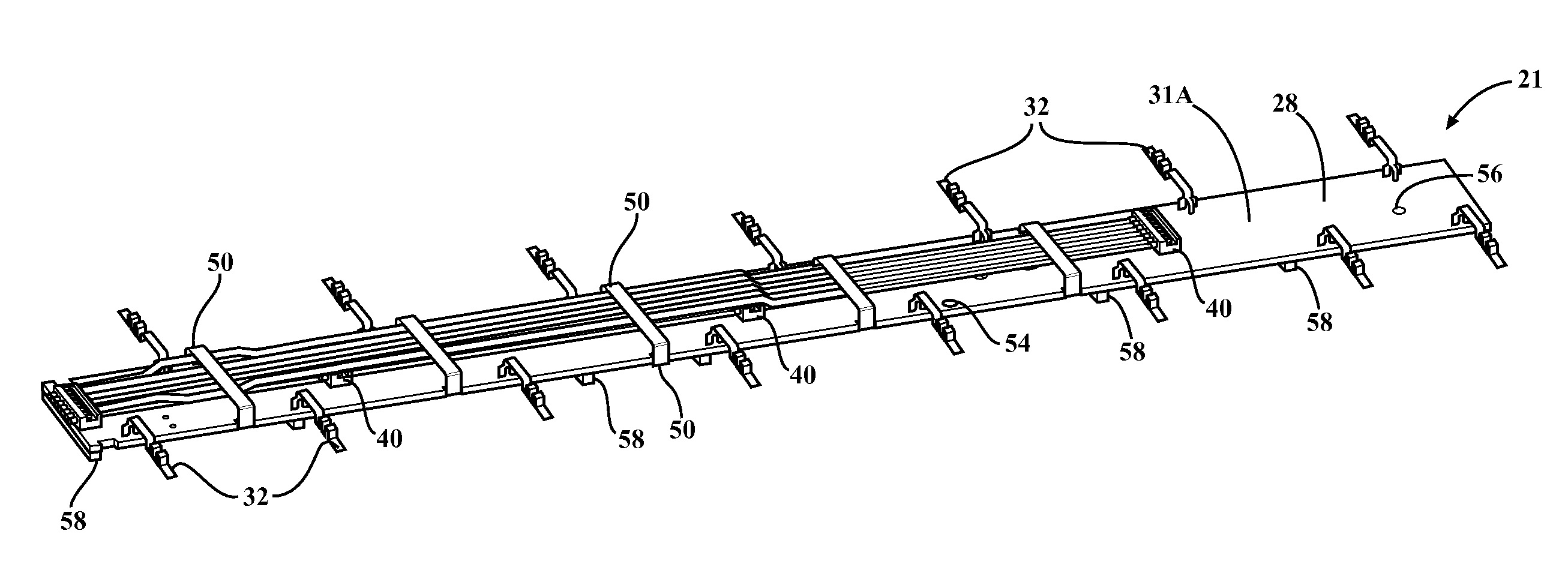

Crimped solder on a flexible circuit board

InactiveUS20100186997A1Electrically conductive connectionsPrinted circuit aspectsFlexible circuitsElectrical connection

Owner:SAMTEC

Electronic device

ActiveUS20140328036A1Printed circuit assemblingPrinted circuit aspectsDielectric substrateInterposer

Owner:TYCO ELECTRONICS LOGISTICS AG (CH)

Component assembly

ActiveUS20130242517A1Well formedDistanceSemiconductor/solid-state device detailsFinal product manufactureThermal deformationEngineering

Owner:MURATA MFG CO LTD

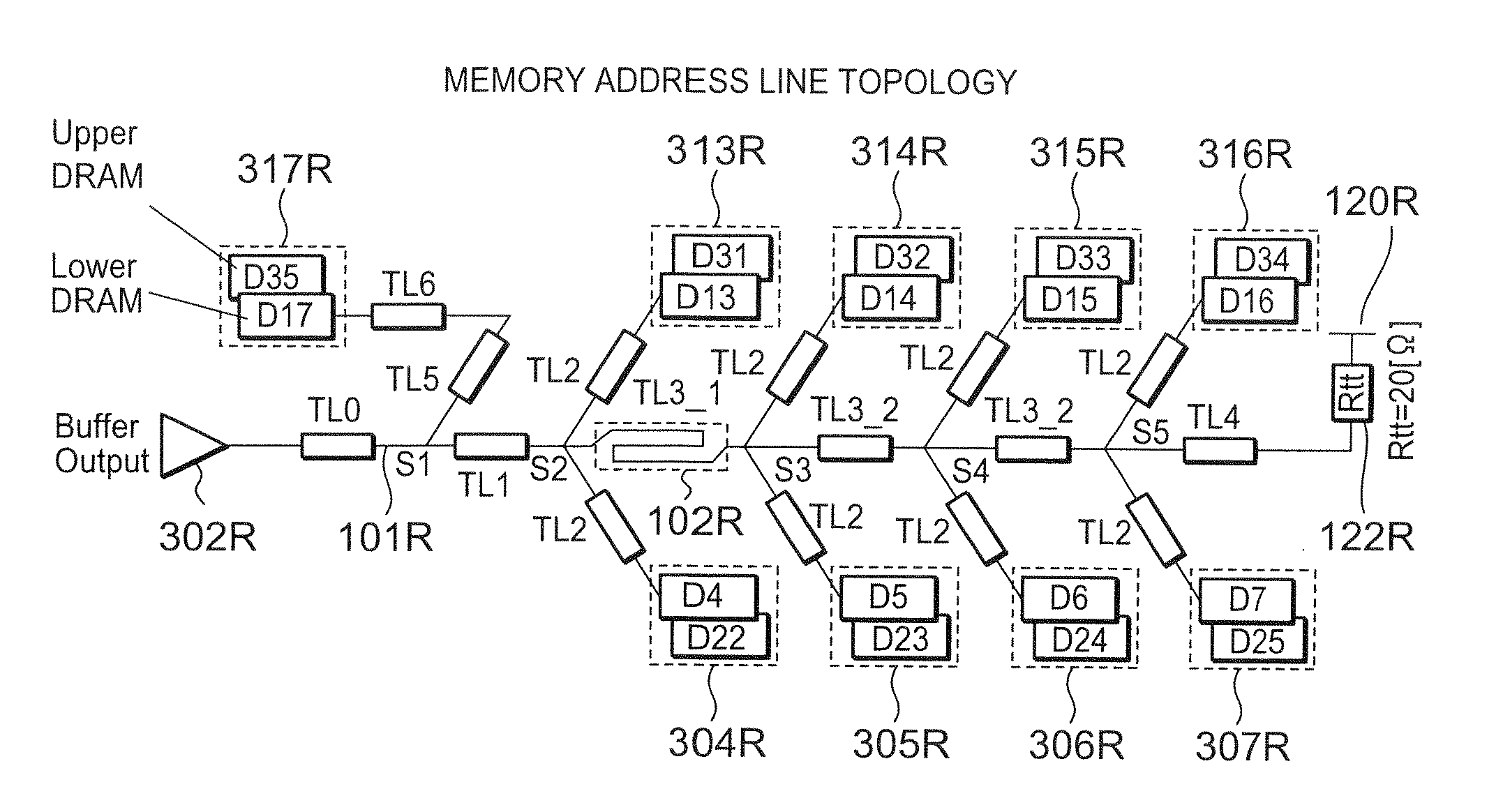

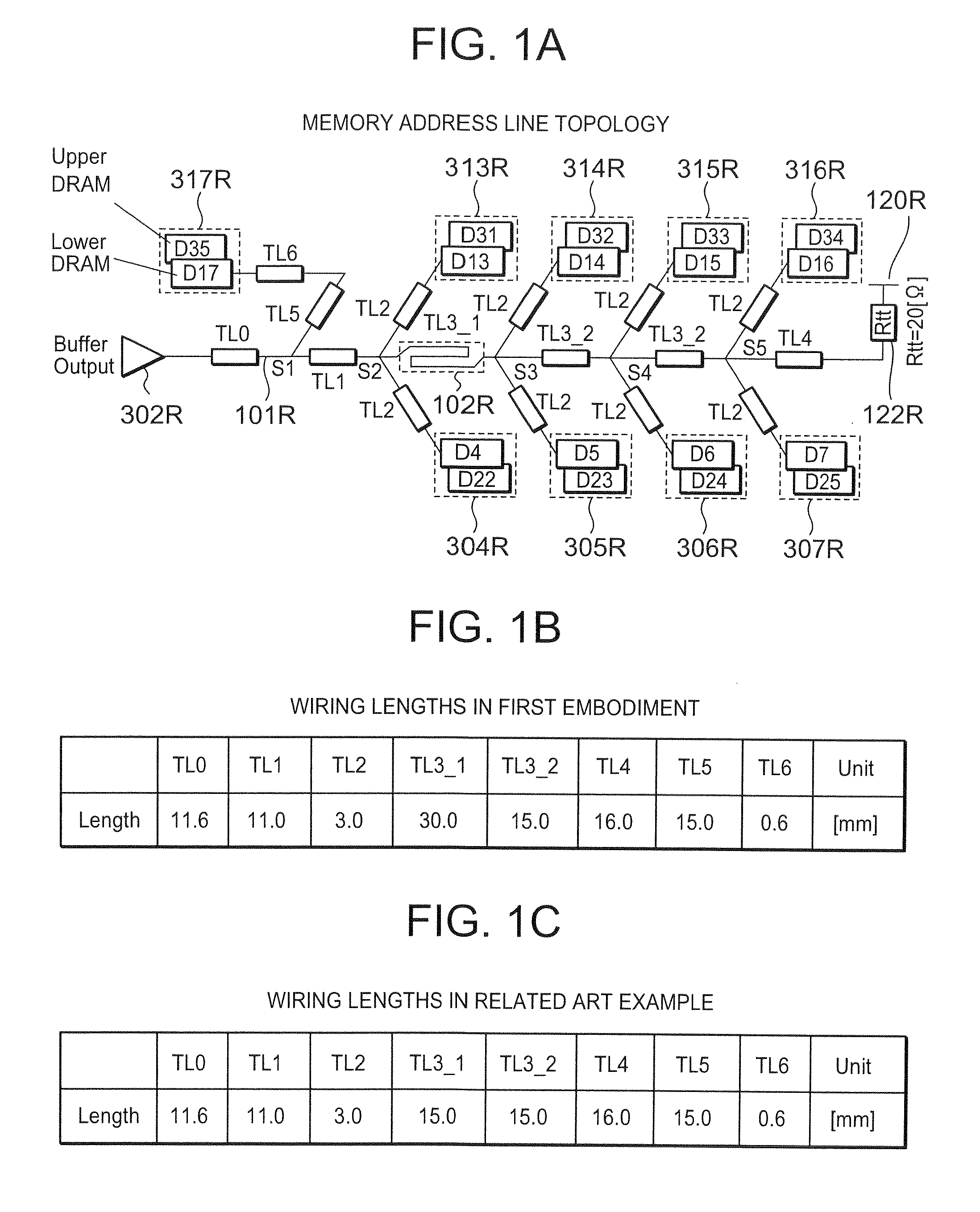

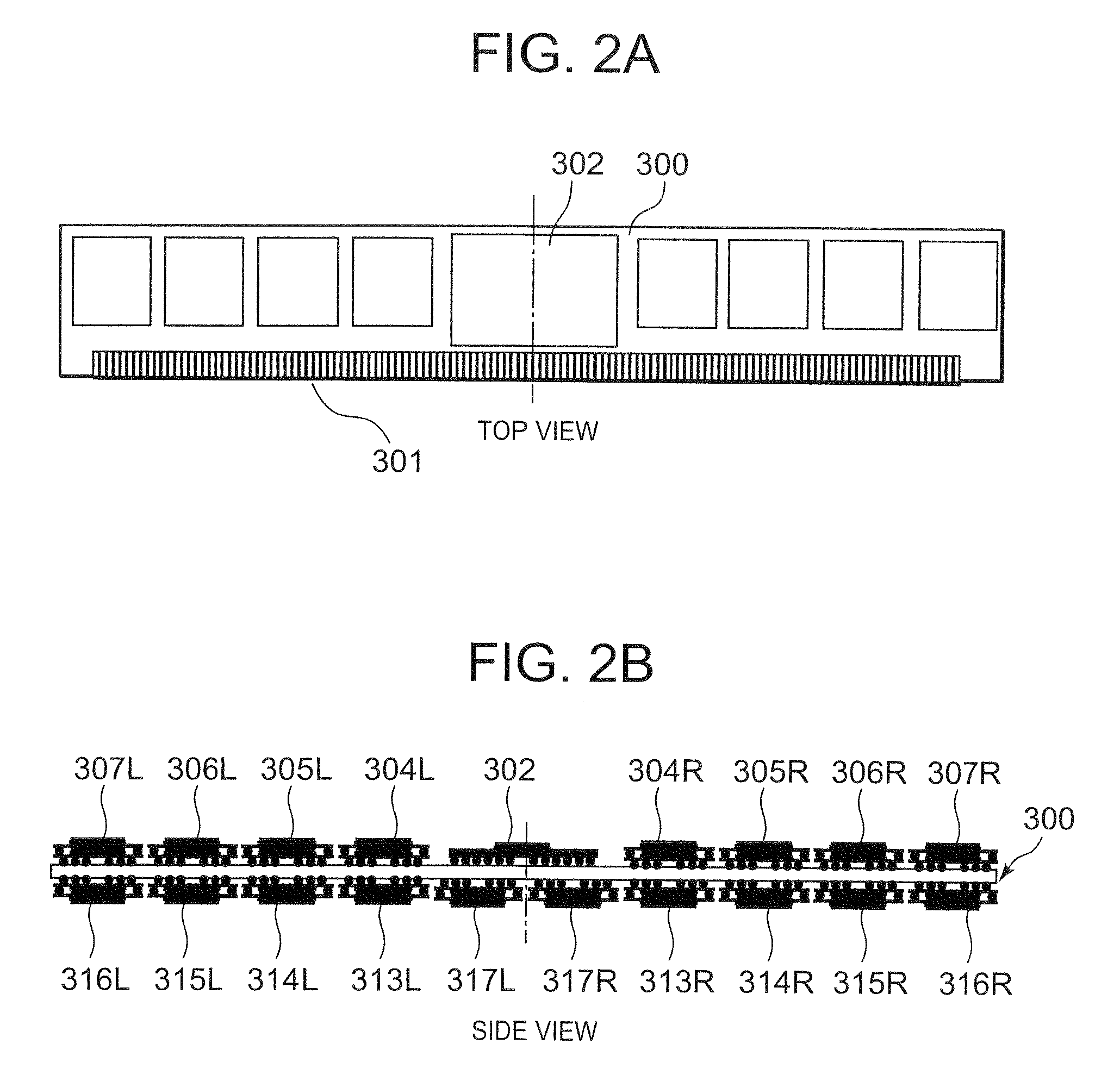

Address line wiring structure and printed wiring board having same

ActiveUS20090086522A1Avoid delayPrevent Waveform DistortionSemiconductor/solid-state device detailsFinal product manufactureShortest distanceEngineering

Owner:LONGITUDE LICENSING LTD

Acrylic flame retardant adhesive composition and acrylic flame retardant adhesive sheet

Owner:SHIN ETSU CHEM IND CO LTD

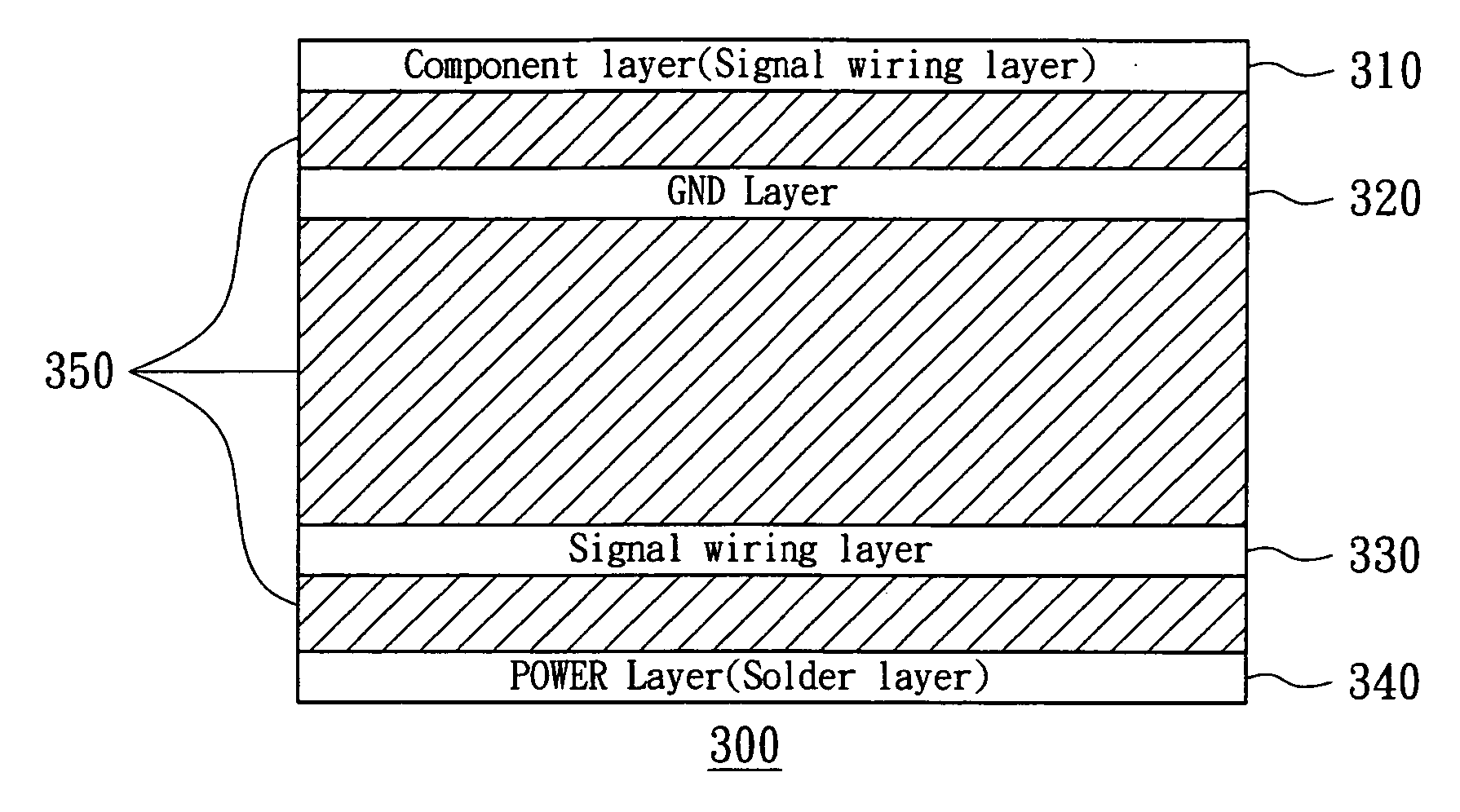

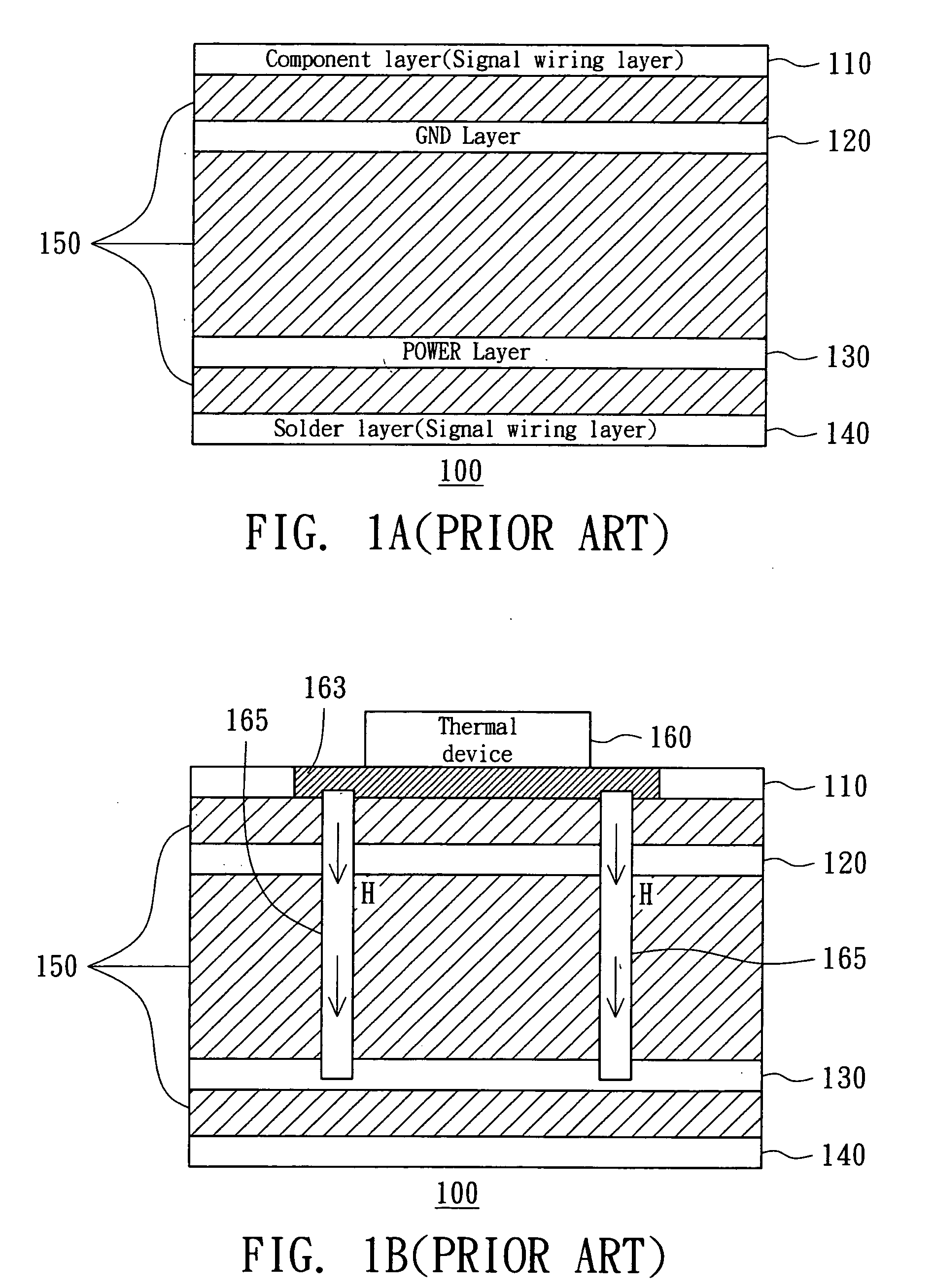

Printed circuit board and method for manufacturing thereof

InactiveUS20080121414A1Improve thermal conductivityPrinted circuit aspectsConductive pattern formationInter layerEngineering

A printed circuit board and a method of manufacturing thereof are disclosed. With a printed circuit board comprising an insulating layer; a circuit pattern formed on one side of the insulating layer; an inter-layer conductive part joining with the insulating layer by passing through the insulating layer, and electrically connected to the circuit pattern; a heat dissipating layer laminated on the other side of the insulating layer; and a heat dissipating coating layer interposed between the insulating layer and the heat dissipating layer, and connected with the inter-layer conductive part, the heat contained in the insulating layer may be delivered to the heat dissipating layer effectively and the efficiency of heat dissipation may be improved.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

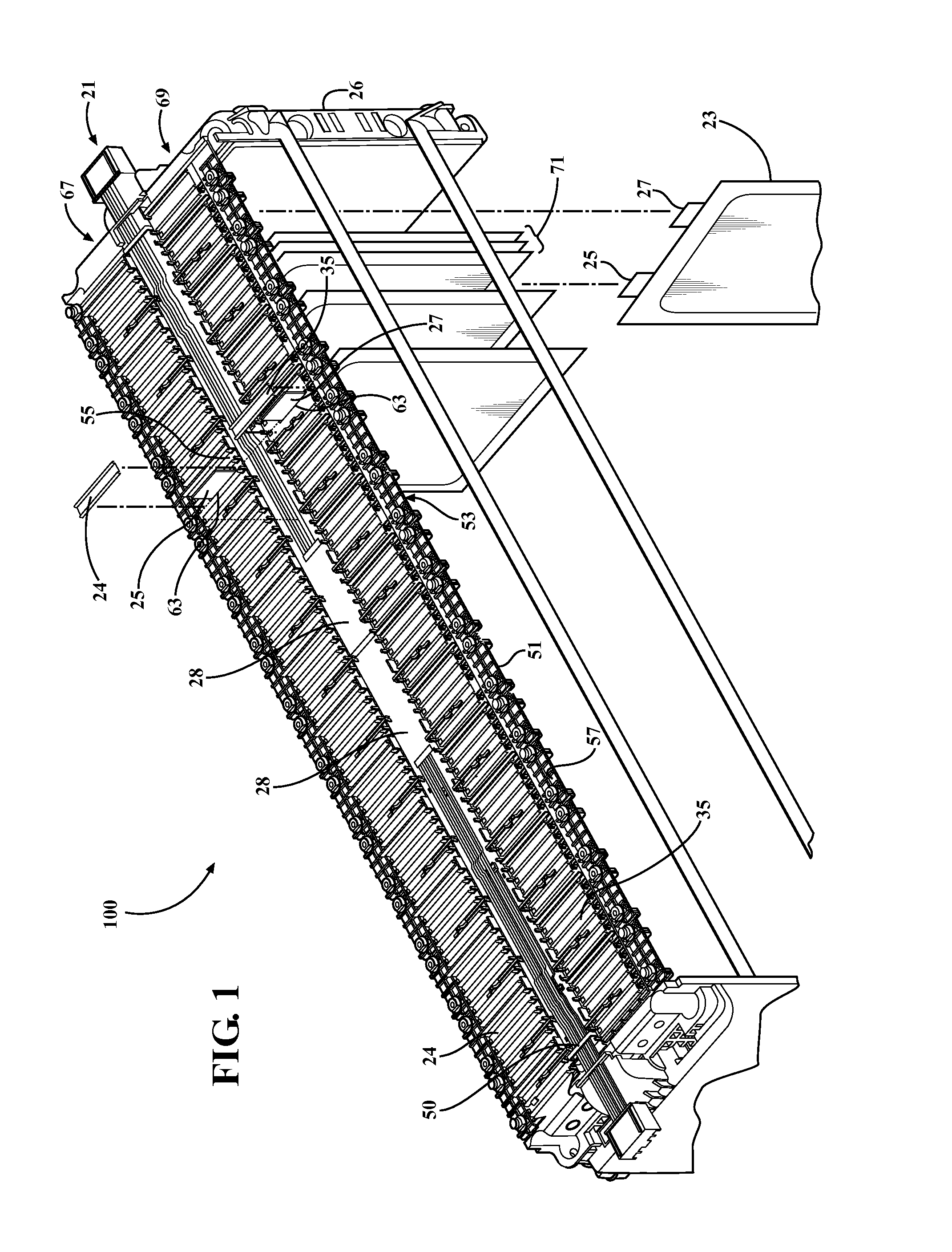

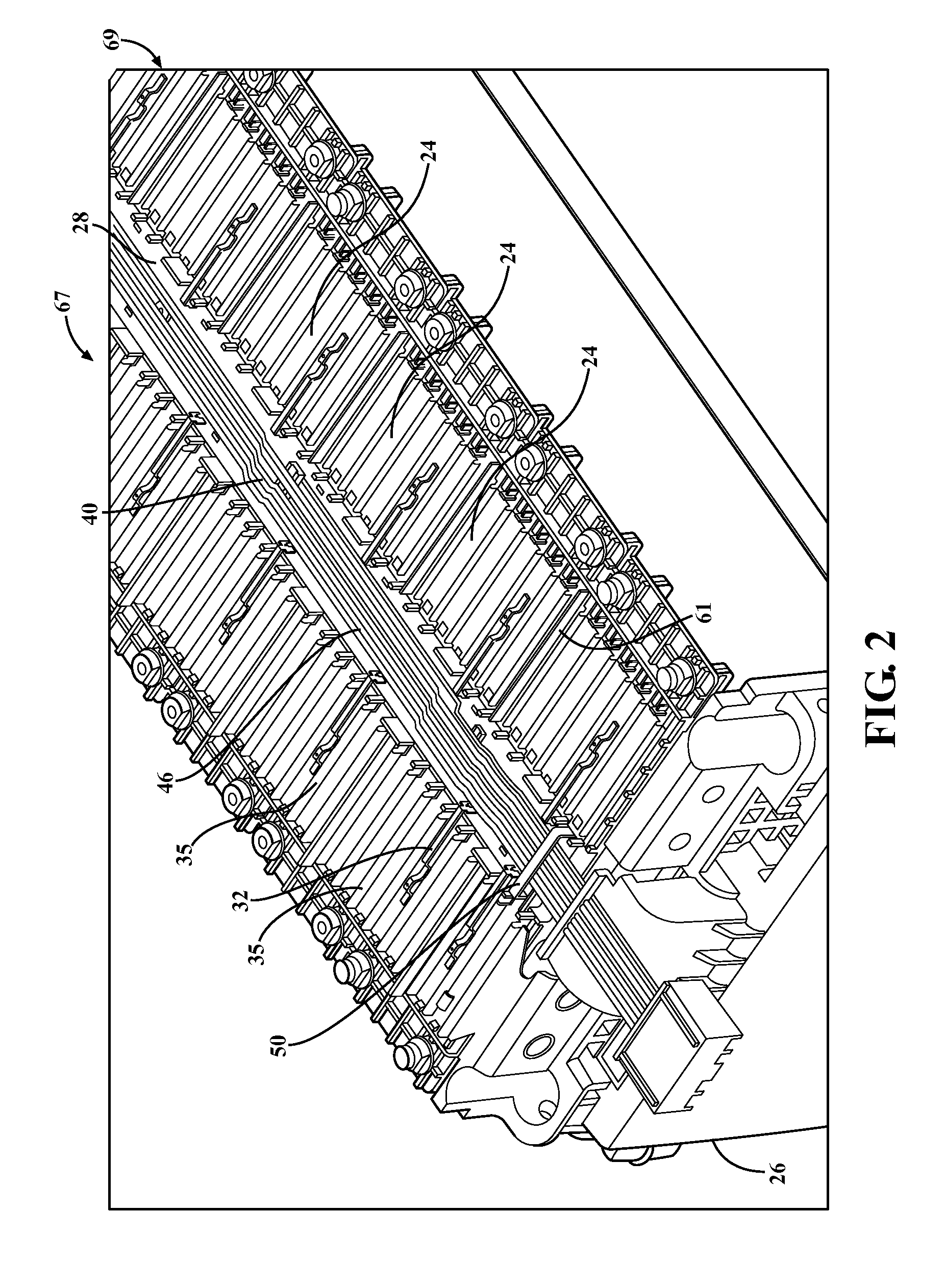

Battery monitoring system

InactiveUS20140003016A1Simple and inexpensive to manufactureEasy to installElectrically conductive connectionsBatteries circuit arrangementsElectricityElectrical battery

Owner:AEES INC

Circuit board with embedded passive component and fabricating process thereof

ActiveUS20070171621A1Improve reliabilityReduce varianceCapacitor with electrode area variationPrinted circuit aspectsEngineeringElectrical and Electronics engineering

Owner:UNIMICRON TECH CORP

PCB

InactiveCN107734839AImprove cooling effectHigh working reliabilityPrinted circuit aspectsCircuit thermal arrangementsEngineeringMetal

The invention relates to the technical field of PCB structures, discloses a PCB. The PCB includes a substrate, a metal block, and a heat dissipating hole; the substrate has a stepped groove; the metalblock is arranged in the stepped groove and same as the stepped groove in shape, and a heat conduction medium is arranged between the top surface of the metal block and a component; the heat dissipating hole is formed in the substrate, and the heat dissipating hole and the metal block can be used for heat conduction. By forming a groove in the PCB, embedding the metal block making direct contactwith the component and forming the heat dissipating hole which can be used for heat conduction with the metal block, heat generated by the component and heat in a metal layer in the PCB can be timelyand rapidly dissipated, the heat dissipation performance of the PCB is improved, and the service life of the PCB and the component is prolonged.

Owner:DONGGUAN SHENGYI ELECTRONICS

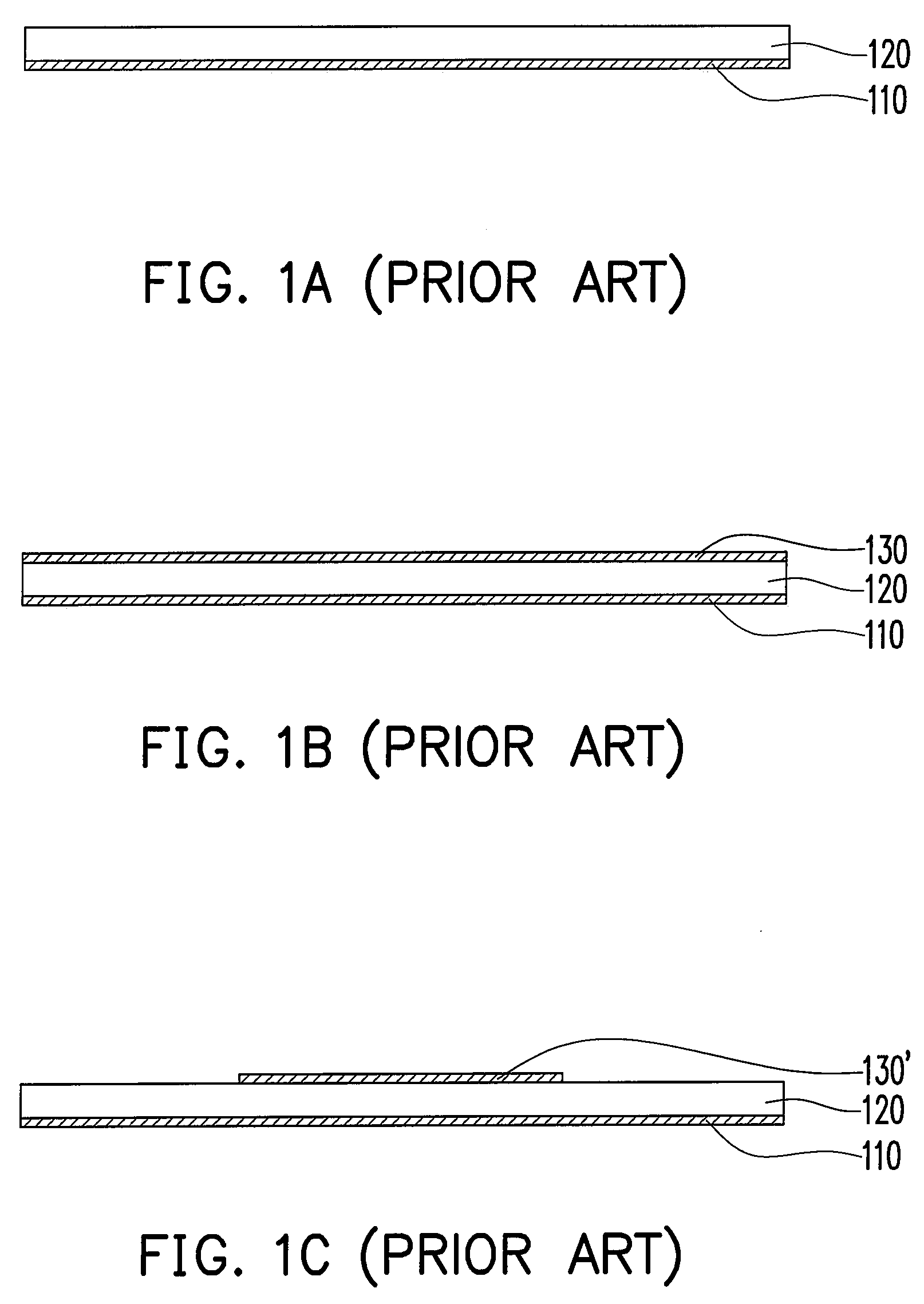

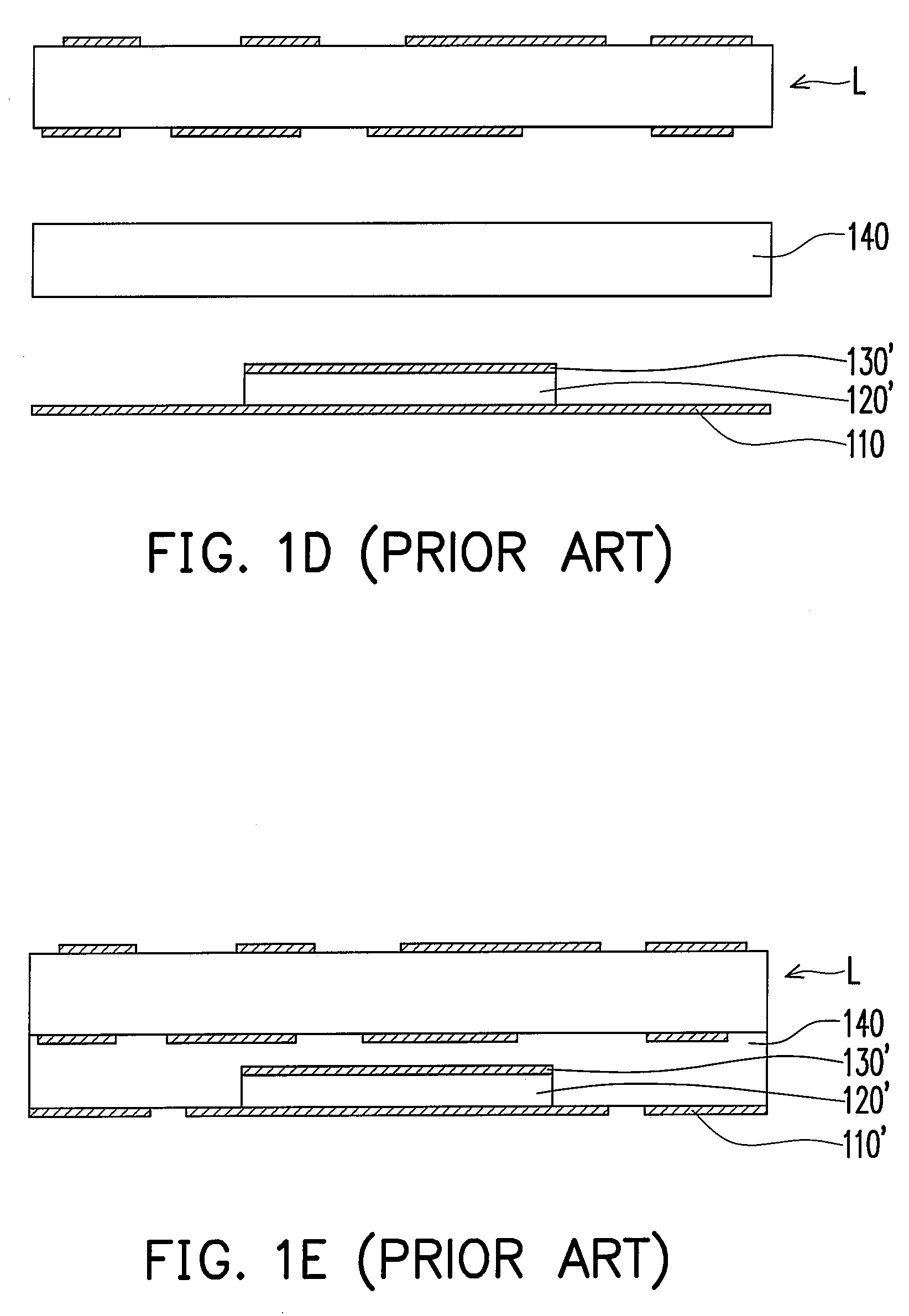

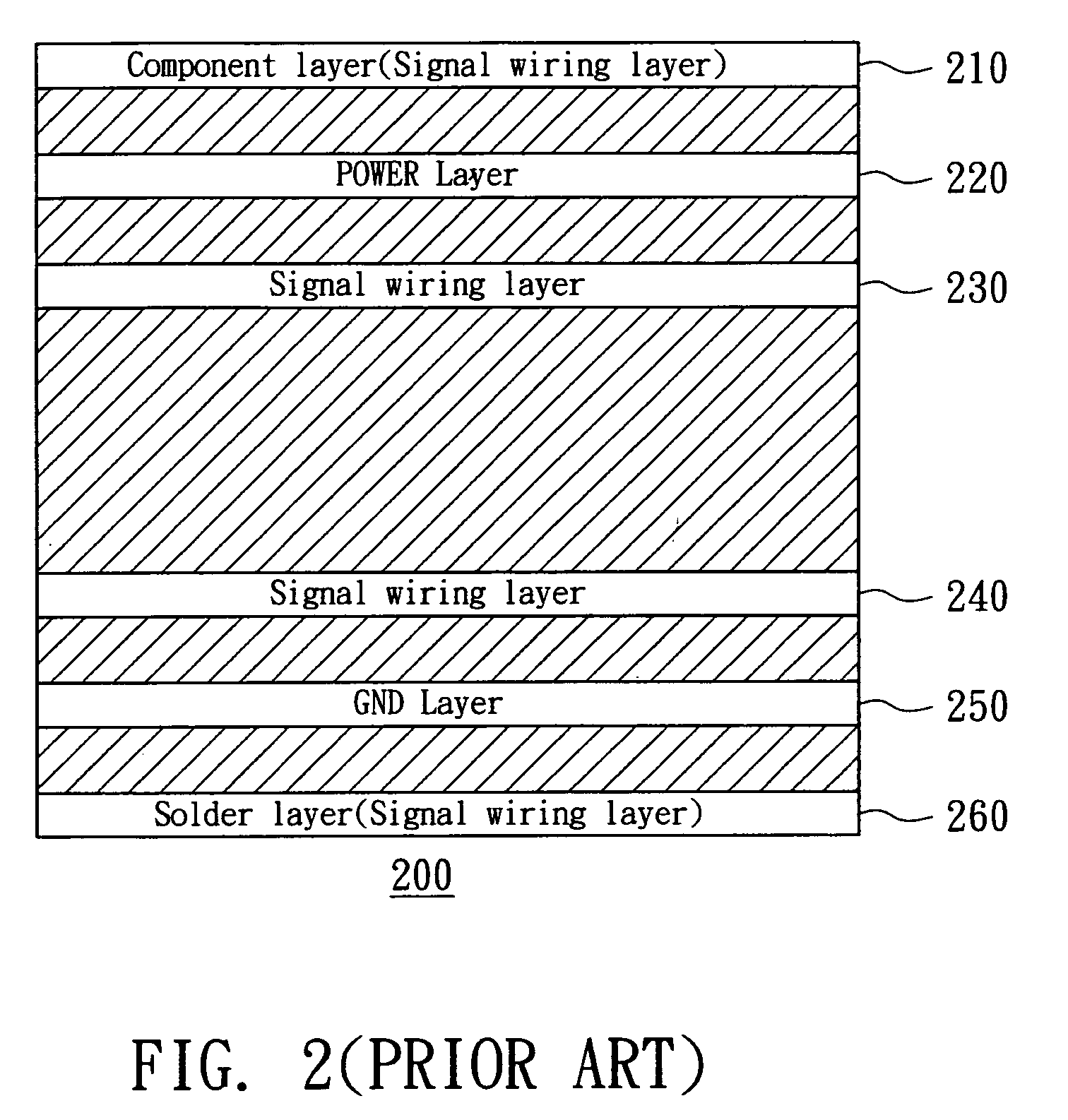

Printed circuit board structure

InactiveUS20060231289A1Increase manufacturing costHeat dissipationPrinted circuit aspectsElectrical connection printed elementsPrinted circuit boardBoard structure

Owner:ASUSTEK COMPUTER INC

Rigid-flexible combined plate and method for plugging blind buried hole thereof

ActiveCN105657970AAchieve paddingSimplified plugging processPrinted circuit aspectsPrinted circuit manufactureEngineering

The invention discloses a rigid-flexible combined plate and a method for plugging a blind buried hole thereof. The rigid-flexible combined plate comprises a rigid sub-plate and a rigid-flexible sub-plate, wherein the rigid sub-plate is fixedly arranged on the rigid-flexible sub-plate; the blind buried hole is formed on the rigid sub-plate and / or the rigid-flexible sub-plate; at least one non-flowing type prepreg is arranged between the rigid sub-plate and the rigid-flexible sub-plate; the blind buried hole is filled with the flowing glue of the non-flowing type prepreg. The method for plugging the blind buried hole of the rigid-flexible combined plate comprises the following steps: supplying the rigid sub-plate and the rigid-flexible sub-plate; forming the blind buried hole on the rigid sub-plate and / or the rigid-flexible sub-plate; performing metallizing treatment on the blind buried hole; stacking at least one non-flowing type prepreg between the rigid sub-plate and the rigid-flexible sub-plate; pressing the rigid sub-plate and the rigid-flexible sub-plate and pressing the flowing glue of the non-flowing type prepreg into the blind buried hole. According to the rigid-flexible combined plate and the method for plugging the blind buried hole thereof, the processing is convenient, the smoothness of the plate is excellent, the special device is saved and the production cost is lowered.

Owner:GUANGZHOU FASTPRINT CIRCUIT TECH +2

Low viscosity precursor compositions and methods for the deposition of conductive electronic features

A precursor composition for the deposition and formation of an electrical feature such as a conductive feature. The precursor composition advantageously has a low viscosity enabling deposition using direct-write tools. The precursor composition also has a low conversion temperature, enabling the deposition and conversion to an electrical feature on low temperature substrates. A particularly preferred precursor composition includes silver metal for the formation of highly conductive silver features.

Owner:CABOT CORP

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap