Method for preparing perylene polyimide derivative film

A technology of perylene imide and derivatives is applied in the field of preparation of perylene imide derivative films, which can solve the problems of metal negative electrode corrosion, unsuitability, low energy consumption, etc., and achieve the effect of short deposition time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

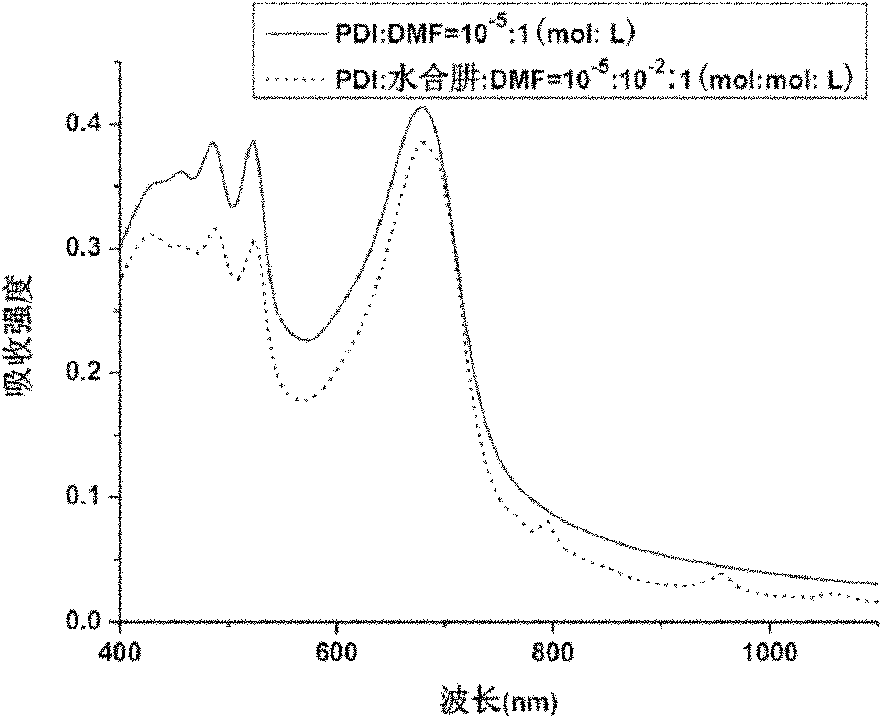

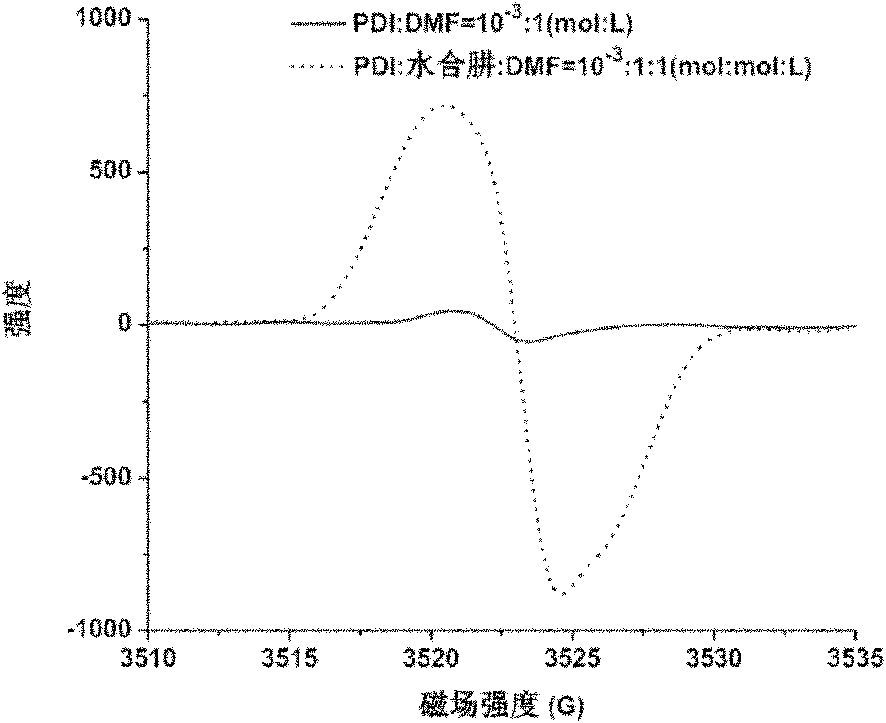

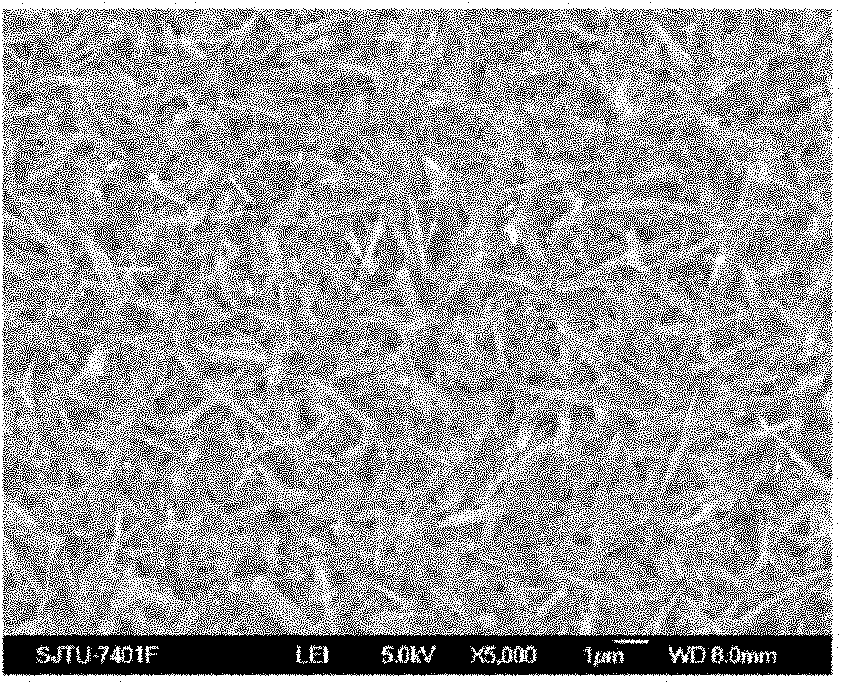

[0034] PDI With DMF to 10 -4 mol:1L ratio mix, add 10 -2 mol: 1L of hydrazine hydrate, ultrasound the mixed solution for 1h; place the positive and negative electrodes in the system, with platinum electrodes as negative electrodes and ITO conductive glass as positive electrodes, the size of the positive and negative electrodes is 1cm×2cm, and the spacing is 10mm , And use detergent, water, ethanol, acetone, ultrasonic cleaning, vacuum drying for 1h; electro-deposition with constant potential method, working voltage of 1.0V, deposition at room temperature (25℃) for 2min; film will be deposited Take out the conductive glass, place it in a closed container and dry it naturally for 5 hours, and then dry it at 80°C under vacuum for 5 hours. The preparation work is completed.

[0035] The structural formula of the PDI film prepared in this embodiment is: The molecular formula is C 26 H 14 N 2 O 4 , The molecular weight is 418.4.

Embodiment 2

[0037] Same as Example 1, but the PDI structural formula is:

[0038] The molecular formula is C 40 H 26 N 2 O 6 , The molecular weight is 630.64.

Embodiment 3

[0040] Same as implementation 2, but PDI and DMF are divided by 10 -5 The ratio of mol:1L is mixed. The structural formula, molecular formula and molecular weight of the PDI film prepared in this embodiment are the same as those in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap