Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

19 results about "Composite film" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A composite film is a feature film whose screenplay is composed of two or more distinct stories. More generally, composite structure refers to an aesthetic principle in which the narrative structure relies on contiguity and linking rather than linearity.

Electronics module having high density interconnect structures incorporating an improved dielectric lamination adhesive

InactiveUS6294741B1Improve electrical performanceAdequate processing propertyInsulating substrate metal adhesion improvementPrinted electric component incorporationComposite filmHigh density

A multi-chip electronics module is provided which utilizes benzocyclobutene as a laminate adhesive for bonding the upper dielectric films in a high density interconnect structure. The benzocyclobutene thermosetting polymer is spin coated on a polyimide film, and baked at low temperature to remove any solvent to leave a B-staged coating on the polyimide film. The composite film can be laminated to an underlying electrical structure using a vacuum laminator and heat. As the heat is applied, the BCB layer softens, flows and then cures to bond the polyimide film to the underlying electrical structure.

Owner:LOCKHEED MARTIN CORP

High strength organic / inorganic nano composite transparent film layer materials and method for preparing same

InactiveCN1699488AHigh refractive indexHigh transparencyCoatingsOptical elementsComposite filmRefractive index

Owner:JILIN UNIV

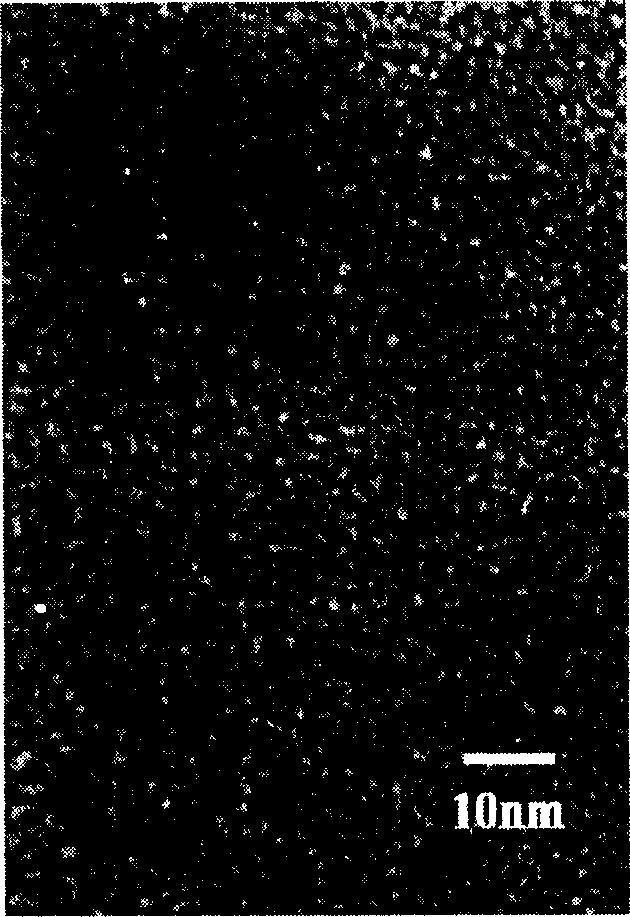

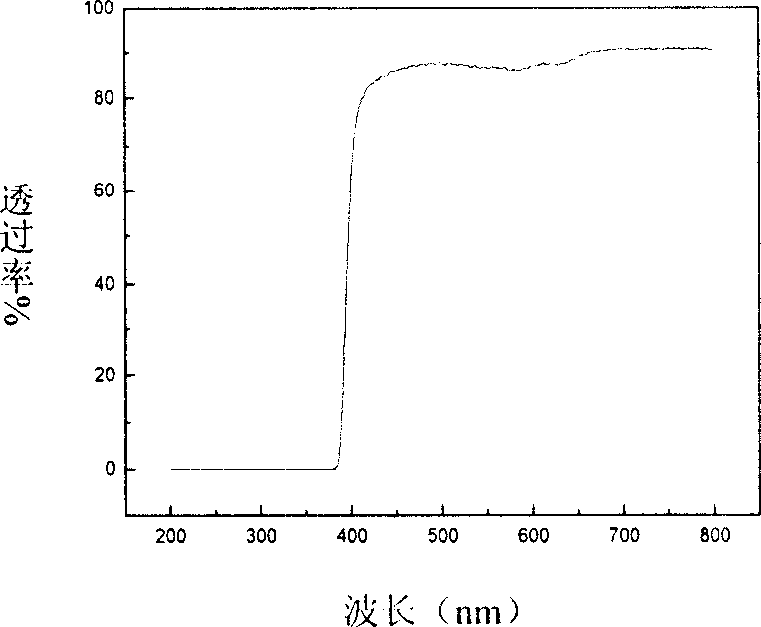

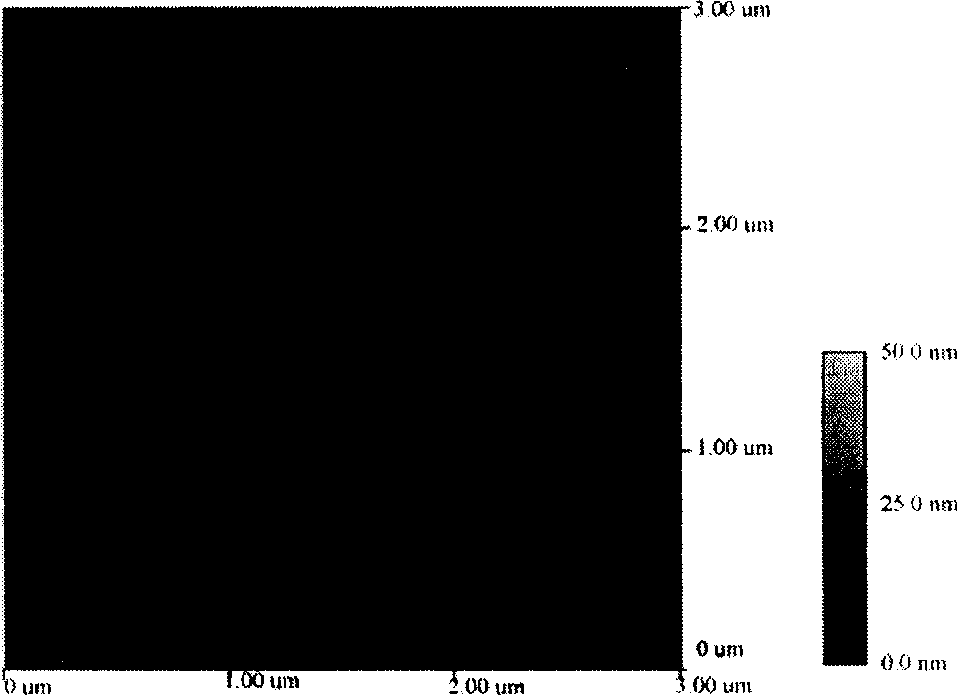

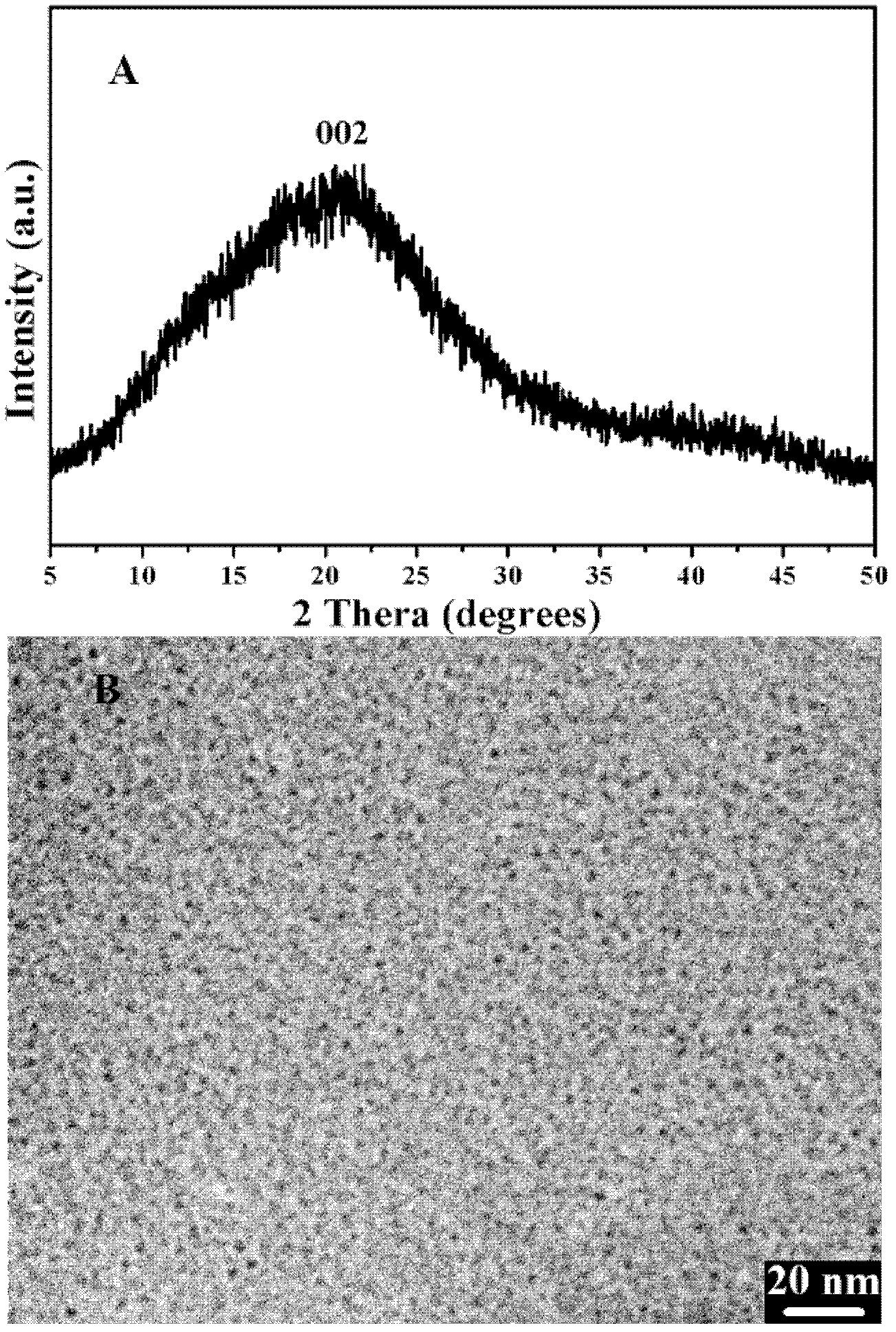

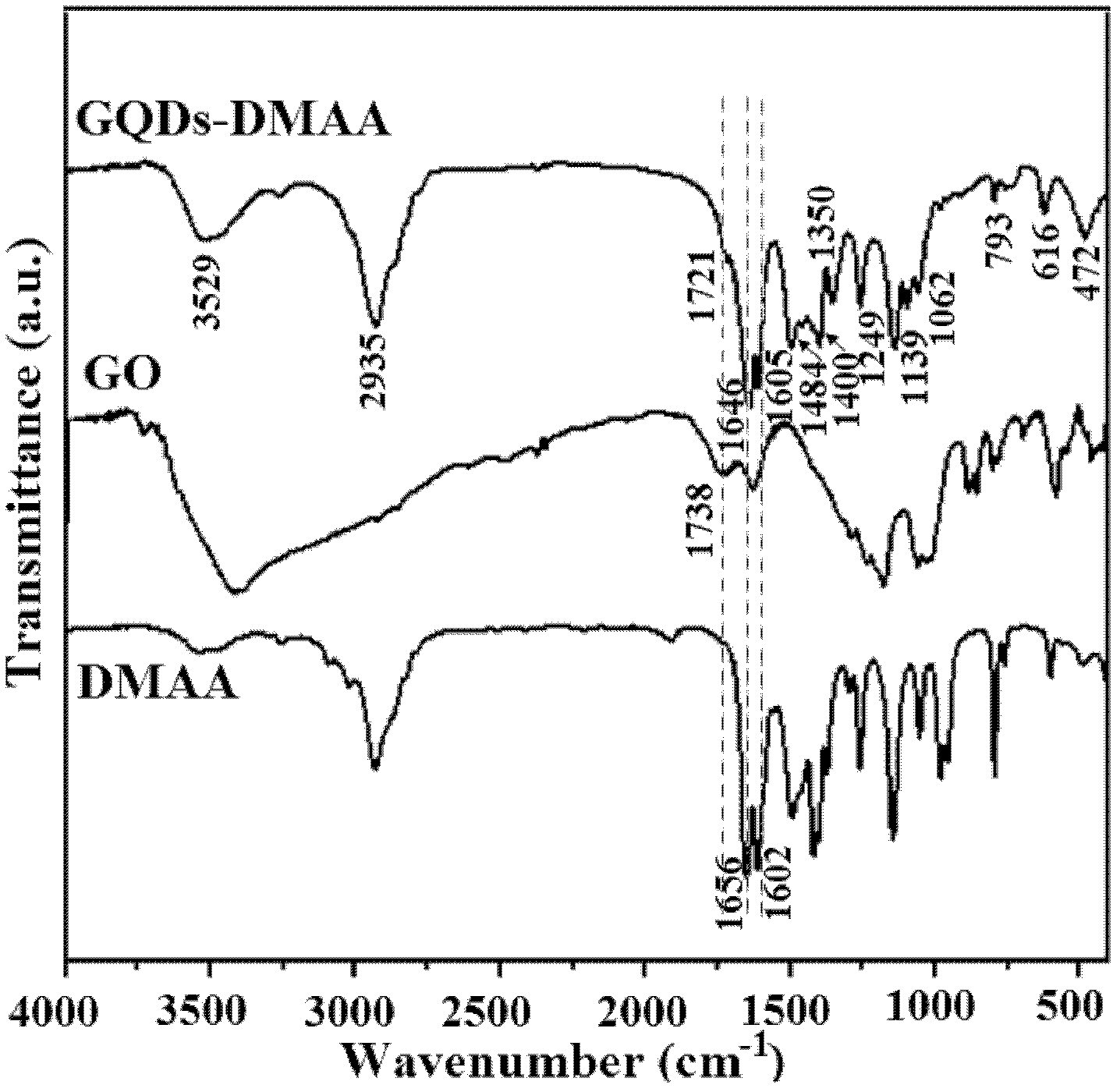

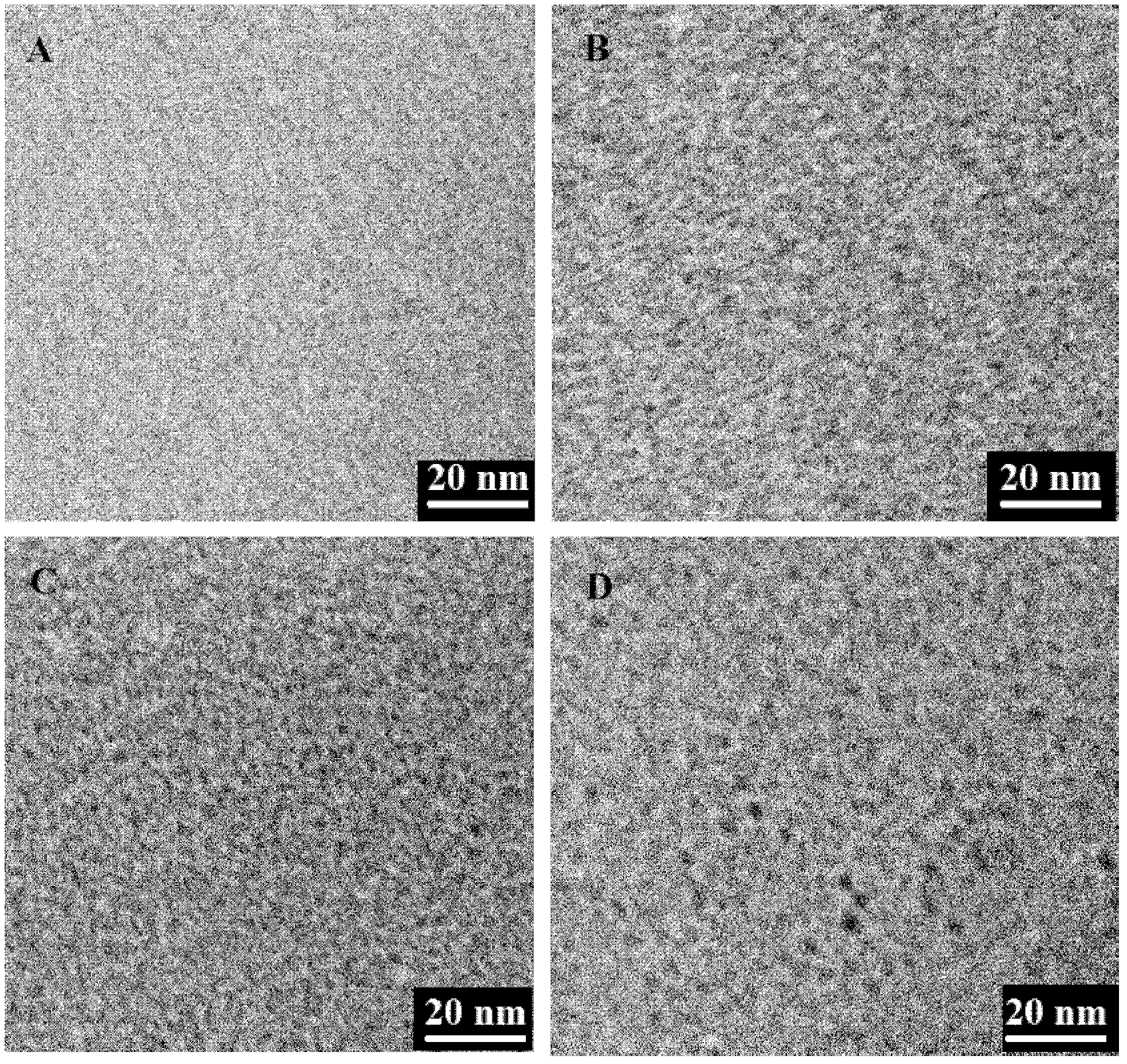

Transparent high-refractivity graphene quantum-dot/polymer nano composite film and preparation method thereof

ActiveCN102643501AGood compatibilityAvoid the downside of refractive index dropComposite filmNano composites

Owner:JILIN UNIV

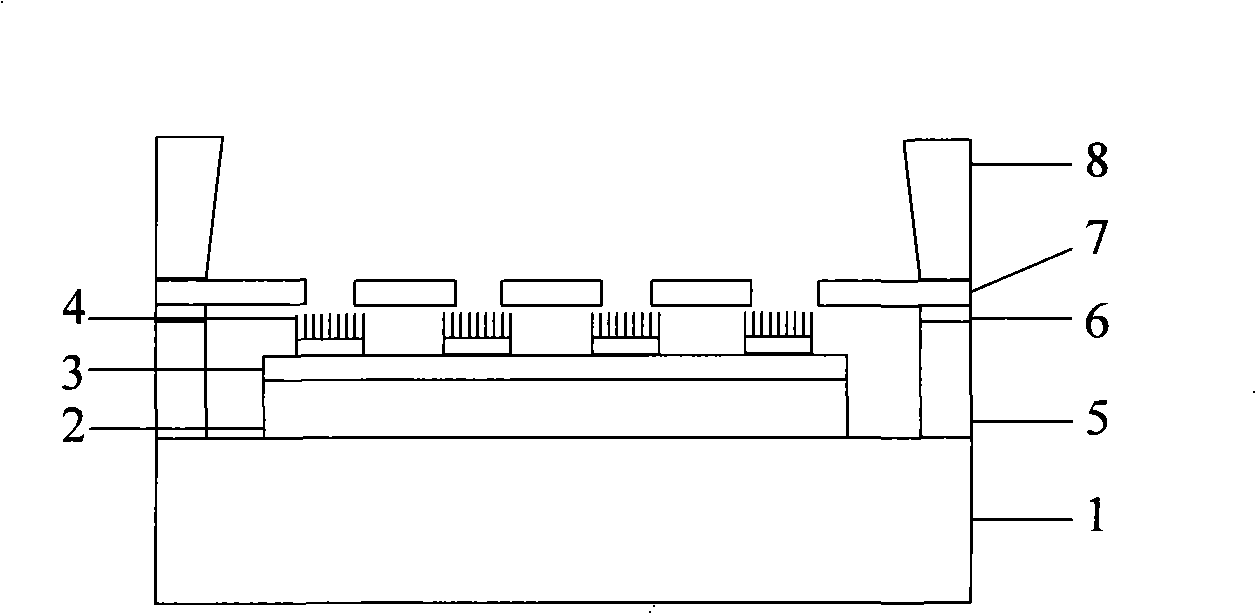

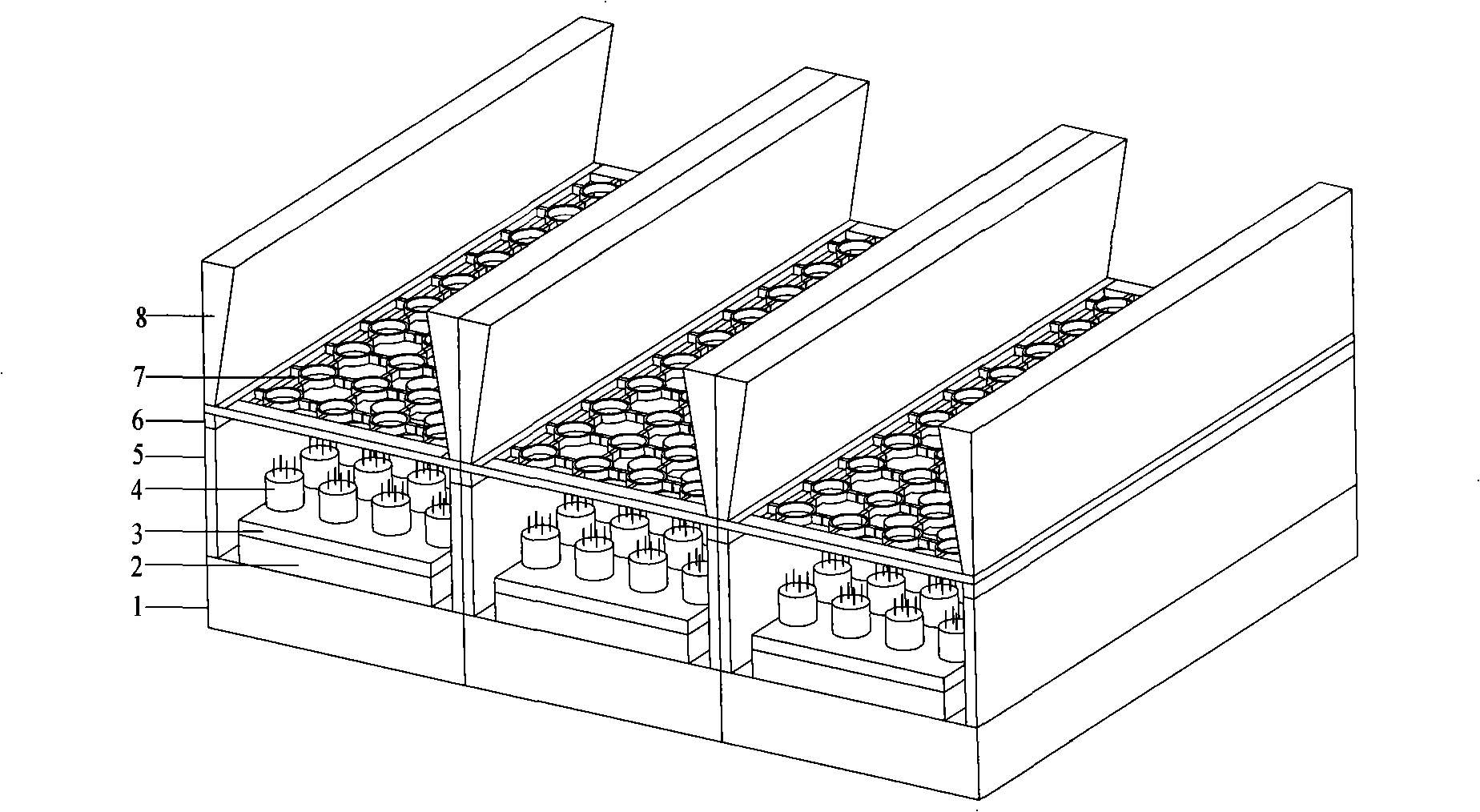

Metal and carbon nanotube or carbon fiber film emission array cathode as well as preparation method thereof

InactiveCN101355001AEasy to implementSimple processCathode ray tubes/electron beam tubesDischarge tube/lamp detailsFiberCarbon fibers

Owner:SHANGHAI JIAO TONG UNIV

Polymer dispersed LCD bistable film and method of manufacture

Owner:HEBEI UNIV OF TECH

Lightweight porous MXene-based composite film electromagnetic shielding material and preparation method thereof

ActiveCN113329603APlay a supporting rolePromote absorptionMagnetic/electric field screeningClimate change adaptationComposite filmThin membrane

The invention discloses a lightweight porous MXene-based composite film electromagnetic shielding material and a preparation method thereof, and belongs to the technical field of film electromagnetic shielding materials and preparation thereof. Self-assembly of MXene and graphene oxide is realized by taking electrostatic interaction force as driving force on MXene modified by a cationic surface modifier and graphene oxide, and then the lightweight porous MXene-based composite electromagnetic shielding material with ultrahigh specific performance is obtained through film casting and high-temperature annealing. The prepared composite film material has excellent electromagnetic shielding effectiveness and specific effectiveness, and when the thickness is only 15 [mu]m, the porous MXene-based composite film obtained by adding 5 wt% of graphene oxide can keep the electromagnetic shielding effectiveness of 49 dB or above in the whole X wave band. The preparation process is simple and easy to operate, and the material is expected to be applied to the fields of aerospace, military equipment, micro electronic equipment, civil electric appliances and the like.

Owner:JIANGNAN UNIV

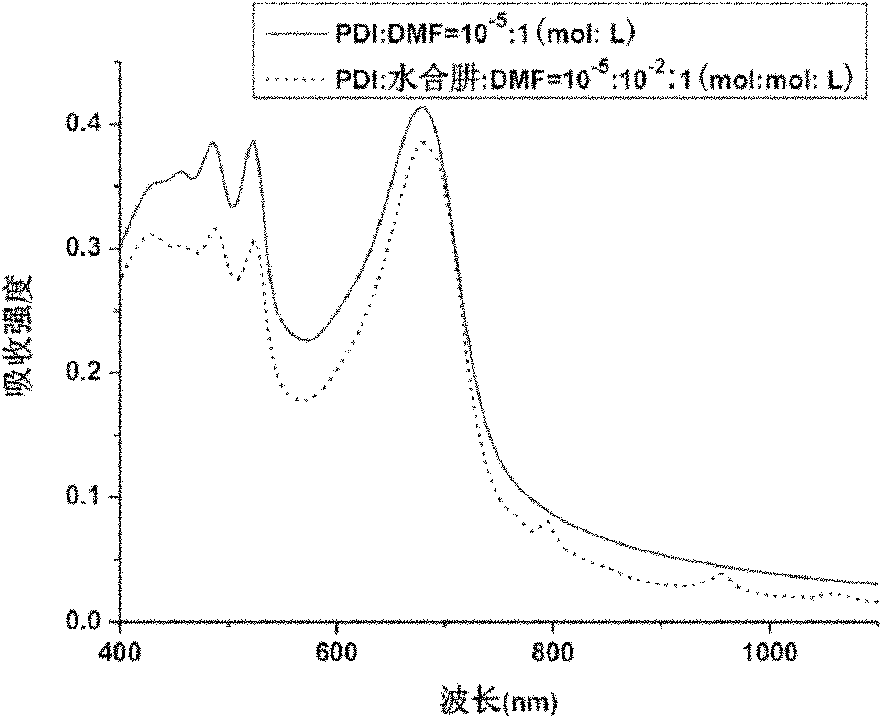

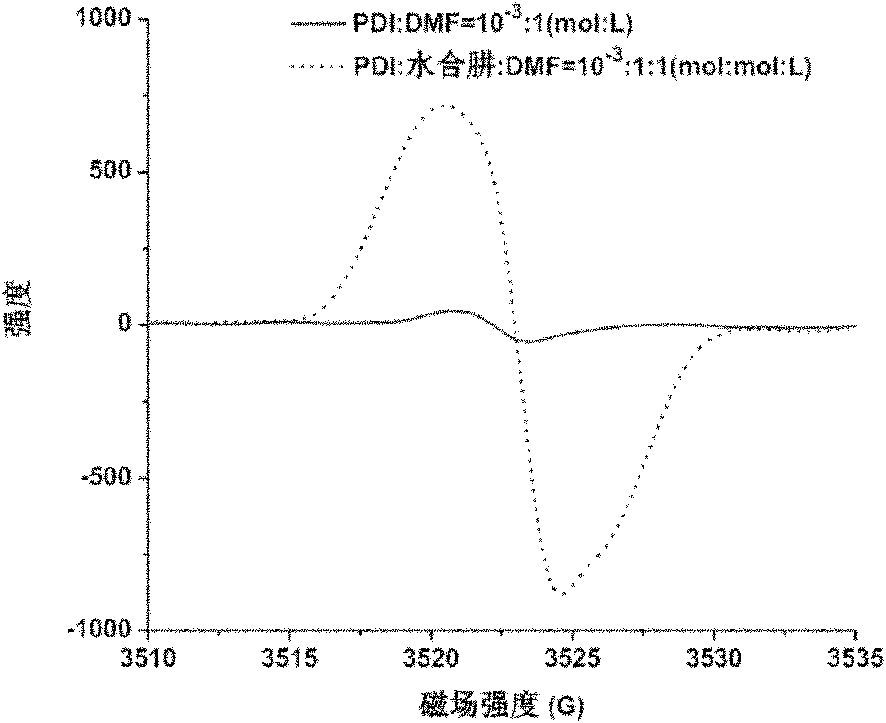

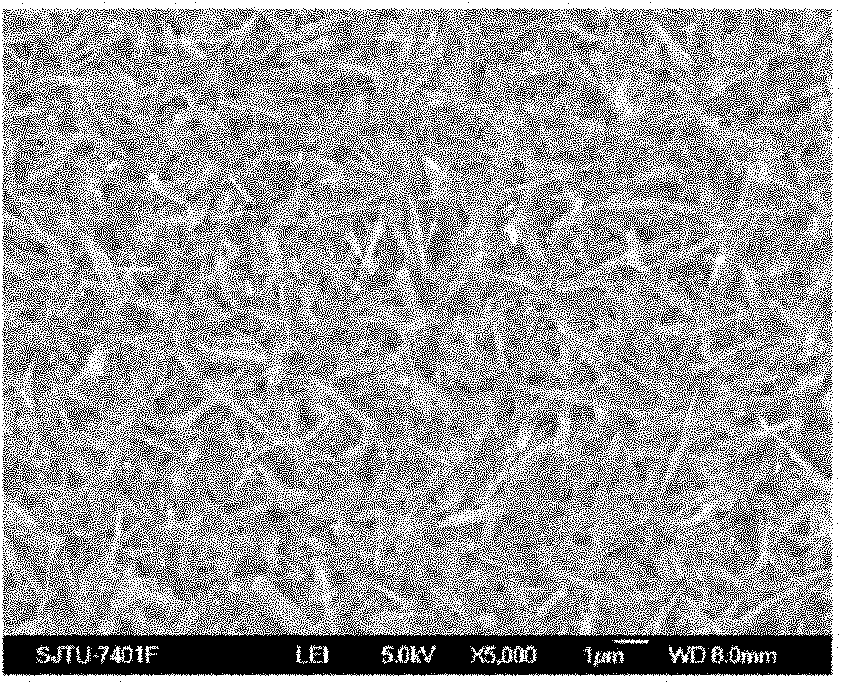

Method for preparing perylene polyimide derivative film

InactiveCN101949026AQuality improvementElectrolysis componentsElectrolytic organic productionComposite filmPolymer science

Owner:SHANGHAI JIAO TONG UNIV

Organic electroluminescent device and method of manufacturing the same

ActiveUS7285340B2Good reliability and durabilityLow moisture permeabilitySolid-state devicesSemiconductor/solid-state device manufacturingOrganic filmComposite film

An organic electroluminescent device which has a low moisture permeability and an oxygen permeability. The organic electroluminescent device includes a substrate, an organic light-emitting unit having a sequentially stacked structure of a first electrode, an organic film, and a second electrode formed on a surface of the substrate, and an organic-inorganic composite film made of a dehydrated polycondensate of a hydrolyzed product of trialkoxy metal formed on an upper surface of the second electrode of the organic light-emitting unit. The organic-inorganic composite film simplifies a manufacture process and has high visible light transmittance. Therefore, the organic-inorganic composite film can be used as an intermediate layer of a front emission type organic electroluminescent device. Also, the organic-inorganic composite film has excellent prevention function of the entry of moisture and / or oxygen. Therefore, the encapsulation of the device is ensured even when a sealing substrate is not separately used, thereby decreasing the total thickness of the device and increasing the life span of the device.

Owner:SAMSUNG DISPLAY CO LTD

Anti-bacterial lighting apparatus

ActiveUS10118170B1Improve the bactericidal effectElectrical apparatusLighting elementsLight equipmentComposite film

A lighting apparatus that includes at least one light source and at least one transparent or translucent lens, and at least one anti-bacterial composite film. The anti-bacterial composite film that includes photocatalytic particles and nano silver particles is formed on at least a part of the outer surface of the lens. With this anti-bacterial composite film, the lighting apparatus retains its germicidal function when the light source is turned off. Moreover, at least 95% of the spectral power distribution (SPD) of the light source comes from the visible light wavelength range (>400 nm). Artificial light sources such as LED can also be used with the anti-bacterial lighting apparatus.

Owner:ALEDDRA INC

Nickel oxide electrochromic composite film and preparation method and application thereof

PendingCN113867064AGood optical modulation amplitudeImprove stabilityVacuum evaporation coatingSputtering coatingComposite filmZinc tin oxide

The invention discloses a nickel oxide electrochromic composite film and a preparation method and application thereof. The nickel oxide electrochromic composite film comprises a nickel oxide layer and an amorphous zinc tin oxide buffer layer which are arranged in a laminated mode. The nickel oxide layer is provided with a crystal nano columnar structure, and the diameter of the crystal nano columnar structure is 10 to 100 nm. The charge capacity of the nickel oxide electrochromic composite film is 6.0 to 12.0 mC *cm<-2>. The nickel oxide electrochromic composite film prepared by the preparation method disclosed by the invention has better optical modulation amplitude, cycling stability and higher charge capacity, and has a good application prospect in a low-temperature coated flexible electrochromic device.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACAD OF SCI

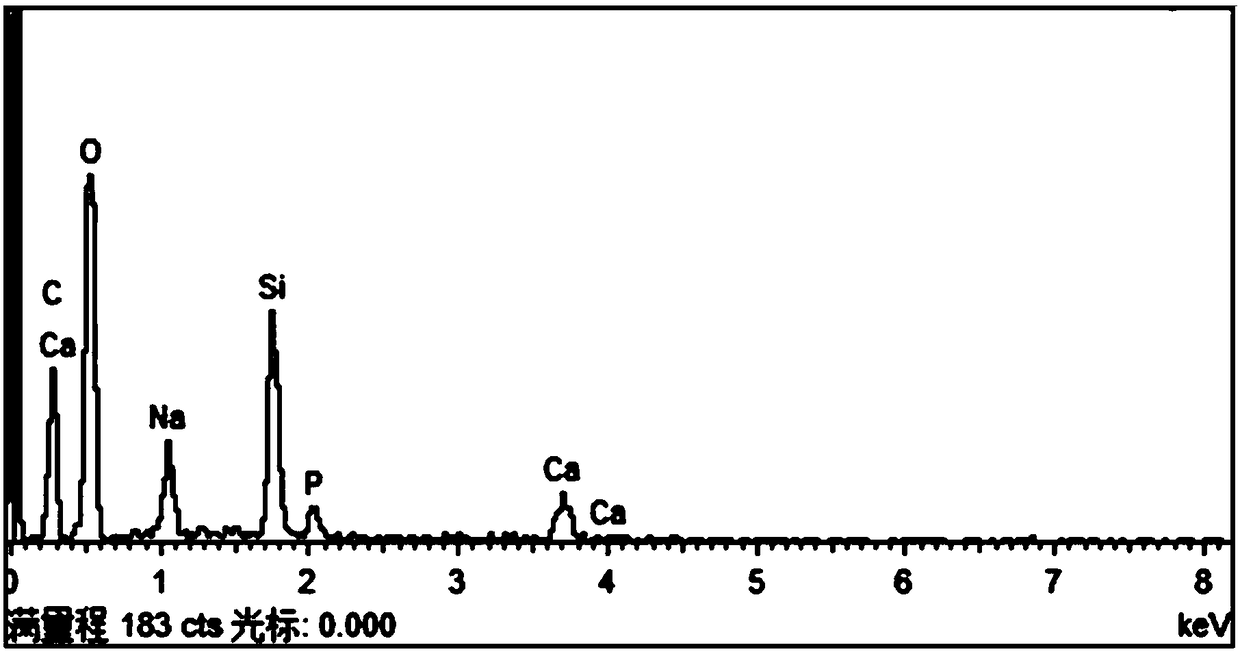

Bioactive glass composite film as well as preparation method and application thereof

ActiveCN108186614ADesensitizationPromote recoveryOrganic active ingredientsInorganic phosphorous active ingredientsComposite filmBiocompatibility Testing

Owner:AFFILIATED STOMATOLOGICAL HOSPITAL OF NANJING MEDICAL UNIV

Copper oxide/carboxymethyl cellulose gel modified composite film, and making method and use thereof

InactiveCN106943883AEfficient separationSimple construction methodSemi-permeable membranesNon-miscible liquid separationCarboxymethyl celluloseComposite film

Owner:JIANGSU UNIV

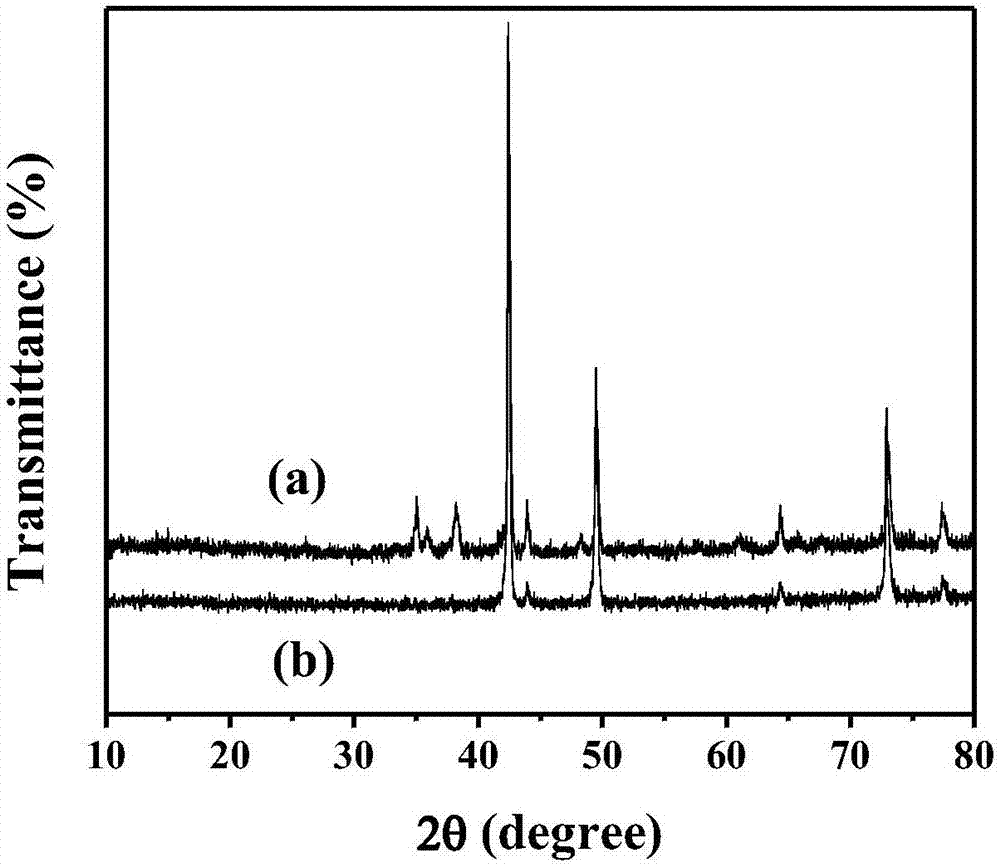

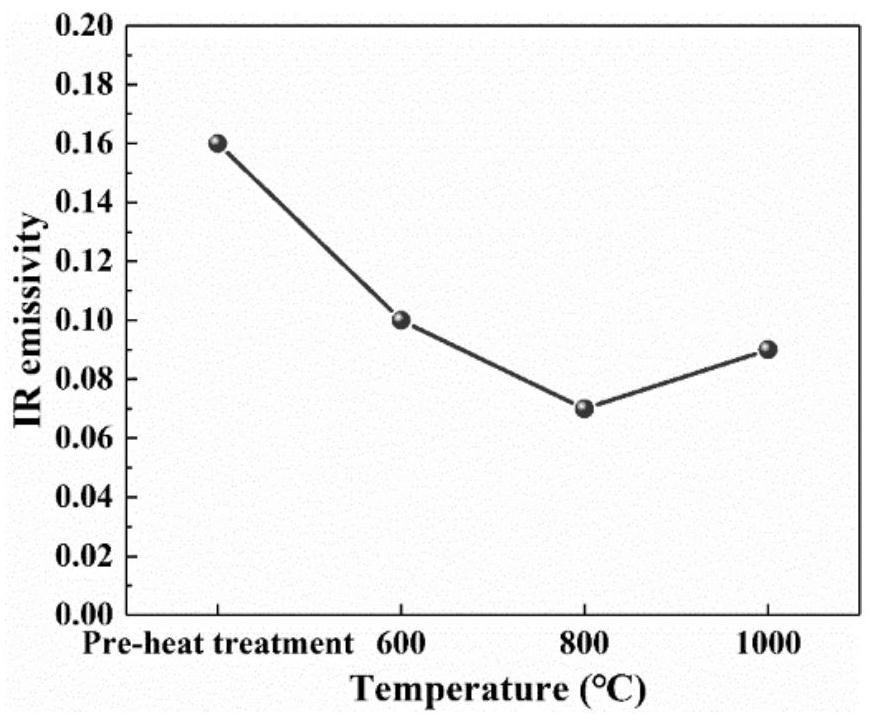

High-temperature-resistant, water-oxygen-resistant and low-infrared-emissivity composite film for ceramic-based composite material and preparation method

ActiveCN113403594AReduce IR emissivityEasy to useVacuum evaporation coatingSputtering coatingComposite filmLow emissivity

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Low-friction thin film for inner wall of solar panel driving bearing and preparation method of low-friction thin film

ActiveCN114107906AReduce coefficient of frictionExtended service lifeVacuum evaporation coatingSputtering coatingComposite filmThermodynamics

The invention provides a low-friction thin film for the inner wall of a solar panel driving bearing and a preparation method of the low-friction thin film, and relates to the technical field of material thin films. The low-friction thin film is of a multi-layer structure, the bottom layer of the thin film is attached to the surface of the inner wall of the bearing, a Ti layer, a MoS2-Ti / Pb layer, a graphene layer and grooves distributed in the surface of the inner wall of the bearing are sequentially arranged from the inner wall of the bearing to the outside, and the grooves are filled with lubricating materials. The preparation technology is simple, the composite film is of a three-layer structure, the thickness is only 2.5 microns, the good low-friction and high-mechanical-strength effects can be achieved, the roughness of the film is lower than 6 nm, the hardness is higher than 7 Gpa, the friction coefficient is lower than 0.03 in the vacuum 7 * 10 <-4 > Gpa environment, and the composite film can be suitable for various complex external environments and has the wear-resisting and lubricating effects.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING) +2

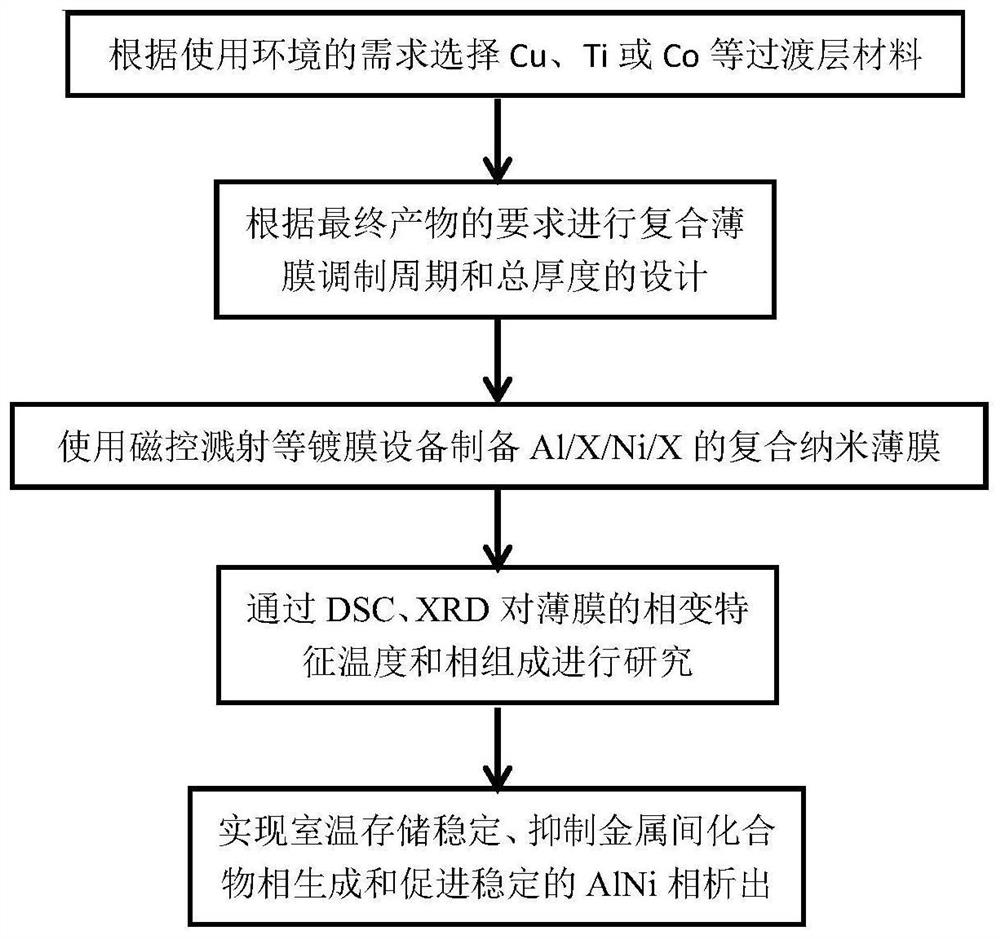

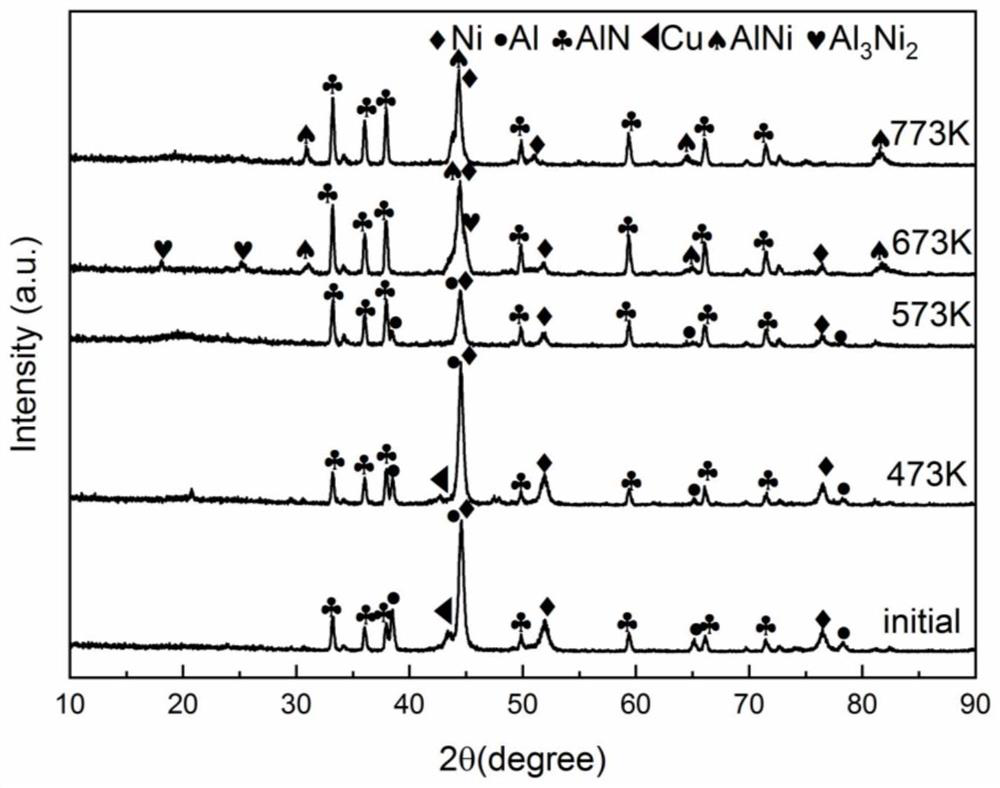

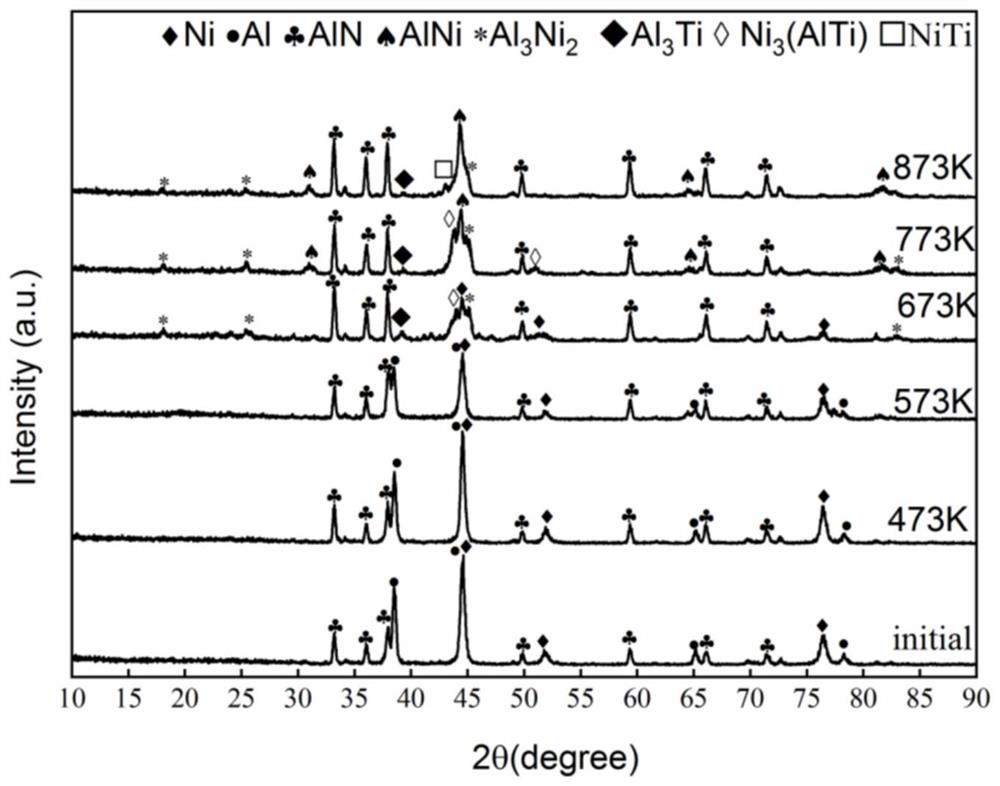

Method for inhibiting generation of ordered intermetallic compound in phase change process of Al-Ni nano multilayer film

ActiveCN113481467AInhibition of interdiffusion behaviorGuaranteed storage stabilityVacuum evaporation coatingSputtering coatingSputteringComposite film

Owner:UNIV OF SCI & TECH BEIJING

Method for forming multilayer composite film and three-dimensional memory device

ActiveCN107579074AIncreasing the thicknessSolve the problem of surface cracking under high stressSolid-state devicesSemiconductor devicesMemory chipComposite film

Owner:YANGTZE MEMORY TECH CO LTD

Novel nylon composite film

Owner:SICHUAN NIUPAISI NEW MATERIALS CO LTD

Encapsulation method of a plurality of 5kg electrodes, composite film and preparation method thereof

Owner:ATLANTIC CHINA WELDING CONSUMABLES

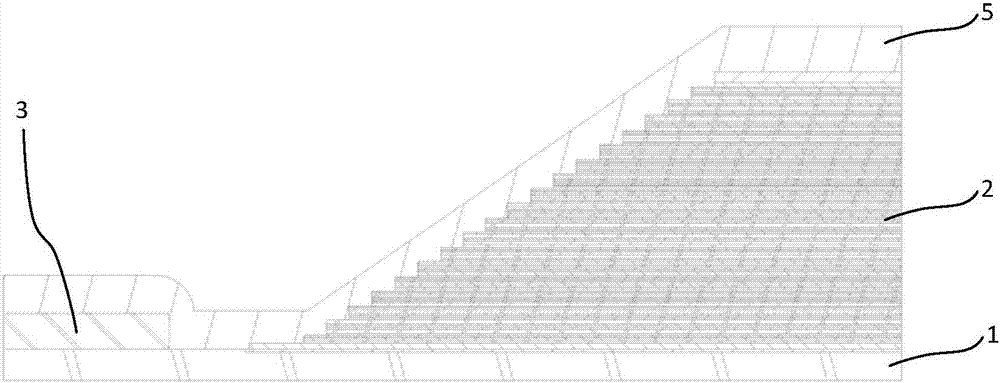

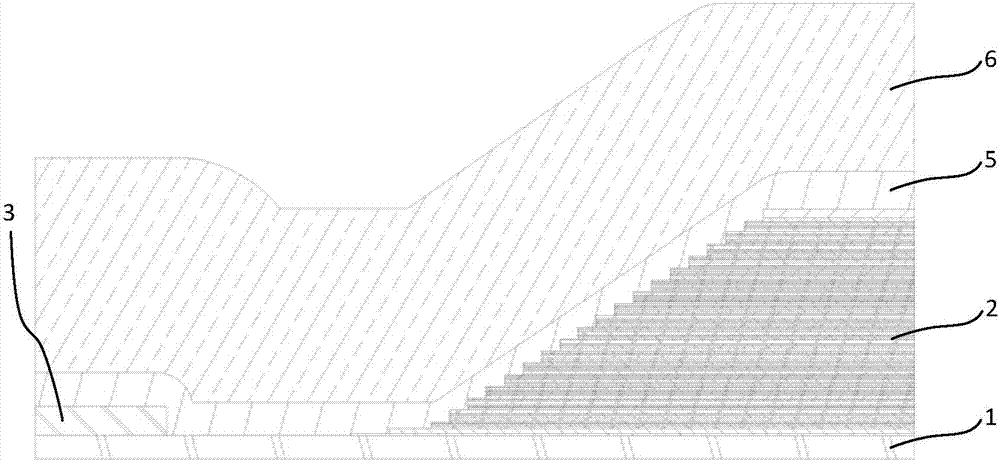

Pulling type solar collection device of solar equipment

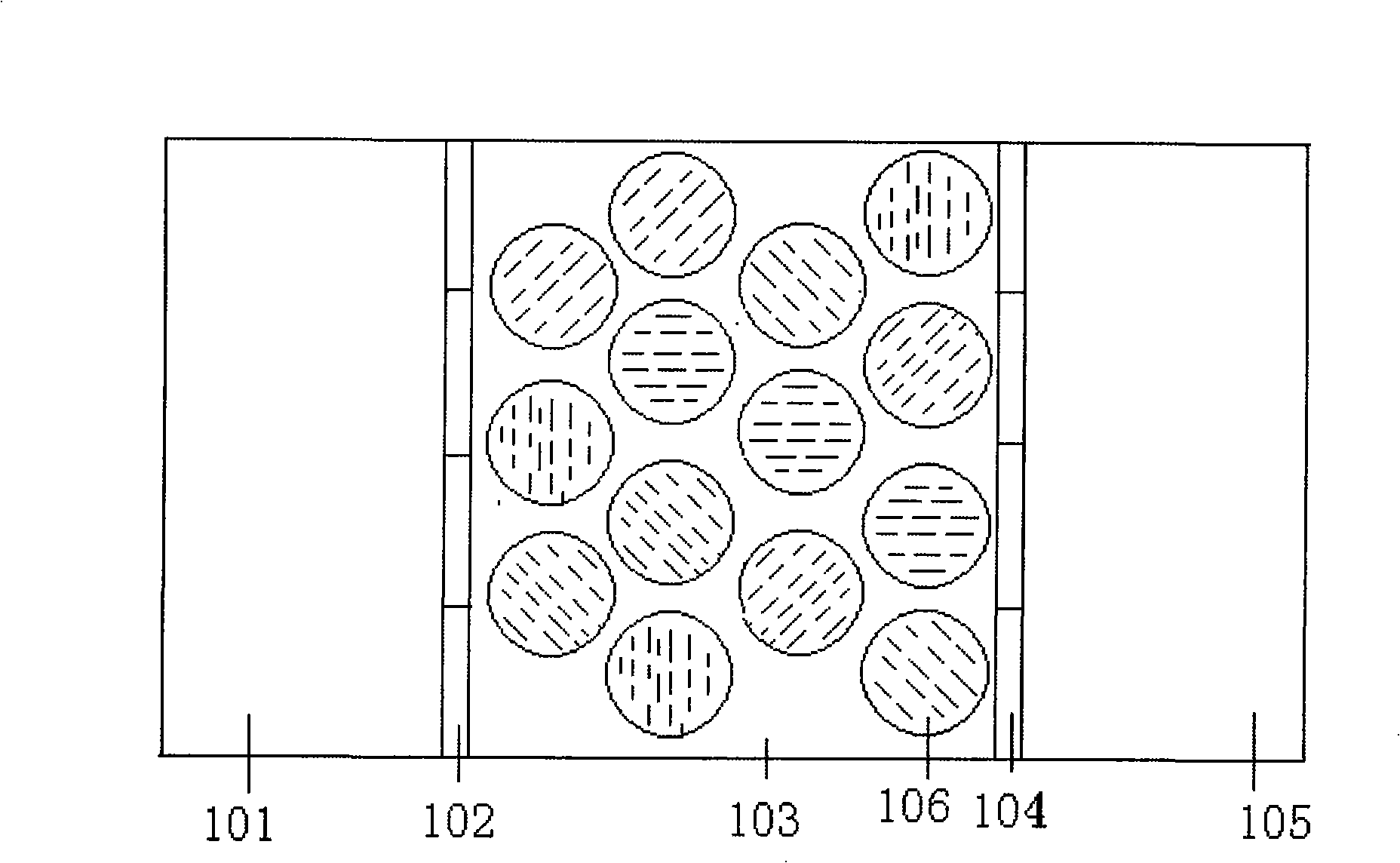

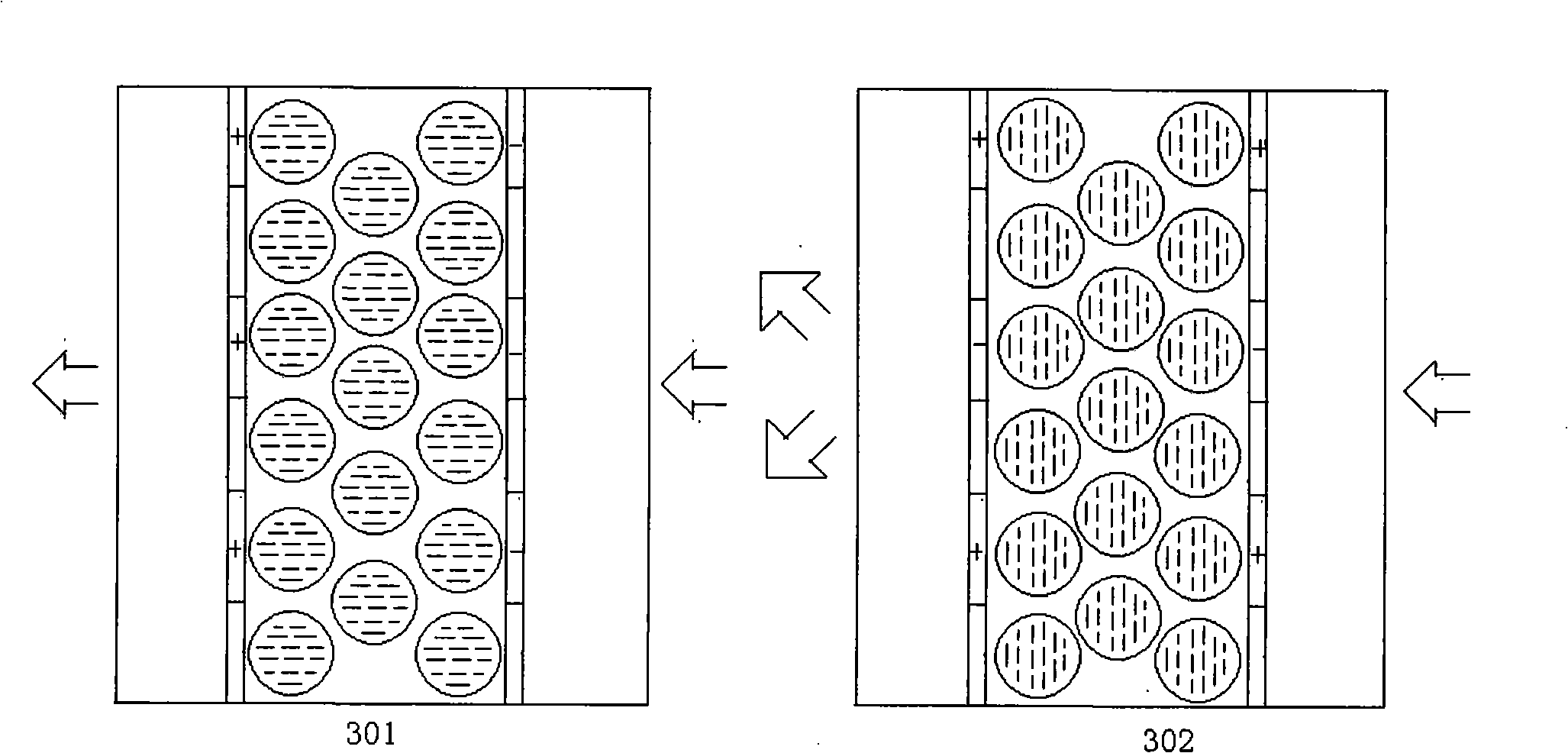

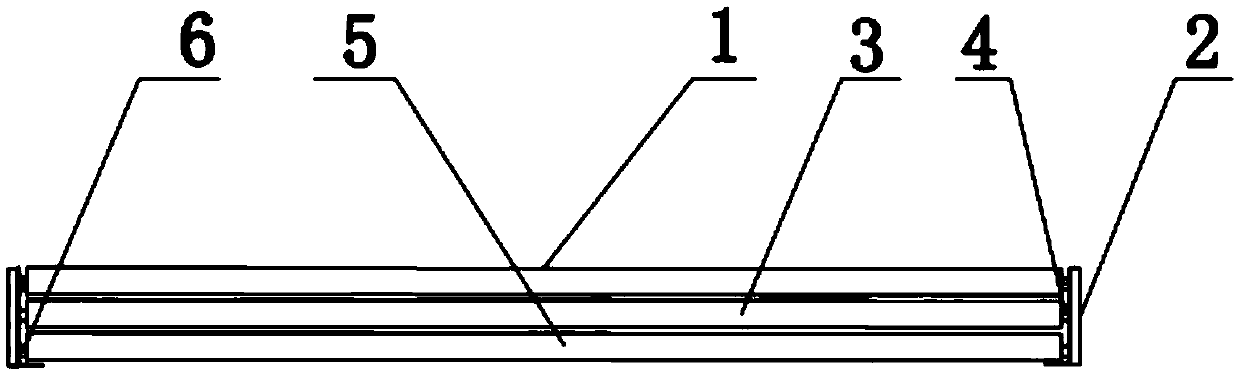

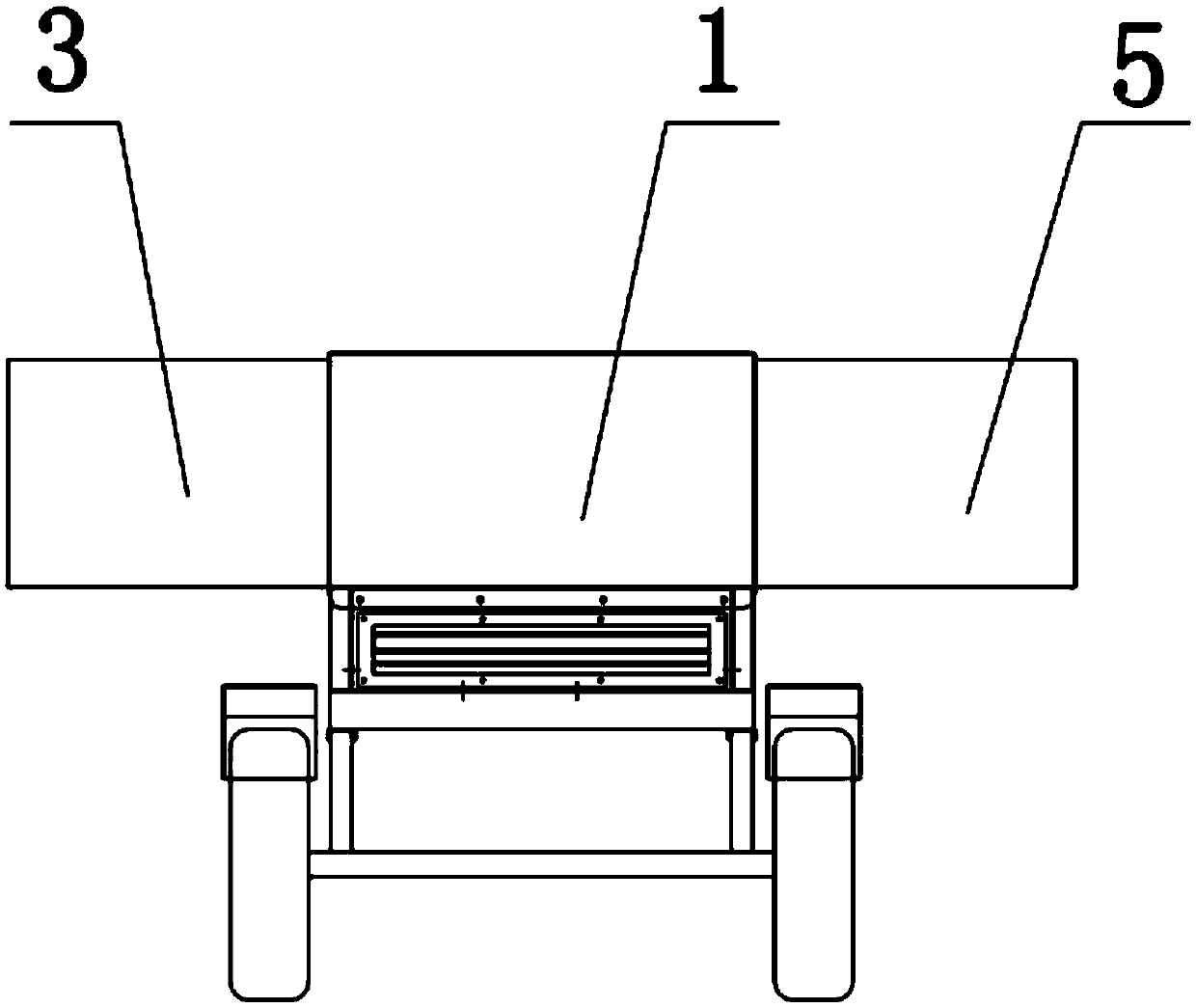

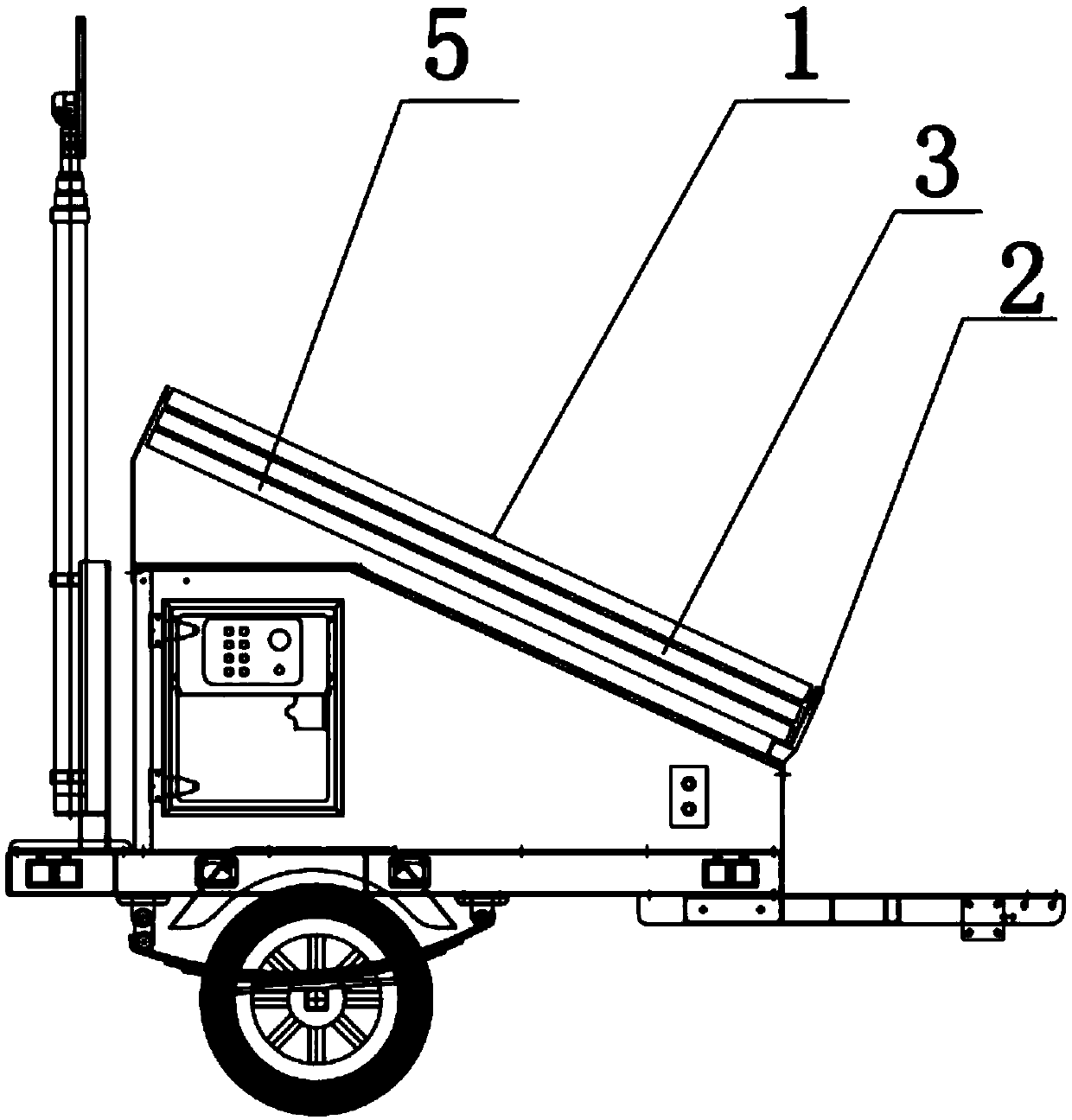

InactiveCN108683404ADoes not affect rewindingImprove adsorption capacityLight-sensitive devicesPhotovoltaicsComposite filmEngineering

Owner:深圳万智联合科技有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap